Combined propeller blade structure

A compound and blade technology, applied in the direction of rotating propellers, rotating propellers, etc., can solve the problems of performance bottlenecks and no further significant improvement, and achieve the effects of improving performance, easy implementation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The detailed description of the present invention is described in the following, and the preferred embodiments described here are used for the purpose of illustration and description, and are not intended to limit the scope of the present invention.

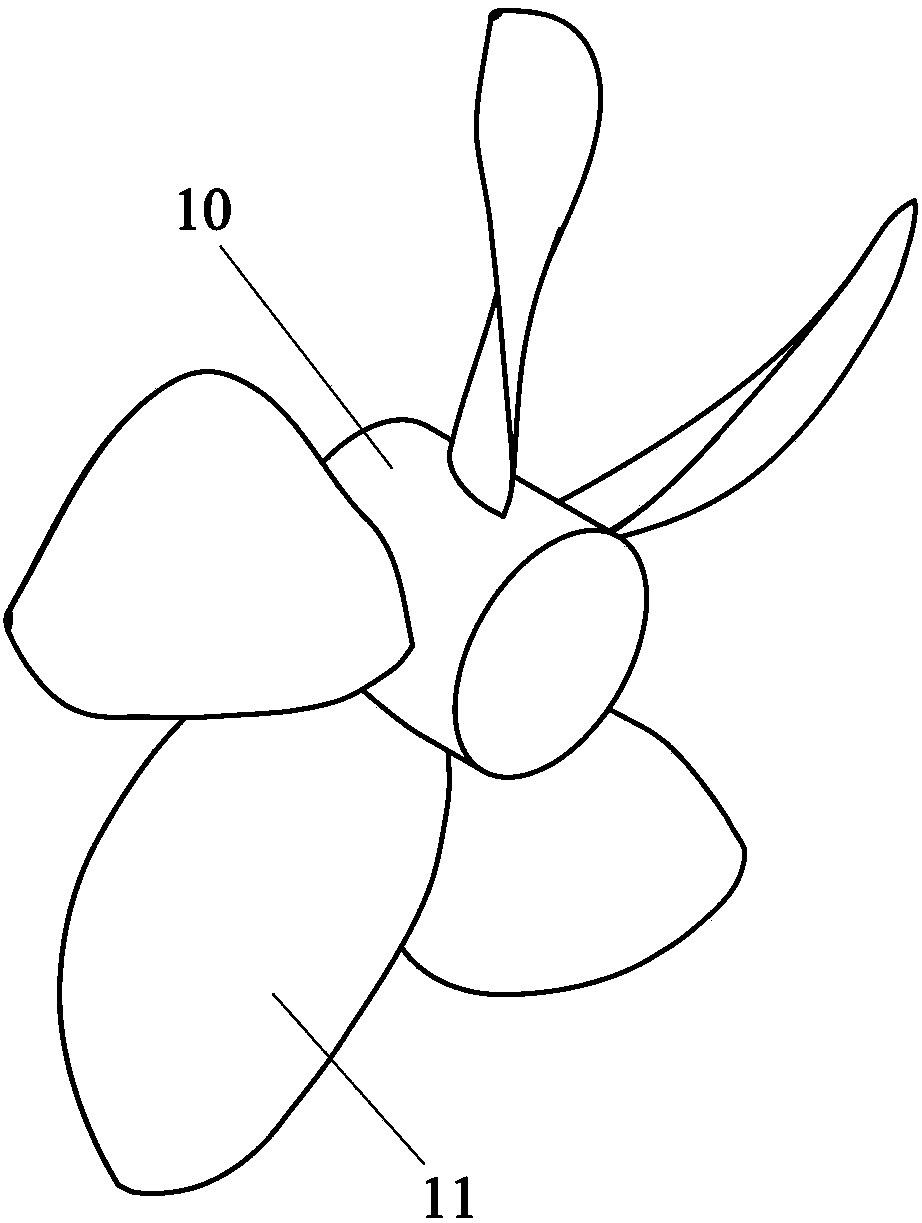

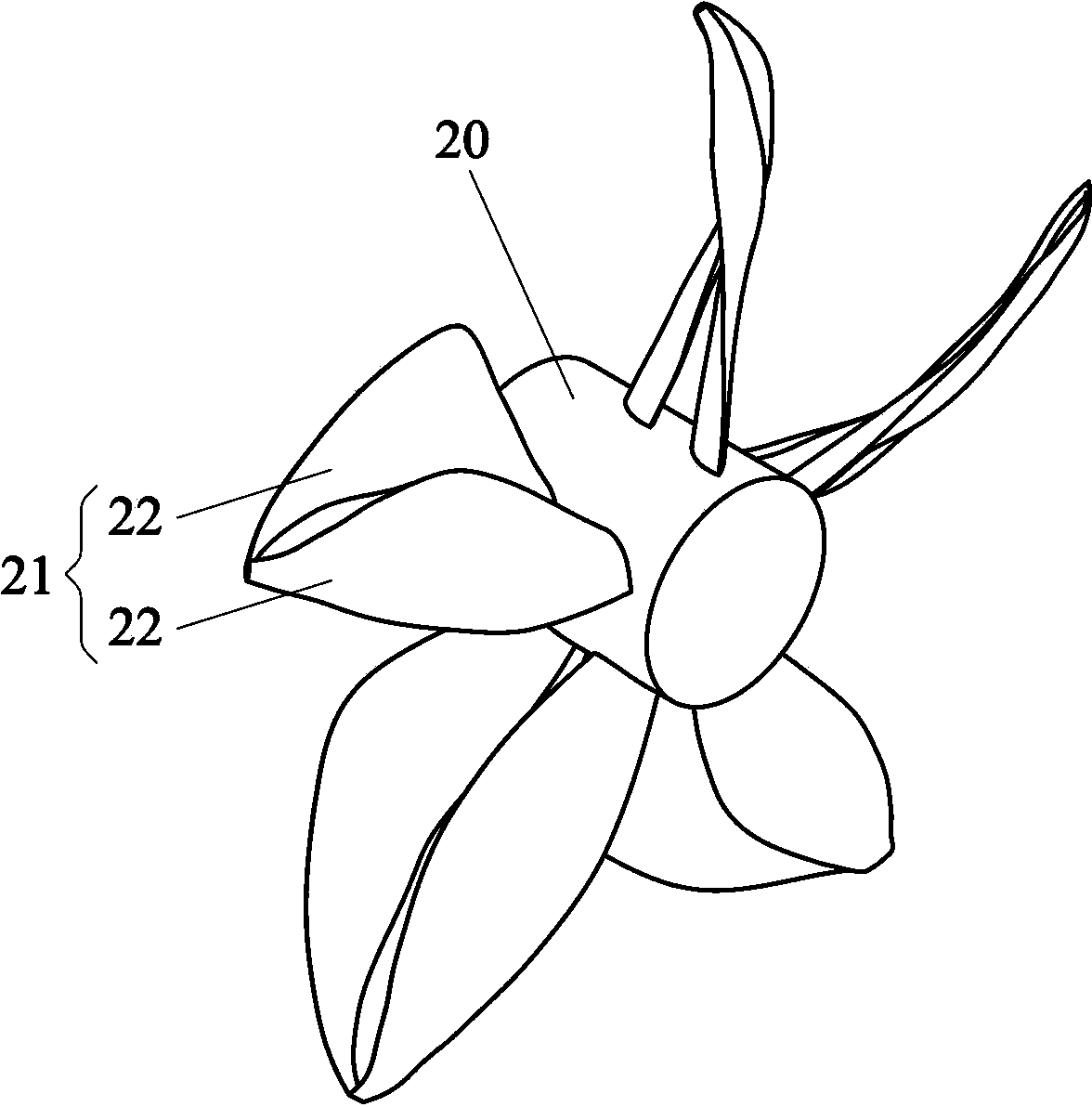

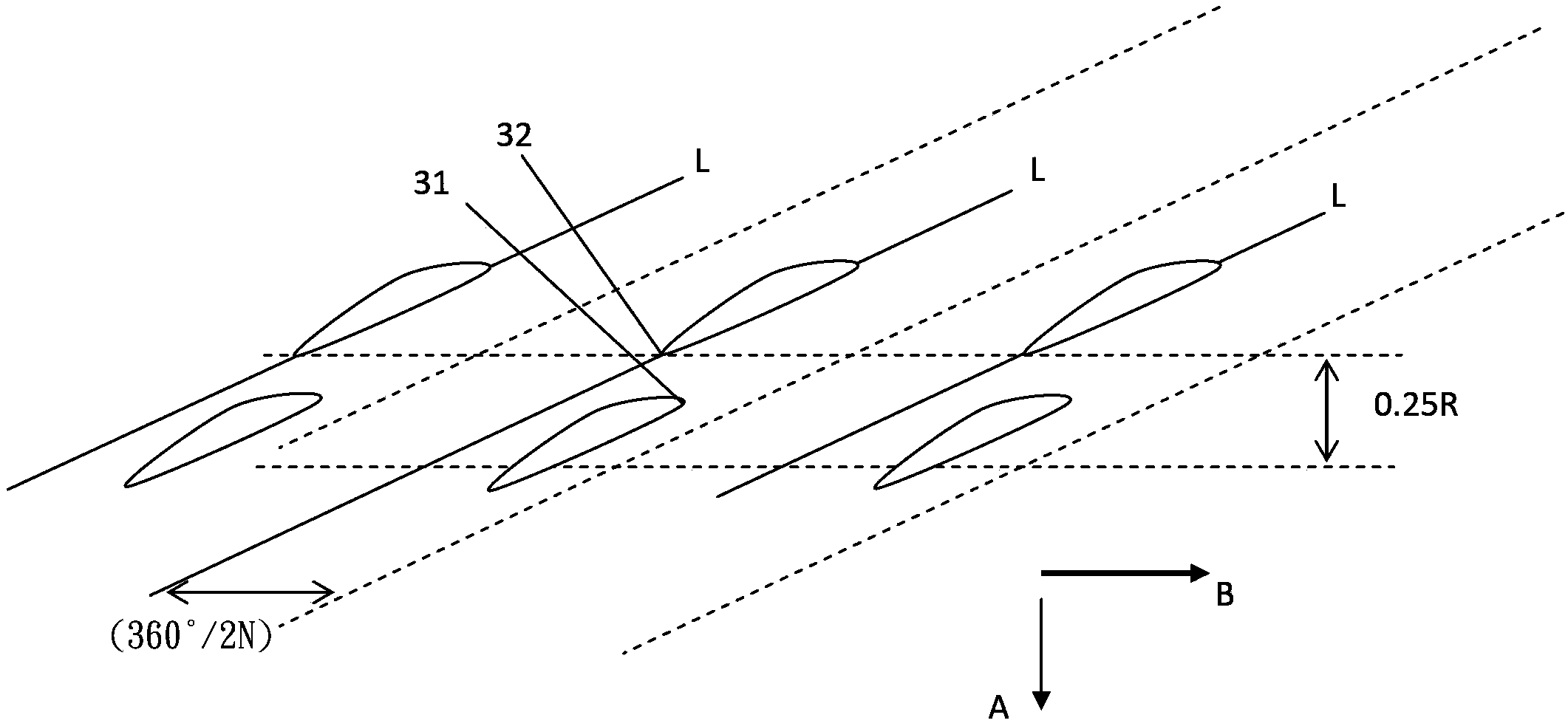

[0020] The present invention discloses a composite propeller blade structure, which is provided with at least one rotating shaft and a rotating side surface corresponding to the rotating shaft, and a plurality of fan blades are arranged on the rotating side surface, and the feature is: each of the aforementioned fan blades It is composed of a plurality of blade units, wherein the distance between any two adjacent blade units is greater than the distance between any adjacent two blade units, and the suction side of the blade unit on the downstream side is located at the pressure of the blade unit on the upstream side. side (Pressure Side); and in any of the equal radius sections of the aforementioned fan blades, the setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com