Whole carbon fiber composite material support between devices

A carbon fiber and carbon fiber weaving technology, which is used in aircrafts, spaceflight aircraft, spaceflight equipment and other directions to achieve the effects of improving connection strength, reducing structural weight and high shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

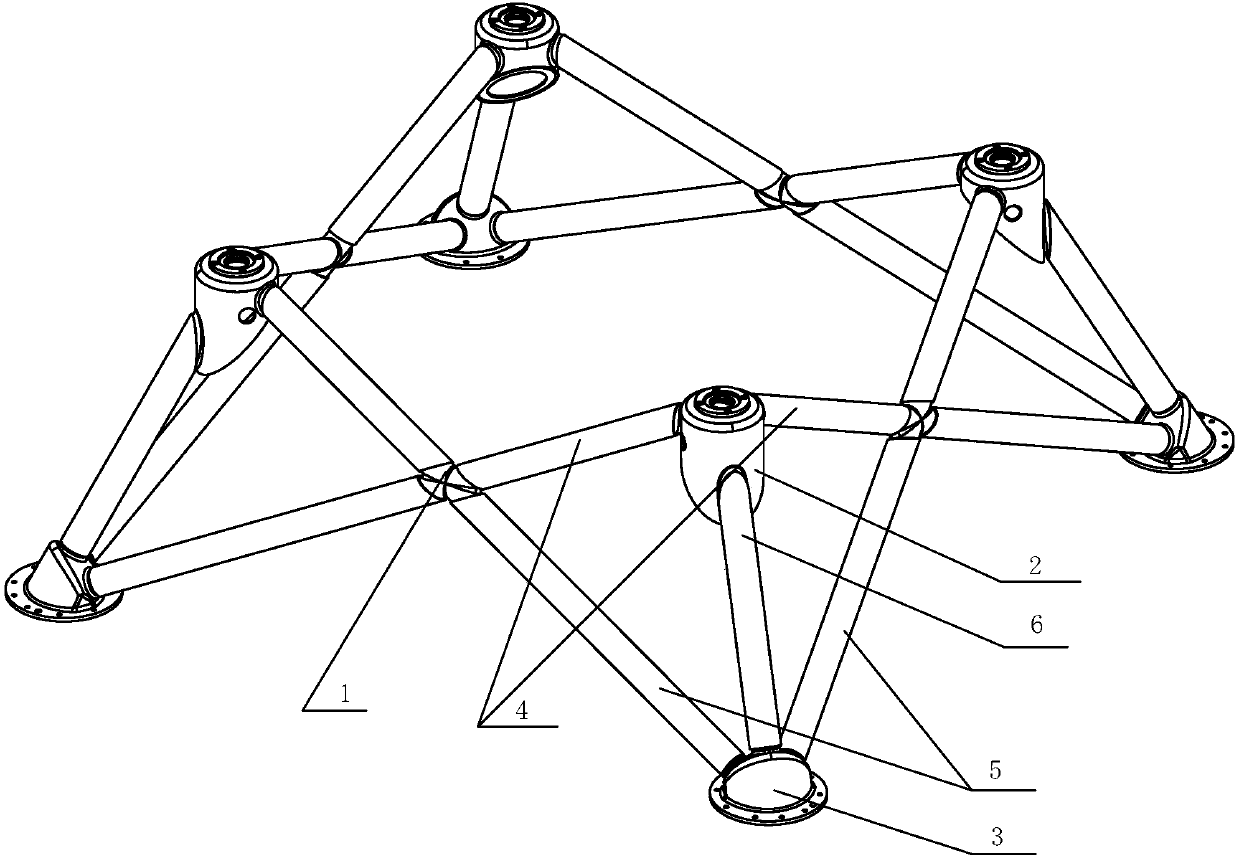

[0032] In order to realize the spacecraft cabin and inter-device connection with high precision, large load capacity, few nodes, and large span, the present invention proposes a full carbon fiber inter-device bracket, such as figure 1 As shown, it includes at least 3 support units, and two adjacent support units are interconnected through a cross joint 1 .

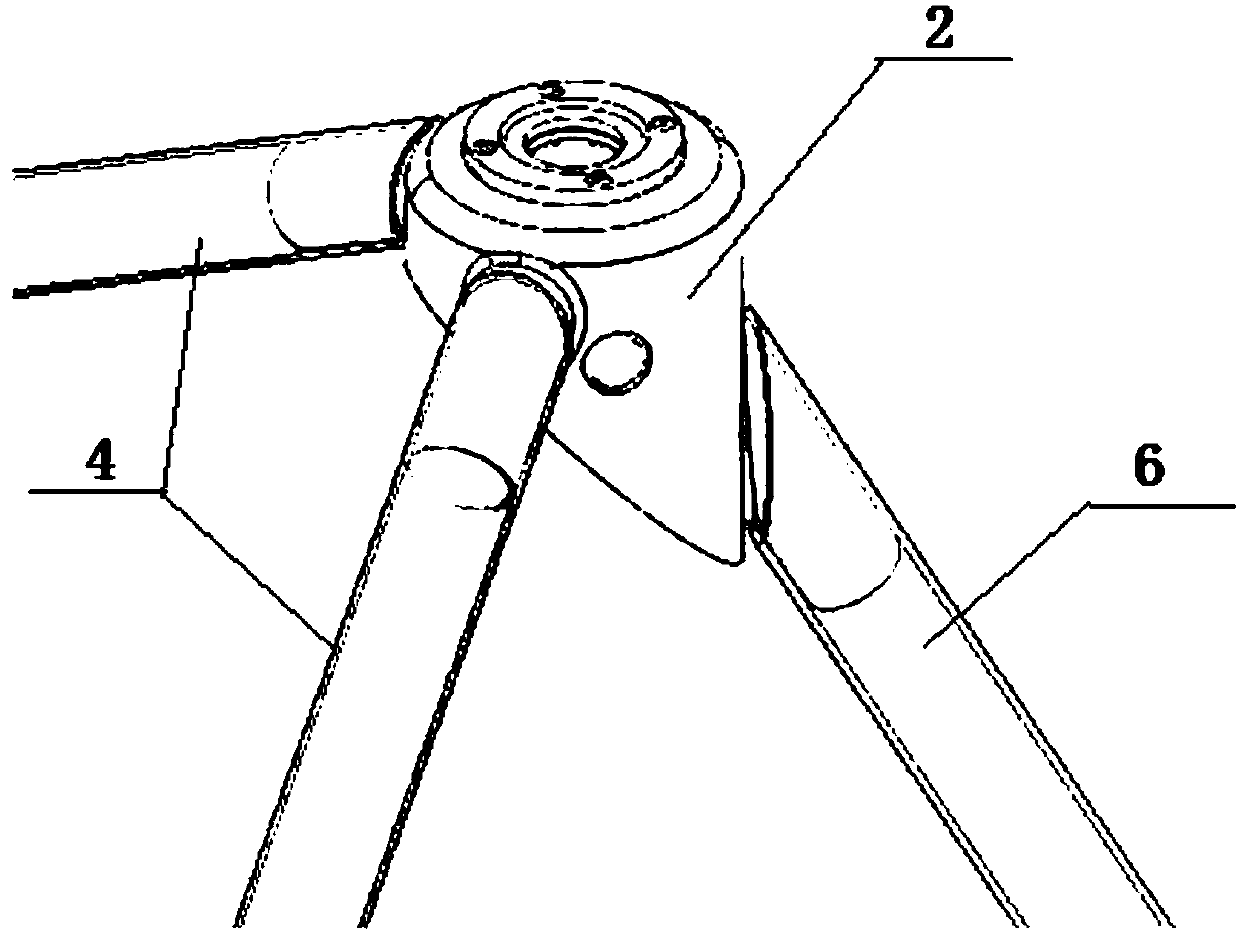

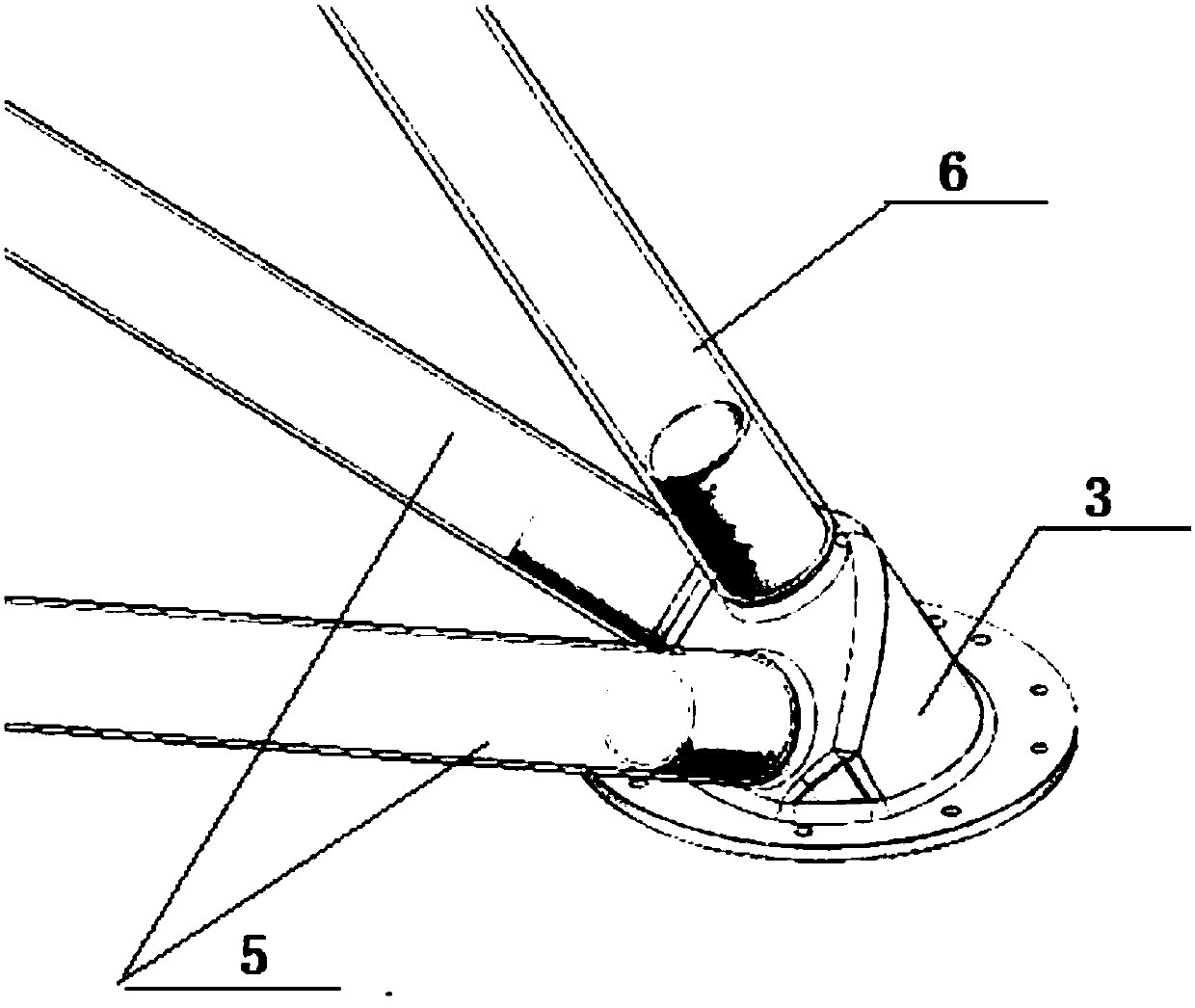

[0033] Each bracket unit includes 1 upper joint 2, 1 lower joint 3, 2 oblique upper rods 4, 2 oblique lower rods 5 and 1 vertical rod 6; for any bracket unit, 2 oblique upper rods 4 and One end of the vertical rod 6 is fixedly connected to the upper joint 2, and the axes of the three rods pass through the same point; one end of the two inclined lower rods 5 and the other end of the vertical rod 6 are fixedly connected to the lower joint 3, and the three rods The axis passes through the same point; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com