Molding grinding wheel dressing data acquiring method based on multi-axis linkage precision measuring system

A precision measurement and multi-axis linkage technology, which is applied in the control of workpiece feed movement, grinding machine parts, abrasive surface adjustment devices, etc., can solve problems such as difficult to achieve quantitative trimming data, and achieve the improvement of shape accuracy and improvement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The invention will be described in further detail below in conjunction with the accompanying drawings.

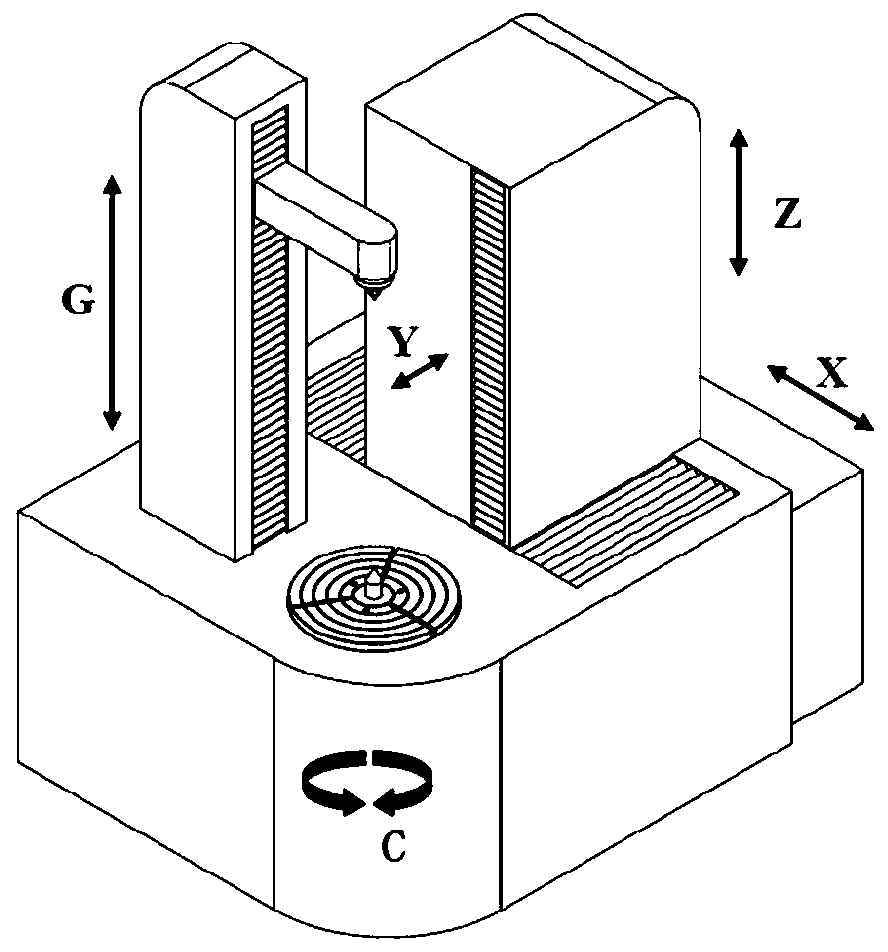

[0040] The forming mold grinding wheel dressing data acquisition method based on the multi-axis linkage precision measurement system provided by the present invention is a new type of measurement implementation and data processing method based on the multi-axis linkage system. Applying this method, combined with high-precision measurement system, numerical control technology, and computer information processing technology, can make multi-axis linkage system realize high-precision numerical control measurement of complex parts. The multi-axis linkage precision measurement system is a four-axis measurement device composed of three cantilever beams and a rotating spindle. It can be equipped with a precision scanning sensor for three-dimensional micro-motion measurement in space to form a seven-axis four-linkage measurement system. The multi-axis linkage precision measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com