Coreless, brushless and toothless big hub motor

An in-wheel motor, ironless technology, applied in motor vehicles, electromechanical devices, electrical components, etc., can solve the problems of loss of flexible braking function, heavy iron core stator coil, affecting motor efficiency, etc., to achieve high utilization of skeleton space, Simple structure and the effect of saving skeleton space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

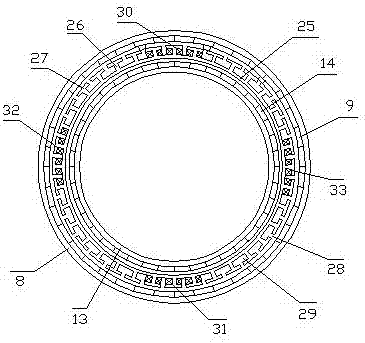

[0010] The iron-coreless, brushless, toothless large hub motor is a low-speed motor, and the magnetic poles of the motor rotor are selected from 40 poles to 60 poles. The magnetic poles of the motor rotor in this scheme are illustrated with 40 poles as an example.

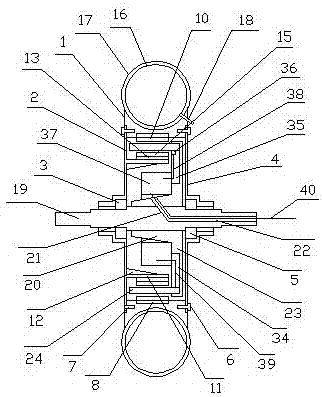

[0011] exist figure 1 , figure 2Among them, the iron-coreless, brushless, toothless large hub motor is provided with a wheel rotor in which the wheel and the hub are closely combined and the hub and the motor rotor are integrated. The wheel rotor is provided with an aluminum alloy hub ring 1, and the aluminum alloy hub ring , The right end is provided with a positioning step, the left hub end cover 2 is installed in the inner circle of the left positioning step, the left bearing frame and the left hub bearing 3 are arranged in the middle of the left hub end cover; the right hub end cover 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com