Composite propeller blade of propeller

A technology of composite materials and propellers, which is applied in propellers, aircraft parts, transportation and packaging, etc., can solve the problems of poor bearing capacity, poor consistency, and prone to defects of propeller blades, and achieve good reliability and safety, and are not easy to dense voids , Excellent bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

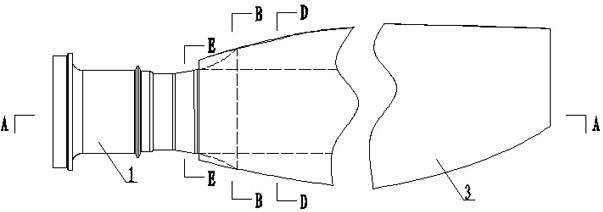

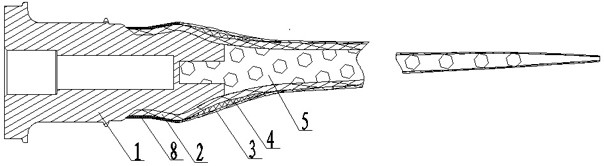

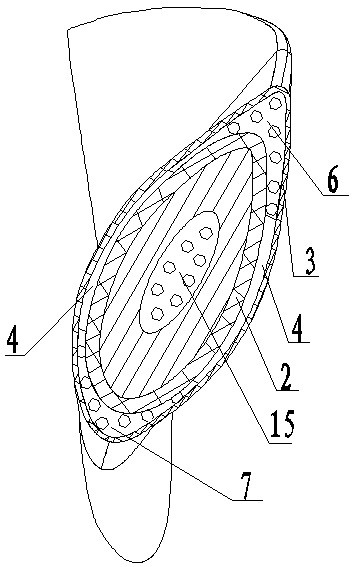

[0026] like Figure 1 to Figure 8 As shown, this embodiment includes a metal blade root 1 and a blade hull. The oar body includes foam core 5, carbon beam 2, front and rear edge filling foam 7, 6, carbon fiber cloth 4, carbon beam winding belt 8 and skin 3. The large end of the metal propeller root 1 is a structure connected to the propeller hoop. In this embodiment, there are 5 cylindrical sections; the small end starts from the back of the end cylinder of the large end, followed by the circular platform I16 with reduced diameter, and the smallest diameter with the circular platform I16. Cylinder I11 with the same diameter, circular platform II13 with larger diameter, transition cylinder II14 with the same large diameter as circular platform II13, and curved surface 17 consistent with the curved surface of the paddle body. The end cylinder o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com