Manufacturing method of split type composite propeller and product

A technology of composite materials and manufacturing methods, which can be applied to household components, household appliances, and other household appliances. It can solve problems such as complex laying procedures, poor connection stability, and discontinuous fibers, and achieve good connection stability, light weight, and Create handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

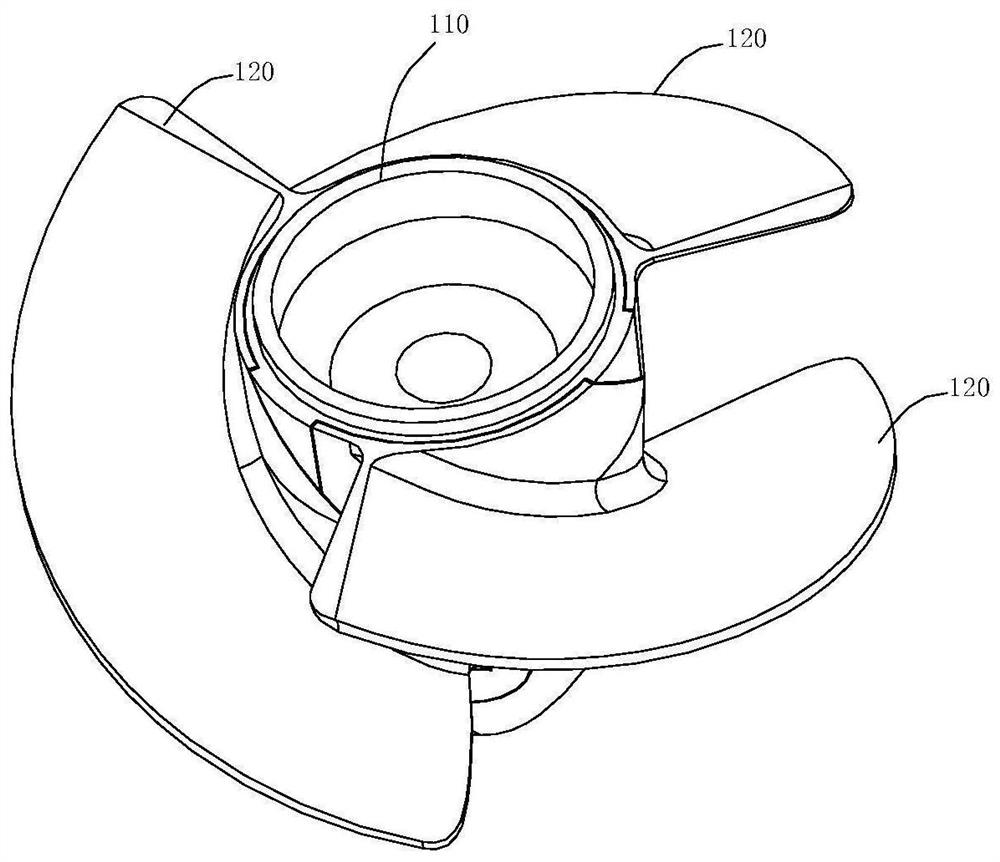

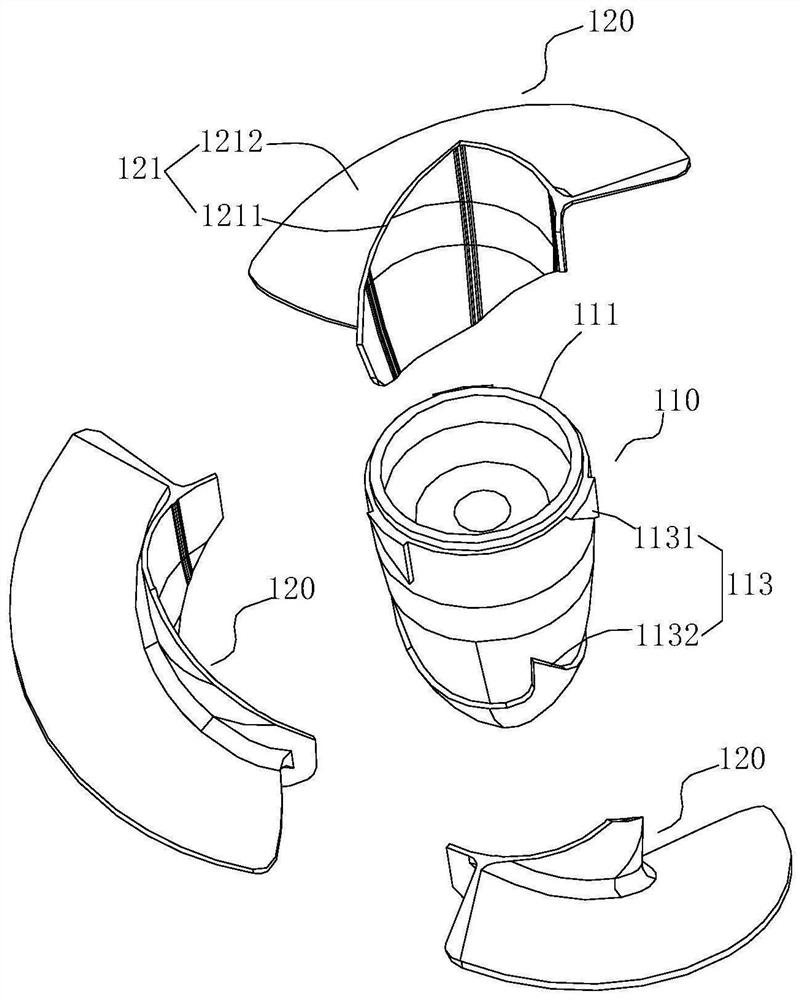

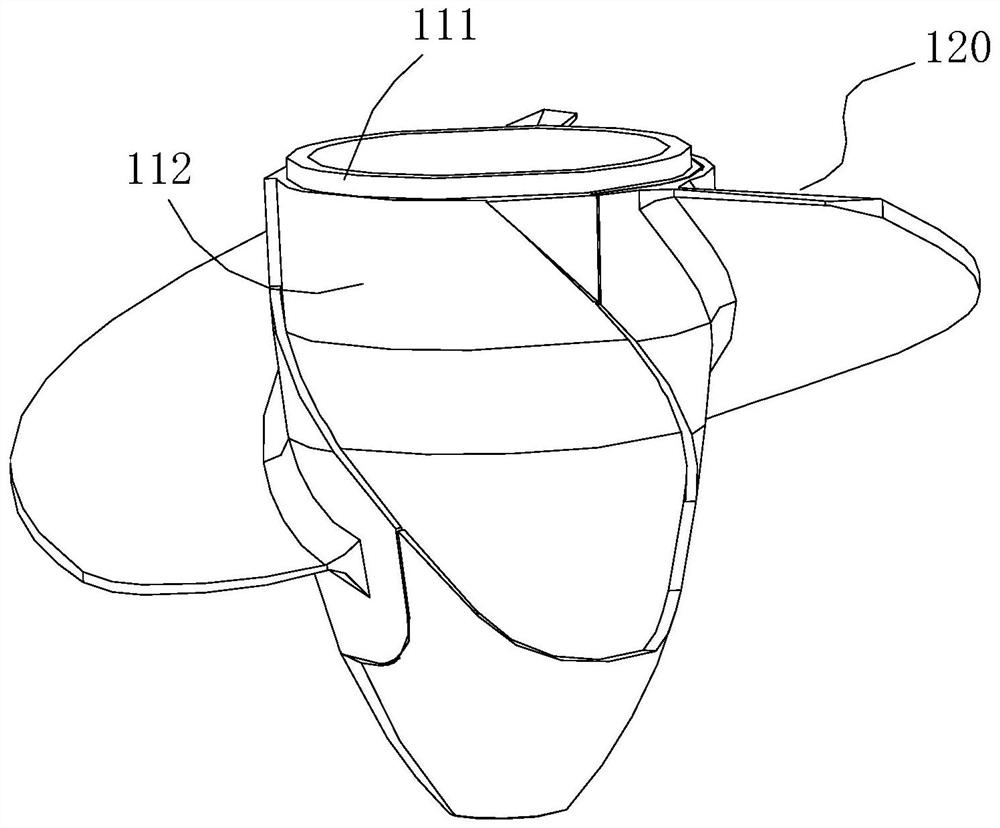

[0070] A method for manufacturing a split composite propeller, comprising:

[0071] 1) Manufacturing steps of propeller hub:

[0072] 1-1) Propeller hub preforming step: pave the prepreg sheet according to the predetermined method to obtain the propeller hub preform;

[0073] 1-2) Propeller hub molding step: put the propeller hub preform into the propeller hub forming mold, heat and pressurize the mold after closing, solidify and mold, and demould to obtain the propeller hub; the outer wall of the propeller hub is uniform in circumferential direction formed with at least two first depressions;

[0074] 2) Propeller production steps:

[0075] 2-1) Blade preforming step: laying prepreg sheets according to a predetermined method to obtain a blade preform;

[0076] 2-2) Blade forming step: put the blade preform into the blade forming mold, heat and pressurize the mold after closing, solidify and mold, and demould to obtain the blade; the blade includes the blade connecting part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com