Preparation method of integrated composite propeller blade for stratospheric airship

A stratospheric airship and propeller blade technology, applied in applications, household appliances, household components, etc., can solve the problems of thin-walled blade delamination, bonding bubbles, etc., to achieve good quality of finished products, improve yield, and improve bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

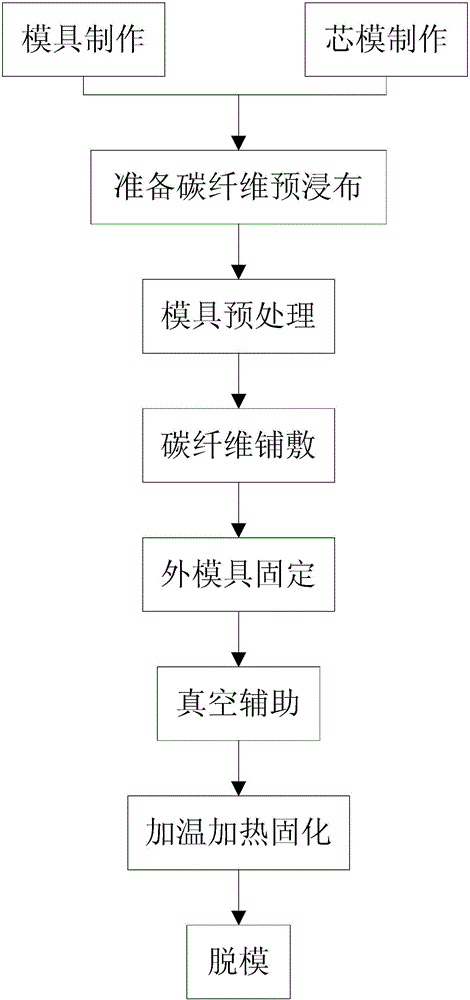

[0039] The preparation method of the propeller blade of the present invention, such as figure 1 shown, including:

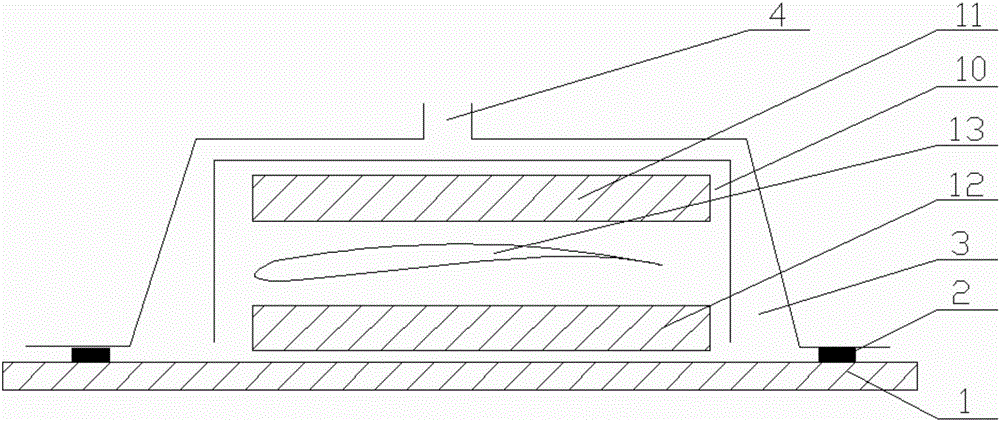

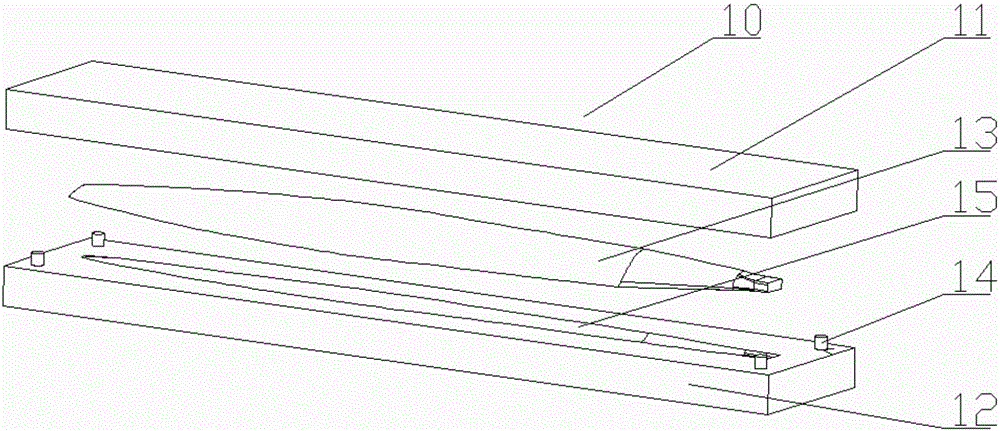

[0040] Step 1: Prepare the mold device for preparing the propeller blade, such as figure 2 As shown, the mold device includes a mold device bottom plate 1, a mold body 10 arranged on the mold device bottom plate 1, a vacuum bag 3 that seals the mold body 10 inside the mold device, and the vacuum bag 3 The upper part has a vacuum nozzle 4, such as image 3 and Figure 4 As shown, the mold body 10 includes an outer mold lower mold 12, a core mold 17 and an outer mold upper mold 11, and the opposite surfaces of the outer mold upper mold 11 and the outer mold lower mold 12 are provided with an outer mold cavity 15 , at least one positioning device 14 is respectively arranged at the corresponding positions outside the cavity 15 of the upper mold 11 of the outer mold and the lower mold 12 of the outer mold, and the upper mold 11 of the outer mold and the lower mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com