Separation method of dropper moving device

A separation method and mobile device technology, applied in the direction of textiles, textiles, papermaking, weaving auxiliary equipment, etc., can solve the problems of cumbersome operation, waste of time, scattered detection positions, etc., to improve work efficiency, fast and fully automatic control, save The effect of removing artificial processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

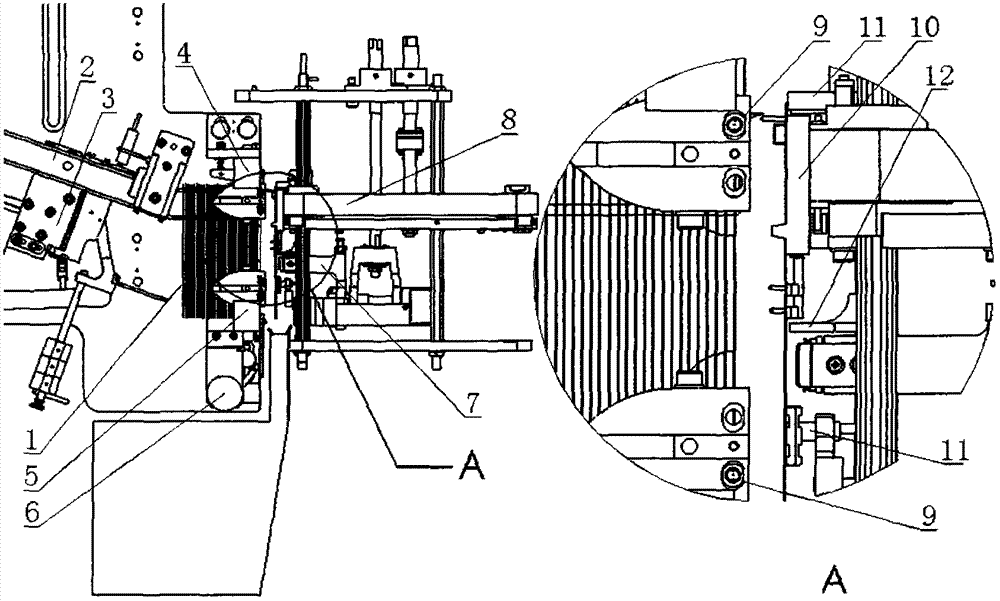

[0019] attached figure 1 Among them, A is the cross-sectional view of the menopause film separating and moving device. The menopause film (1) on the introduction guide rail (2) is stacked and pressed down to the designated position by the force of the weight mechanism (3), and then introduced into the tail end of the guide rail (2). The upper limit hook (4) and the lower limit hook (5) hook the upper and lower parts of the menopause sheet at the front end of the stack, and the suction cup mechanism (7) moves to the surface of the menopause sheet (1) arranged at the front end at a speed of 100 mm / s to carry out Adsorb, then move backward to separate the first and second pieces of the menopause sheet (1) at the front end of the layered menopause sheet, and at the same time spray air from the upper and lower air nozzles (9) for 0.05s. When the first menopause sheet (1) is separated, it bends instantly The deformation produces elasticity, and through the principle of leverage, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com