Fixing method, fixing apparatus and image formation device

An image and fixing roller technology, applied to the electrical recording process using the charge pattern, equipment and instruments for the electric recording process using the charge pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

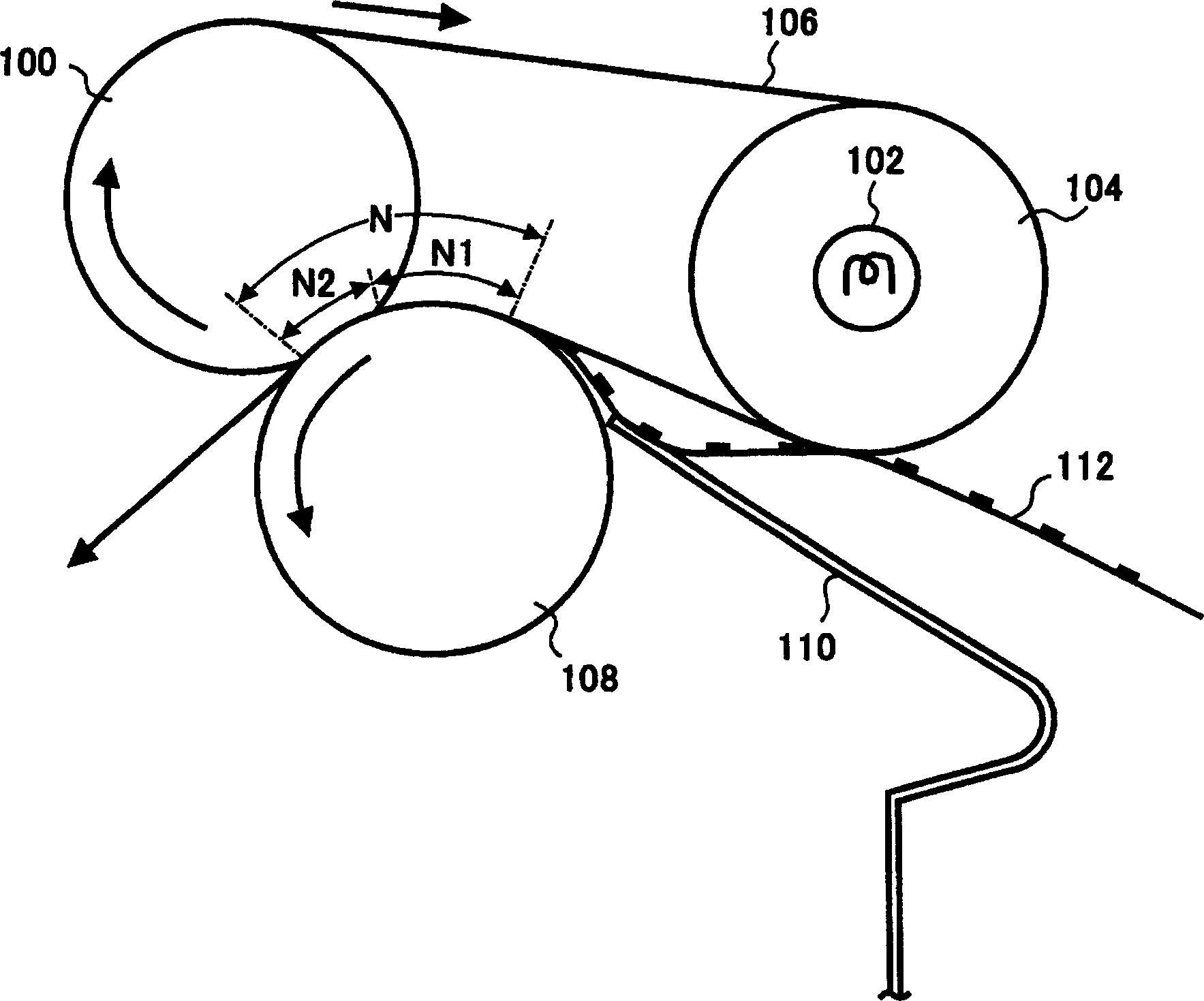

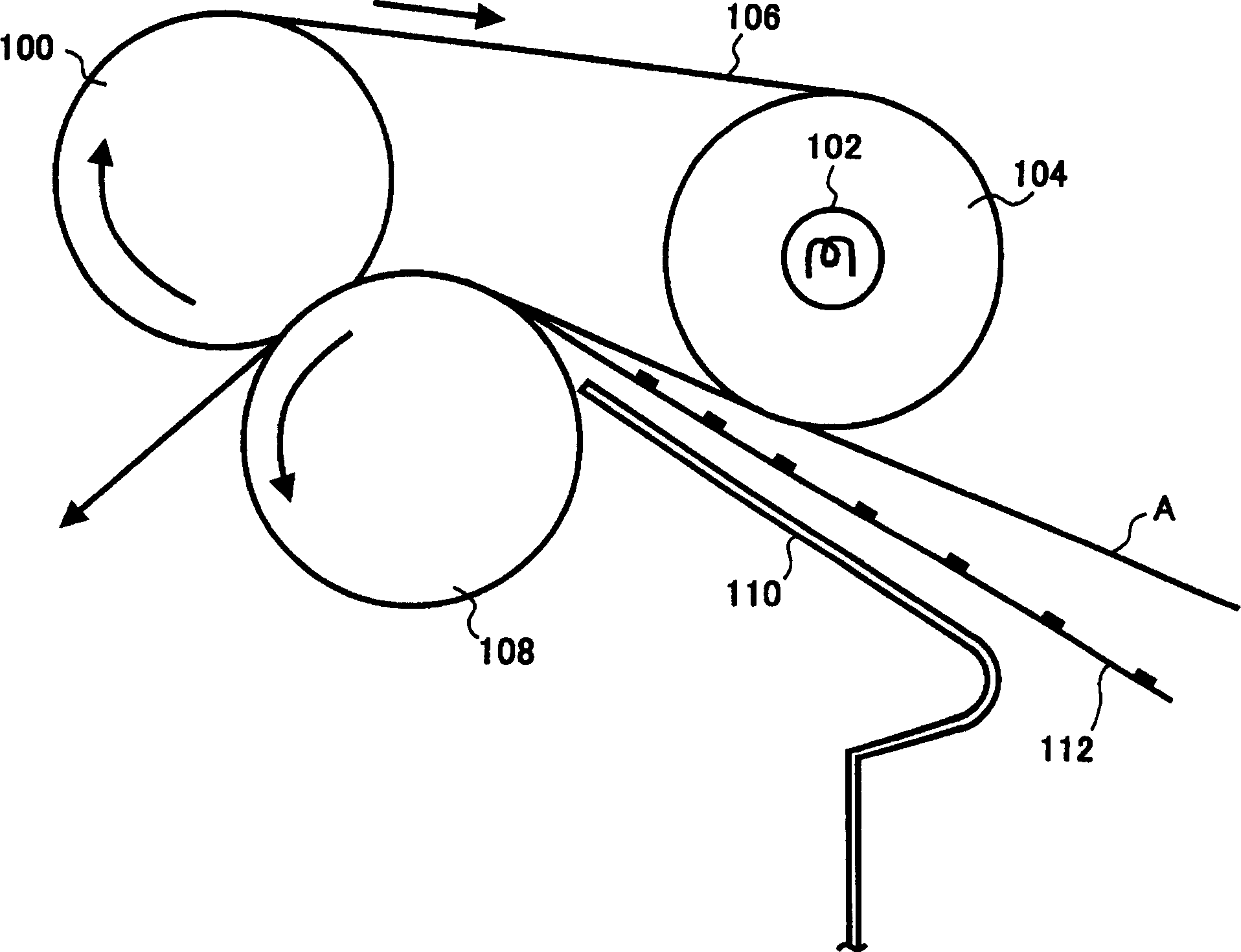

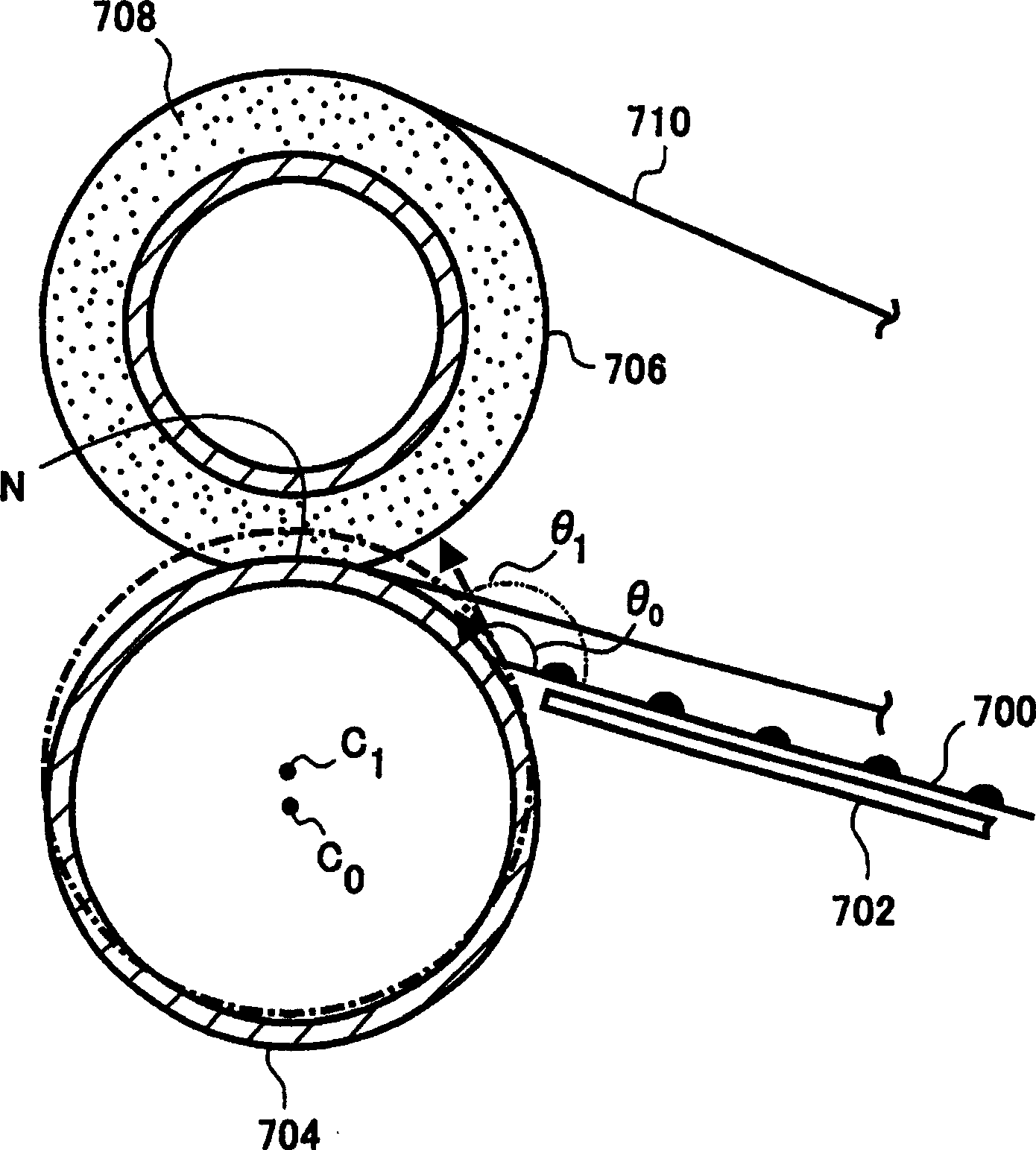

[0111] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0112] first refer to Figure 4 The overall configuration and functions of a color copier as an image forming apparatus will be briefly described.

[0113] Writing optical unit 300 as an exposure device converts color image data from color scanner 200 into optical signals, performs optical writing corresponding to a document image, and forms an electrostatic latent image on photoreceptor 302 as an image carrier. The writing optical unit 300 is composed of a laser diode 304, a polygon mirror 306 and its rotation motor 308, an f / θ lens 310, a reflection mirror 312, and the like.

[0114] As shown by the arrow in the figure, the photoreceptor 302 rotates in the counterclockwise direction, and the photoreceptor cleaning assembly 314, the discharge lamp 316, the potential sensor 320, and the developer selected in the rotary developing device 322 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com