Patents

Literature

62results about How to "High shape precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

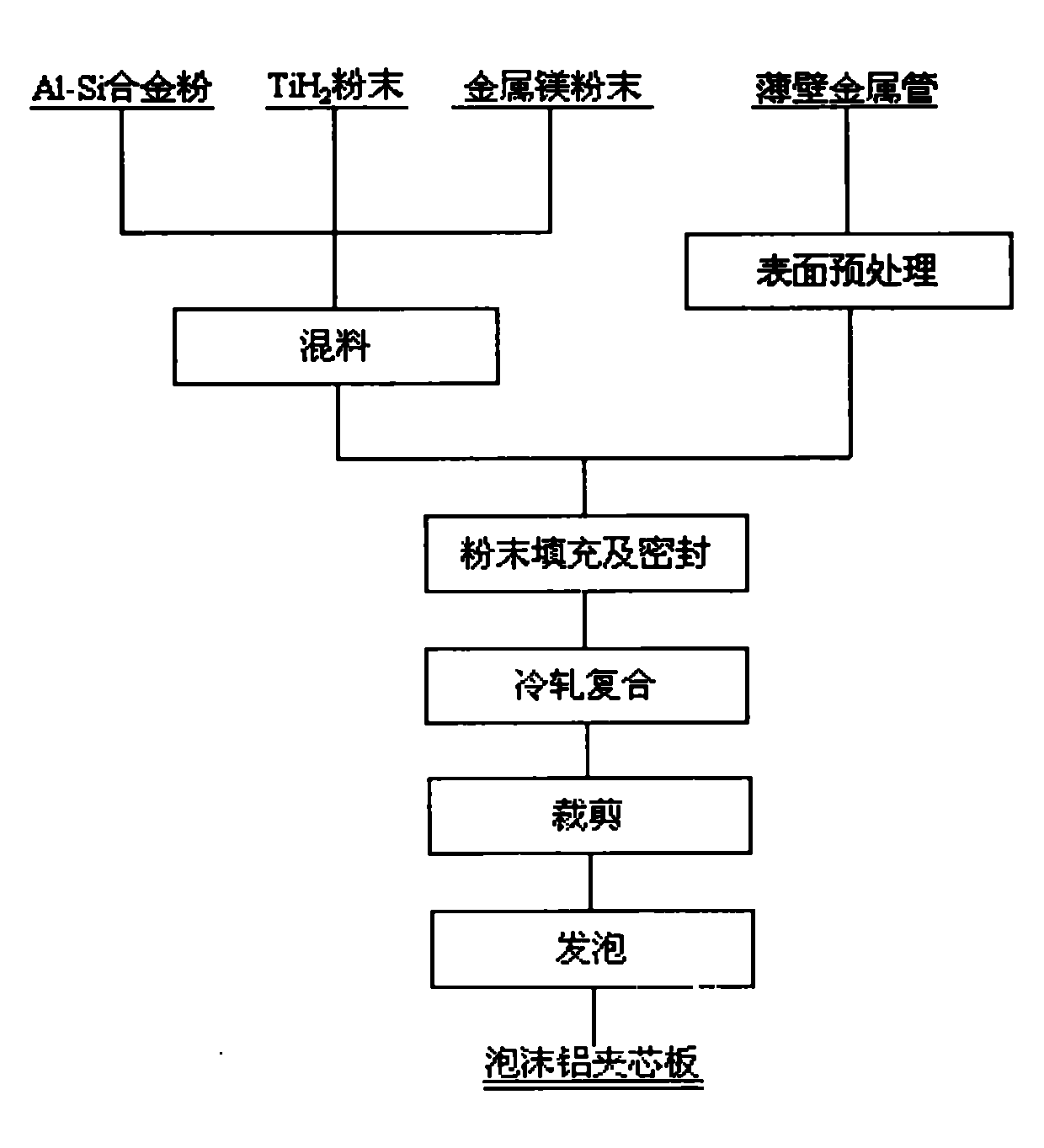

Method for manufacturing foamed aluminum sandwich plate

The invention relates to a method for manufacturing a foamed aluminum sandwich plate, which belongs to the field of porous foam metal and laminar composite materials. The method comprises the following steps of: uniformly mixing aluminum-silicon alloy powder prepared by an atomization method, and foaming agent titanium hydride powder and metal magnesium powder in a certain ratio; filling the powder into a thin-wall steel (or aluminum alloy) tube with one sealed end; sealing the other end of the tube after powder filling and preparing a rolled blank; rolling and compounding at a slow speed on a cold rolling mill; trimming an obtained composite plate and cutting a foamed preformed blank according to the size of a foaming mold; foaming the preformed blank in a steel mold in a limited way; adjusting foaming temperature and foaming time as required; and foaming at a high temperature for a short period of time to obtain a high-quality foamed aluminum sandwich plate with a uniform foam structure in a core layer, good interface bonding, high thickness accuracy and excellent plate profile. The method has the outstanding characteristics of low equipment requirement, high plate profile accuracy of a product, high three-point bending strength and the like and is advantaged technology suitable for mass industrial production of foamed aluminum sandwich structural materials.

Owner:NORTHEASTERN UNIV

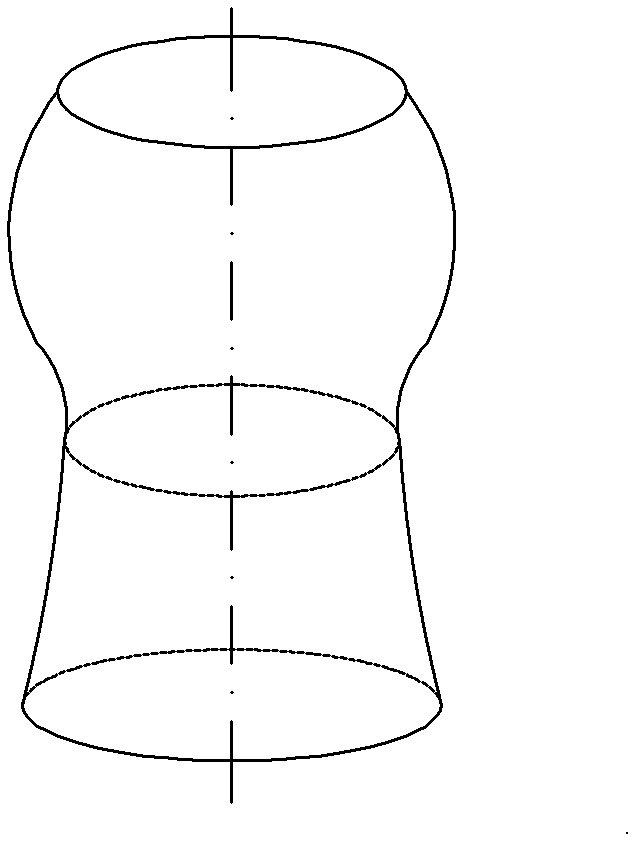

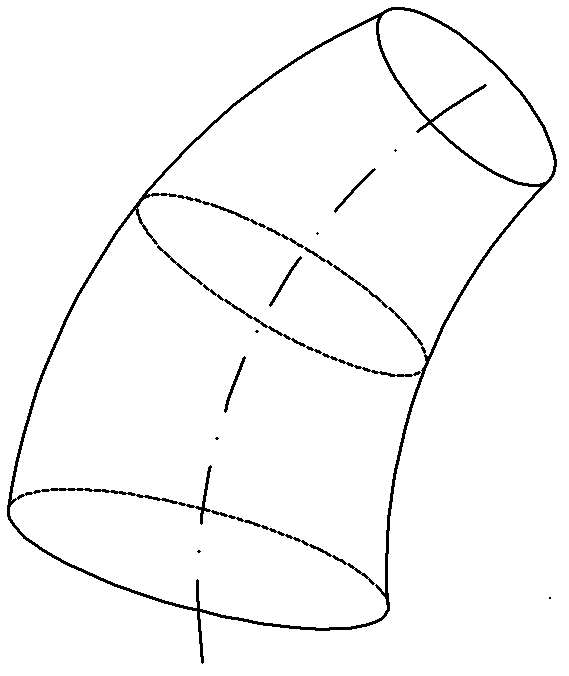

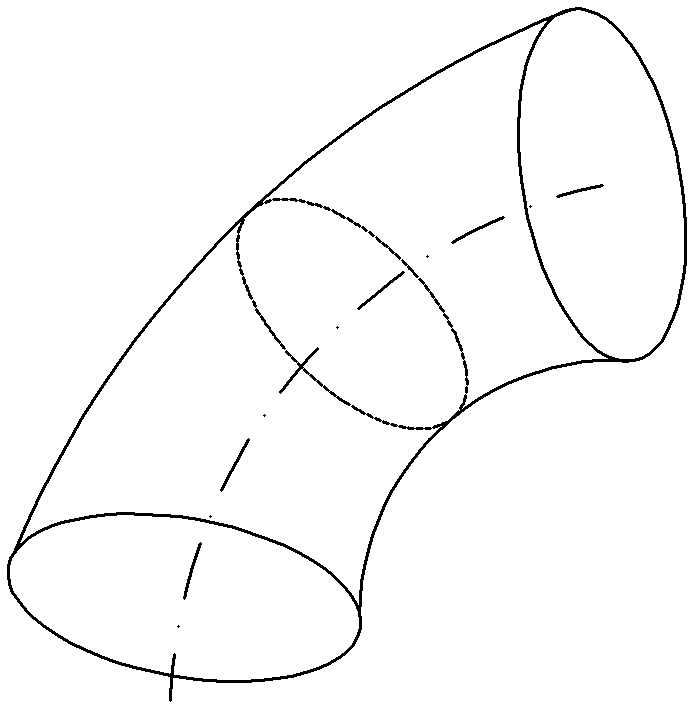

Automatic fiber laying variable-angle path planning method for non-developable curved surface part

The invention discloses an automatic fiber laying variable-angle path planning method for a non-developable curved surface part, which relates to a fiber laying path plan making method for a non-developable curved surface part and is used for solving the problem that in the complexity of a fiber laying process, the appearance accuracy and various properties of a composite material are influenced by inevitable shearing and re-conveying phenomena occurring in the automatic fiber laying process of the non-developable curved surface part. In a scheme I, the method comprises the following steps of: acquiring data information from a non-developable revolving barrel part; calculating the laying reference angle of a presoaked tow on each intersection line; determining points on an initial path; determining points on other paths; and making a path line. A scheme II is different from the scheme I in that data information is acquired from a non-developable curved surface variable-section conical shell part; and a scheme III is different from the scheme I and the scheme II in that data information is acquired from a non-developable curved surface variable-section joint part. The method is used for planning an automatic fiber laying variable-angle path on the outer surface of the non-developable curved surface part.

Owner:HARBIN INST OF TECH

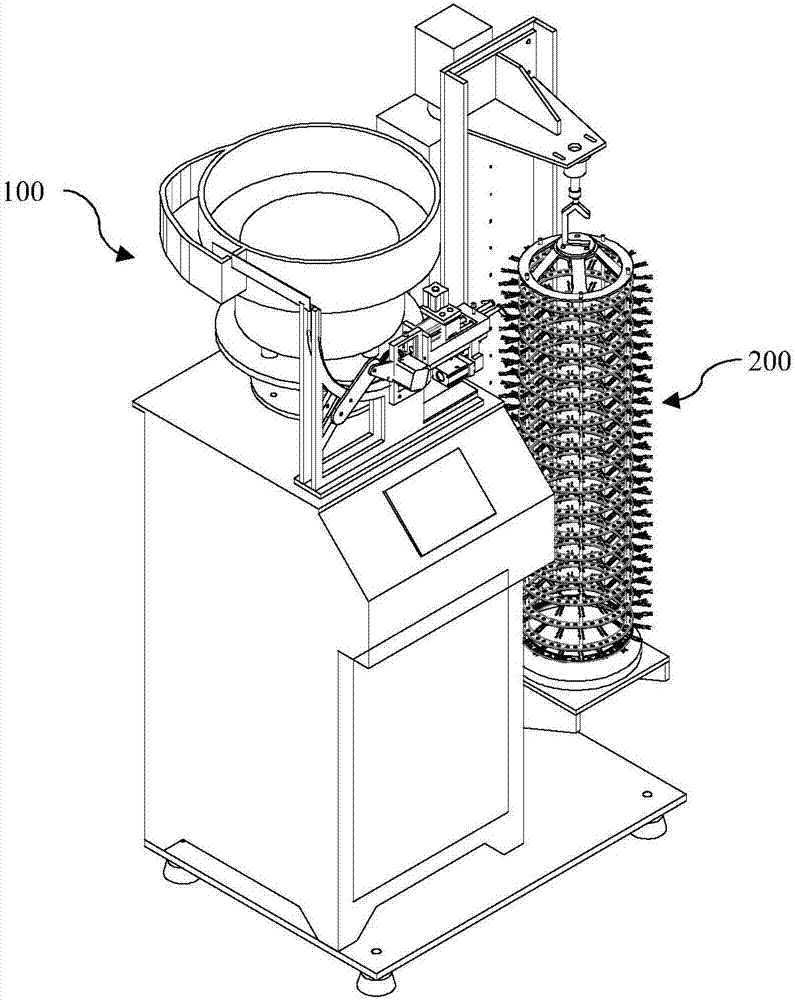

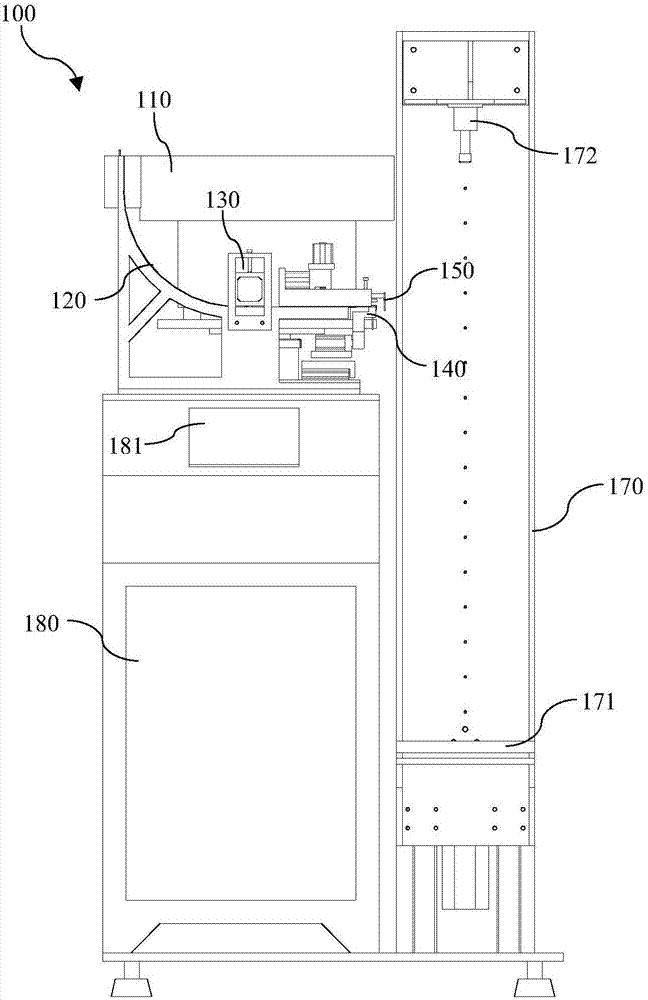

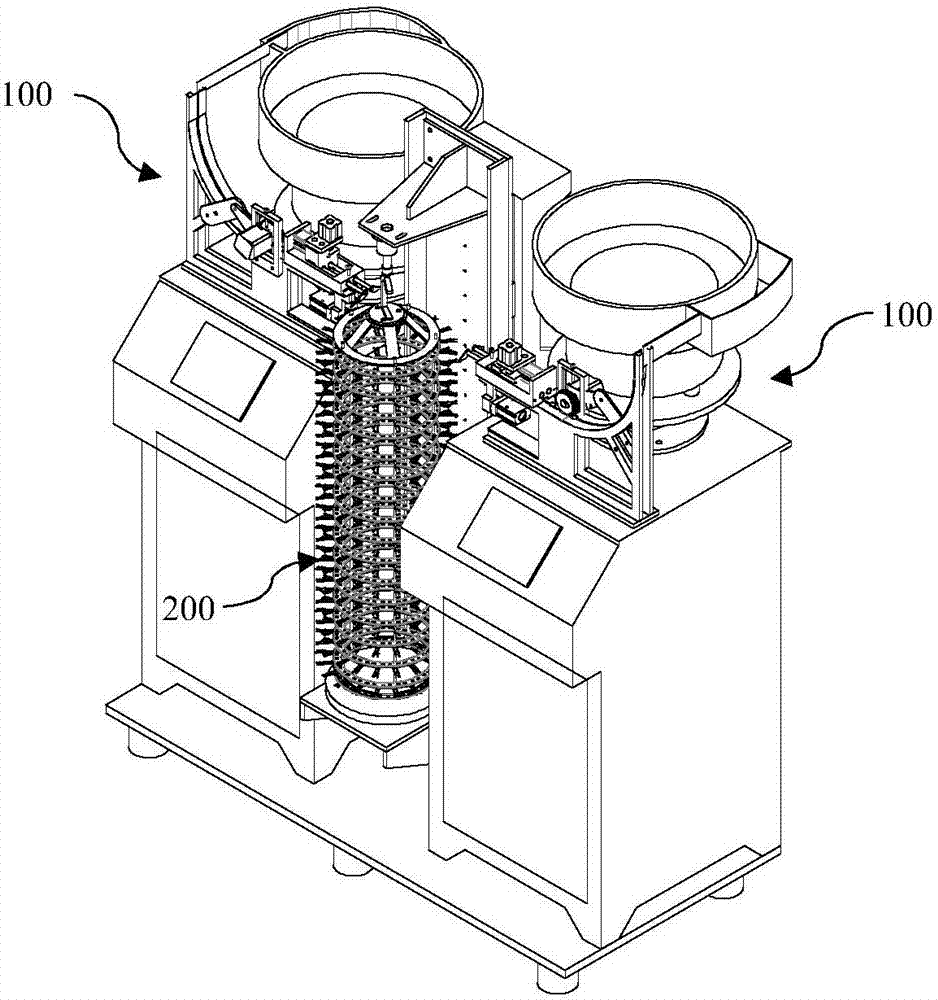

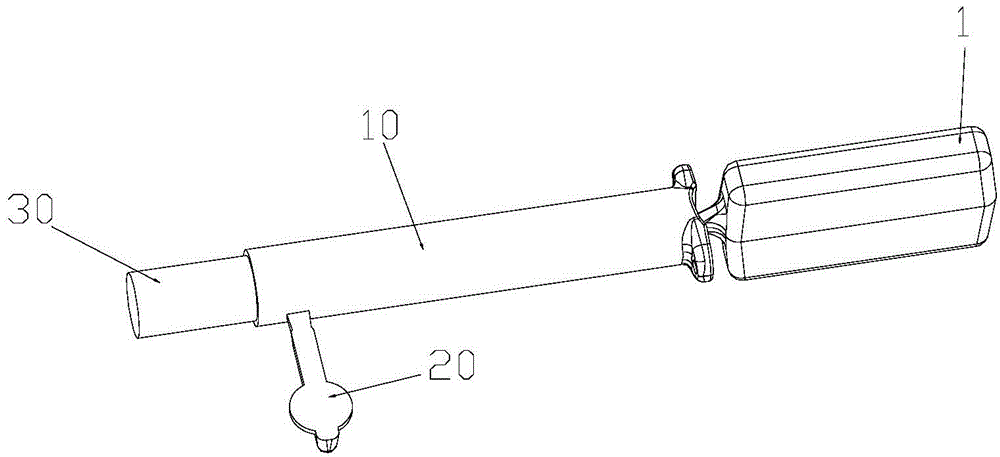

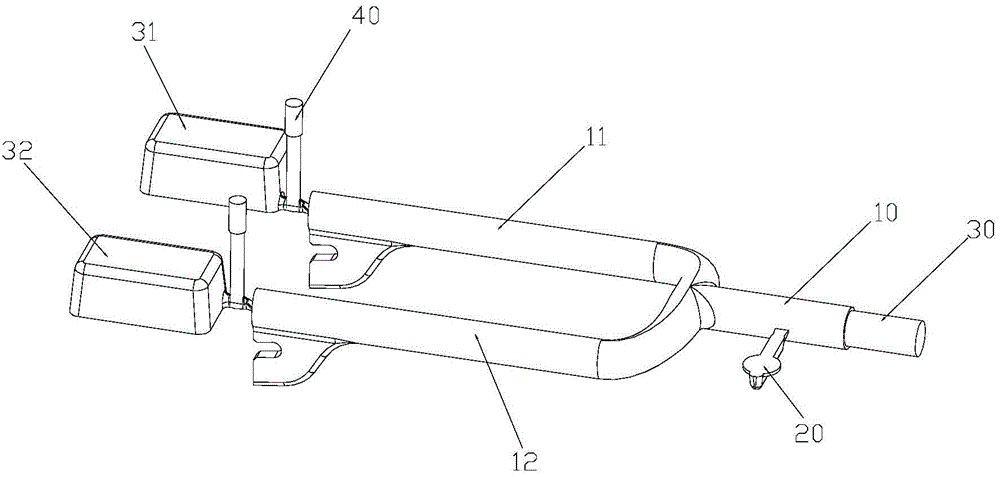

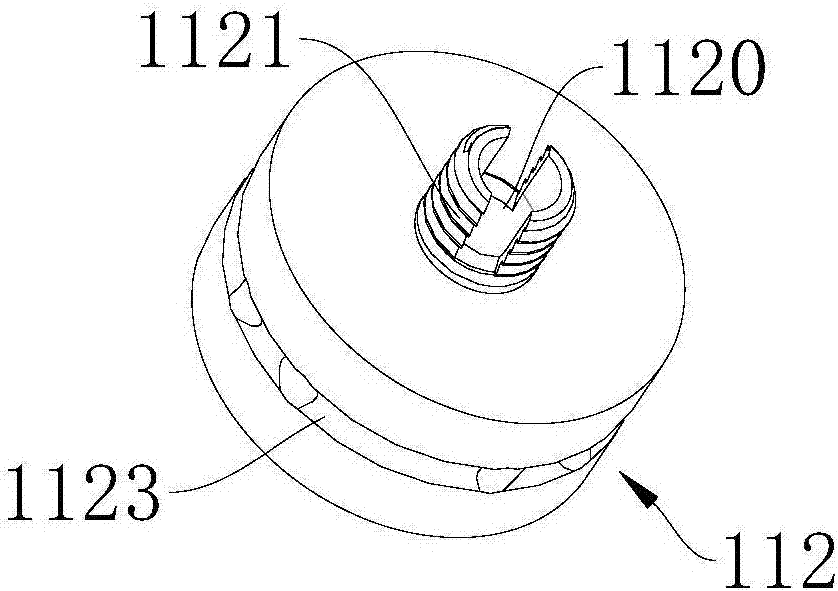

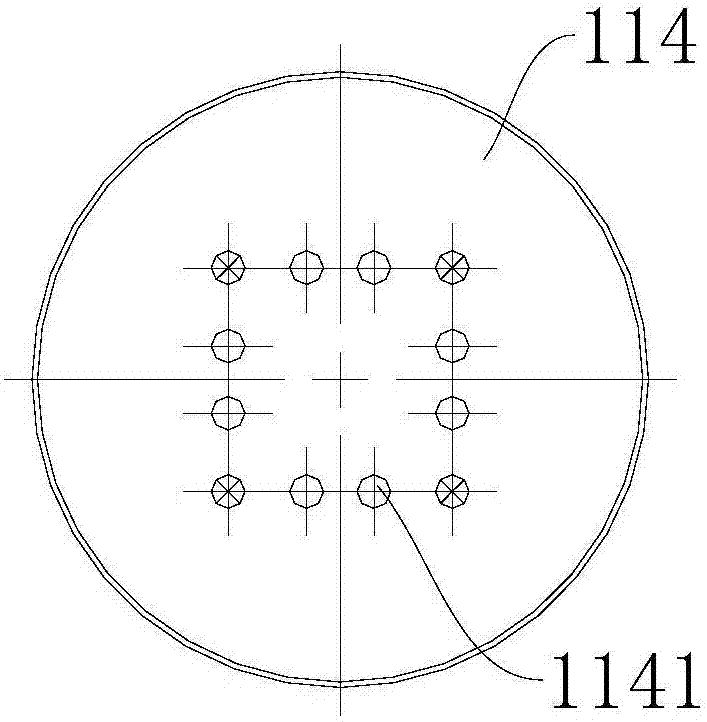

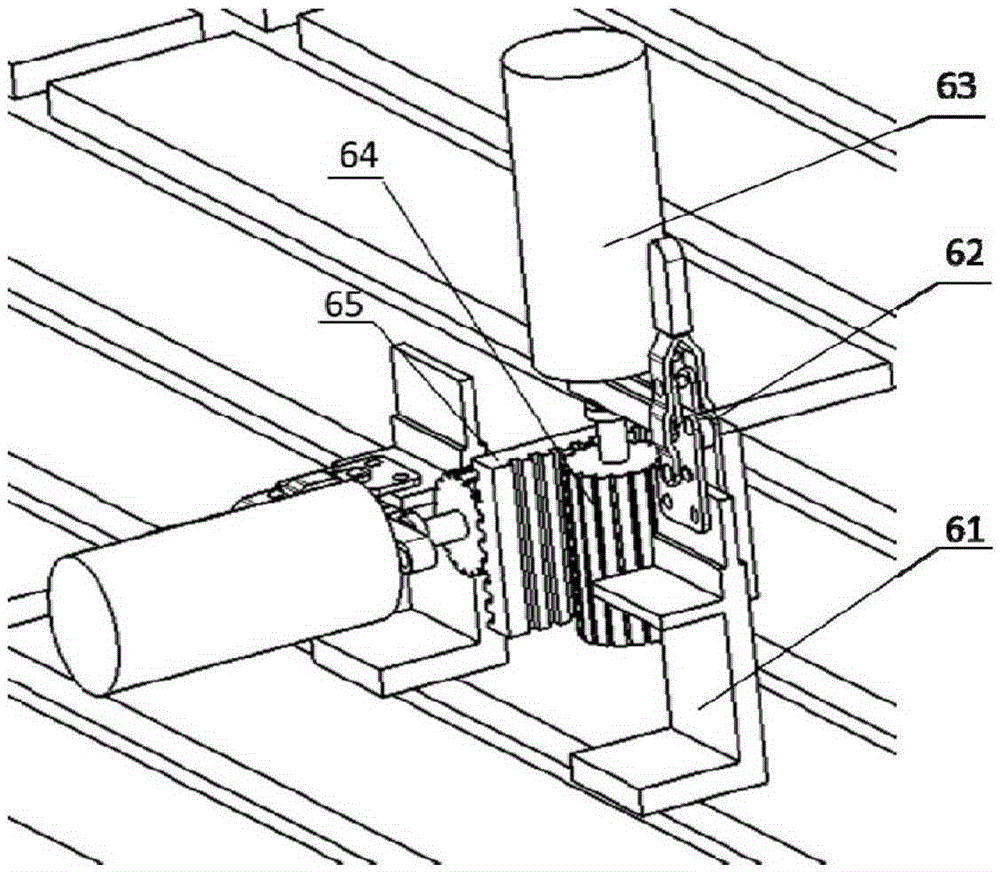

Automatic zipper head hanging device

PendingCN107080334AWide versatilityControl positioning stopSlide fastenersStructural engineeringElectrical and Electronics engineering

The invention discloses an automatic zipper head hanging device. The automatic zipper head hanging device comprises a hanging machine provided with a rack, and a hanging tool installed on the hanging machine and used for hanging a hanging needle of the zipper head, wherein a guide rail for a zipper head to move, a manipulator for clamping the zipper head and a conveying drive assembly capable of driving the zipper head to move on the guide rail, and the manipulator can clamp the zipper head on the guide rail and hang the zipper head on the hanging needle of the zipper head. The automatic zipper head hanging device can rapidly, stably and firmly hang the zipper head on the hanging tool, the electrical conductivity of the zipper head in contact with the hanging tool is good, the electroplating quality is improved, and the product quality of the zipper head, especially the high-quality zipper head is greatly improved.

Owner:石狮市八九机械设备有限公司

Processing mechanism and processing method of main body component of bicycle

InactiveCN103552220AUniform wall thicknessHigh shape precisionDomestic articlesCycle framesHigh pressure waterHigh pressure

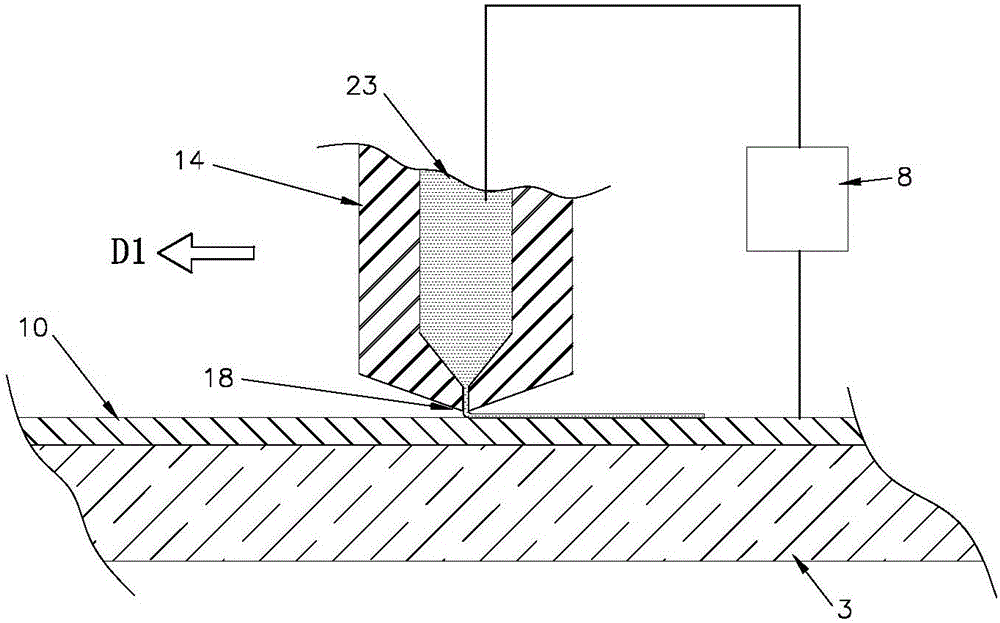

The invention provides a processing mechanism and a processing method of a main body component of a bicycle. The processing mechanism is characterized in that a water needle for injecting water into a cavity is arranged at a main cavity channel of the cavity of a mold, wherein the front part of the water needle is inserted into the cavity, and a material overflowing cavity for containing overflowed materials is communicated with the other end, opposite to the direction of the water needle, of the main cavity channel through an overflowing pipe; a closeable glue feeding member for injecting glue materials is further arranged at the side wall of the main cavity channel. According to the processing mechanism and the processing method, a water-assisted molding process is introduced into an injection molding process, the two processes are organically combined, and high pressure water is utilized for driving the redundant glue materials in a product out of the cavity, so that the component product is very rapid to cool, and pressure maintaining and cooling processes in the normal injection molding process can be omitted; furthermore, the product can be molded at a time, so that the efficiency is greatly improved, meanwhile, the strength is guaranteed, the wall thickness of the component is very uniform, the shape precision is greatly improved as well, the shapes of bicycle components such as bicycle frames having more braches are diversely designed, and the weights of the bicycle components are light.

Owner:TIANJIN SILVER BASSIS TECH CO LTD

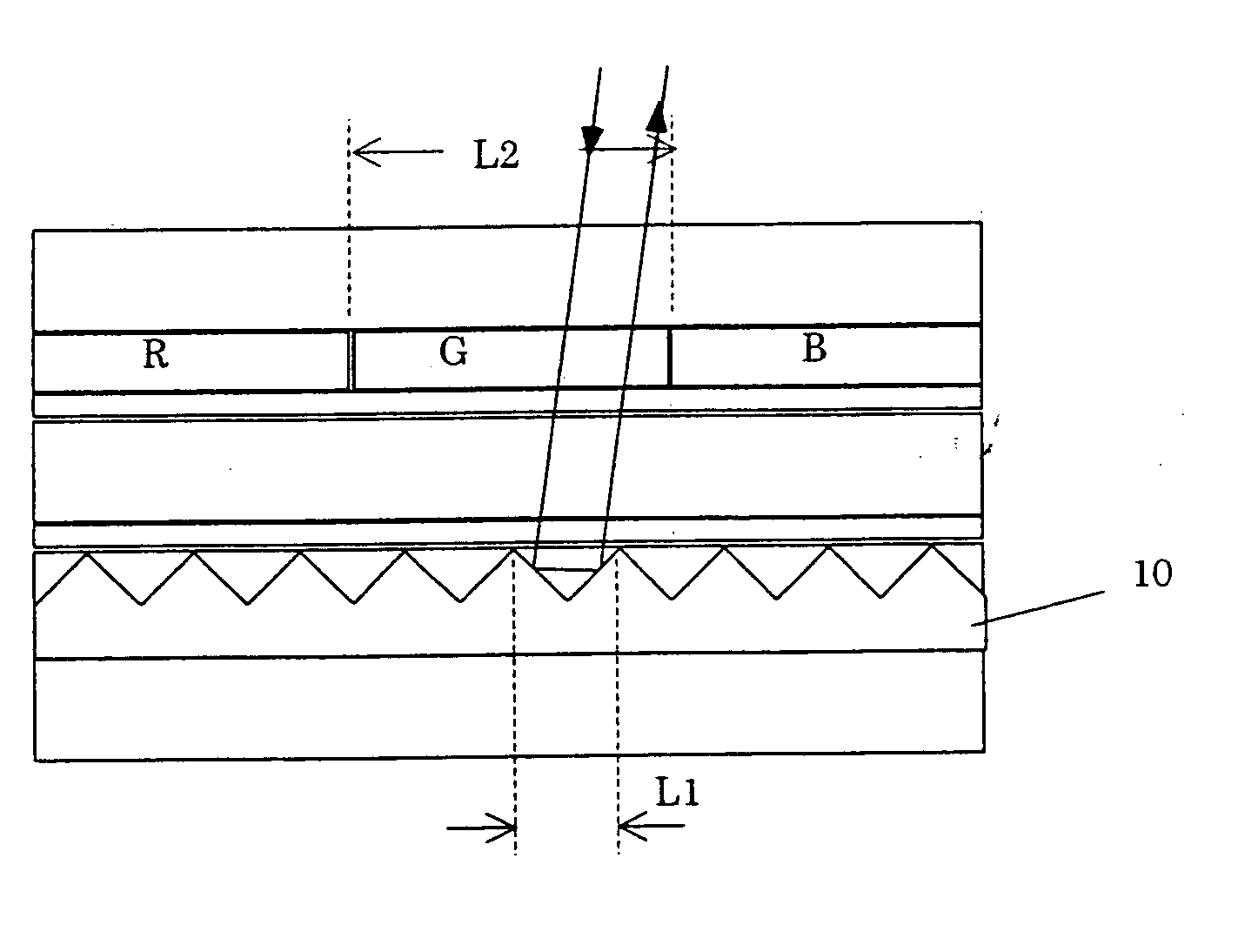

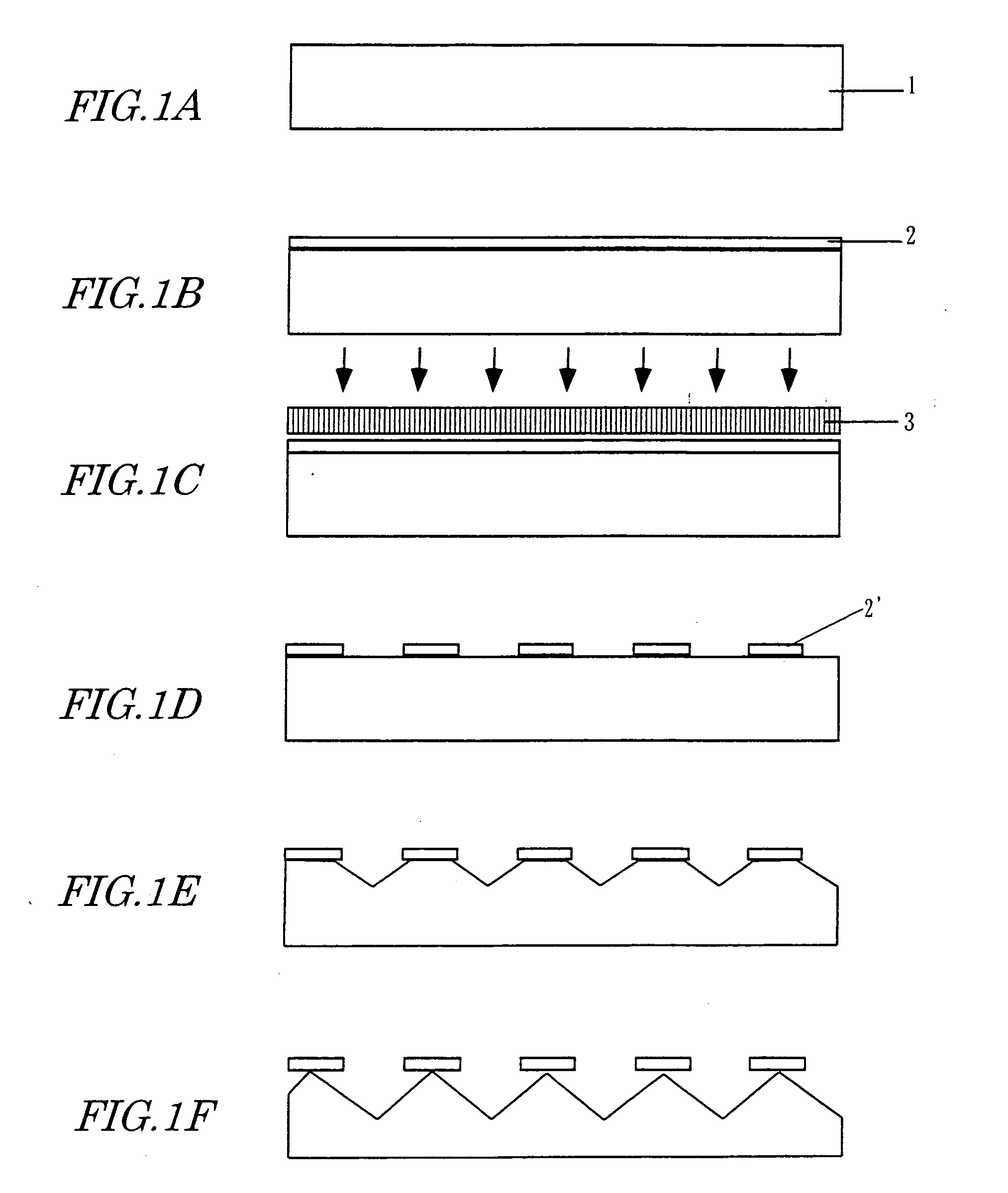

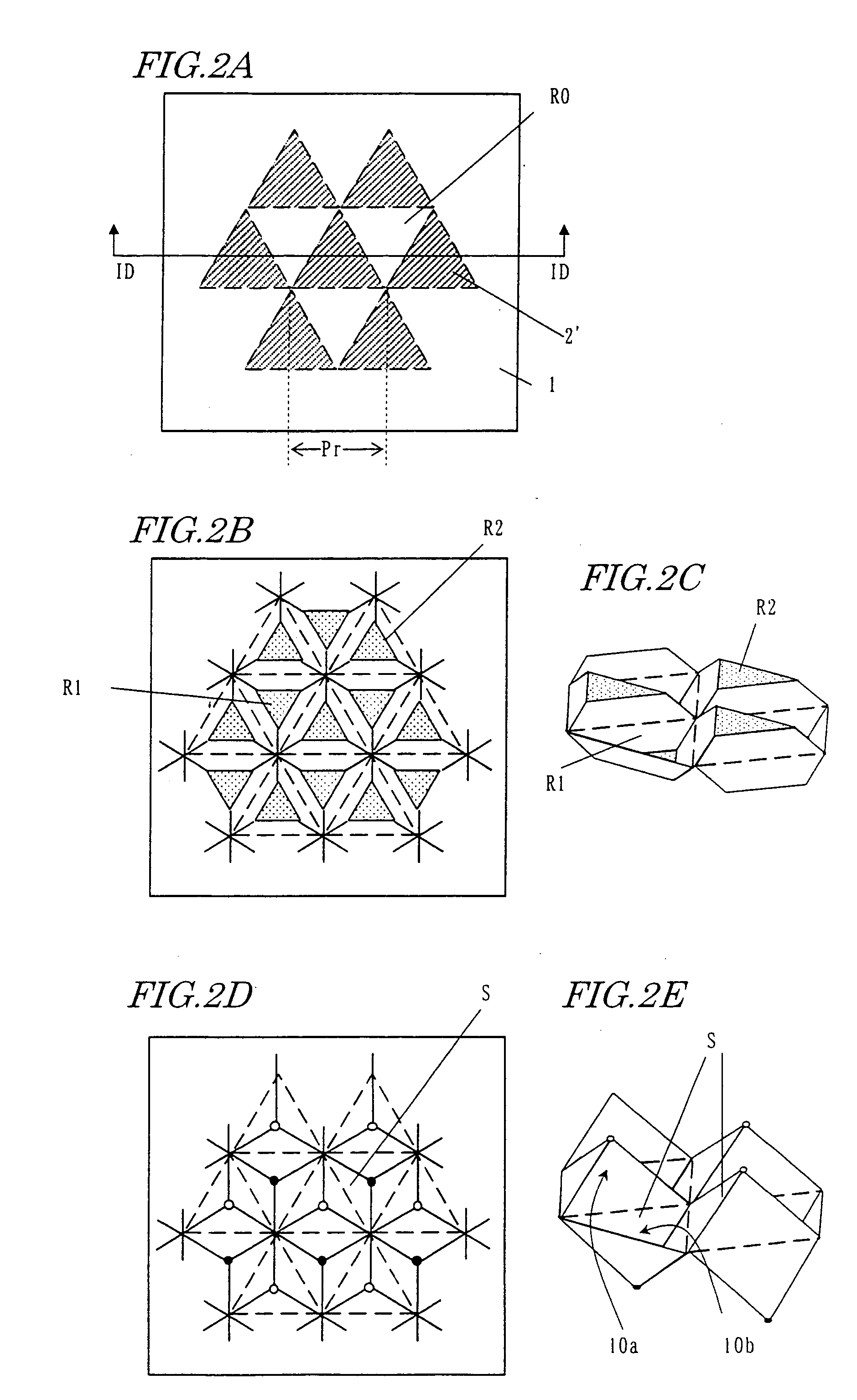

Micro corner cube array, method of making the micro corner cube array and reflective type display device

InactiveUS20060146237A1Small sizeHigh shape precisionNon-linear opticsOptical elementsEtching rateCrystal plane

A method of making a micro corner cube array includes the steps of: preparing a substrate, at least a surface portion of which consists of cubic single crystals and which has a surface that is substantially parallel to {111} planes of the crystals; and etching the surface of the substrate anisotropically, thereby forming a plurality of unit elements for the micro corner cube array on the surface of the substrate. Each of these unit elements is made up of a number of crystal planes that have been formed at a lower etch rate than the {111} planes of the crystals.

Owner:SHARP KK

Composite mold for integrally molding inner profile of ribbed composite wall panel

The invention belongs to the polymer matrix composite molding technology, and relates to a composite mold for integrally molding an inner profile of a ribbed composite wall panel. The molding mold comprises an upper flange molding soft mold body, a web molding soft mold body, an upper R corner molding soft mold body and a lower flange and R corner molding soft mold body. The upper R corner molding soft mold body of the composite mold is made of a rigid and flexible blended and cured material, and therefore the rigidity of a soft mold upper R corner area is increased, the pressure in a tank is better transmitted to an upper R corner area of the ribbed composite wall panel, and the defects of upper R corner area hole concentration, layering, appearance deviation and the like can be effectively avoided. The lower flange and R corner molding soft mold body is utilized for guaranteeing the inner quality and appearance accuracy of a lower flange and a lower R corner area, especially a side profile of the lower flange and R corner molding soft mold body is chamfered according to the theoretical appearance of an inner profile of a lower R corner of each rib, the procedure of preparing a lower R corner molding soft mold body by entering the tank is omitted, the mold manufacturing cost is reduced, and the appearance accuracy of the lower R corner area is improved.

Owner:AVIC COMPOSITES

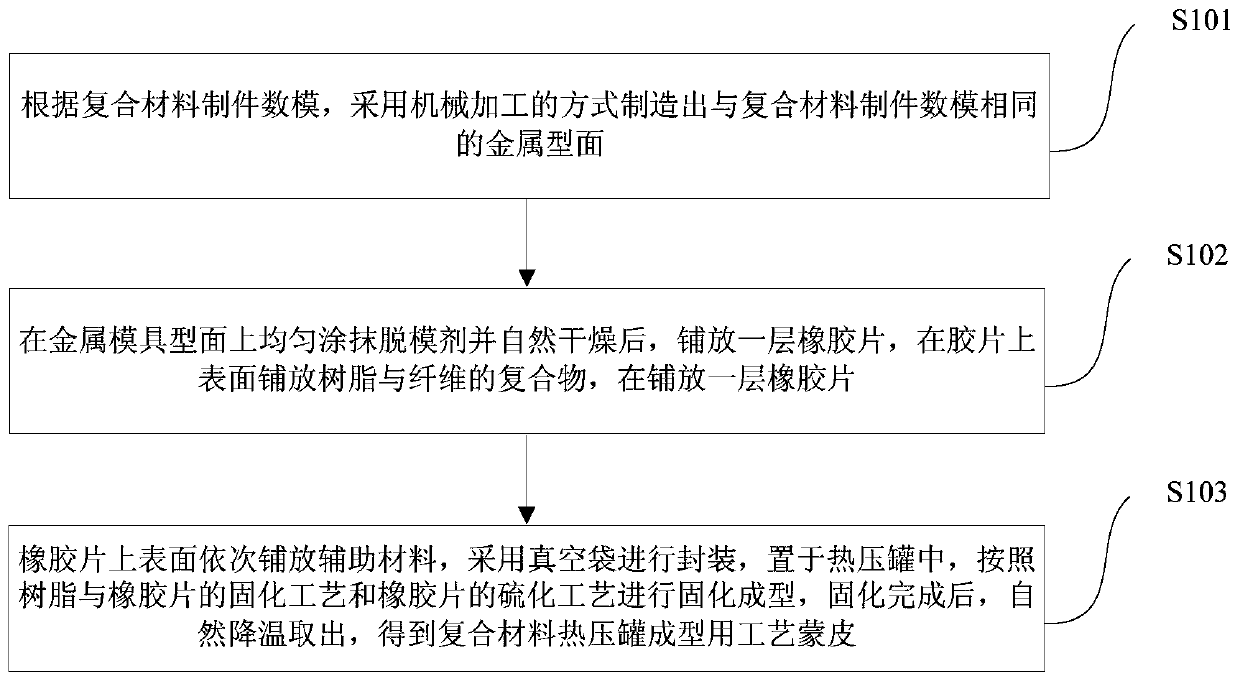

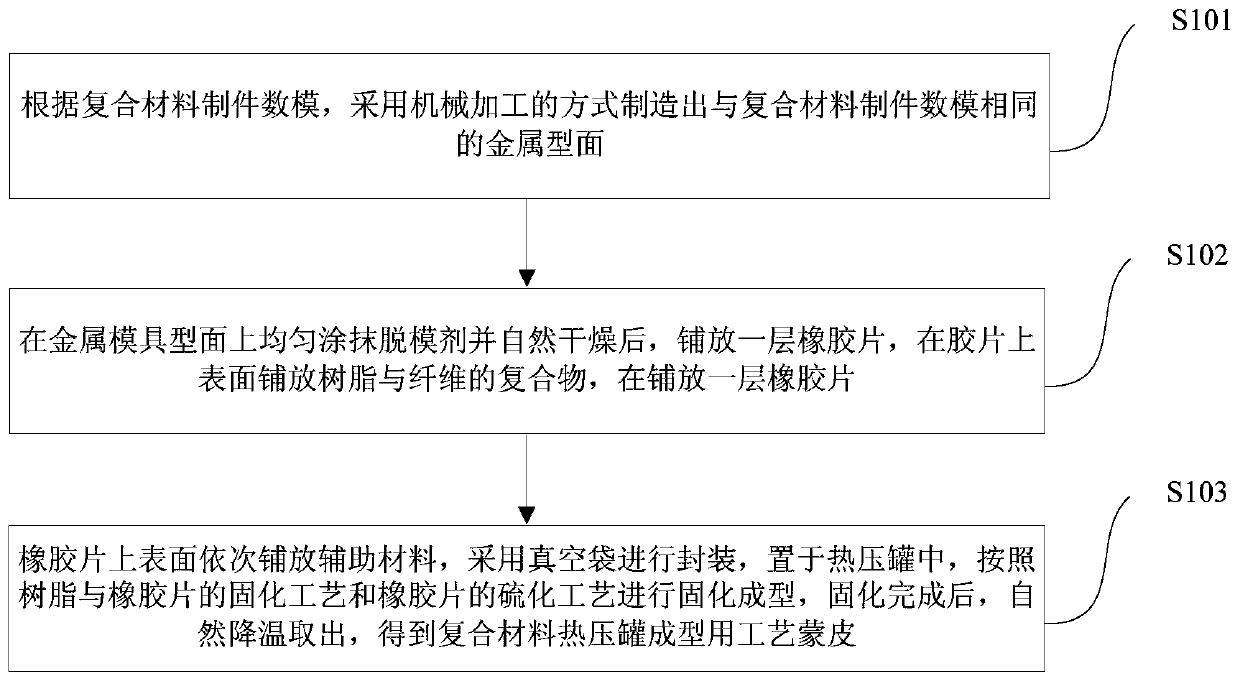

Process skin for autoclave forming of composite product and preparation method of process skin

The embodiment of the invention discloses a process skin for autoclave forming of a composite product and a preparation method of the process skin. In the autoclave forming process, the process skin is put on the upper surface of the composite product, an auxiliary material is put on the upper surface of the process skin, under the pressure applied by an autoclave, a prepreg preform is overall pressed downwards, the internal quality is improved, and wrinkles, caused by the weak deformation capacity of the auxiliary material, generated on the surface of the composite product are avoided. Meanwhile, a molded surface consistent with the upper surface of the composite product is arranged on the process skin, so that the appearance precision of the composite product is well guaranteed. The process skin can be widely applied to autoclave forming of composite products with complex shapes, and the appearance precision and the internal quality of the products are greatly improved.

Owner:AVIC BASIC TECH RES INST

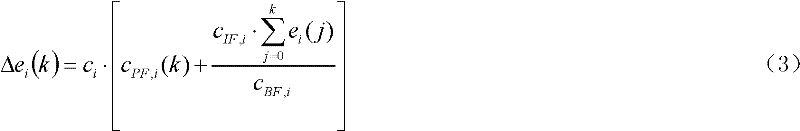

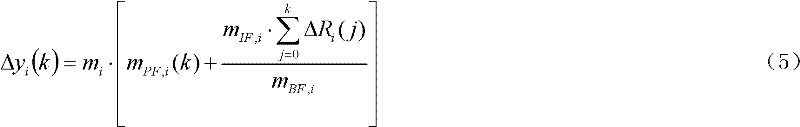

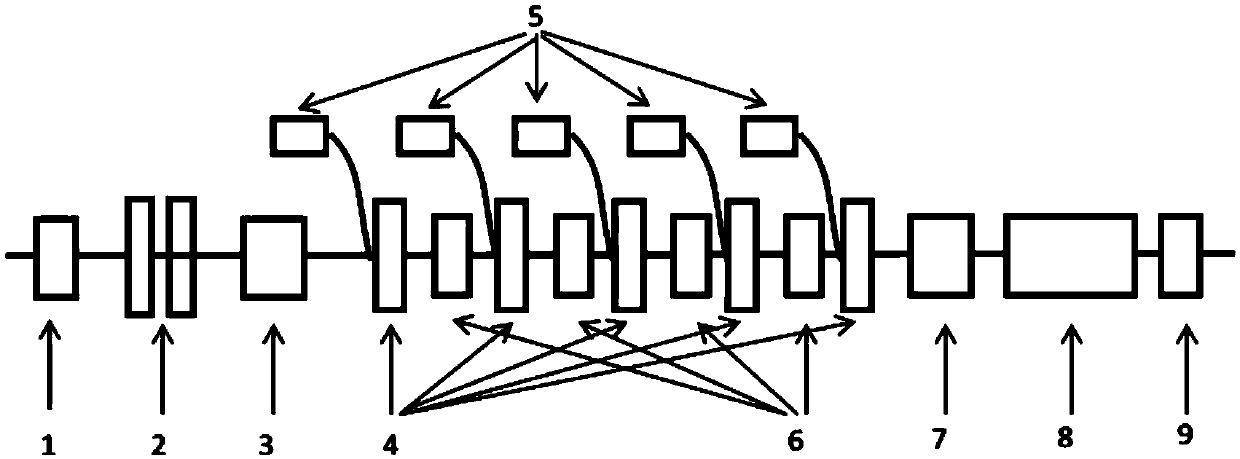

Pipe shape control method for rolling seamless steel pipe by using seven-frame tandem mill

InactiveCN102303051AHigh precisionAvoid interferenceRoll mill control devicesMetal rolling arrangementsEngineeringData treatment

The invention discloses a pipe shape control method for rolling a seamless steel pipe by using a seven-frame tandem mill, which aims to provide a control method for processing data by using on-line detection pipe shape information and controlling rolling parameters in real time by integrating thickness errors, ellipticity errors and straightness errors which influence pipe shapes so as to ensure the accuracy of the pipe shapes. The method comprises the following steps of: 1) presetting the rolling parameters; 2) calculating rolling reduction and rolling force according to actually-measured wall thickness, ellipticity and straightness, namely making the rolling reduction, the wall thickness errors, the ellipticity errors and the straightness errors form a matrix, simplifying the matrix to be a corresponding relationship between the rolling reduction and a single parameter by an elimination method, calculating the rolling reduction caused by the wall thickness errors, the rolling reduction caused by the ellipticity errors and the rolling reduction caused by the straightness errors respectively, and calculating the rolling force by using the sum of the calculated rolling reduction caused by the wall thickness errors, the ellipticity errors and the straightness errors; and 3) modifying the rolling force and roller gap numerical values in real time in the rolling process.

Owner:TIANJIN UNIV OF COMMERCE

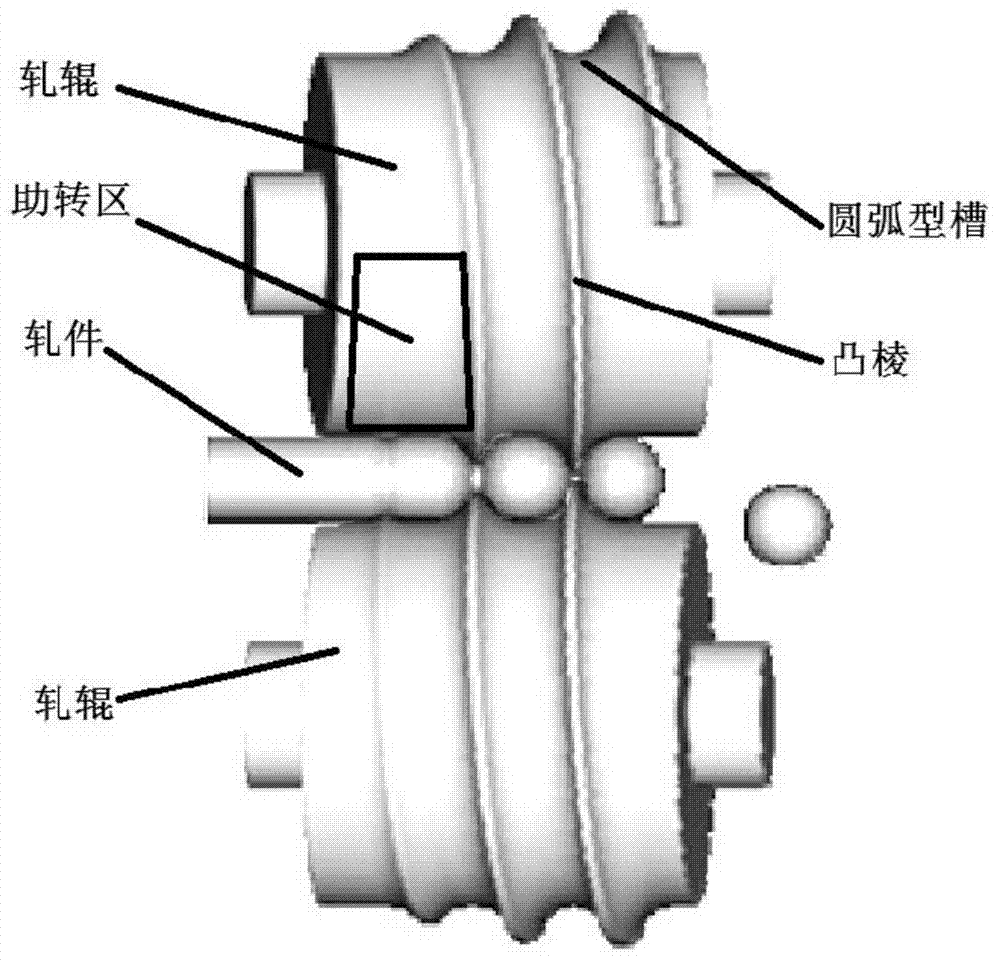

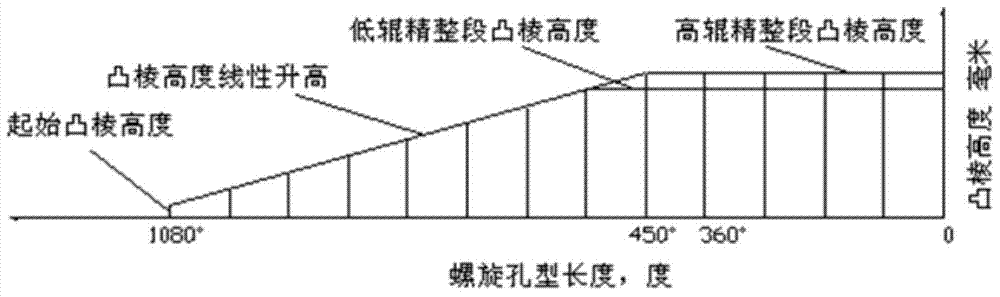

Anode tin ball inclined rolling forming device and method

InactiveCN104707865AEasy to shapeHigh shape precisionMetal rolling stand detailsBearing componentsStrip millRoom temperature

The invention provides an anode tin ball inclined rolling forming device and method. A pure tin material is prepared into a straight rod material with the length of 2m-6m and the diameter which is 93%-97% of the diameter of a rolled thin ball. The method comprises the following steps: conveying the straight rod material into a two-rolled inclined rolling machine at a room-temperature state, and rolling the straight rod material into a tin ball under the action of an inclined rolled spiral hole pattern roller, wherein the diameter of the inclined rolling roller of the thin ball is 5-10 times as much as that of the rolled thin ball; the spiral hole pattern is composed of a circular-arc-shaped groove and a bead; the total length of the hole pattern in the peripheral direction is 900-1260 degrees; the circular arc of the circular-arc-shaped groove is equal to the radius of the rolled tin ball; the bead is linearly raised from bottom to top according to one or two folding lines; the two rollers are divided into high and low rollers according to the height of the finishing section of the bead; the inlet of a roller spiral pattern groove is a conversion assisting region; and the tin material takes industrial water as a cooling lubricant in an inclined rolling process. The anode tin ball inclined rolling forming device and method have the beneficial effects that an annular belt formed by forging is removed, a product has good appearance and high precision, no oil dirt is caused and the production efficiency is high.

Owner:UNIV OF SCI & TECH BEIJING

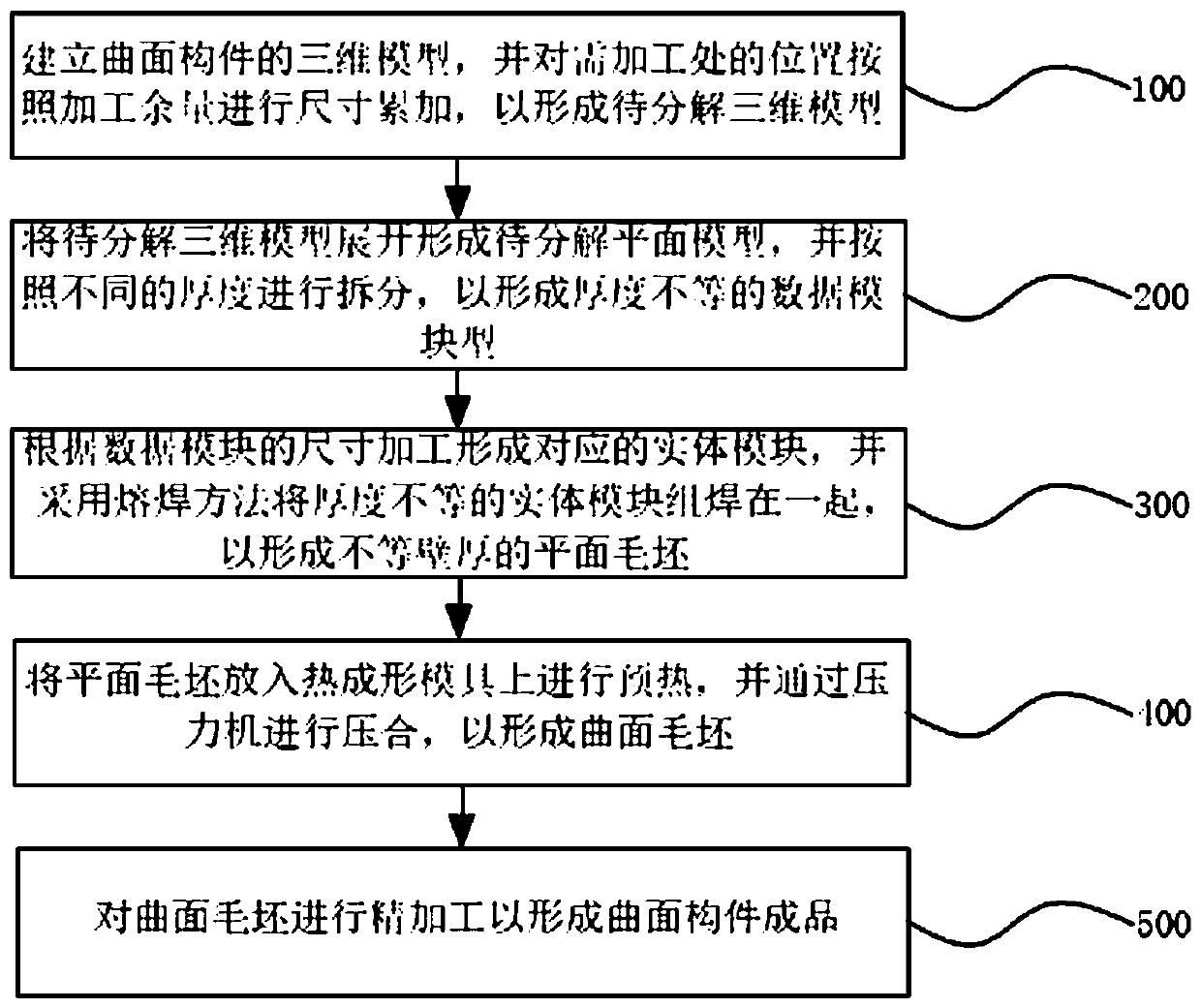

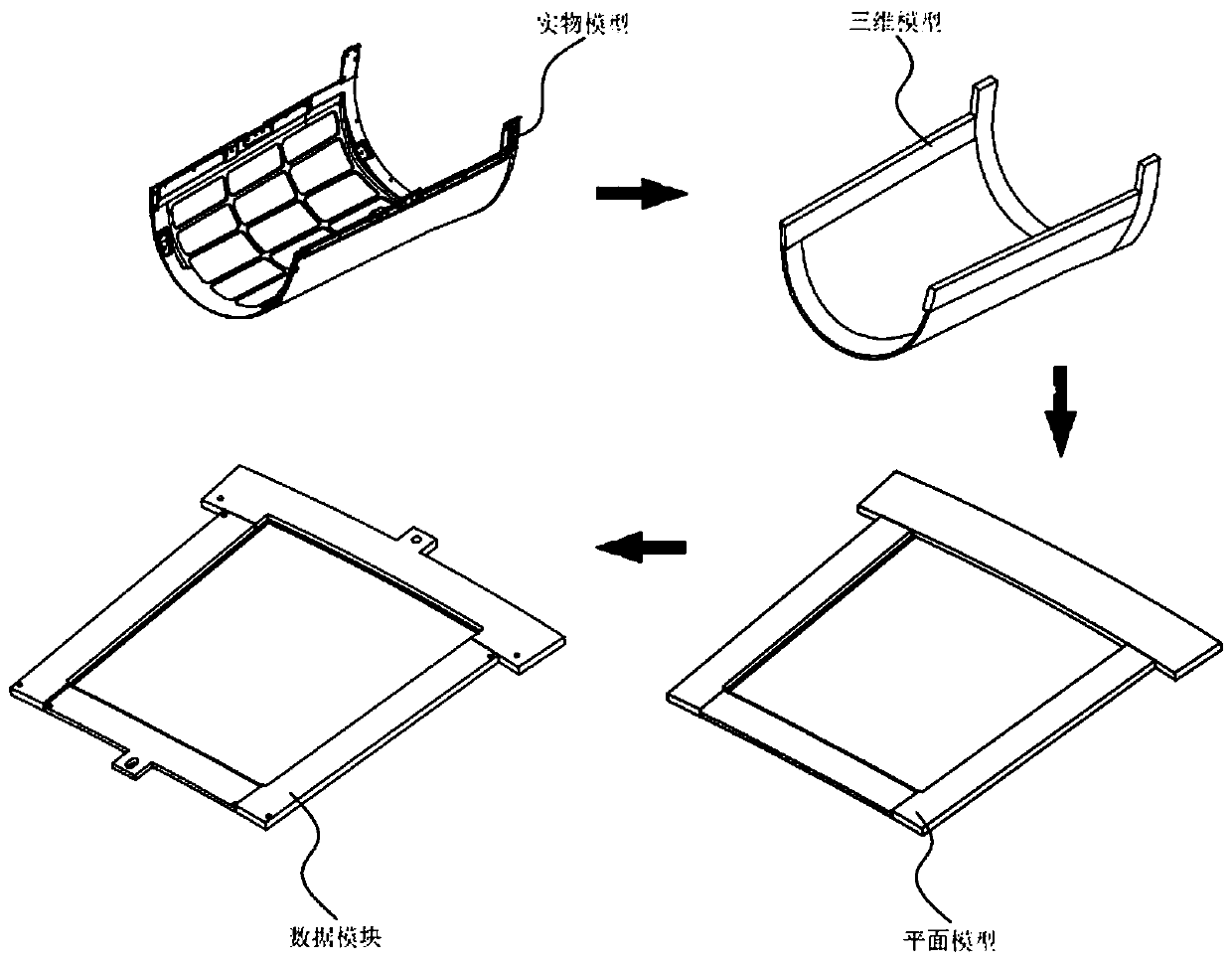

Manufacturing method of unequal-wall-thickness curved surface part

ActiveCN110625344AShorten the development process routeReduce development costsSpecial data processing applications3D modellingThree dimensional modelMachine press

The invention discloses a manufacturing method of an unequal-wall-thickness curved surface part. The method comprises the steps that a three-dimensional model of the curved surface part is built, theposition required to be machined is subjected to size accumulation according to the machining allowance, and a three-dimensional model to be decomposed is formed; the three-dimensional model to be decomposed is unfolded to form a plane model to be decomposed, according to different thicknesses, dismounting is carried out, and data modules with uneven thicknesses can be formed; according to the size of the data modules, corresponding solid modules are formed through machining, a fusion welding method is adopted for installing and assembling the solid modules with the unequal thicknesses, and anunequal-wall-thickness plane workblank is formed; the plane workblank is put on a hot forming mold to be preheated, press fitting is carried out through a press machine, and a curved surface workblank is formed; and the curved surface workblank is subjected to finish machining to form a curved surface part finished product. Through one-time thermal forming, forming of the unequal-wall-thickness curved surface part can be achieved, the development process of the part is shortened, the development cost is reduced, the thermal forming has the effect of removing stress, and the heat treatment isnot needed.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

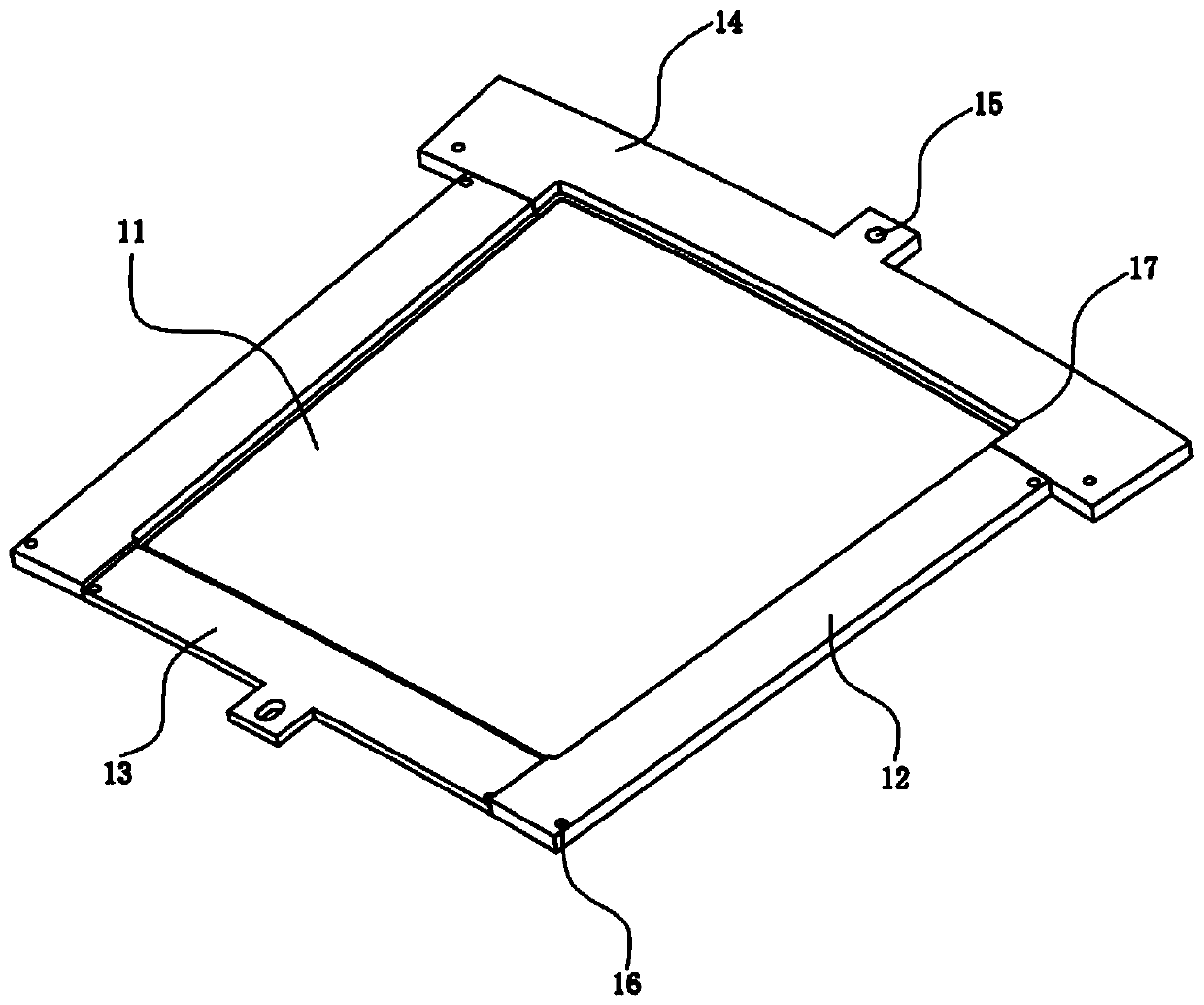

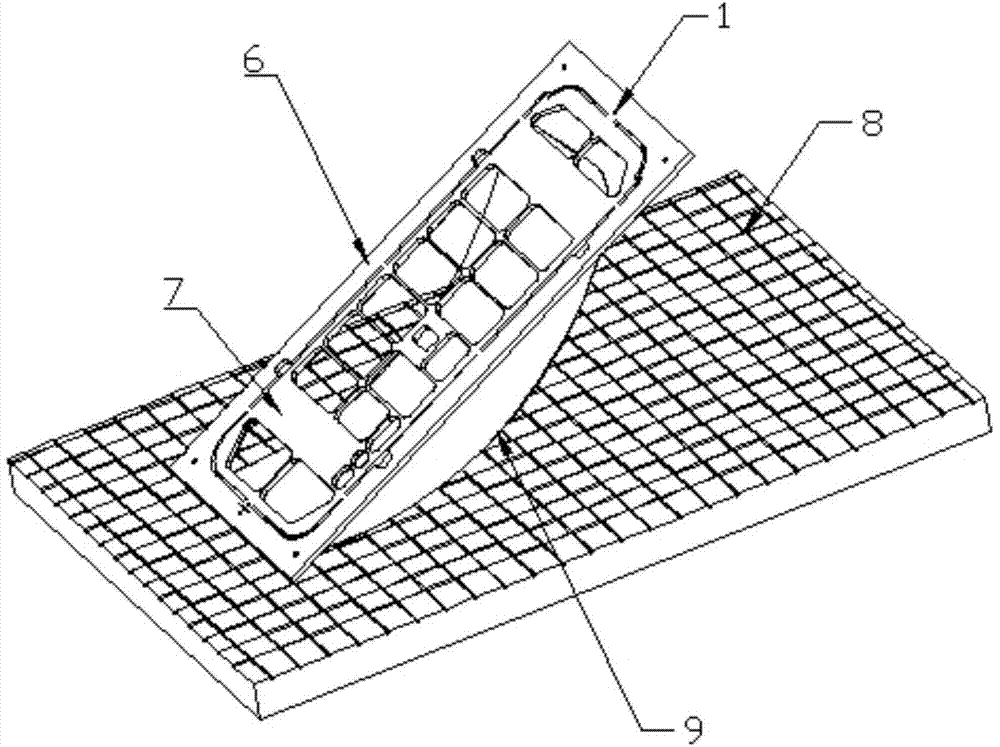

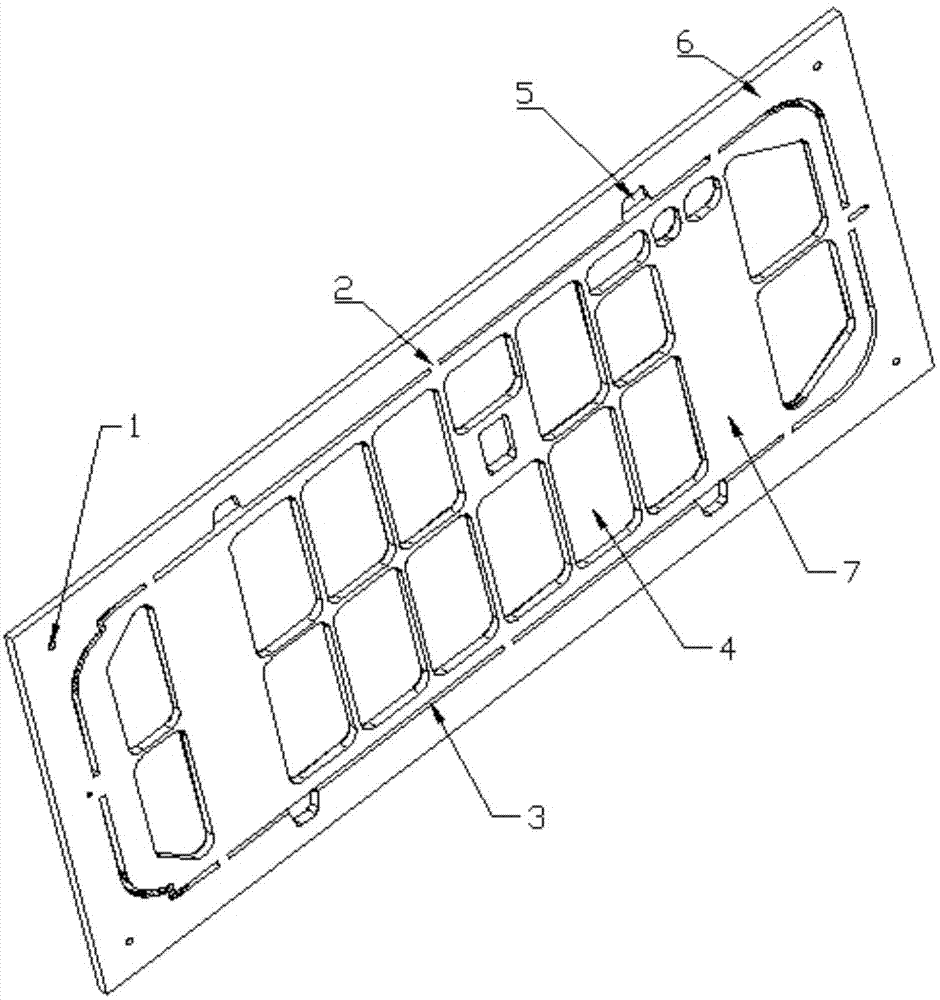

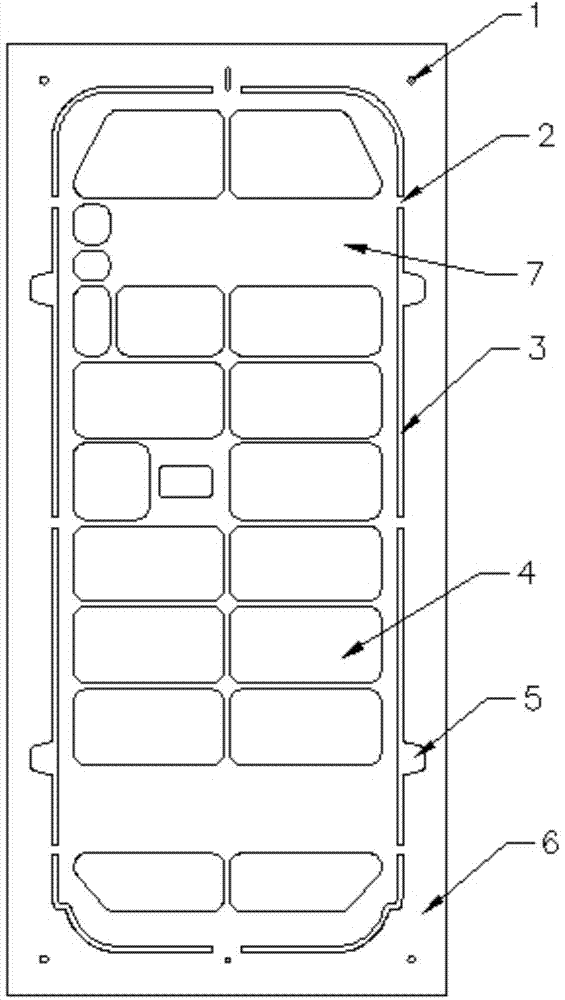

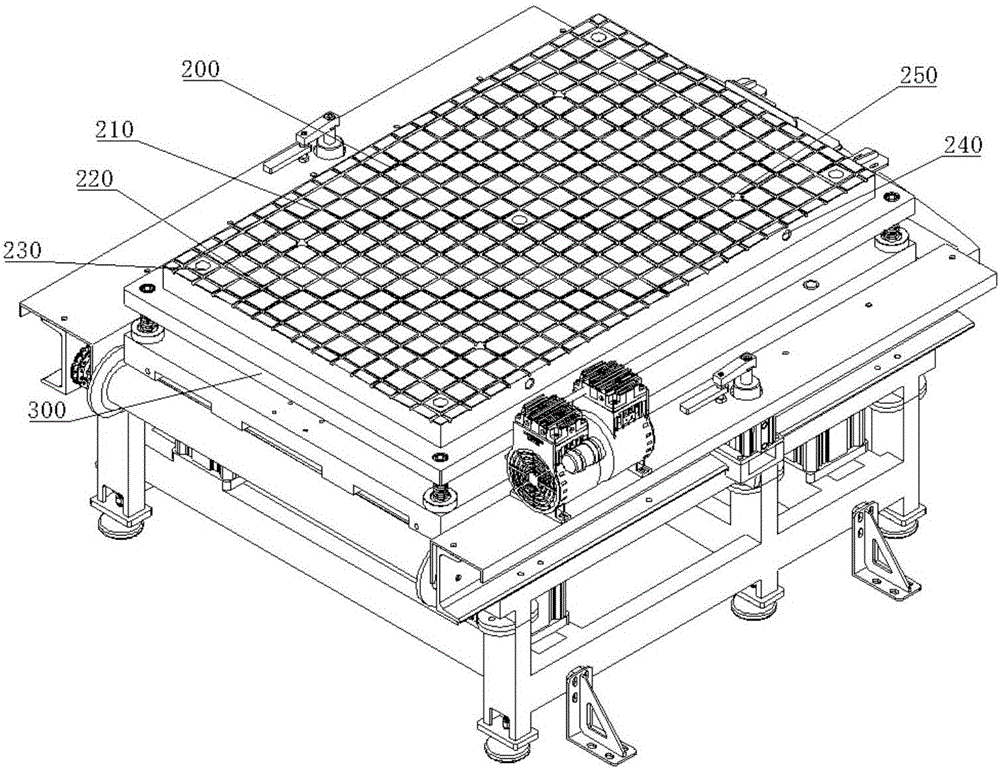

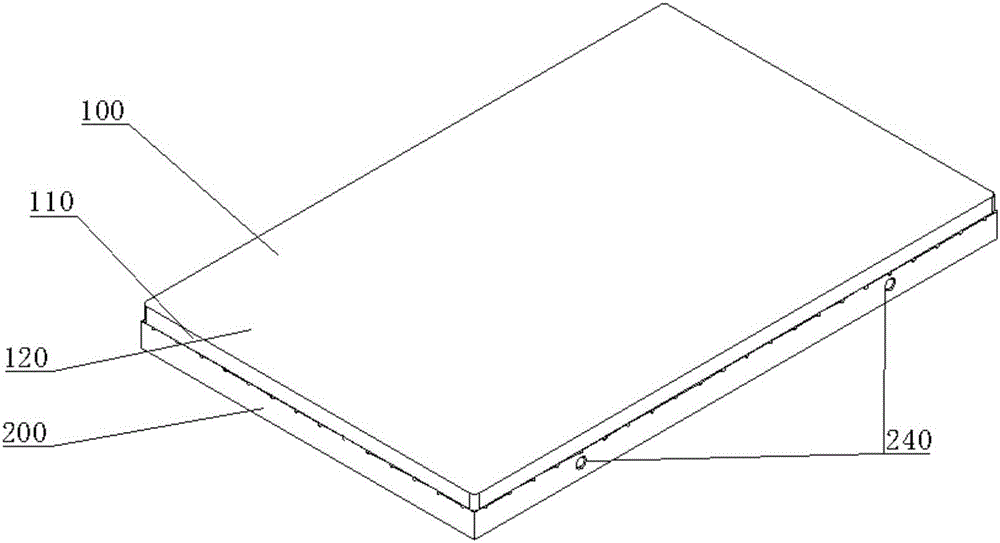

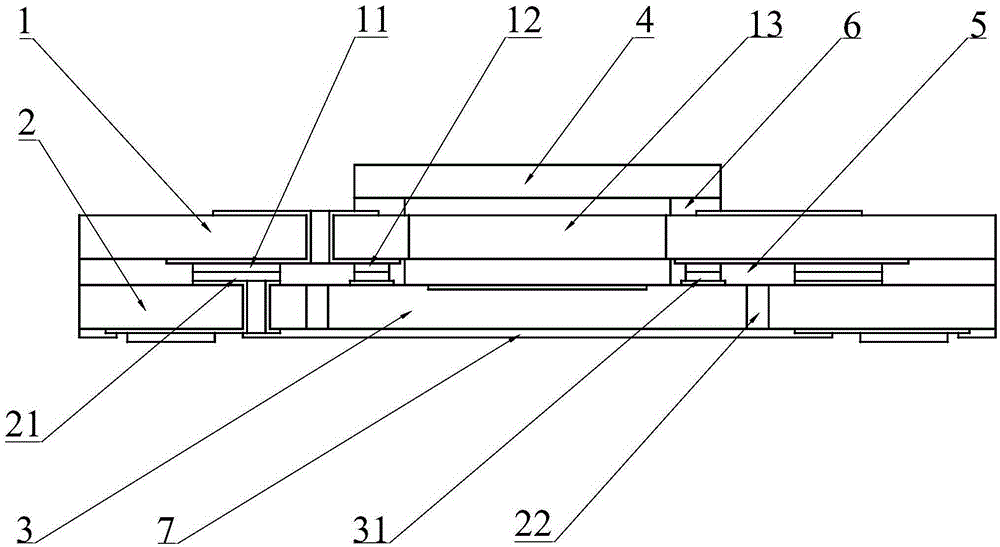

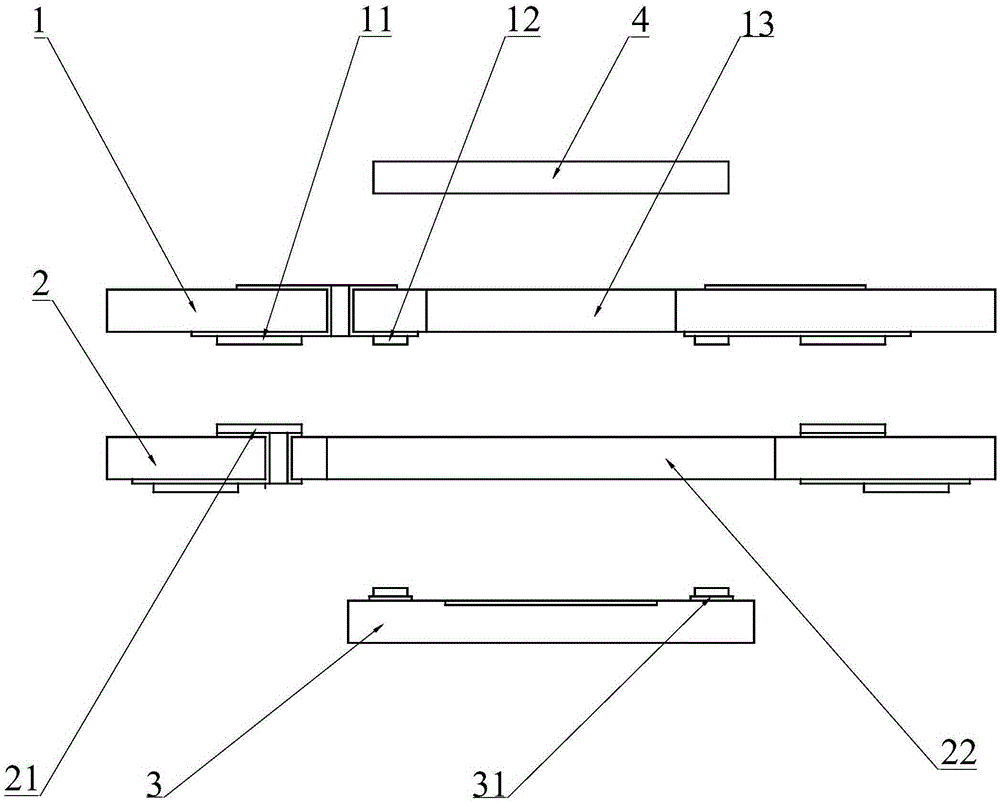

Thin skin milling device and method for milling by utilizing device

InactiveCN103920915AImprove machining accuracyReduce usage timeMilling equipment detailsPositioning apparatusThinning skinBiomedical engineering

The invention relates to a thin skin milling device. The thin skin milling device comprises a vacuum platform, thin skin and a profiling compression clamp, wherein the thin skin is arranged on the vacuum platform, the profiling compression clamp is arranged on the thin skin, the surface area of the vacuum platform is larger than that of the profiling compression clamp, and the surface area of the profiling compression clamp is larger than that of the thin skin; the profiling compression clamp is a rectangular thick aluminum plate, cutting troughs matched with the outer contour of the thin skin are formed in the periphery, close to the edge, of a surface plane of the thick aluminum plate, sunken milling regions matched with sunken regions of the thin skin are formed in the surface of the thick aluminum plate, an outer contour compression region is arranged at the region, outside of the cutting troughs, on the profiling compression clamp, and an interior compression region is arranged at the region, inside the cutting troughs, on the profiling compression clamp. By milling the skin by virtue of the thin skin milling device, the phenomenon that skin is scrapped due to the overcutting as the skin is intermittently desorbed from the vacuum platform and looses and shakes in a milling process can be effectively avoided.

Owner:AVIC SAC COMML AIRCRAFT

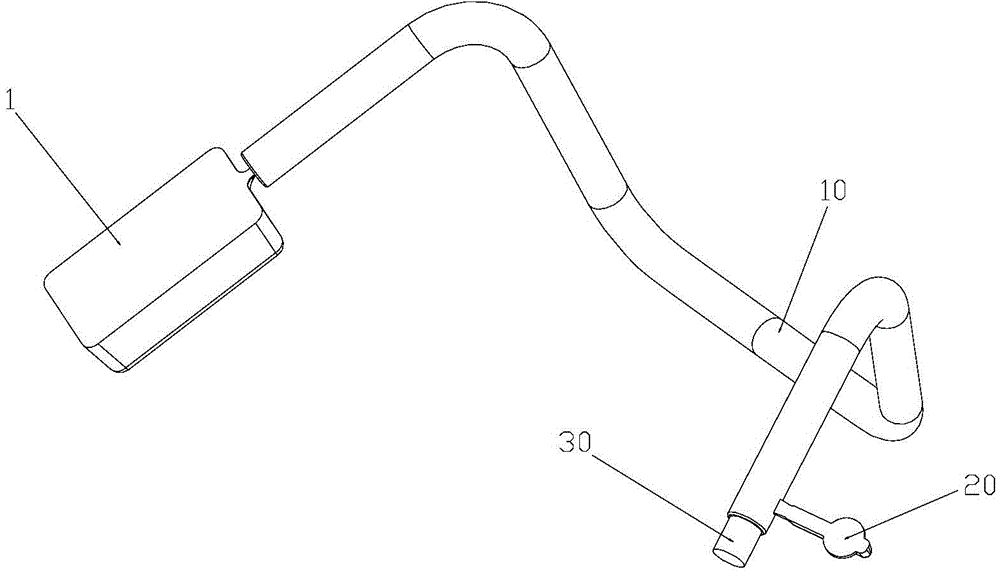

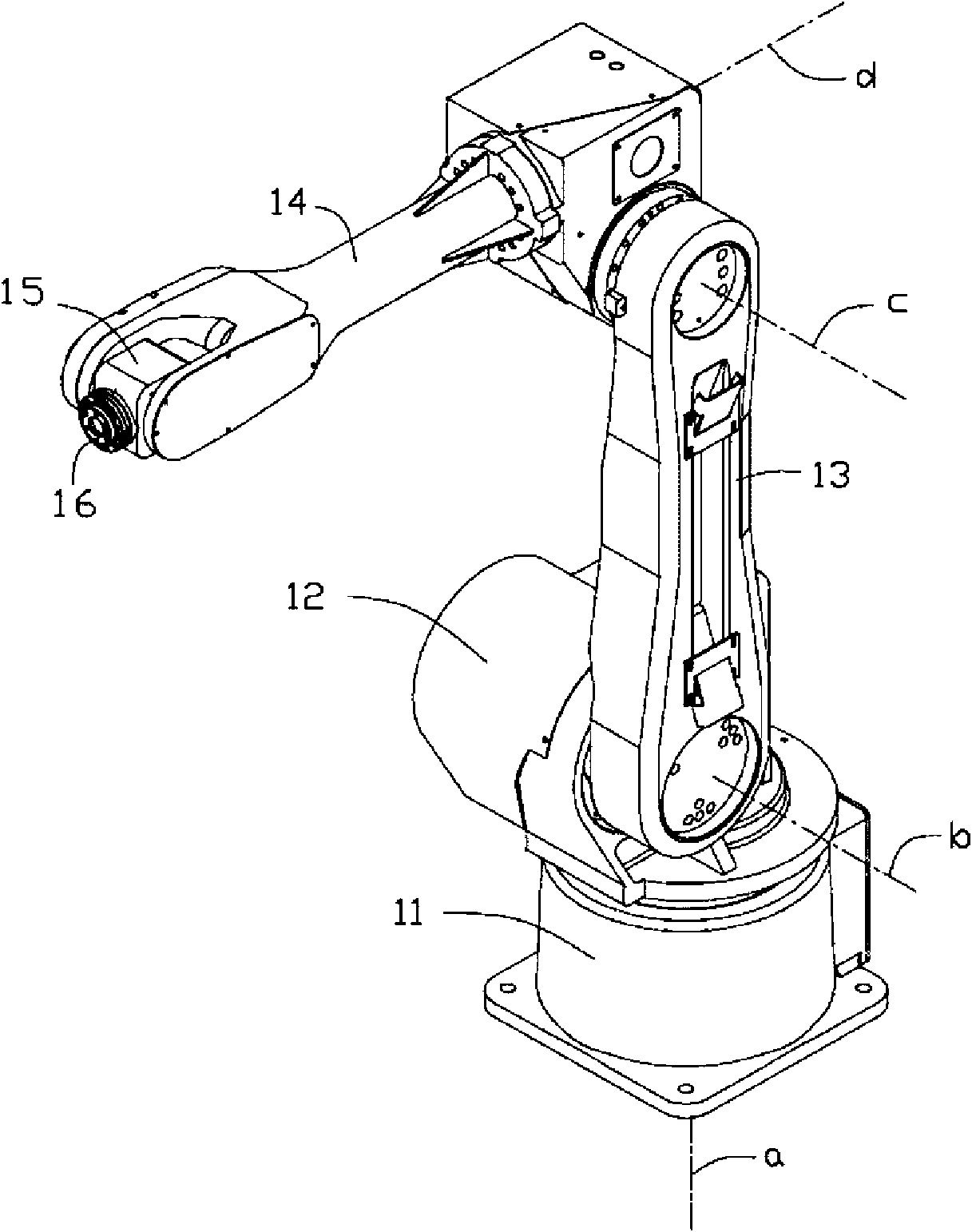

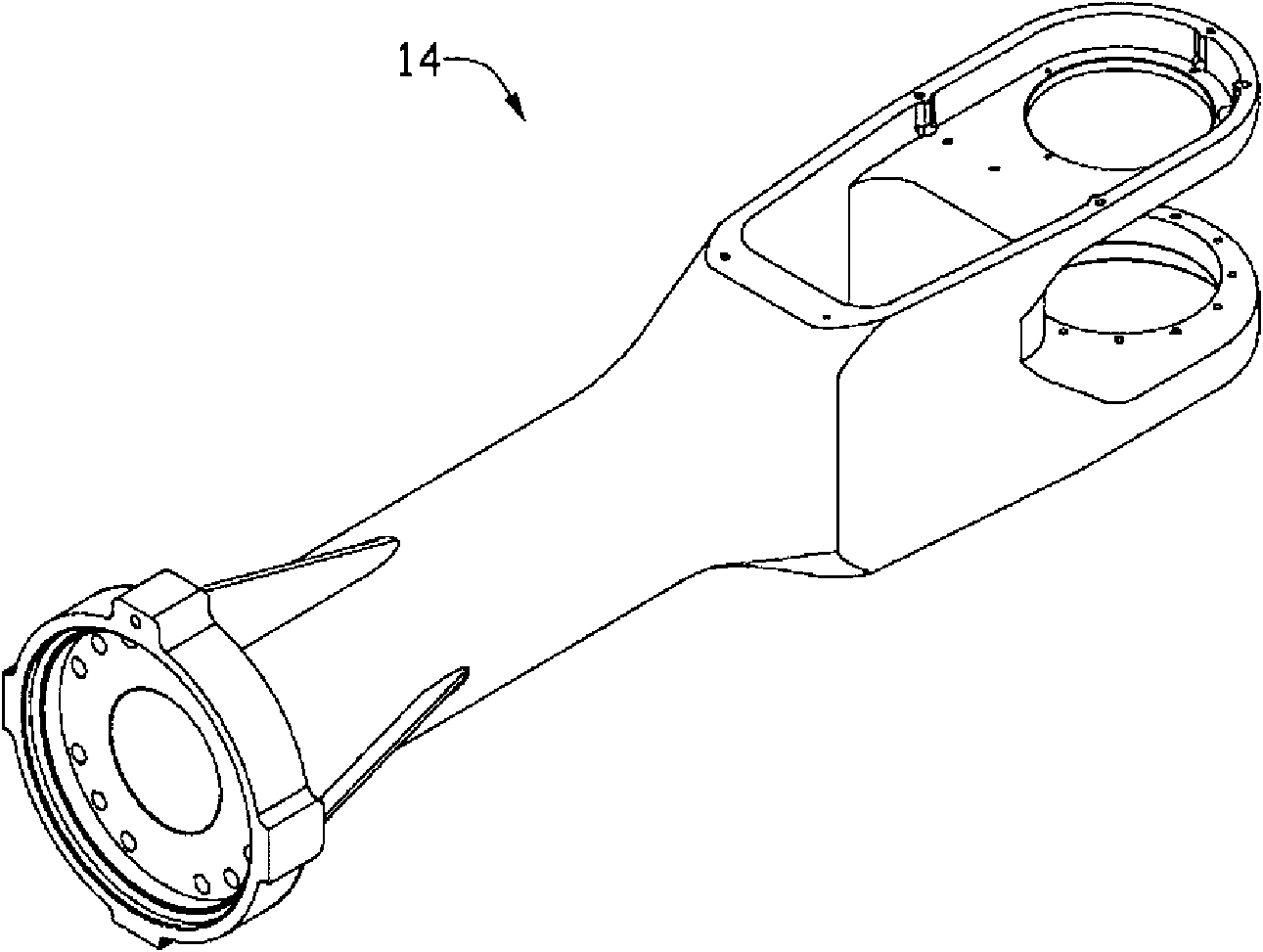

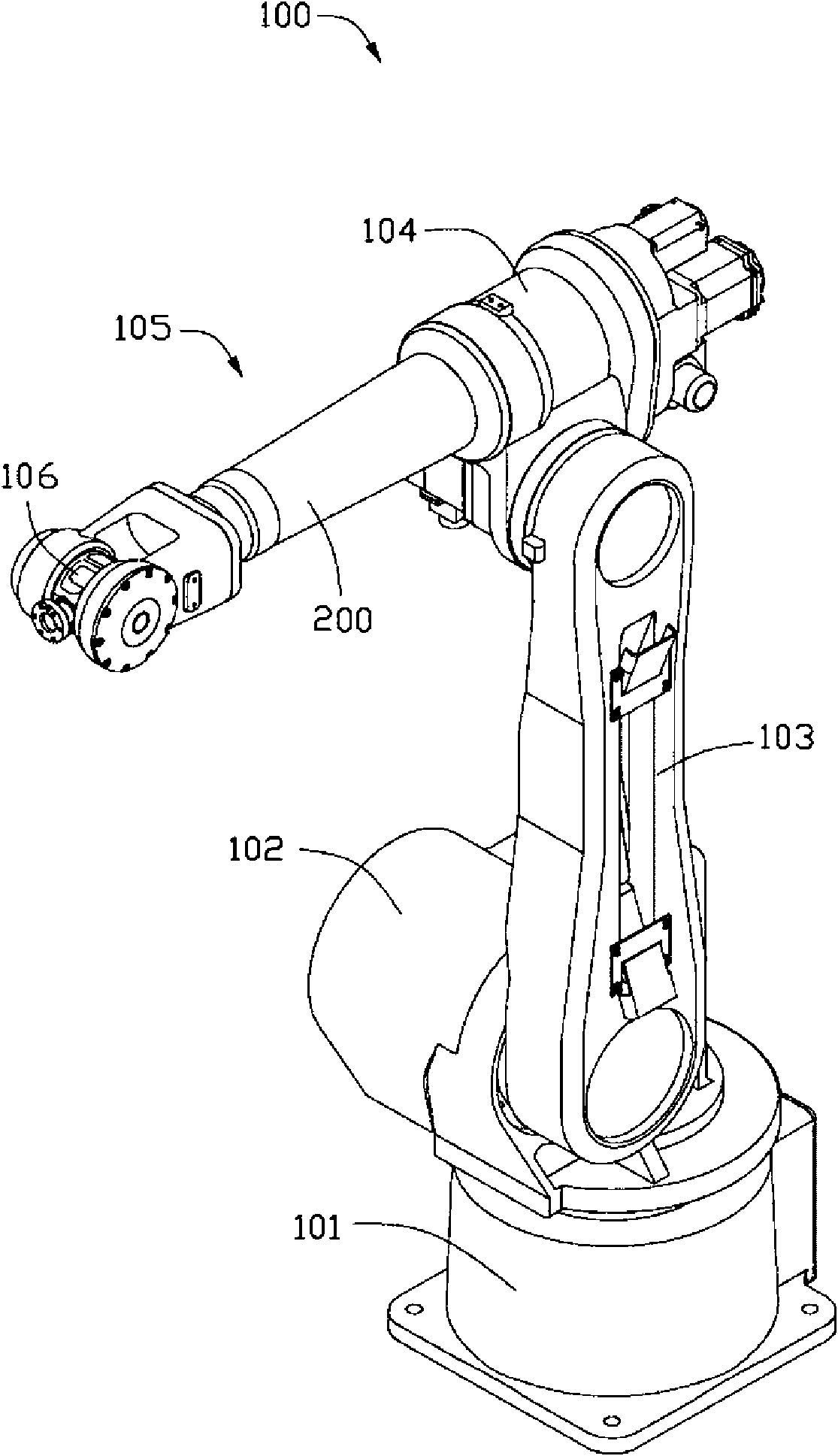

Robot arm component, manufacturing method thereof and robot with arm component

InactiveCN102059695AImprove stabilityReduce weightProgramme-controlled manipulatorMechanical apparatusEngineeringMechanical engineering

The invention discloses a robot arm component which comprises a connecting piece and a supporting member which are separately formed. The connecting piece rotates and is installed to the robot. The supporting member and the connecting piece are fixedly connected. The connecting piece is a revolving body, and the interior of the revolving body is provided with a first cavity penetrating two ends and extending along a straight line. The interior of the supporting member is provided with a second cavity which is communicated with the first cavity of the connecting piece. The invention also provides a manufacturing method of the robot arm component and a robot with the arm component. The robot arm component has the advantages of simple structure and the like, and is convenient to cast.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Working table for FDM printing equipment

InactiveCN106515021AHigh shape precisionReduce casting costsManufacturing heating elementsManufacturing auxillary operationsViscosityElectrical and Electronics engineering

The invention provides a working table for FDM printing equipment. The working table comprises an adsorption platform. The first face of the adsorption platform is coated with a clad layer of a first material, and the second face opposite to the first face and a heating slab are in thermal coupling, wherein the clad layer has no viscosity in a normal temperature state and is bonded to a printing mold in a heating state. According to the purpose, the working table for the FDM printing equipment can grab the mold firmly in the mold printing process, and can be disassembled conveniently.

Owner:NINGXIA KOCEL MOLD

Three-dimensional metal printing method integrating machining technology and three-dimensional metal printing equipment

InactiveCN106312064AHigh strengthImprove the bonding force between layersAdditive manufacturing apparatusIncreasing energy efficiencyElectrical resistance and conductanceHigh density

The invention discloses a three-dimensional metal printing method integrating a machining technology and three-dimensional metal printing equipment. The three-dimensional metal printing method comprises the core steps of: adopting molten or softened and flowable metal to be contacted with printed metal in a three-dimensional printing process, applying electric current between the molten or softened and flowable metal and the printed metal, rising the temperature of or melting a contact part between the printed metal and the molten or softened and flowable metal by a resistance heating mode to form a metal part with high structural strength, and further machining the printed metal with a cutter. The generated metal part has high density and forming precision; a printing process of each pixel point is monitored; a detachable auxiliary bracket, a printable large part and a damage repairable metal part can be generated synchronously; the equipment is simple in structure and the cost is low. The method and the equipment have a substantial progress.

Owner:NANJING TAITAO INTELLIGENT SYST CO LTD

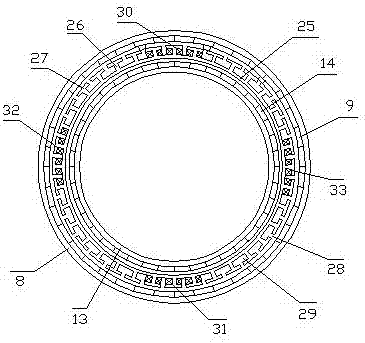

Coreless, brushless and toothless big hub motor

ActiveCN106877539AImprove reliabilityHigh installation mechanical strengthMagnetic circuit rotating partsStructural associationElectricityStator coil

A coreless, brushless and toothless big hub motor is composed of a wheel rotor, a coreless stator and a loop controller. As a coreless toothed slot type stator coil replaces a core stator coil, the overall weight is reduced, the efficiency is increased, the structure is simple, and the cost is low. The coreless toothed slot type stator coil has no magnetic field resistance. The motor can slide in an idle state. An electric vehicle without power can be ridden as easily as a bicycle, and has an anti-charging flexible brake function. The toothed slot type stator coil is wound in the same way as the toothed slot type stator coil of the existing big-hub motor, and has the advantages of mature process and easy manufacture. The ratio of effective area of lines of magnetic force cut by 36 single coils is large. There is no core loss, and the line loss is small. The toothed slot type stator coil is formed by winding multiple strands of enameled wires in parallel. The process is simple, flexible, reliable, and high in rate of skeleton space utilization. The loop controller makes effective use of the remaining space inside the wheel rotor, and thus, the overall configuration structure is simplified.

Owner:DAAO ELECTRIC JIANGSU

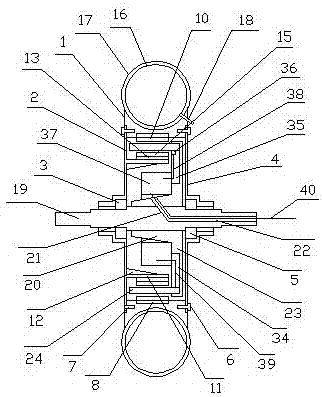

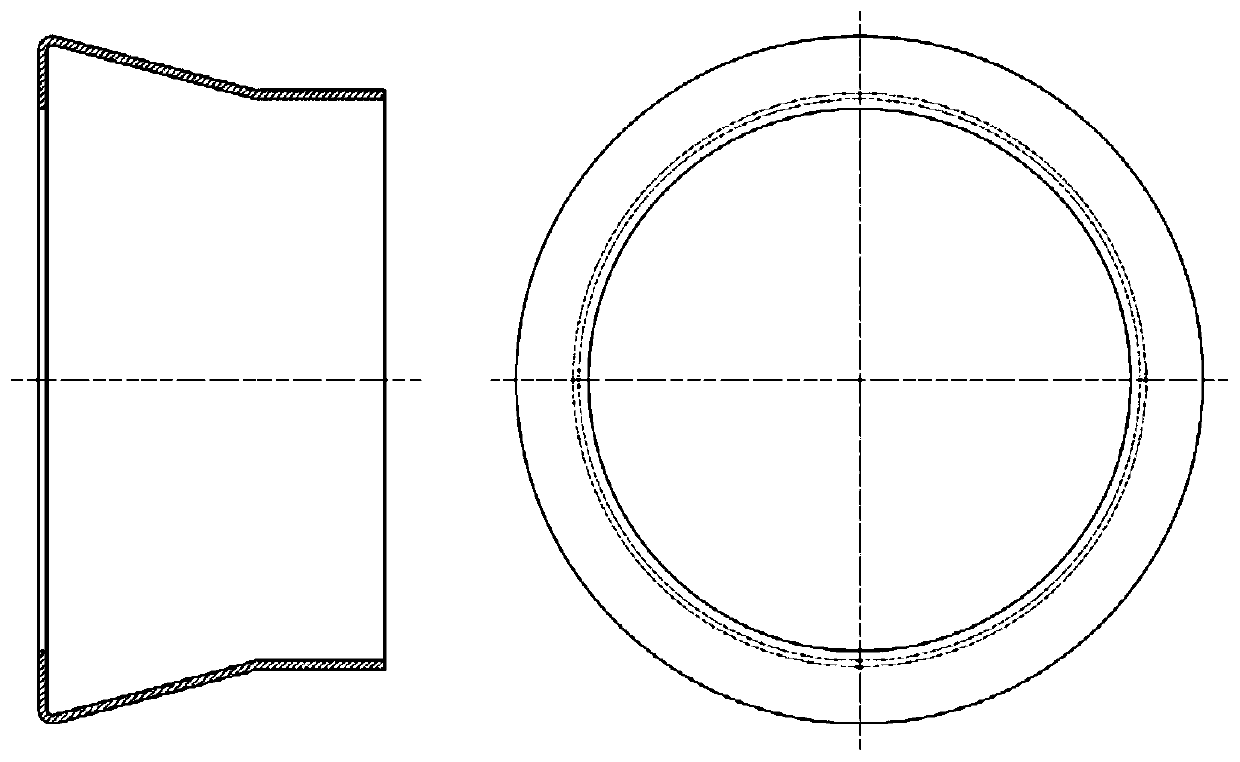

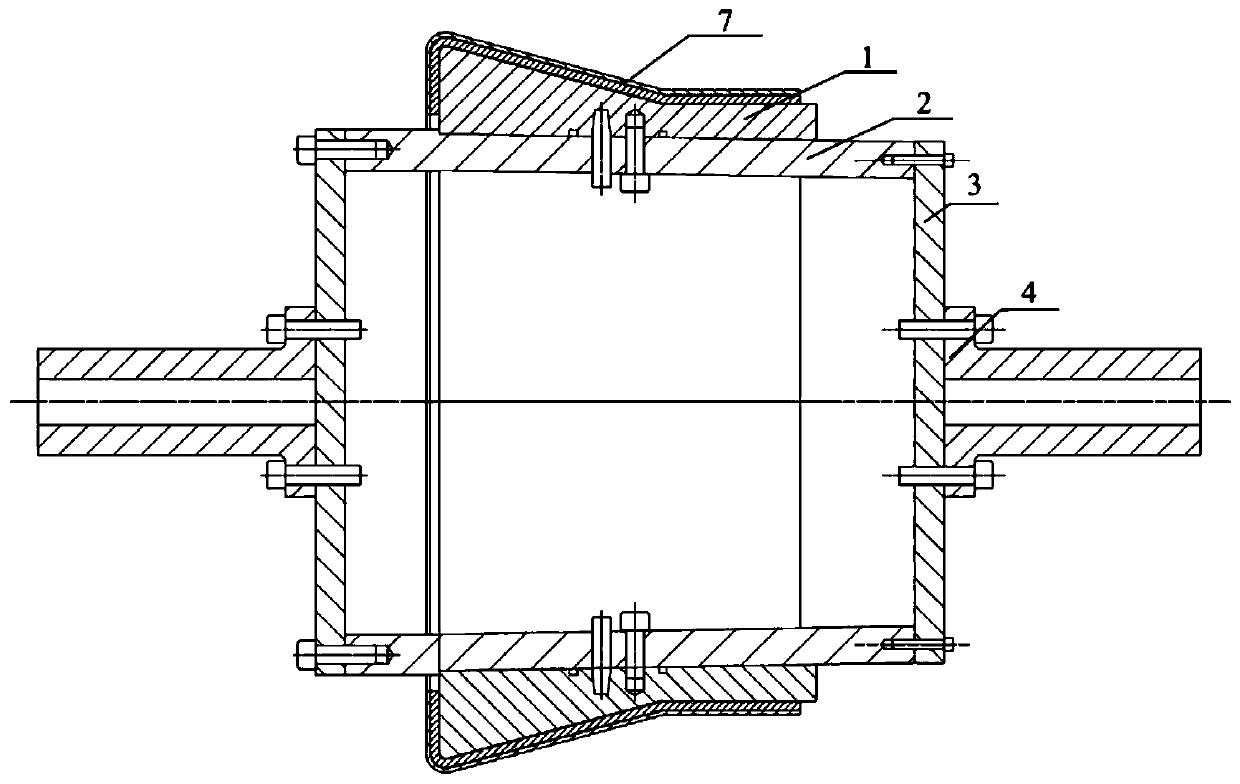

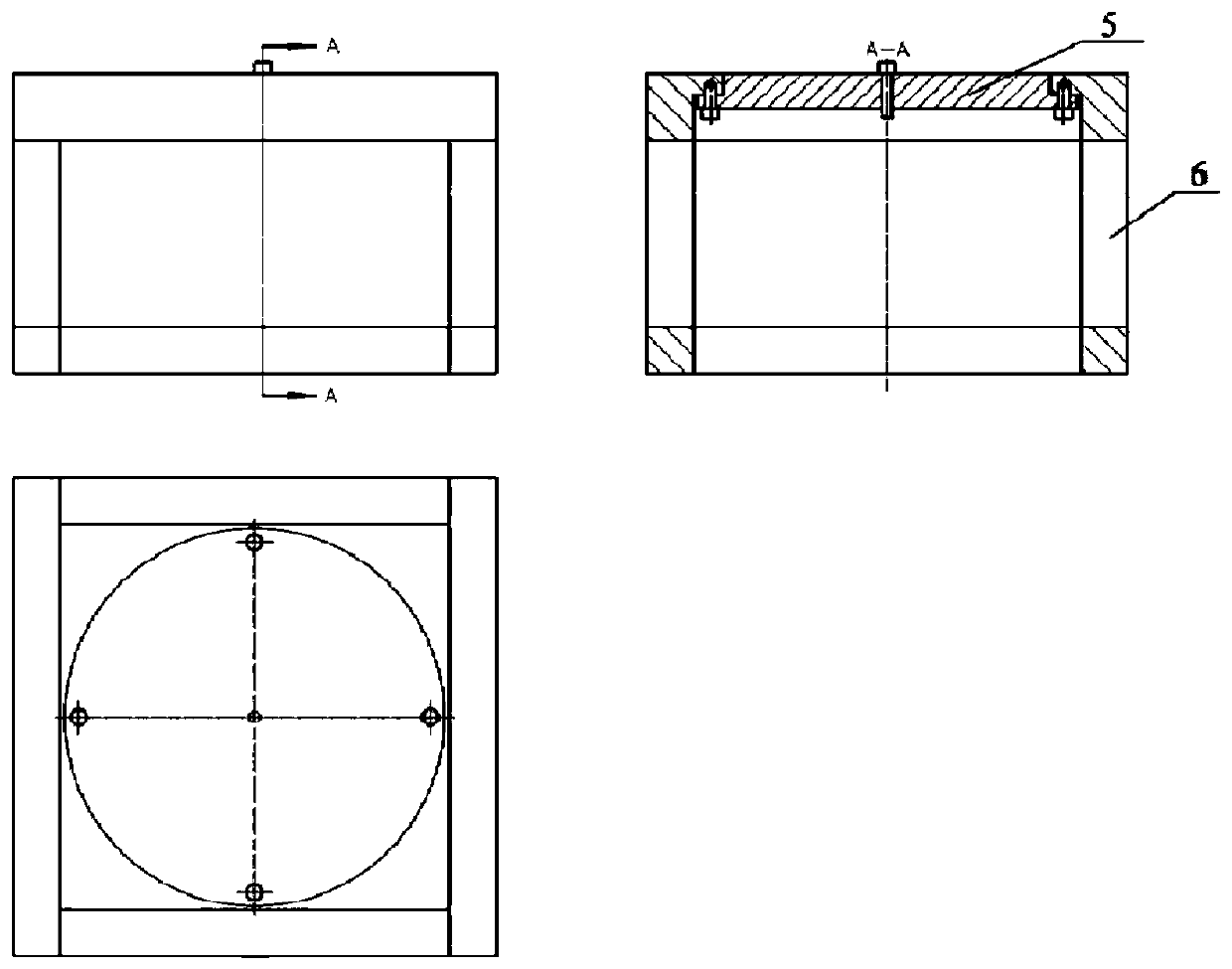

Forming die for cylindrical composite component with flanging and preparation method

ActiveCN111376389AHigh shape precisionImprove molding qualityDischarging arrangementMouldsMold removalCeramic matrix composite

The invention relates to a forming die for cylindrical composite component with flanging and a preparation method. The die comprises a core barrel, an insert, an end cover, a flange shaft, a pressureleveling plate and a demolding tool. The demolding tool comprises a demolding frame and a top plate. By means of the technical scheme of the forming die for the cylindrical composite component with the flanging and the preparation method, the problem that the difficulty of forming a variable-section cylindrical ceramic-based composite material thin-wall component with flanging is large can be solved. Sufficient forming pressure can be provided for prepreg in the forming process, so that each profile surface of a component is uniformly stressed, and the defects of the component are avoided. Through the block insert design and the demolding tool, it is ensured that the component can be safely and smoothly removed from a mold after formed, and the forming quality and the forming efficiency ofthe component are improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

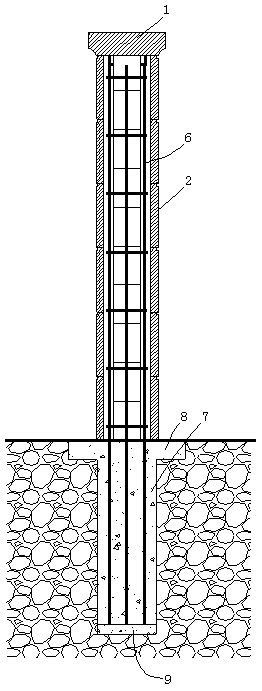

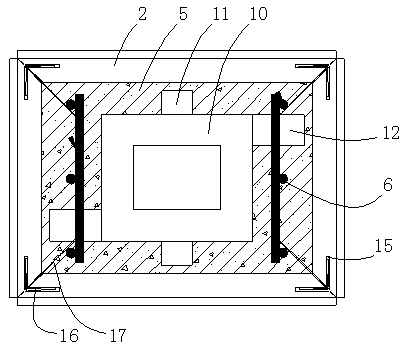

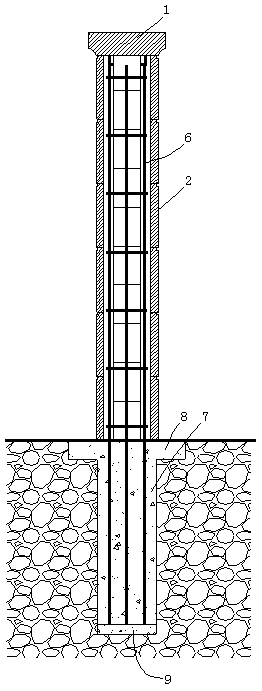

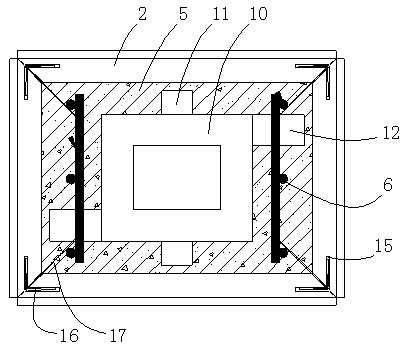

Enclosing wall stand column construction method

The invention discloses an enclosing wall stand column construction method. The enclosing wall stand column construction method comprises the following steps: a of downwards deeply excavating foundation pits at a depth exceeding 800 cm along a design position of a stand column; b of pouring the foundation after the foundation pit are excavated, pre-embedding two vertical rows of reinforcing steelbars in the foundation, and upwards forming a reinforcing steel bar net rack; c, enclosing four panels at the outer side of the reinforcing steel bar net rack and leveling to define a stand column section below the stand column, placing an inner barrel body into the stand column section, and repeating the step until needed enclosing wall stand column height; and f of pouring a concrete structure,and covering a top cover before concrete is solidified, thereby accomplishing enclosing wall stand column construction. The method has the advantages of being convenient in construction, being capableof reducing a construction excavation soil size, improving construction efficiency, being good in construction quality, being high in enclosing wall stand column outline precision, being good in environment friendliness, and the like.

Owner:重庆长赛新材料科技有限公司

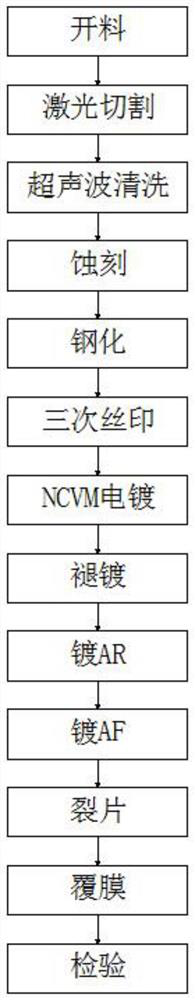

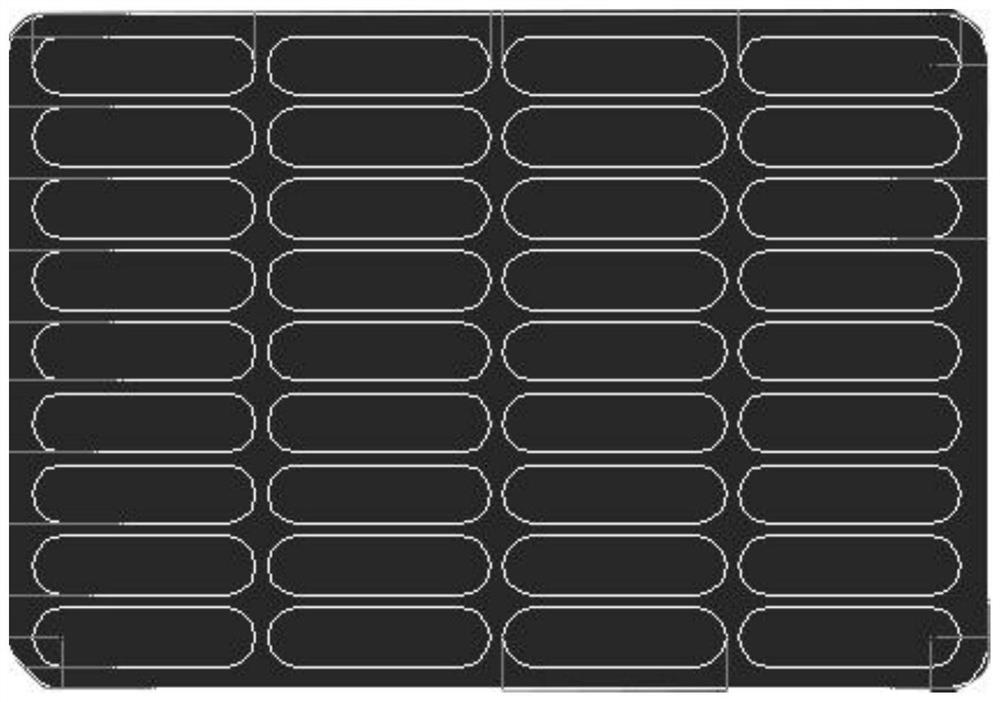

Manufacturing process of mobile phone camera lens

InactiveCN111683167ASave manual processSave manpowerCoatingsGlass severing apparatusScreen printingManufacturing technology

The invention discloses a manufacturing process of a mobile phone camera lens. The manufacturing process comprises the steps of cutting, laser cutting, ultrasonic cleaning, etching, tempering, tertiary silk-screen printing, NCVM electroplating, deplating, AR plating, AF plating, splitting, film coating and inspection. Compared with a small piece CNC technological process, the technological processhas the advantages that manual processes such as piece placing and dispensing after cutting are omitted, manual processes such as tempered frame inserting and frame taking are omitted, and manual stations such as piece placing in silk-screen printing are omitted; the appearance precision of the product is improved; the laser cutting process is used for scribing the outer contour, so that the boundary dimension precision of the product is improved and appearance, size and precision of the product are improved; a secondary tempering process is adopted, so that the impact strength of the cameralens is improved, and the spontaneous explosion rate is reduced; and the yield is improved: the comprehensive yield of the product is averagely improved by more than 10%.

Owner:SHENZHEN RUI EURO OPTICAL ELECTRONICS CO LTD

Lapping and polishing tool and polishing machine

ActiveCN107116417AGood for controlling uniformityImprove distributionOptical surface grinding machinesPolishingEngineering

The invention provides a lapping and polishing tool and a polishing machine, and relates to the technical field of computer control optical surface formation. The lapping and polishing tool is used for being mounted on the polishing machine; the polishing machine comprises a polishing machine body; the lapping and polishing tool comprises a polishing component and a polishing mold layer; the polishing component comprises a flow guide part; the polishing mold layer is connected with one side of the flow guide part; the other side of the flow guide part is used for being connected with the polishing machine body; the flow guide part is provided with a fluid channel; the polishing mold layer is provided with a liquid outlet channel; one end of the fluid channel communicates with the liquid outlet channel; and the other end of the fluid channel penetrates through the flow guide part. The lapping and polishing tool has the benefits as follows: the distribution uniformity of a polishing solution is effectively controlled, the polishing solution is enabled to permeate into the bottom of the polishing tool, the polishing efficiency is improved, lot of heat in the central area at the bottom of the lapping and polishing tool is carried away, the element surface is stably polished, and the element surface figure accuracy is high; as the polishing machine provided by the invention adopts the lapping and polishing tool, the polishing efficiency is further improved, the element surface is stably polished, and the element surface figure accuracy is high.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

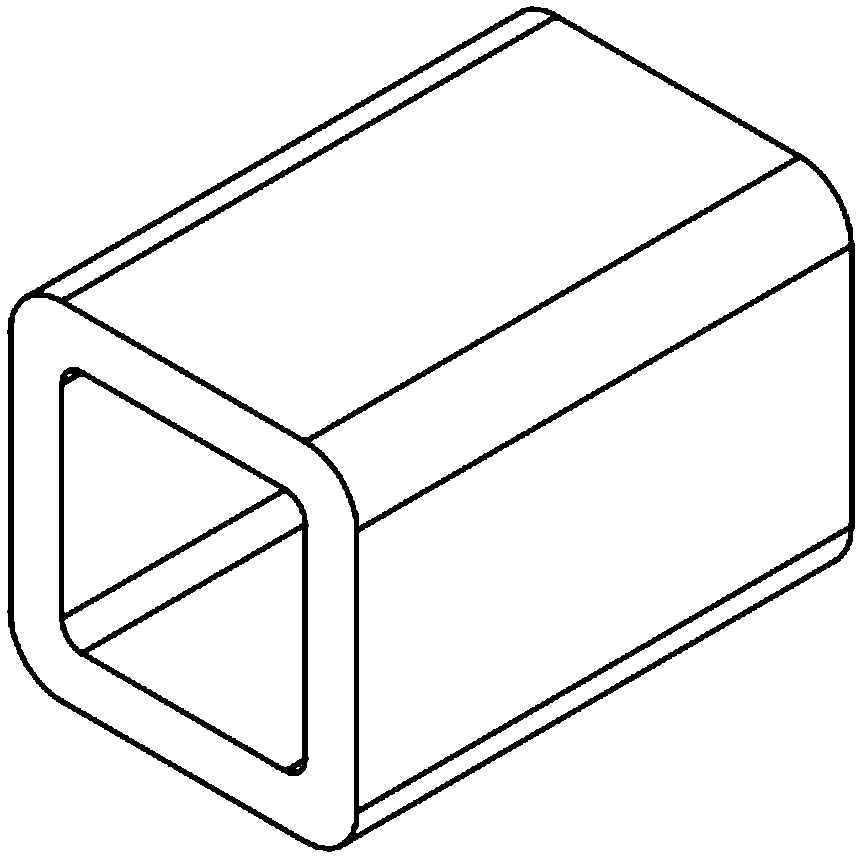

Square rectangular steel pipe with corner thickening and cold-heat composite molding and preparation method thereof

PendingCN110726064AIncrease productivityScale upElongated constructional elementsTemperature control deviceStraight tubeEngineering

The invention discloses a square rectangular steel pipe with corner thickening and cold-heat composite molding and a preparation method thereof. The outer corner radius of the square rectangular steelpipe satisfies the following conditions: when t is less than or equal to 6mm, R is greater than 0 and less than 2.0t; when t is greater than 6 and less than or equal to 10mm, R is greater than 0 andless than 2.5t; and when t is greater than 10mm, R is greater than 0 and less than 3.0t, wherein t is the wall thickness of the straight pipe section of the square rectangular steel pipe, R is the outer corner radius of the four corners of the square rectangular steel pipe, and the corner wall thickness of the square rectangular steel pipe is between 1.0t and 1.8t. According to the square rectangular steel pipe with corner thickening and cold-heat composite molding and the preparation method thereof, the hot forming technology is introduced into a traditional roll-bending forming process, thatis, the local induction heating technology. High temperatures can reduce the forming force of materials and improve the forming performance of the materials; and meanwhile, the phenomena of the residual stress caused by work hardening and cracking which is possibly caused can be eliminated, a corner profile of the square rectangular steel pipe subjected to cold-heat composite molding is dense, the radii of an inner corner and an outer corner are small, the angle of the corner is close to 90 degrees, and the corner is thickened.

Owner:SINO RES INST OF ROLL FORMING IND CAOFEIDIAN CO LTD

Making technology of sensor packaging sheet

InactiveCN105428380AHigh shape precisionImprove fitSolid-state devicesRadiation controlled devicesWork in processDegrees of freedom

The invention discloses a making technology of a sensor packaging sheet. By using the making technology, a process is simple, a degree of freedom is high and production precision is high too. A technical scheme is characterized by a) selecting an upper substrate, a lower substrate and several chips and carrying out pre-processing; b) coating a first adhesive material on a bottom surface of the upper substrate and successively carrying out exposure, PEB and development on the first adhesive material; c) carrying out alignment and attaching on the bottom surface of the upper substrate and a top surface of the lower substrate; d) selecting a plurality of chips, wherein the lower substrate is provided with several placing holes and the chips pass through the placing holes from a bottom surface of the lower substrate to the top surface and carry out alignment and attaching with the bottom surface of the upper substrate; e) carrying out whole plate lamination on the upper substrate, the lower substrate and the chips after attaching to obtain a semi-finished product A; f) attaching a top surface of the semi-finished product A to several optical filters and processing a reinforced layer on a bottom surface to obtain a semi-finished product B; g) carrying out solidification on the first adhesive material after the step e or the step f. The whole making technology has high precision and the process is simple.

Owner:江西芯创光电有限公司

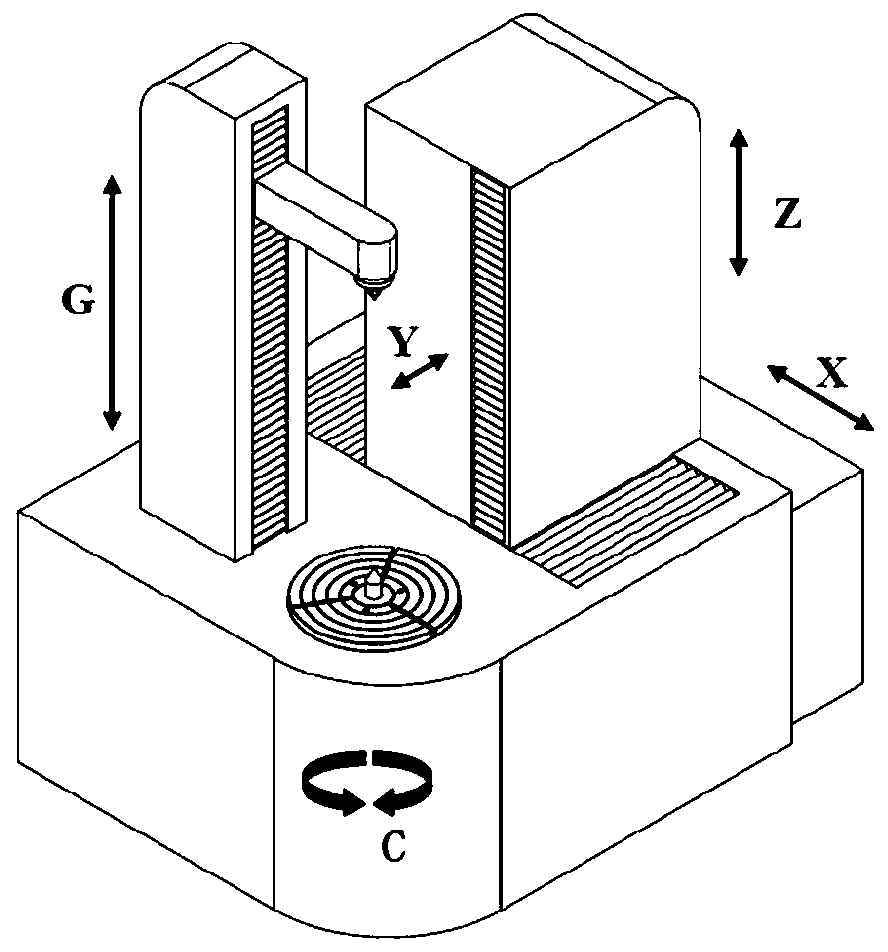

Molding grinding wheel dressing data acquiring method based on multi-axis linkage precision measuring system

ActiveCN109794856AHigh shape precisionHigh precisionGrinding feed controlAbrasive surface conditioning devicesComplex typeMulti axis

The invention discloses a molding grinding wheel dressing data acquiring method based on a multi-axis linkage precision measuring system. According to the molding grinding wheel dressing data acquiring method, a test piece of a complex type wire part is installed in the multi-axis linkage precision measuring system, a segmented dual-axis linkage measuring path is adopted to project a motion control scheme after basic data are inputted into a necessary software of the multi-axis linkage precision measuring system, an equal arc-length differential sampling method is adopted to collect measuringdata, theoretical design points are then fitted to determine the normal vector of each point, the theoretical design points are taken as moving window interpolation centers, local curvilinear functions of the measured data in the design points are determined by adopting a moving window Lagrange interpolation polynomial, the distances from the theoretical design point to local curves is calculatedin accordance with the design points, the normal vectors and the local curves, and the distances is namely the normal error values of the theoretical design points of a grinding wheel, that is the reference data of the secondary grinding wheel dressing. According to the molding grinding wheel dressing data acquiring method, the secondary grinding wheel dressing data is thus acquired through the detection of complex type wire part contour error results acquired by forming grinding.

Owner:XI AN JIAOTONG UNIV

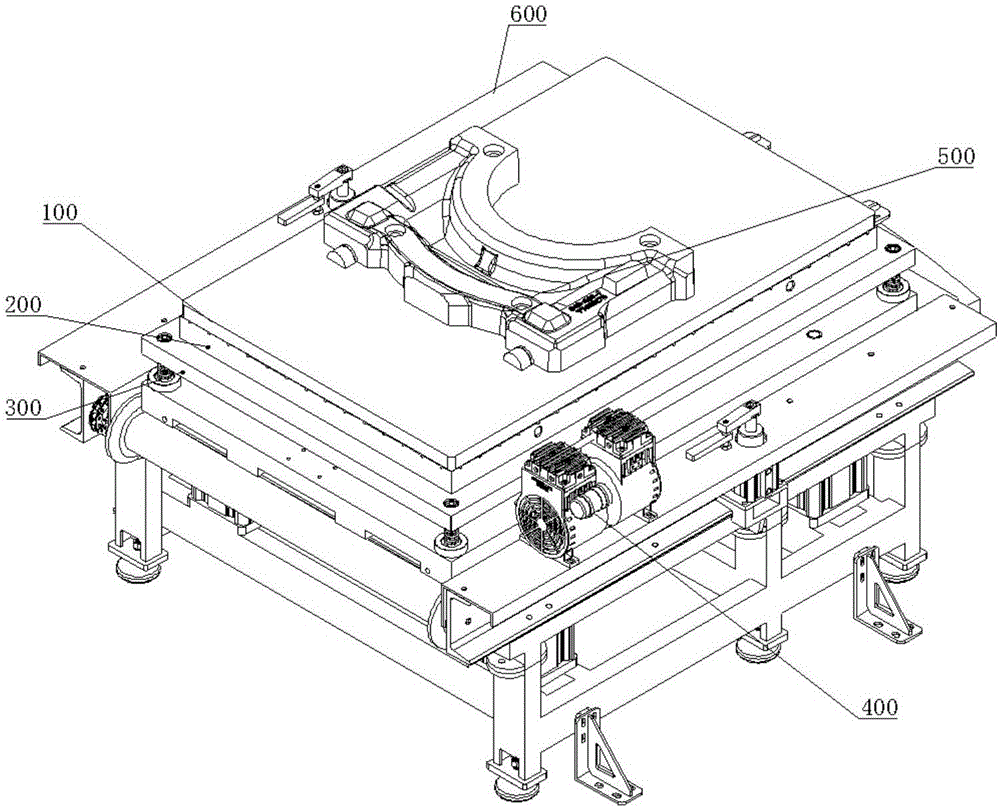

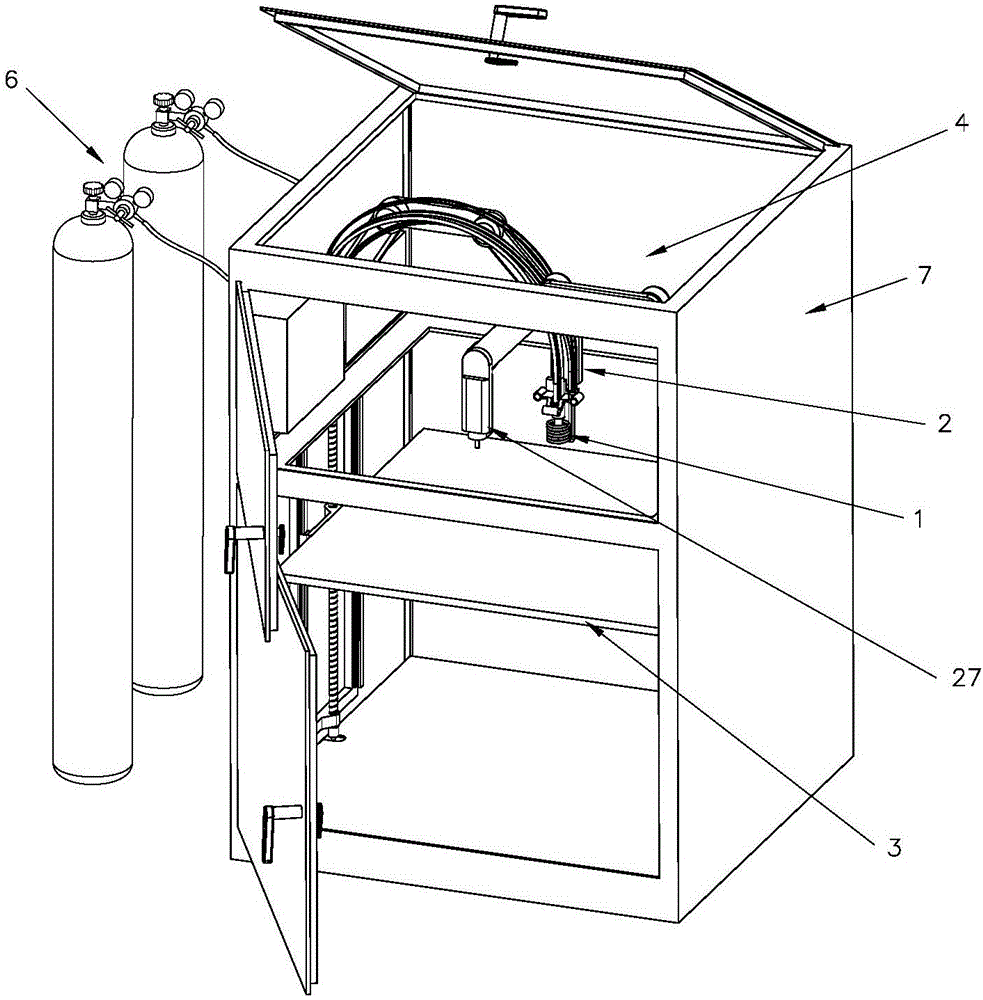

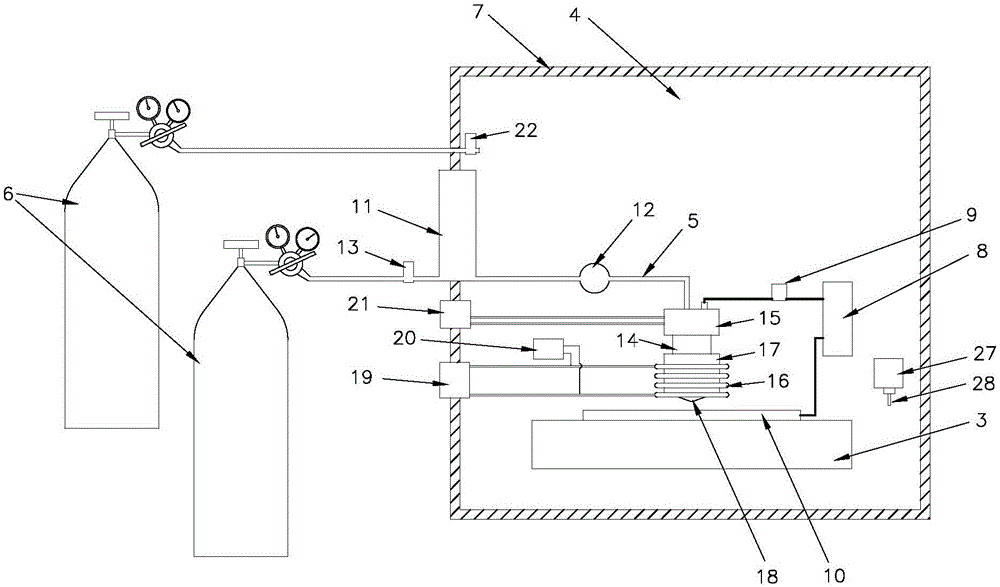

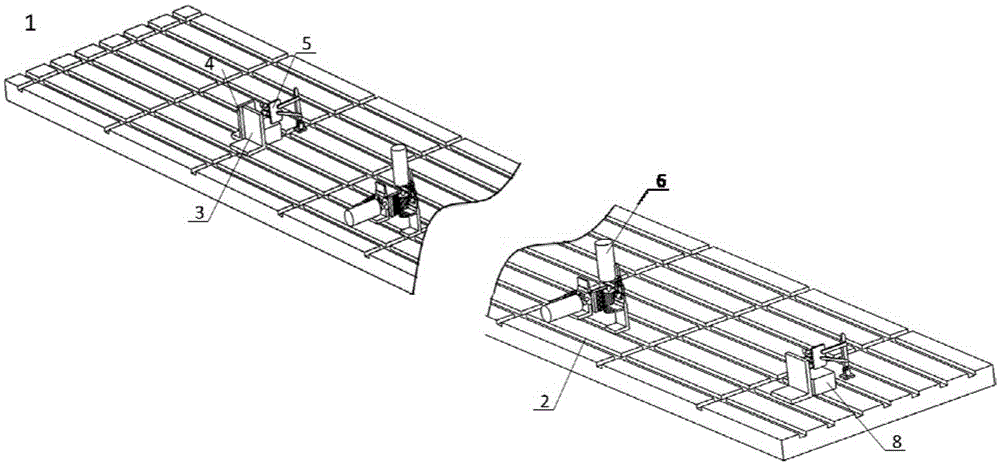

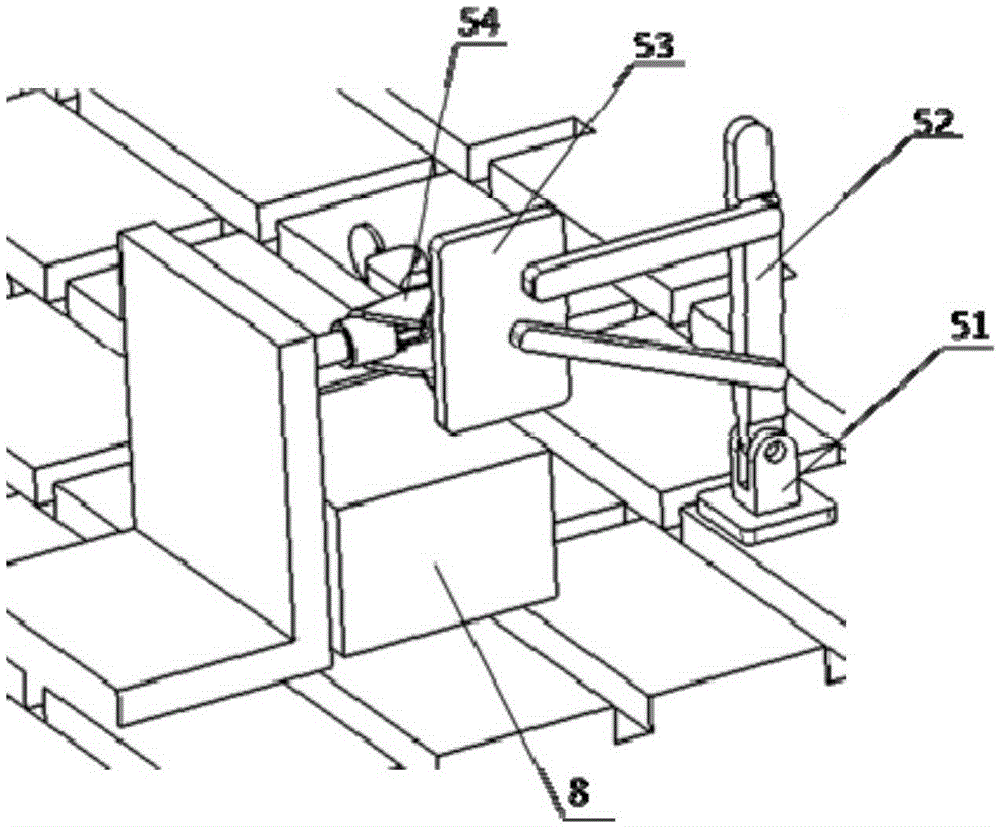

Residual stress releasing process device and stress releasing method for manufacturing process of long truss of wing

InactiveCN105385841AHigh shape precisionImprove processing qualityProcess efficiency improvementEngineeringAirplane

The invention provides a residual stress releasing process device and a stress releasing method for the manufacturing process of a long truss of a wing, belonging to the field of manufacturing of aerospace components. The residual stress releasing process device comprises a base platform, a bottom vertical positioning block, a transverse positioning block, a longitudinal positioning block, a transverse clamping device and a magnetic vibration device and can release the residual stress in the long truss of the aircraft wing. The invention provides the intelligent residual stress releasing tool applied in the vibration aging treatment process of the long truss of the aircraft wing. The magnetic vibration device can be controlled through an upper computer, so that the vibration frequency, the vibration direction and the size of vibration force of each vibration position can be adjusted. Moreover, a driving member and a driven member in the magnetic vibration device do not directly contact with each other and carry out conduction by relying on magnetic force, so that the residual stress releasing process device has the characteristics of stationary vibration and overload protection, and the damage to the long truss caused by excessive vibration is avoided. The residual stress releasing process device is easy to operate, the long truss can be quickly clamped on the tool, and the effective releasing for the inner residual stress is realized.

Owner:SHANGHAI JIAO TONG UNIV

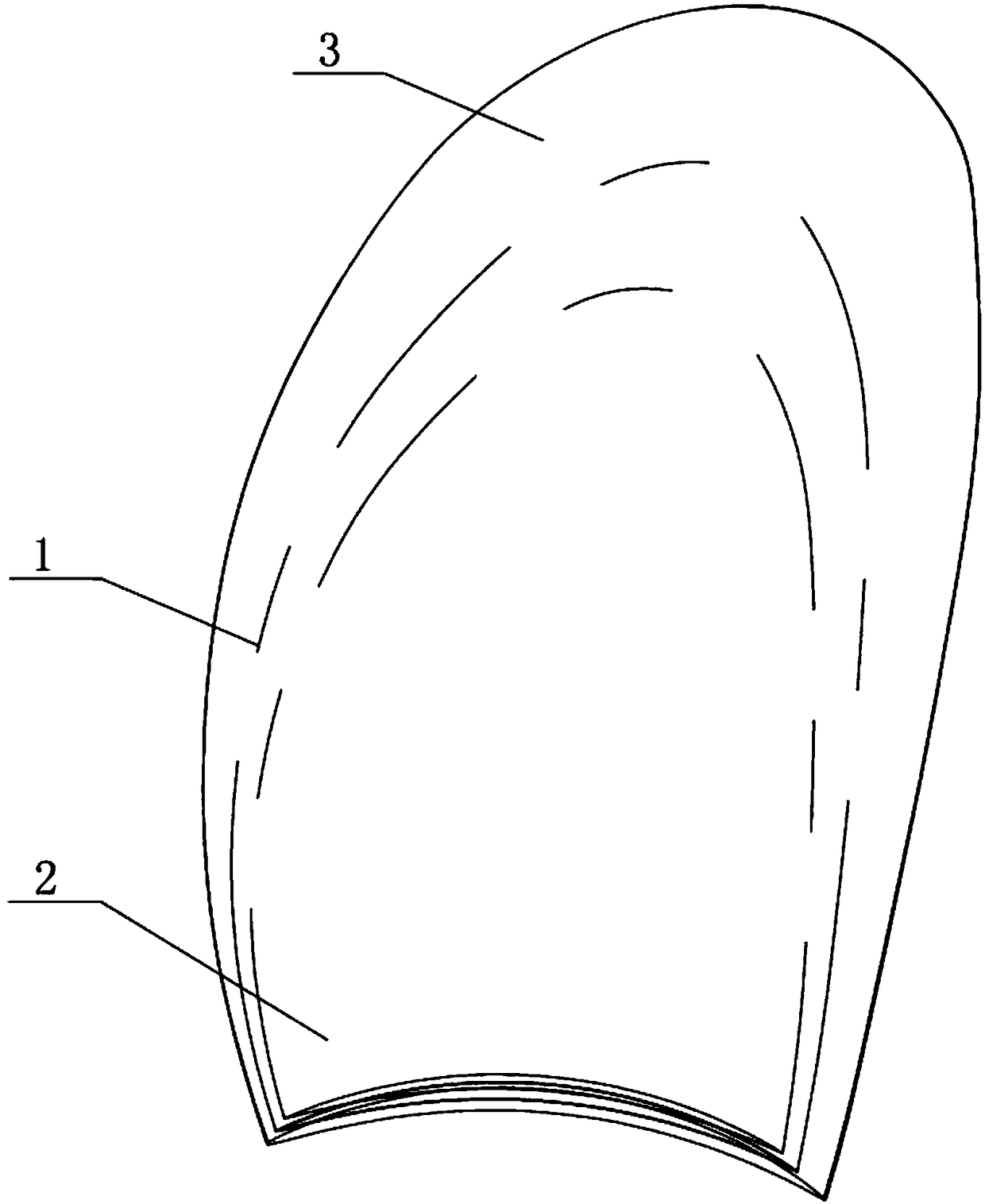

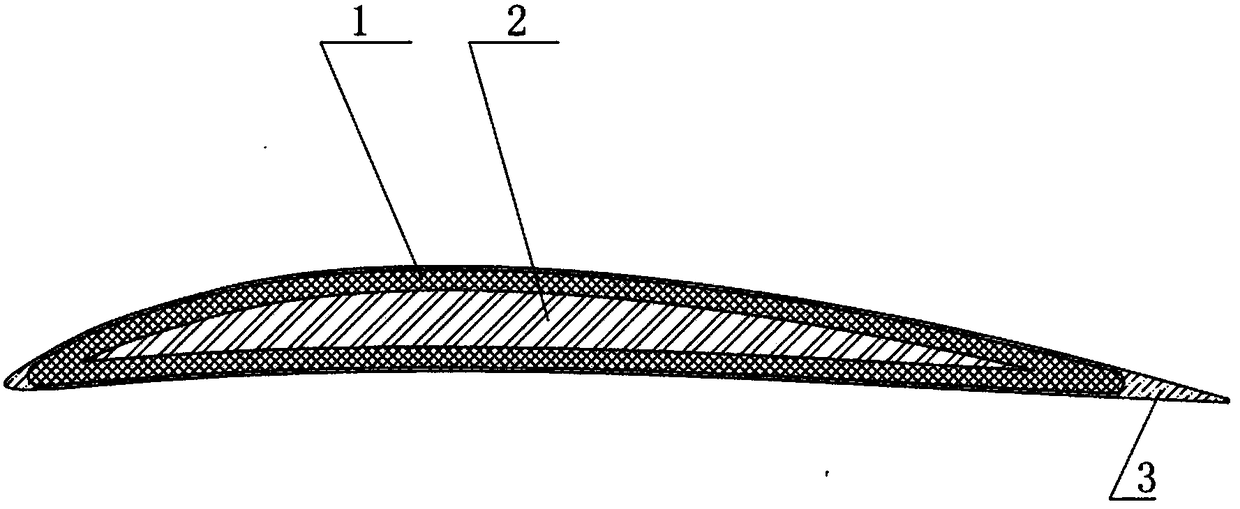

A kind of ship composite material propeller blade preform and preparation method thereof

The invention relates to a performed composite propeller blade of a ship and a manufacturing method of the performed composite propeller blade. Compared with a metal propeller, the preformed composite propeller blade has the advantages that the weight is low, corrosion resistance is good, the hydrodynamic performance is superior, cavitation can be delayed, cavitation corrosion is reduced, the acoustic characteristic is excellent, noise of the propeller is lowered, and the stealth performance of the ship can be easily improved. Fiber covers serve as a primary bearing mechanism, and the fiber covers are designed to be of identical thickness and cover the whole blade. By means of the performed composite propeller blade of the ship and the manufacturing method of the performed composite propeller blade, quasi two-dimensionalization of complex three-dimensional weaving is effectively achieved. The problems of delamination and stripping of guide edges and following edges of an original blade are effectively solved, the weaving difficulty is reduced, and cost is reduced; and the dead load of the propeller blade can be greatly reduced, and the appearance precision of the propeller blade is improved.

Owner:中国船舶重工集团公司第七〇二研究所

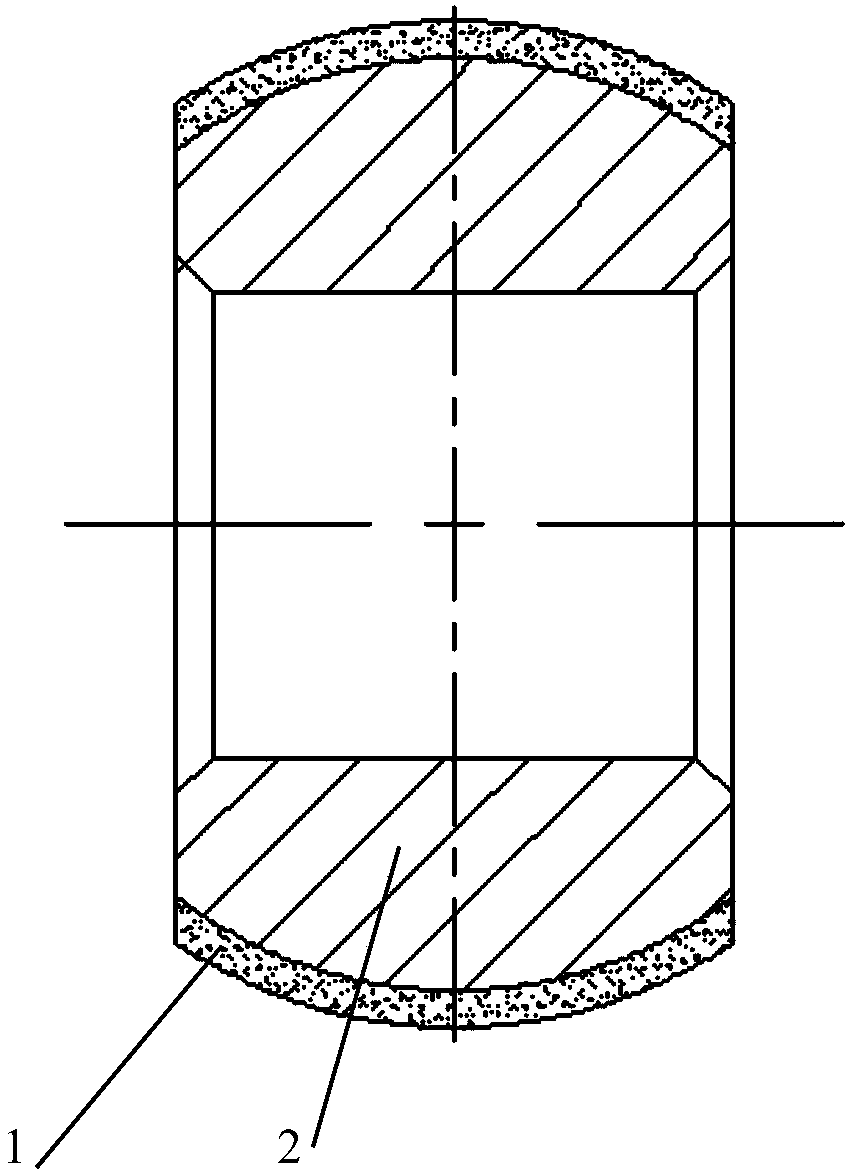

Surface processing method for self-lubricating joint bearing after hard chromium plating of spherical surface of inner ring of self-lubricating joint bearing

The invention provides a surface processing method for a self-lubricating joint bearing after hard chromium plating of the spherical surface of an inner ring of the self-lubricating joint bearing. Thesurface processing method comprises the following steps that S1, a pig iron rod is used for being matched with grinding paste 1 for rough grinding processing; S2, a copper rod is used for being matched with grinding paste 2 for fine grinding processing; and S3, a polishing cloth is used for being matched with grinding paste 3 for polishing processing. Compared with the prior art, the surface processing method has the following beneficial effects that under meeting the requirement of hard chromium plating of the spherical surface of the inner ring of the product, it is ensured that geometricaltolerance such as the size, the roundness, the symmetry degree, the spherical difference and the surface roughness of the bearing meets design requirements, and the appearance precision of the bearing is further improved.

Owner:上海市轴承技术研究所有限公司

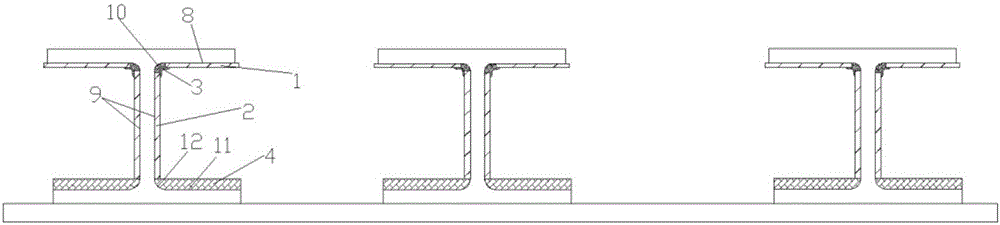

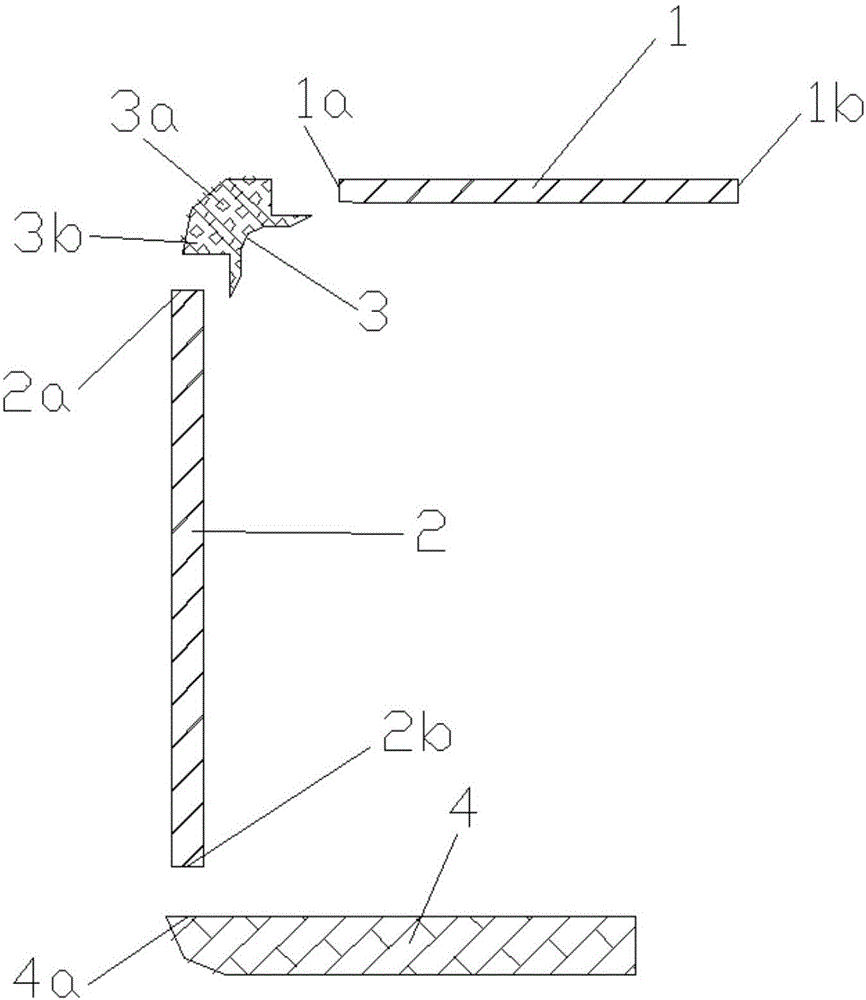

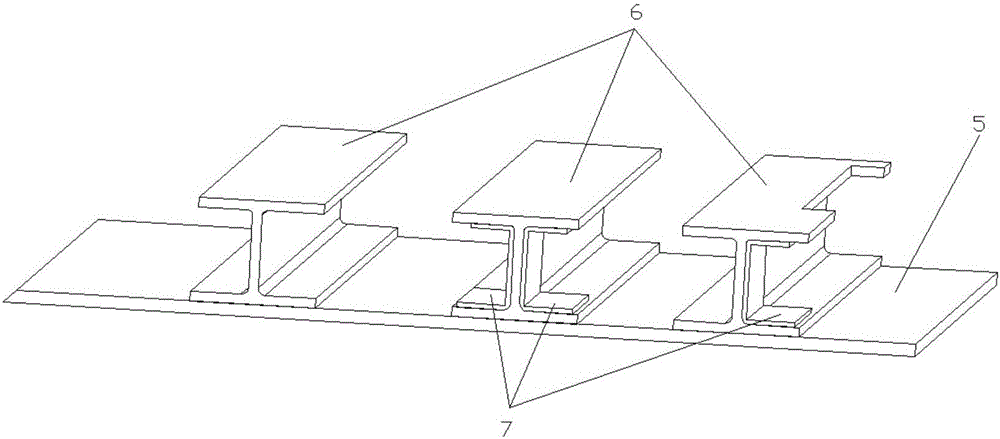

Fence stand column facilitated construction

ActiveCN110984692AHigh shape precisionPromote environmental protectionFencingArchitectural engineeringStructural engineering

The invention discloses a fence stand column facilitated construction. The fence stand column includes a stand column body in an overall rectangular column body shape and a top cover at the upper endof the stand column body, the outer part of the stand column body is obtained by splicing a plurality of hollow stand column sections in the height direction, a concrete structure is poured inside thestand column body, the fence stand column is characterized in that each stand column section is obtained by splicing four panels in the circumferential direction, the outer sides of the panels are the molding surfaces, the inner sides of the panels are the inner cavity surfaces, a vertically arranged inner cylinder body is arranged at the central position of the inner part of each stand column section, the stand column sections are vertically butted and stacked, and the integrally poured concrete structure is arranged between the inner cylinder bodies and the panels. The fence stand column has the advantages that construction can be facilitated, the construction efficiency is improved, the construction quality is good, the shape accuracy of the fence stand column is high, and the environmental protection property is good.

Owner:重庆长赛新材料科技有限公司

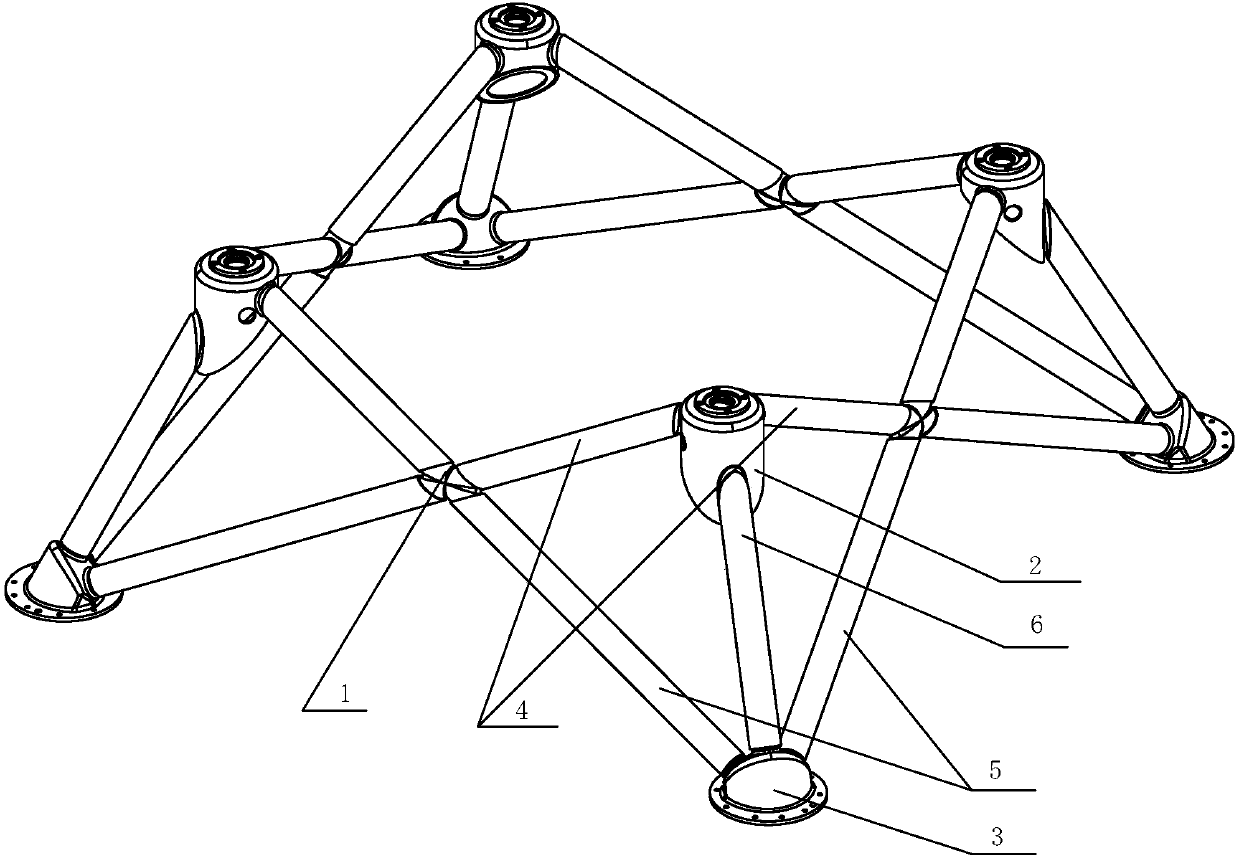

Whole carbon fiber composite material support between devices

ActiveCN107804485ASatisfy the demand of bearing loads in all directionsReduce local additional bending momentCosmonautic vehiclesCosmonautic partsFiberUpper joint

The invention discloses a whole carbon fiber composite material support between devices. All upper joints are fixedly connected with all lower joints through a cross rod system to form a prism-shapedsupporting structure; every joint is capable of being fixedly connected with two adjacent supporting units through a standing rod and two slanting rods to form a stable tetrahedral structure, and thedemands of every upper joint bearing load in each direction are met; a reasonable configuration is conducted to every joint, a truss rod system is obtained by rod pieces axis crossing through one point, and the probability of the occurrence of local additional bending moment load and the like is reduced; hollow pipes are installed on the joints, the hollow pipes are sleeved with, hinged to and fixedly connected with the rod pieces, so that connection strength is further improved to bear larger load. Because carbon fiber joints and the rod pieces are adopted as a main body of the support, and the hinge is adopted, structure weight is reduced, and thermal stress between components is reduced; the reasonable structure rod pieces configuration is adopted, and reliability of the hinge is improved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

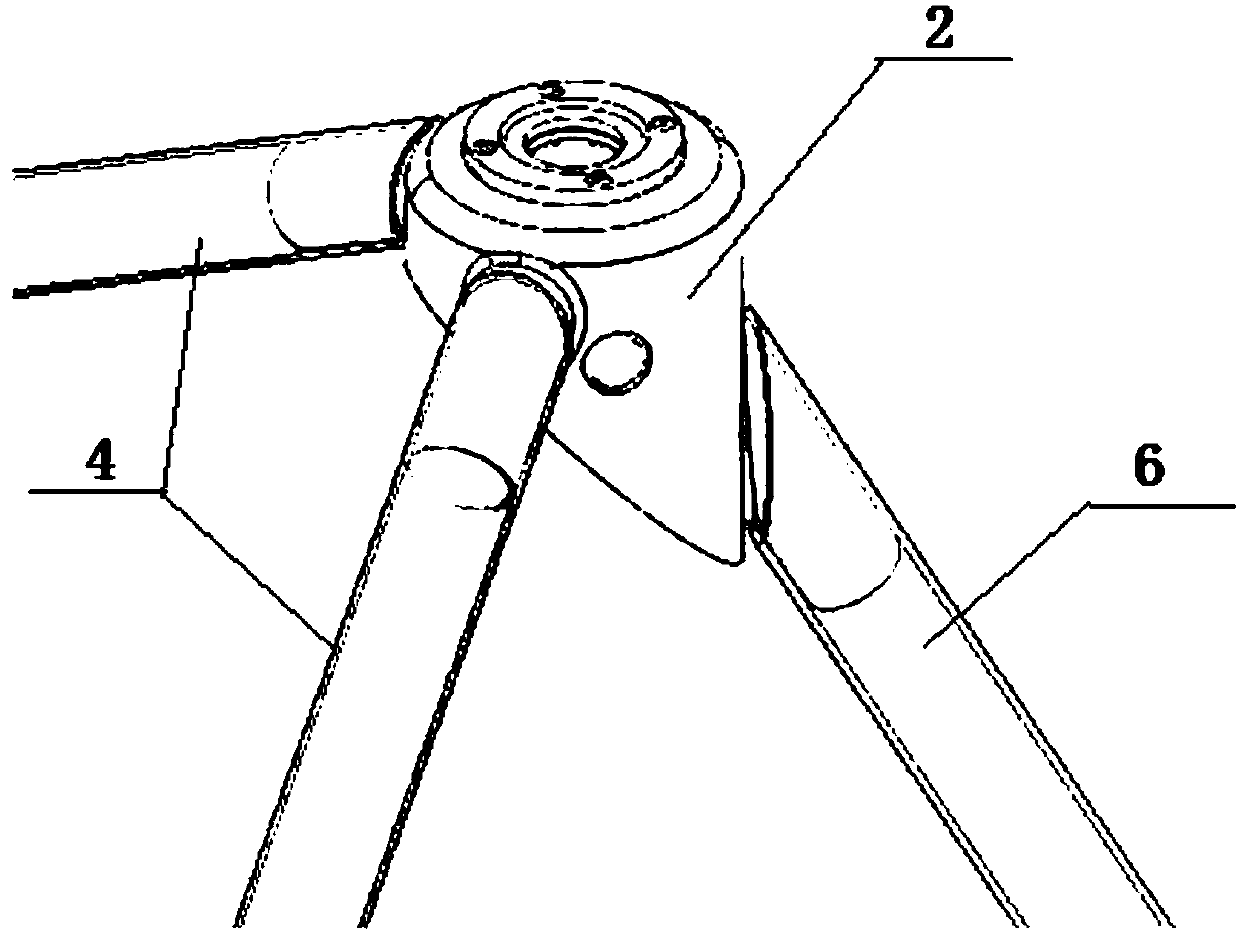

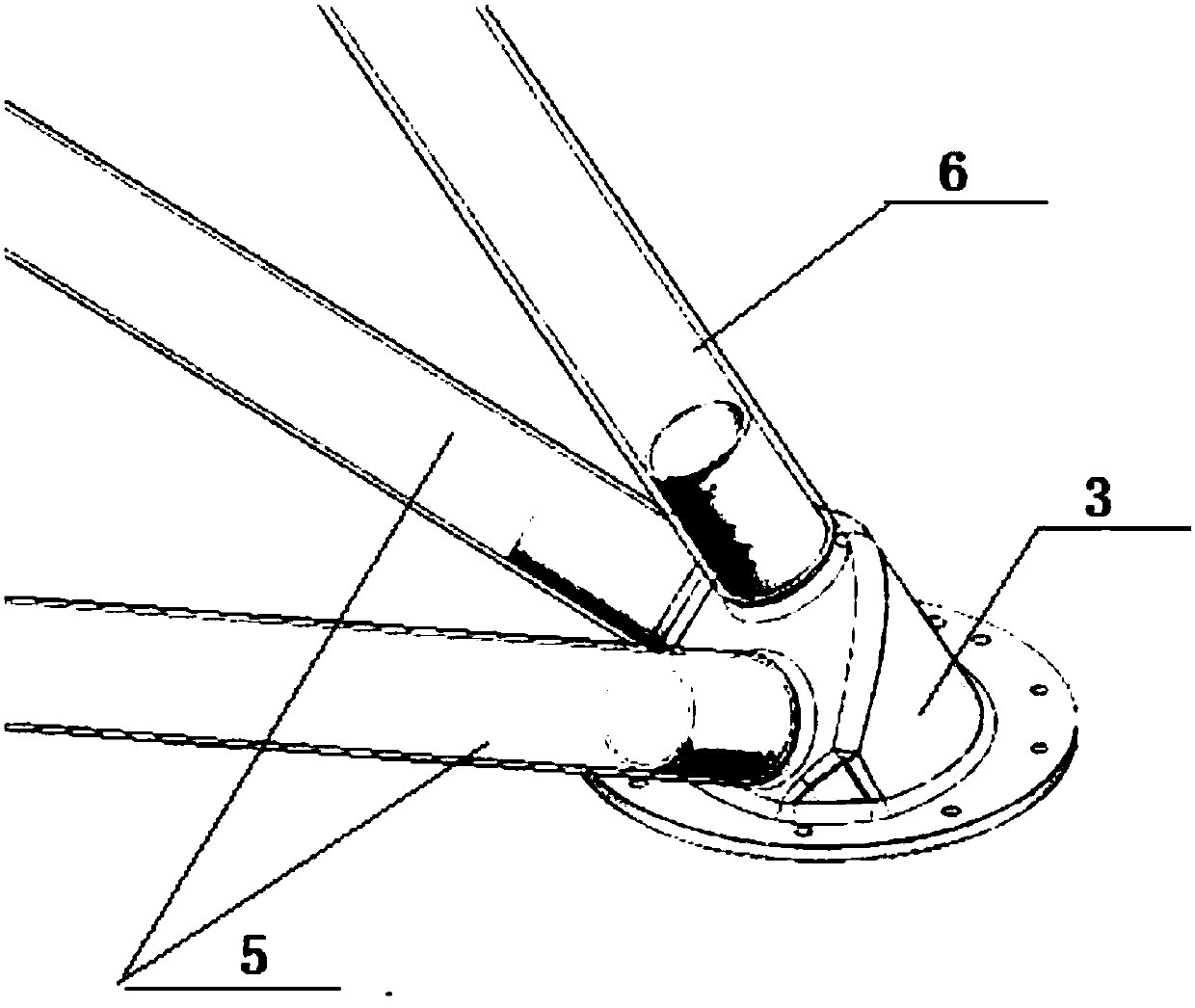

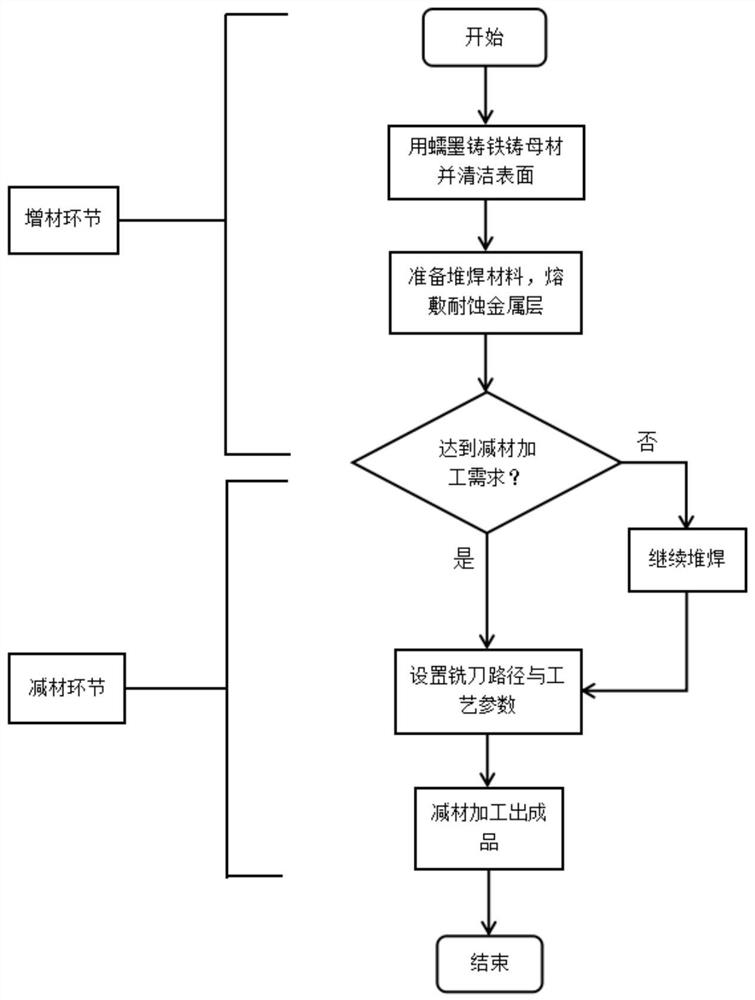

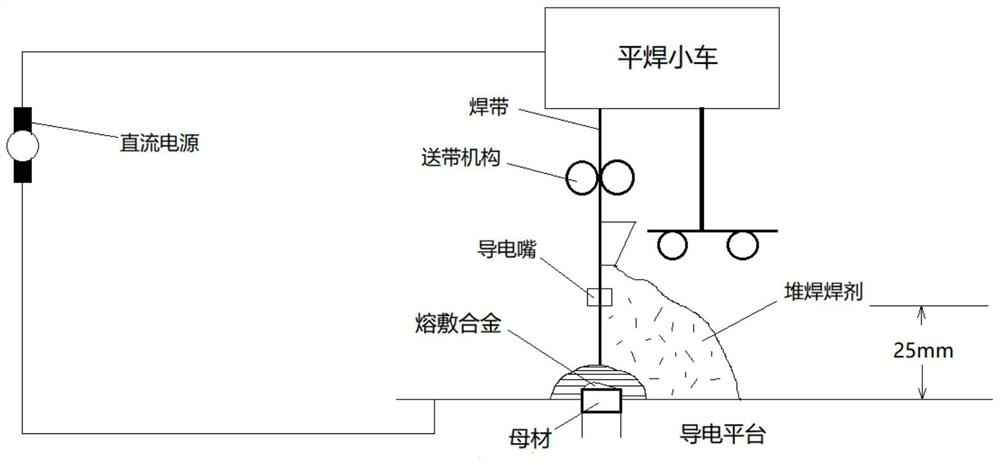

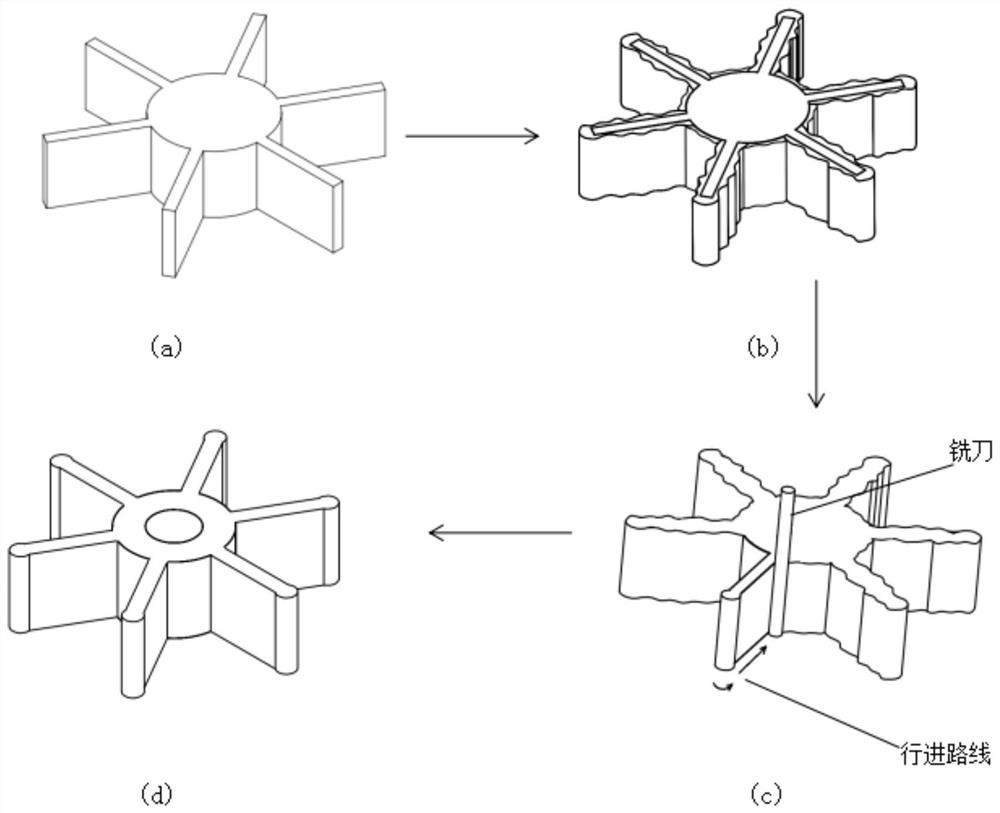

Composite manufacturing method of corrosion-resistant impeller of sea water pump

InactiveCN111958181AHigh shape precisionGuaranteed corrosion resistancePump componentsPumpsMilling cutterSS - Stainless steel

The invention provides a composite manufacturing method of a corrosion-resistant impeller of a sea water pump. The method specifically comprises two processes of material adding and material reducing.The material adding process comprises the following steps: A1, casting a base metal by using vermicular graphite cast iron and cleaning the surface; A2, preparing a welding material, and uniformly coating the surface of the base metal with a layer of 316 L stainless steel in a deposition mode by a strip electrode electroslag surfacing method till the external dimension reaches the subsequent machining requirement. The material reducing process comprises the following steps: B1, planning a milling cutter path and process parameters according to the shape of a finished product, and B2, millingthe finished product through material reducing machining. The method has the technical advantages that process operation is simple, production automation is convenient to realize, universality is high, and the method can be applied to manufacturing other parts; the performance advantages of high strength of the vermicular graphite cast iron and strong corrosion resistance of the 316 L stainless steel are fully combined, and the manufactured finished product has the characteristics of high strength and corrosion resistance; and meanwhile, the strip electrode electroslag surfacing is mainly adopted to deposit corrosion-resistant alloy, and the defect of the large dilution rate of an MIG additive manufacturing method is overcome.

Owner:南通河海大学海洋与近海工程研究院

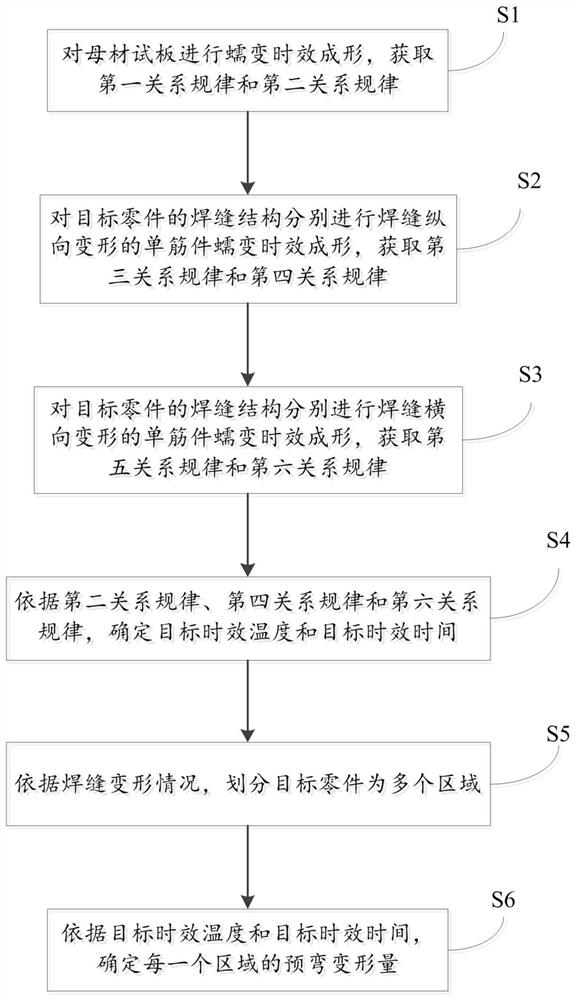

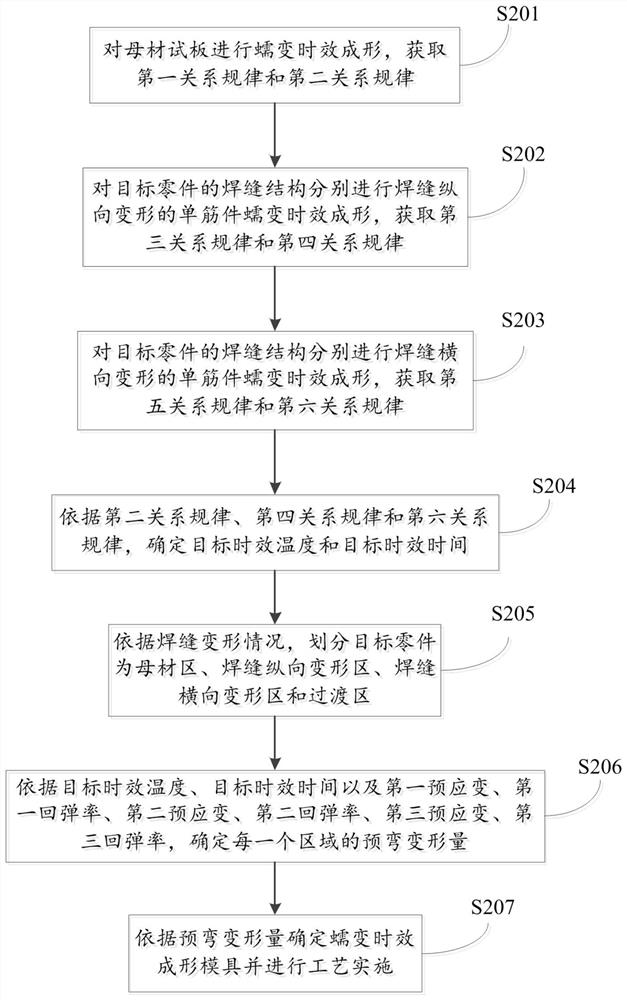

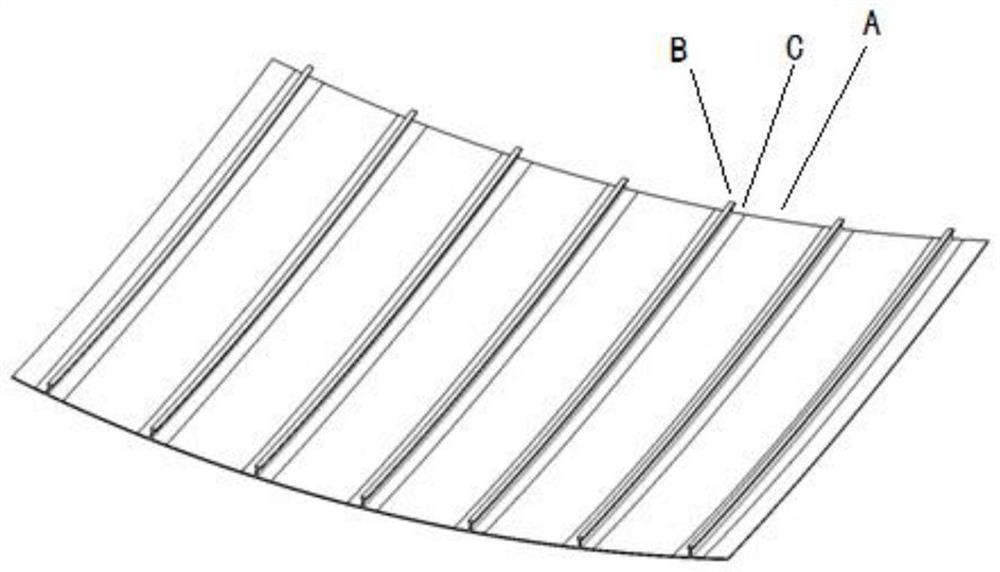

Method for controlling appearance precision during creep aging forming of ribbed wall panel

InactiveCN111719095AAvoid scrappingHigh shape precisionWelding residual stressStructural engineering

The invention discloses a method for controlling the appearance precision during creep aging forming of a welded ribbed wall panel. The method comprises the following steps of performing creep aging forming on a base material test panel, and acquiring a first relationship rule and a second relationship rule; performing welding seam longitudinal and transverse deformation single-rib piece creep aging forming on a welding seam structure of a target part, and acquiring a third relationship rule, a fourth relationship rule, a fifth relationship rule and a sixth relationship rule; determining the target aging temperature and the target aging time according to the second relationship rule, the fourth relationship rule and the sixth relationship rule; dividing the target part into a plurality ofregions according to the deformation conditions of a welding seam; and determining the pre-bending deformation amount of each region according to the target aging temperature and the target aging time. The purpose of the method for controlling the appearance precision during creep aging forming of the welded ribbed wall panel is to solve the problems that material properties vary due to the welding seam, and deformation is not coordinated due to welding residual stress.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

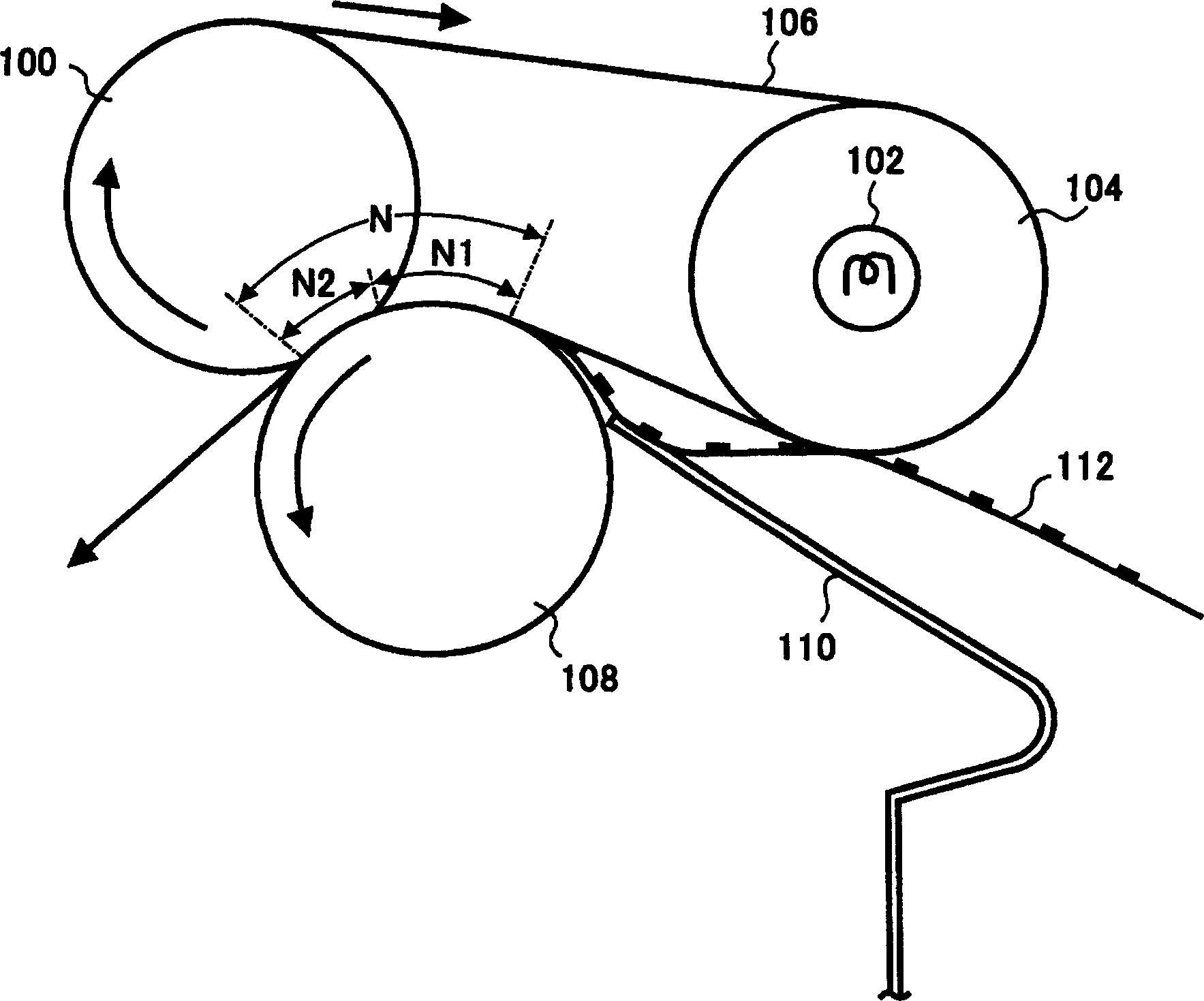

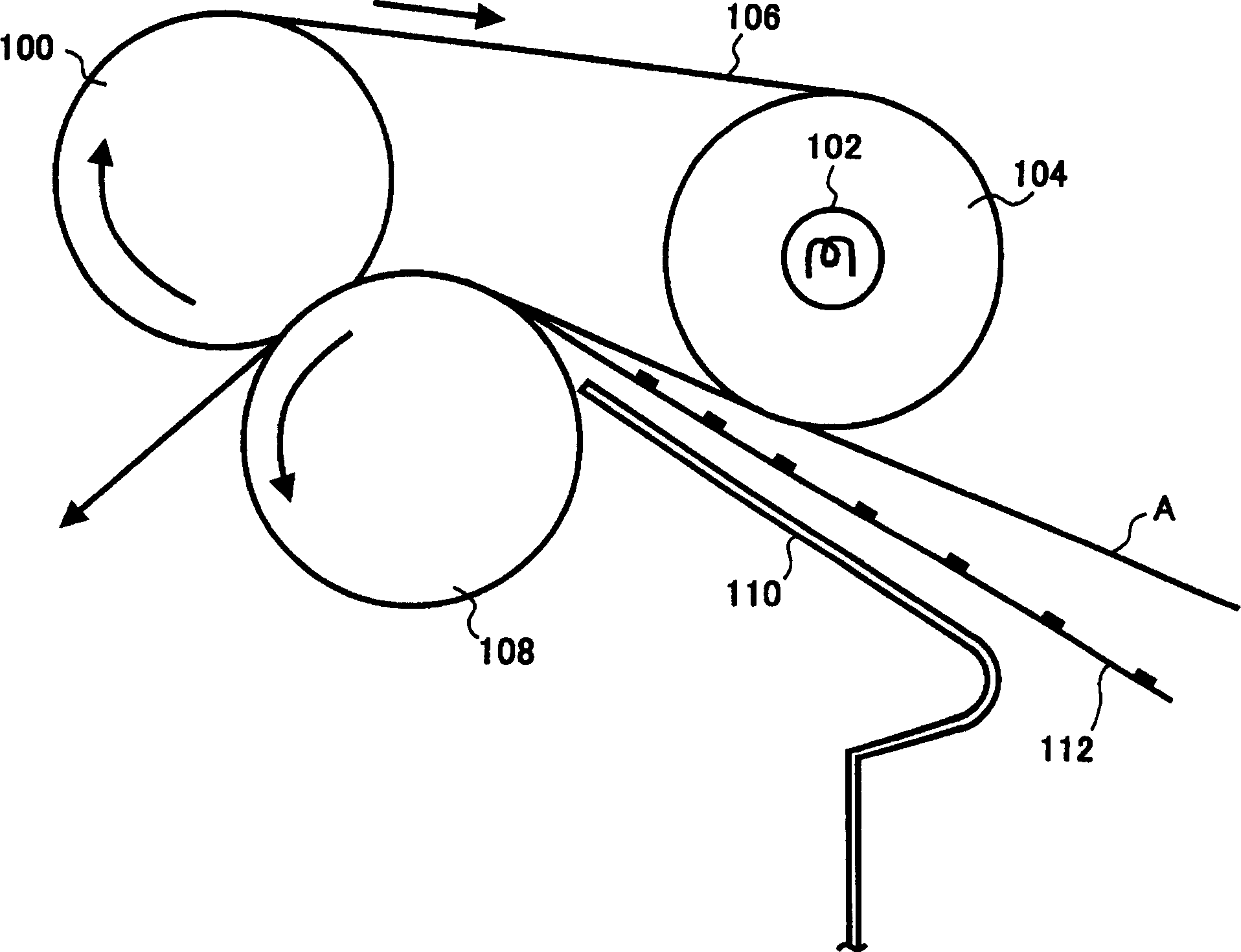

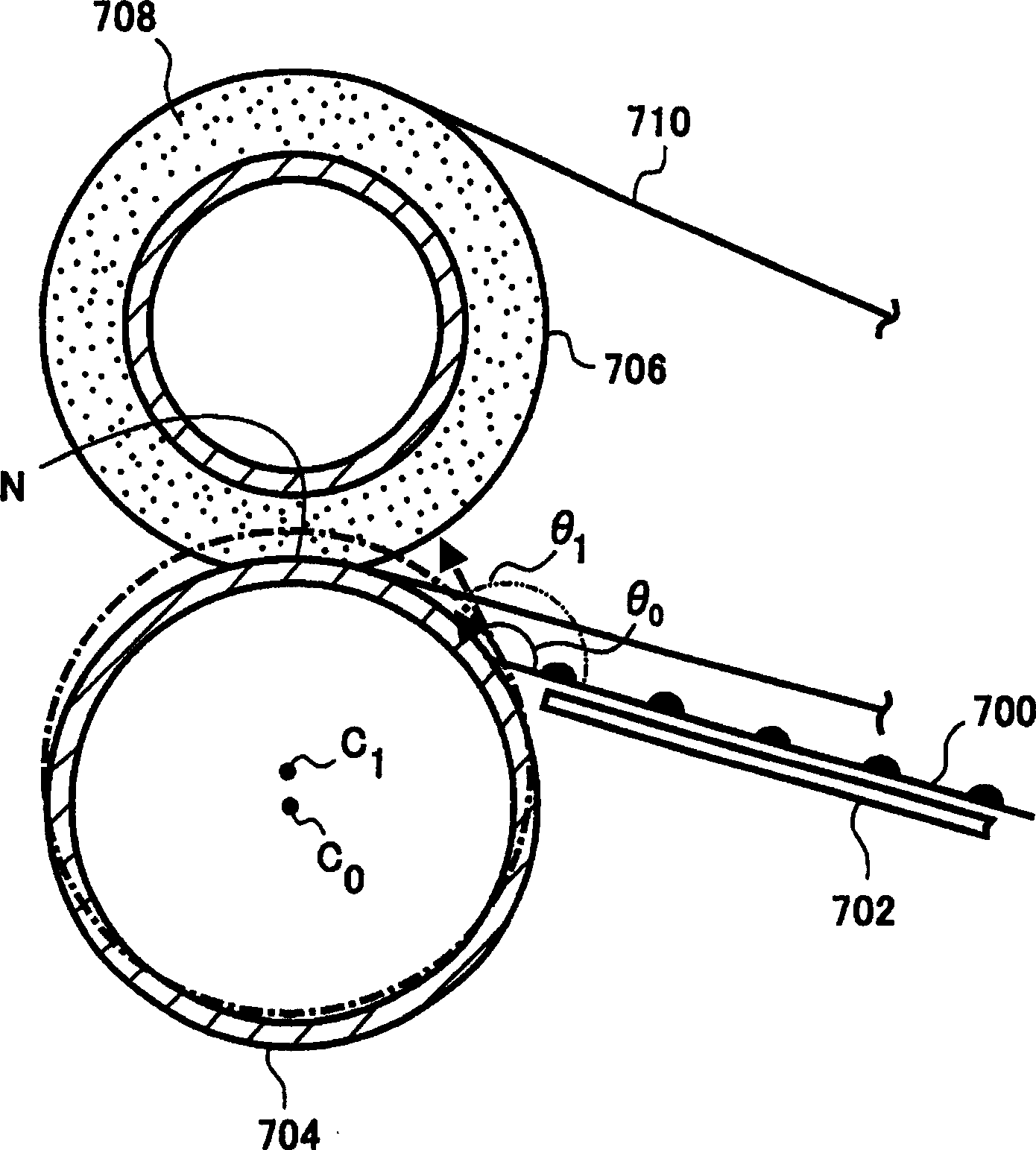

Fixing method, fixing apparatus and image formation device

InactiveCN1218226CAdjust the fusing pressureDoes not affect glossElectrographic process apparatusImage formationMechanical engineering

The present invention relates to a fixing method, fixing apparatus, and image formation device. The fixing belt 408 racks between the fixing roller 402 and heating roller 406. The pressure roller 412 pushes the fixing roller to form a second fixing-process area. The supporting roller 416 contacts inside the fixing belt 408 and winds the fixing belt around a surface of the pressure roller 412 to form a first fixing-process area. The pressure applying member applies a pressure to the heat roller in a direction opposite to an ejection of the recording sheet to adjust a fixing pressure of the pressure applying member to set a optimum fixing pressure not to generate a crinkle. The pressure roller has a hard structure not easier to deform than the fixing roller and improve the reproducibility and stability of linear velocity in fixing.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com