Patents

Literature

727results about How to "Reduce inhalation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

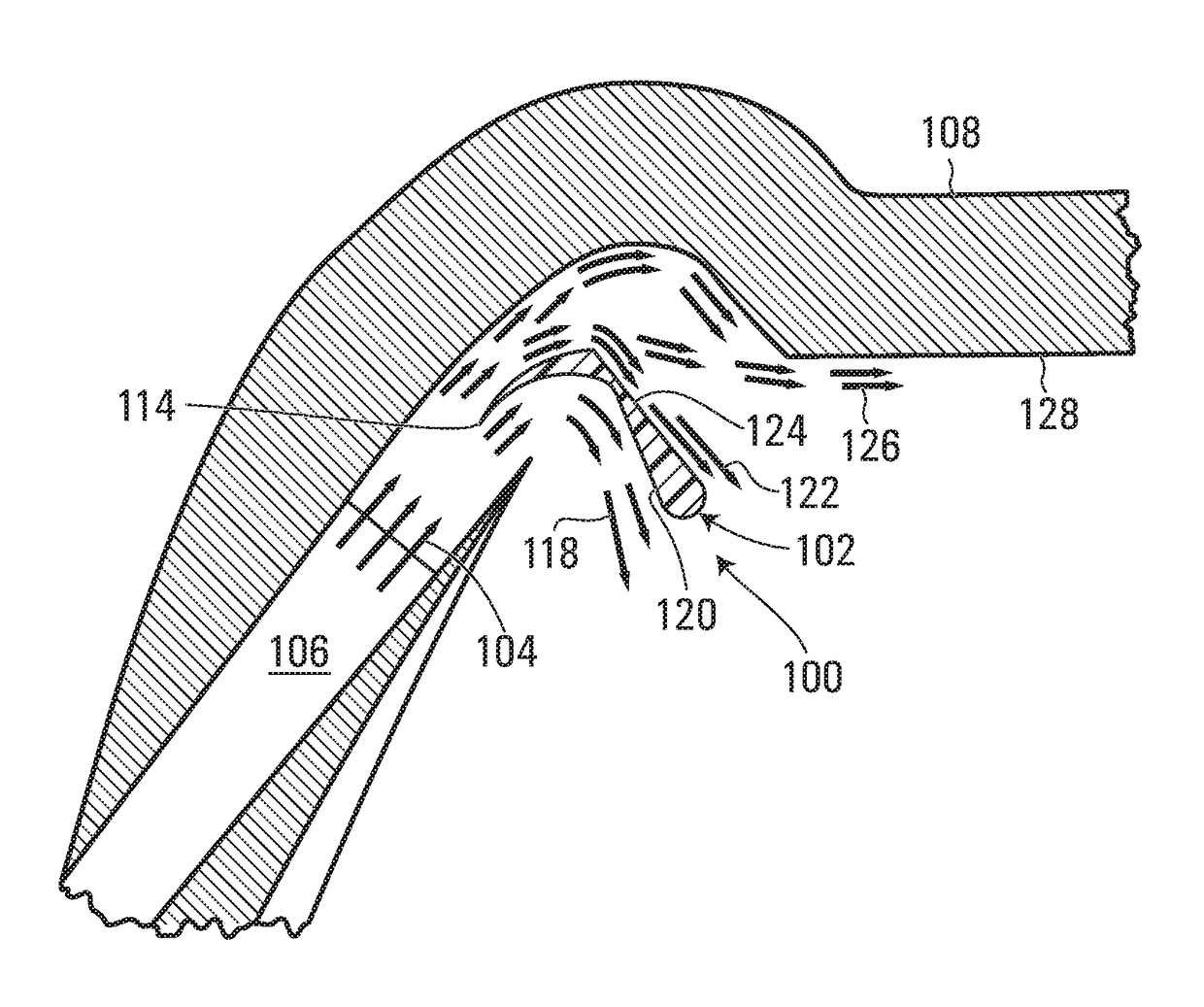

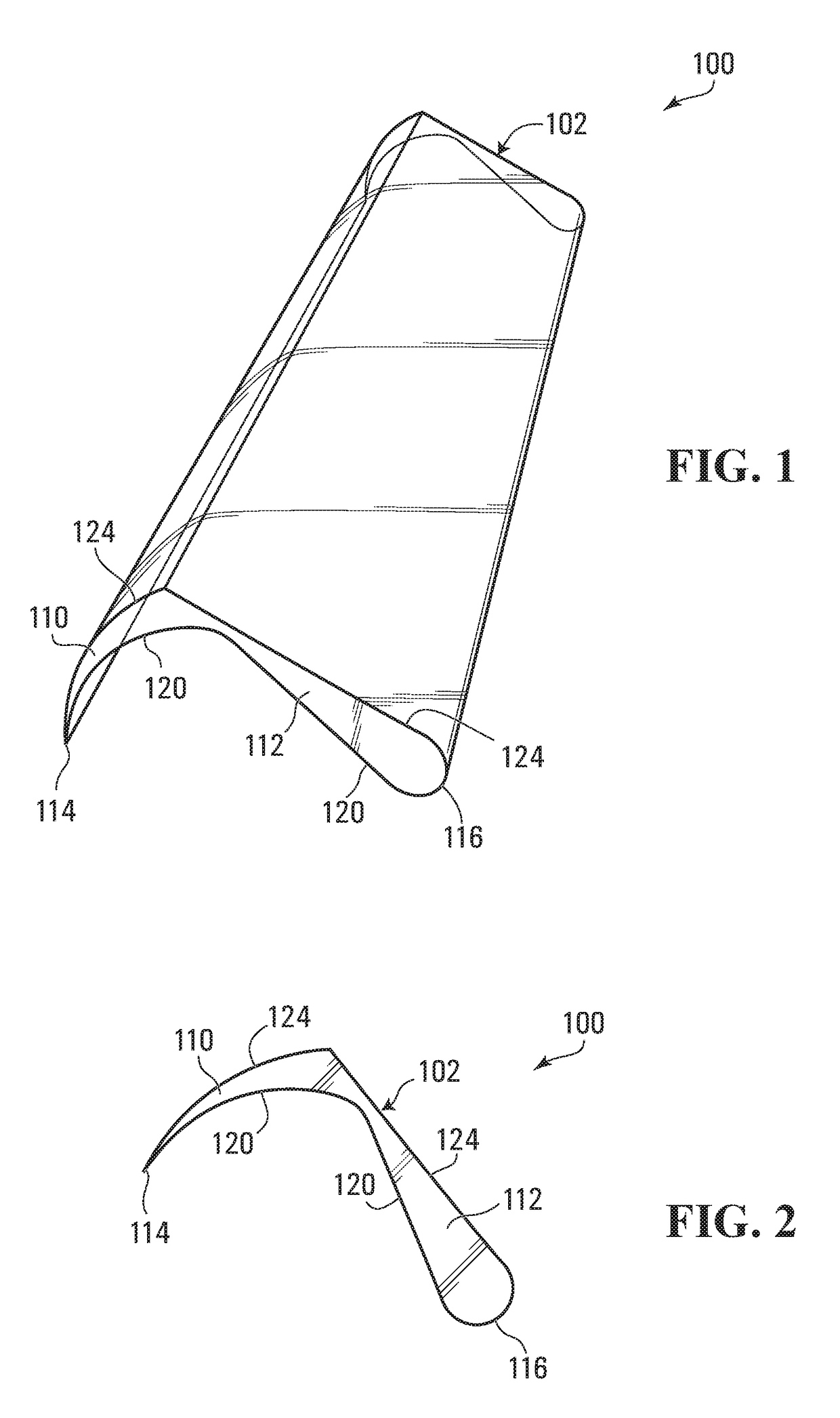

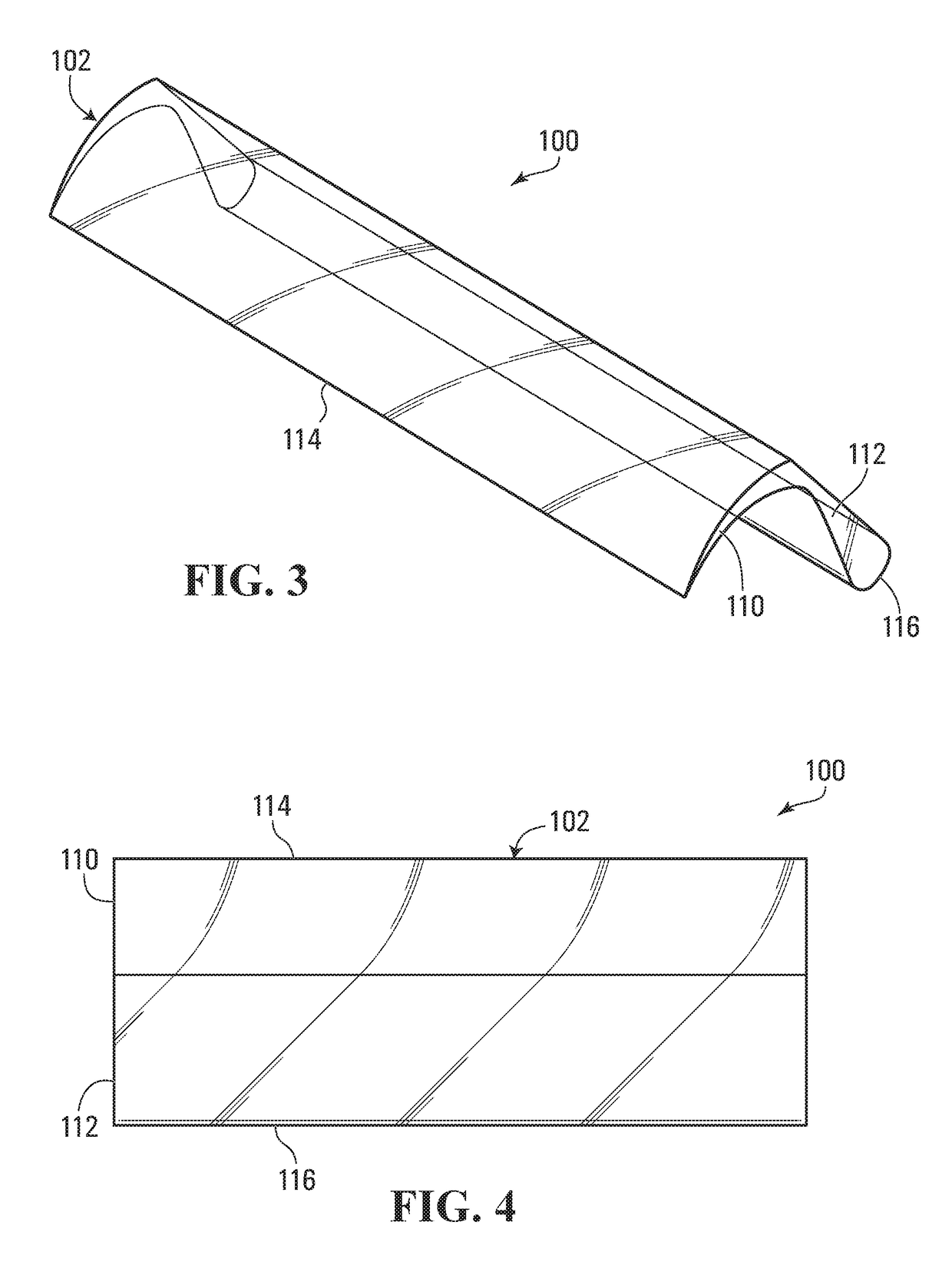

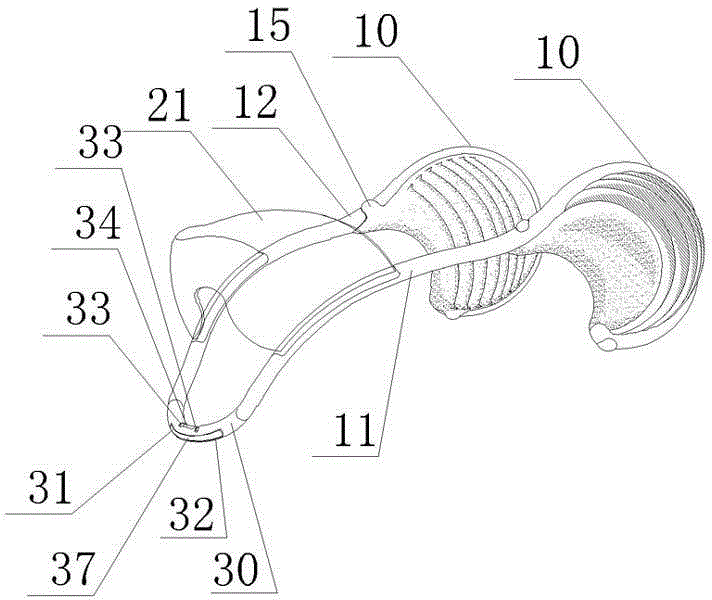

Airflow modification apparatus and method

ActiveUS9725178B2Raise the ratioDecrease their propagationGeometric CADAir-treating devicesNacelleAirplane

Owner:WANG RAYMOND R M

Preparation method of large-size aluminum alloy ingot

The invention discloses a preparation method of a large-size aluminum alloy ingot, relating to a preparation method of aluminum alloy ingots, and the provided preparation method of a large-size aluminum alloy ingot solves the problem of easy cracking during preparing the large-size aluminum alloy ingots by the traditional aluminum alloy ingot preparation method. The method comprises the following steps of: spreading and scattering a NO. flux at the bottom of a smelting furnace; adding aluminum ingots, electrolytic copper, zinc ingots, aluminum-silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-chromium intermediate alloy and aluminum-titanium intermediate alloy into the smelting furnace and spreading and scattering a covering agent; heating to ensure that the materials are smelted, sequentially adding a zirconium composite salt and magnesium ingots as well as smelting and refining to obtain an aluminum alloy melt; filtering the aluminum alloy melt and then pouring into a crystallizer; and finally, obtaining the large-size aluminum alloy ingot through casting. The thickness of the ingot prepared by using the method is 500-600mm, the width is 1,600mm, and the length is 1,500-2,500mm. The ingot has no cracks, good surface quality and uniform internal grains, and the yield is not smaller than 65 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

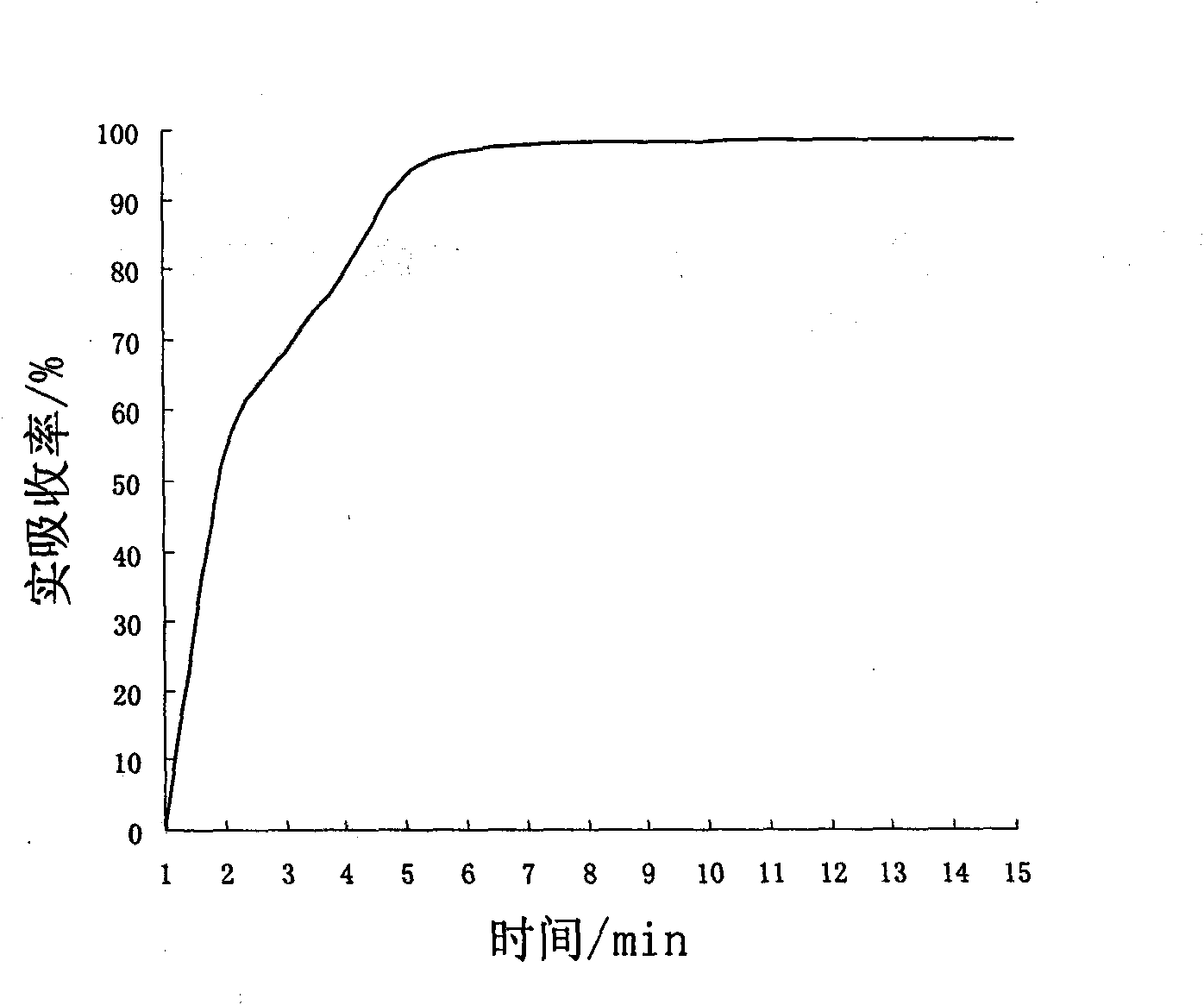

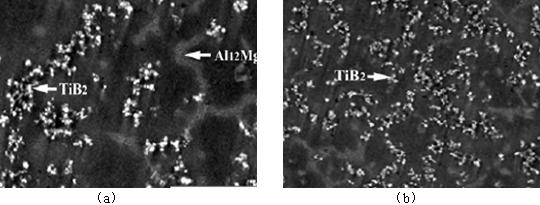

Additive for smelting aluminium alloy and preparation method and application method thereof

The invention relates to an additive for smelting aluminium alloy and a preparation method and an application method thereof, relating to the technical field of nonferrous alloy manufacturing with a special additive. The additive is composed of metal powder, cosolvent, heat-generating agent, detonating agent and moisture proof agent. The preparation method comprises the following steps: raw materials comprising the following by mass percentage, 70-81.5% of metal powder, 15-20% of cosolvent, 2-5% of heat-generating agent, 1-3% of detonating agent and 0.5-2% of moisture proof agent, are fully mixed evenly into compound powder with a ball mill, and the mixture is put into a mould, and is performed with cold pressing by a hydraulic pressure machine so as to obtain the additive for smelting aluminium alloy. The application method of the invention comprises the following steps: a graphite crucible filled with a pure aluminium pig is arranged in a resistance furnace to be heated until the aluminium pig is melted into aluminium liquid, and then the additive is added to react with the aluminium liquid so as to obtain aluminium alloy. Under the condition that the quality of aluminium alloy is not lowered, the additive solves the problems of high dissolving temperature, low absorptivity and unstable absorptivity of the additive.

Owner:HEBEI UNIV OF TECH

Preparation method of large-size aluminum alloy ingot

The invention discloses a preparation method of a large-size aluminum alloy ingot, relating to a preparation method of aluminum alloy ingots and solving the problems of easy cracking and difficult forming during preparing the large-size aluminum alloy ingots by the traditional aluminum alloy ingot preparation method. The method comprises the following steps of: spreading and scattering a NO.1 flux at the bottom of a smelting furnace; adding aluminum ingots, electrolytic copper, zinc ingots, aluminum-silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-chromium intermediate alloy and aluminum-titanium intermediate alloy into the smelting furnace and spreading and scattering a covering agent; heating to ensure that the materials in the smelting furnace are smelted; adding magnesium ingots and then smelting; then refining to obtain an aluminum alloy melt; filtering the aluminum alloy melt and then pouring into a crystallizer; and finally, obtaining the large-size aluminum alloy ingot through casting. The thickness of the prepared ingot is 500-600mm, the width is 600mm, and the length is 2,000-3,500mm. The ingot has no cracks, good surface quality and uniform internal grains, and the yield is not smaller than 90.5 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Environment friendly low-gas-content aluminum alloy ingot and production method thereof

The invention discloses an environment friendly low-gas-content aluminum alloy ingot which comprises the following components in percentage by weight: 1.6-3.3 percent of Cu, 9.8-11.8 percent of Si, 0-0.29 percent of Mg, 0-0.08 percent of Zn, 0-0.8 percent of Fe, 0-0.48 percent of Mn, 0-0.48 percent of Ni, 0-0.1 percent of Ti, 0-0.1 percent of Pb, 0-0.2 percent of Sn, 0-0.25 percent of other trace elements and the balance of aluminum. Meanwhile, the invention also discloses a production method of the environment friendly low-gas-content aluminum alloy ingot. The environment friendly low-gas-content aluminum alloy ingot has the advantages of low gas and dreg content, high aluminum liquid cleanness and good mechanical and machining properties. The production method has the advantages of low production cost and high efficiency and effectively solves the pollution problem of the secondary aluminum industry.

Owner:YE CHIU METAL RECYCLINGCHINALTD

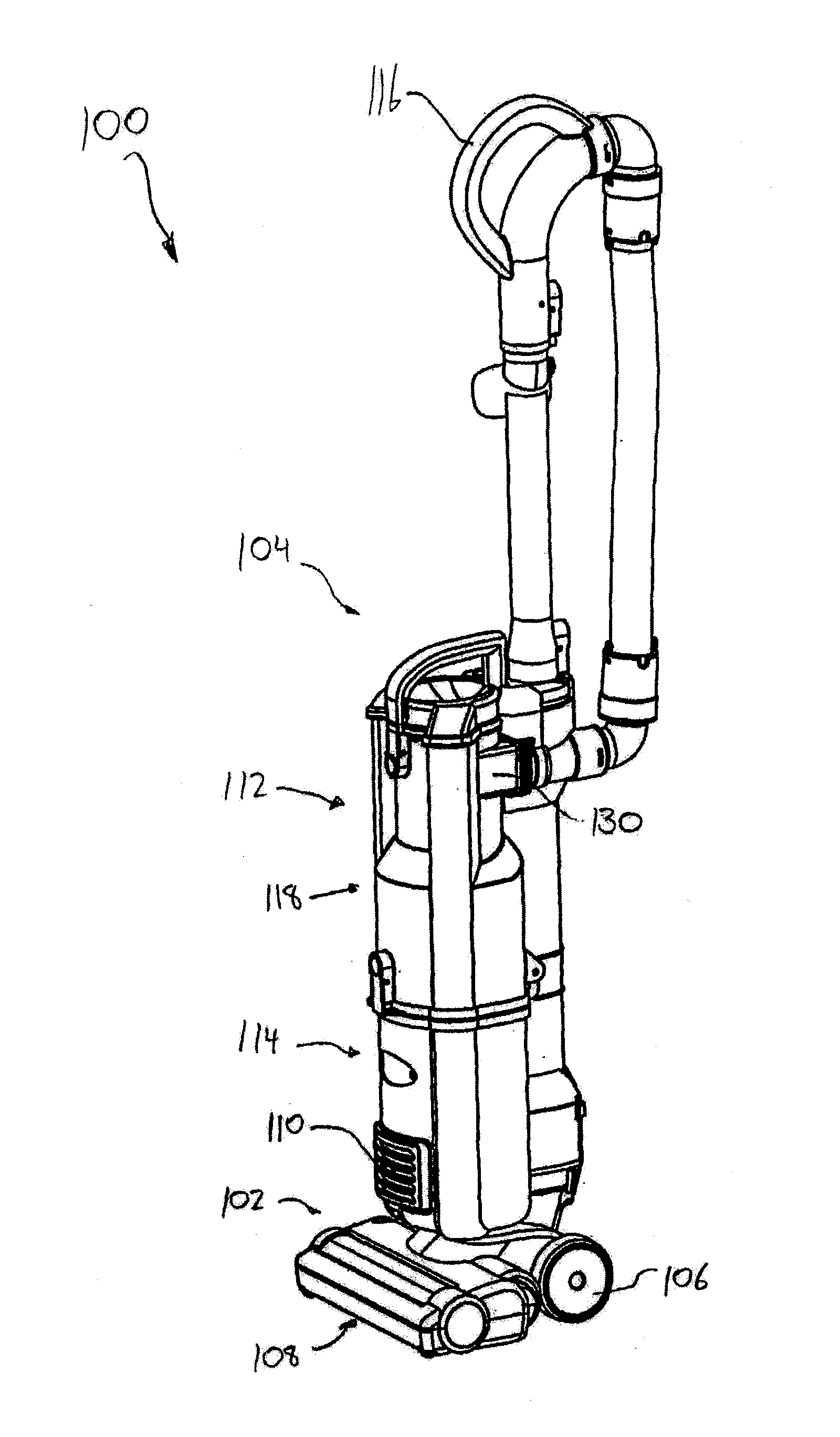

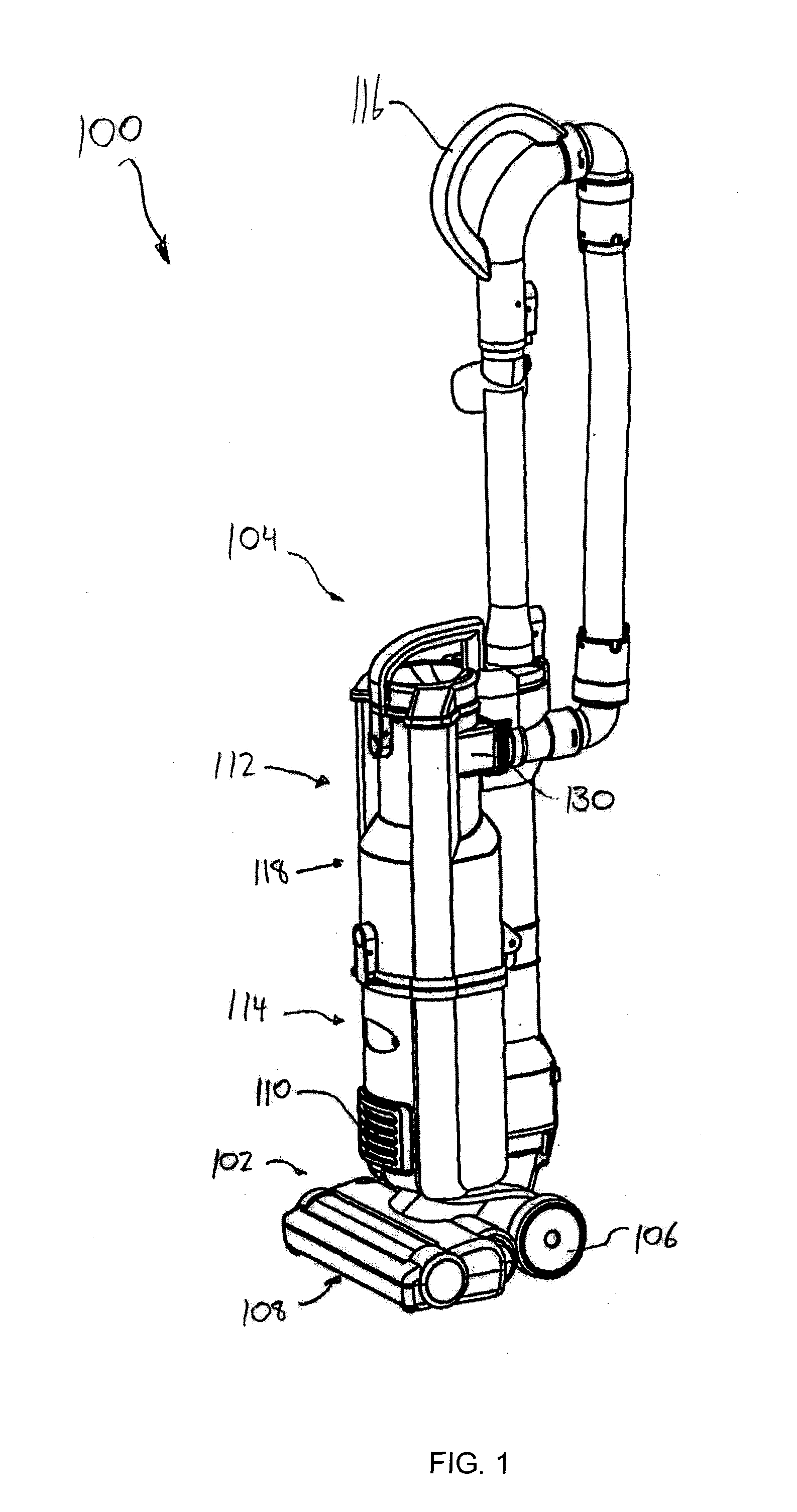

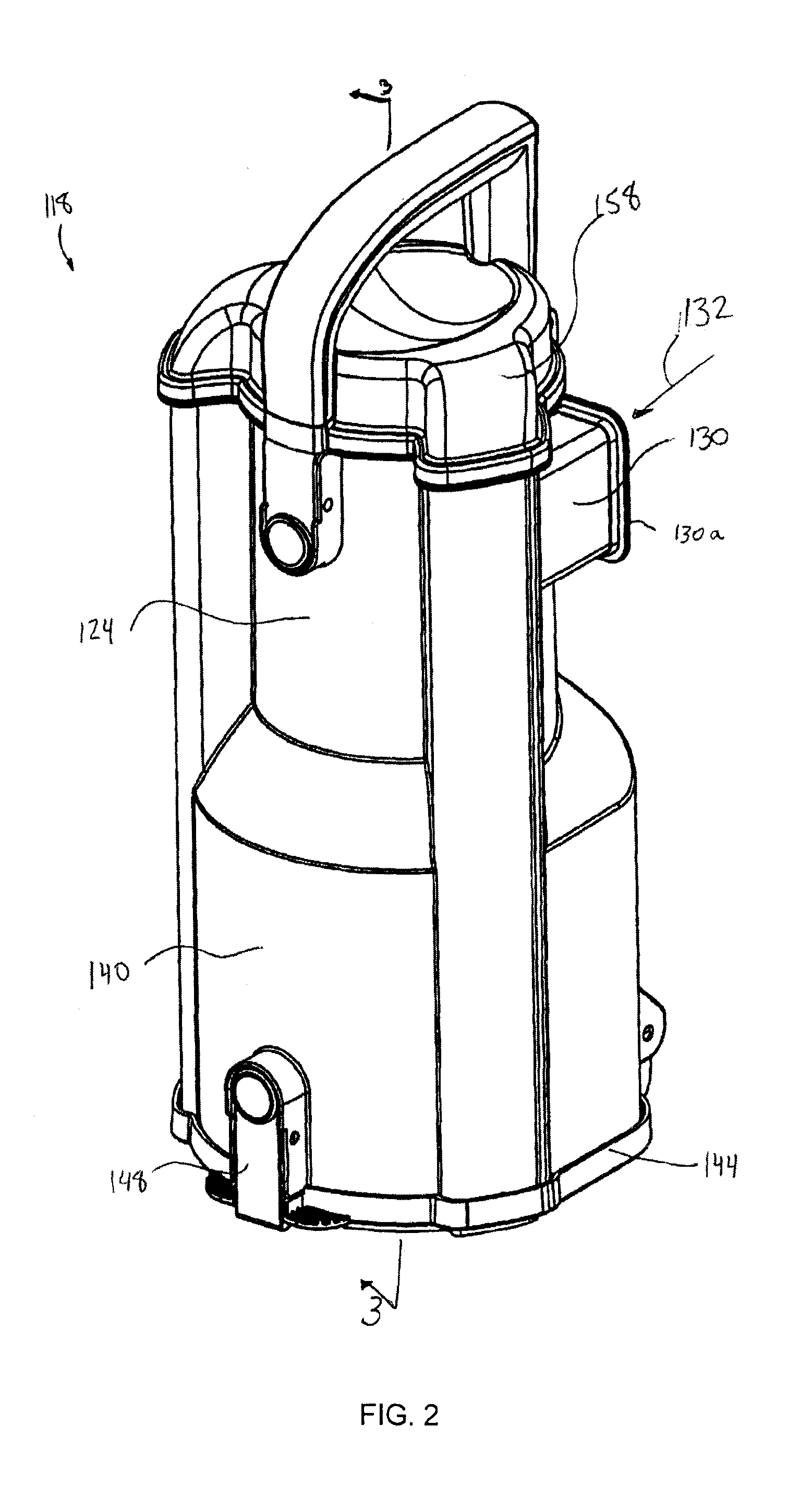

Surface Cleaning Apparatus

ActiveUS20140053367A1Improve performanceReduce air velocityCleaning filter meansSuction filtersCycloneSurface cleaning

A surface cleaning apparatus comprises an air flow path extending from a dirty air inlet to a clean air outlet and includes a suction motor. The surface cleaning apparatus may be battery powered and / or may have a power requirement of 200 Watts or less. A cyclone chamber is provided in the air flow path and has an air outlet which is covered by a screen. In one embodiment, there is an absence of a vortex finder. In another embodiment, a vortex finder that extends into the cyclone chamber less than the height of the cyclone inlet and optionally less than the height of the cyclone inlet may be provided.

Owner:OMACHRON INTPROP

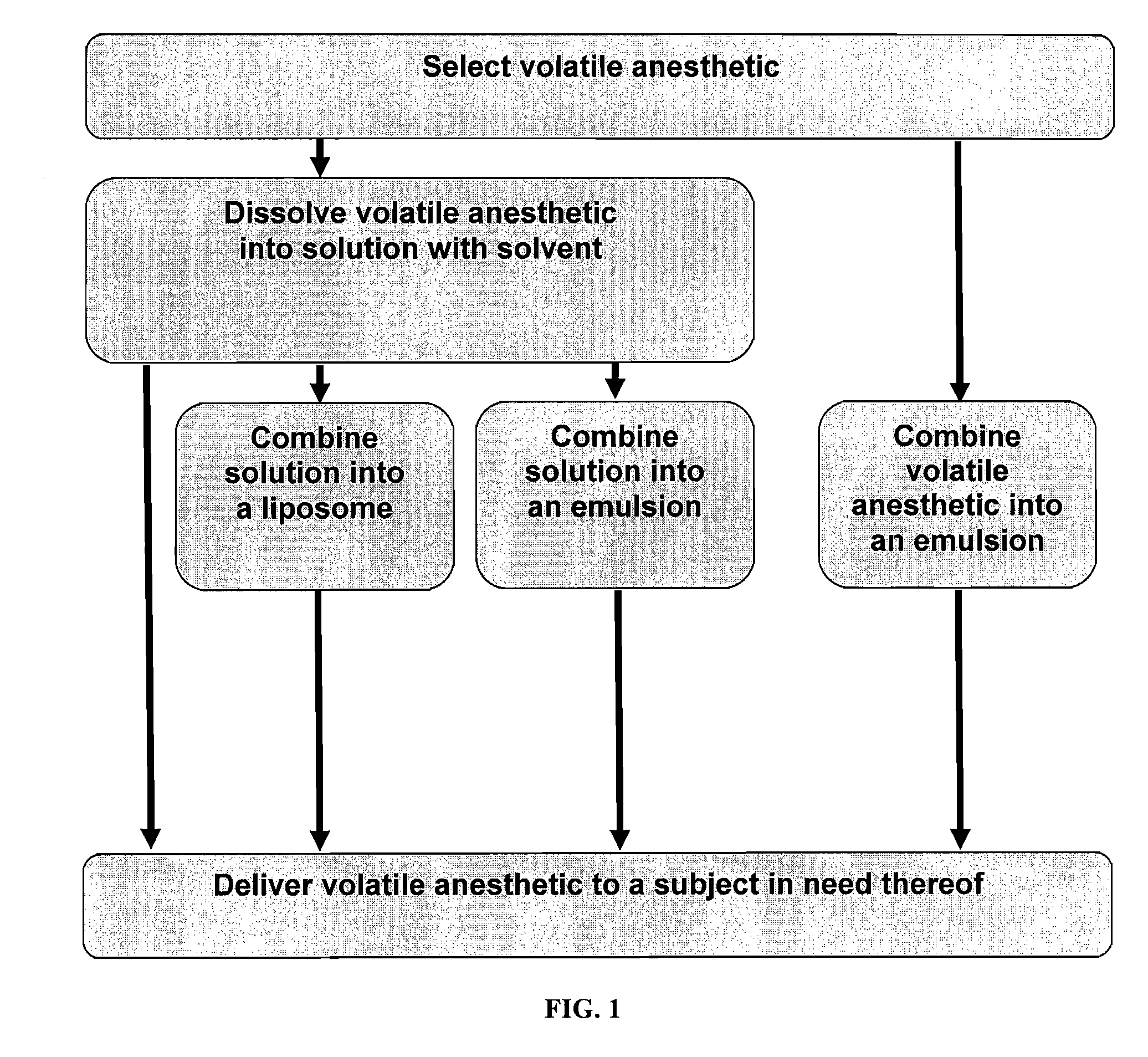

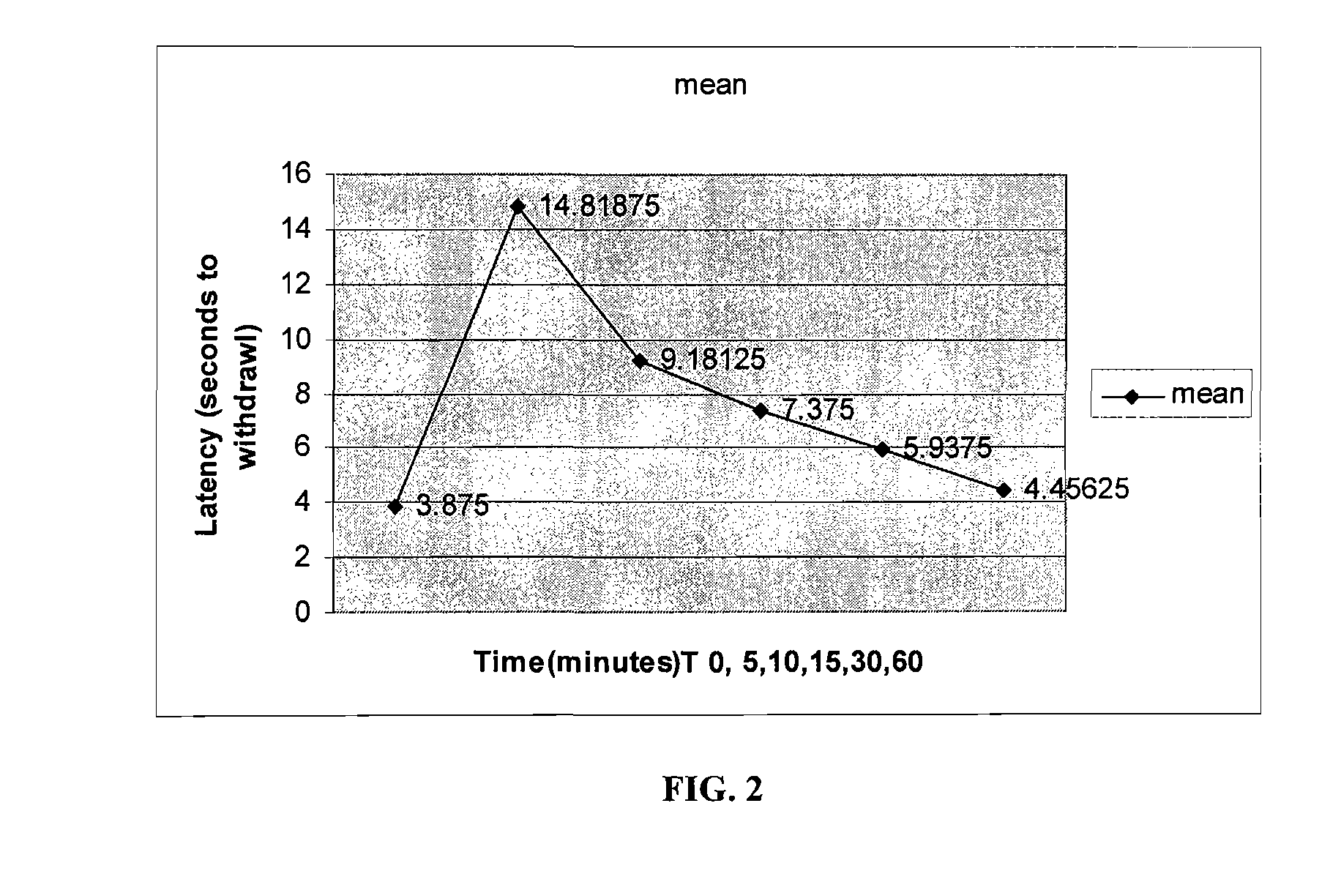

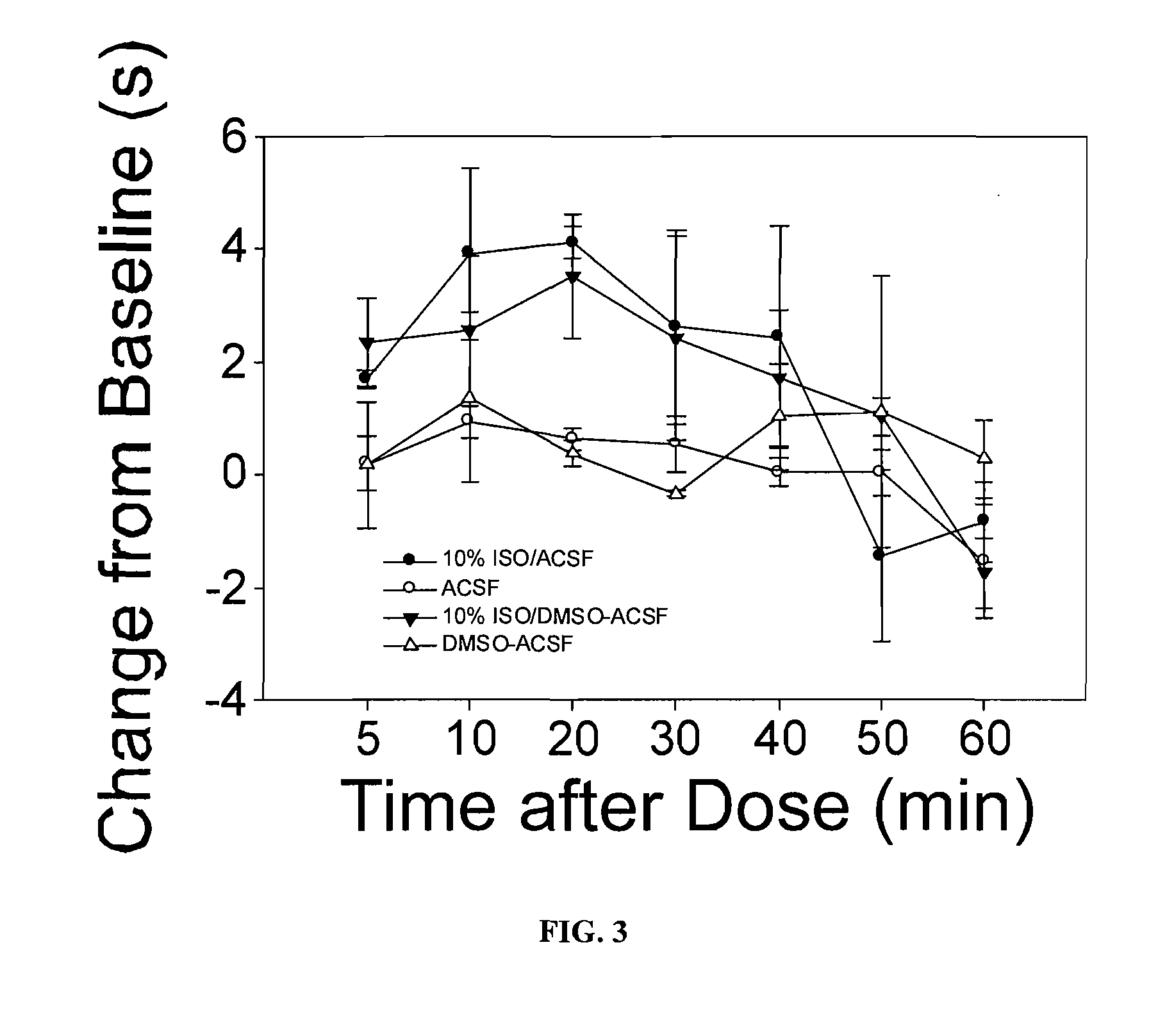

Volatile Anesthetic Compositions and Methods of Use

InactiveUS20110159078A1Excellent characteristicsImprove propertiesBiocideNervous disorderEmulsionMotor function

The present invention provides methods for reducing pain in a subject in need thereof by delivering a volatile anesthetic in a solution or an emulsion that can additionally include an extractive solvent in an amount effective to reduce pain without substantially interfering with motor function. Chronic or acute pain may be treated, or the volatile anesthetic may be delivered as a regional anesthetic to a subject to anesthetize a portion of the subject prior to surgery. Dosing regimes including a one-time administration, continuous and / or periodic administration are contemplated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

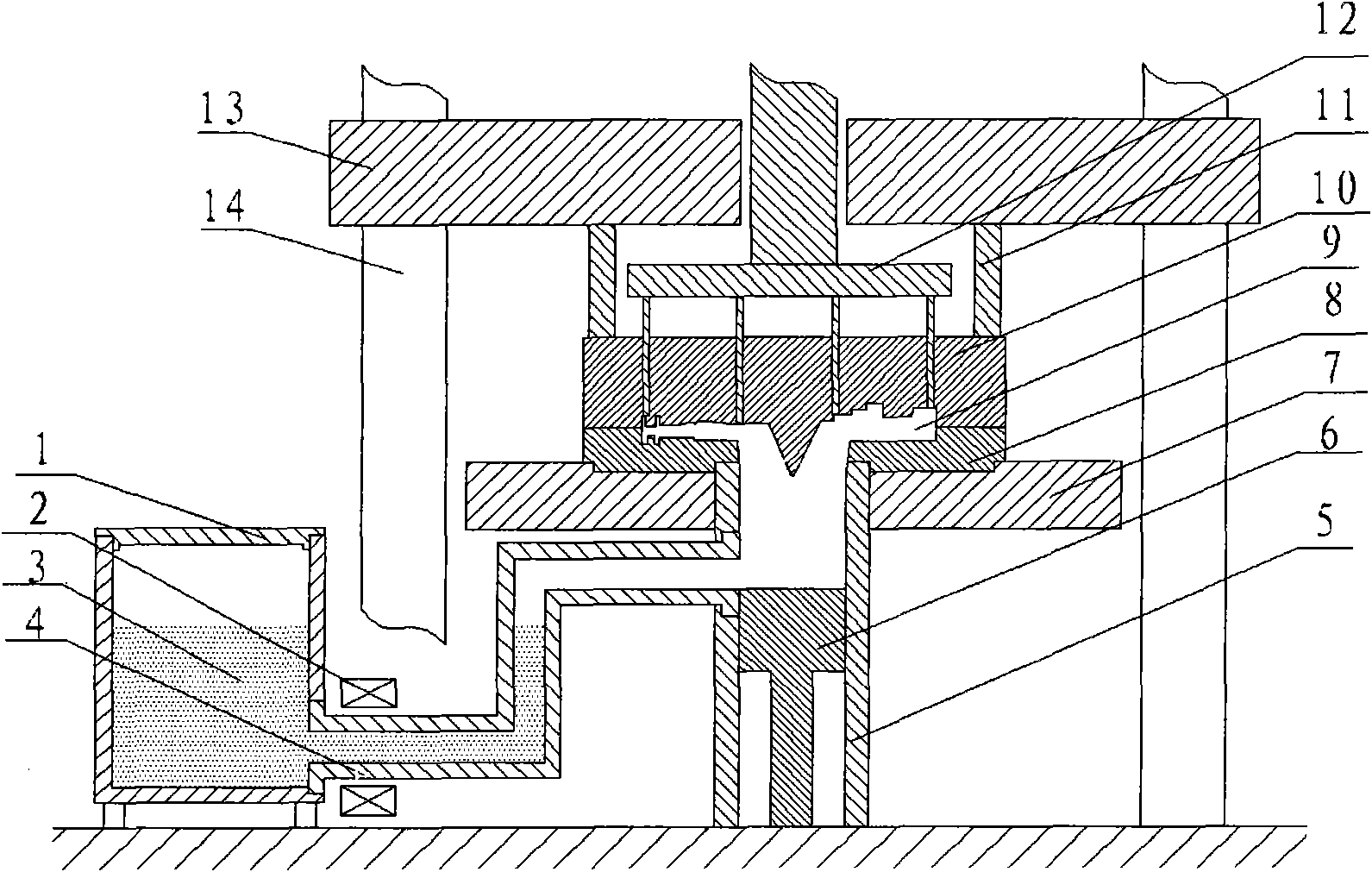

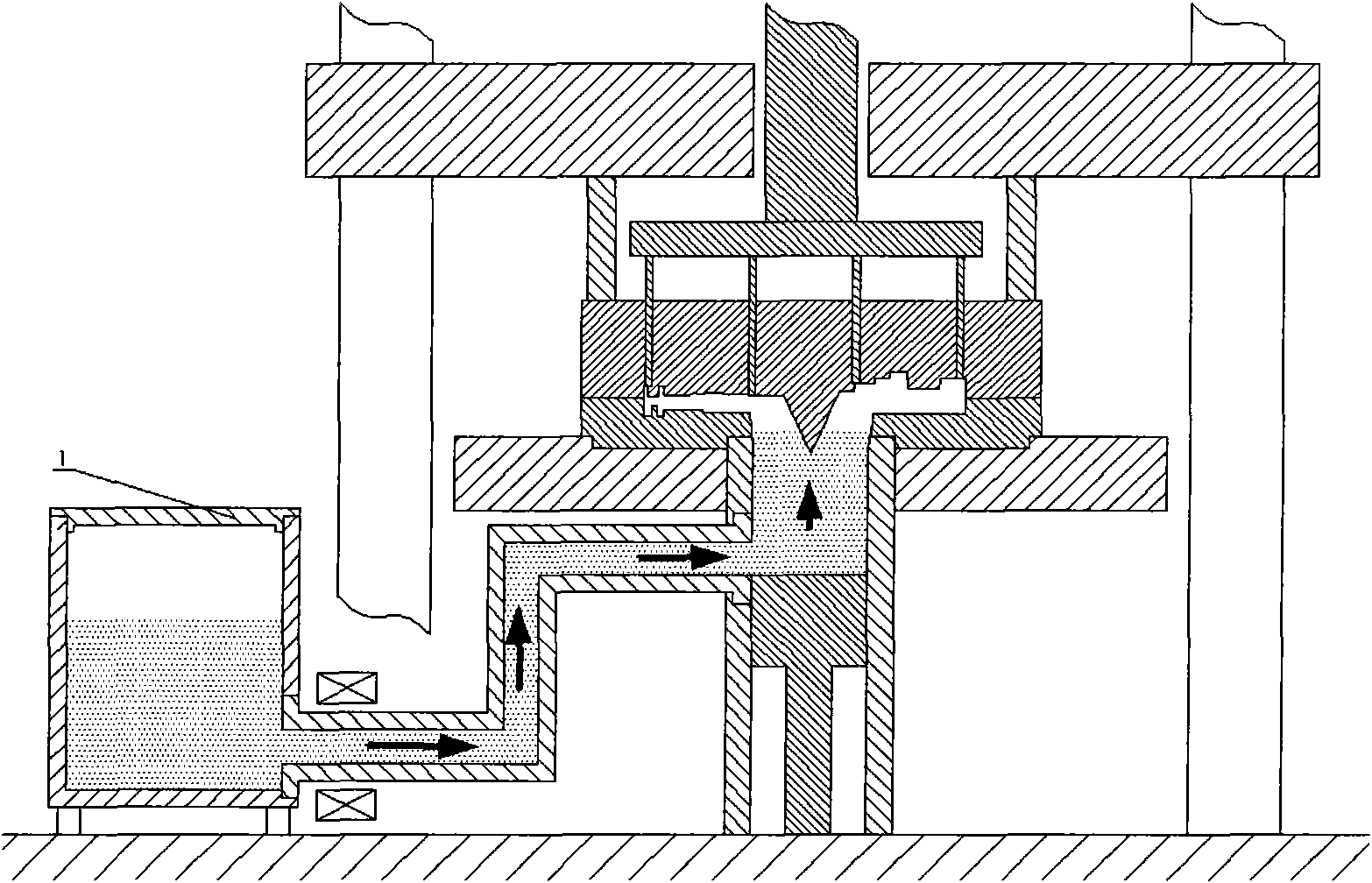

Method for indirect extrusion casting by utilizing filling of electromagnetic force and device thereof

The invention relates to a method for indirect extrusion casting by utilizing the filling of electromagnetic force and a device thereof. In the method, electromagnetic force is utilized to introduce liquid metal into an extrusion chamber to fill part of a mould cavity by a transmission pipeline; when the liquid metal in the mould cavity reaches a preset quantity, the transmission of the liquid metal is stopped; and an extrusion punching head ascends to push the liquid metal to fill the part which is not full in the mould cavity and continuously ascends to extrude and shape the liquid metal, and the liquid metal in the transmission pipeline flows back to a thermal insulation furnace under the function of reverse electromagnetic force. The invention has simple and convenient method, high automatization degree, good stability and skillful structural design of a special device. The liquid metal is transmitted and filled by a sealed transmission pipeline, and oxidation and air suction are reduced; the flow speed and the flow rate are controllable, and the quantification of extrusion casting is realized; at the time of extrusion shaping, the liquid metal in the transmission pipeline flows back, and the production efficiency is enhanced; and the friction and the abrasion of the extrusion punching head and the extrusion chamber are reduced, and the service lives of the extrusion punching head and the extrusion chamber are enhanced.

Owner:SOUTH CHINA UNIV OF TECH

Smelting method for stably increasing content of boron in boron-containing steel

The invention relates to a smelting method for stably increasing the content of boron in boron-containing steel. The smelting method is characterized in that high-carbon ferromanganese, high-carbon ferrochromium and iron-core aluminum are subjected to the deoxidation alloying in the steel tapping process of a converter, and a whole-course bottom argon blowing and wash heat technology is adopted for reducing oxygen content and nitrogen content in the steel; after steel tapping is completed, molten steel is lifted to an argon station, and the molten steel is converted to an LF (Ladle Furnace) after ferroaluminium is added for adjusting the activity of oxygen in the steel to a required control range; and submerged arc operation, soft argon blowing control, a deep deoxidation technology and a titanium alloy technology are adopted for refining in the LF, then boron alloying is carried out, and later the long-time soft argon blowing is carried out, thus the recovery rate of boron in the steel reaches 82%-86%, the problems of low and instable recovery rate of boron are solved, the fluctuation quantity between the furnaces is less than 0.0005%, the ideal control level is achieved, the dependence of boron alloying on vacuum refining is eliminated, and the requirement of subsequent process for the quality of the boron-containing steel is ensured.

Owner:WUKUN STEEL

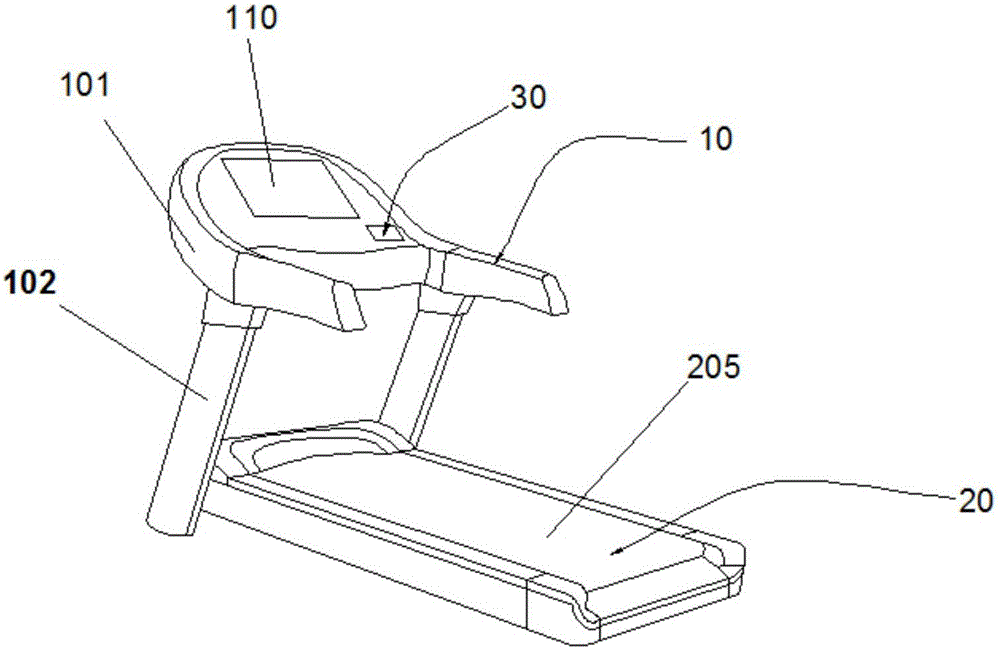

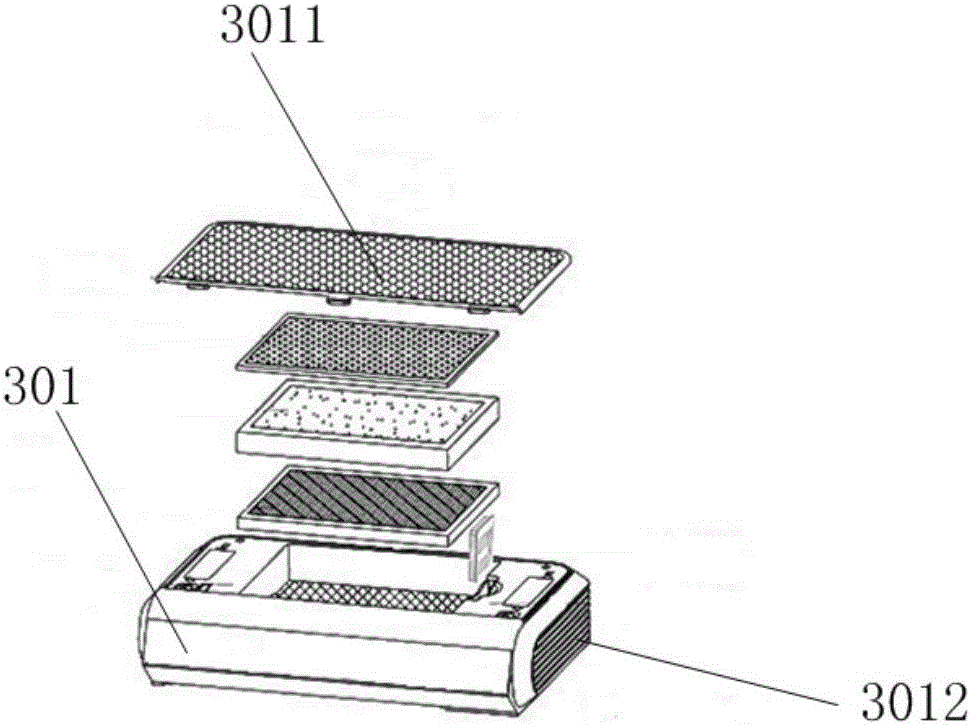

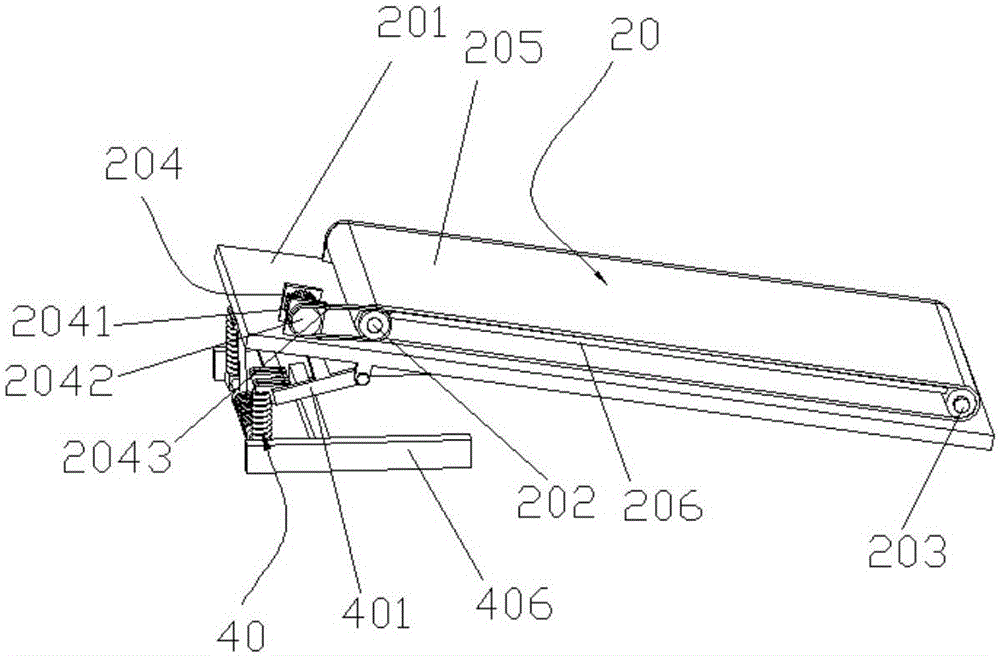

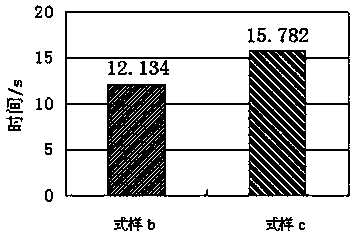

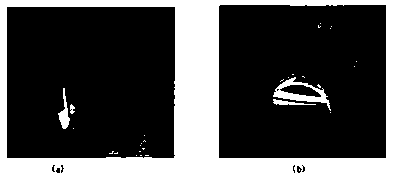

Running machine and fitness equipment

InactiveCN106422175AImprove indoor air qualityGood practicality and functionalityDispersed particle filtrationTransportation and packagingPhysical exerciseFiltration

The invention provides a running machine and fitness equipment, and relates to the technical field of living and working. The running machine comprises a frame and a running platform. The running platform comprises a running platform support, a first rotating shaft, a second rotating shaft, a driving device, a running belt and a load-bearing plate. The first rotating shaft is hinged to one end of the running platform support, the second rotating shaft is hinged to the other end of the running platform support, the driving device drives the first rotating shaft to rotate, the running belt is positioned on the first rotating shaft and the second rotating shaft, and the load-bearing plate is covered with the running belt. An air purification device is arranged on the frame, and comprises a shell, an air inlet, an air outlet, a filtration component and an air duct. The air inlet and the air outlet are arranged on the shell, the filtration component is connected with the shell, and the air duct is positioned between the filtration component and the air inlet. The air inlet, the air duct, the filtration component and the air outlet are communicated sequentially. The running machine and the fitness equipment have the advantage that the technical problem that body builders cannot take exercises and build up bodies in a good fitness environment is solved.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Preparation and application methods of carbon fiber mat surface antioxidation coating

InactiveCN103774435ARaw materials are easy to getWide range of optionsFibre treatmentHeating/cooling textile fabricsFiberCarbon fibers

The present invention provides preparation and application methods of a carbon fiber mat surface antioxidation coating; after chemical modification of matrix resin by use of an inorganic acid salt, the matrix resin is used as a precursor for blending with inorganic powder, and then coats the surface of a carbon fiber mat thermal insulation material by a brush, and then a high temperature coating with antioxidation and thermal erosion resistance is prepared by curing, carbonization, high temperature and other processes. The raw materials are easy to get, the optional range is wide, the preparation process is simple, the cost is low, the prepared coating structure reduces the specific surface area of the carbon fiber mat thermal insulation material, and further suppresses the aerobic oxidation phenomenon of the carbon fiber mat thermal insulation material at a low temperature, in the environment of high temperature and inert atmosphere, the material surface has a certain of thermal erosion resistance, the service life and long-acting thermal insulation ability of a carbon fiber mat can be prolonged, in addition, the slag-off phenomenon of the coated carbon fiber mat in the use process is suppressed, and the application scope of the carbon fiber mate is broaden.

Owner:GANSU HAOSHI CARBON FIBER

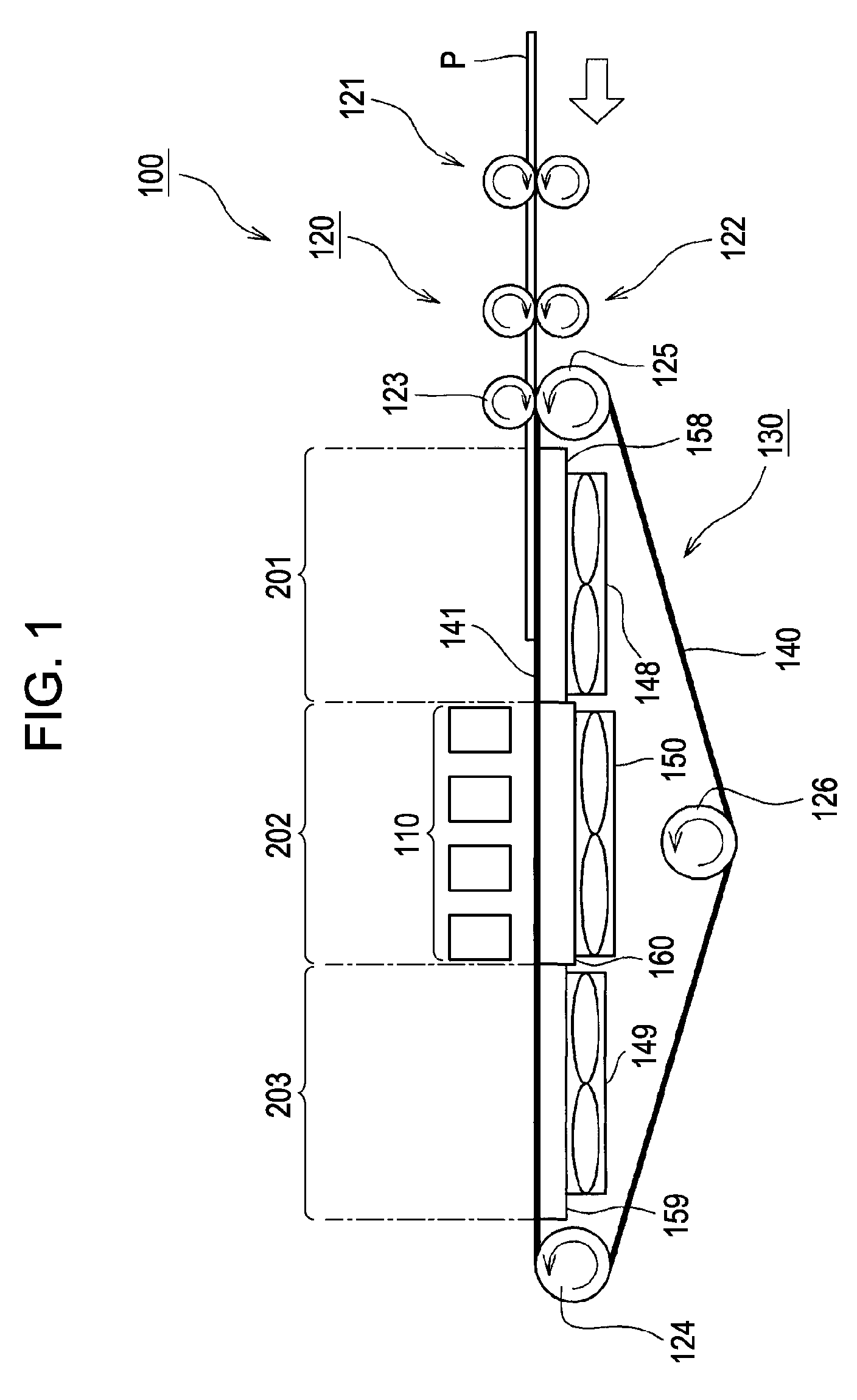

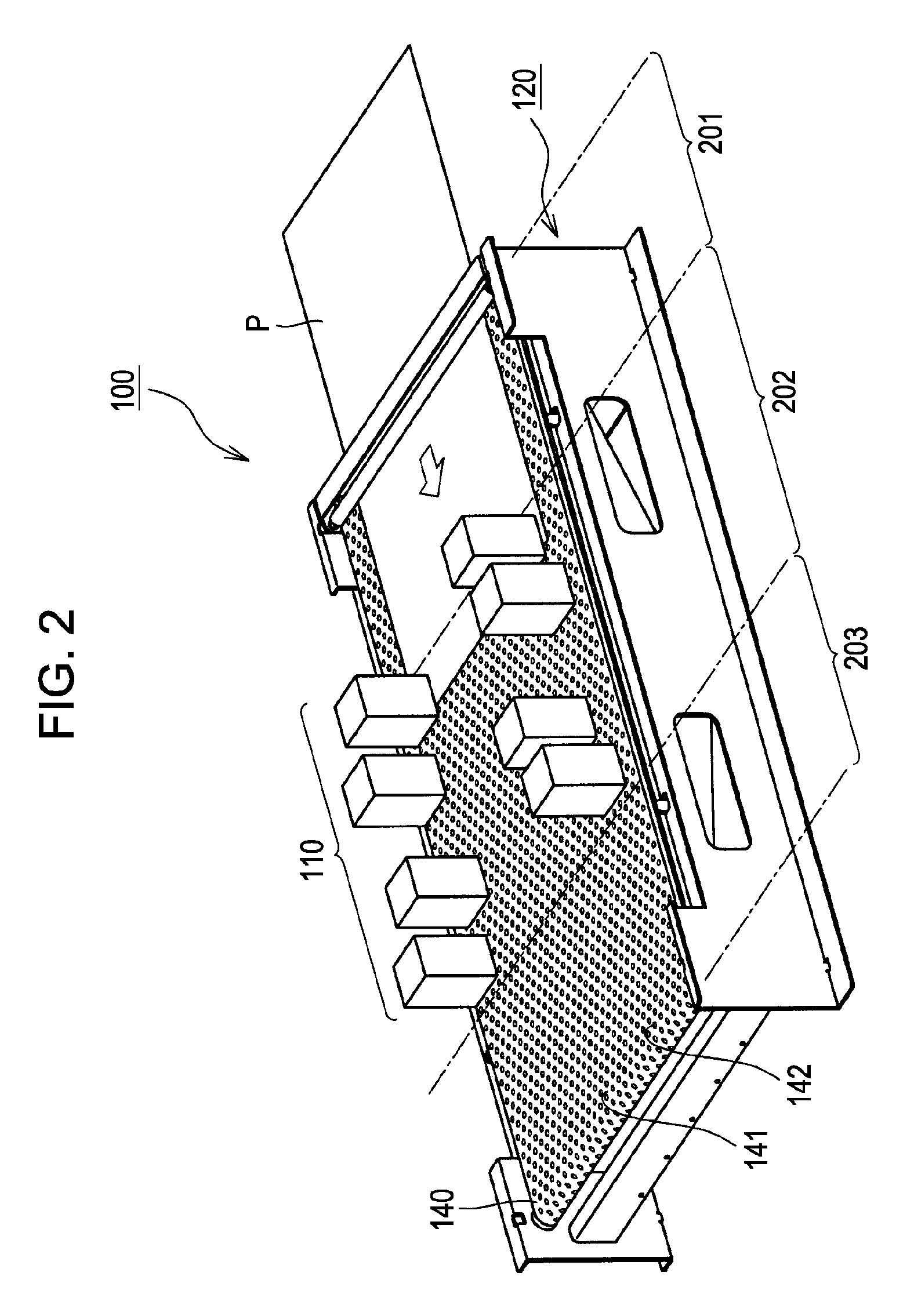

Recording device

ActiveUS20090244244A1Suppress floatingSufficiently suppress floatingOther printing apparatusRecording headEngineering

A recording device includes: a first suction unit which has a support member for supporting a recording medium and a plurality of suction holes provided in the support member to support the recording medium under control that a second suction force of the suction holes not covered by the recording medium is restricted to be smaller than a first suction force of the suction holes covered by the recording medium; a recording head which performs recording on the recording medium supported by the first suction unit.

Owner:SEIKO EPSON CORP

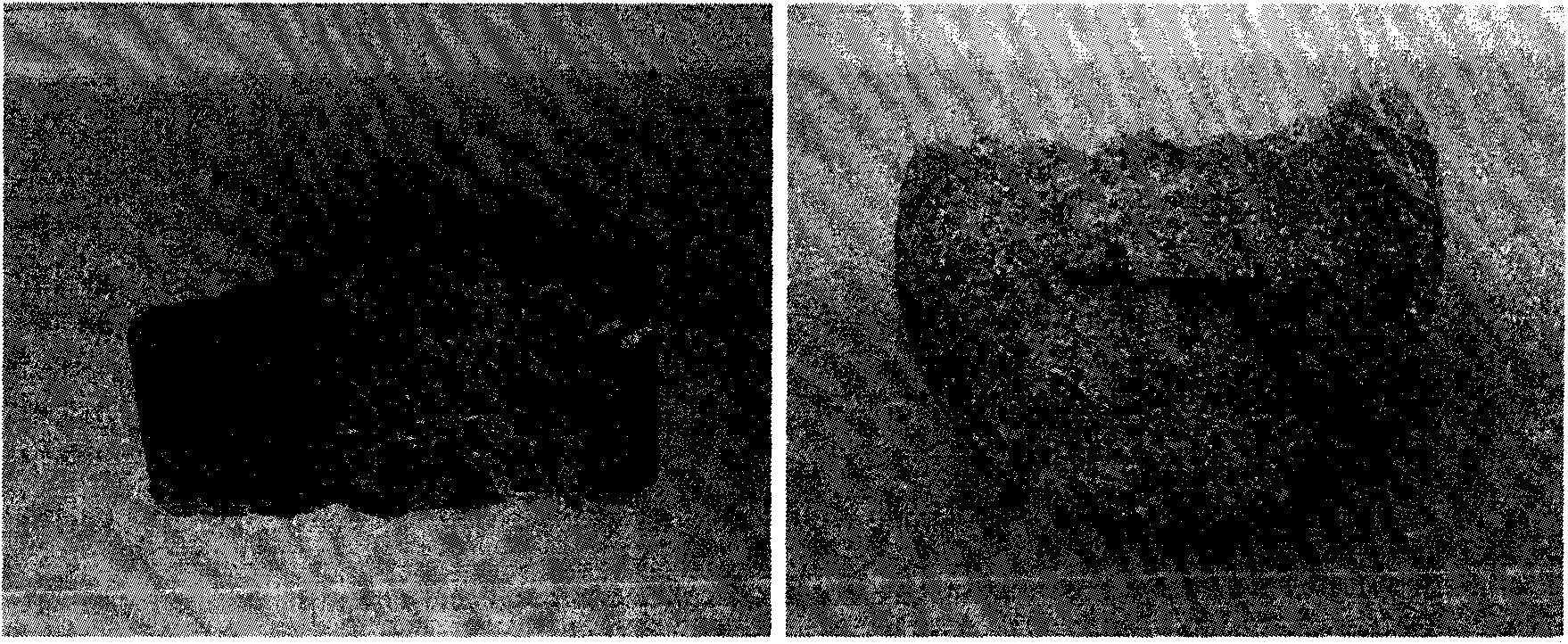

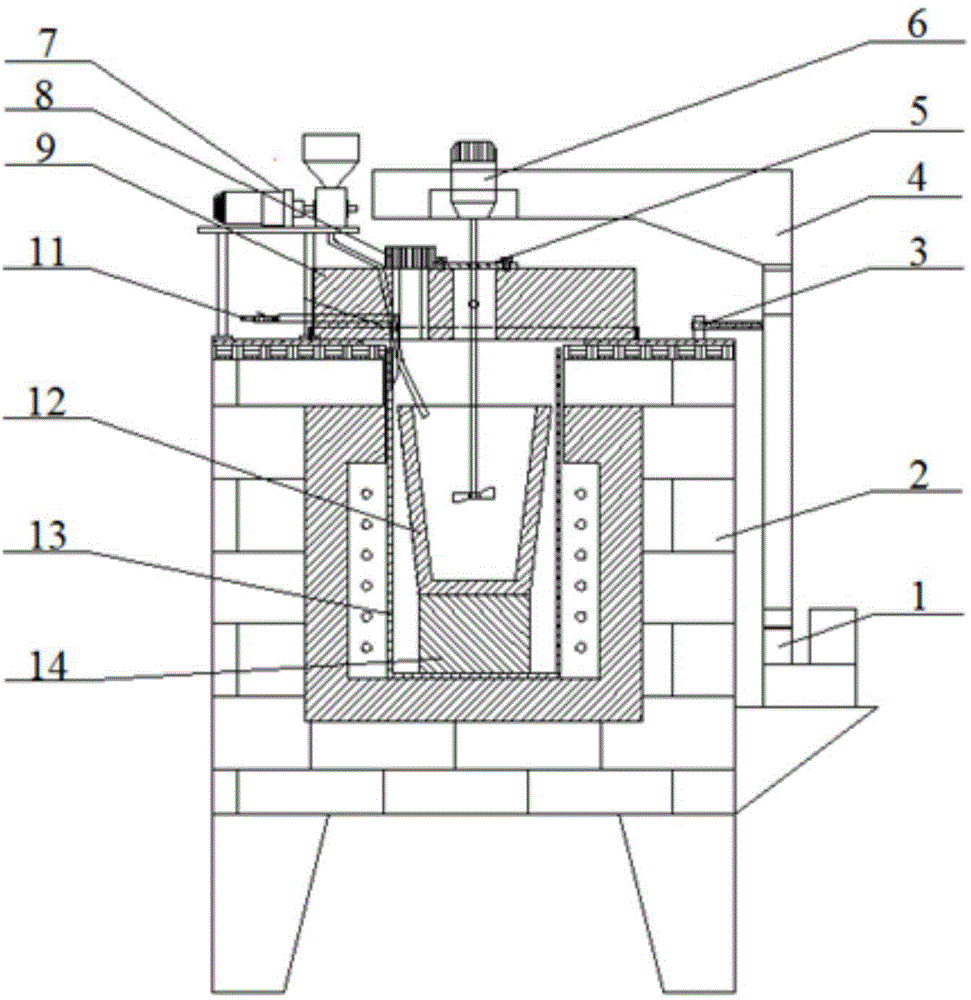

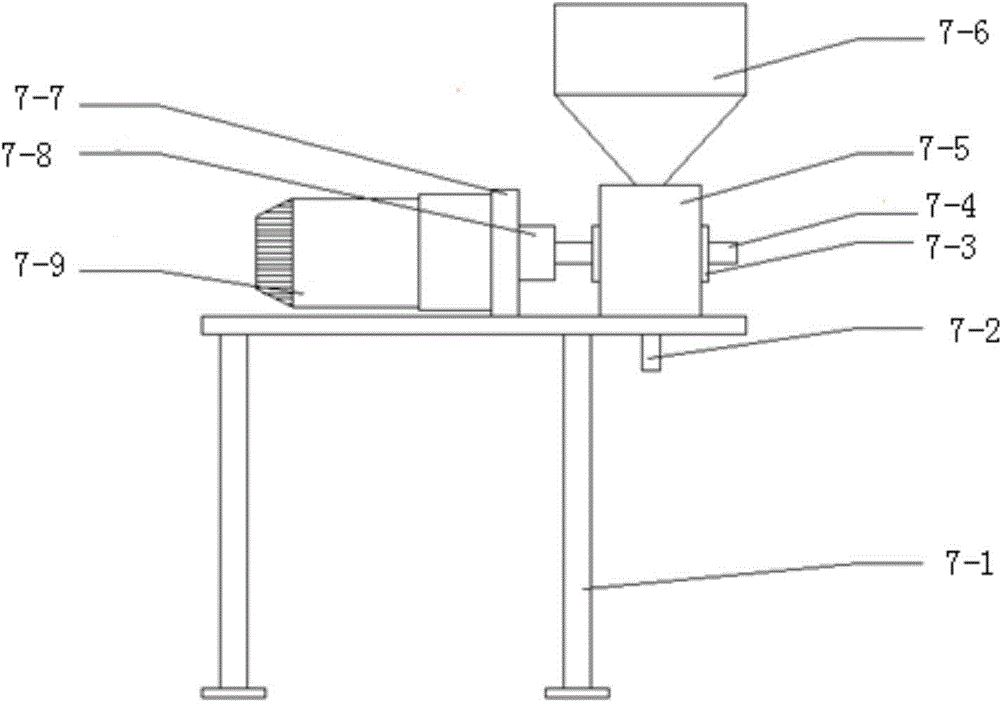

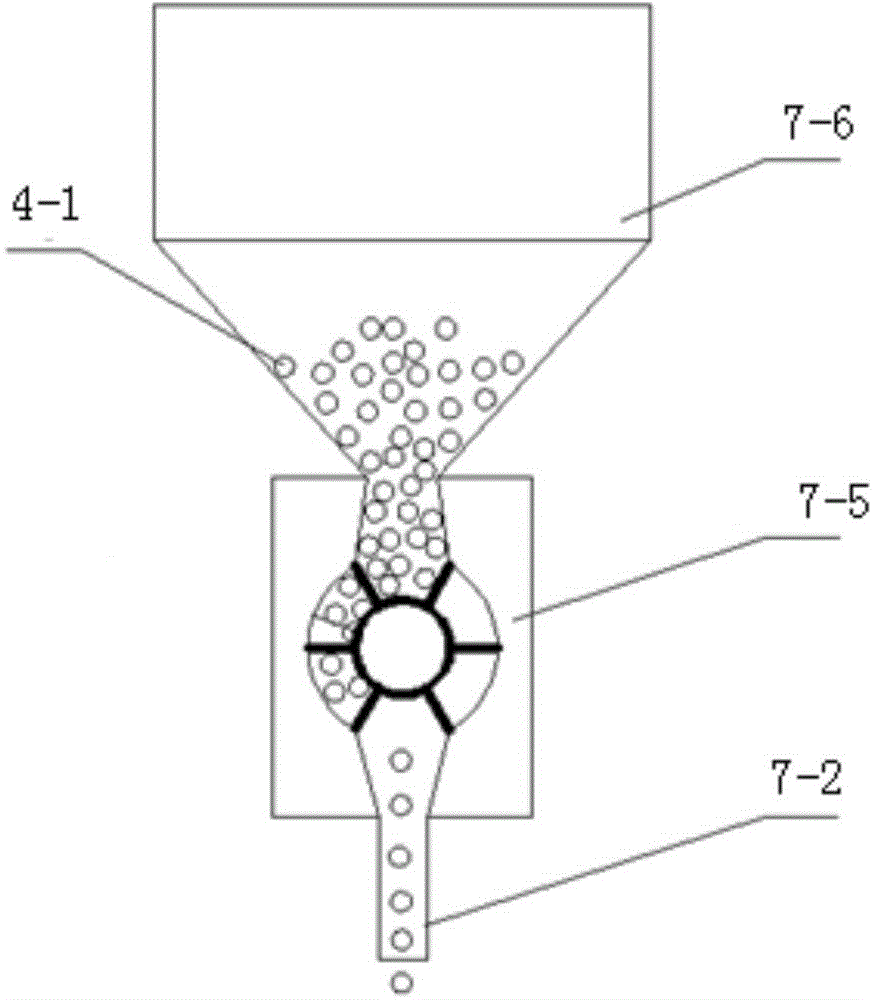

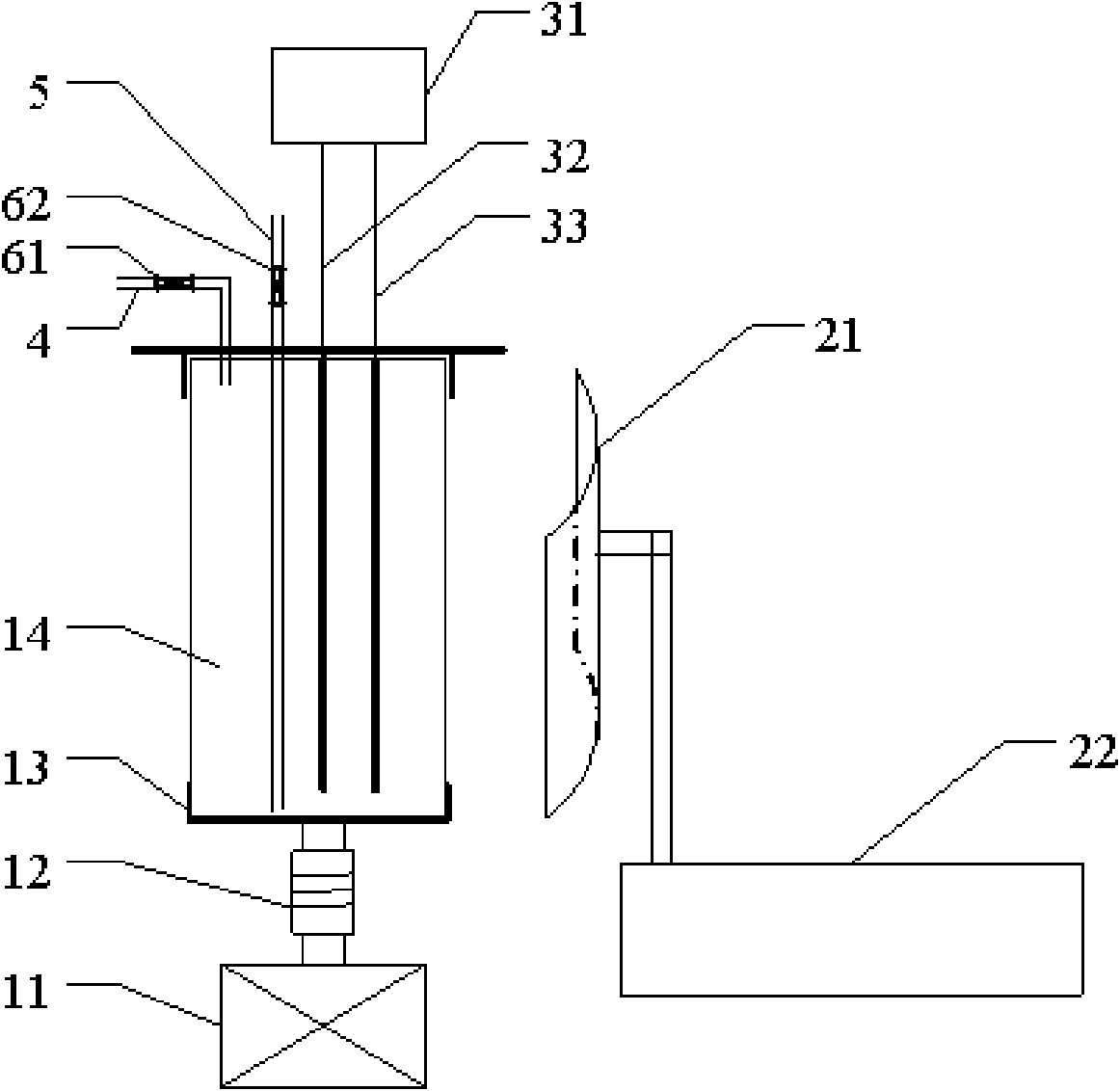

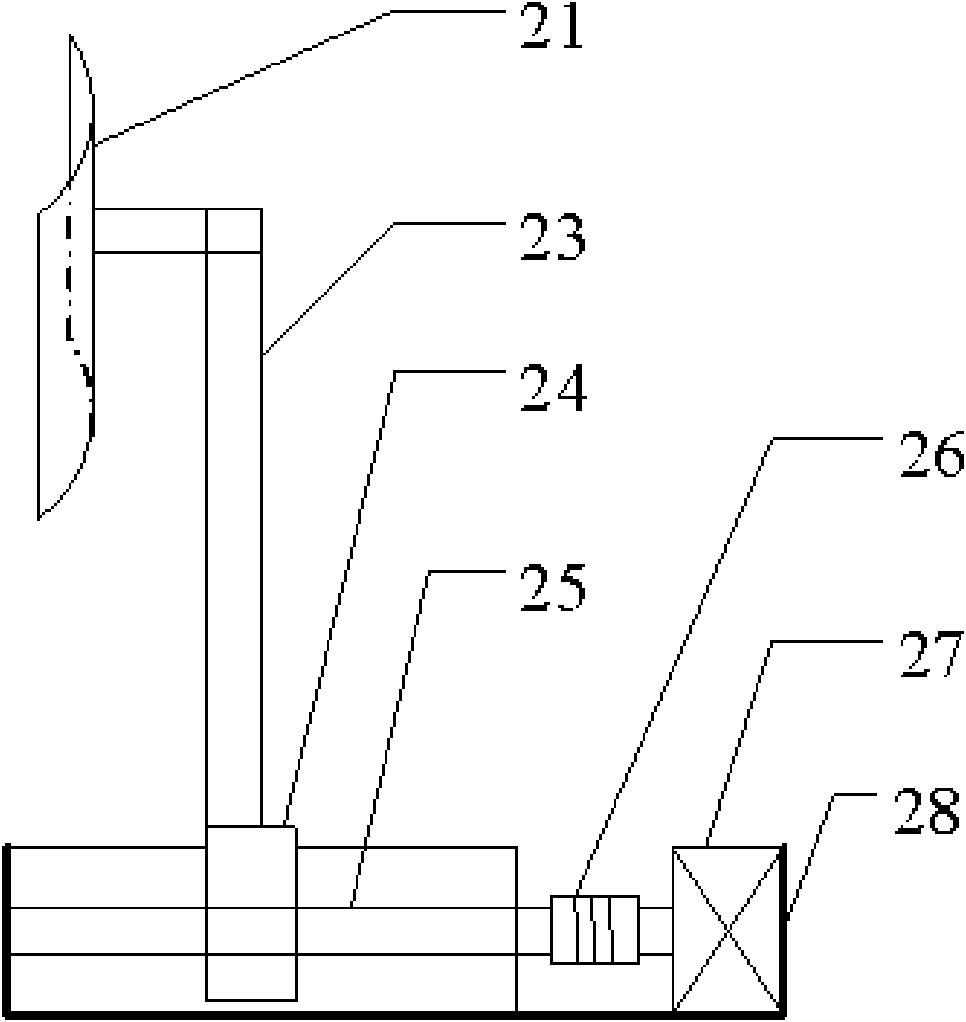

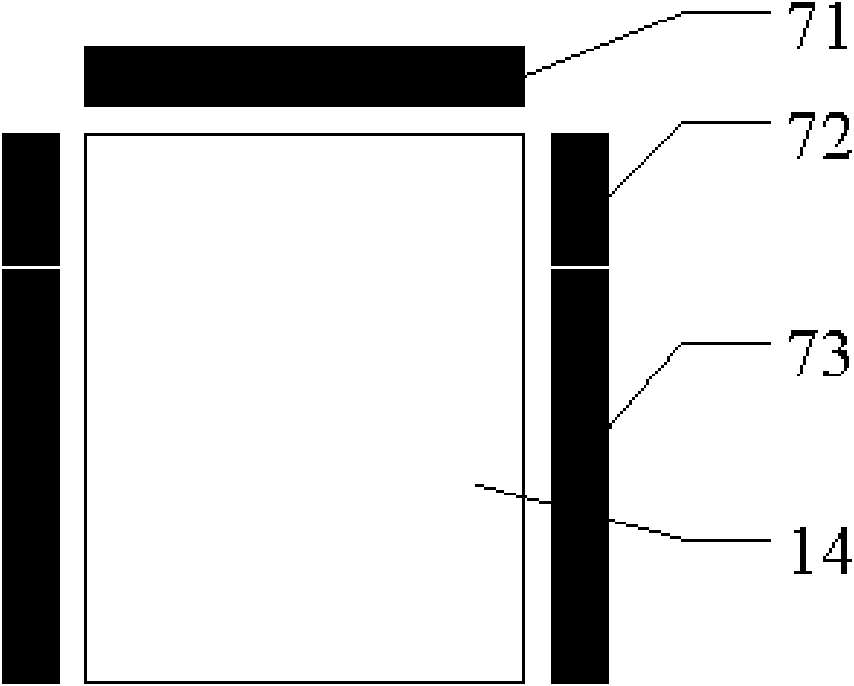

Device and method for preparing particulate-reinforced aluminum matrix composites by stirring and casting

ActiveCN104152727AImprove efficiency and stabilityGood for even distributionAluminum matrix compositesGas protection

The invention discloses a device and a method for preparing particulate-reinforced aluminum matrix composites by stirring and casting. The device comprises a lifting mechanism, a resistance furnace, a fixed column, a supporting mechanism, a stirring device, a particulate conveying device, a furnace lid, a feeding hole, a gas inlet tube, a graphite crucible and a stainless steel crucible. The device for preparing particulate-reinforced aluminum matrix composites by stirring and casting can be used for quantitatively conveying and adding reinforced particulates, and realizing gas protection and automatic preparation. The device is delicate in structural design, simple and convenient to operate, high in automation degree and good in stability. By virtue of the gas protection, gas absorption and surface oxidization of a melt in a preparation process based on stirring and casting are reduced; the quantitative conveying and adding of the reinforced particulates are realized by virtue of the particulate conveying device; the quantitative control on a stirring position and a stirring speed is realized by virtue of the lifting device and the stirring device, and thus, the performance and preparation efficiency of a composite material are well improved.

Owner:SOUTH CHINA UNIV OF TECH

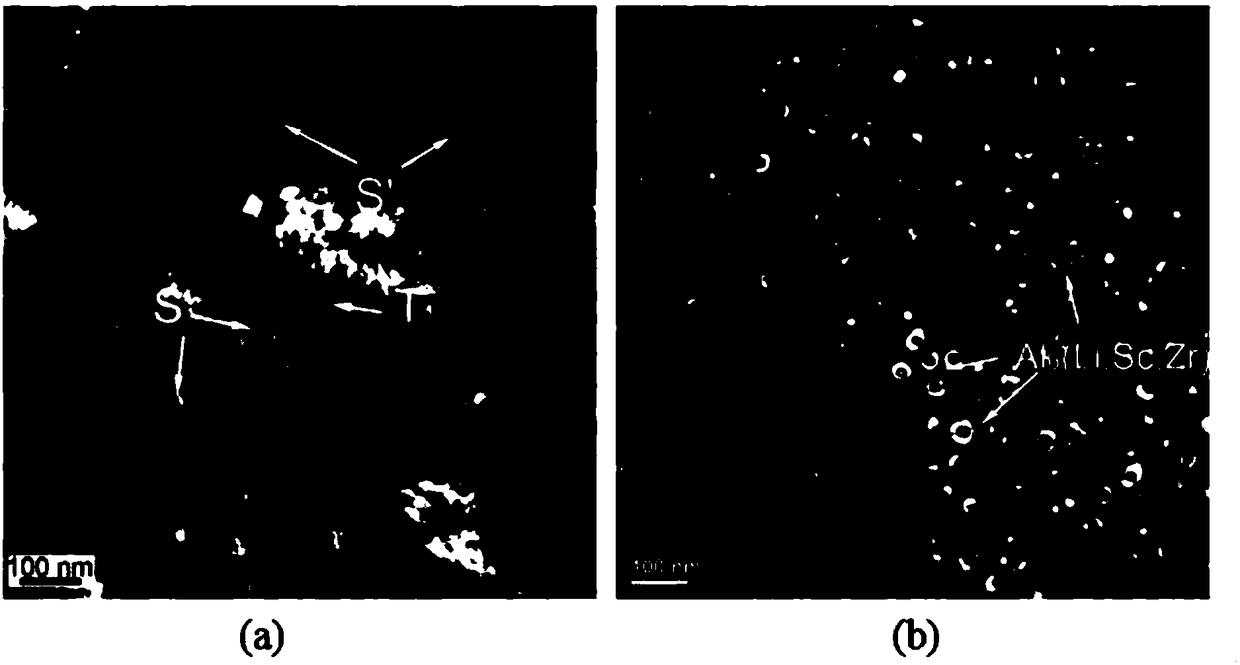

A scandium-containing cast aluminum-lithium alloy and a preparation method thereof

A novel scandium-containing cast aluminum-lithium alloy is disclosed. The alloy includes, by weight, 1.6-1.99% of Li, 0.9-1.9% of Cu, 0.2-0.7% of Mg, 0.1-0.25% of Zr, 0.05-0.35% of Sc, and impurity elements which are Fe, Si, Na, K and P, with the balance being Al, with the Fe content being less than 0.15% and the total content of the impurity elements being less than 0.25%. During preparation, Al-Cu and Al-Zr master alloys, pure aluminum, pure Mg and pure Li are smelted to obtain an aluminum alloy; then three stages of solid solution heat treatment are performed including solid solution heat treatment at 440-460 DEG C for 32 h, solid solution heat treatment at 510-520 DEG C for 24-32 h and solid solution heat treatment at 530-540 DEG C for 1-6 h; and after water quenching, artificial ageing treatment at 150-190 DEG C is performed for 16-48 h to obtain the novel scandium-containing cast aluminum-lithium alloy. The obtained novel scandium-containing cast aluminum-lithium alloy has a uniform microscopic structure, stable performance, density lower than density of traditional aluminum alloys, higher elastic modulus and rigidity, and other mechanical properties, and is low in cost. Theultimate tensile strength of the novel scandium-containing cast aluminum-lithium alloy can be 450-490 MPa and the specific elongation is 4.5-7.0%.

Owner:SHANGHAI JIAO TONG UNIV

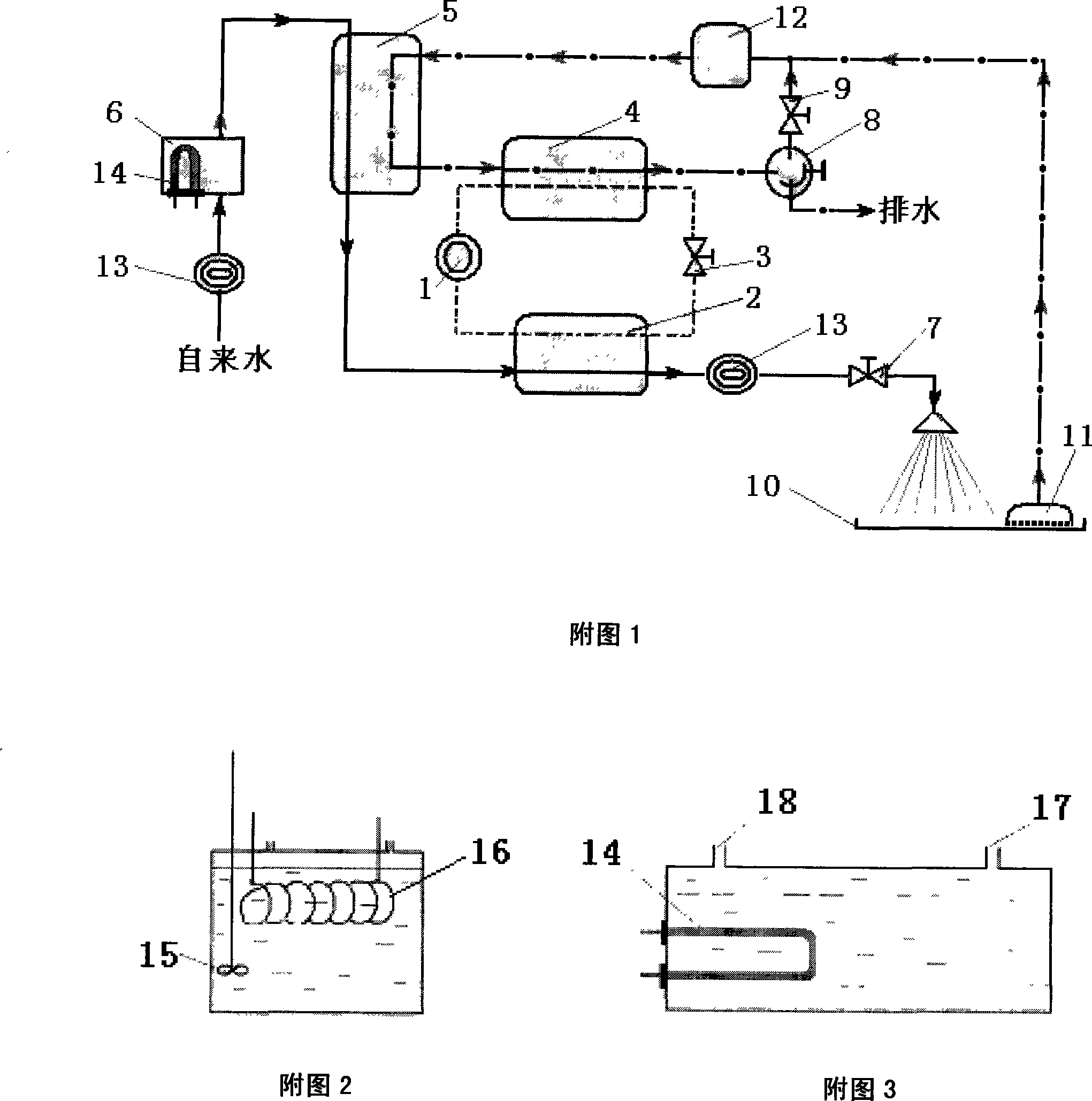

Method for Improving double heat pump hot-water system startup and adjustment performance

The invention discloses a novel method for starting and regulating working performances of a modified double heat pump bath hot-water system (i.e. a device for utilizing waste water and waste heat after bath to produce bath hot water). The method is implemented by adding a temperature-balancing tank and an electric heater at the water inlet end to shorten the start-up time and save water, and utilizing a three-way energy efficiency valve and a solenoid valve to regulate the volume of inlet waste water and thus to control the outlet water temperature. The invention has the advantages of high energy-efficiency ratio, rapid heating, and good start-up and temperature-regulation performances; and can work at a temperature below 5 DEG C.

Owner:党路明

Agilawood cigar and preparation method thereof

The invention discloses a processing technology of a cigar raw material tobacco. The processing technology comprises the following steps of: evenly spraying agilawood essential oil ethanol solution with 0.1%-0.5% of volume percentage composition onto the cigar raw material tobacco, and putting the sprayed cigar raw material tobacco into a fermentation chamber to be accumulated and fermented, wherein the weight ratio of the agilawood essential oil ethanol solution to the cigar raw material tobacco is (0.2-1): 100. The cigar raw material tobacco processed by the technology sends out a faint scent of agilawood, so that the irritation can be obviously reduced. The invention further discloses a preparation technology of a cigar based on the processing technology and the cigar prepared by the preparation technology, wherein the cigar can generate the faint scent of the agilawood when being burnt, so that the sharp taste of the tobacco can be eliminated, the throat can be wetted, and the inhalation of the nicotine and the inhalation of the second hand smoking by surrounding people can be further reduced under the action of the agilawood.

Owner:袁恩泽

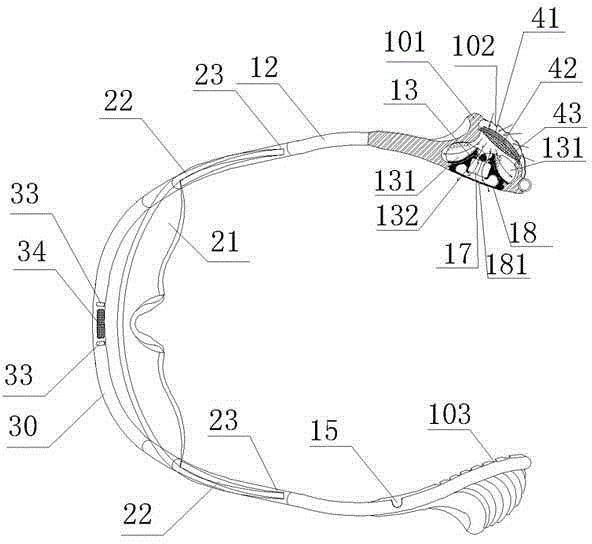

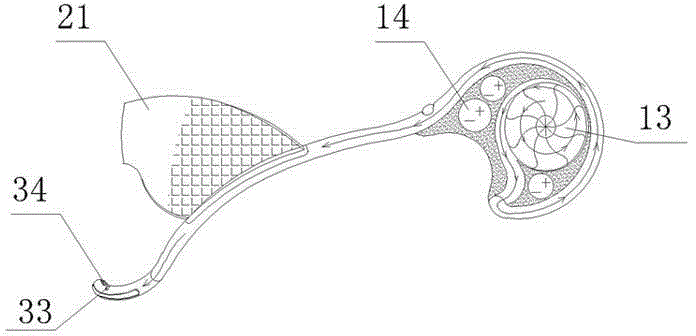

Breathable glasses with air purifying function

ActiveCN104857648AReduce consumptionProtect healthGogglesDispersed particle filtrationAir filterIsolation layer

The invention relates to breathable glasses with an air purifying function. The glasses comprise two air filters arranged on the left side and right side, air delivery pipes arranged on the left side and right side, an air curtain jetting and air delivery device and a binoculus protecting cover, wherein each air filter comprises a filter shell, a composite filtering layer, a built-in air sensor, an intelligent sensing chip, a double-channel variable-frequency turbofan, a micro motor, a battery, a power control switch, and a lower air delivery conversion connector. Air is jetted from the air curtain jetting and air delivery device through an upper air curtain air outlet groove, a lower air curtain air outlet groove and two breathing air delivery holes to form an air curtain isolation layer, surrounding unclean air is blocked, and a large amount of clean air jetted from the two breathing air delivery holes is inhaled by a user. When a portable external air filter is arranged, the glasses can be worn for a long time. When the glasses are used, only a small part of the face is covered, and facial expression is not affected during communication. Unclean air can be isolated for a short term or long term, so that people are prevented from inhaling dust, smoke, plant pollen, bacteria, fine particles and the like, and air communicable disease are prevented.

Owner:广州软图信息科技有限公司

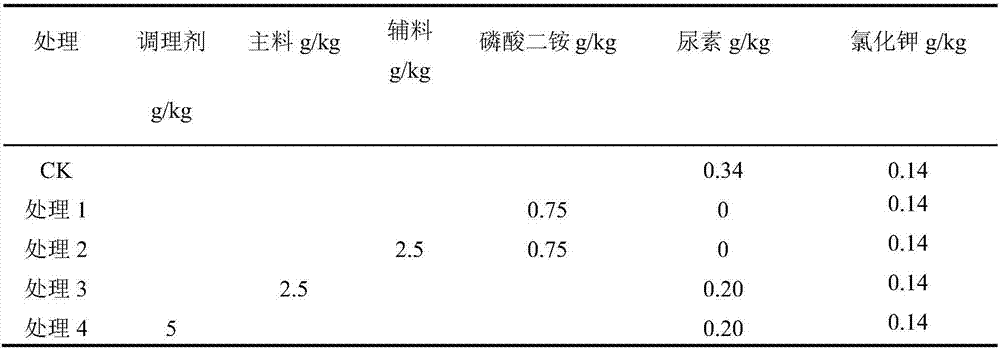

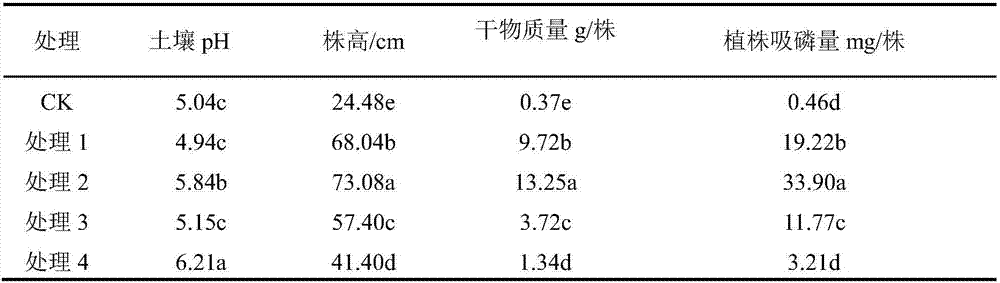

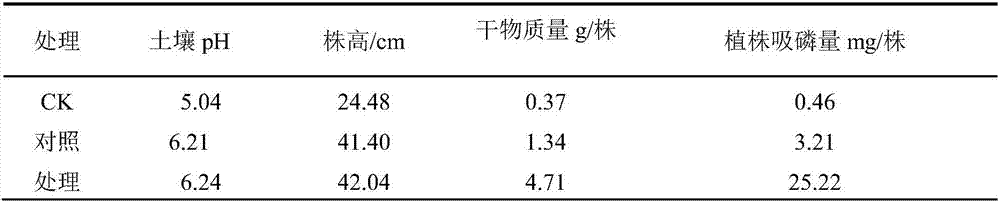

Nutrient sustained-release acid soil conditioner and preparation method thereof

InactiveCN107226762AImprove textureTrace element balanceCalcareous fertilisersThomas phosphate fertilisersSodium BentonitePotassium

The invention discloses a nutrient sustained-release acid soil conditioner. The nutrient sustained-release acid soil conditioner is prepared from the following substances in parts by weight: 20 to 30 parts of phosphate tailings, 28 to 31 parts of dolomite, 18 to 25 parts of quick lime, 15 to 20 parts of phosphatic fertilizer, 4 to 6 parts of bentonite and 0 to 10 parts of potassium humate. The nutrient sustained-release acid soil conditioner is suitable for acid soil areas in the south, which are large in rainfall amount and large in leaching amount, and supplements part of nutrients. Meanwhile, the aluminum toxicity risk can be reduced, and nutrient elements such as calcium, magnesium and the like are provided.

Owner:CHINA AGRI UNIV

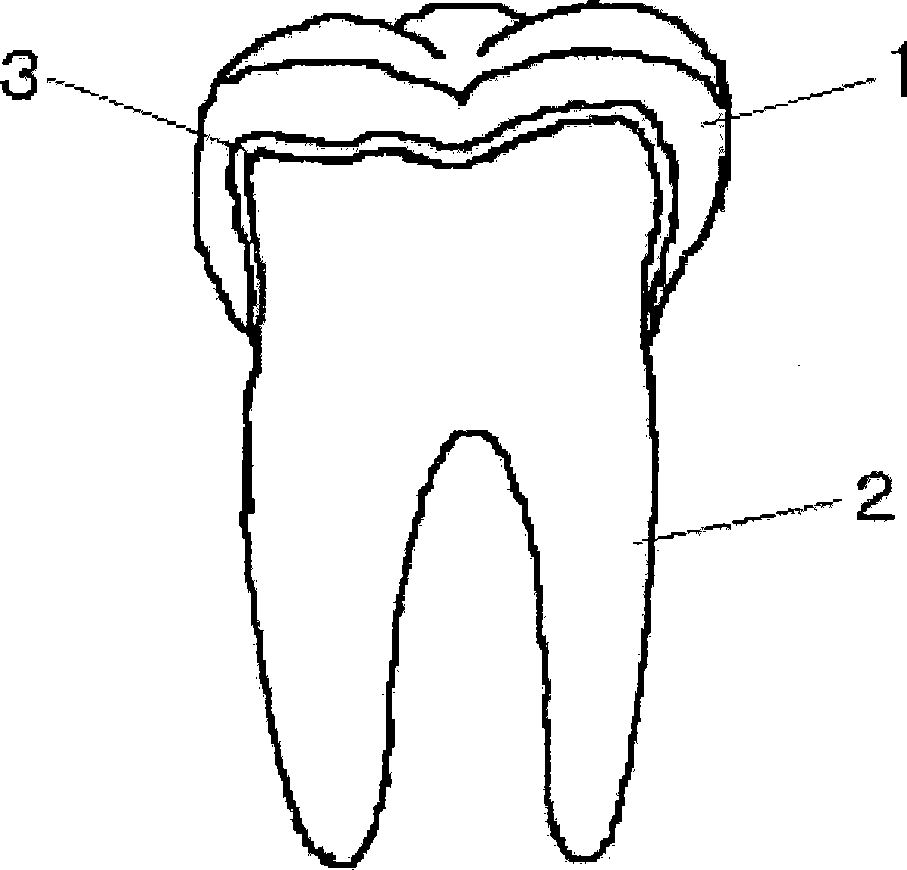

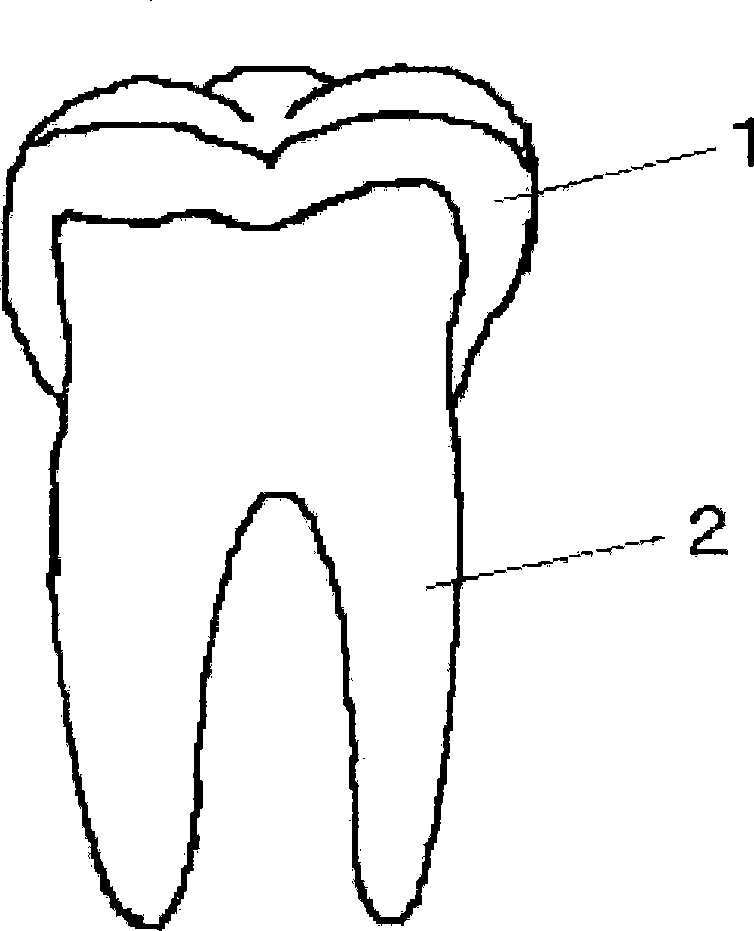

Tooth for dental arch model and method of producing the same

A tooth to be used in a dental arch model with which dental students can conduct dental works in the oral cavity and practice treatments. More specifically, a tooth composition for formation trainings such as anchor tooth formation and cavity preparation. Since conventionally used dental arch models have cutting properties different from natural teeth, dental students having completed formation trainings such as anchor tooth formation and cavity preparation by using these conventional models are frequently puzzled to have different cutting and handling properties upon dental works in the oral cavity in practice. That is, these conventional dental arch models are largely different from natural teeth in cutting properties including the slipperiness and easiness in cutting. A tooth for a dental arch model simulating the enamel texture and the dentin texture constituting a natural tooth whereby even the difference in cutting properties between the enamel texture and the dentin texture constituting a natural tooth can be reproduced by forming at least the enamel part with the use of a baked inorganic powder such as alumina.

Owner:SHOFU INC

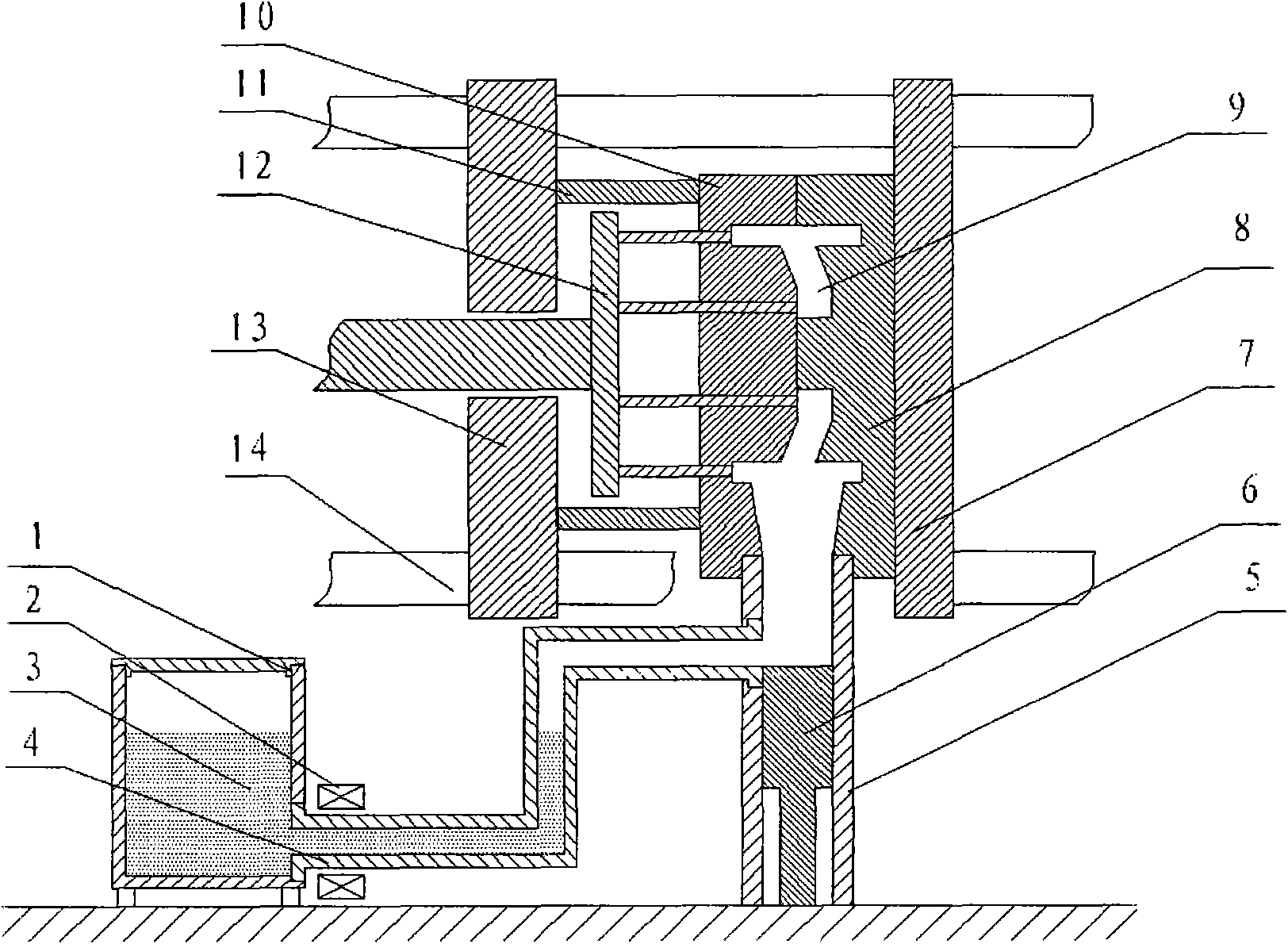

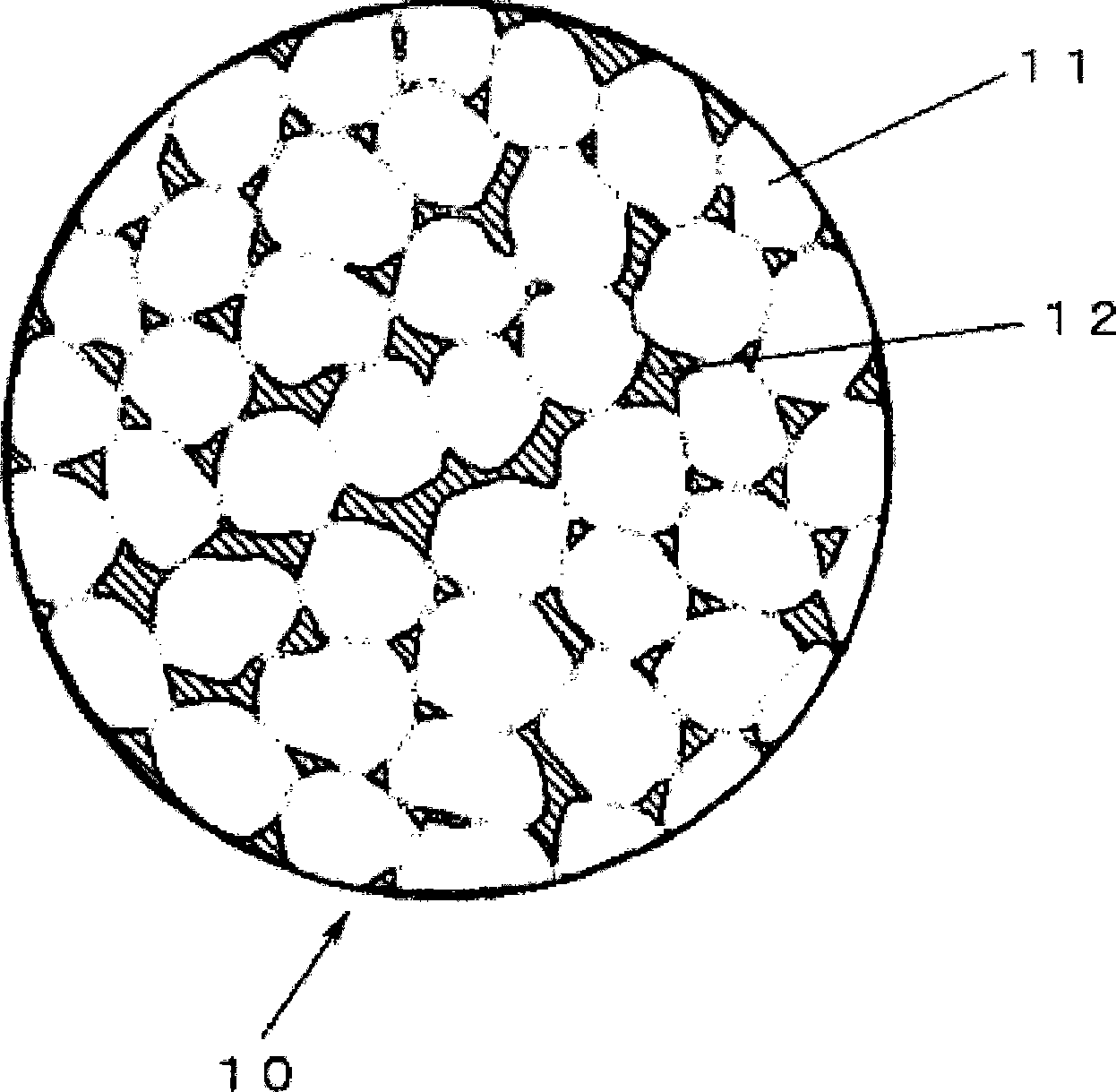

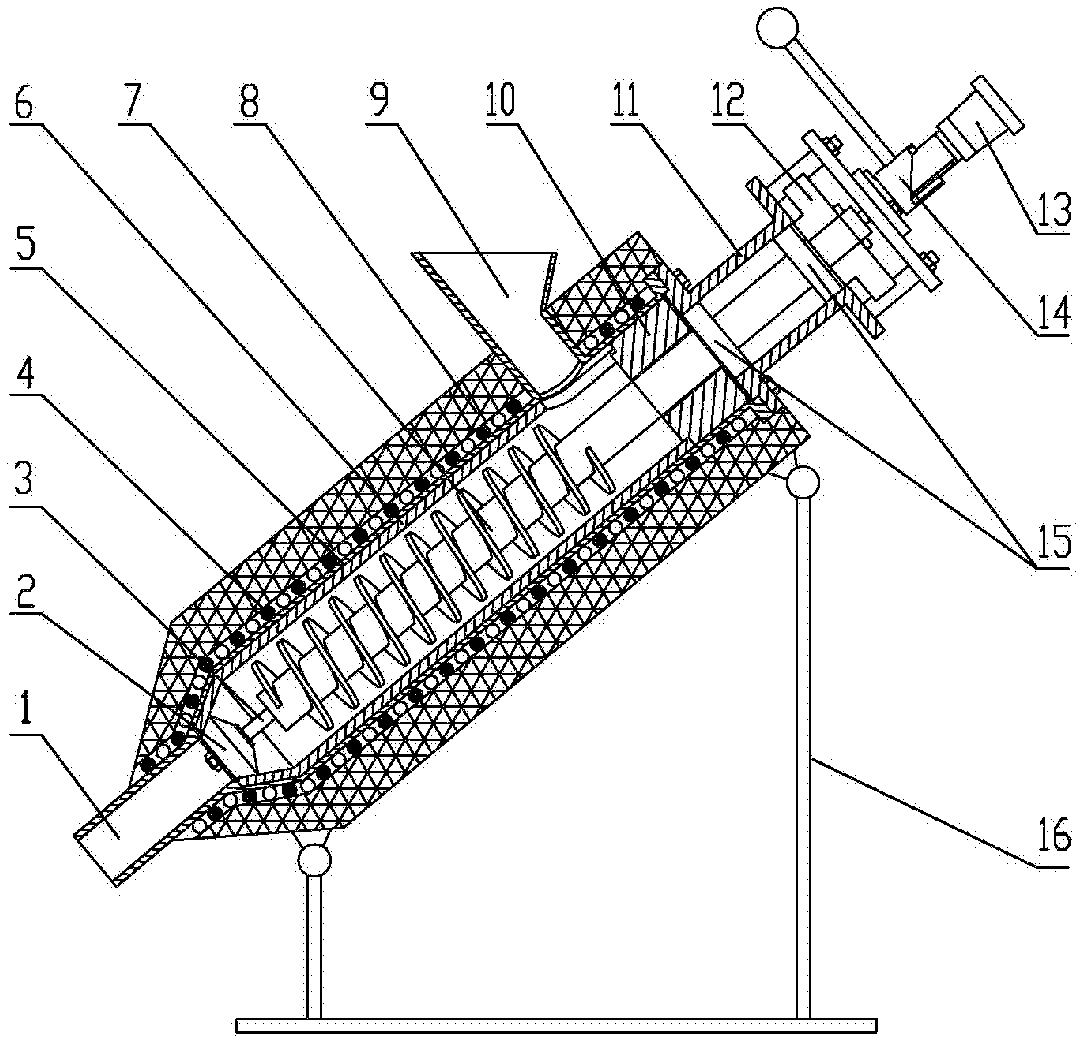

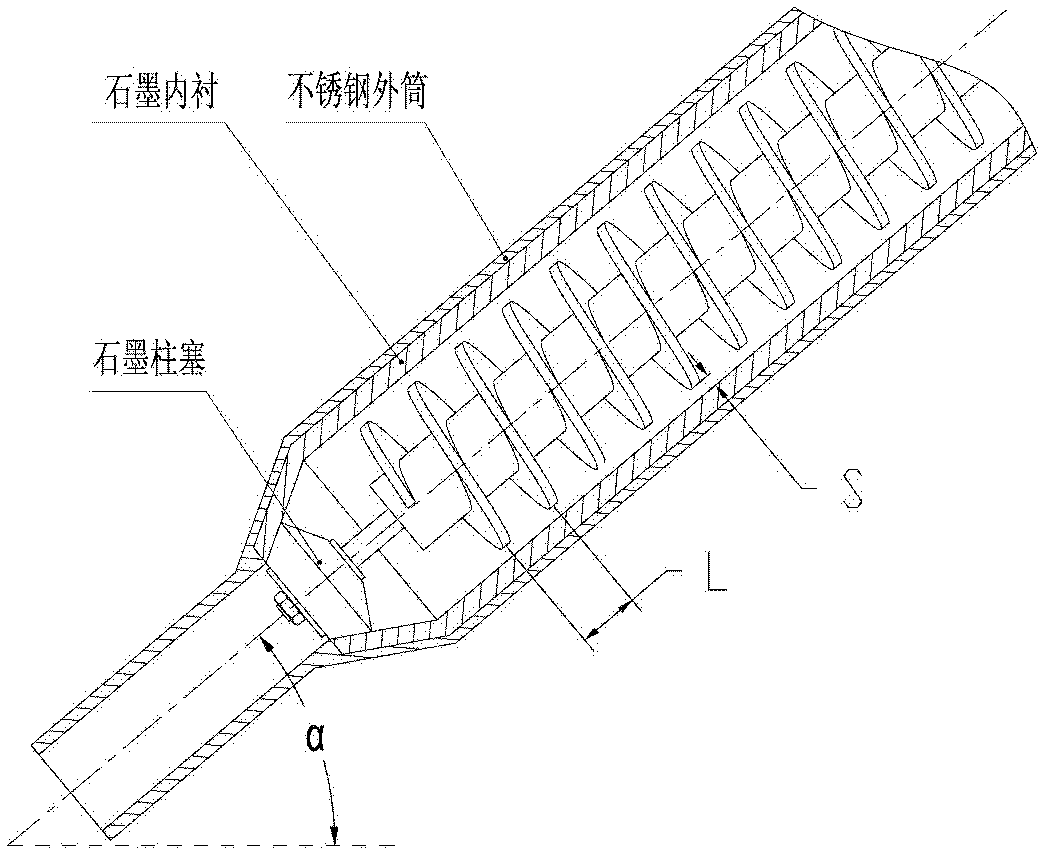

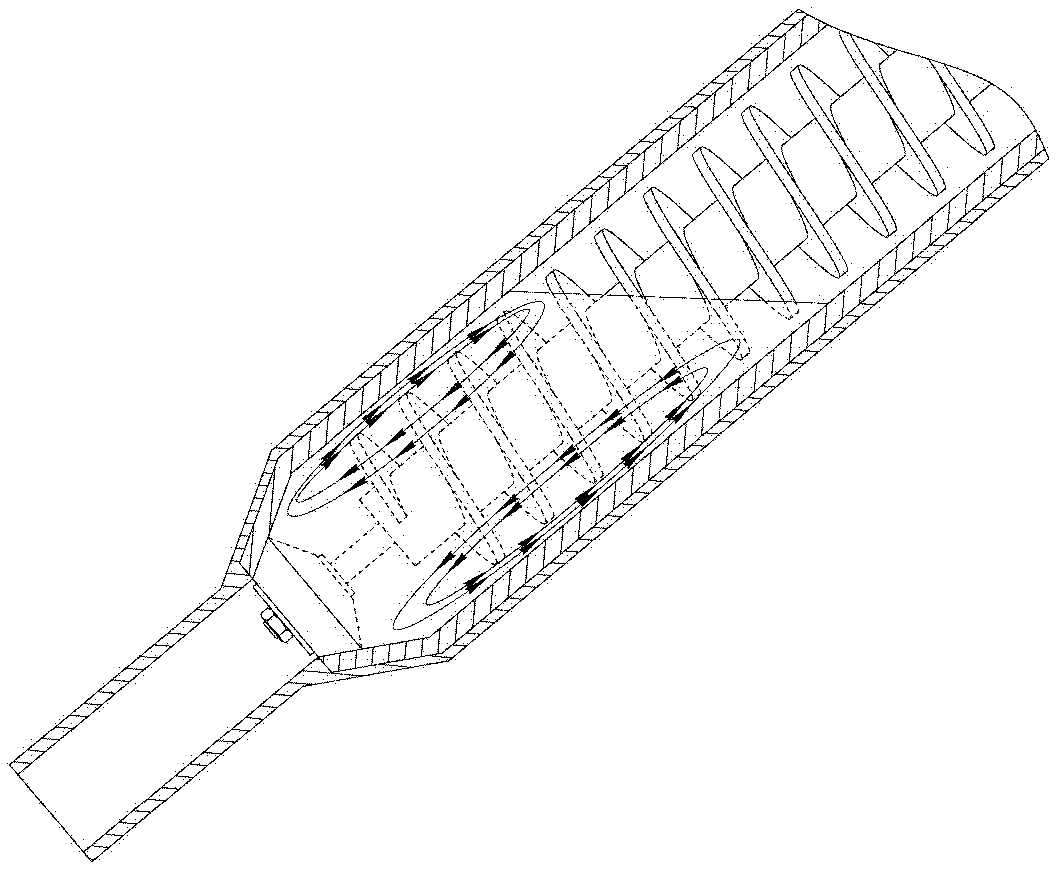

Light alloy semi-solid slurry preparation device

InactiveCN102358922AEasy to prepareCompact structureRotary stirring mixersStirring devicesInsulation layerShear stress

A light alloy semi-solid slurry preparation device belongs to the technical field of semi-solid metal processing. The device comprises a discharge hole 1, a graphite plunger 2, a discharge core rod 3, a heating cooling element 4, a stainless steel outer cylinder 5, a graphite inner liner 6, a stirring screw rod 7, an insulating layer 8, a charge hole 9, a graphite heat insulation ring 10, a bearing pedestal 11, a transmission gear 12, a pressure spring adjusting handle 13, a discharge handle 14, a bearing 15, and a support 16. According to the invention, based on a high speed shearing deformation principle, forced convection is produced when the alloy melt is under the action of the stirring screw rod during the continuous cooling process; the primary solid phase is crushed, spheroidized,or directly grows into a sphere under the action of a shear stress field, and thus semi-solid alloy slurry is prepared. The advantages of the invention are that: the structure is simple and compact; the operation is convenient; the device is easy to clean; the control precision is high; the continuous work is stable and reliable; the integrated technical process from light alloy semi-solid slurrypreparation to rheological forming is easy to realize.

Owner:UNIV OF SCI & TECH BEIJING

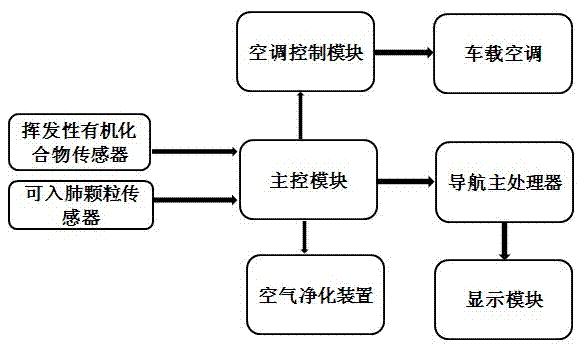

Healthful navigation system

InactiveCN102806825AImprove air qualityReduce inhalationAir-treating devicesEquipment ReuseNavigation system

The invention belongs to the automotive electronics field, which particularly relates to a healthful navigation system. The healthful navigation system can be used for automatically detecting and purifying air in an automobile and quickly improving the air quality in the automobile. The healthful navigation system comprises a master control module, an air conditioner control module, an air detection module and an air purification device, wherein the air purification device is started when the current air quality information in the automobile is obtained from the air detection module by the master control module and the air quality does not reach the preset standard; the air conditioner control module is controlled to enable an automobile air conditioner to enter an external circulation mode; and the purification speed of the air in the automobile is quickened. According to the healthful navigation system disclosed by the invention, the automobile air conditioner system is fully utilized; on the premise that the purification speed of the air in the automobile is quickened, the equipment reuse ratio is improved, and the cost is lowered; and meanwhile, more space in the automobile is saved.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

Bioreactor applied to magnetic nano-catalyst

InactiveCN101654655ASuppress foamReduce damageStress based microorganism growth stimulationNano catalystMagnet

The invention discloses a bioreactor applied to magnetic nano-catalyst which has the structure that one end of a first shaft coupling is connected with an output shaft of a first motor and the other end is connected with a connecting disc; a reaction vessel is installed on the connecting disc, provided with an input pipe and an output pipe with valves, and is installed with a temperature control apparatus. In use, the magnetic nano-catalyst is arranged in the reaction vessel and is adsorbed on the wall of the reaction vessel by means of a magnet. The magnetic nano-catalyst is uniformly mixed and conveniently recycled and and has the advantages of improving the catalyst using efficiency, flexibility to different technologies and reducing pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

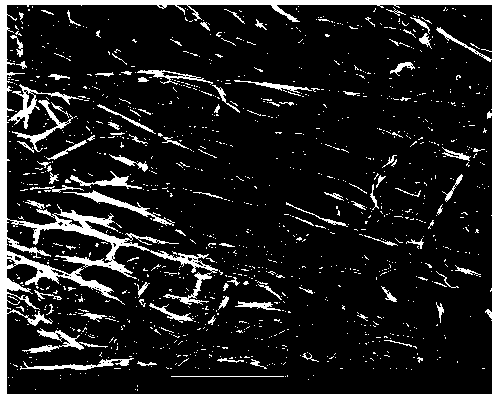

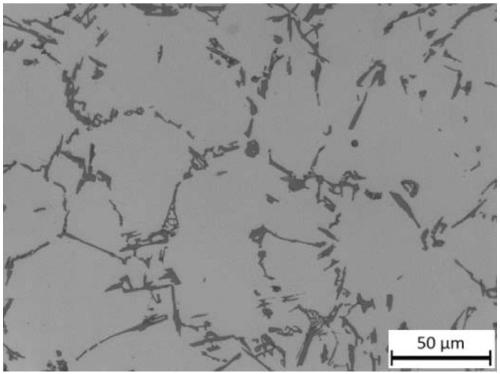

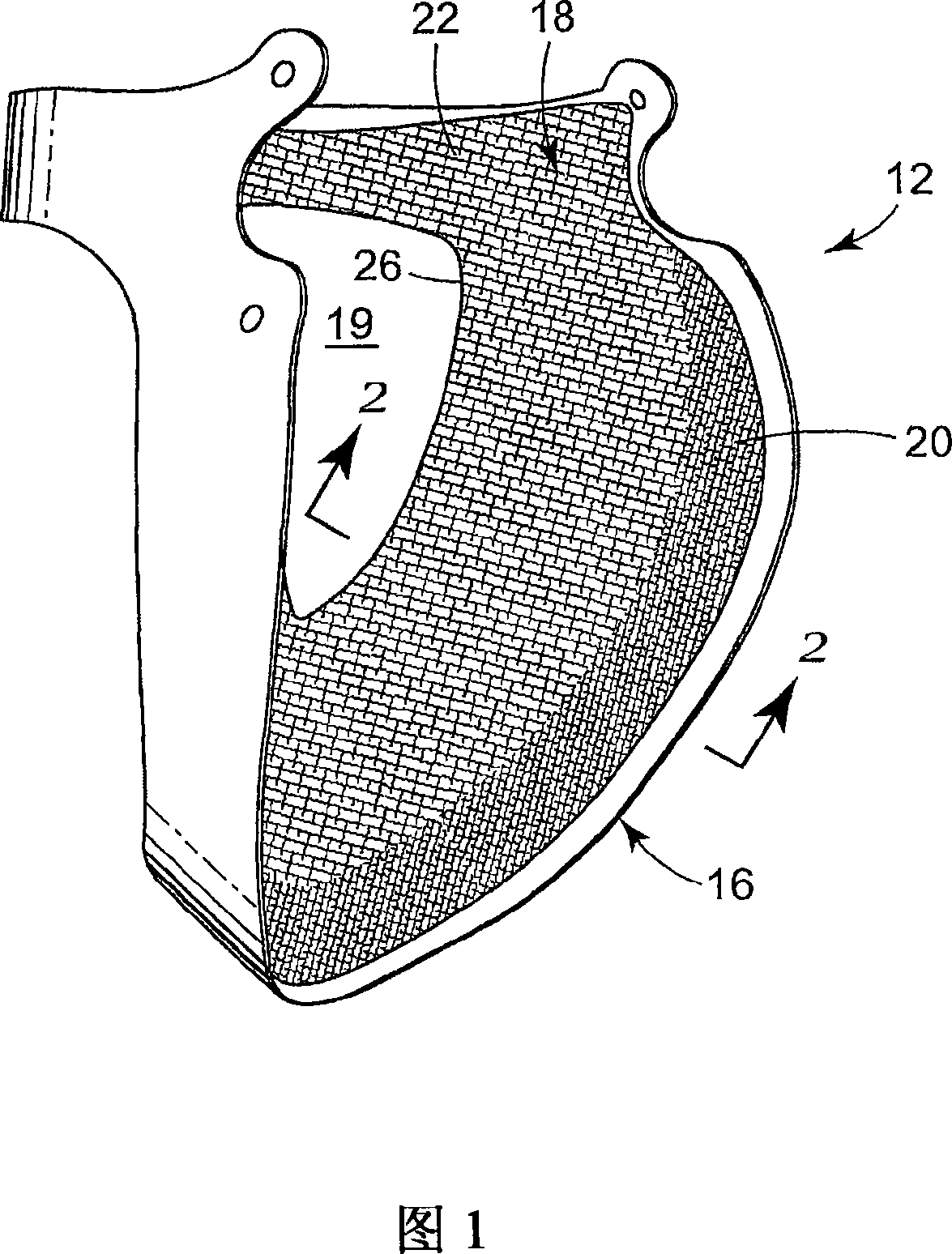

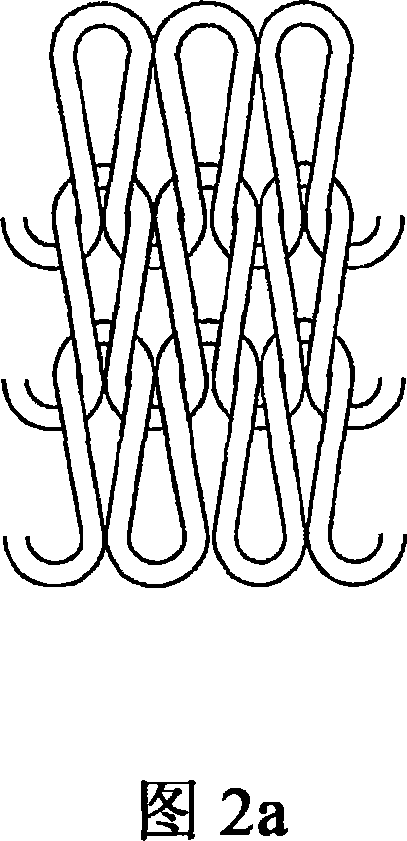

Ligament support and preparation method thereof

InactiveCN104043148AEliminate biocompatibilityAdjustable widthNon-woven fabricsProsthesisFiberNanofiber

The invention relates to a ligament support containing silk fibroin compound oriented nanofiber and a preparation method thereof, and belongs to the technical field of medical apparatus and instruments. The ligament support is prepared from oriented fiber combining silk fibroin with a medical high molecular synthetic material and has a porous three dimensional structure, the mass ratio of the silk fibroin and medical high molecular synthetic material in the compound oriented fiber is (1-20):(1-1), the diameter of the compound oriented fiber is 500nm-10000nm, the thickness of the ligament is 1mm-10mm, and the width of the ligament is 1mm-15mm. The ligament support has a uniform microstructure and good biocompatibility, provides a matrix structure for growing of ligament cells, and can be used for increasing the tensile strength of the ligament due to the compound fiber orientated structure. The ligament support is simple in preparation method and convenient to operate, the preparation process is controllable, and the preparation method is suitable for preparing the ligament supports of various sections and lengths.

Owner:WUHAN TEXTILE UNIV

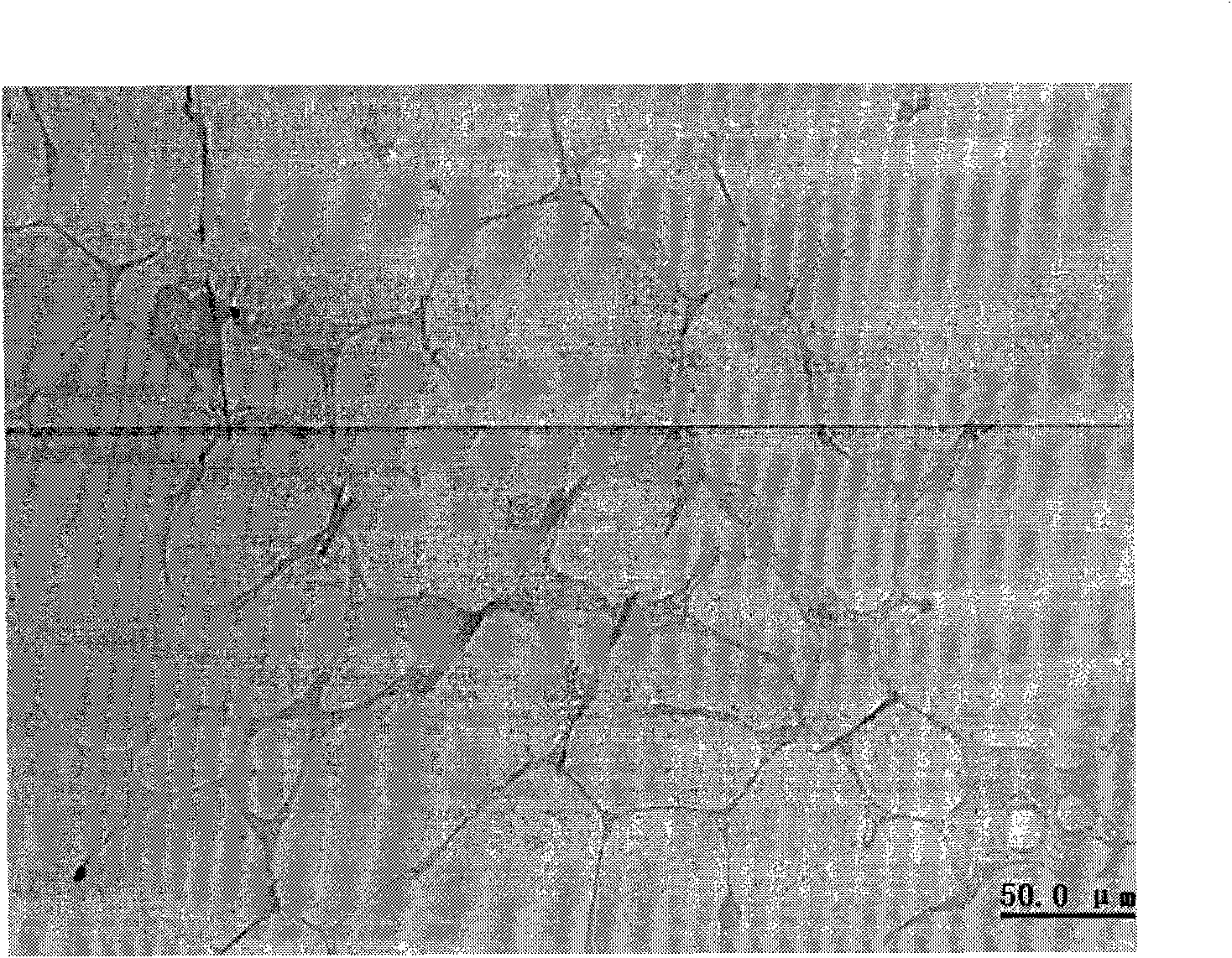

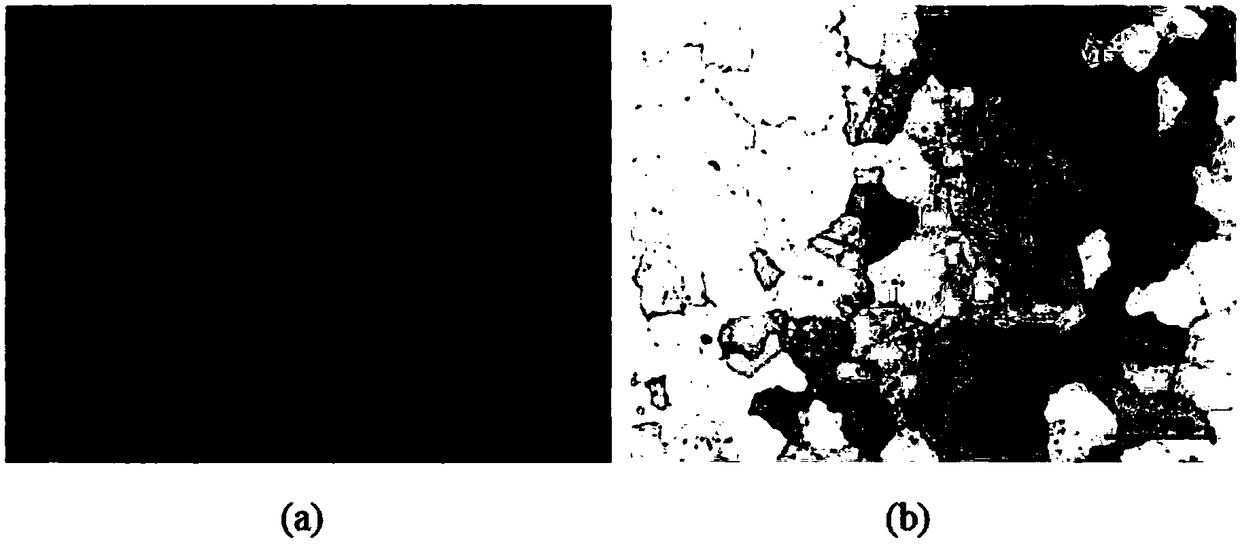

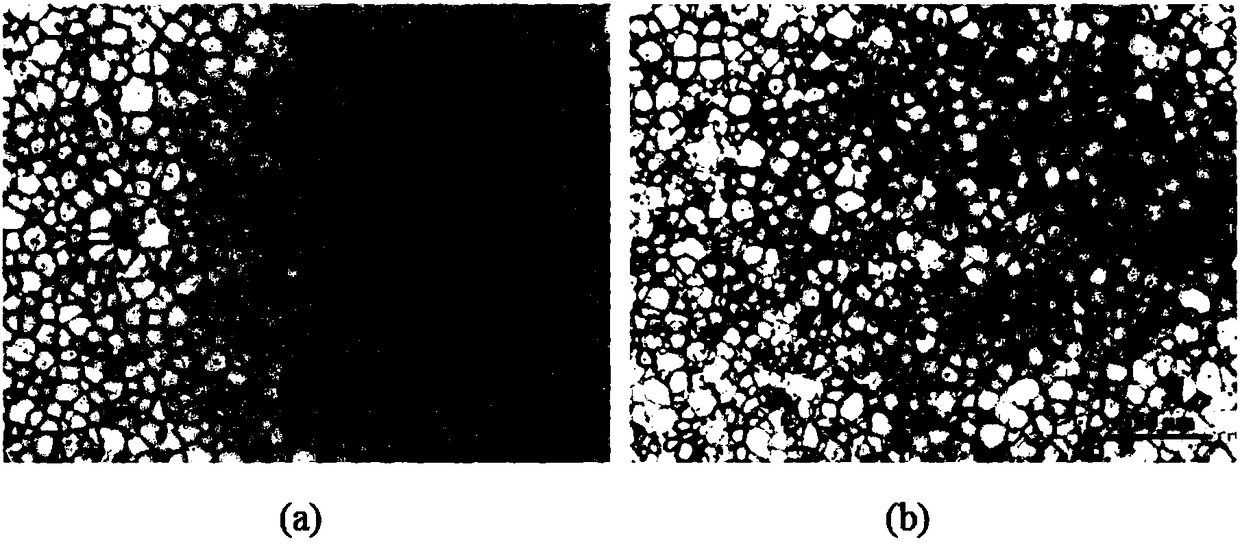

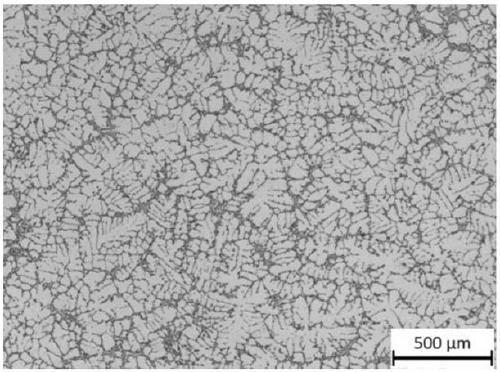

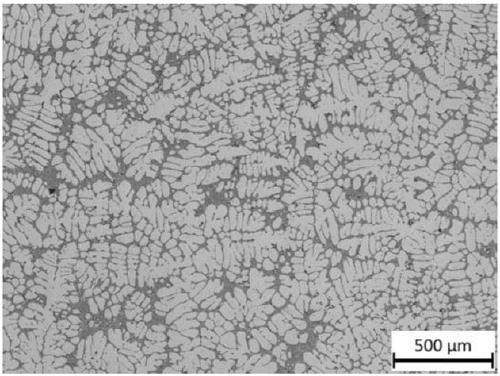

Composite metamorphic agent and composite metamorphic method of cast aluminum-silicon alloy

The invention discloses a composite metamorphic agent and a composite metamorphic method of a cast aluminum-silicon alloy, and relates to the technical field of metamorphism of cast aluminum alloys. The composite metamorphic method mainly uses the composite metamorphic agent for metamorphism. The composite metamorphic agent comprises an Al-Ti-B intermediate alloy, an Al-Sr intermediate alloy and an Al-RE intermediate alloy; the appending proportion of the Al-Ti-B intermediate alloy is 0.01%-0.04% of the melt mass of the cast aluminum-silicon alloy; the additive amount of Sr in the Al-Sr intermediate alloy is 0.01-0.05% of the melt mass; and the additive amount of RE in the Al-RE intermediate alloy is 0.01%-0.1% of the melt mass. According to the composite metamorphic method of the cast aluminum-silicon alloy, the cost is low, operation is easy, the purpose of synchronously refining alpha-Al crystalline grains and metamorphic eutectic silicon can be achieved through composite metamorphism, the additive amount of the Sr, and Al-Ti-B is decreased, thus the tensile strength and elongation of the alloy can be improved, and meanwhile, the strength and toughness of a cast aluminum alloy can be improved.

Owner:GUANGDONG INST OF NEW MATERIALS

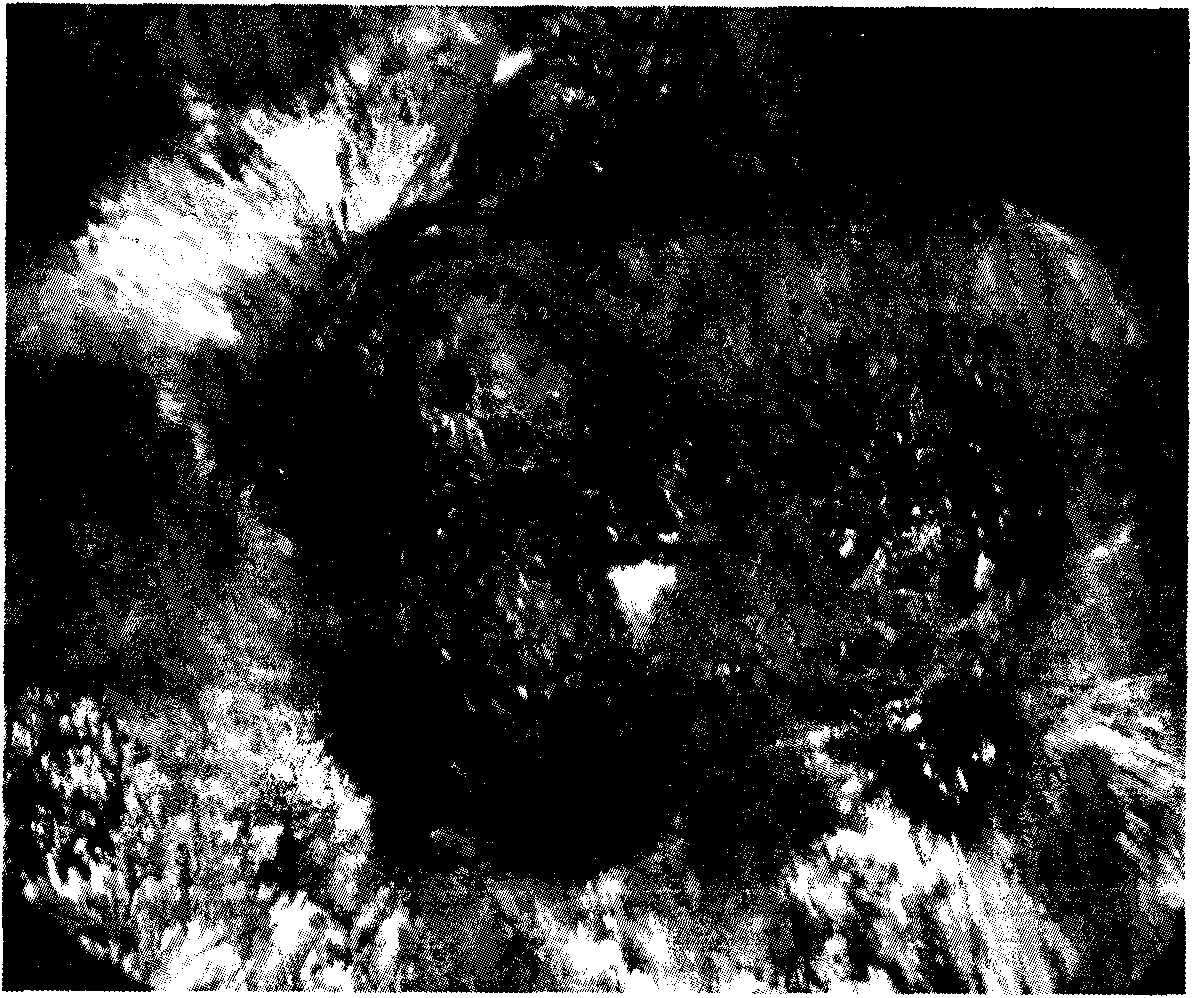

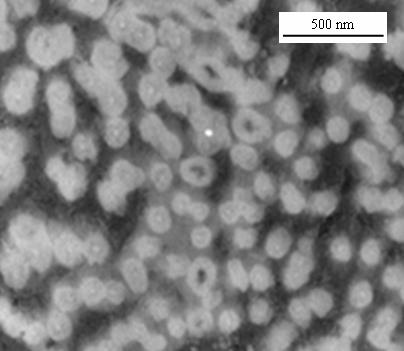

Method for preparing nano particle enhanced magnesium-based composite material

The invention discloses a method for preparing a nano particle enhanced magnesium-based composite material, and relates to the technical field of magnesium-based composite material preparation. A two-step synthesis method is adopted in the method, wherein in the first step, a master alloy containing nano enhanced particles is generated by in-situ reaction in an aluminum melt under the composite action of a pulse magnetic field and a pulse electric field; and in the second step, after magnesium or magnesium alloy melt is melted, the prepared master alloy is added into the melt, and uniform mixing of the master alloy in the melt and dispersion of the particles are promoted by the external electric and magnetic fields. The method has the main advantages that: the particle phase in the magnesium-based composite material is controlled in nano scale and dispersed uniformly; compared with a one-step direct synthesis method, the number of the particle phase in the composite material prepared by adopting the method is easily accurately regulated and controlled, the melting time of the magnesium melt is shortened, and oxidation and combustion loss of the magnesium are controlled; and in addition, low air suction amount of the magnesium melt is favorable for controlling the tissue defects such as loose, hole shrinkage and the like of the magnesium-based composite material.

Owner:JIANGSU UNIV

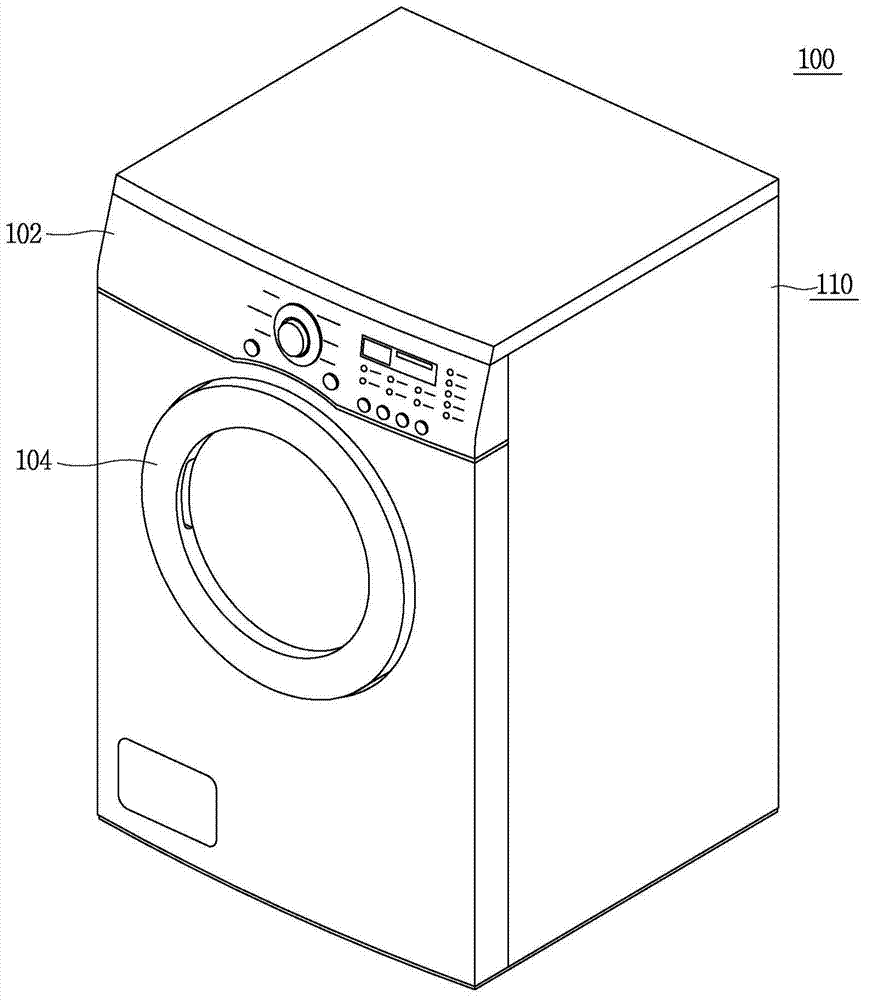

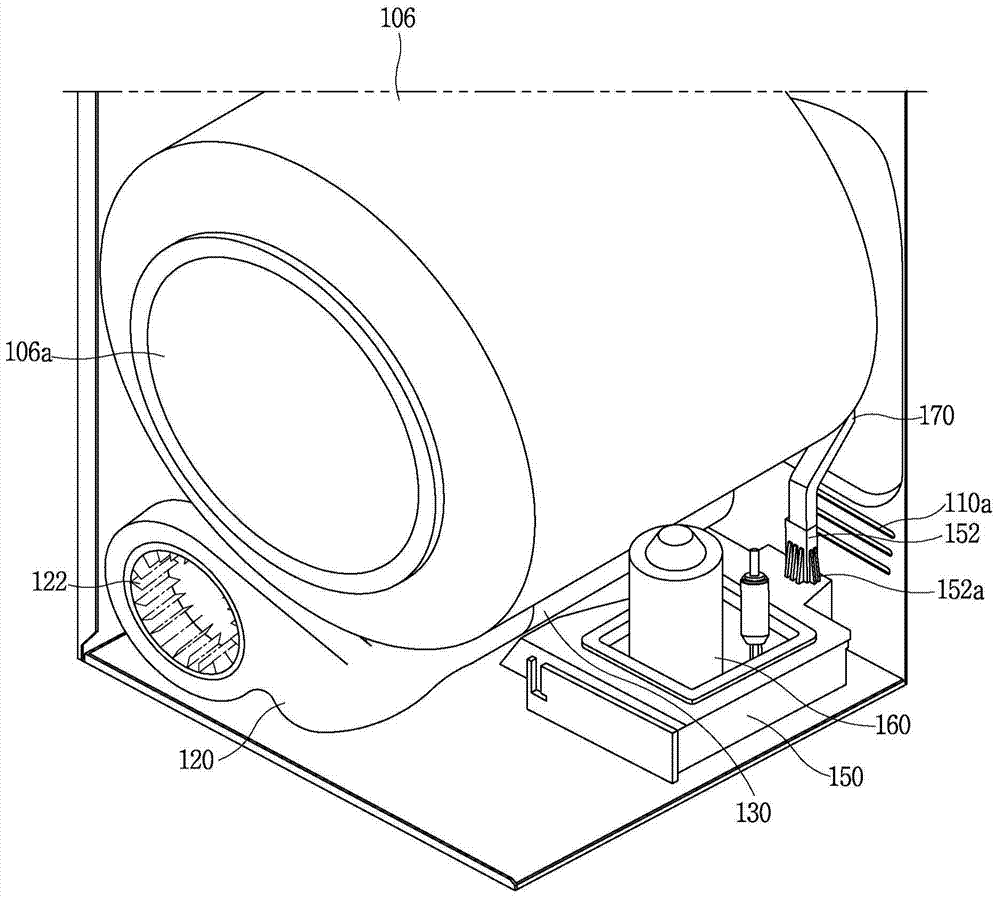

Dryer with heat pump

InactiveCN103835107AShorten the lengthEasy to replaceTextiles and paperLaundry driersEngineeringInhaled air

A dryer with a heat pump that includes a cabinet , a drum installed within the cabinet, and an exhaust duct configured to exhaust air from the drum to outside of the cabinet . The dryer also includes a fan configured to inhale air from the drum and pump the air to the exhaust duct, an evaporator configured to exchange heat with air being exhausted through the exhaust duct, and a condenser disposed at a rear side of the drum. The dryer further includes an intake passage member configured to guide air that has passed through the condenser into the drum and a compressor and an expansion apparatus configured to define a heat pump along the evaporator and condenser.

Owner:LG ELECTRONICS INC

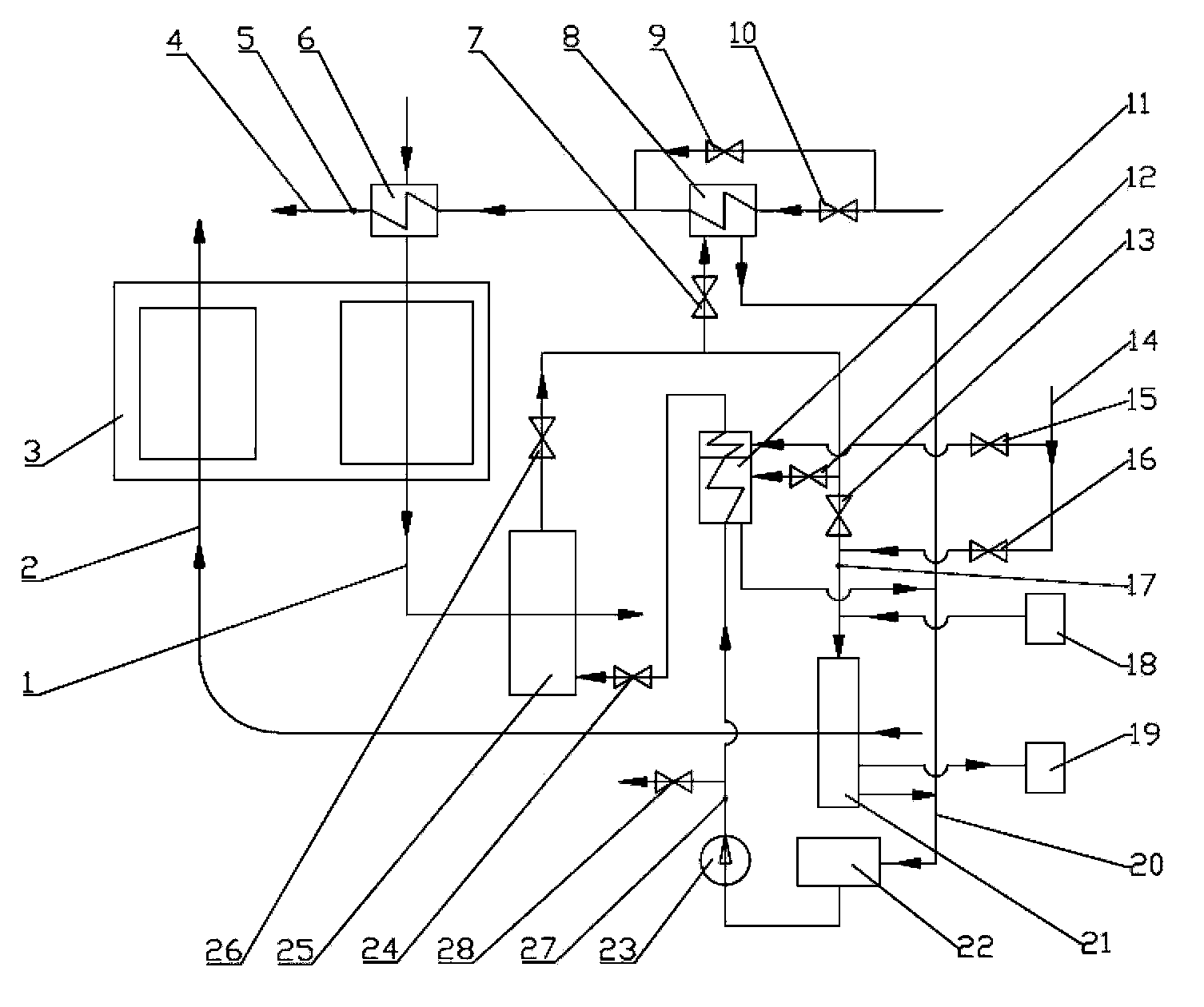

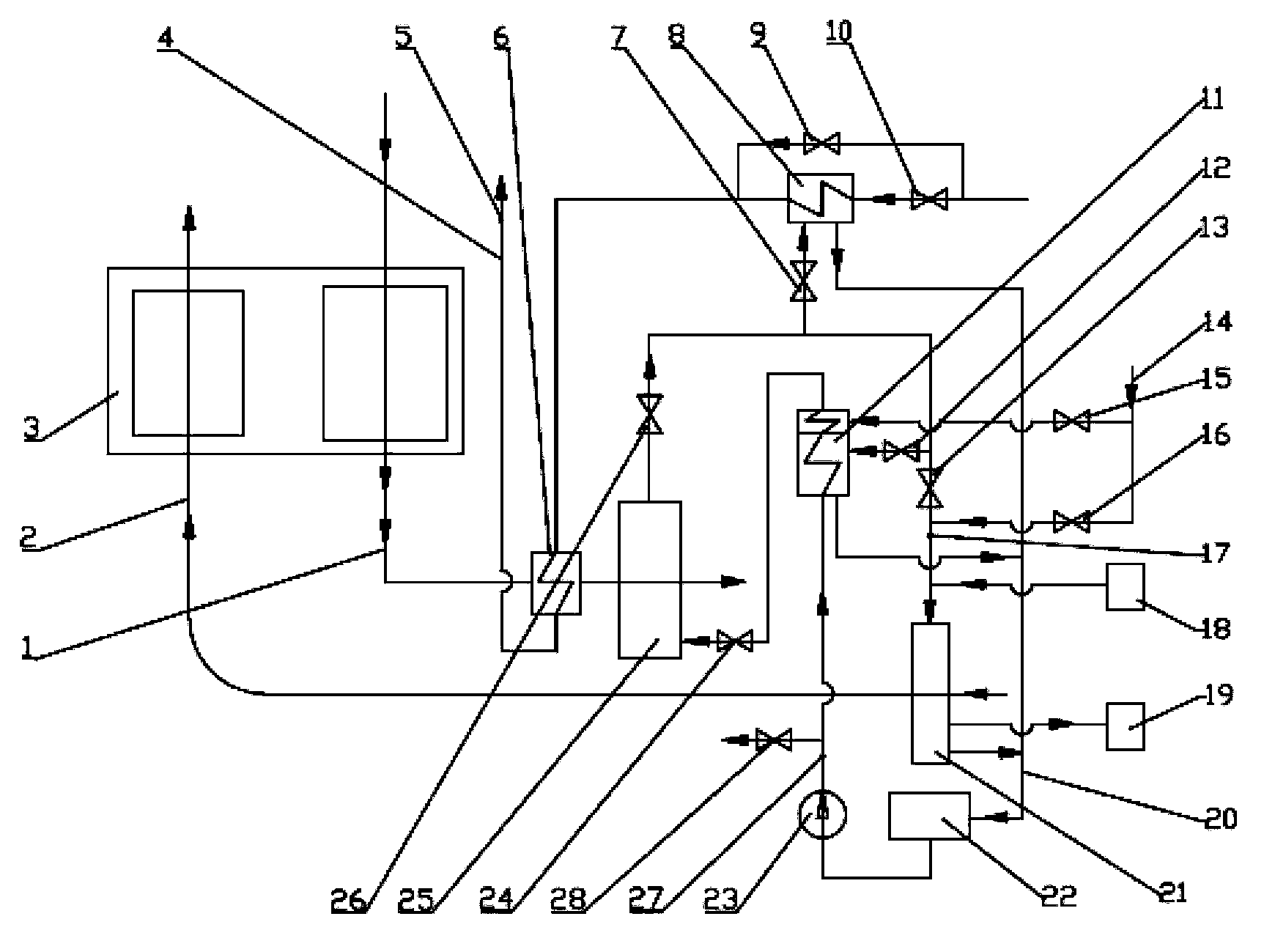

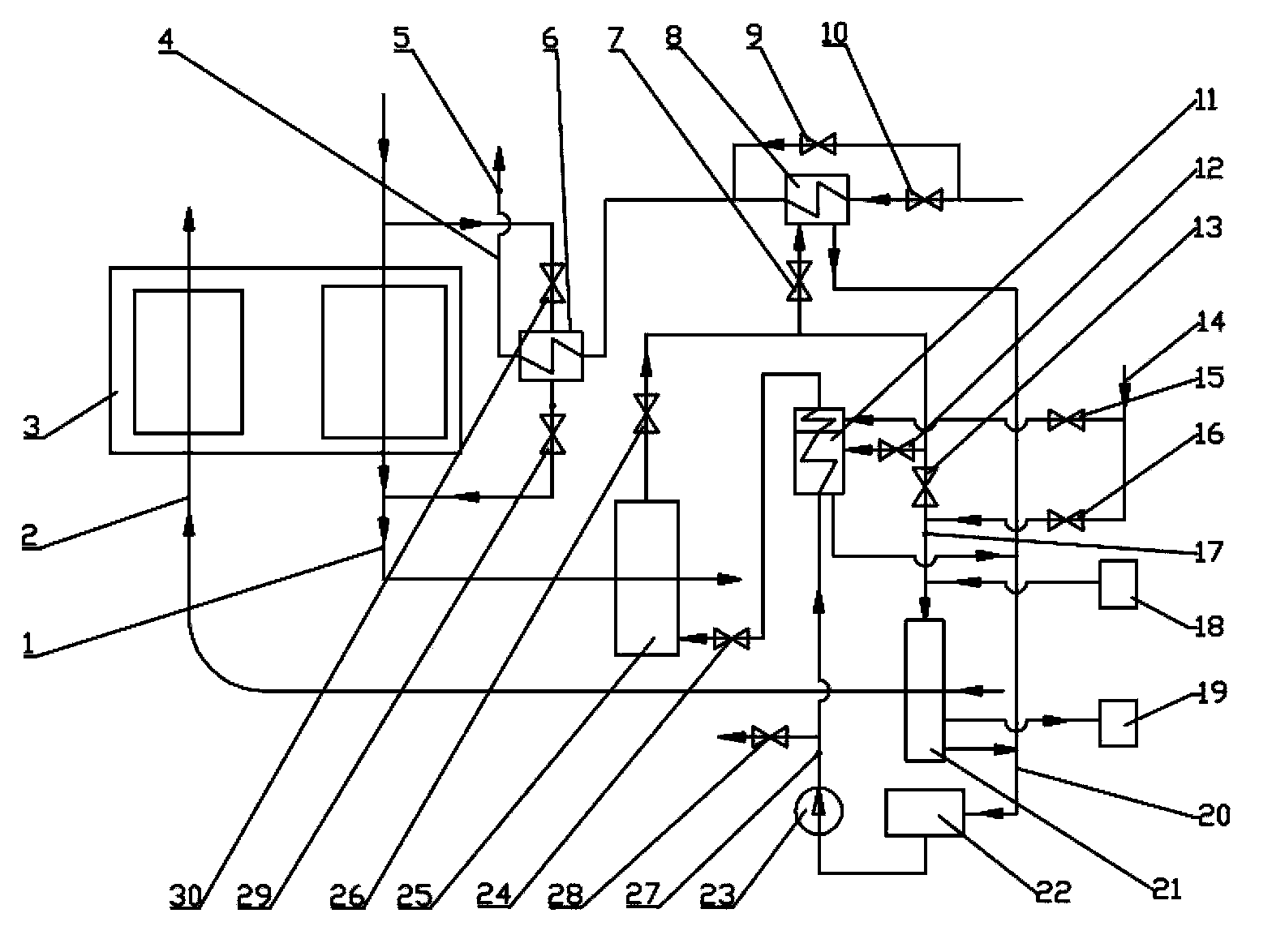

Sub-control phase-change heat exchange system and method based on grading combination heat exchange

InactiveCN103808178AIncrease temperatureImprove energy qualityIndirect heat exchangersAir preheaterHigh energy

The invention discloses a sub-control phase-change heat exchange system based on grading combination heat exchange. The sub-control phase-change heat exchange system comprises a flue, an air channel, an air pre-heater, an external water pipeline, a steam supply valve of a low-temperature water heater, the low-temperature water heater, a water inlet valve of the low-temperature water heater, a steam-liquid heat exchanger, a steam supply valve of the steam-liquid heat exchanger, a steam supply valve of an air channel heat exchanger, an external steam supply valve of the air channel heat exchanger, a main water draining pipeline, the air channel heat exchanger, a water tank, a water pump, a water inlet valve of a flue heat exchanger, the flue heat exchanger, and a steam outlet valve of the flue heat exchanger. According to the sub-control phase-change heat exchange system, heat release exchangers which utilize the waste heat of recycled flue gas are arranged in a grading combination mode; according to different situations such as ambient air temperature, operating conditions and the like, the waste heat can be utilized to heat boiler supplied air, condensed water on the side of a steam turbine and the like in a combination mode; meanwhile, the temperature of the condensed water is improved through grading heating, higher energy quality is obtained, and the optimal economic benefit of recycling the waste heat is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

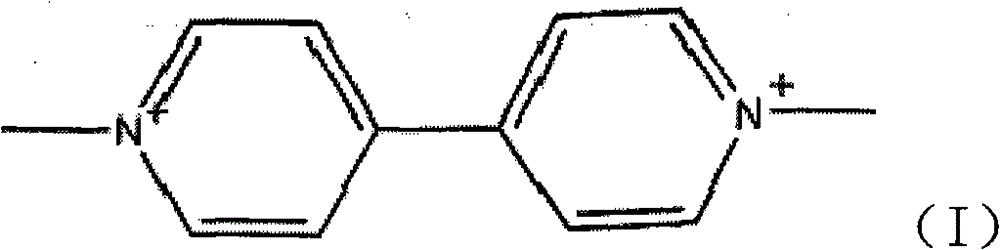

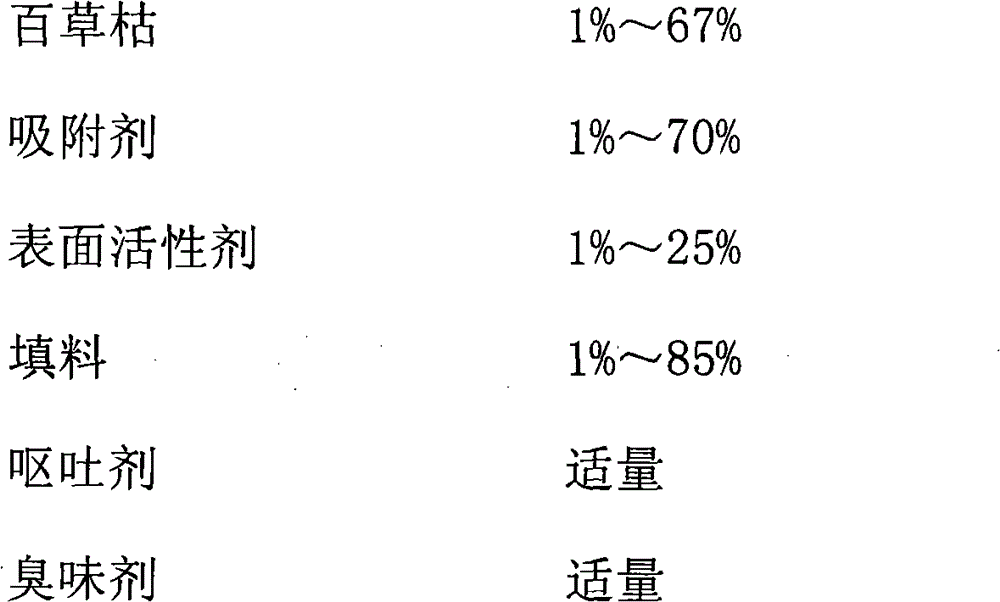

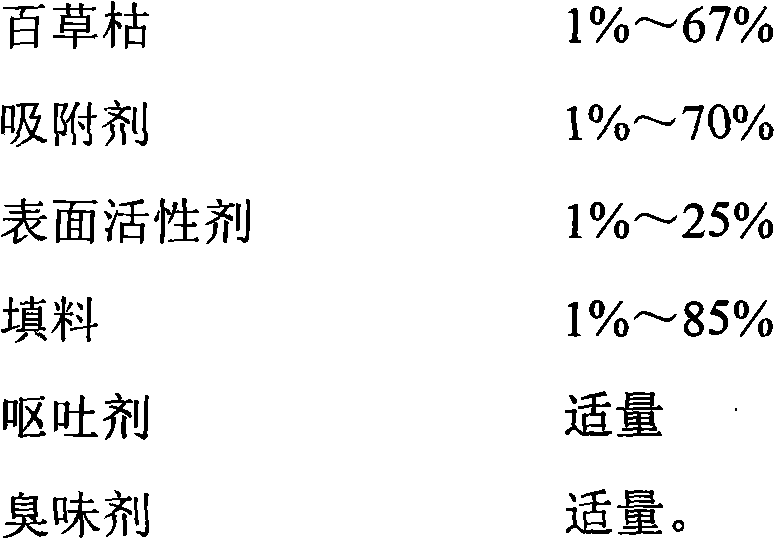

Paraquat solid preparation and preparation method thereof

ActiveCN103053527AAvoid it happening againSimple and fast operationBiocideAnimal repellantsAdjuvantParaquat

The invention provides a paraquat solid preparation and a preparation method thereof. The dosage form comprises paraquat salt solution, adsorbents, surfactants and fillers. The solid preparation is prepared by adsorbing the paraquat solution with the solid adsorbents, then adding the ground fillers to prepare a solid and then adding the surfactants, nauseants and other adjuvants. Further, the preparation method comprises the steps of improving the concentration of the paraquat solution and reducing the moisture via water absorbing treating agents and then preparing the solid preparation according to the above method.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

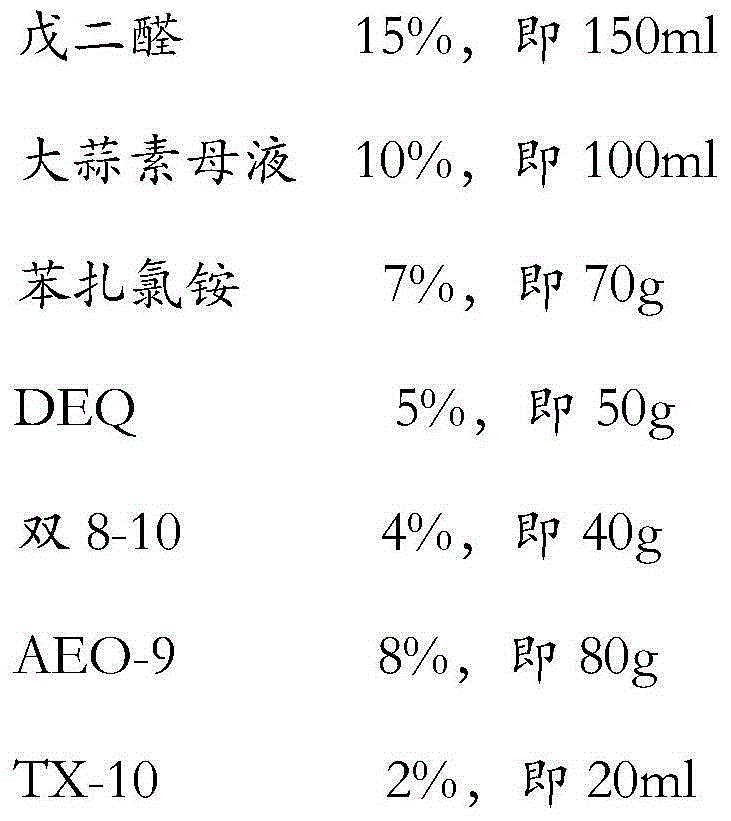

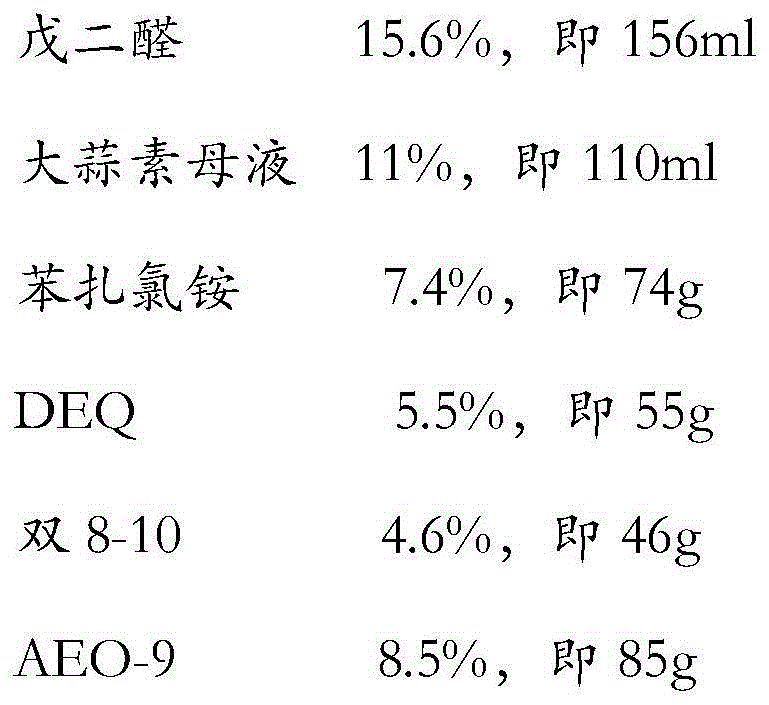

Disinfectant and preparation method thereof

ActiveCN104940183AImprove the bactericidal effectPlay a synergistic roleAntibacterial agentsAntiviralsFoaming agentQuaternary ammonium cation

The invention discloses a disinfectant and its preparation method. The disinfectant comprises a compound glutaraldehyde solution and a foaming agent. Volume ratio of the compound glutaraldehyde solution to the foaming agent is 5:1. The compound glutaraldehyde solution comprises glutaraldehyde, benzalkonium chloride, double-chain quaternary ammonium salt A, double-chain quaternary ammonium salt B, a nonionic surfactant A and a nonionic surfactant B. The double-chain quaternary ammonium salt A and the double-chain quaternary ammonium salt B are different substances. The nonionic surfactant A and the nonionic surfactant B are different substances. By cooperatively using glutaraldehyde, two kinds of double-chain quaternary ammonium salts and two kinds of nonionic surfactants, the synergistic effect is achieved, effects are enhanced, and sterilization is comprehensive.

Owner:SHANDONG SINDER TECH

Supplied air helmet having a knitted face seal

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com