Performed composite propeller blade of ship and manufacturing method of performed composite propeller blade

A composite material and preform technology, which is used in the construction of rotating propellers, ships, ships, etc., can solve the problems of difficult three-dimensional braiding preforms, difficult to ensure vibration noise, complex shapes, etc., to avoid delamination and peeling, Excellent acoustic characteristics and improved stealth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

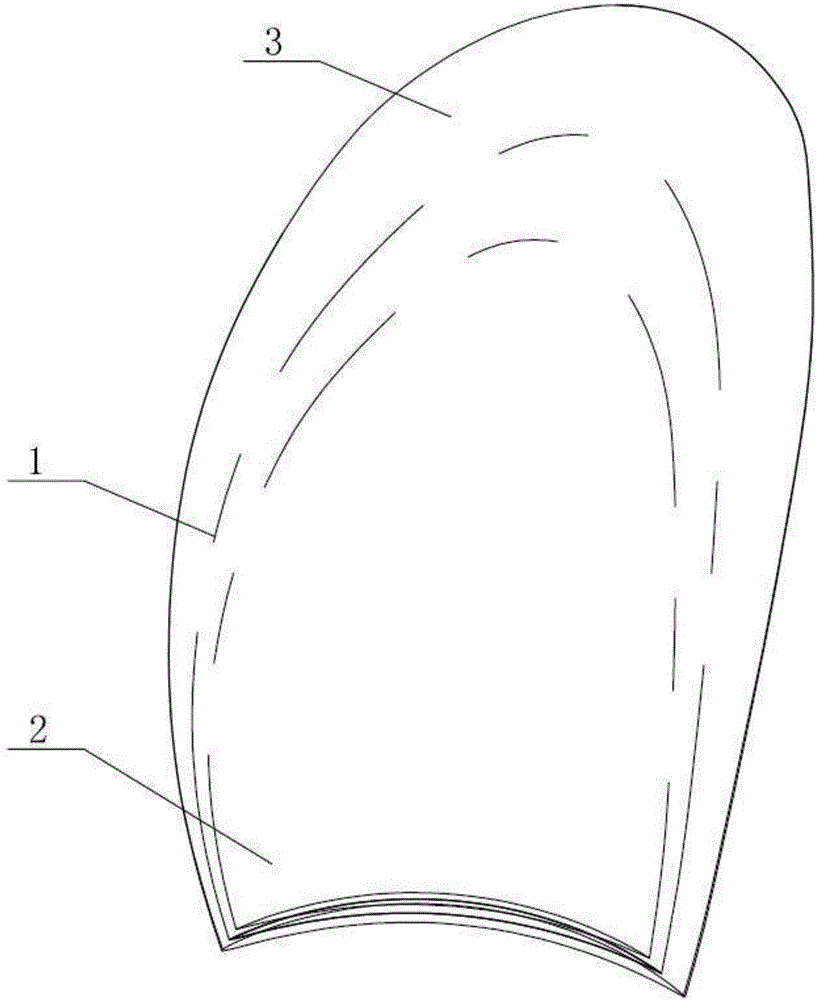

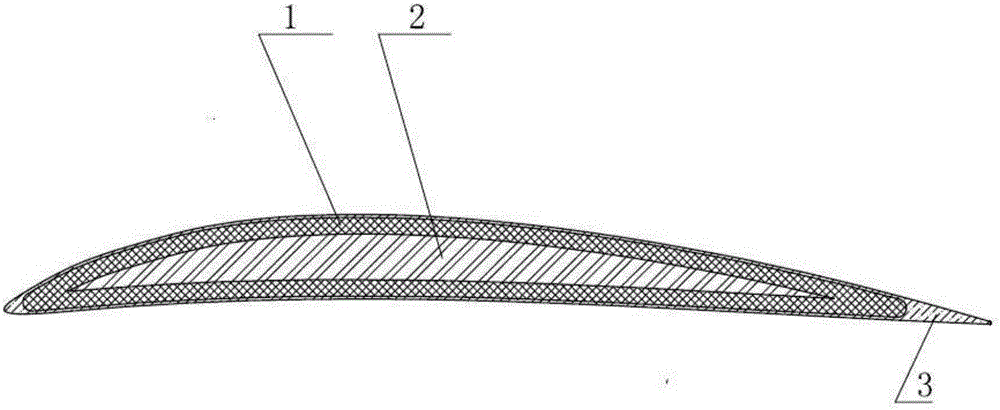

[0027] Such as figure 1 , figure 2 Shown, a kind of ship composite material propeller blade preform preparation method comprises the following steps:

[0028] The first step: use CFD software to calculate the hydrodynamic load of the propeller blade under the design working condition, and then design the equal-thickness fiber sleeve 1, the thickness of the above-mentioned equal-thickness fiber sleeve 1 is 5mm, and the fiber angle is [0 / 30 / 0 / 30] s. After checking by the finite element software, the design of the fiber sleeve 1 of equal thickness meets the strength and deformation requirements of the propeller blade.

[0029] Step 2: Design and manufacture a core mold according to the thickness of the equal-thickness fiber sleeve 1 obtained in the first step. The core mold design method is to use three-dimensional modeling software to offset the blade surface and blade back of the propeller blade along the negative normal direction by 5mm (the Offset distance is identical w...

Embodiment 2

[0033] Embodiment 2 (design for the propeller of diameter 500mm):

[0034] Such as figure 1 , figure 2 Shown, a kind of ship composite material propeller blade preform preparation method comprises the following steps:

[0035] The first step: use CFD software to calculate the hydrodynamic load of the propeller blade under the design working condition, and then design the equal-thickness fiber sleeve 1, the thickness of the above-mentioned equal-thickness fiber sleeve 1 is 3 mm, and the fiber angle is [-30 / 0 / 45 / -30 / 0 / 45]s. After checking by the finite element software, the design of the fiber sleeve 1 of equal thickness meets the strength and deformation requirements of the propeller blade.

[0036] Step 2: Design and manufacture a core mold according to the thickness of the equal-thickness fiber sleeve 1 obtained in the first step. The core mold design method is to use three-dimensional modeling software to offset the blade surface and blade back of the propeller blade al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com