Manufacturing process of mobile phone camera lens

A mobile phone camera and manufacturing process technology, which is applied in the field of mobile phone cameras, can solve the problems of high labor consumption and low product precision, and achieve the effects of improving the accuracy of the shape and size, saving manual work stations, and reducing the self-explosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

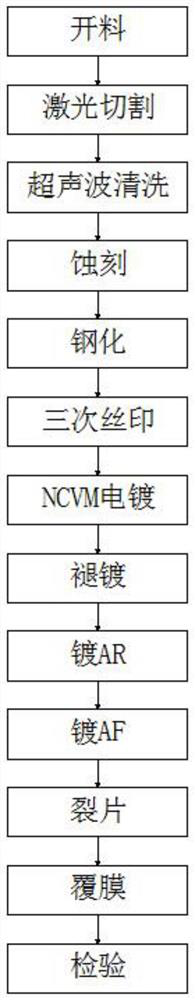

[0046] Such as figure 1 A mobile phone camera lens manufacturing process shown includes the following steps:

[0047] S1: material cutting, such as figure 2 As shown, the 1900*1500mm glass raw material is divided into 123*85mm glass middle pieces by a glass cutting machine, and the thickness of each group of glass middle pieces is 0.5mm;

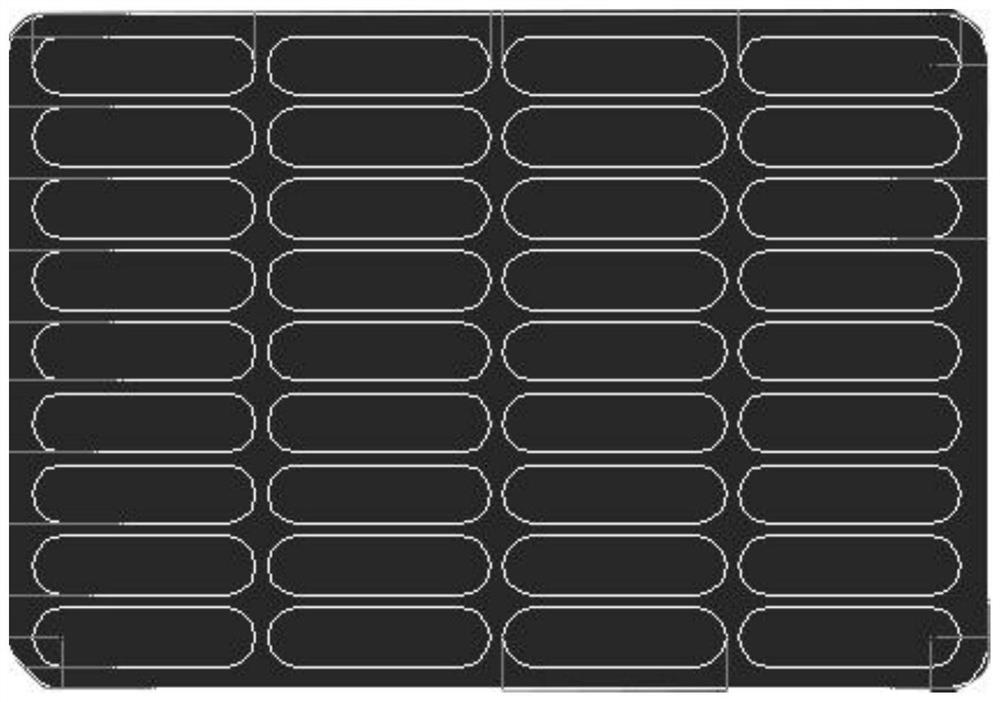

[0048] S2: laser cutting, such as image 3 As shown, according to the size and outer contour of the camera, the outer contour of the camera in this embodiment is preferably elliptical, the length of each camera is 27.5mm, and the width is 6.29mm. The laser cutting machine processes according to the set processing track Outline of 36 groups of cameras, including 4 groups in the horizontal direction and 9 groups in the vertical direction, with a cutting depth of 0.3-0.35mm, which is convenient for the subsequent splitting process;

[0049] S3: Ultrasonic cleaning, immerse the cut glass middle piece in the flowing water tank and rinse for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com