Patents

Literature

375results about How to "Reduce air velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

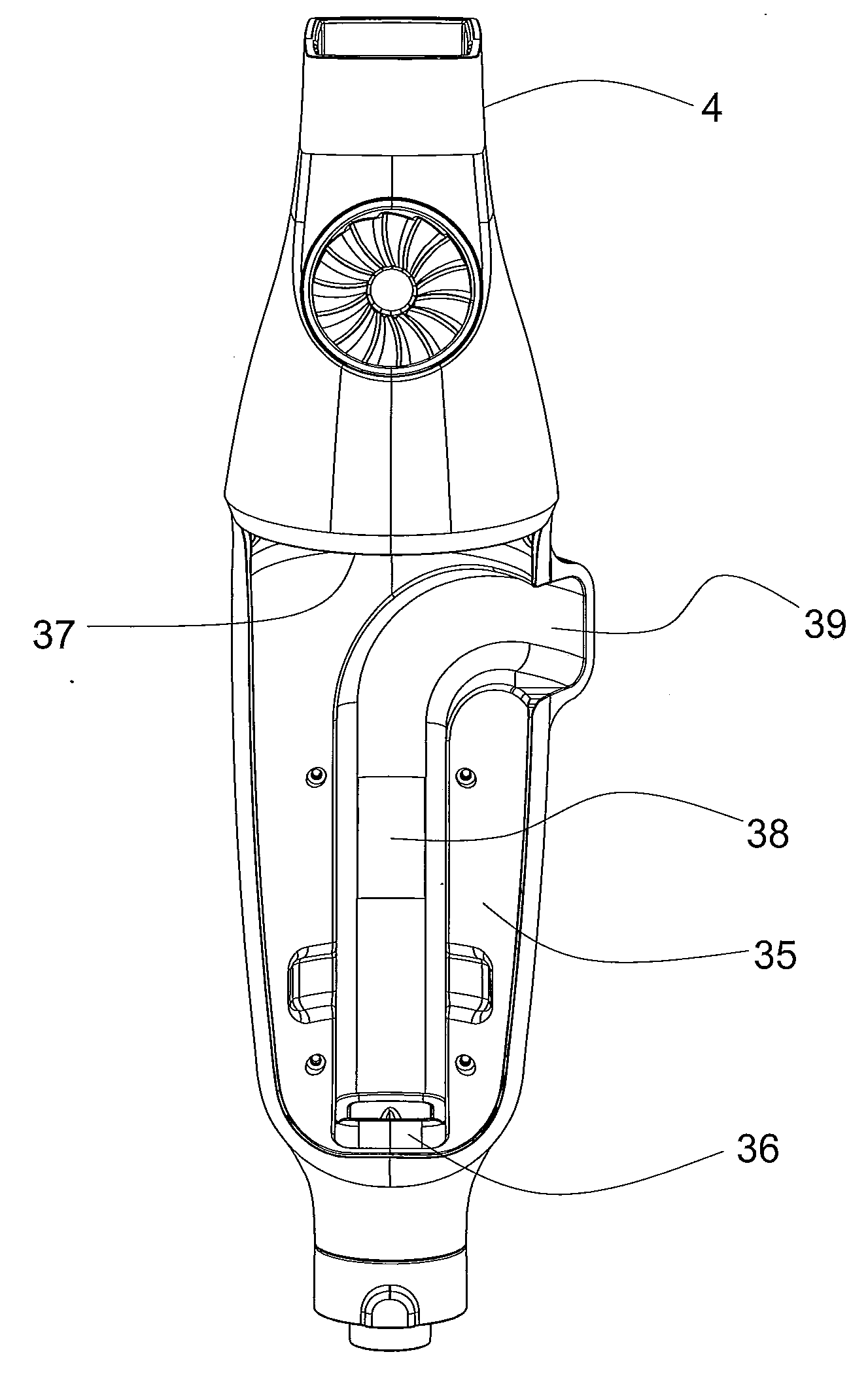

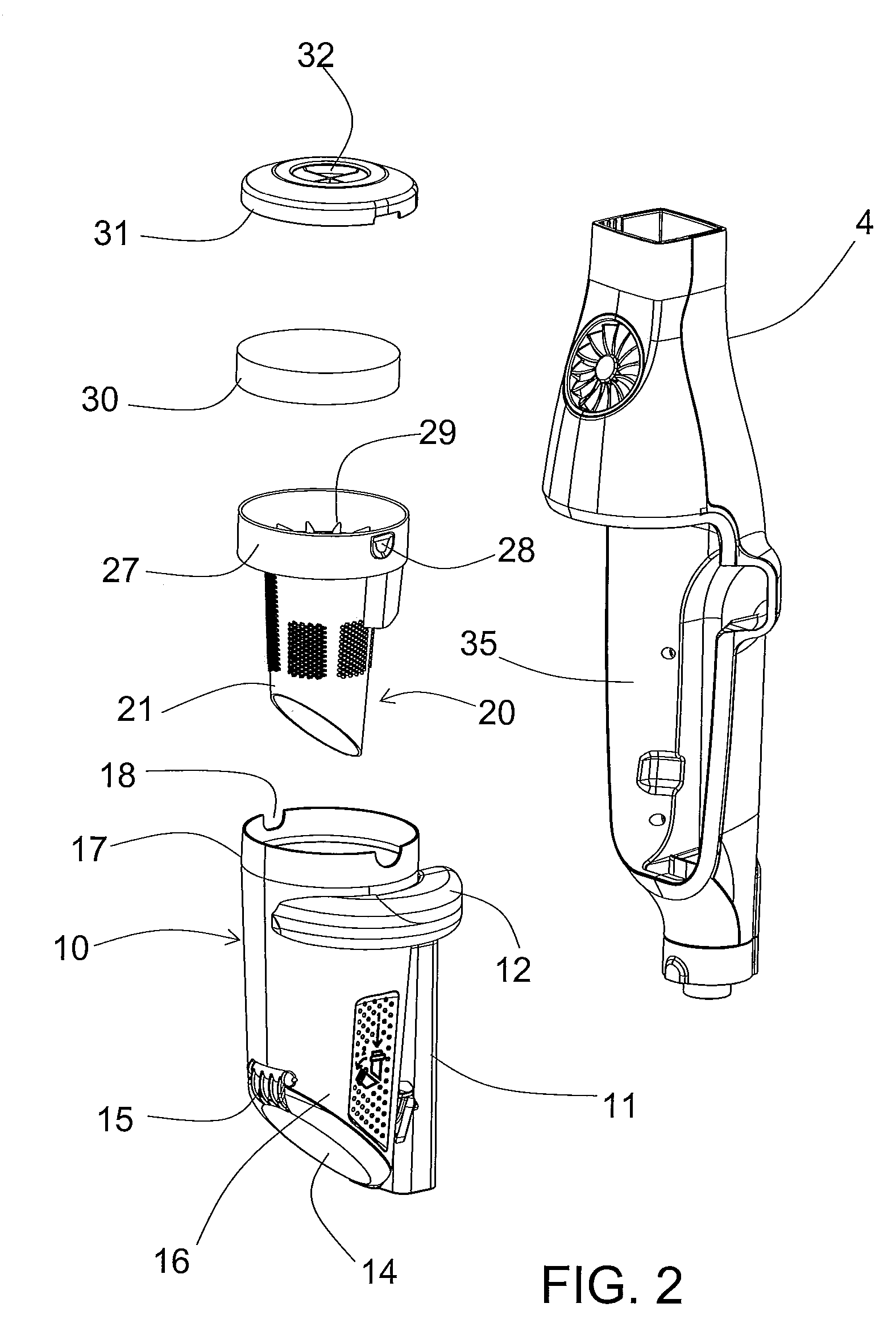

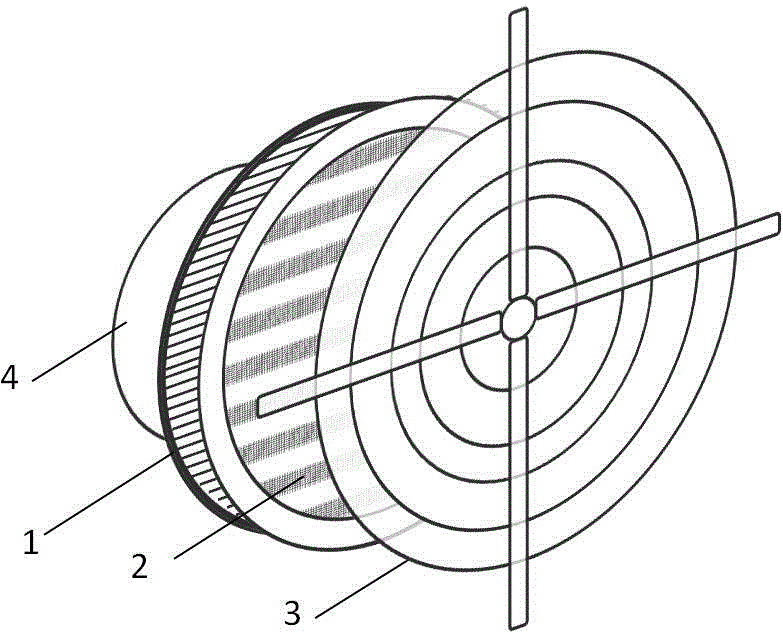

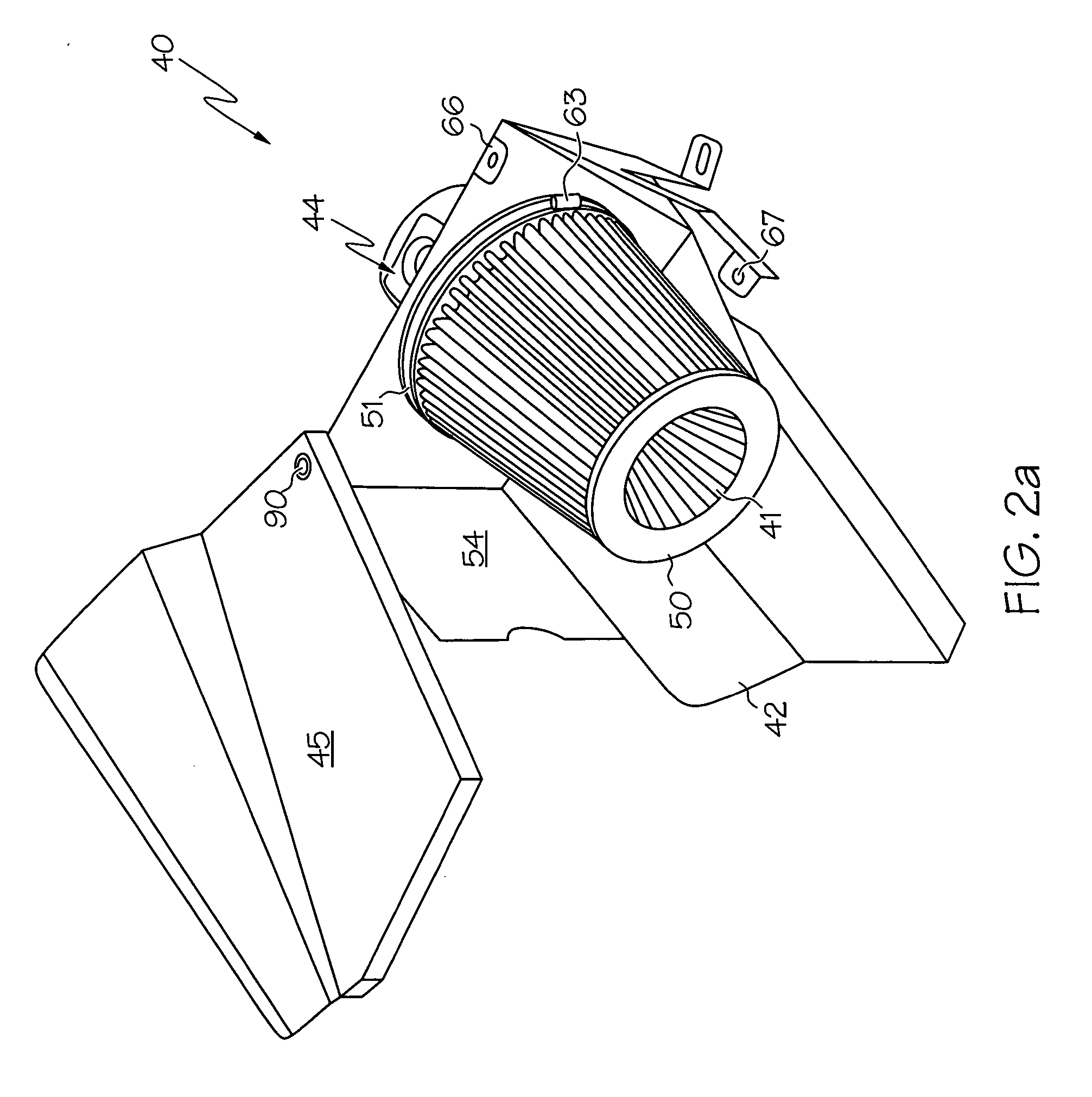

Cyclonic Separation Device With Acceleration Ramp

InactiveUS20100175219A1Streamlining assembly costStreamlining manufacturing costCleaning filter meansAuxillary pretreatmentCyclonic separationEngineering

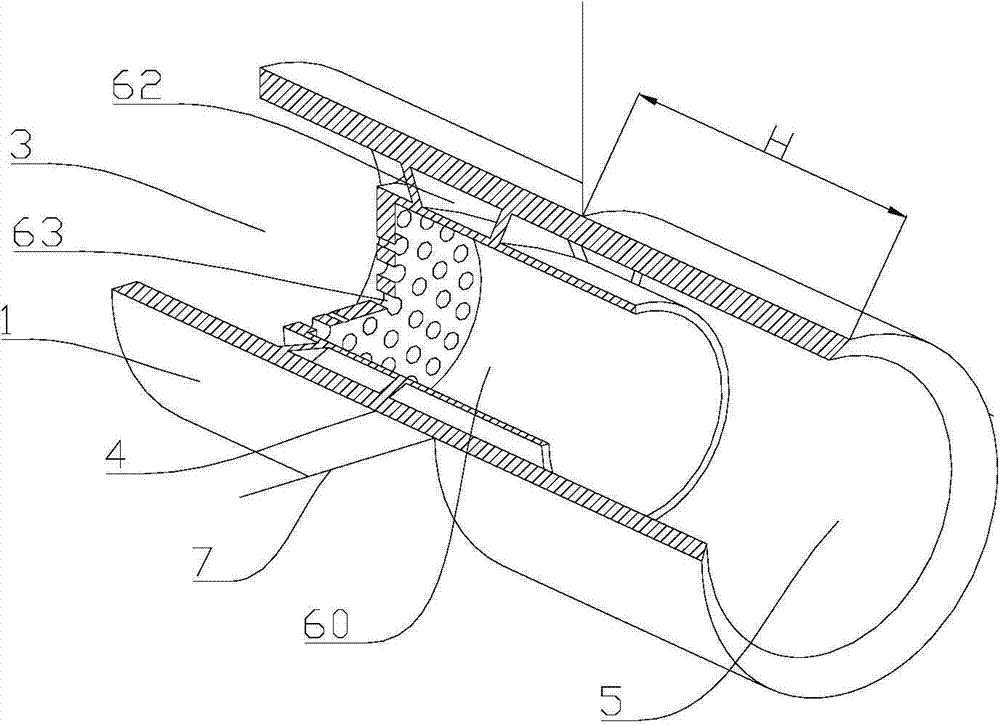

A cyclonic separation device for dust and debris in vacuum cleaners, comprising a roughly cylindrical interior cyclonic chamber connected to an air intake, as well as a separator filter located in the central part of the interior chamber, comprising a tube segment to direct airflow to the air intake with this tube segment located around the roughly cylindrical interior cyclonic chamber, from a starting point to an end point near the air intake, with the cross-section of this tube segment near the end point being smaller than that near the starting point in order to form an acceleration ramp for the airflow between these two points.

Owner:SEB SA

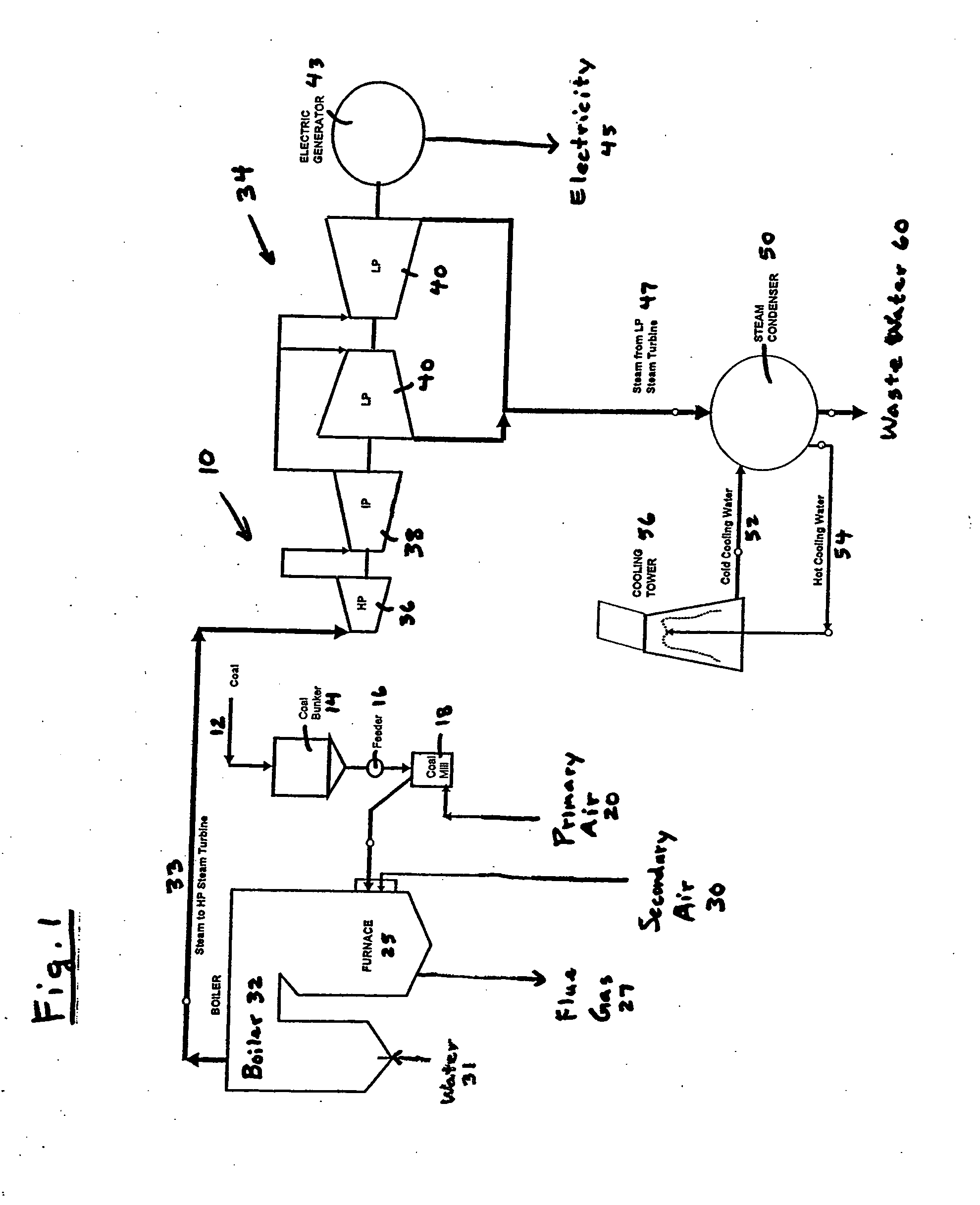

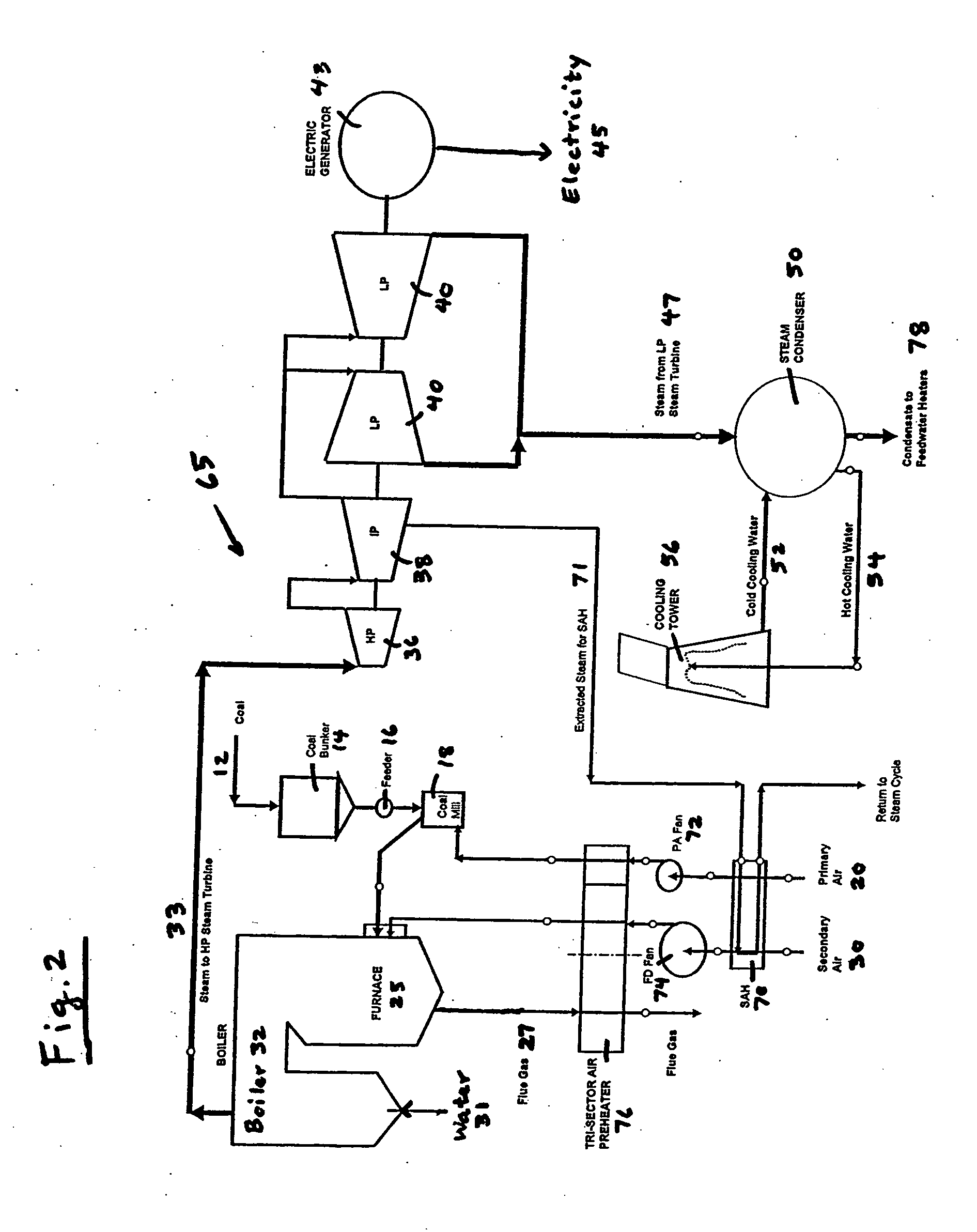

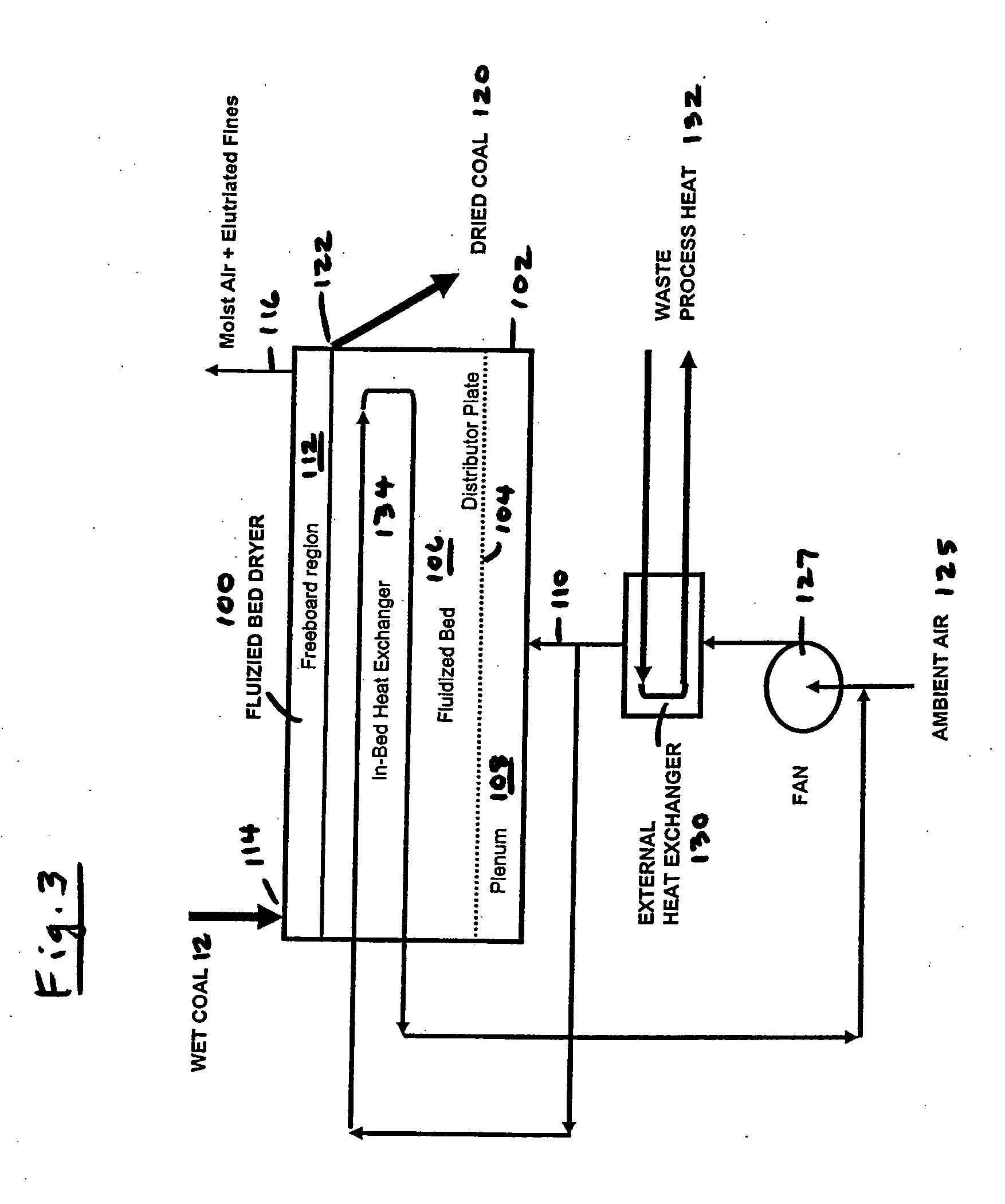

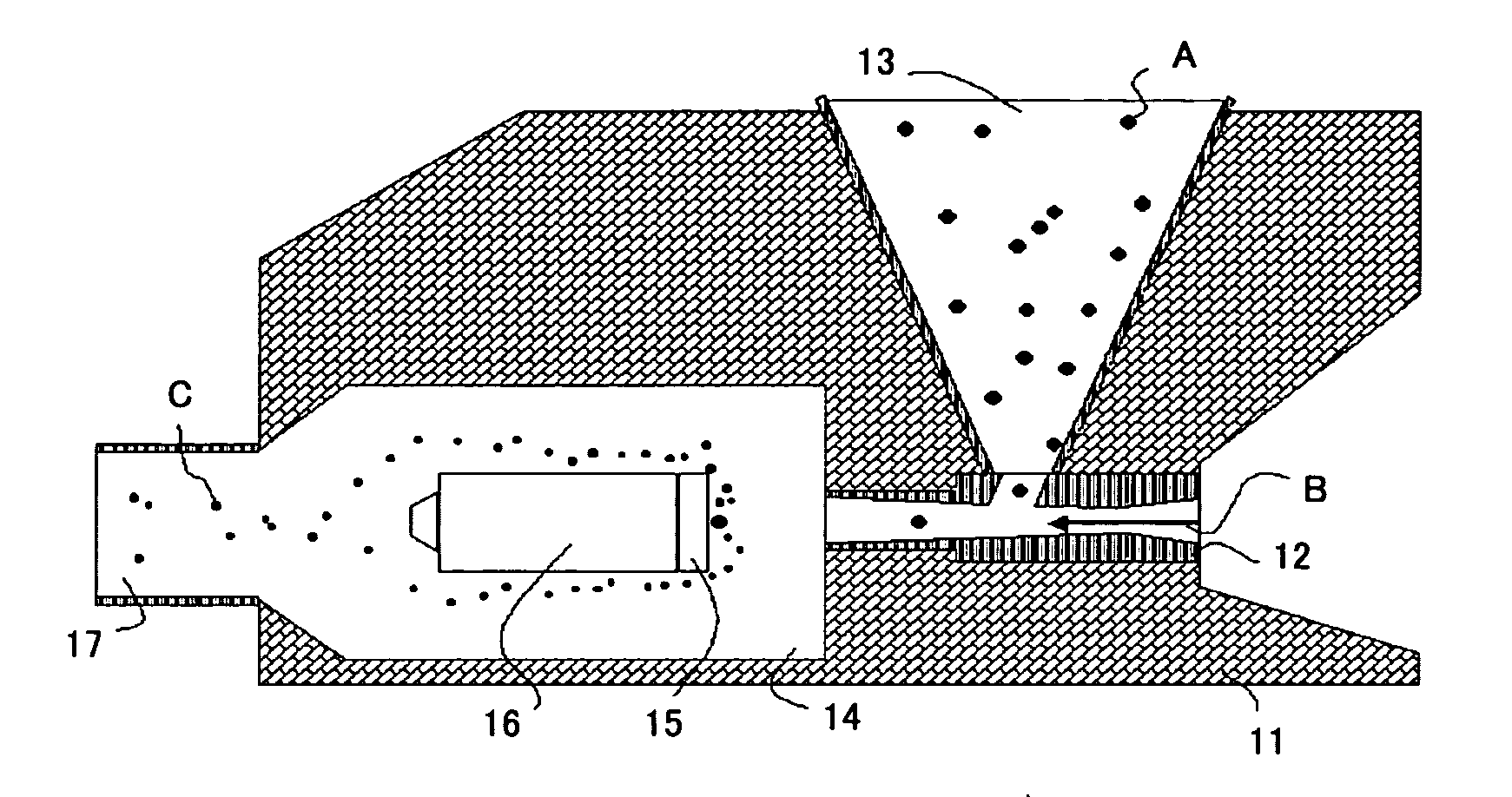

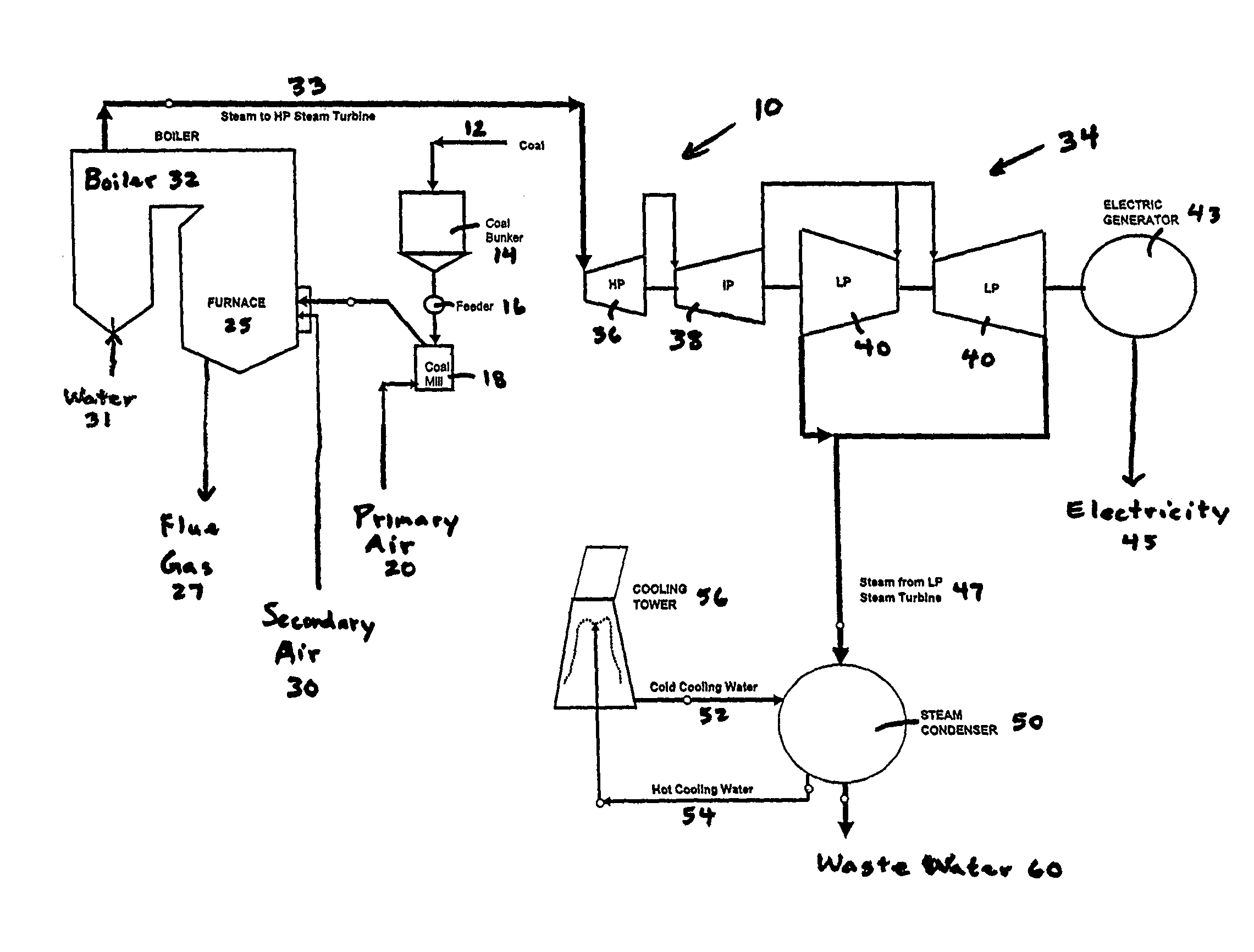

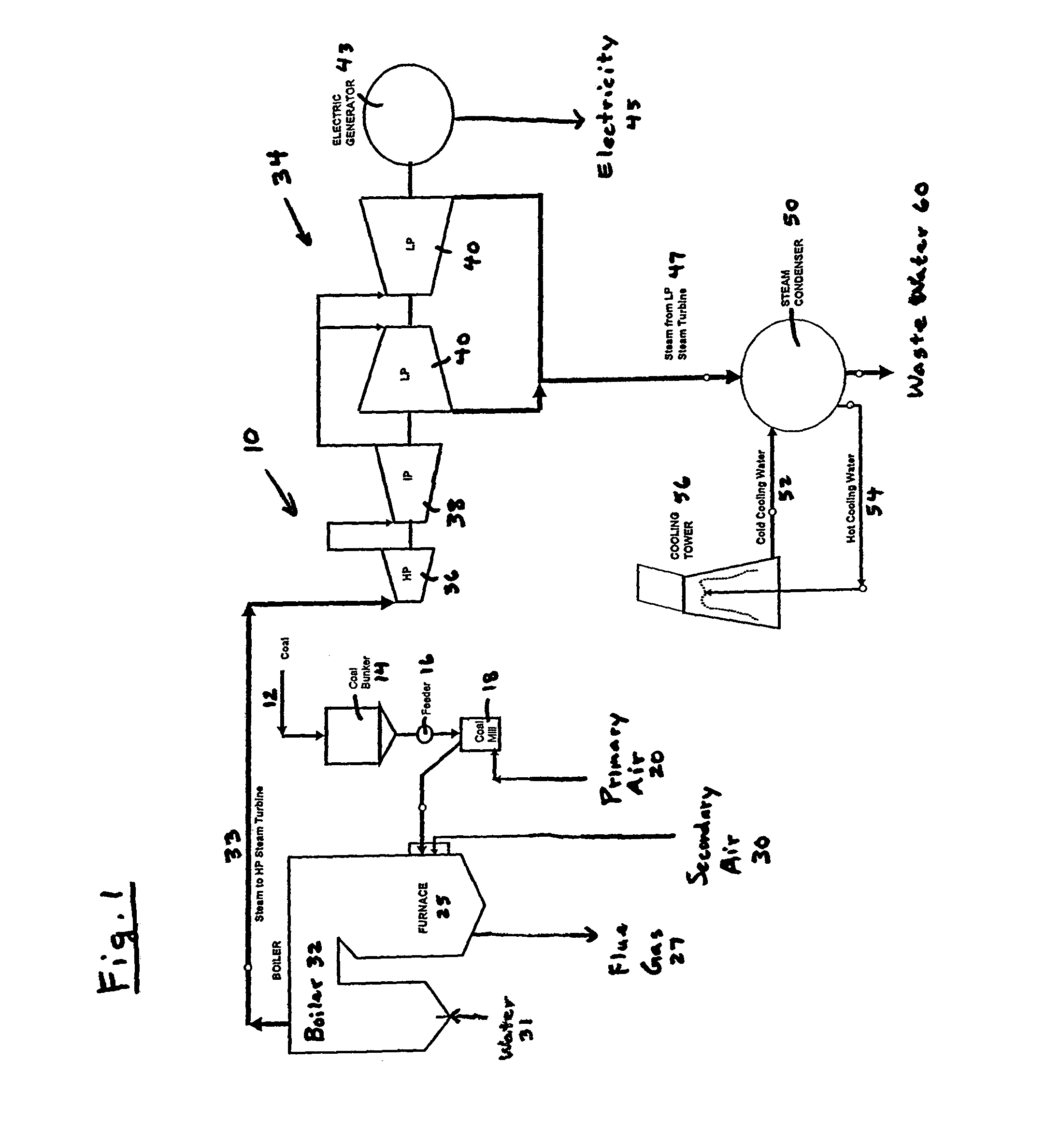

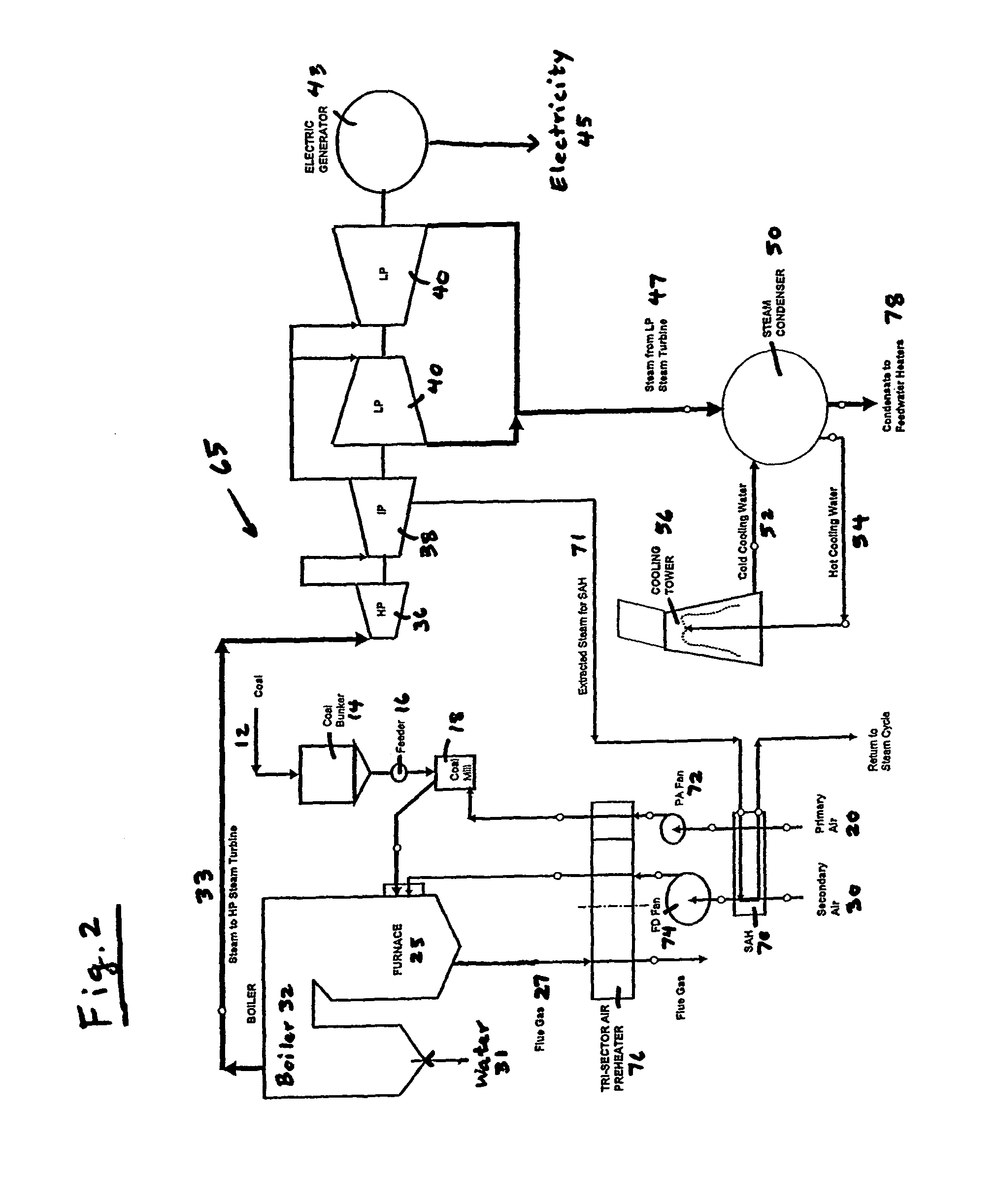

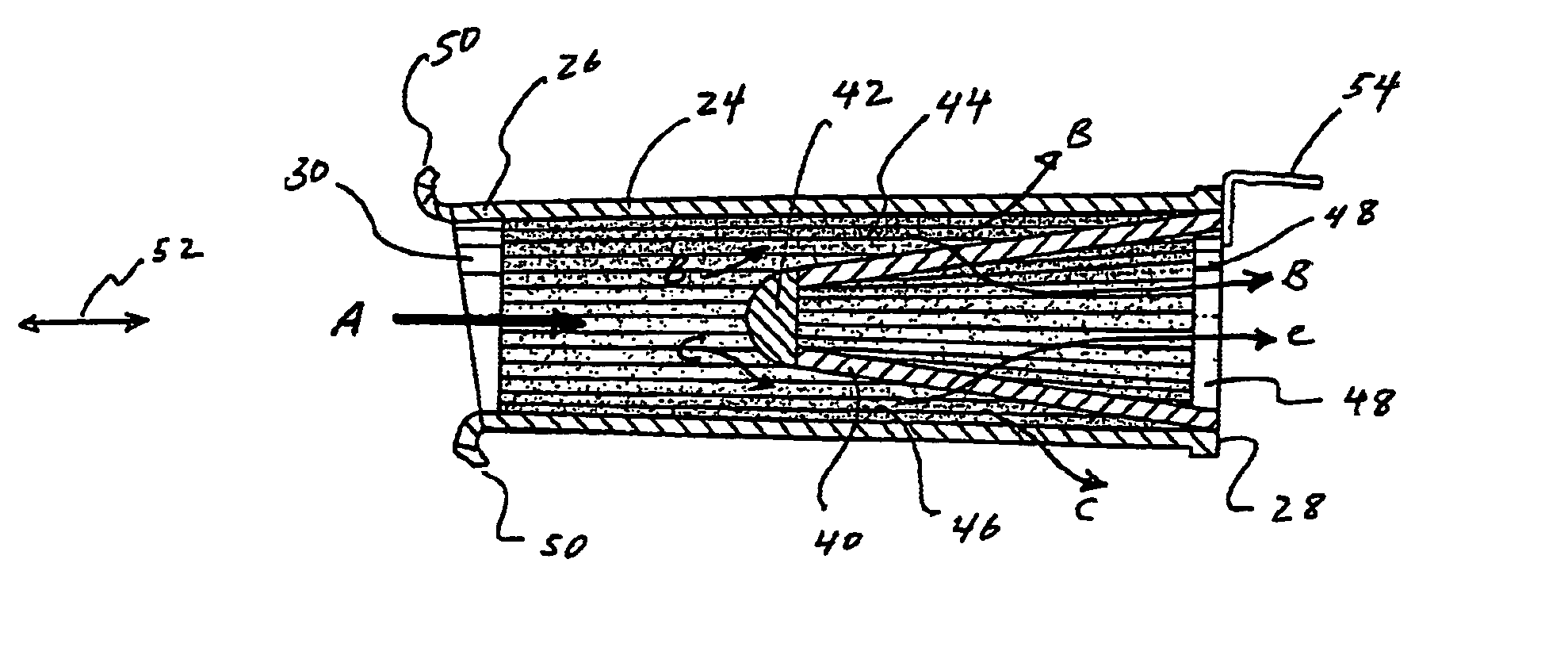

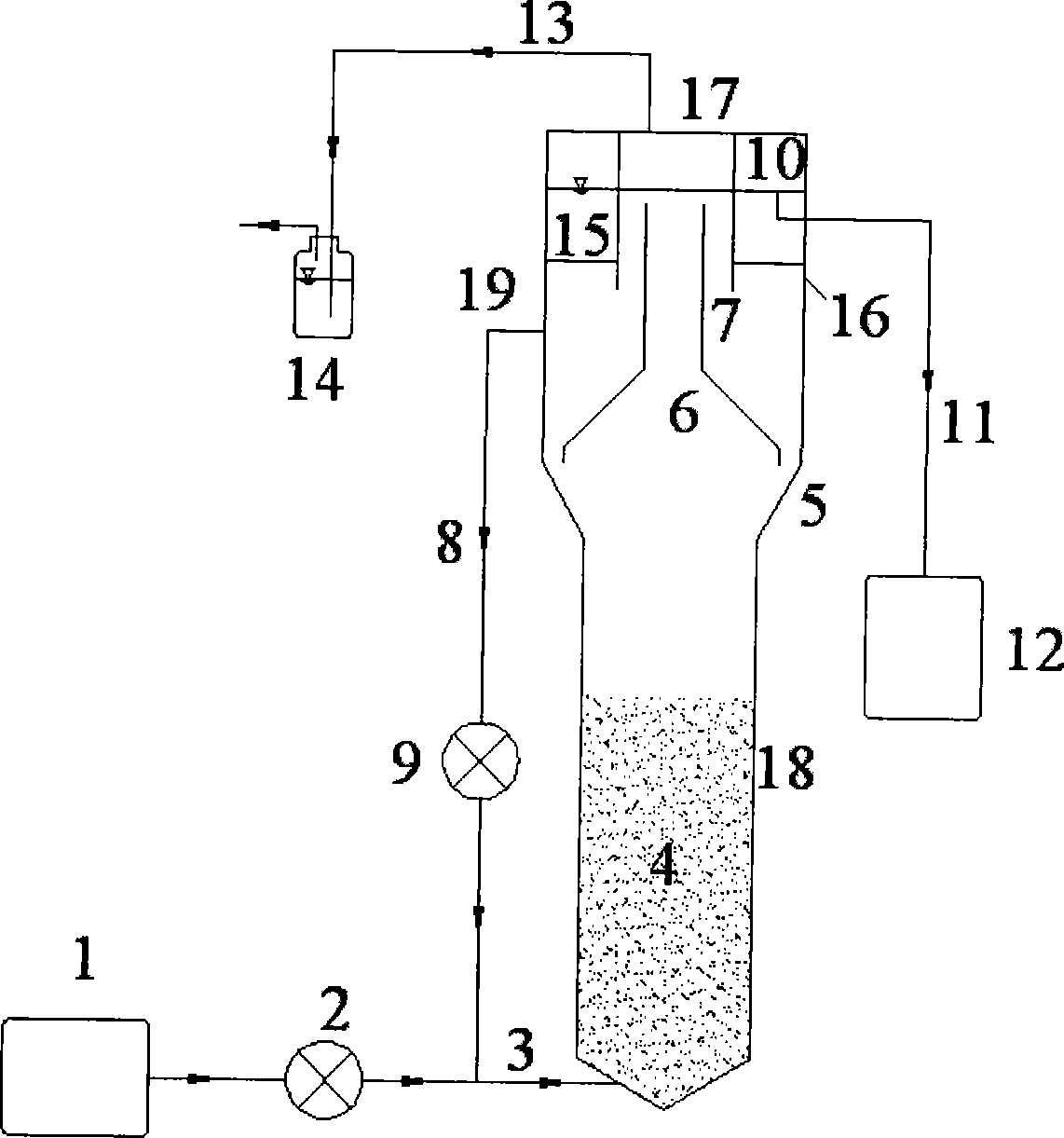

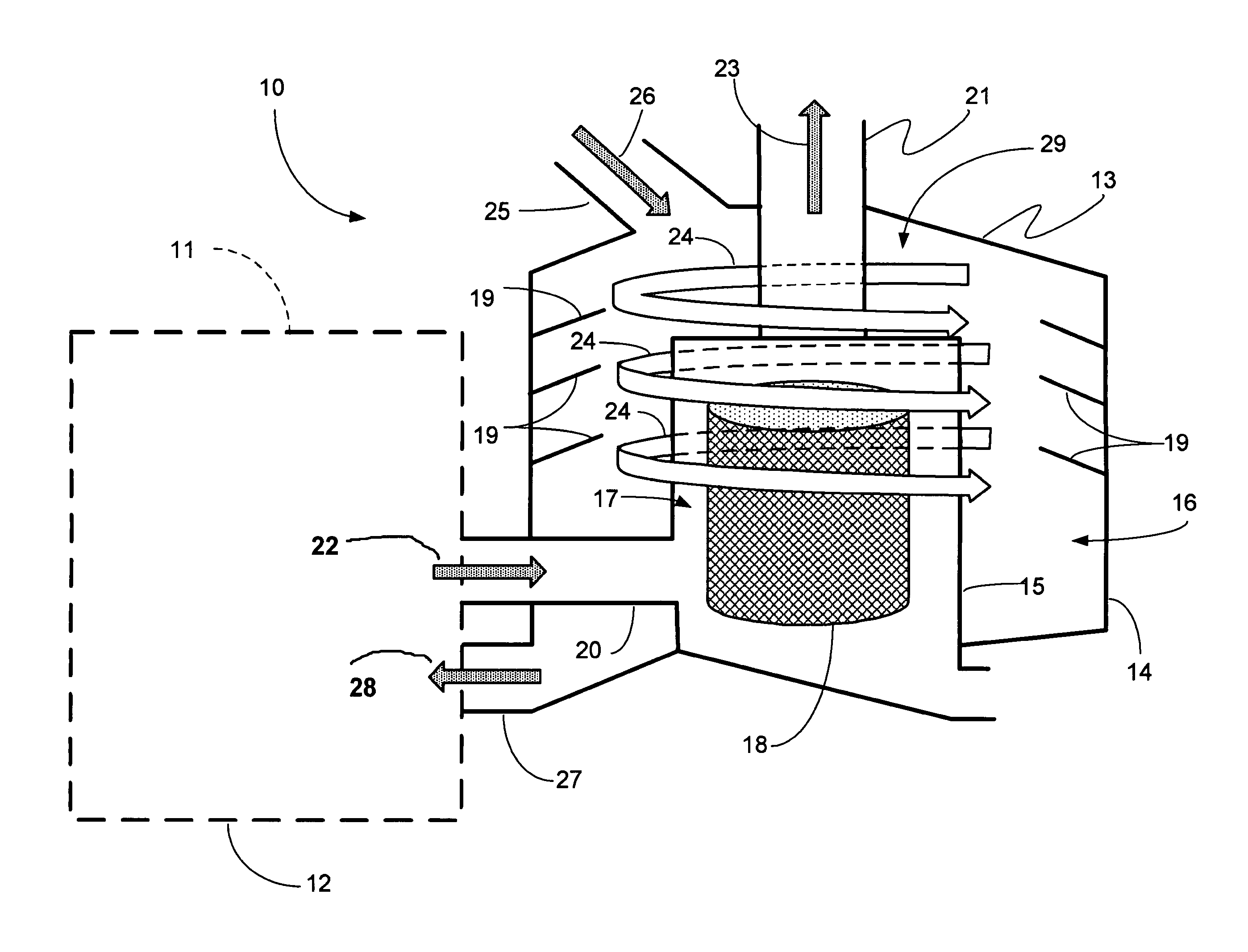

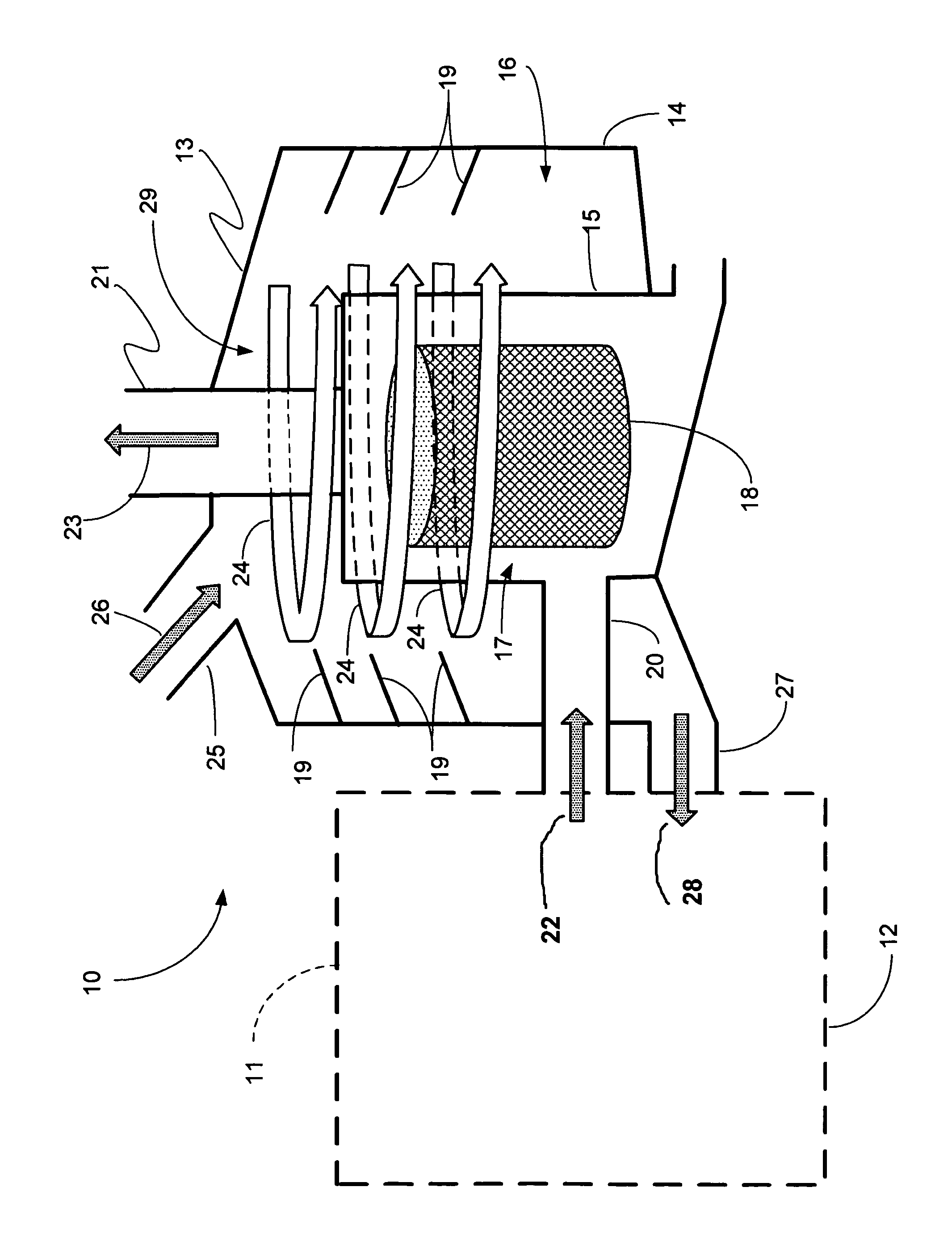

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

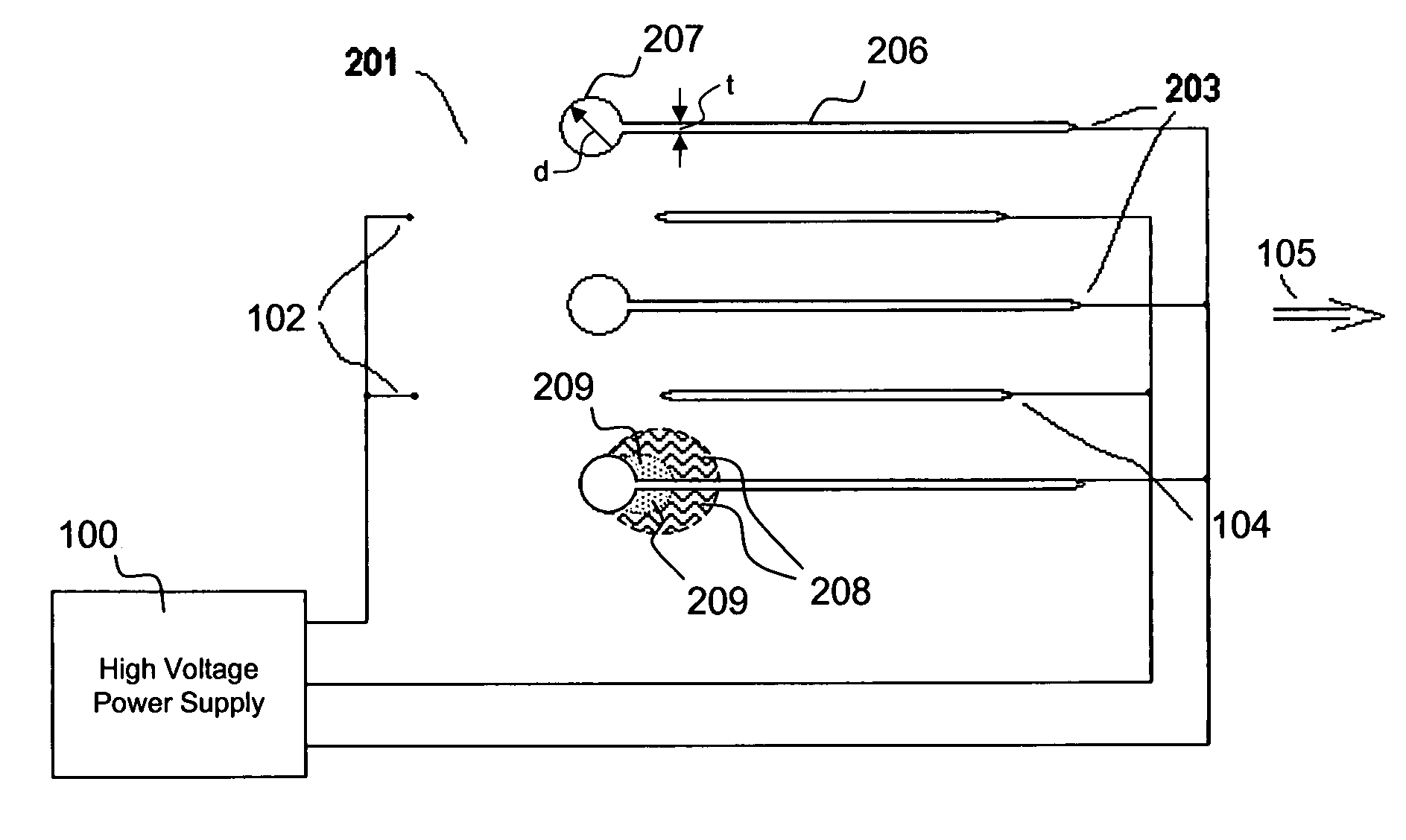

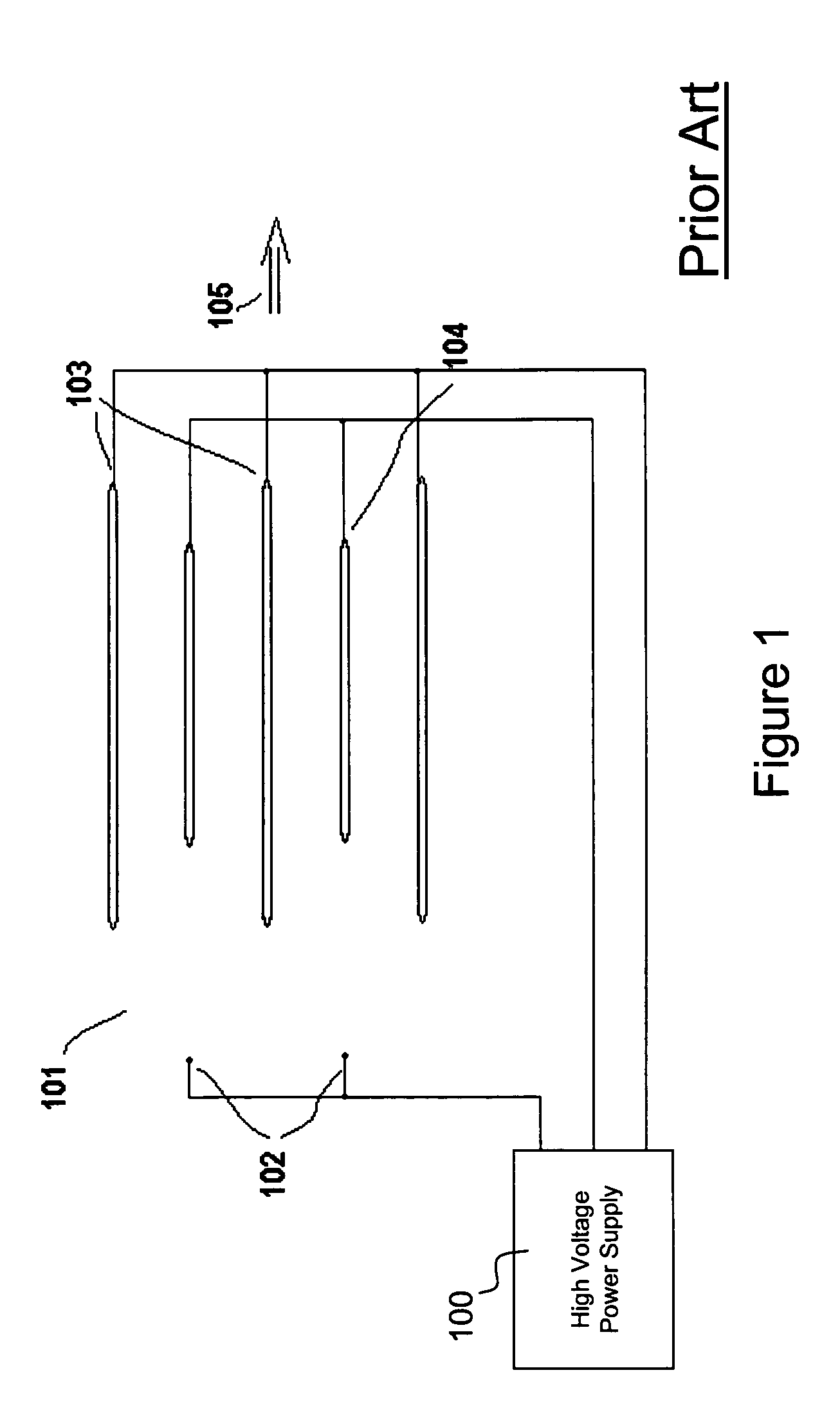

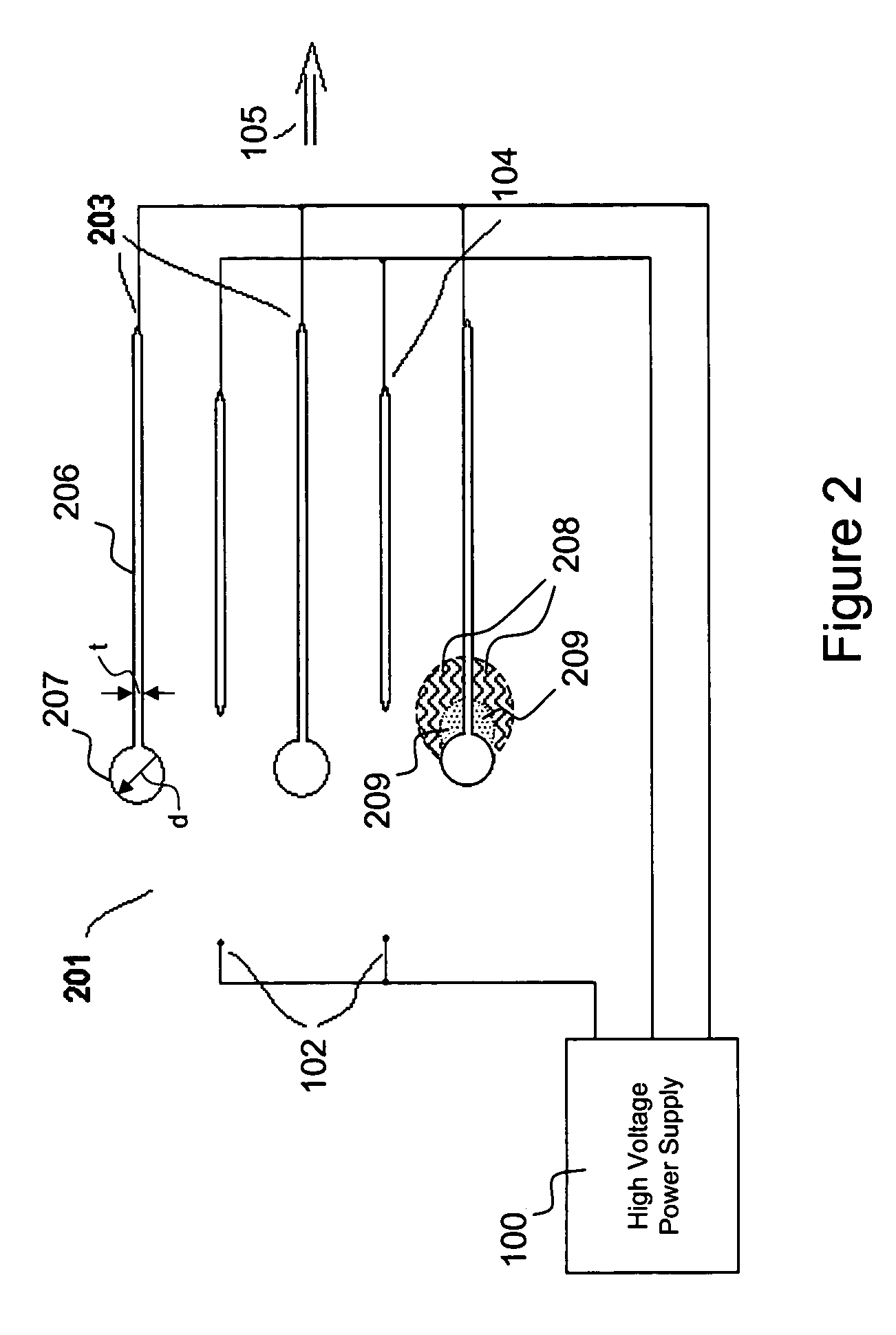

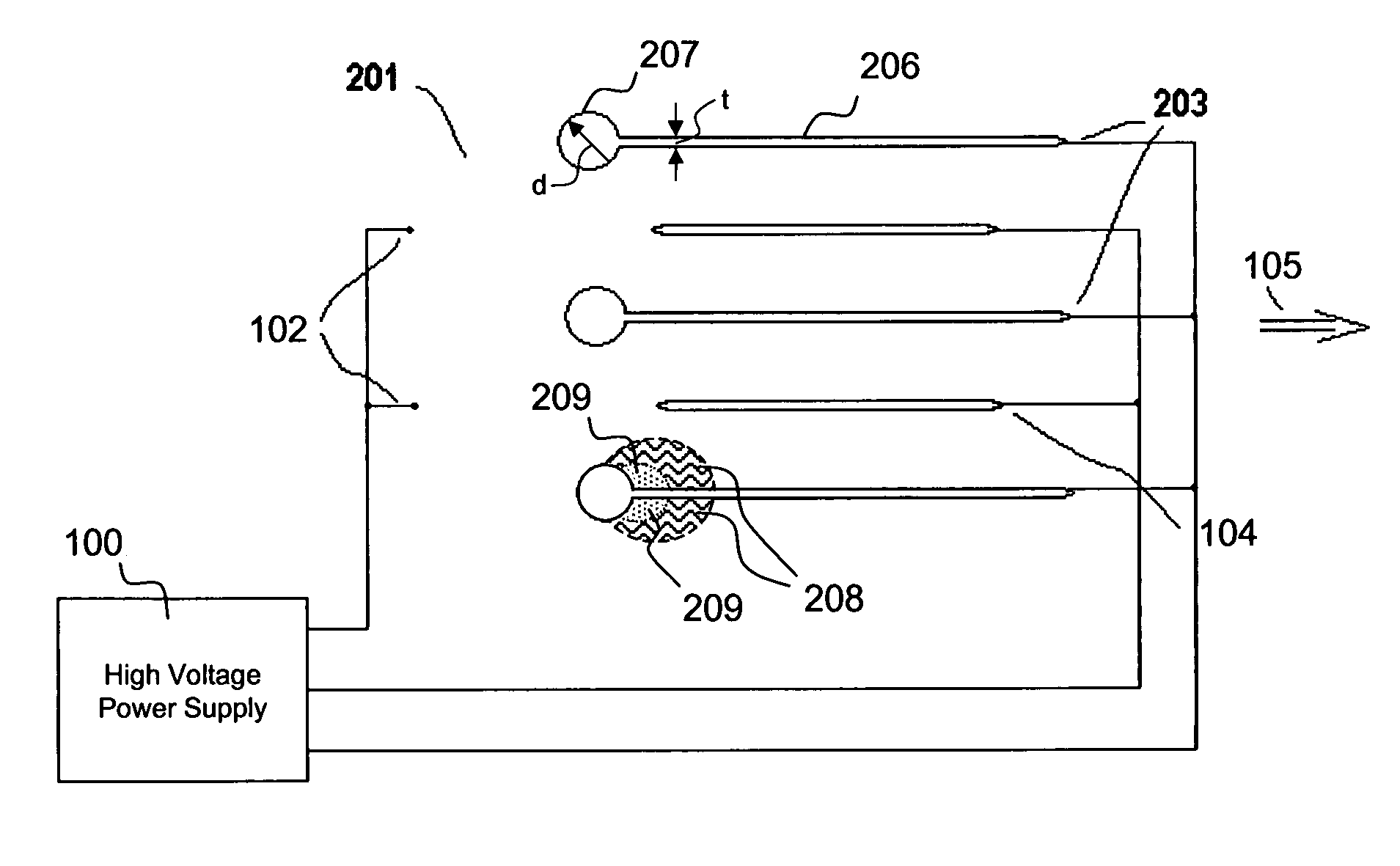

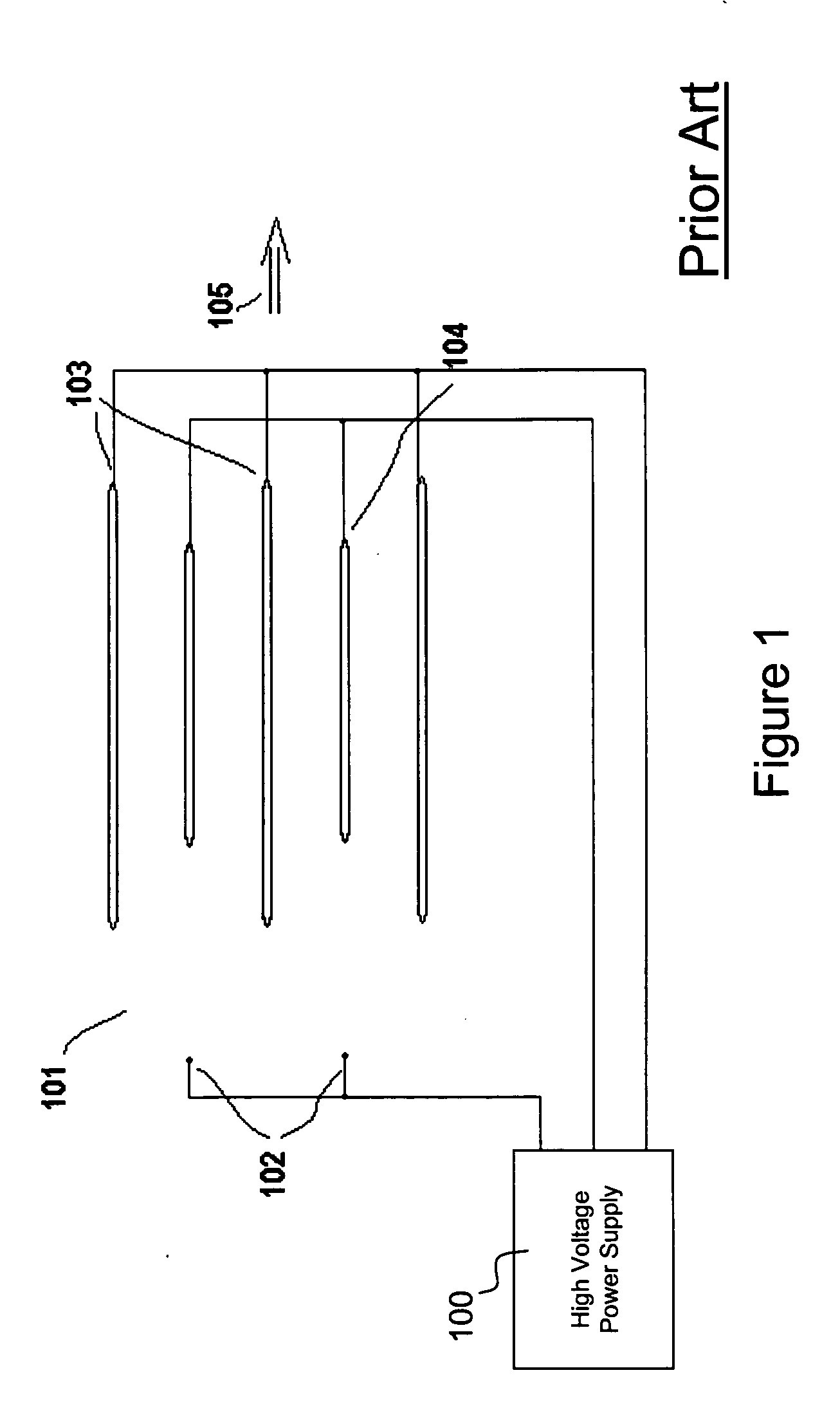

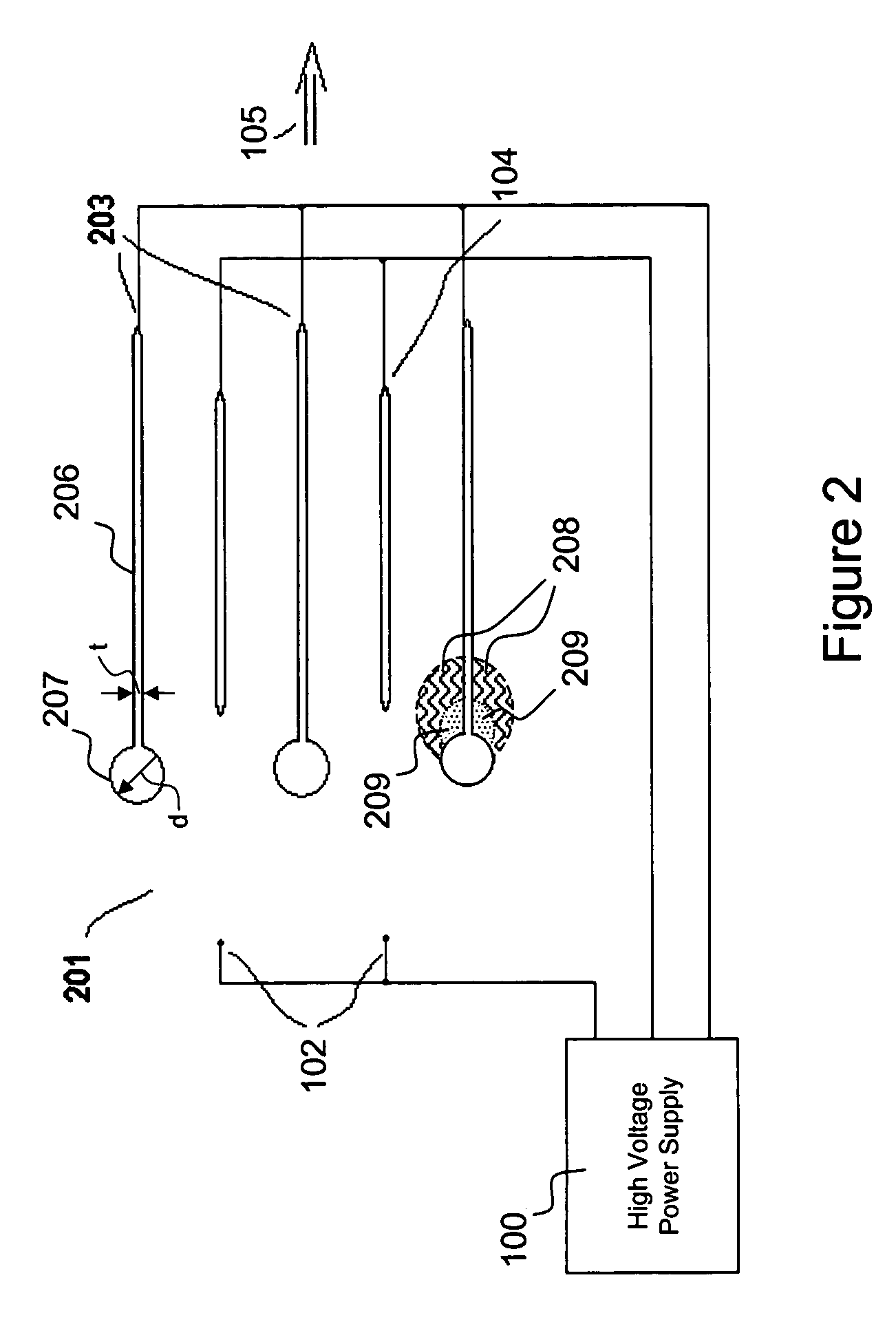

Electrostatic air cleaning device

InactiveUS7150780B2Limiting particulate removalControl speedElectric discharge tubesMaterial analysis by electric/magnetic meansParticulatesCorona discharge

An electrostatic air cleaning device includes an array of electrodes. The electrodes include corona electrodes connected to a suitable source of high voltage so as to generate a corona discharge. Laterally displaced collecting electrodes include one or more bulges that have aerodynamic frontal “upwind” surfaces and airflow disrupting tailing edges downwind that create quite zones for the collection of particulates removed from the air. The bulges may be formed as rounded leading edges on the collecting electrodes and / or as ramped surfaces located, for example, along a midsection of the electrodes. Repelling electrodes positioned between pairs of the collecting electrodes may include similar bulges such as cylindrical or semi-cylindrical leading and / or trailing edges.

Owner:KRONOS ADVANCED TECH

Electrostatic air cleaning device

InactiveUS20050150384A1Limiting particulate removalControl speedElectric discharge tubesMaterial analysis by electric/magnetic meansParticulatesCorona discharge

An electrostatic air cleaning device includes an array of electrodes. The electrodes include corona electrodes connected to a suitable source of high voltage so as to generate a corona discharge. Laterally displaced collecting electrodes include one or more bulges that have aerodynamic frontal “upwind” surfaces and airflow disrupting tailing edges downwind that create quite zones for the collection of particulates removed from the air. The bulges may be formed as rounded leading edges on the collecting electrodes and / or as ramped surfaces located, for example, along a midsection of the electrodes. Repelling electrodes positioned between pairs of the collecting electrodes may include similar bulges such as cylindrical or semicylindrical leading and / or trailing edges.

Owner:KRONOS ADVANCED TECH

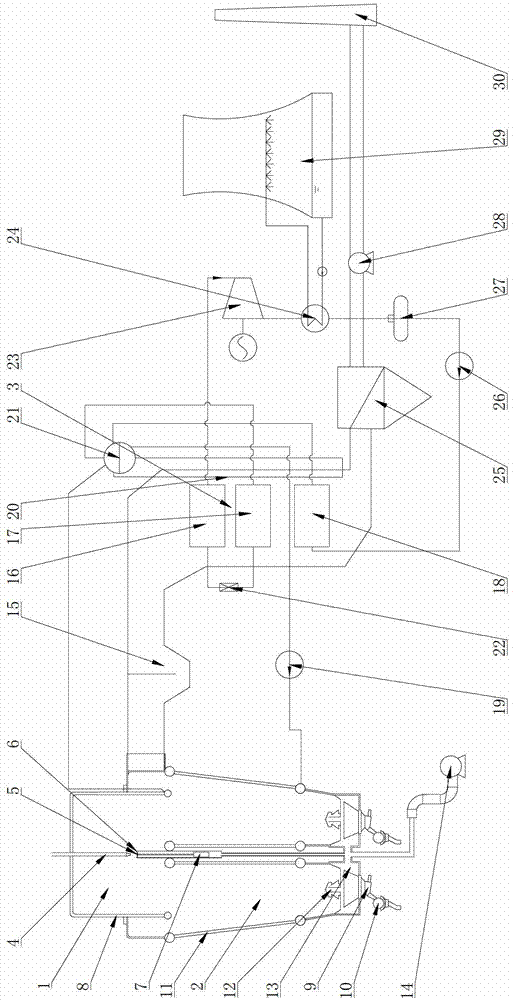

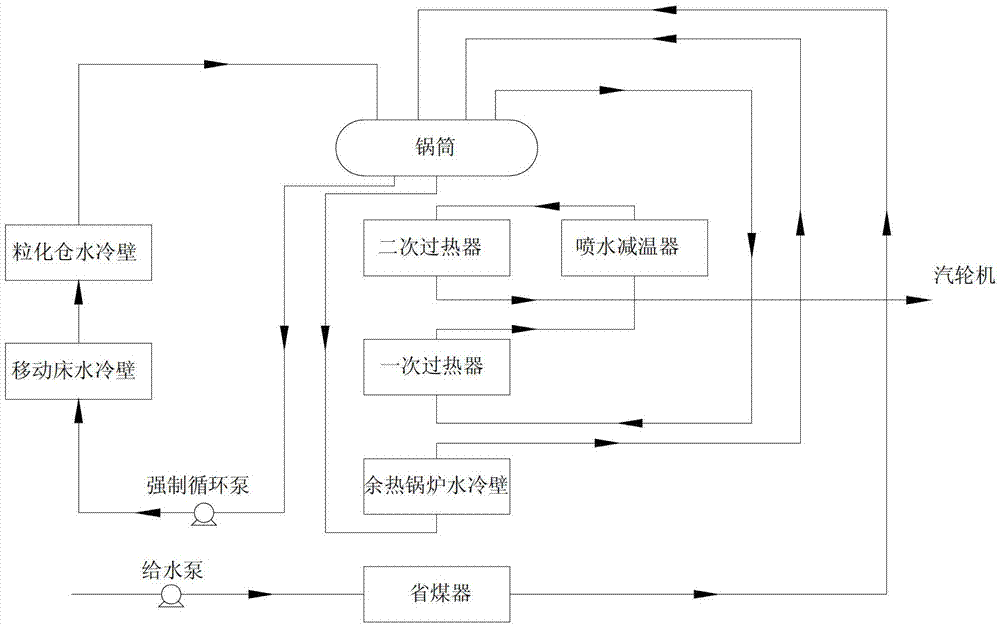

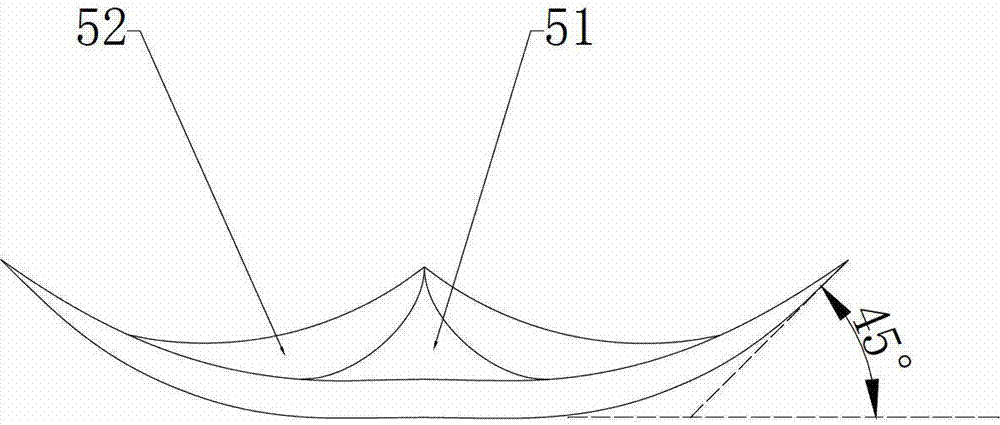

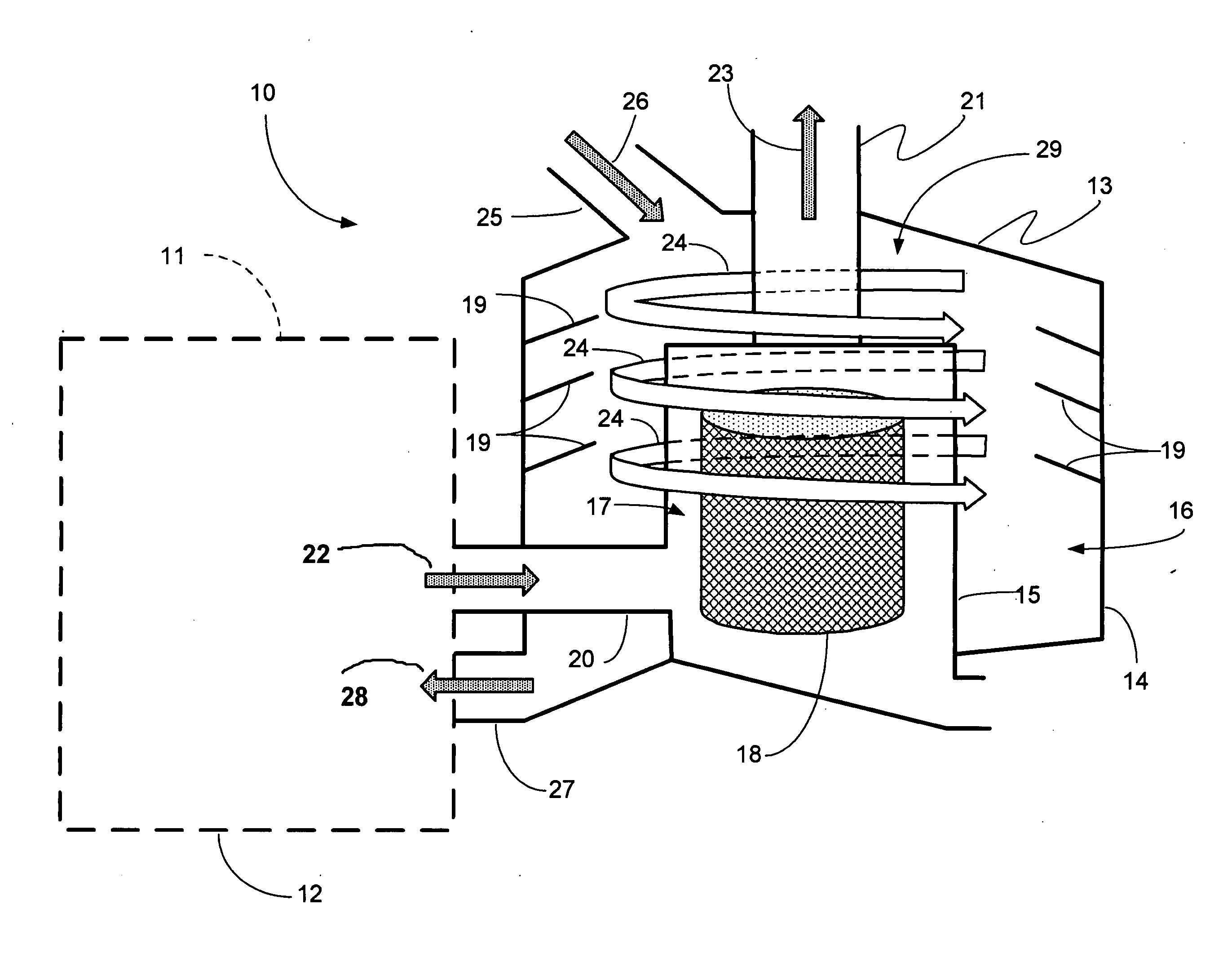

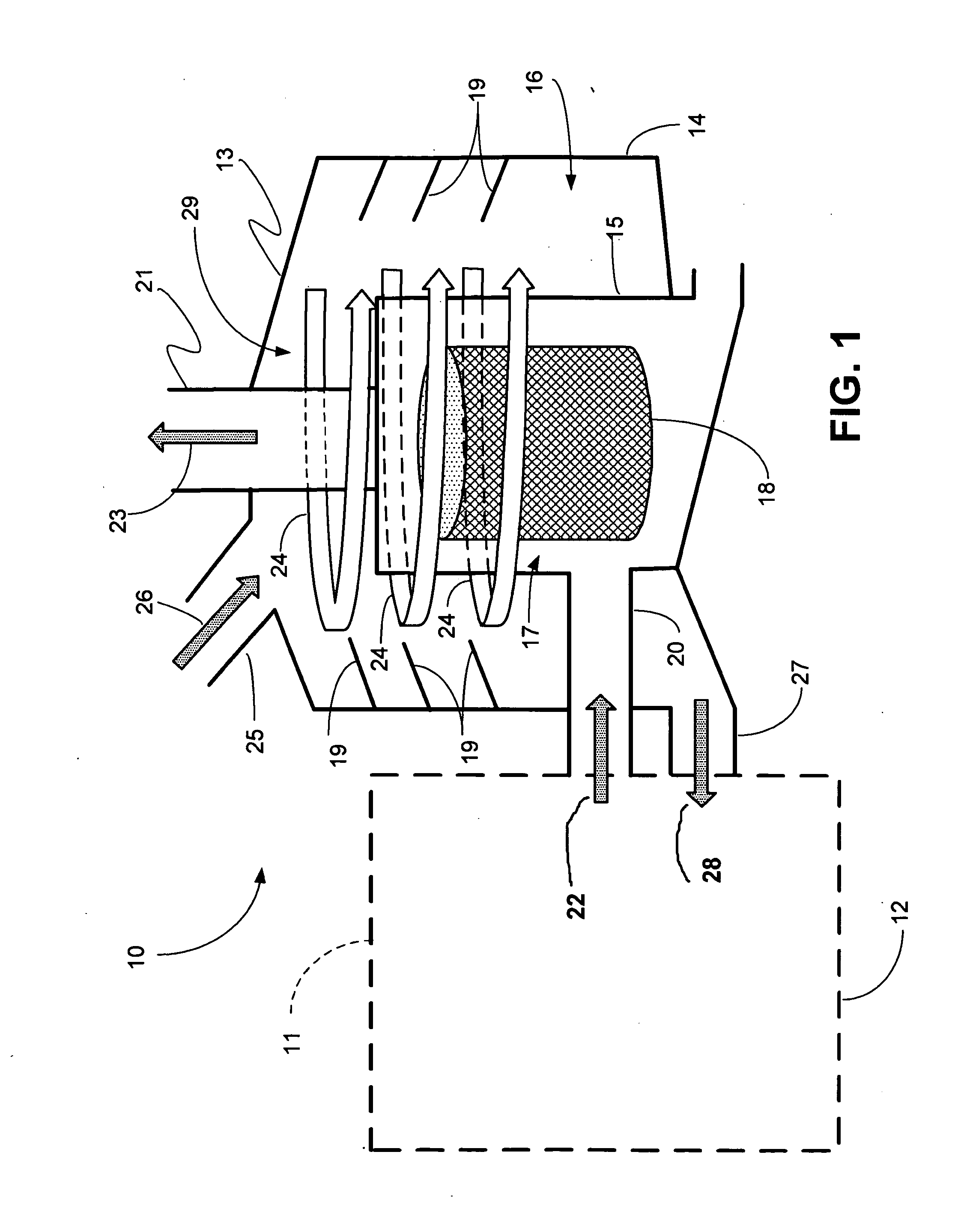

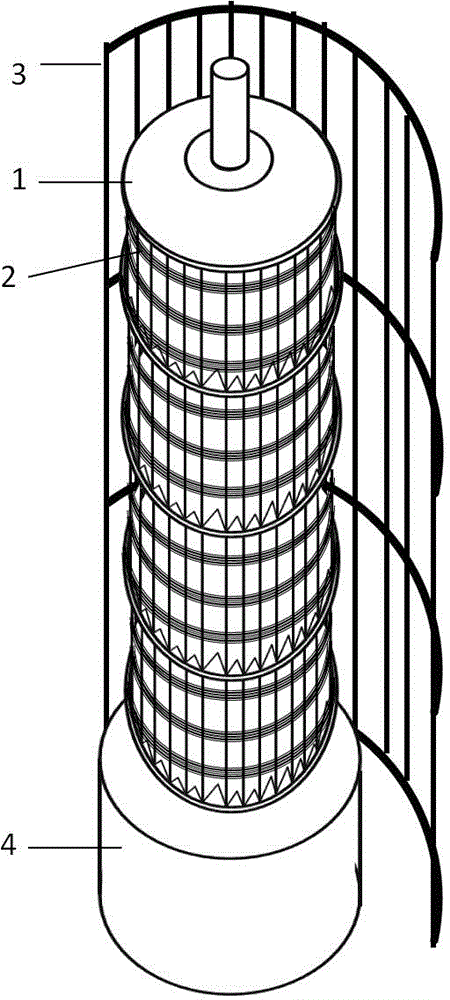

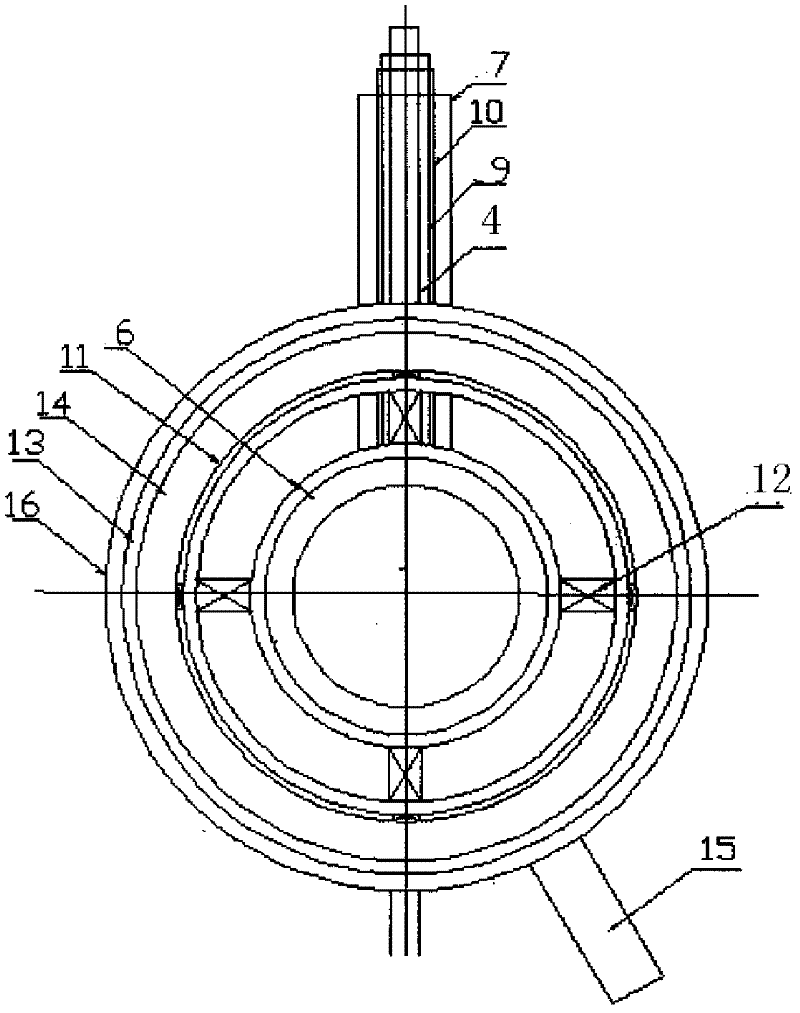

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

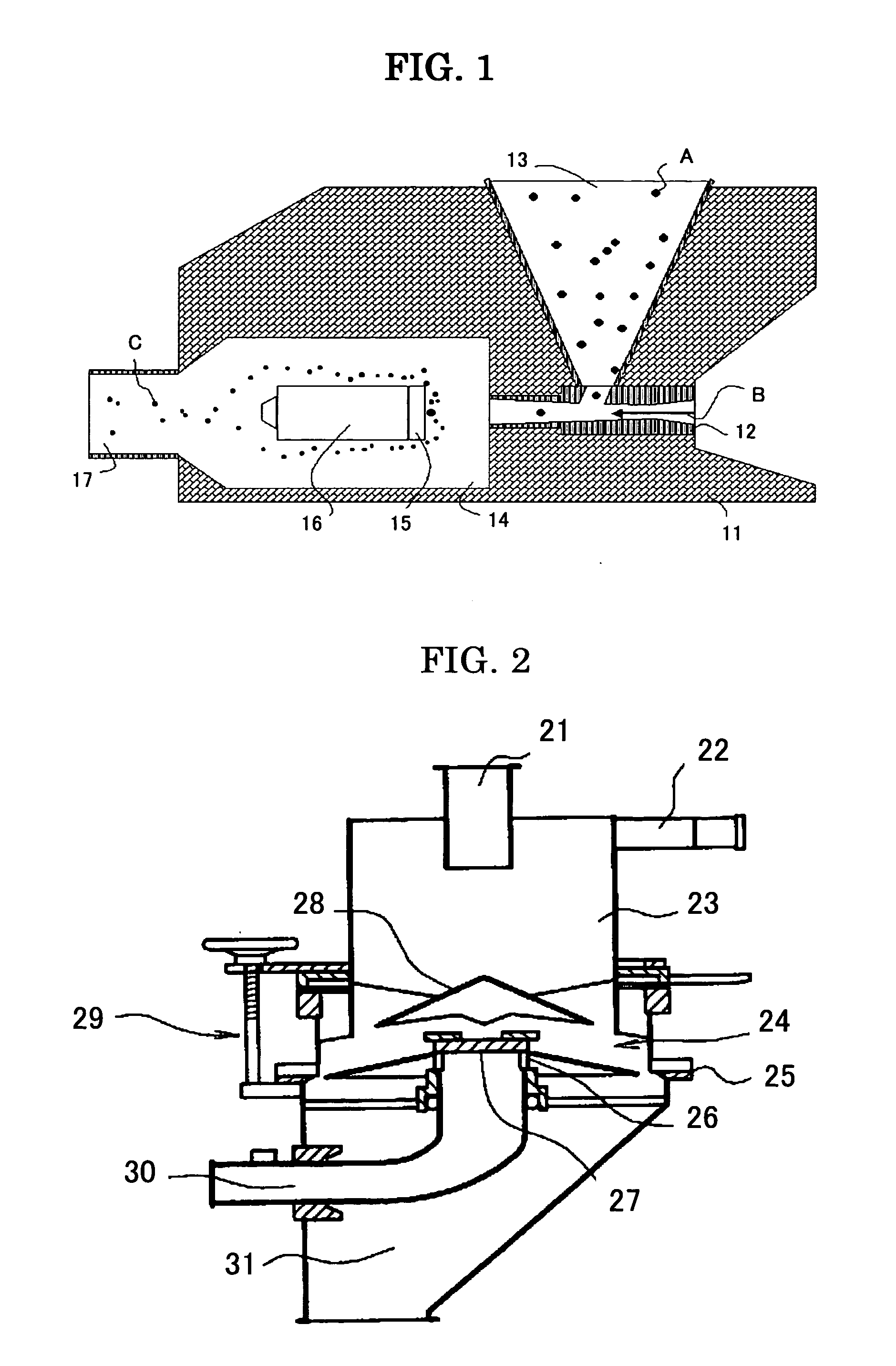

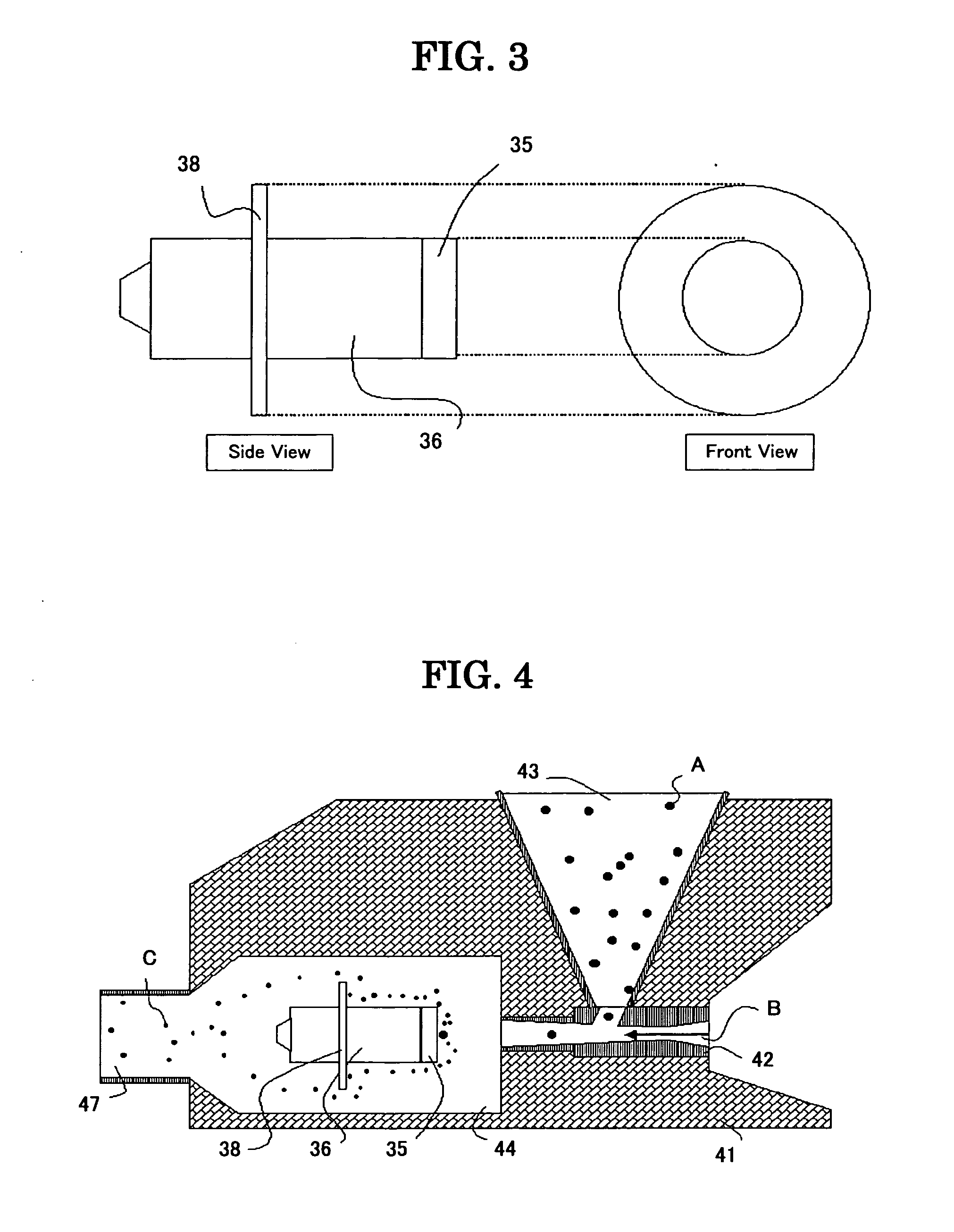

Milling and classifying apparatus, collision mill, air classifier, toner, and method for producing toner

ActiveUS20060032952A1Improve image qualitySmall particle sizeGas current separationDevelopersEngineeringAir classifier

Disclosed is a milling and classifying apparatus, adapted to produce toner fine particles, comprising a collision mill, and an air classifier, wherein the collision mill comprises a jet nozzle room, a path, a collision plate, and a collision member mounted to a support of the collision plate at downstream of the collision plate, the air classifier comprises a dispersion room and a classification room, the classification room is disposed below the dispersion room, and a flow stabilizer is arranged at a central suction of the separator core to control swirl stream generated within the classification room so as to centrifuge the powder into coarse particles and fine particles by action of the swirl stream.

Owner:RICOH KK

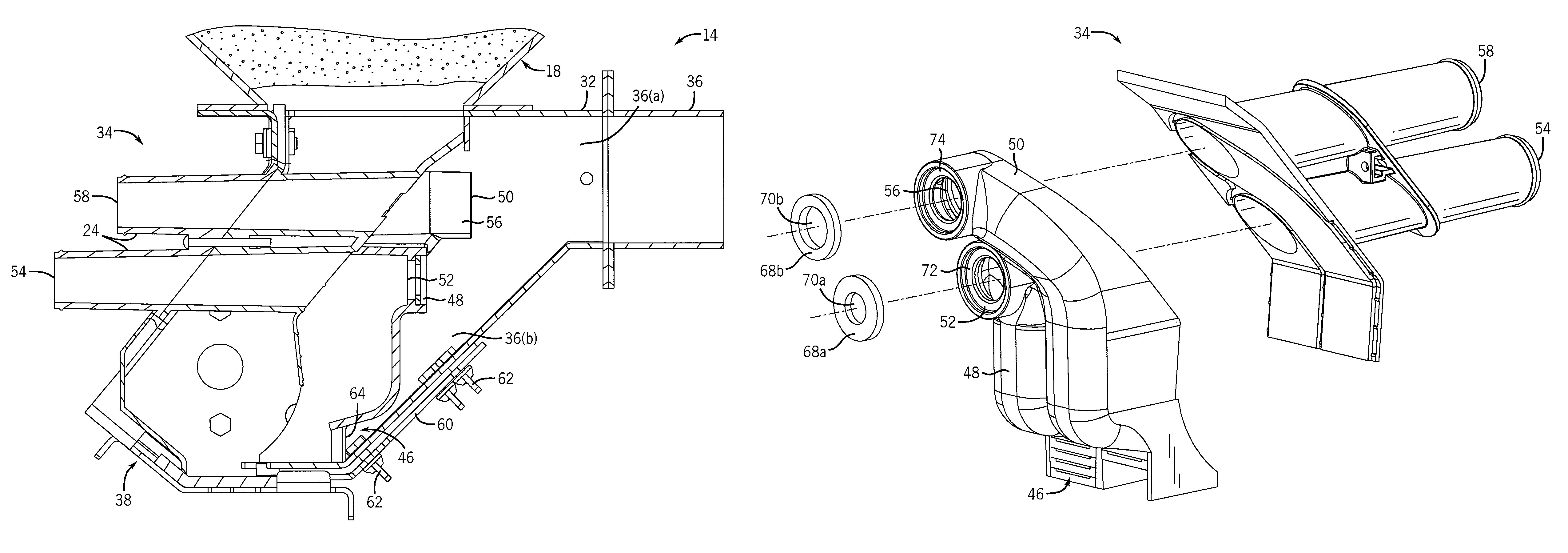

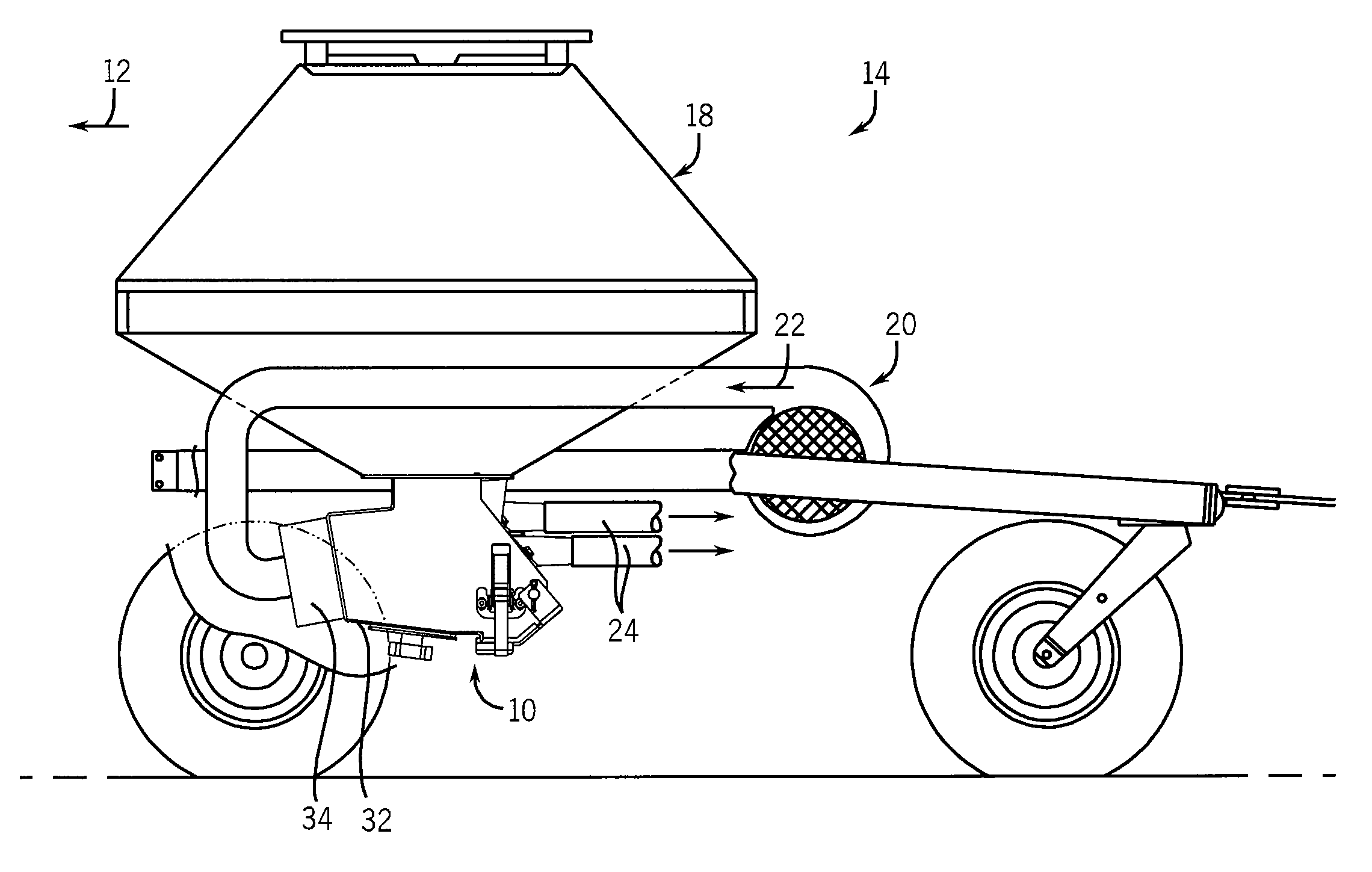

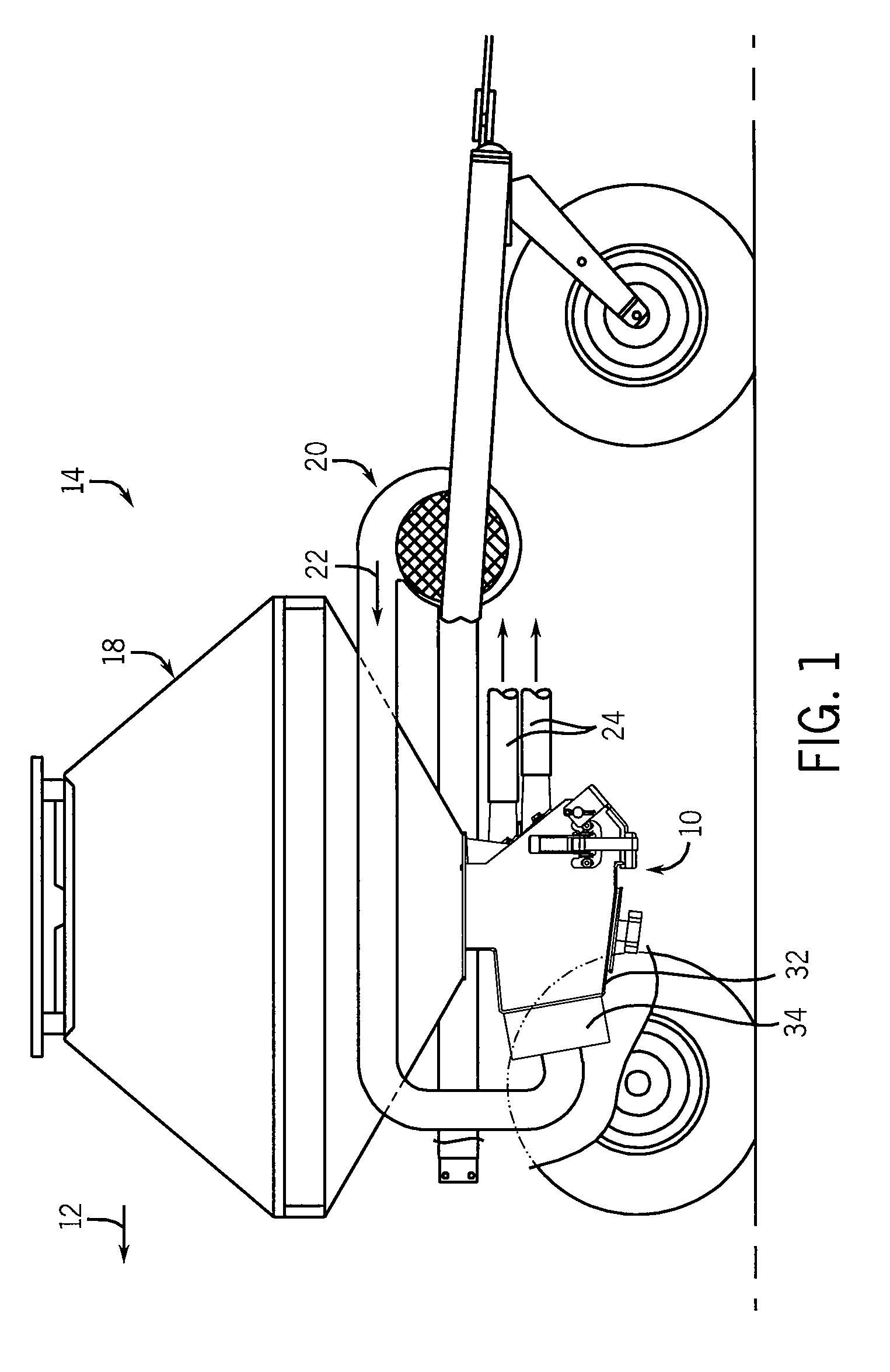

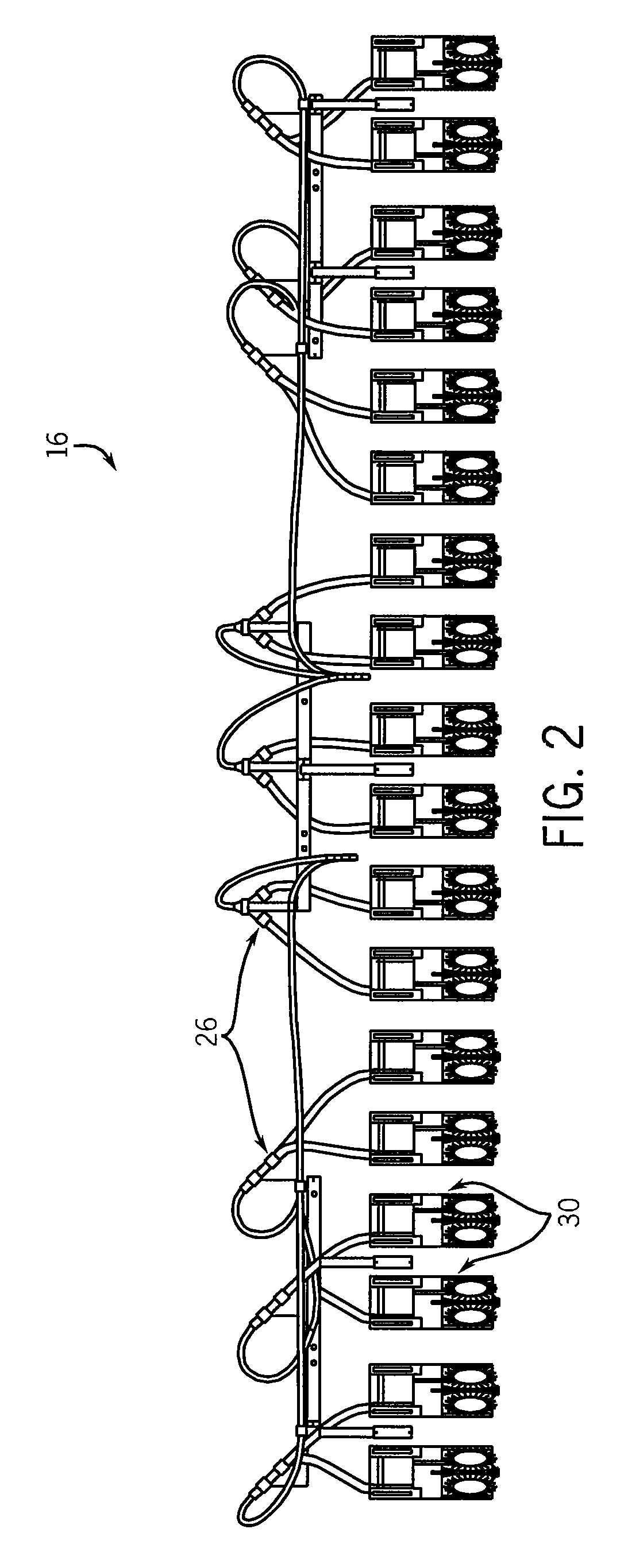

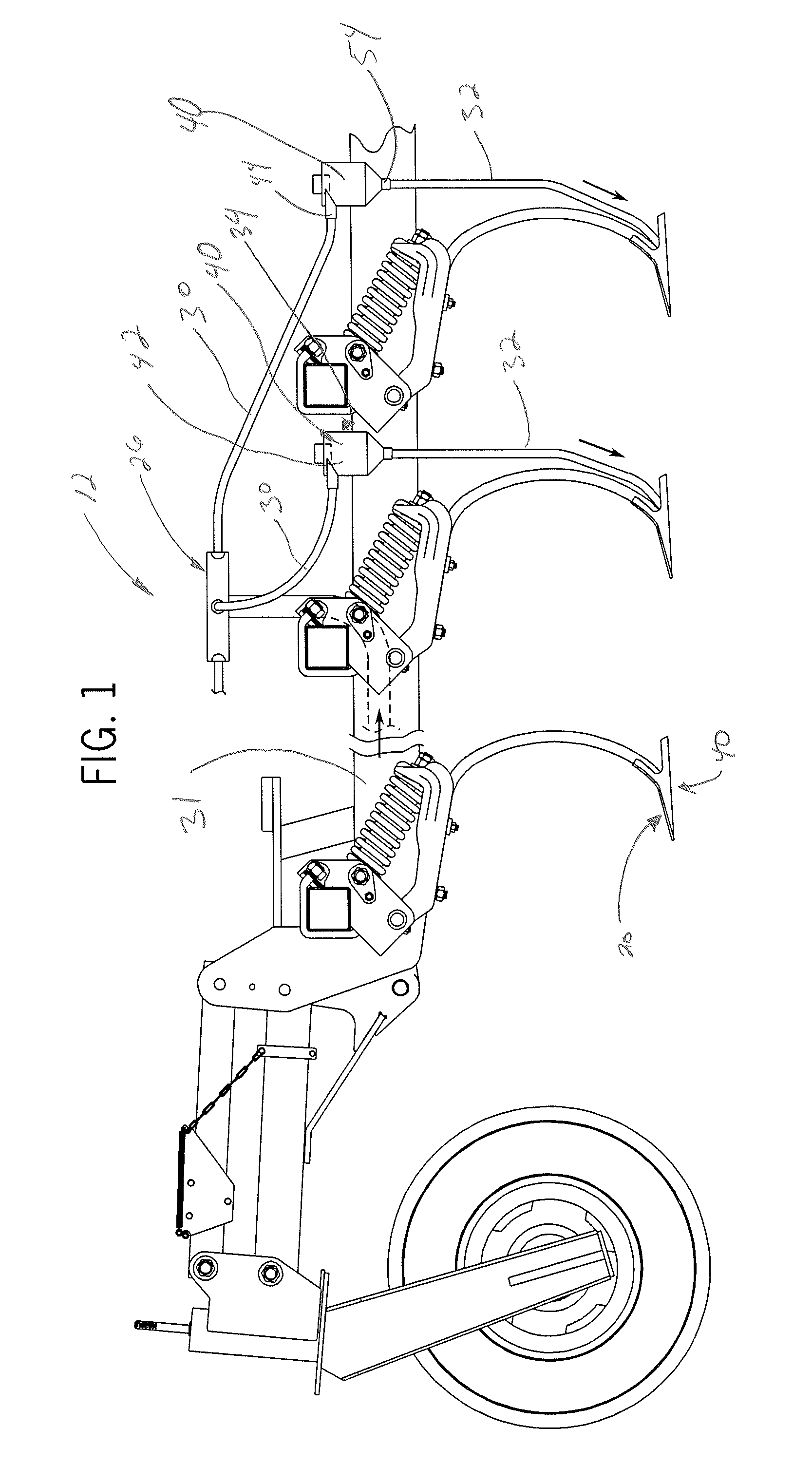

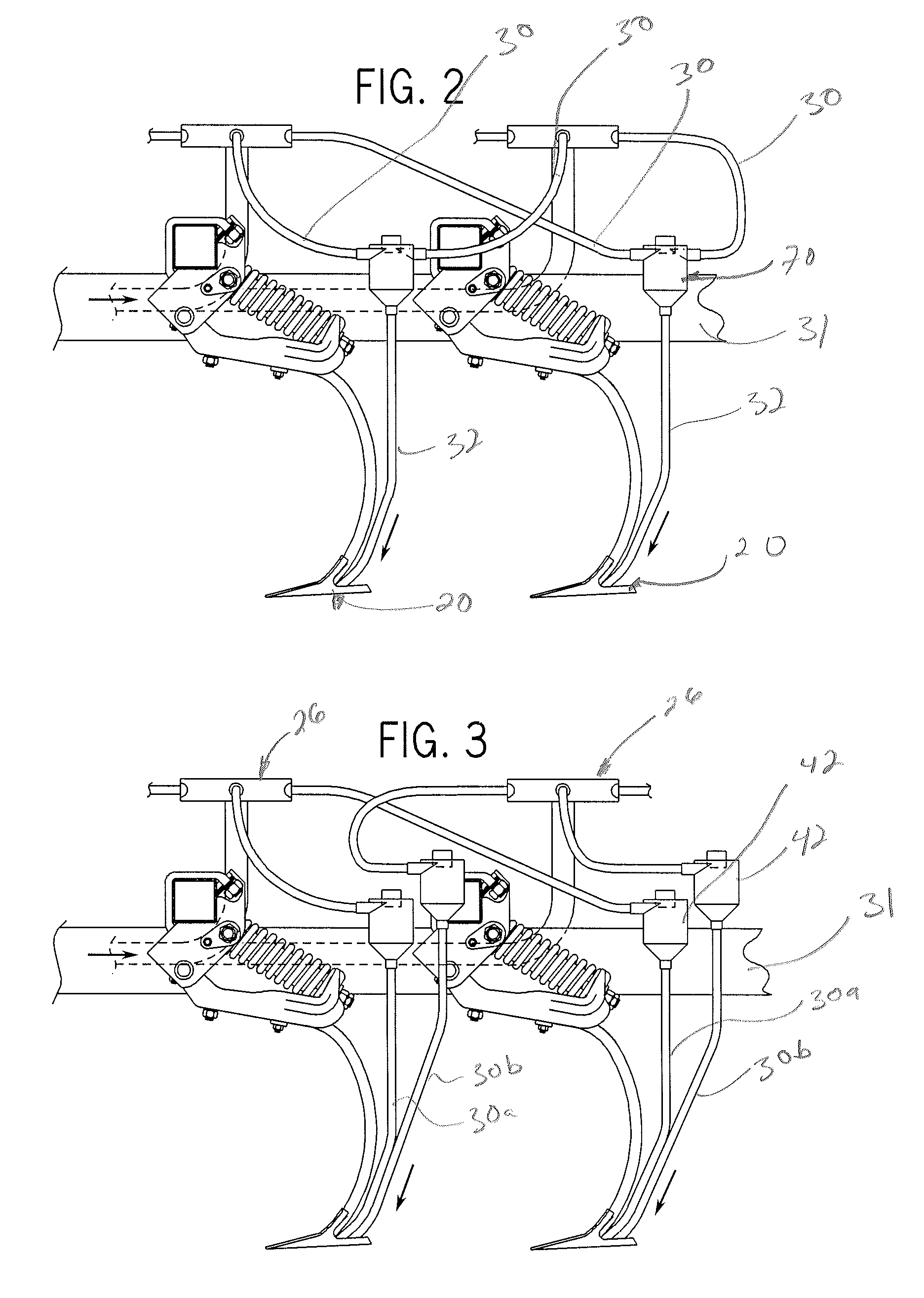

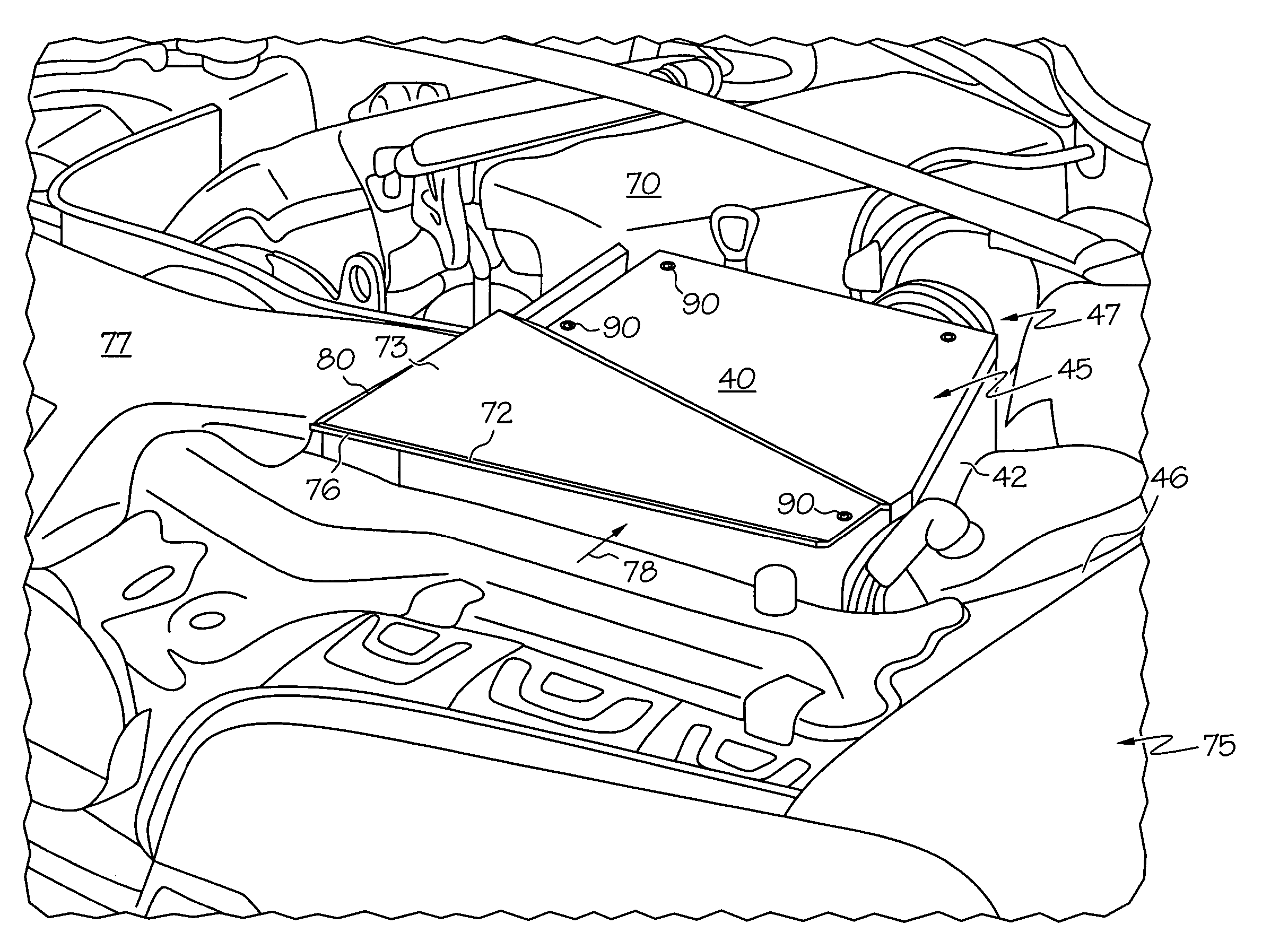

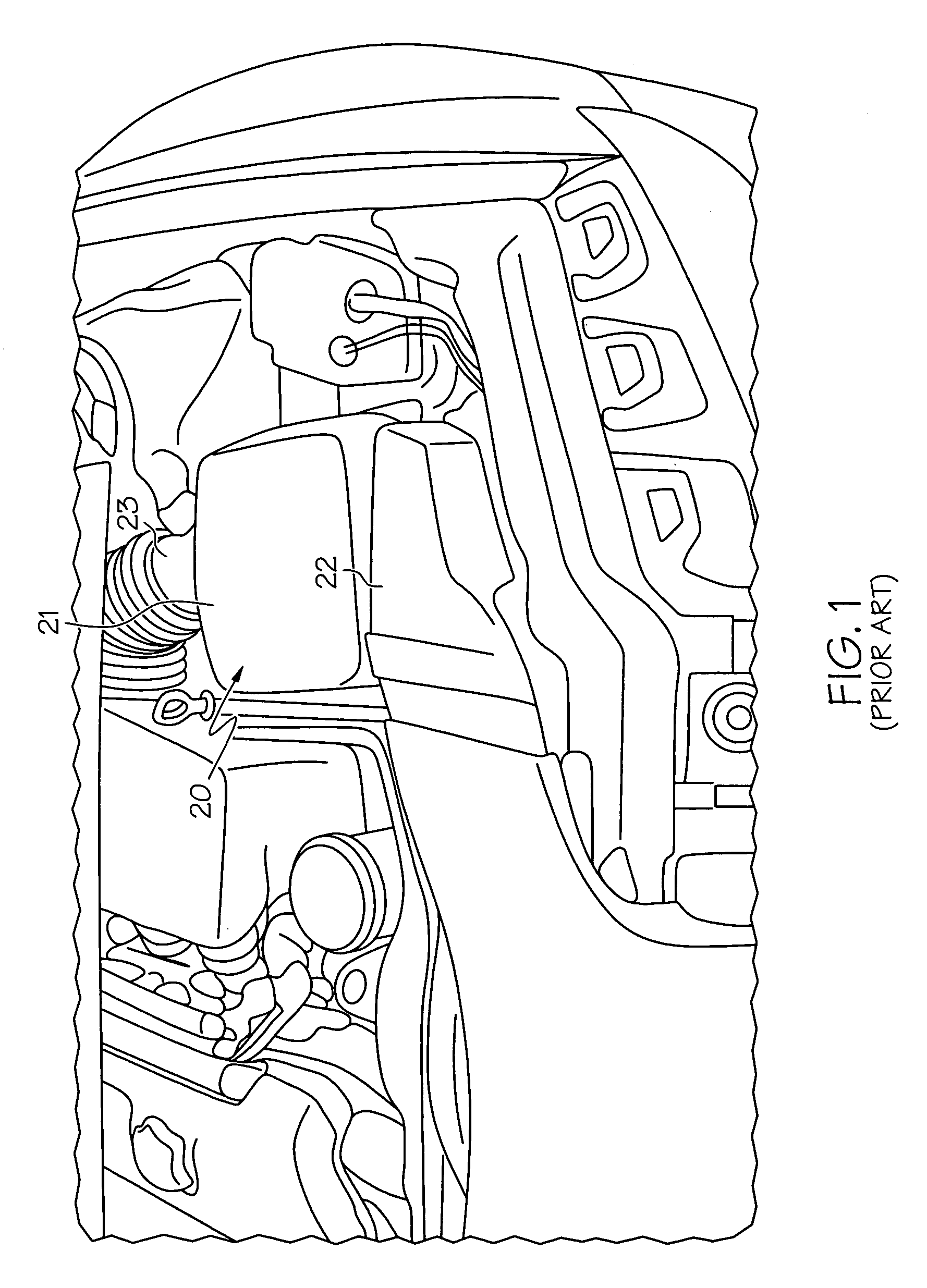

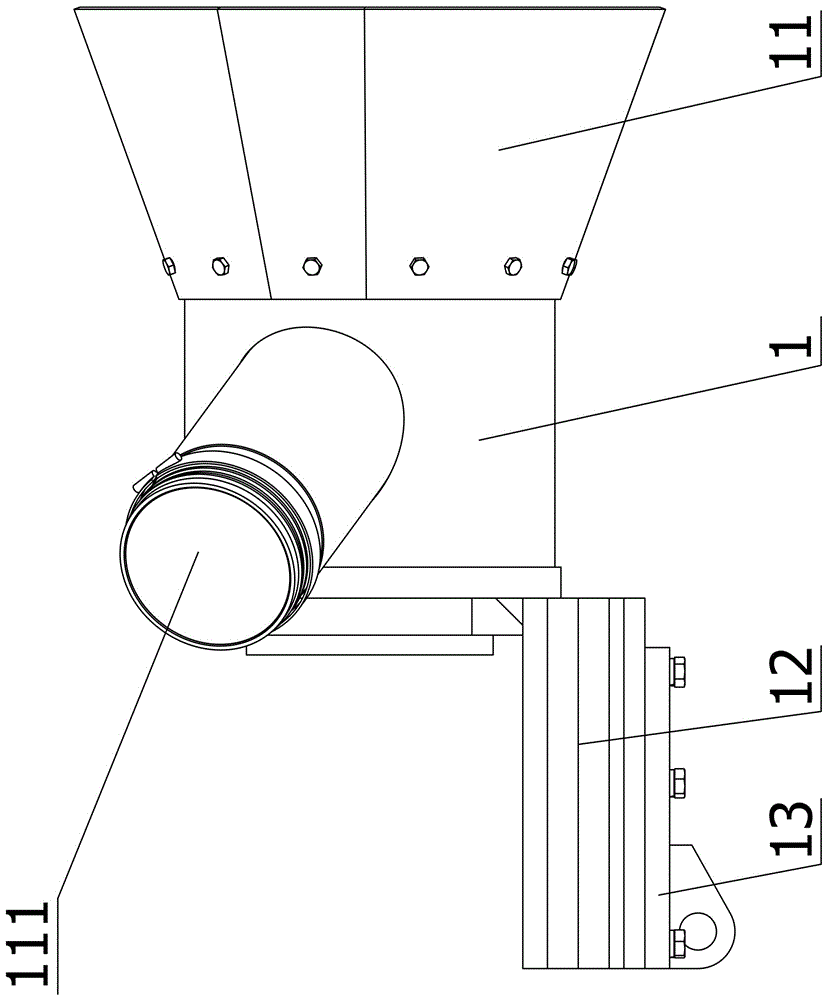

Inductor assembly for a product conveyance system

An inductor assembly is configured to be attached in flow communication to receive a flow of product from a storage hopper of a product conveyance system. The product conveyance system includes a forced fluid source mounted thereon and operable to provide a forced fluid stream to the inductor assembly. The inductor housing includes an inlet configured to direct a first portion of the forced fluid stream in a path to engage the flow of product so as to generate the combined stream of forced fluid and product. The inductor assembly further includes multiple inductor segments, wherein each inductor segments defines at least one conduit having an inlet and an outlet. One or more of the inlets may be configured to restrict air and product flow therethrough.

Owner:CNH IND CANADA

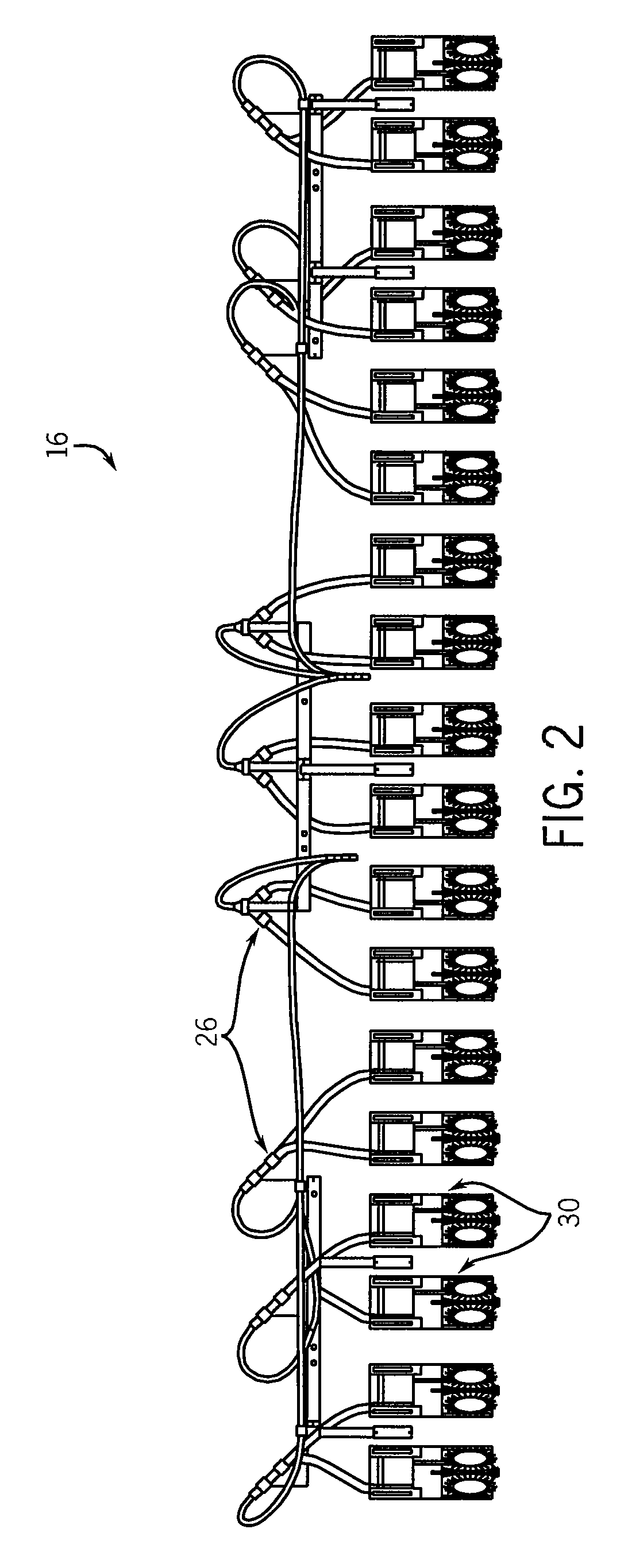

Inductor Assembly For A Product Conveyance System

An inductor assembly is configured to be attached in flow communication to receive a flow of product from a storage hopper of a product conveyance system. The product conveyance system includes a forced fluid source mounted thereon and operable to provide a forced fluid stream to the inductor assembly. The inductor housing includes an inlet configured to direct a first portion of the forced fluid stream in a path to engage the flow of product so as to generate the combined stream of forced fluid and product. The inductor assembly further includes multiple inductor segments, wherein each inductor segments defines at least one conduit having an inlet and an outlet. One or more of the inlets may be configured to restrict air and product flow therethrough.

Owner:CNH IND CANADA

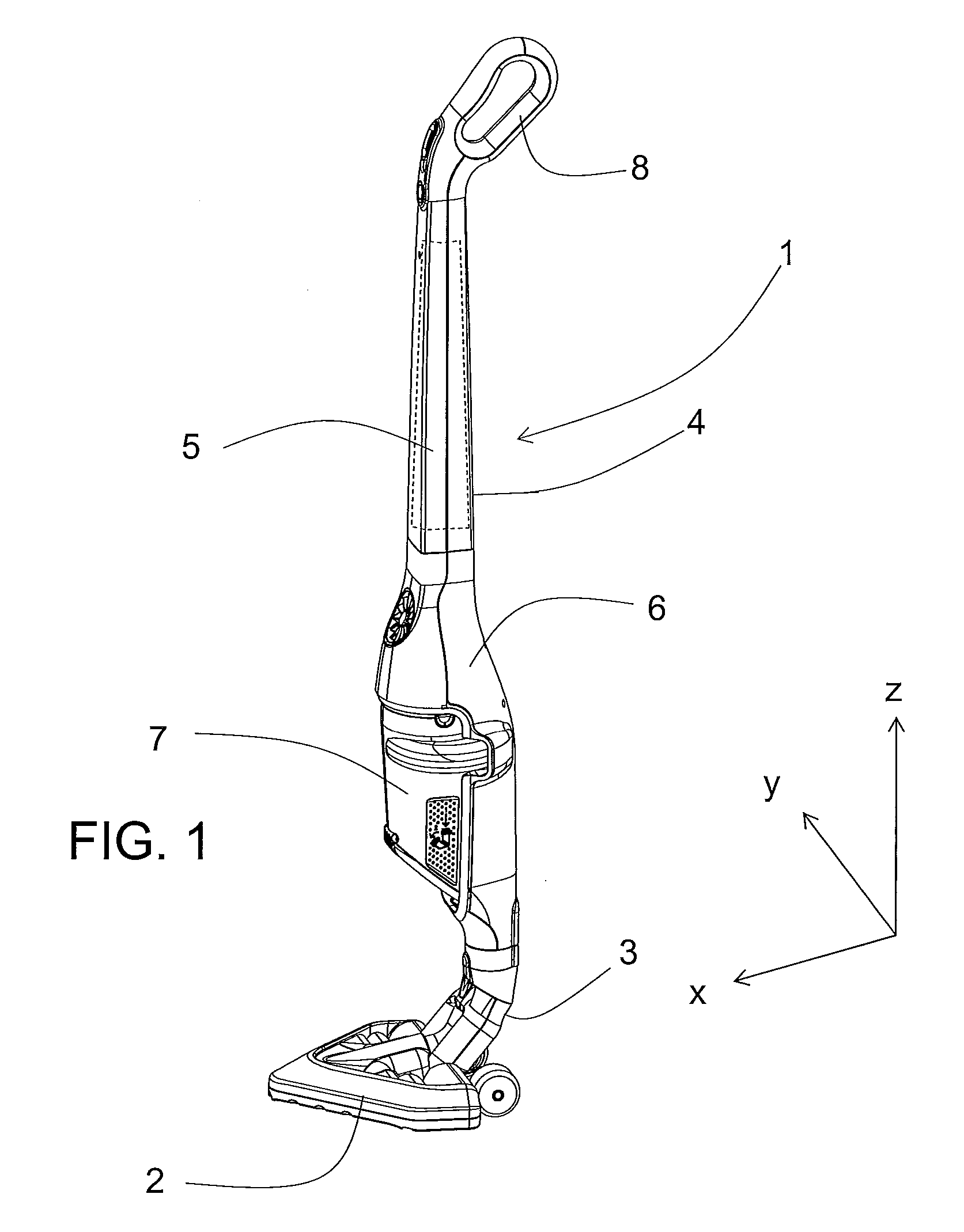

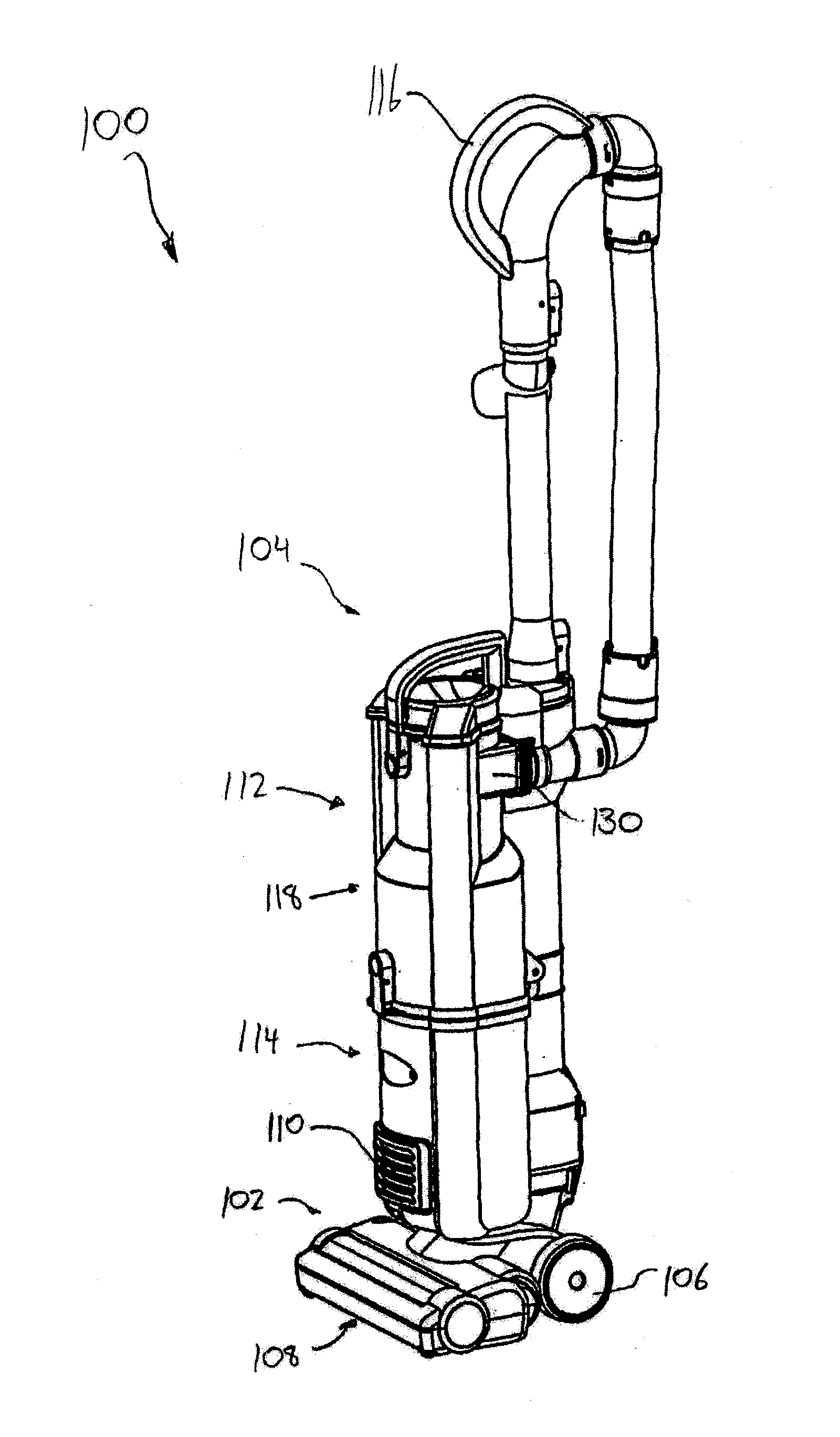

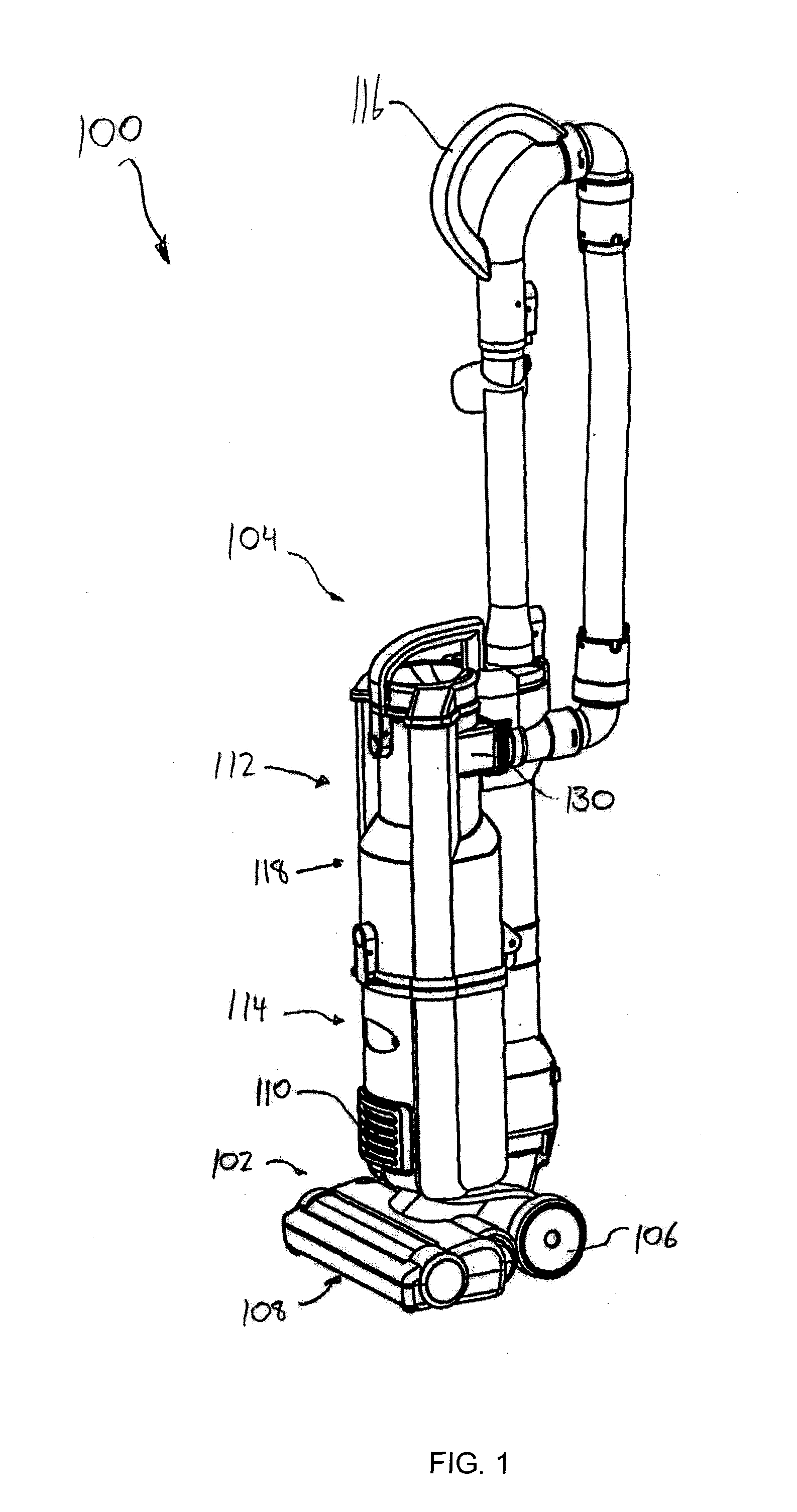

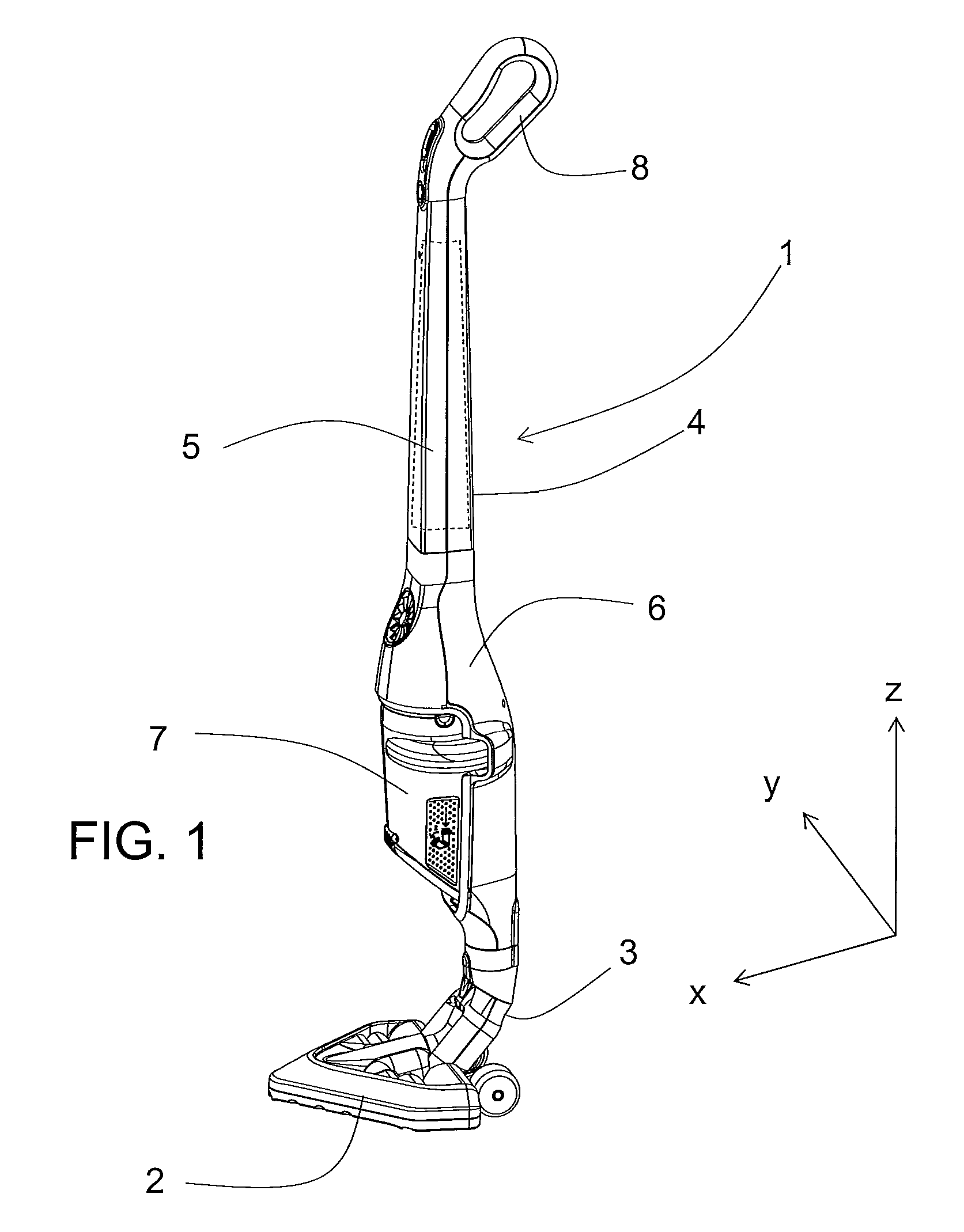

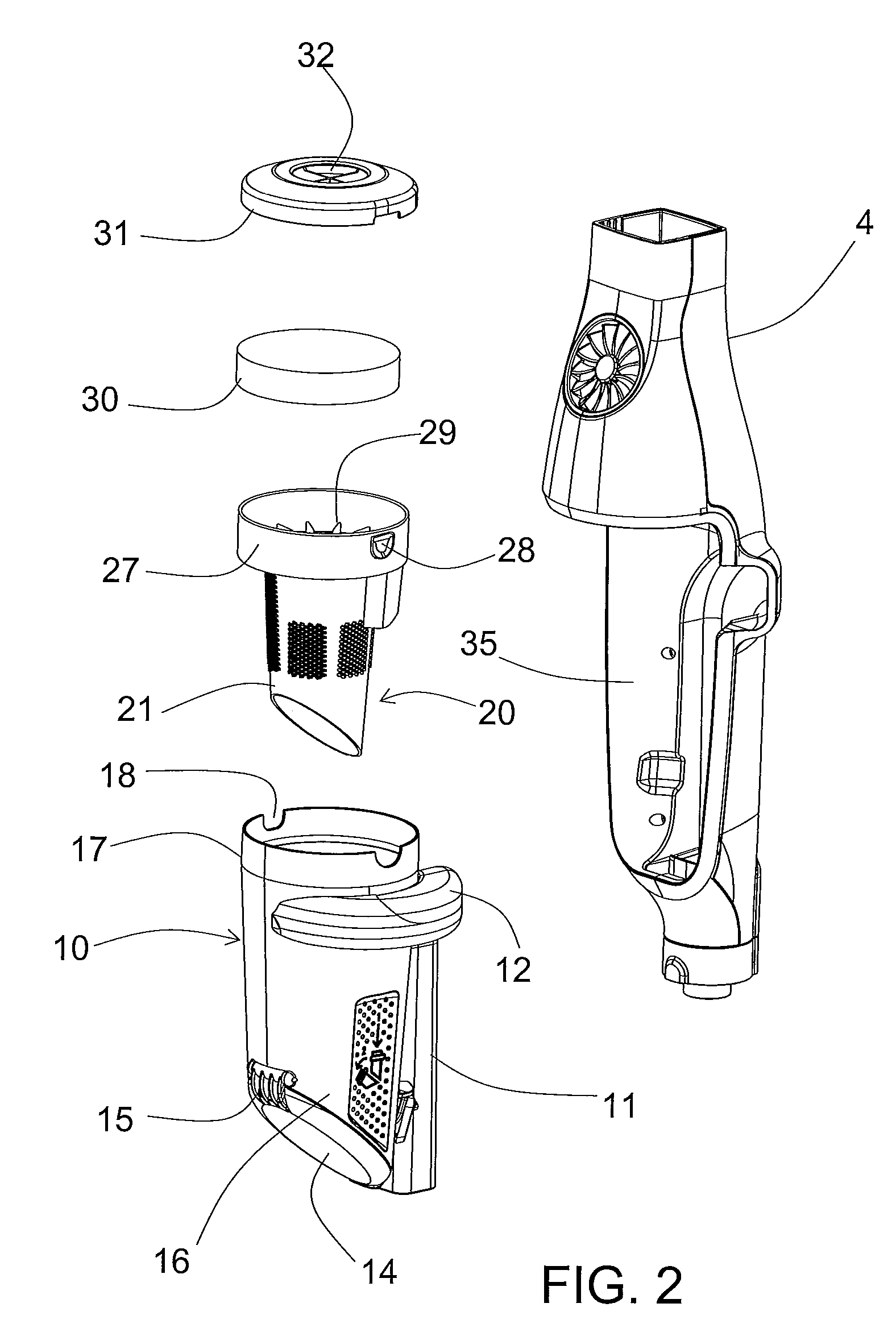

Surface Cleaning Apparatus

ActiveUS20140053367A1Improve performanceReduce air velocityCleaning filter meansSuction filtersCycloneSurface cleaning

A surface cleaning apparatus comprises an air flow path extending from a dirty air inlet to a clean air outlet and includes a suction motor. The surface cleaning apparatus may be battery powered and / or may have a power requirement of 200 Watts or less. A cyclone chamber is provided in the air flow path and has an air outlet which is covered by a screen. In one embodiment, there is an absence of a vortex finder. In another embodiment, a vortex finder that extends into the cyclone chamber less than the height of the cyclone inlet and optionally less than the height of the cyclone inlet may be provided.

Owner:OMACHRON INTPROP

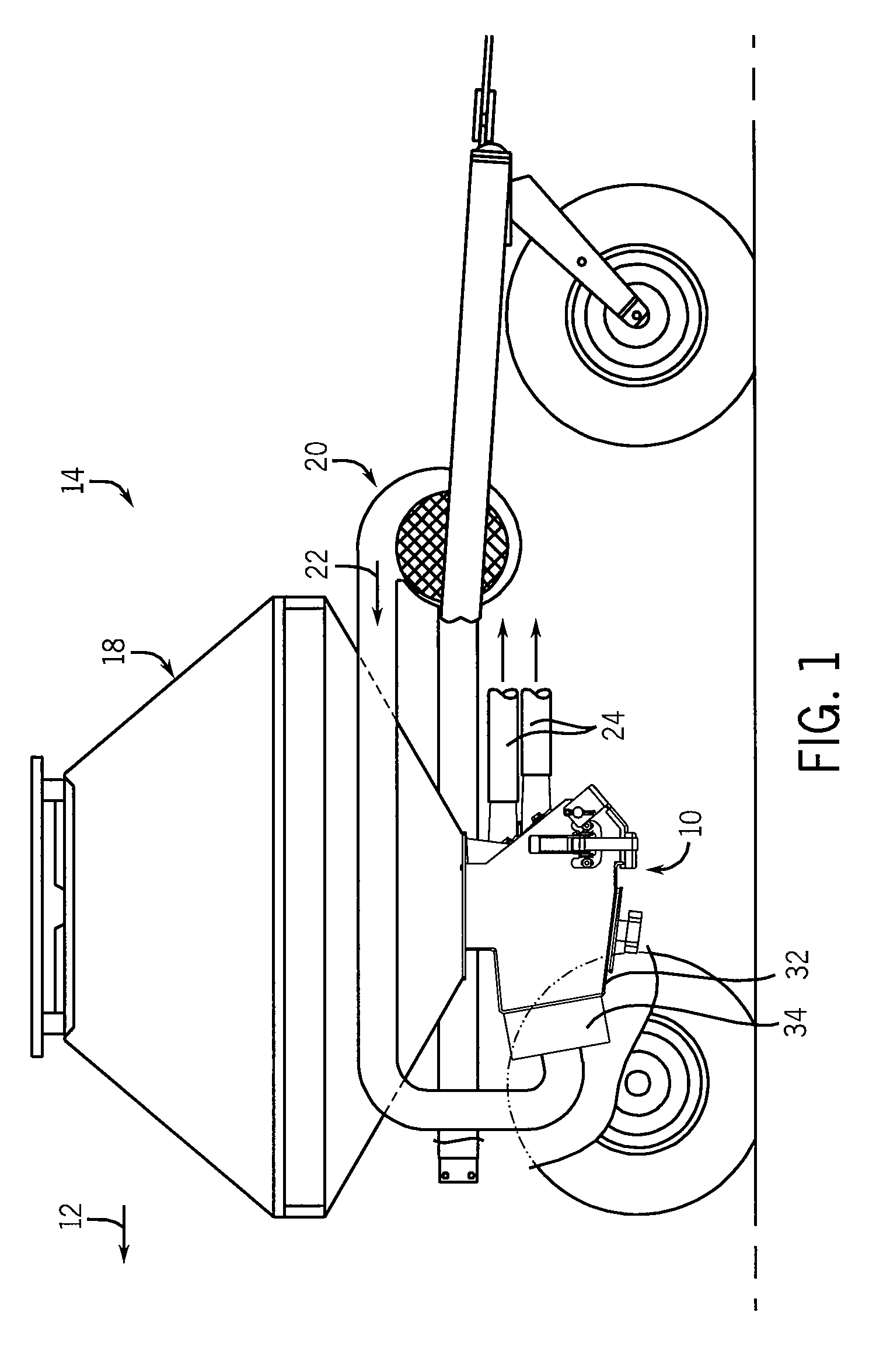

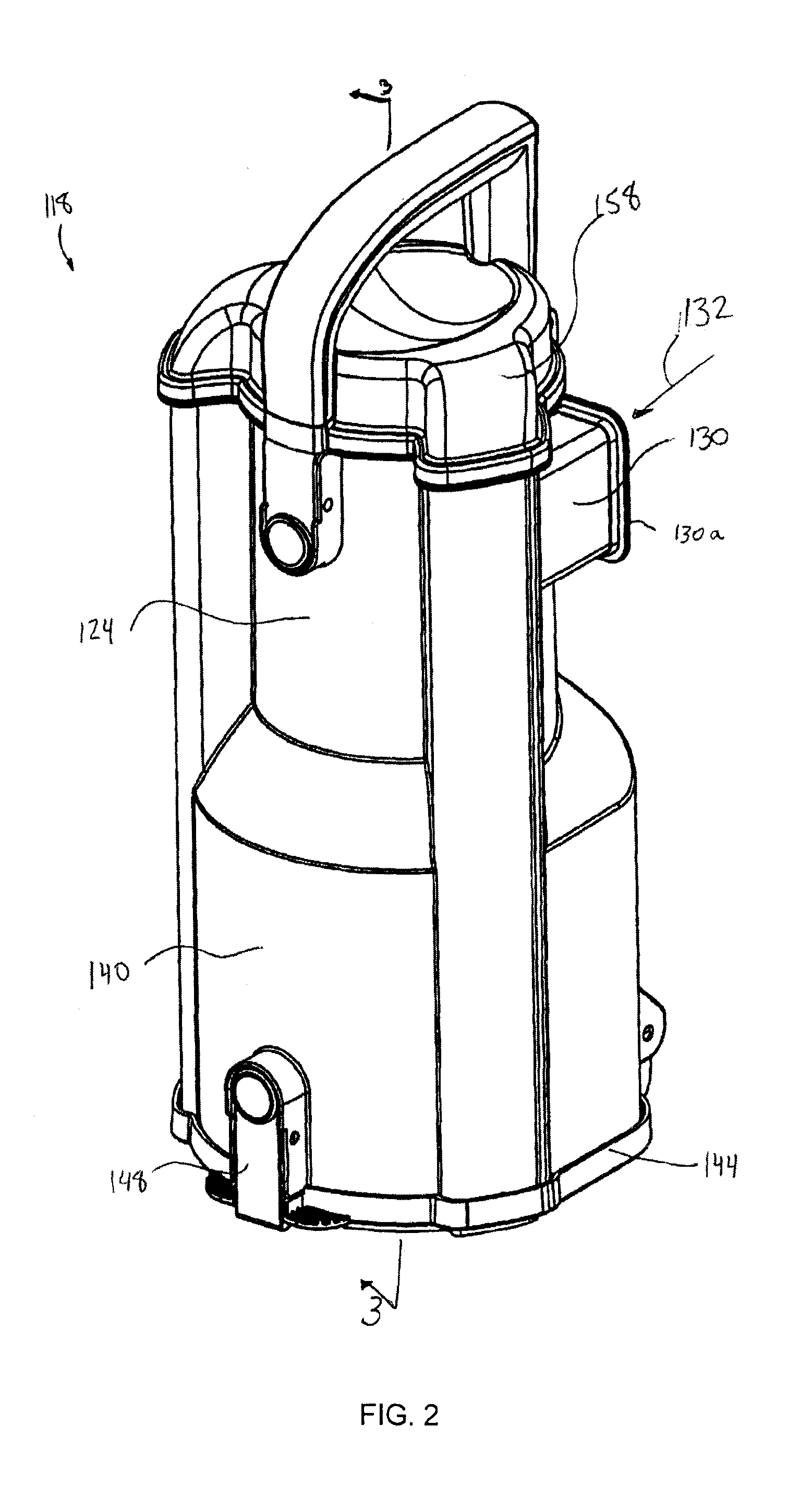

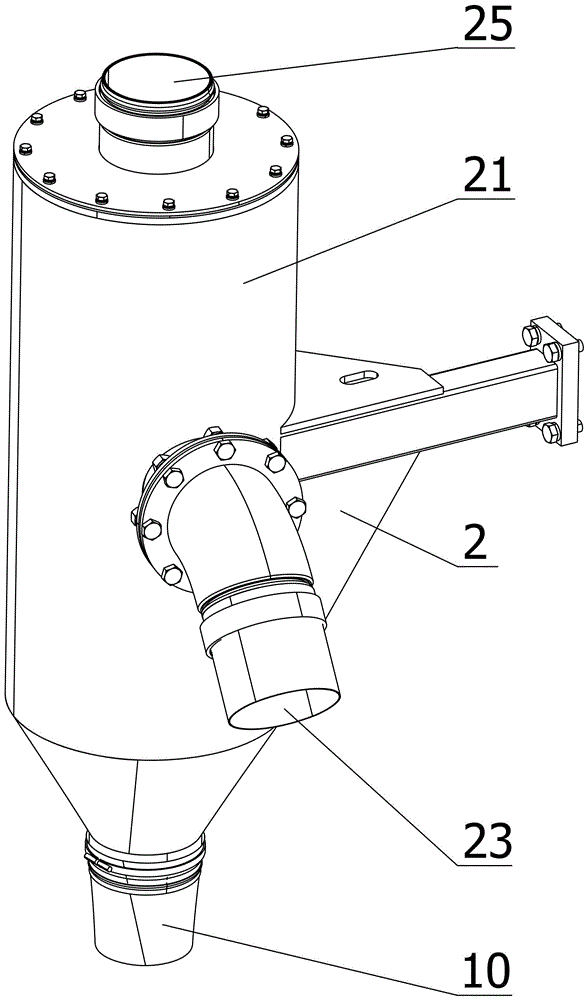

Cyclone assisted product delivery system for soil openers

A pneumatic agricultural product delivery system configured to reduce the velocity of agricultural product entering a furrow is disclosed. The system includes at least one product supply chamber, a furrow opening device configured to engage the ground to create a furrow, a plurality of tubes providing an interior passage extending from the product supply chamber to a cyclone rigidly mounted to the tool bar. A pneumatic pressure source is pneumatically coupled to the interior passage to supply pressurized air to the interior passage to move product within the interior passage and a product placement tube extends from an outlet of the cyclone to a location adjacent the furrow opening device.

Owner:CNH IND CANADA

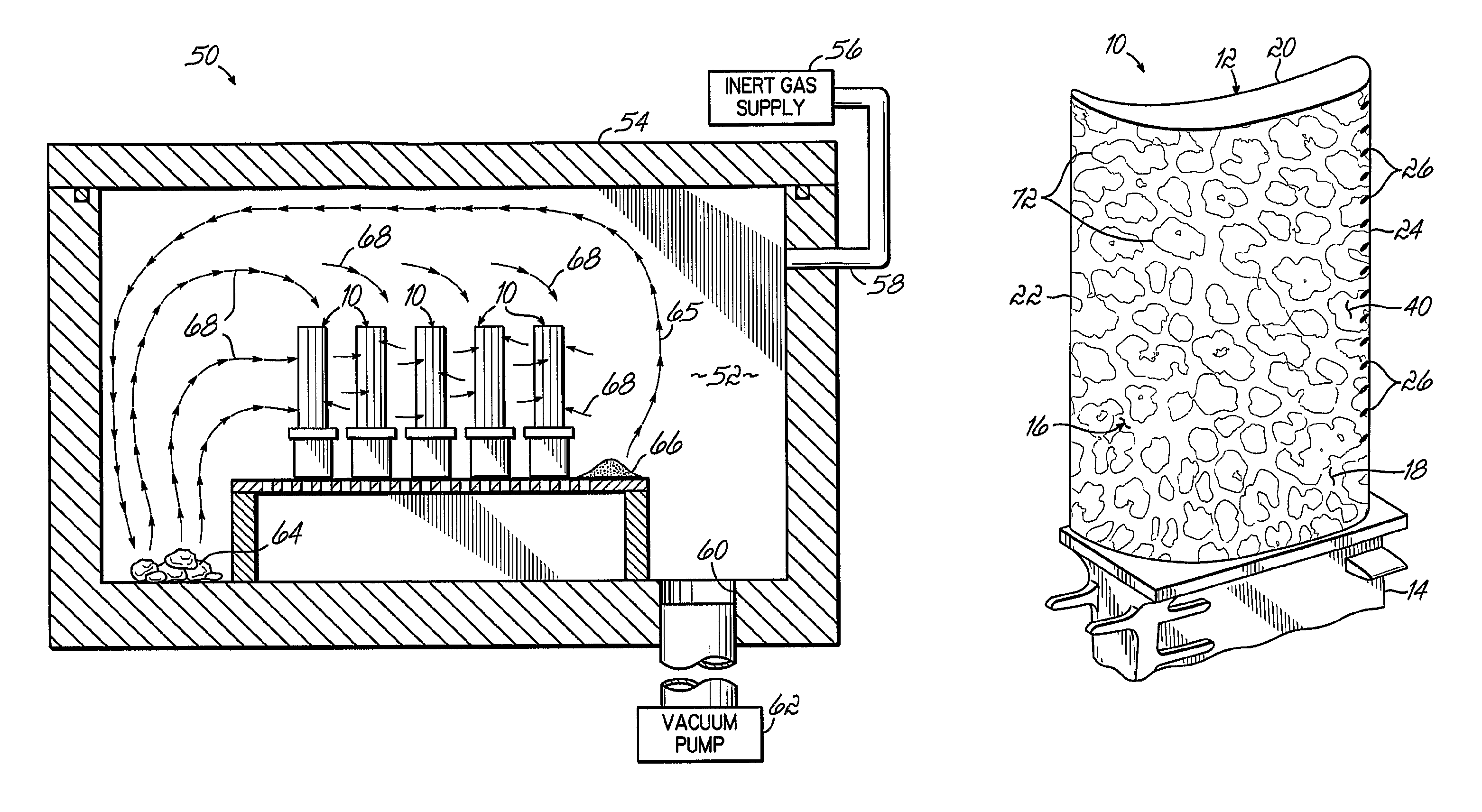

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS8579999B2Improve efficiencyIncrease heatDrying solid materials with heatSolid fuelsFluidized bed dryingMoisture

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

Clothes dryer apparatus with improved lint removal system

InactiveUS20090255145A1Maximize contact timeMaximize energy transferDrying solid materials with heatDrying gas arrangementsFiltrationPulp and paper industry

A method and apparatus for removing lint from air that is discharged from a clothes dryer uses a lint filtration housing mounted on the frame of the clothes dryer, the filtration housing having an interior that contains a filter for removing lint from the dryer exhaust air flow stream. The housing provides an influent fitting for transmitting heating exhaust air from the drying chamber to the housing interior. An ambient air supply enables ambient air to be added to the filtration housing interior. One or more vanes is provided that create an annular vortex within the filtration housing interior. The flow of the annular vortex within the filtration housing interior can be between about 500 and 3,000 cubic feet per second. A flow line transmits pre-heated air from the filtration housing interior to the dryer interior.

Owner:PELLERIN MILNOR

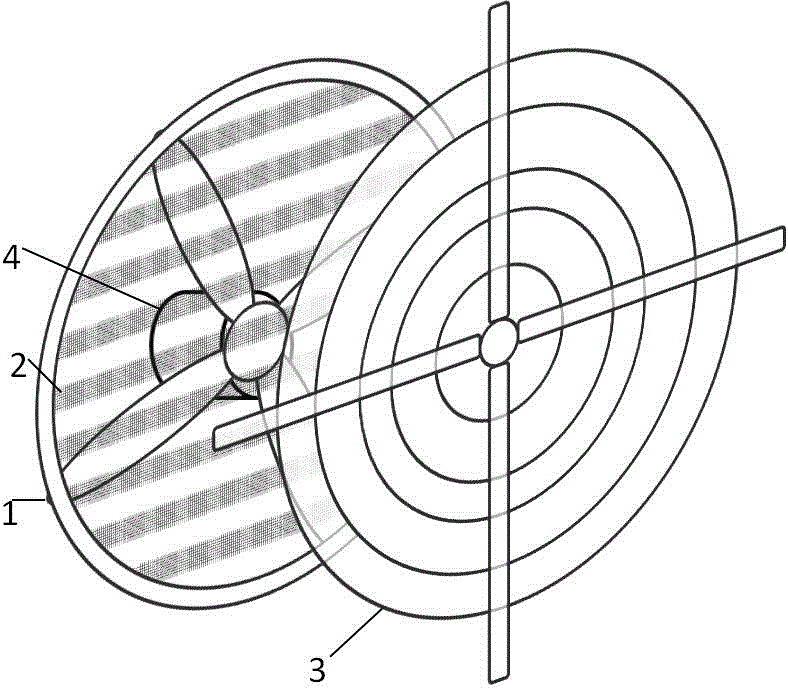

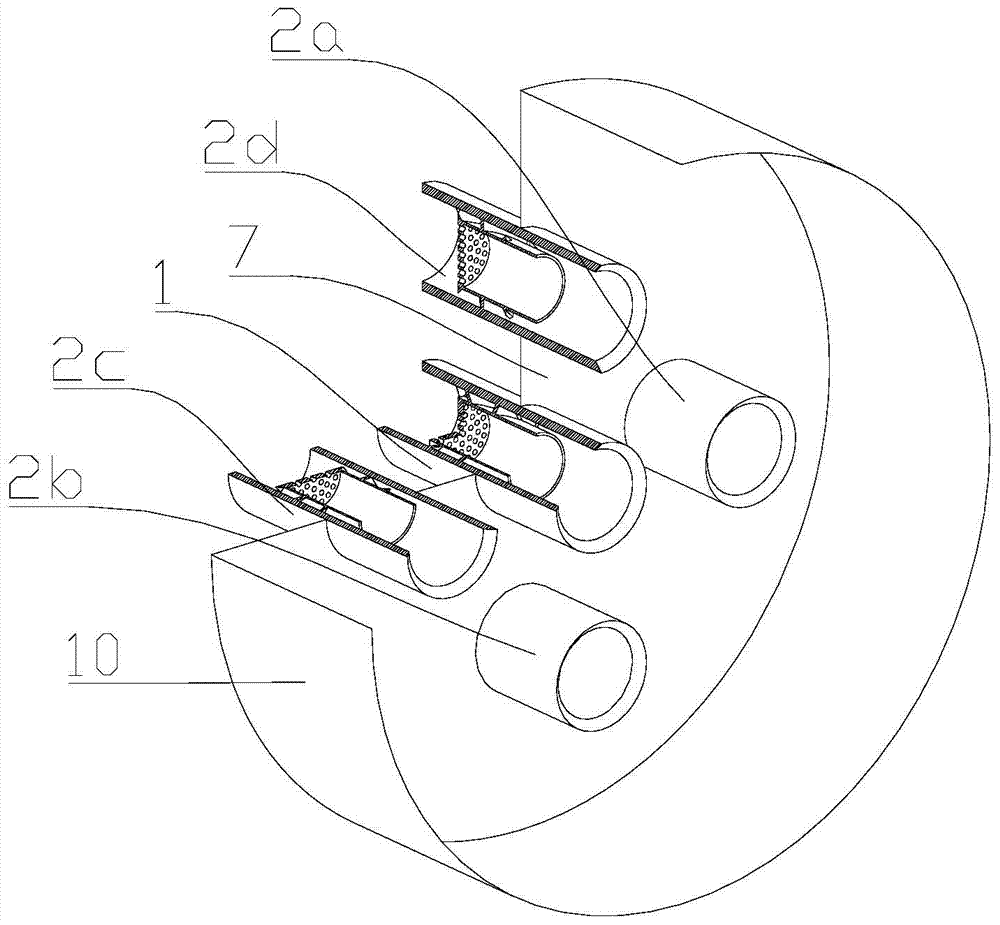

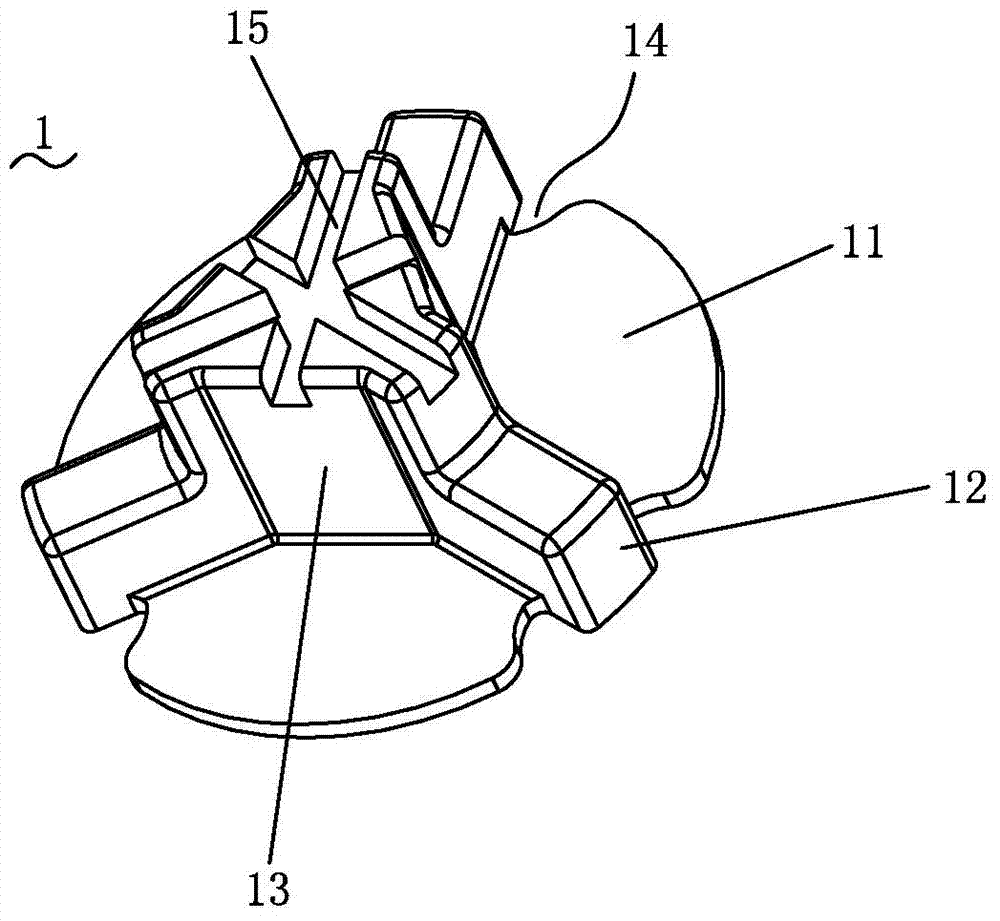

Electric discharging device of rotation electrode

InactiveCN105478240APrevent escapeReduce rapid ablationElectrode constructionsPlasma techniqueImpellerElectric discharge

The invention belongs to the technical field of low-temperature plasma application, and relates to an electric discharging device of a rotation electrode. The device comprises an impeller, a rotation electrode, a fixed electrode, and an electric motor, wherein the rotation electrode is arranged between the electric motor and the fixed electrode, and is fixedly arranged on the impeller or a shaft of the electric motor. The electric motor drives the impeller and the rotation electrode to move. High voltage is applied between the rotation electrode and the fixed electrode, and corona discharging is generated between the two electrodes. Since the electric motor drives the rotation electrode to move, corona rotates with the movement to draw a large-volume plasma area. Plasma is uniformly dispersed in a whole airflow channel between the two electrodes. Therefore, the electric discharging device can be applied to an air purifier and allows no dead corner to be left during purification. Moreover, the rotation electrode can greatly reduce the ozone yield, and prolongs the service life of asymmetric electrodes.

Owner:孙红梅

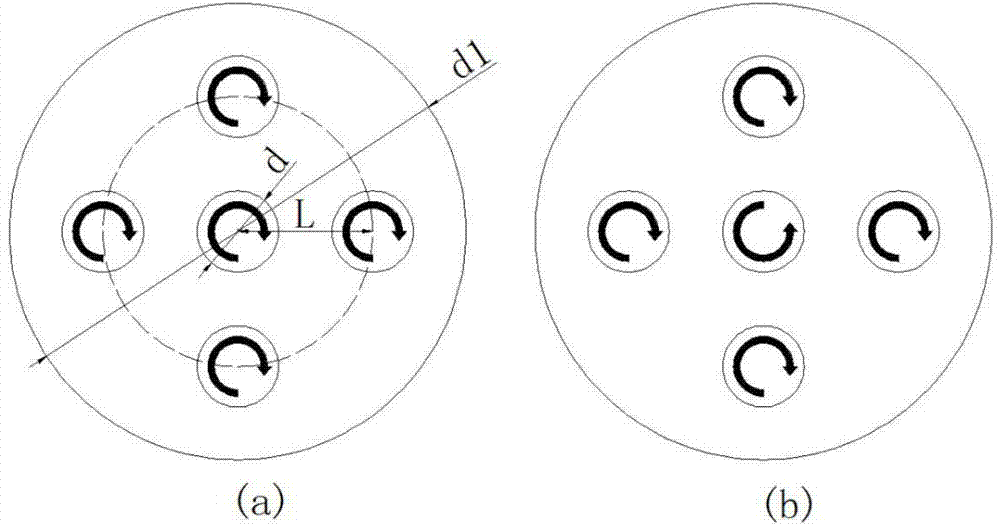

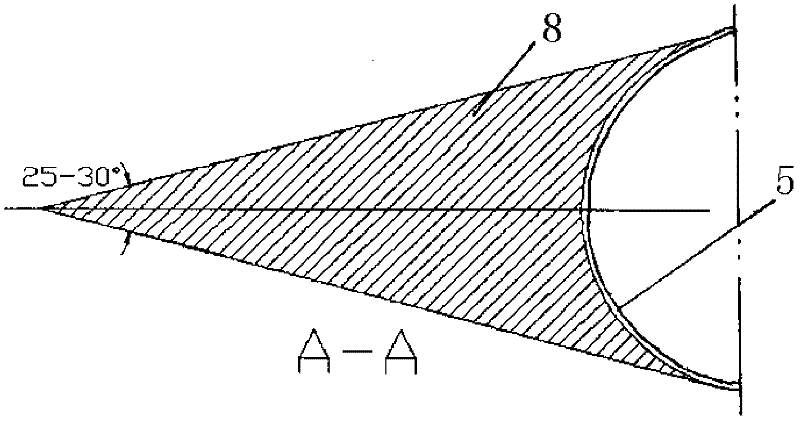

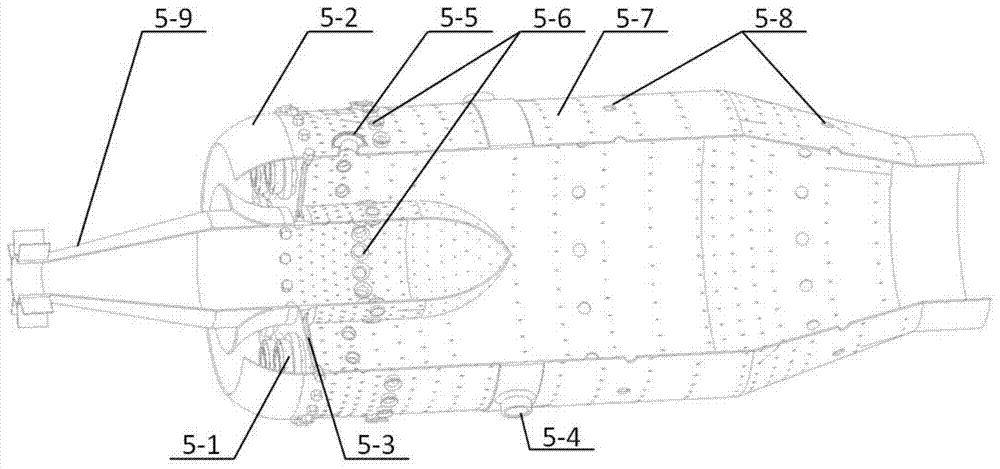

Five-nozzle combustor structure applied to gas turbine low-pollution combustion chamber

ActiveCN104728866AReduce air velocityIncrease load turndown ratioContinuous combustion chamberCombustion chamberCombustor

The invention discloses a five-nozzle combustor structure applied to a gas turbine low-pollution combustion chamber, the combustor is composed of five low-swirl nozzles, the surrounding nozzles are arranged evenly at equal intervals in the circumferential direction along the central nozzle, and the swirling flow directions of the surrounding nozzles are the same. The swirling flow direction of the central nozzle is the same as or opposite to the swirling flow directions of the surrounding nozzles. Lean premixed combustion of gas fuel and air is adopted, the flame residence time is reduced, the flame temperature is reduced, and the aim of low emission is achieved. The five-nozzle combustor structure applied to the gas turbine low-pollution combustion chamber has the advantages of being stable in combustion, low in emission, low in noise, reasonable in design, simple in structure, and suitable for the gas turbine low-pollution combustion chamber.

Owner:SHANGHAI JIAO TONG UNIV

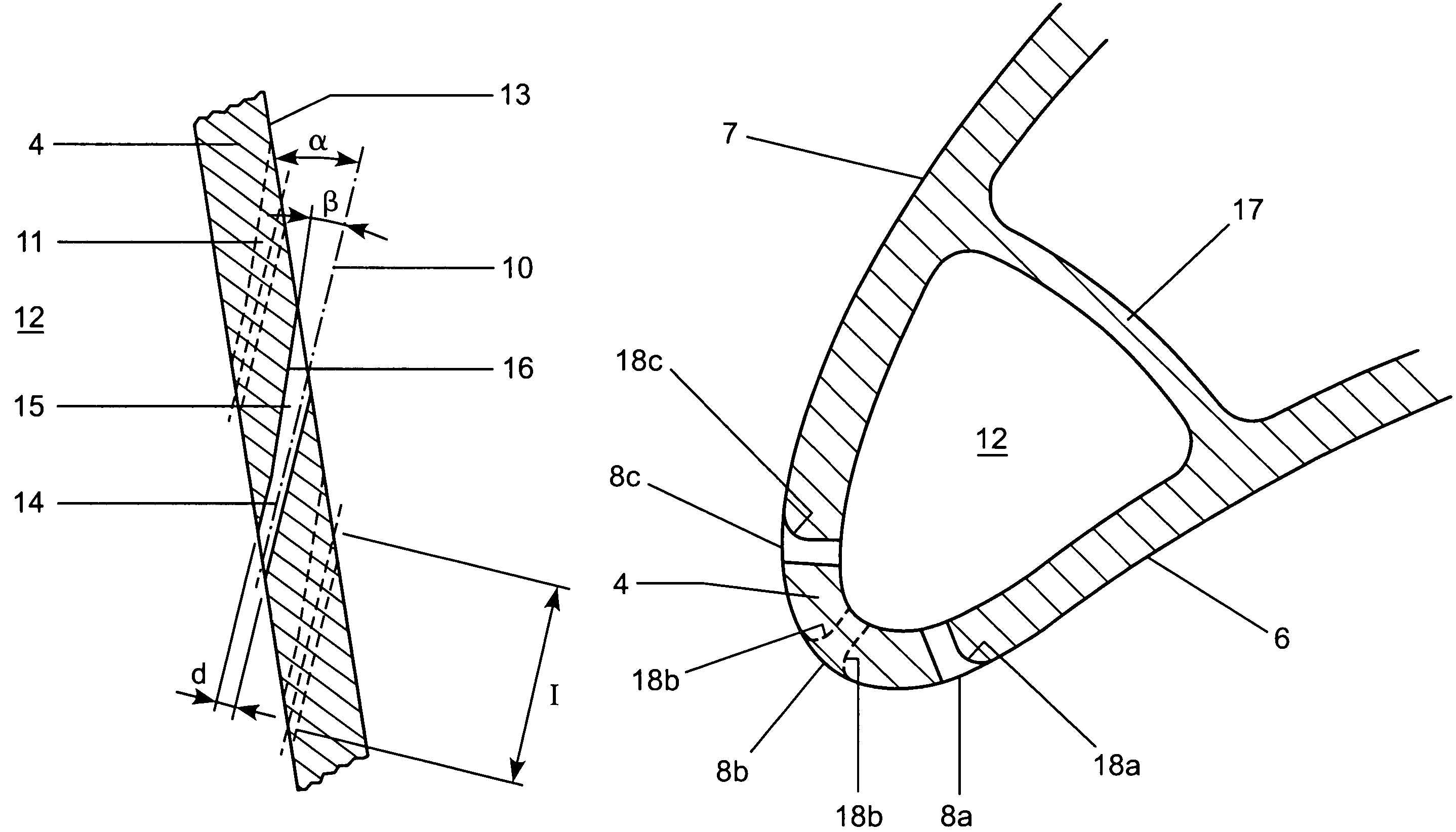

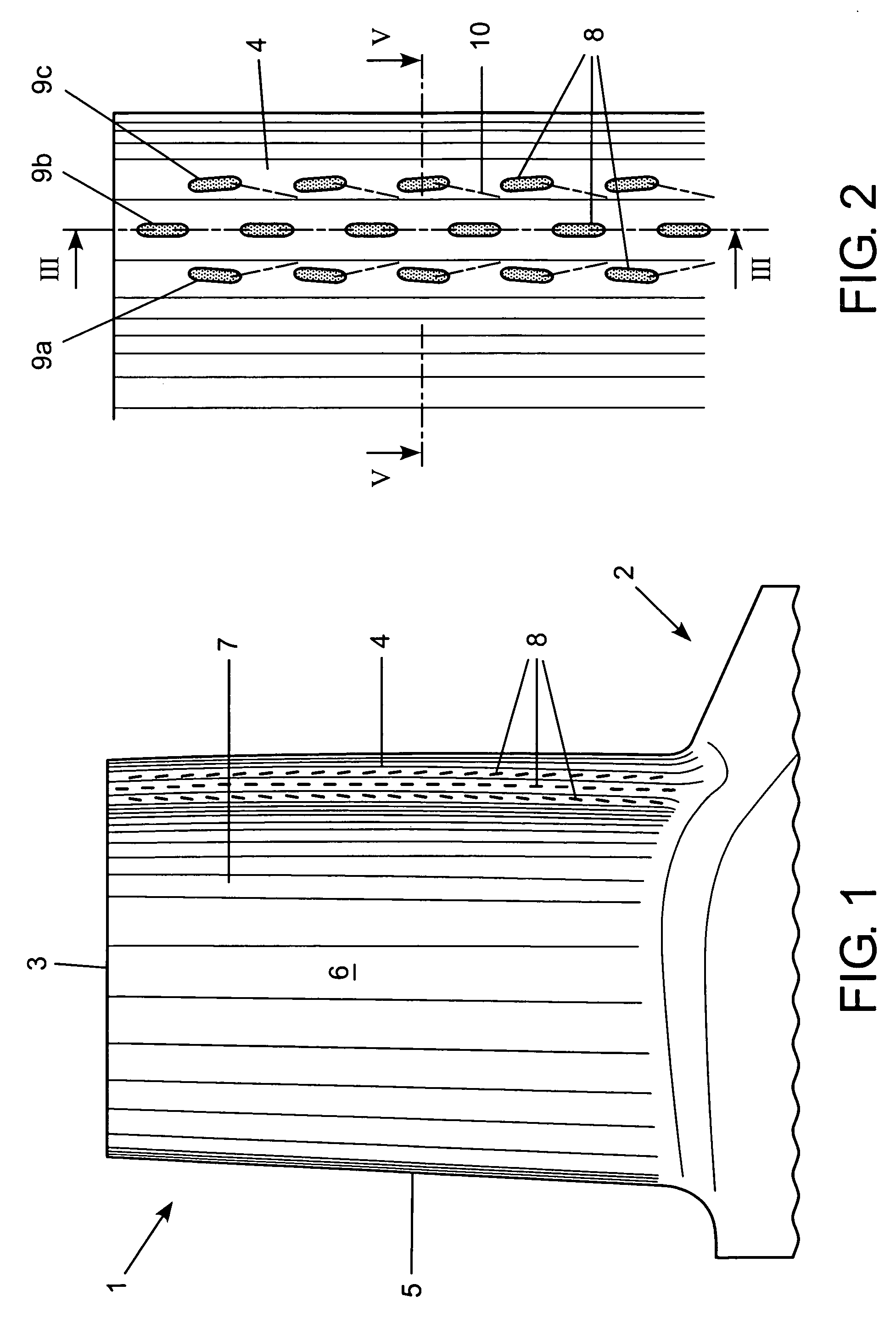

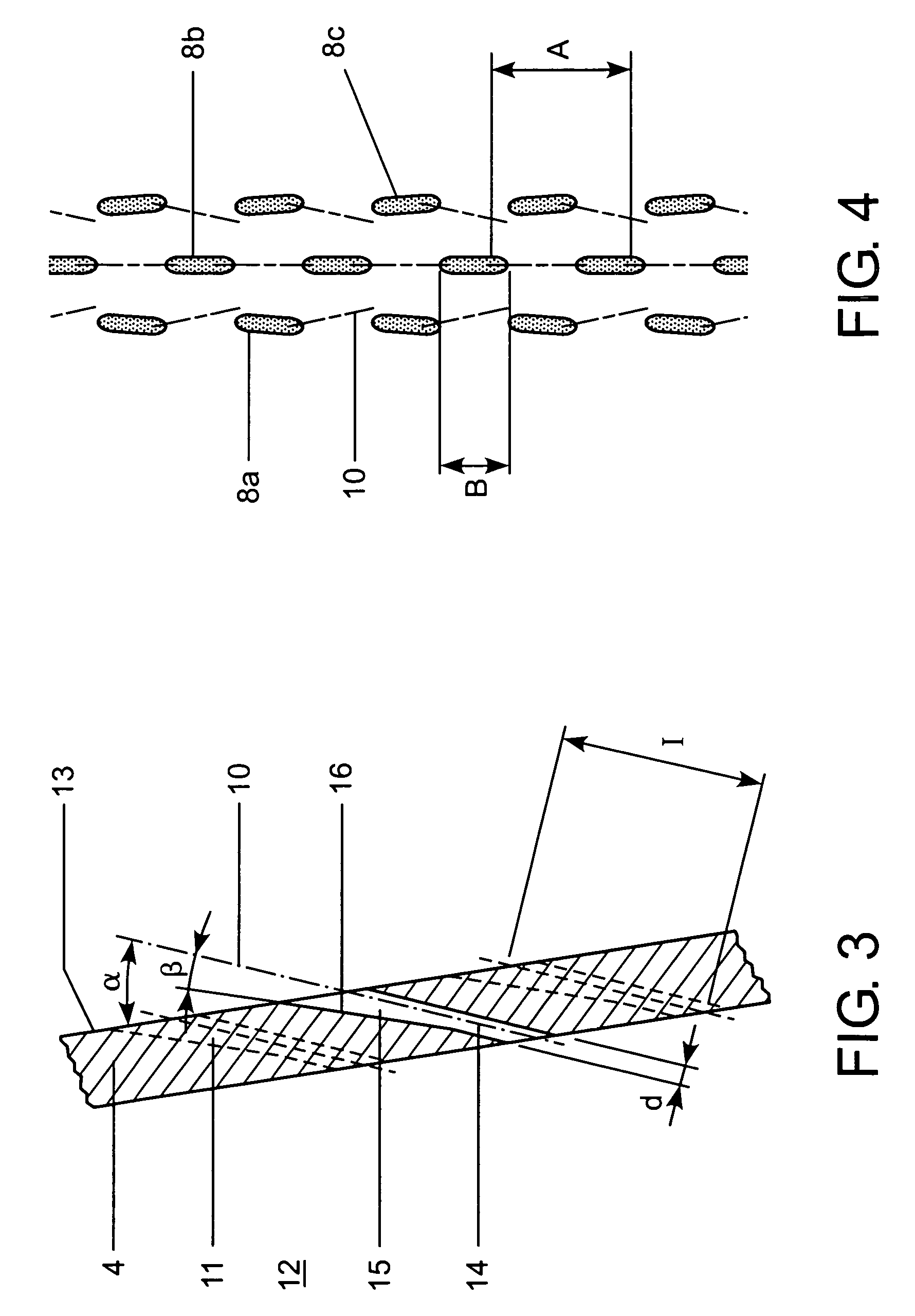

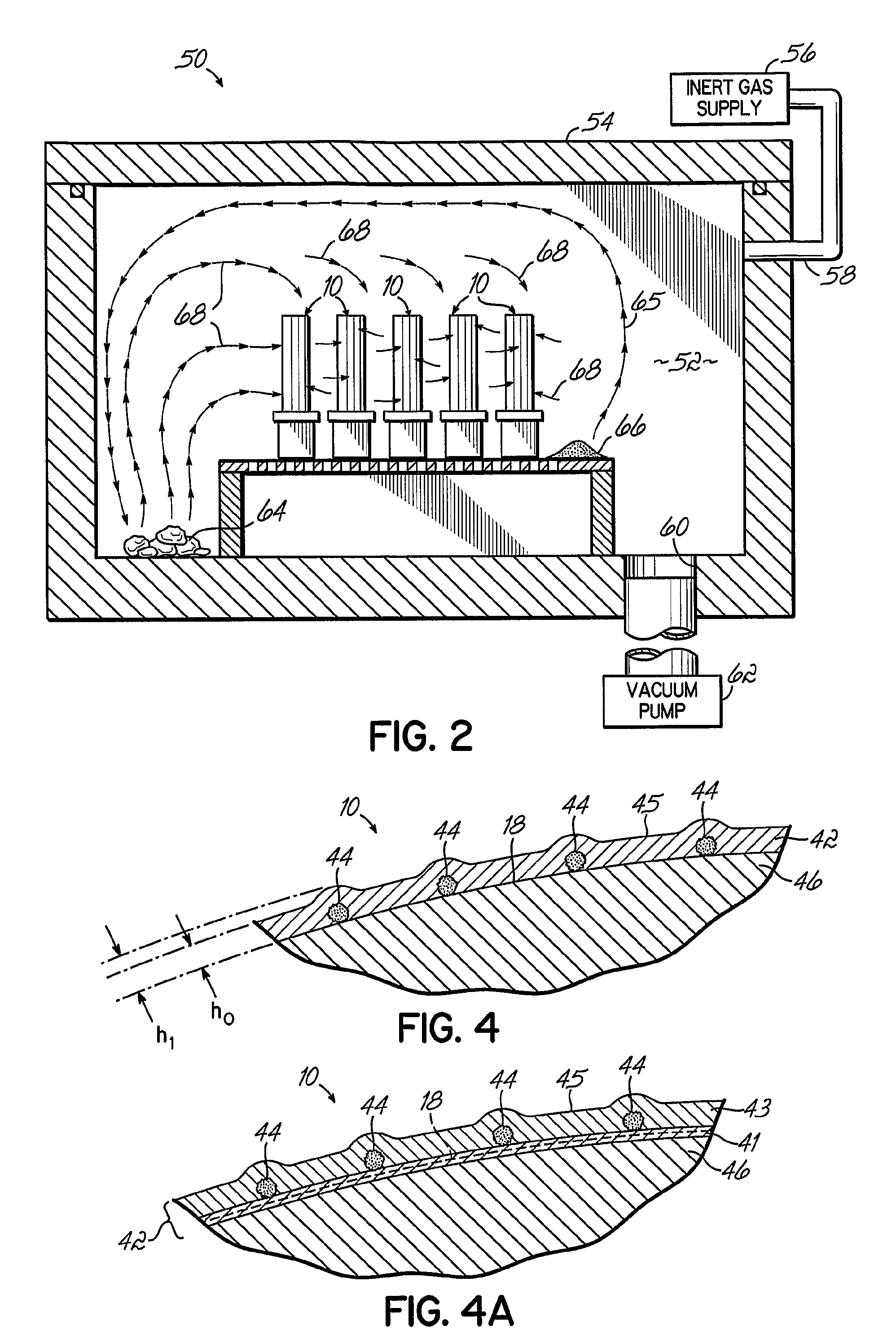

Gas turbine airfoil leading edge cooling construction

InactiveUS7300252B2Improved film coolingReduce formationBlade accessoriesMachines/enginesLeading edgeTrailing edge

A gas turbine airfoil with a pressure sidewall (6) and a suction sidewall (7) extends from a root (2) to a tip (3) and from a leading edge (4) to a trailing edge (5). It comprises several film cooling holes with exit ports (8). The film cooling holes have a sidewall that is diffused in the direction of the tip (3) of the airfoil (1) at least over a part of the film cooling hole. Furthermore, the film cooling holes each have flare-like contour near the outer surface of the leading edge (4). The film cooling holes according to the invention provide an improved film cooling effectiveness due to reduced formation of vortices and decreased penetration depth of the cooling air film.

Owner:ANSALDO ENERGIA IP UK LTD

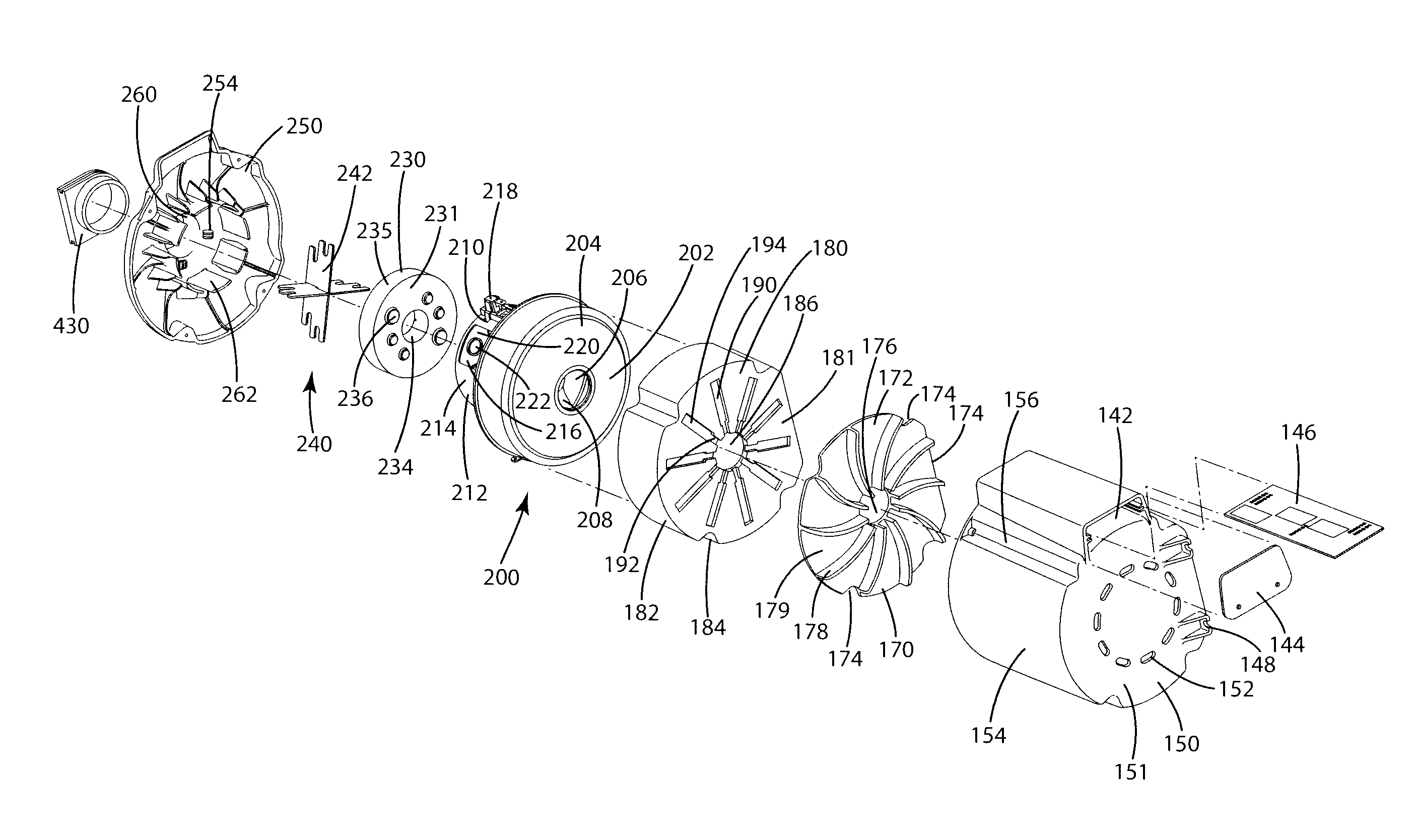

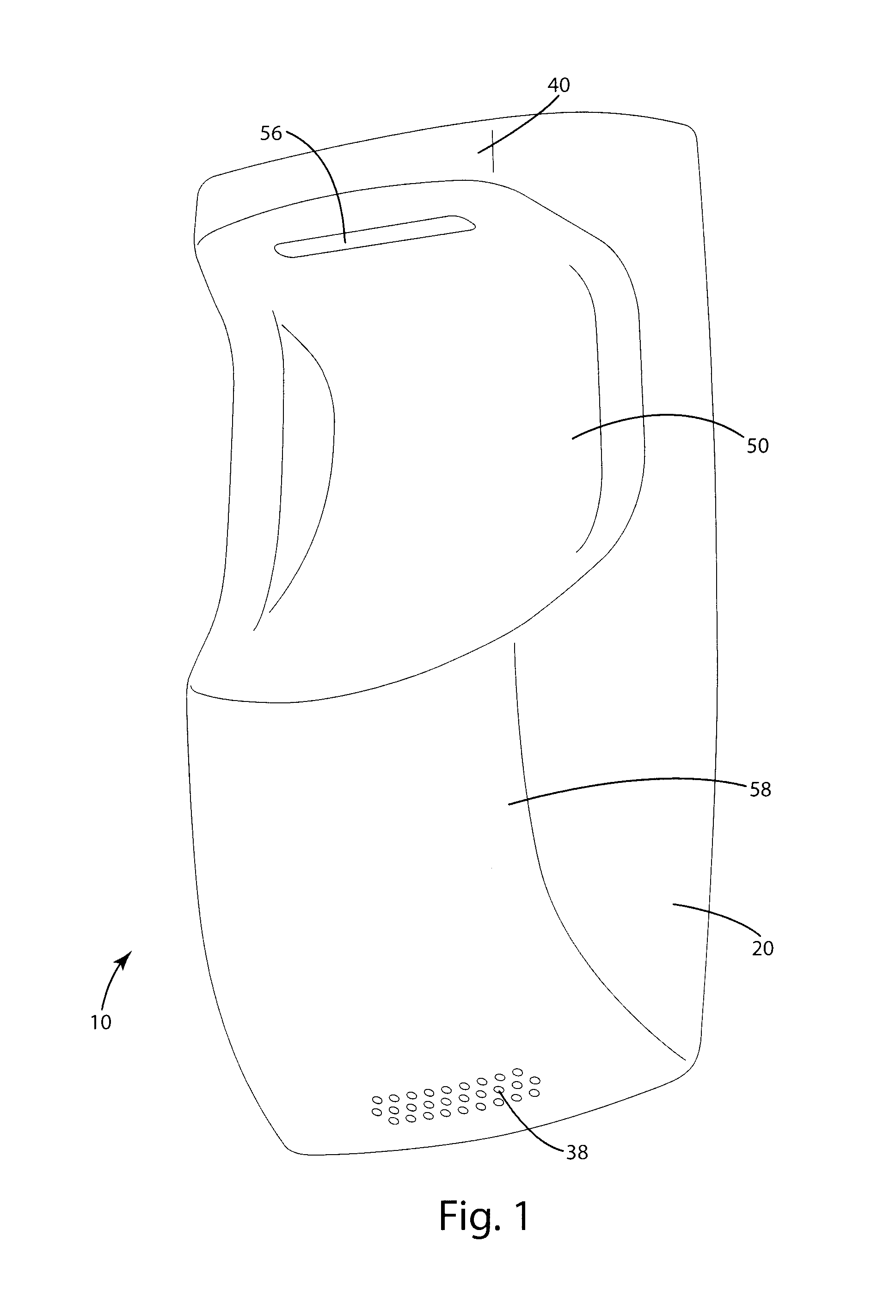

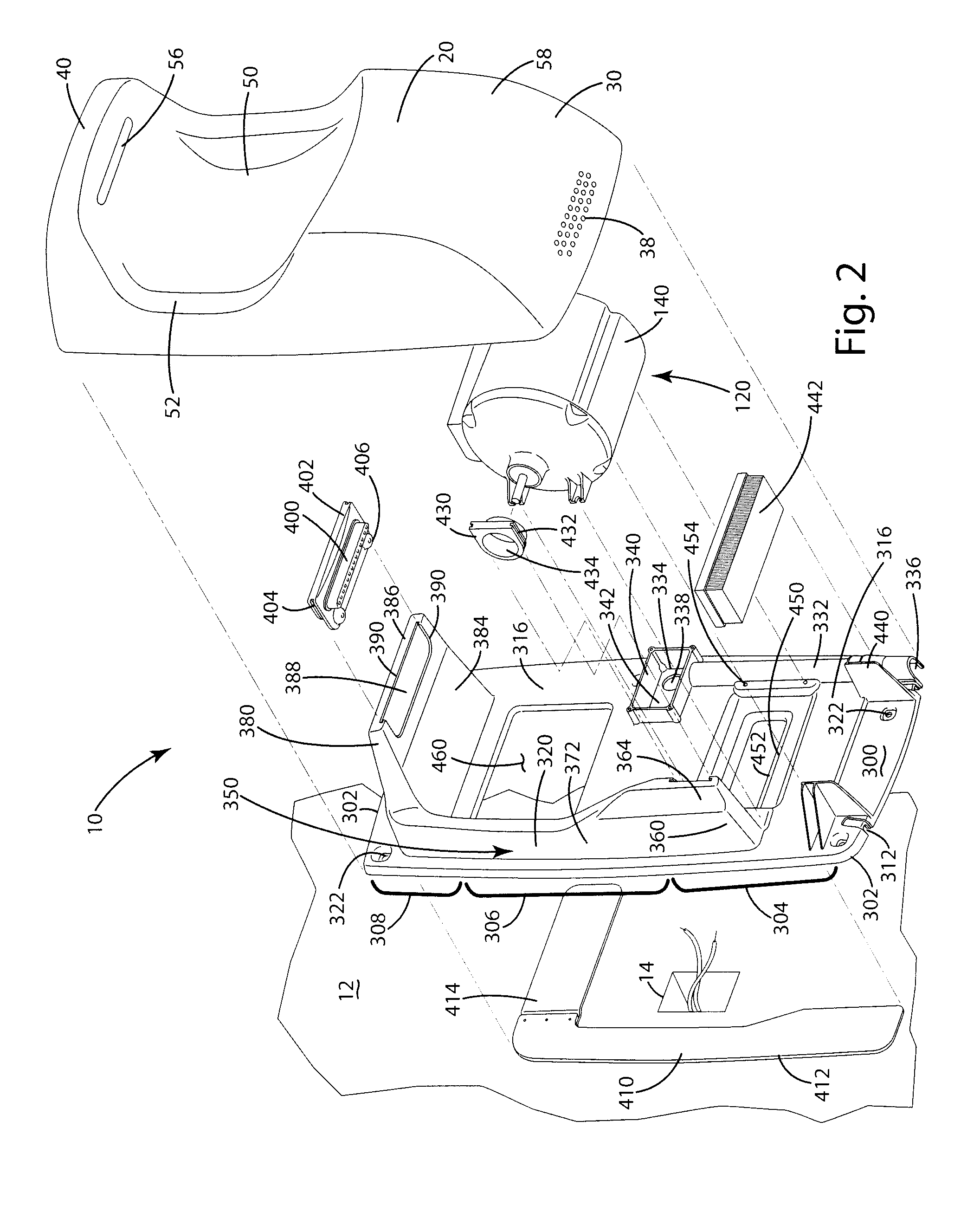

Blower assembly for hand dryer

ActiveUS20140212304A1Easy to assembleEasy maintenancePump componentsPiston pumpsField serviceElectric motor

A dryer with a modular blower assembly that allows easy assembly and field servicing through replacement of the blower assembly as a unit. The blower assembly generally includes unique motor mounts that allow a motor assembly to be secured within a housing without being directly fastened to other members.

Owner:AMERICAN DRYER LLC

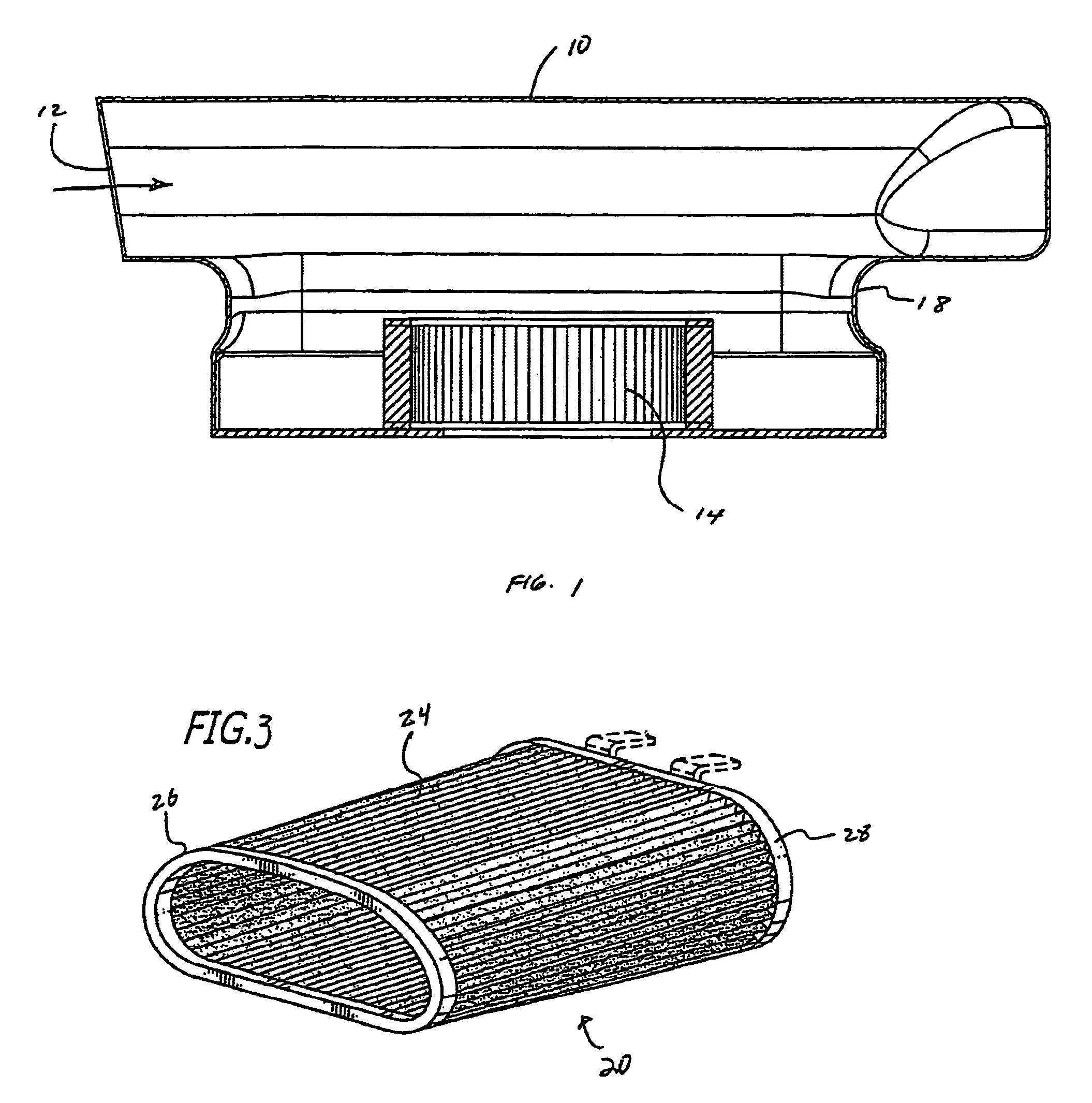

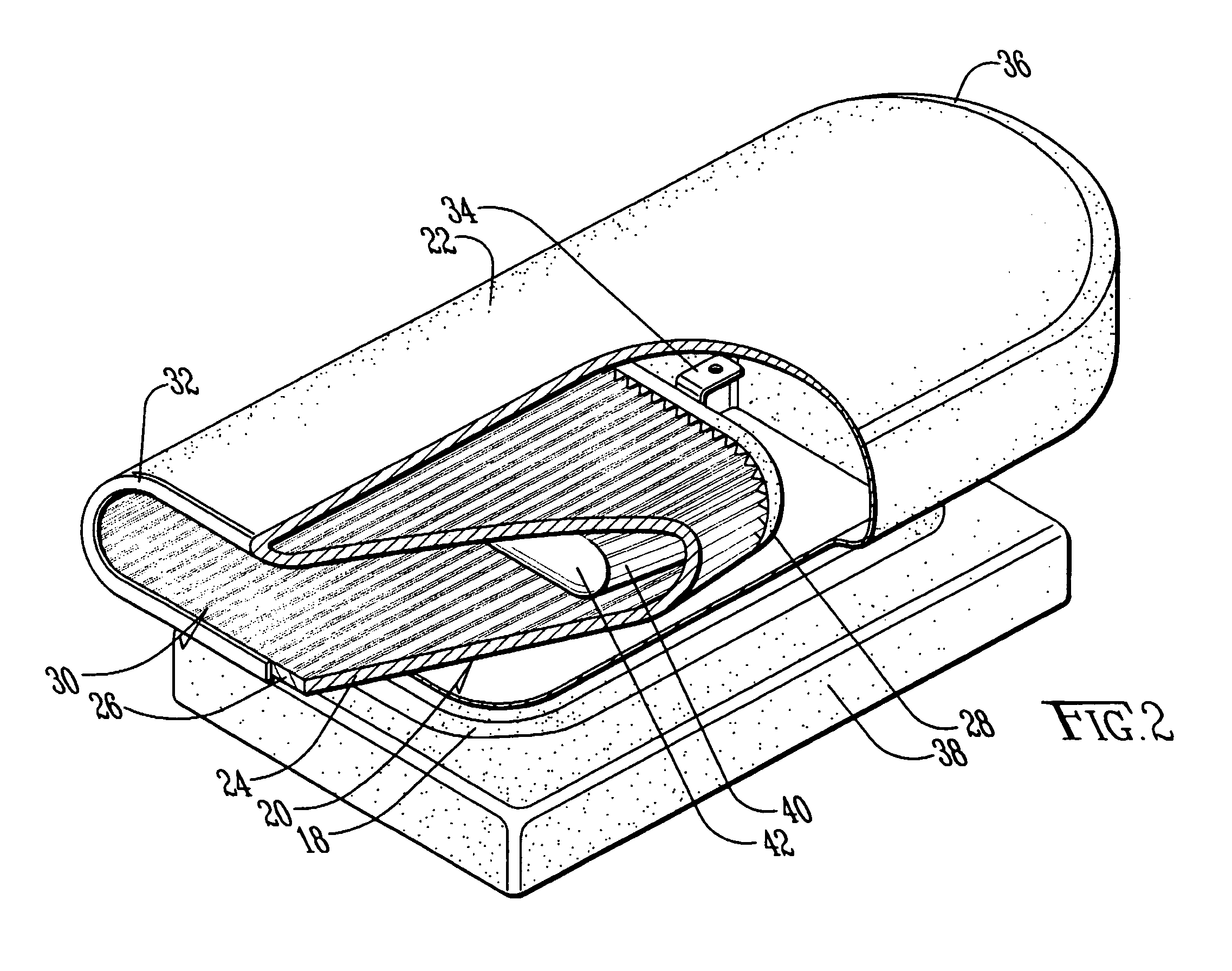

Air filter for a scoop

ActiveUS7452395B2Minimize occurrenceIncrease in sizeCombination devicesNon-fuel substance addition to fuelAir filterEngineering

Owner:K&N ENGINEERING INC

High flow air filtration system

InactiveUS20070044750A1Reduce air velocityGas treatmentNon-fuel substance addition to fuelAir filtrationStream flow

A high flow air filtration system comprises a filter within a housing, a cover removably attached to the housing, an adapter between and in flow communication with the filter and an air intake of an engine. The cover includes a diverter, a flow directing portion, and a lip. The diverter is positioned between the filter and a flow of air from the vehicle ducting. The diverter slows the velocity of the flow and alters its path. The flow directing portion is adapted to direct the flow downward towards the filter. The lip is positioned along the front edge of the cover to increase the volume of external air entering the housing.

Owner:ADVANCED FLOW ENG

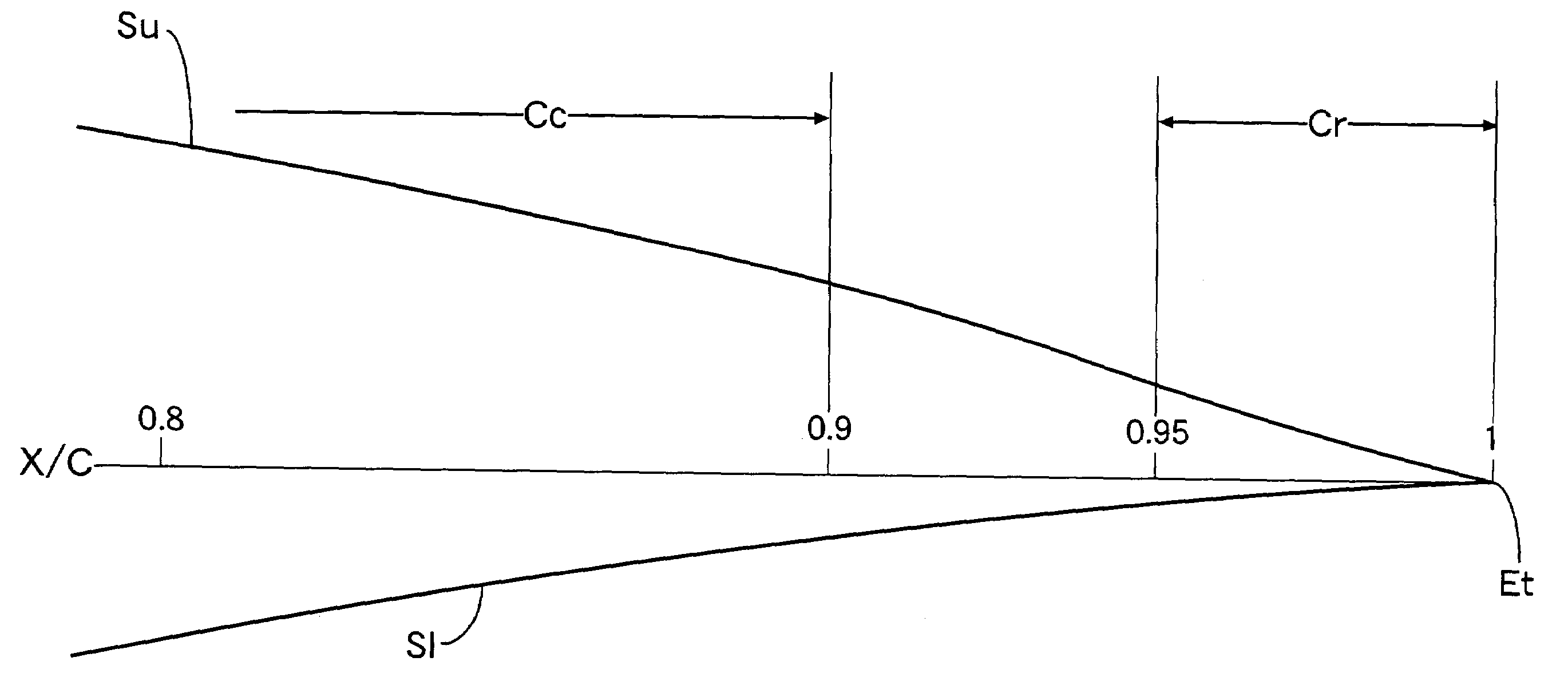

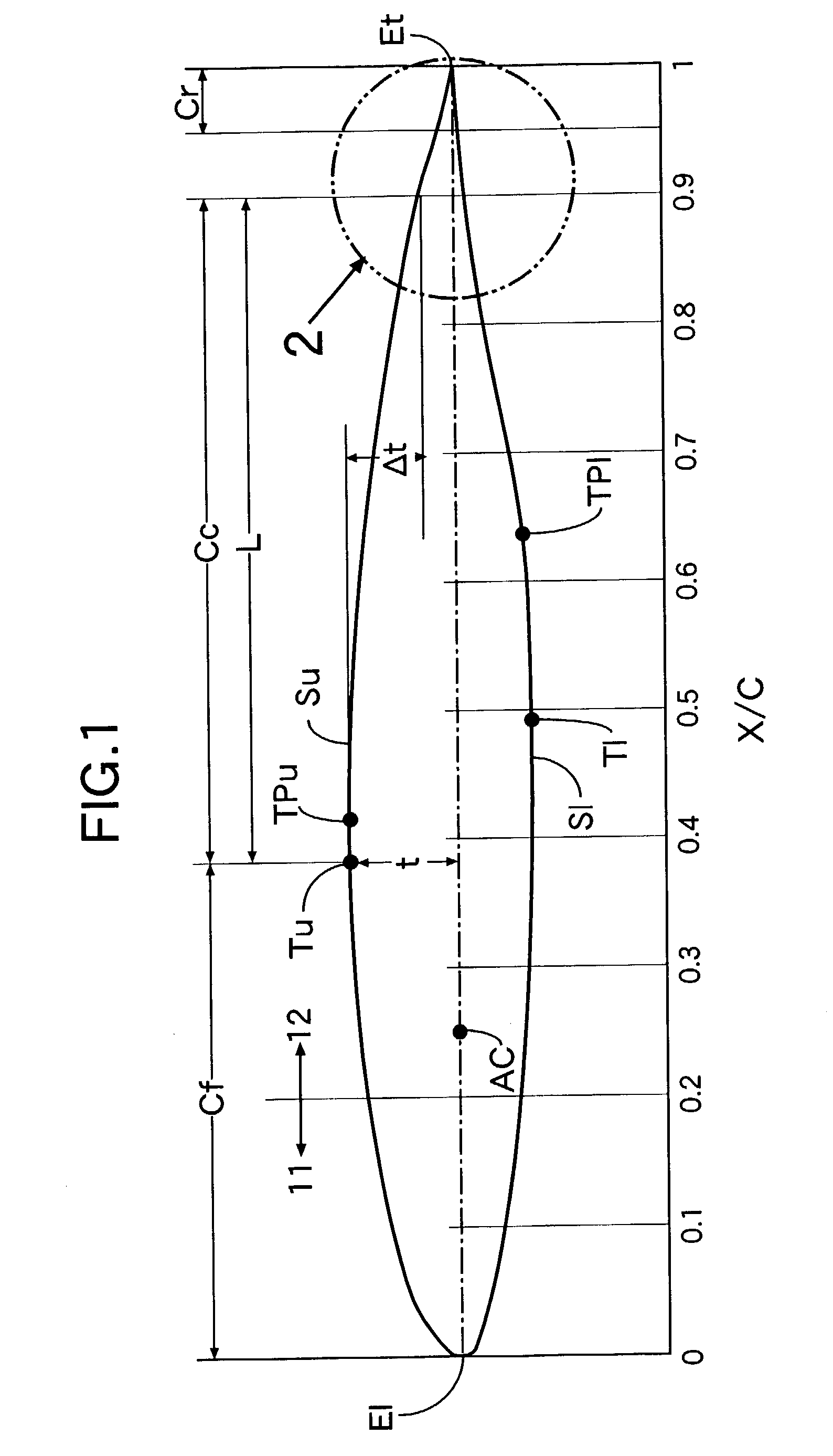

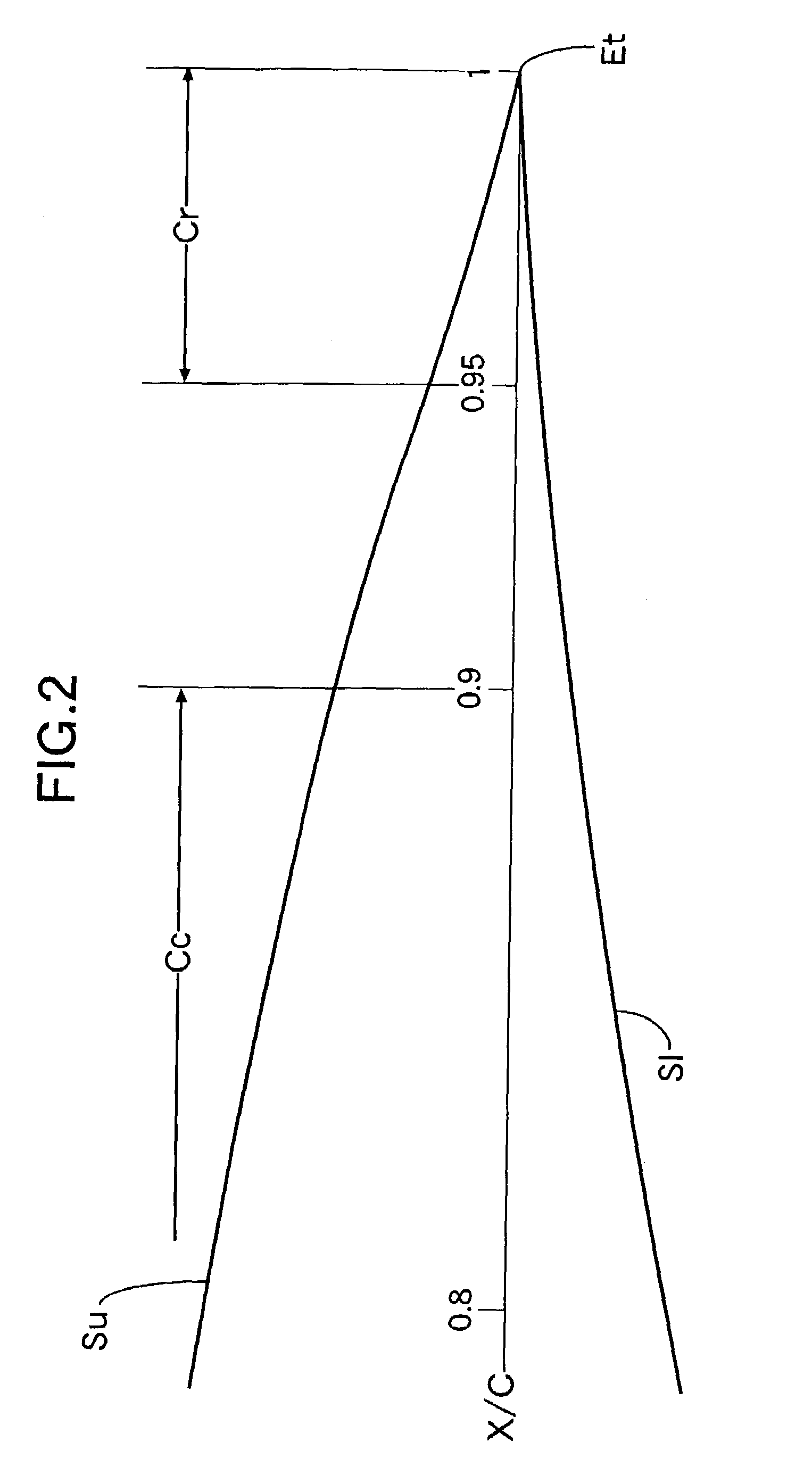

Laminar-flow airfoil

ActiveUS7093792B2Reduce resistanceDecrease an undesirable head-lowering pitching momentWing shapesAll-wing aircraftLeading edgeTrailing edge

An upper wing surface of a laminar-flow airfoil for decreasing an undesirable head-lowering pitching moment around an aerodynamic center of the airfoil. The upper wing surface includes: a convex front profile portion extending from a leading edge to a largest-thickness point located corresponding to 38% of a wing chord length. A convex central profile portion extends from the largest-thickness point to a position corresponding to 90% of the wing chord length at which a value obtained by dividing a thicknesswise difference between the position and the largest-thickness point by a distance in a direction of the wing chord from the largest-thickness point is equal to or smaller than 0.12. A concave rear profile portion extends from a position corresponding to 95% of the wing chord length to the trailing edge. The rear profile portion forms a pressure gradient is steeper than that formed by the central profile portion.

Owner:AMERICAN HONDA MOTOR COMPANY

Anaerobic ammonoxidation bacterium concentrating device

InactiveCN101195803AEasy to separateEasy to captureApparatus sterilizationMicroorganism based processesSludgeGas cylinder

The invention discloses a high- efficient enrichment device of the anaerobic ammonium oxidation bacteria. The lower circular cylinder of the main body of the device is connected with an upper circular cylinder through an increasing coupling, a sealing cover is arranged at the top part of the upper circular cylinder, an air outlet pipe is arranged on the sealing cover and is connected with a gas washing bottle, grain bamboo charcoal carriers are installed at the lower part of the lower circular cylinder, a primary gas-liquid-solid three phase separating component is arranged inside the upper circular cylinder, a secondary mud water separating component is arranged on the outer side, a grain sludge blocking component is arranged between the secondary mud water separating component and the upper circular cylinder, a grain sludge collecting opening is arranged at the lower part of the secondary mud water separating component, a overflow dam is arranged at the upper part of the grain sludge blocking component and is connected with a water outlet tank through a water collecting pipe, a water inlet pipe is arranged at the bottom part of the lower circular cylinder and is connected with the water inlet tank through a water inlet pump, a returning pipeline is arranged on the side wall at the middle part of the upper circular cylinder, and the returning pipeline passing a returning pump directly enters into the water inlet pipe through a three way pipe. The invention can block the anaerobic ammonium oxidation bacteria on the surface of the carrier, and obtains the enrichment culture of the anaerobic ammonium oxidation bacteria with high activity; the culture presents red, and the character is obvious; the culture is grain sludge, and is easy to be obtained.

Owner:ZHEJIANG UNIV

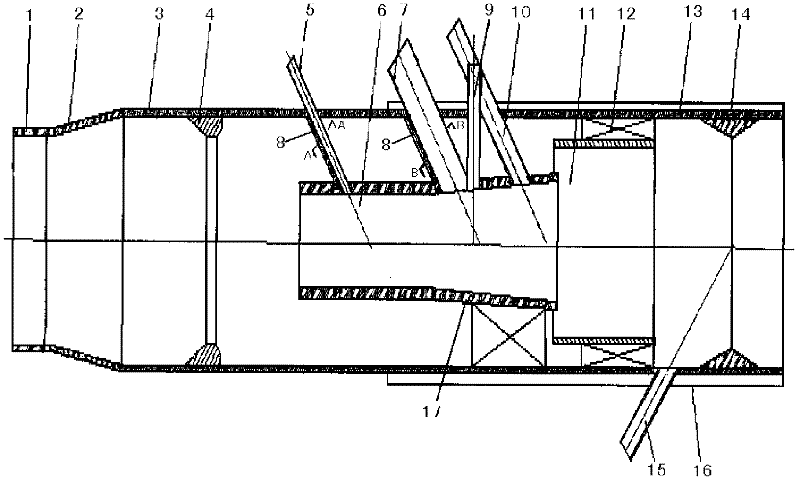

Oxygen-enriched ignition and low-load stable combustion coal combustor

InactiveCN102418922AAvoid large changes in flow performanceReduce air velocityPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationSocial benefitsCombustion chamber

The invention discloses a novel oxygen-enriched ignition and low-load stable combustion coal combustor which belongs to the field of parts of coal-fired boilers of heat power stations. An increasing section of the combustor, a coal dust concentration device, a primary coal dust combustion chamber, a secondary coal dust combustion chamber and a nozzle streamline concentration device are coaxially arranged on a combustor body; and a primary combustion chamber oxygen supply pipe, a gasified oil oxygen enrichment combustion cylinder, a flame check device, and a switchable oxygen enrichment gasified oil gun sleeve are all distributed on the same profile to reduce the flow resistance of coal dust, and avoid coal dust accumulation in a wake backflow area. By using an oxygen supply device, and the coal dust concentration device, high-coal-dust-concentration, high-oxygen-concentration and high-flame-temperature areas are formed twice by the gasified oil oxygen enrichment combustion cylinder in the combustor, and the heating and boosting requirements of blackfurnace starting ignition of low-quality coal of a coal-powder boiler can be met and low-load stable combustion can be realized by adjusting oxygen concentration, coal dust concentration, and oil gun output. The novel oxygen-enriched ignition and low-load stable combustion coal combustor can also adapt to multi-coal wide-range characteristics and has great economic and social benefits.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Cloth negative pressure finishing singeing device

InactiveCN107217436AAvoid cloggingSingeing orderlyMechanical cleaningPressure cleaningFiberEngineering

The invention relates to a cloth negative pressure finishing singeing device, which comprises a frame, a cloth guide roller, a carding assembly and a negative pressure hair removal assembly. During the rotation, the fibers attached to the surface of the cloth are erected, adsorbed and pulled; there is a fluff shaping space between the negative pressure hair removal component and the cloth. And the adsorption holes and the deflectors and heating wires respectively arranged on both sides of the removal pores, the airflow flows along the hair removal chamber and is guided by the deflectors to form an airflow acceleration zone, and a negative pressure zone is formed between the deflectors and the adsorption holes; The carding component erects the fiber and shapes it, and then pulls the fiber with the adsorption force to contact the heating wire to realize singeing. At the same time, the broken fiber is collected by the airflow conduction separation component, which solves the problems existing in the prior art. Poor singeing effect and inconvenient dust removal technical problems.

Owner:长兴天赫纺织科技有限公司

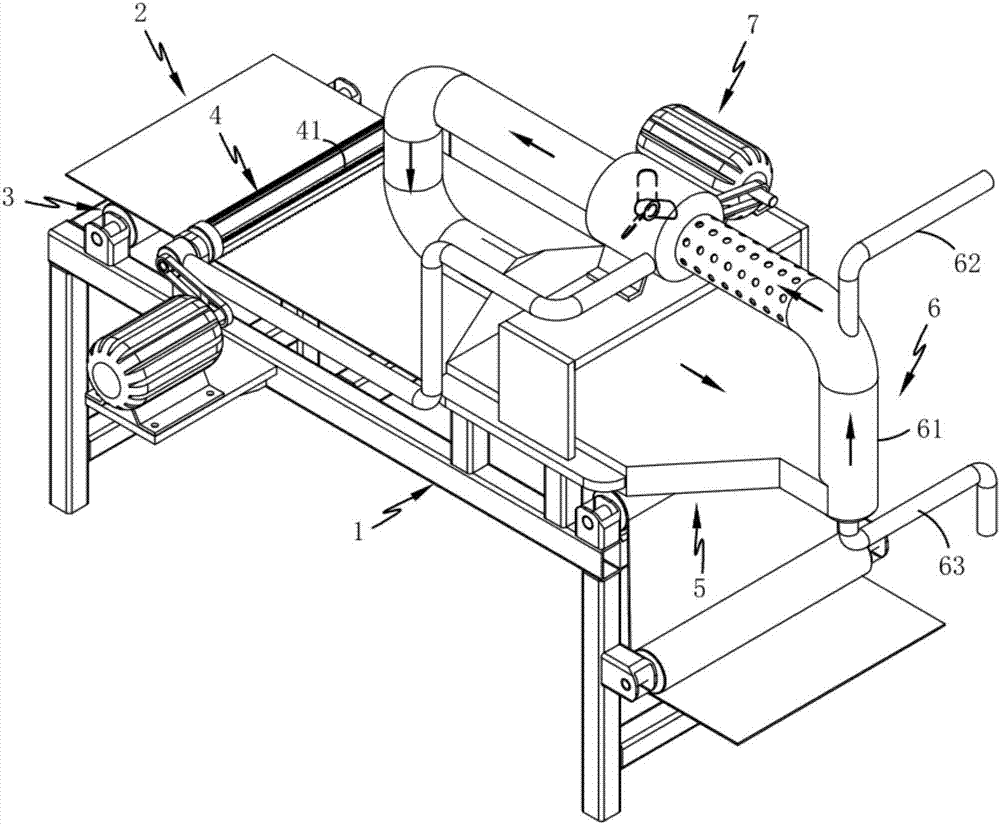

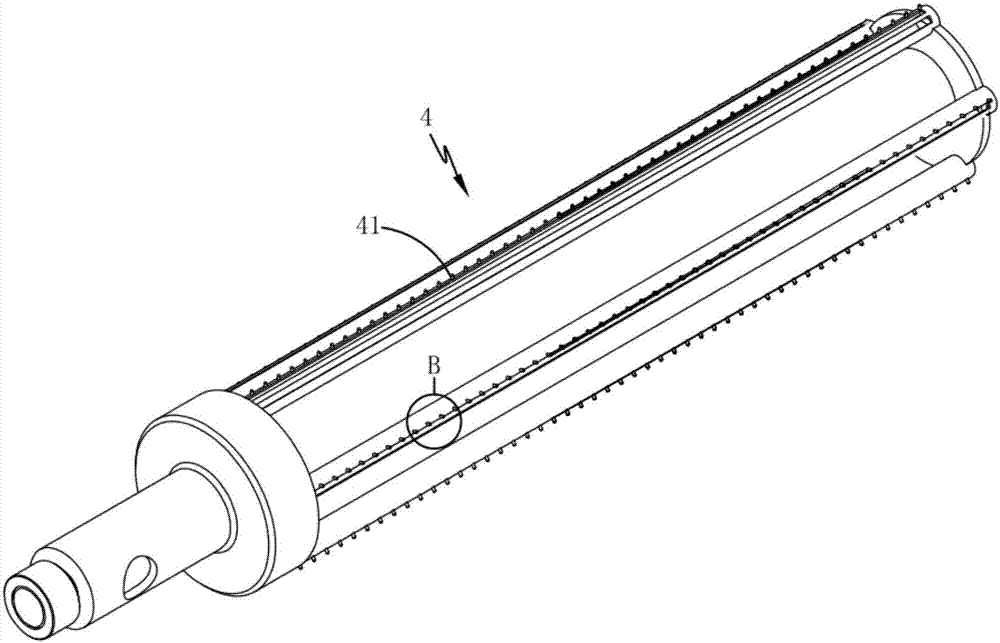

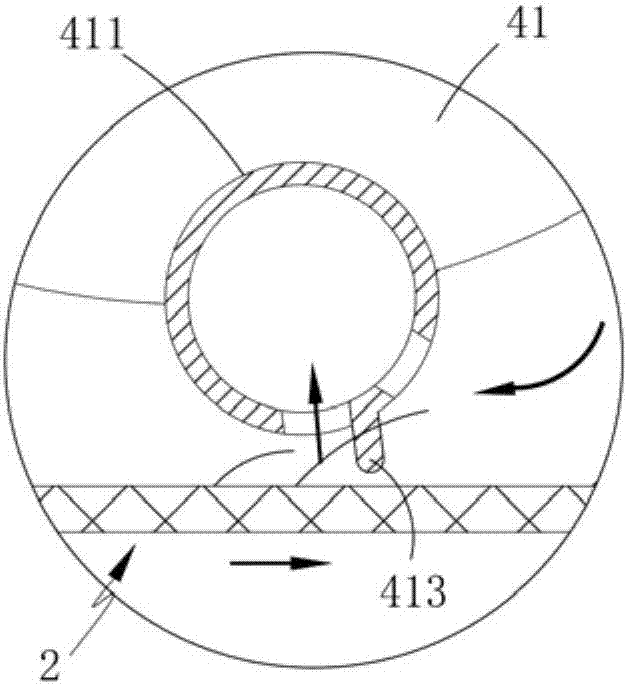

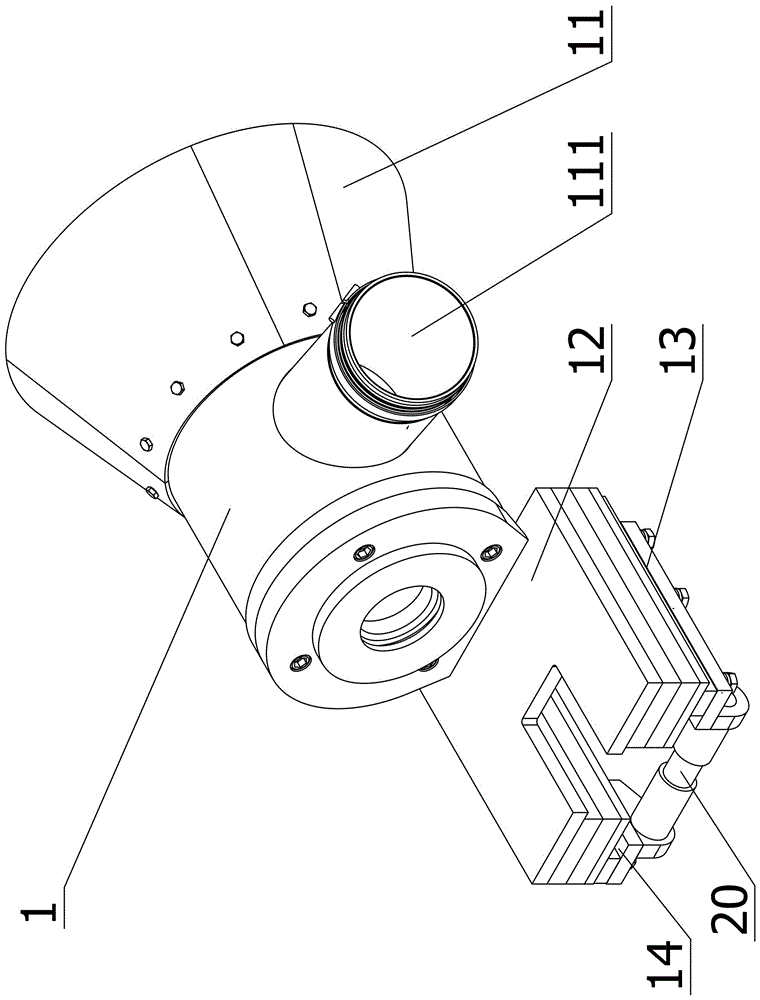

Two-stage dry dust cleaning device and down-hole drilling machine including same

The invention provides a two-stage dry dust cleaning device and a down-hole drilling machine including the same. The two-stage dry dust cleaning device comprises a dust catching part, a first stage dust cleaning part and a second stage dust cleaning part. The dust catching part, the first stage dust cleaning part and the second stage dust cleaning part are connected with flow guiding pipes sequentially; and a centrifugal exhaust fan with an air outlet is installed on the second stage dust cleaning part. According to the down-hole drilling machine provided with the two-stage dry dust cleaning device, rock dust generated from drilling operation is sequentially sucked into the dust catching part, the first stage dust cleaning part and the second stage dust cleaning part from the drilling positions through the sucking power of the centrifugal exhaust fan, and the rock dust is collected into the first stage dust cleaning part and the second stage dust cleaning part according the sizes of the dust particles; and tilting baffles are arranged on air flow paths in the first stage dust cleaning part and the second stage dust cleaning part, and a filtering element capable of adsorbing the light dust is arranged in the second stage dust cleaning part, so that dust sucking effect is improved, working environment and human health are protected, damage to the centrifugal exhaust fan is reduced, and using quality of the down-hole drilling machine is ensured.

Owner:广东孔山重工机械有限公司

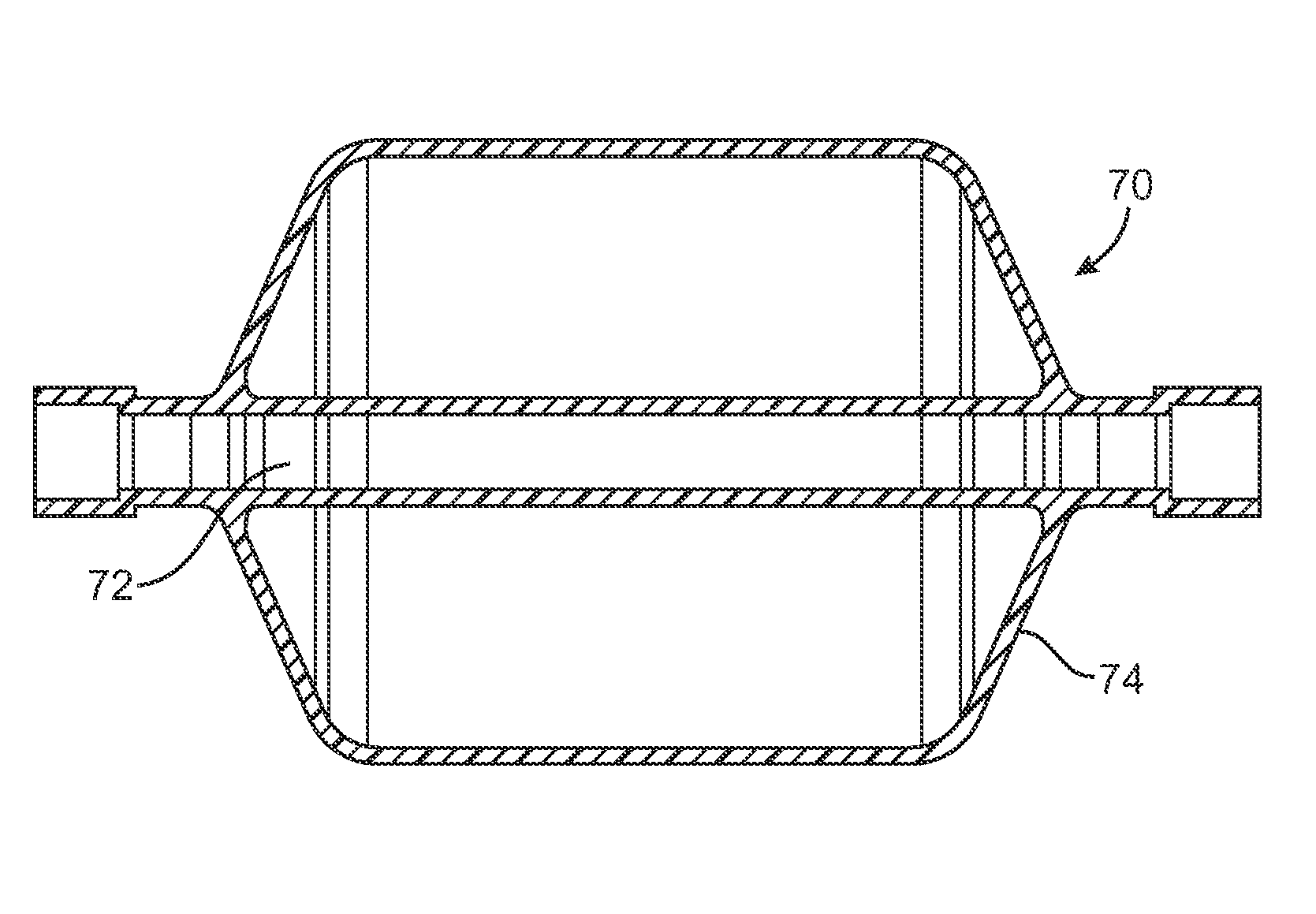

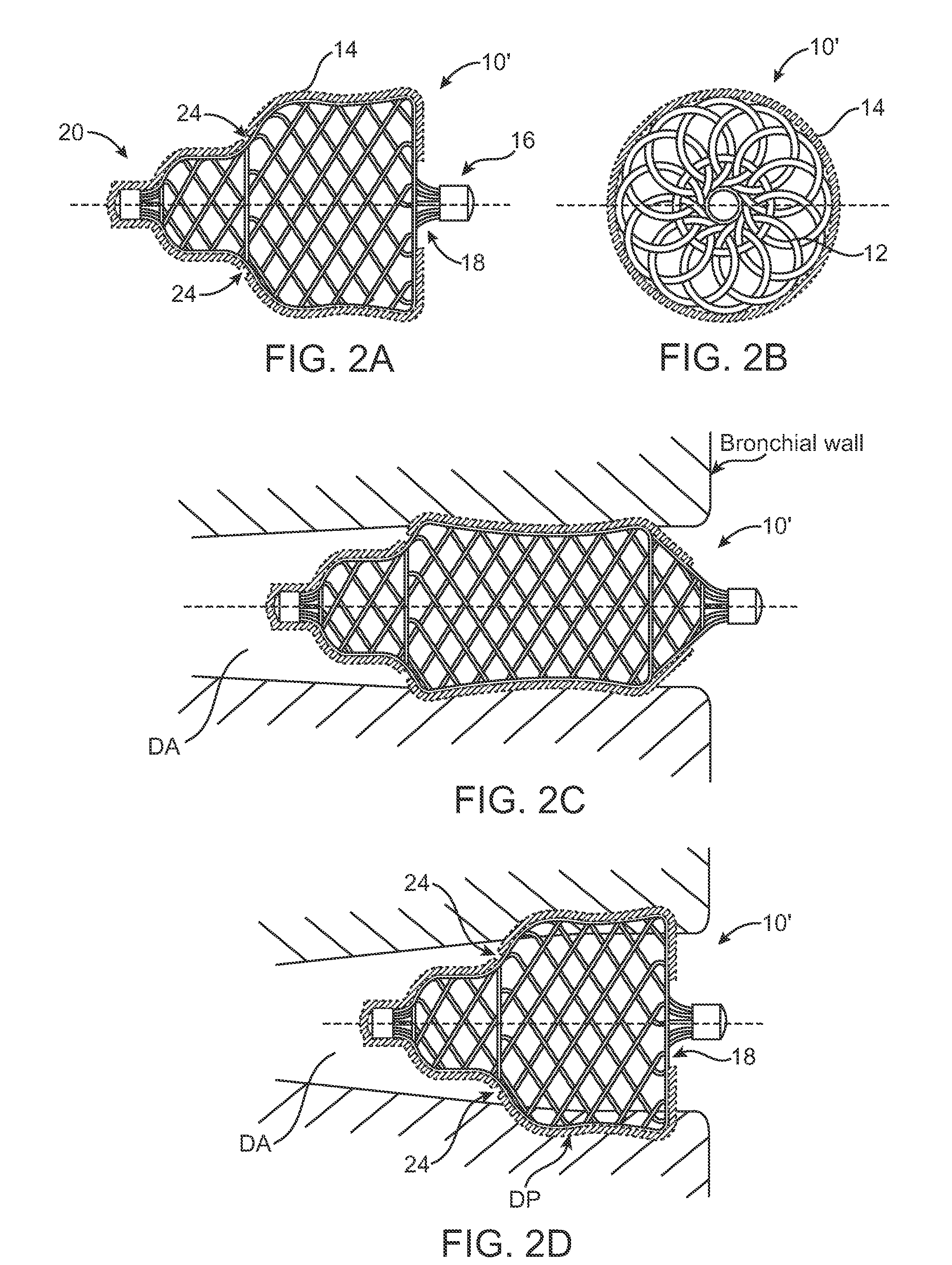

Methods and devices to induce controlled atelectasis and hypoxic pulmonary vasoconstriction

Owner:PULMONX

Clothes dryer apparatus with improved lint removal system

InactiveUS8166670B2Maximize contact timeMaximize energy transferDrying solid materials with heatDrying gas arrangementsFiltrationPulp and paper industry

A method and apparatus for removing lint from air that is discharged from a clothes dryer uses a lint filtration housing mounted on the frame of the clothes dryer, the filtration housing having an interior that contains a filter for removing lint from the dryer exhaust air flow stream. The housing provides an influent fitting for transmitting heating exhaust air from the drying chamber to the housing interior. An ambient air supply enables ambient air to be added to the filtration housing interior. One or more vanes is provided that create an annular vortex within the filtration housing interior. The flow of the annular vortex within the filtration housing interior can be between about 500 and 3,000 cubic feet per second. A flow line transmits pre-heated air from the filtration housing interior to the dryer interior.

Owner:PELLERIN MILNOR

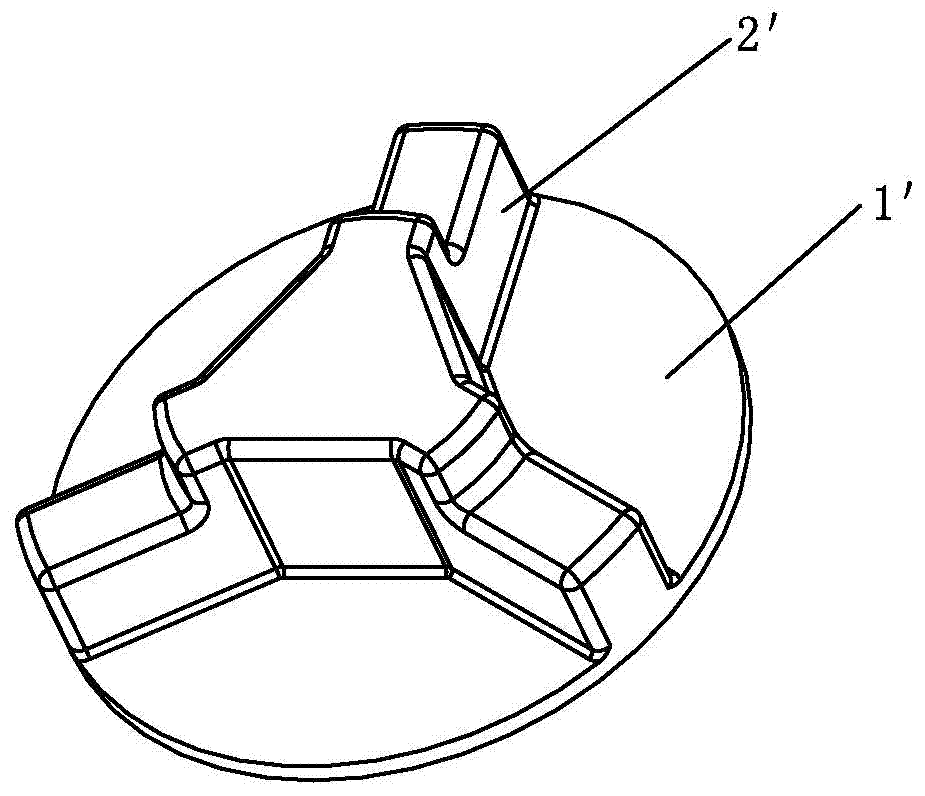

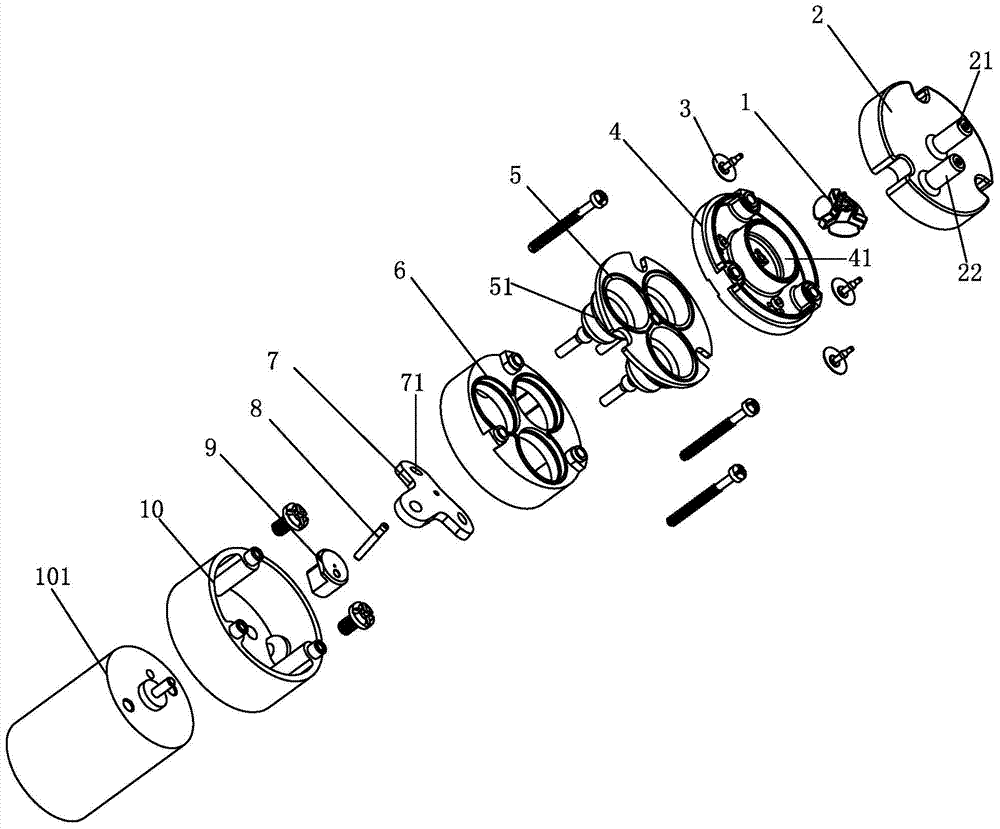

Valve block with improved air tightness and air pump

ActiveCN103573613APrevent archingGuaranteed air tightnessPositive displacement pump componentsLiquid fuel engine componentsAir pumpEngineering

The invention discloses a valve block with improved air tightness and an air pump, wherein the valve block is provided with at least two elastically swinging blades, the blades are separated by radially arranged ribs, and a buffering structure is arranged at the end part, used for connecting the rib, of each blade to provide a deformation buffering space for the assembly and extrusion of each blade. The air pump is provided with the valve block with improved air tightness, and each blade of the valve block, as a one-way air outlet valve block of the air pump, is matched in the air pump. The structure of the valve block is improved to effectively prevent each blade in the valve block from deforming or bulging during the assembly, so that the air tightness of the air pump is greatly improved.

Owner:XIAMEN KOGE MICRO TECH

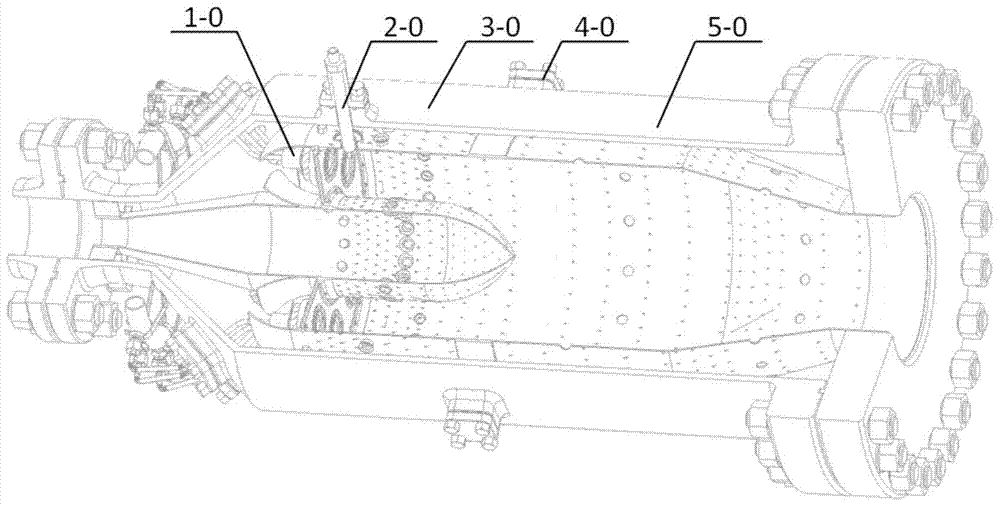

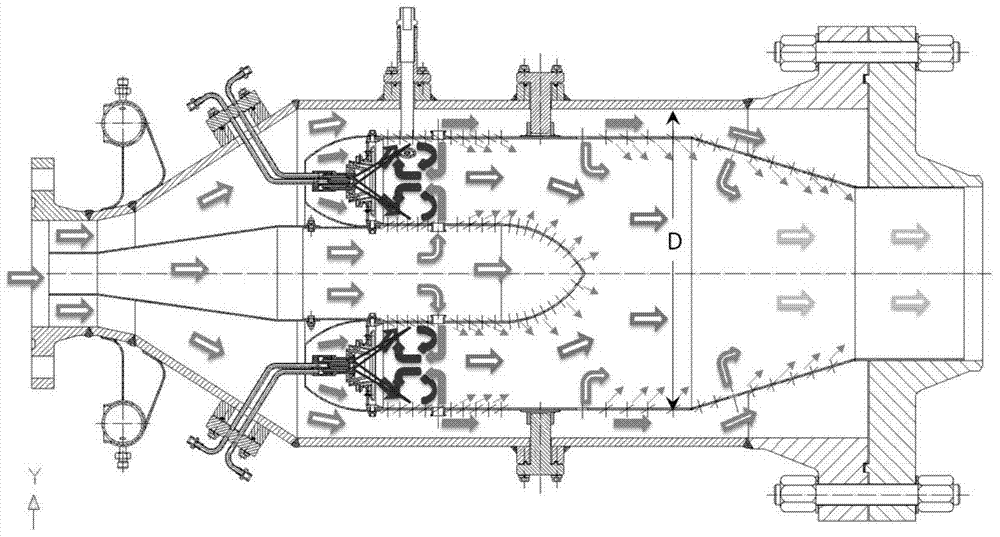

Annular combustion chamber fuel gas generator using alcohol as fuel

ActiveCN103697471AImprove atomization effectImprove ignition reliabilityBurnersAlcoholCombustion chamber

The invention belongs to the technical field of fuel gas generators, and particularly relates to an annular combustion chamber fuel gas generator. The annular combustion chamber fuel gas generator using alcohol as fuel comprises a plurality of dual-oil path centrifugal sprayers (1-0) distributed uniformly along the peripheral direction, a plasma ignition electric nozzle (2-0), a shell (3-0), a positioning pin (4-0) and a flame drum (5-0); the flame drum (5-0) is arranged in the shell (3-0) and is coaxial with the shell (3-0), and two cavity paths are formed between the flame drum and the shell; the dual-oil path centrifugal sprayers (1-0), the plasma igniter (2-0) and the positioning pin (4-0) are combined and assembled with the flame drum (5-0) by the shell (3-0). The fuel gas generator uses air as an oxidizing agent and the alcohol as the fuel, so the fuel gas has high enthalpy value. Air is very easy to obtain, and the alcohol is low in price, so the disadvantages of low enthalpy value and high operation cost of fuel gas of the existing fuel gas generator in the application field are solved.

Owner:AECC SICHUAN GAS TURBINE RES INST

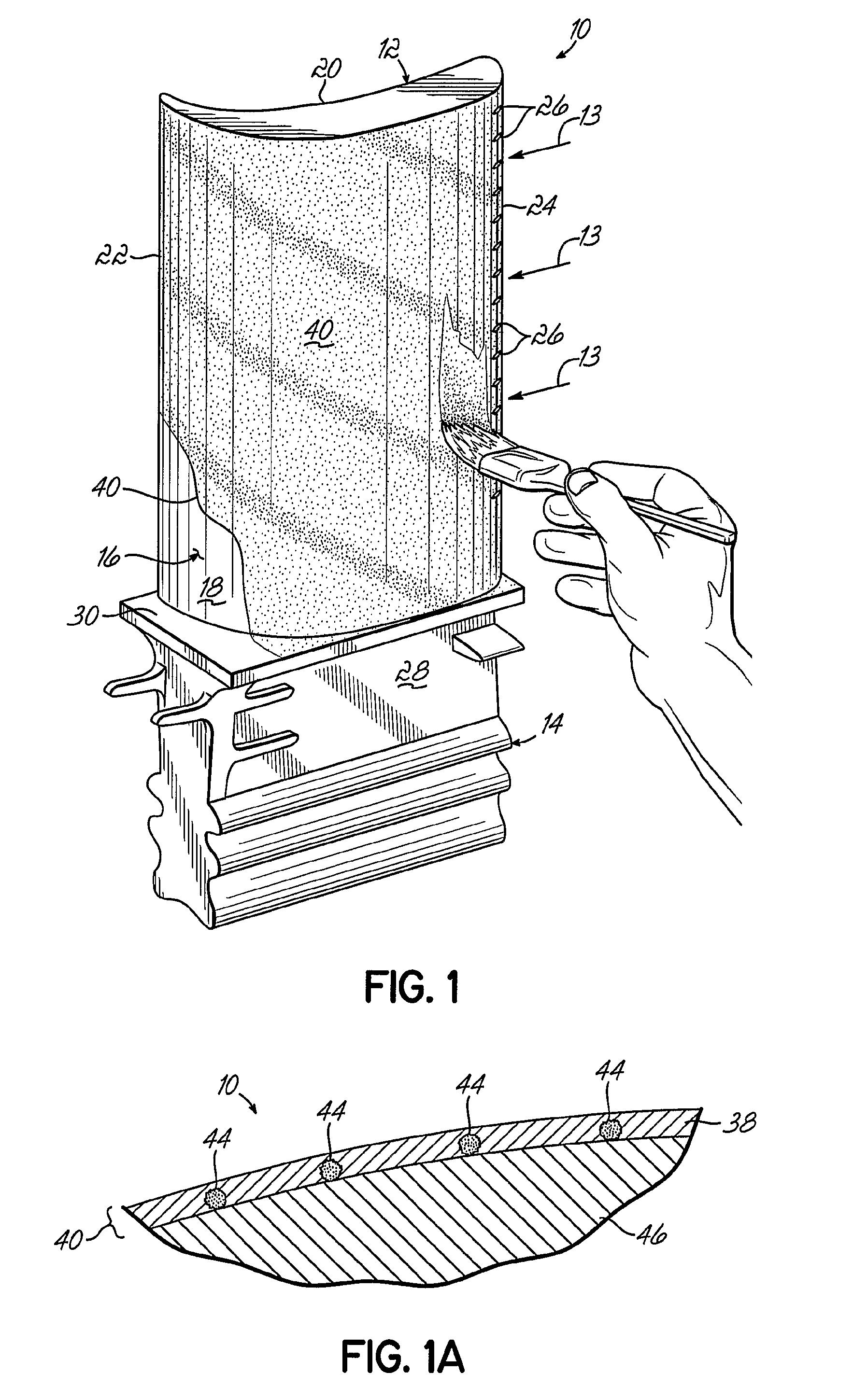

Roughened coatings for gas turbine engine components

ActiveUS8137820B2Improve surface roughnessReduce air velocityPropellersBlade accessoriesSurface roughnessEngineering

Owner:AEROMET TECH

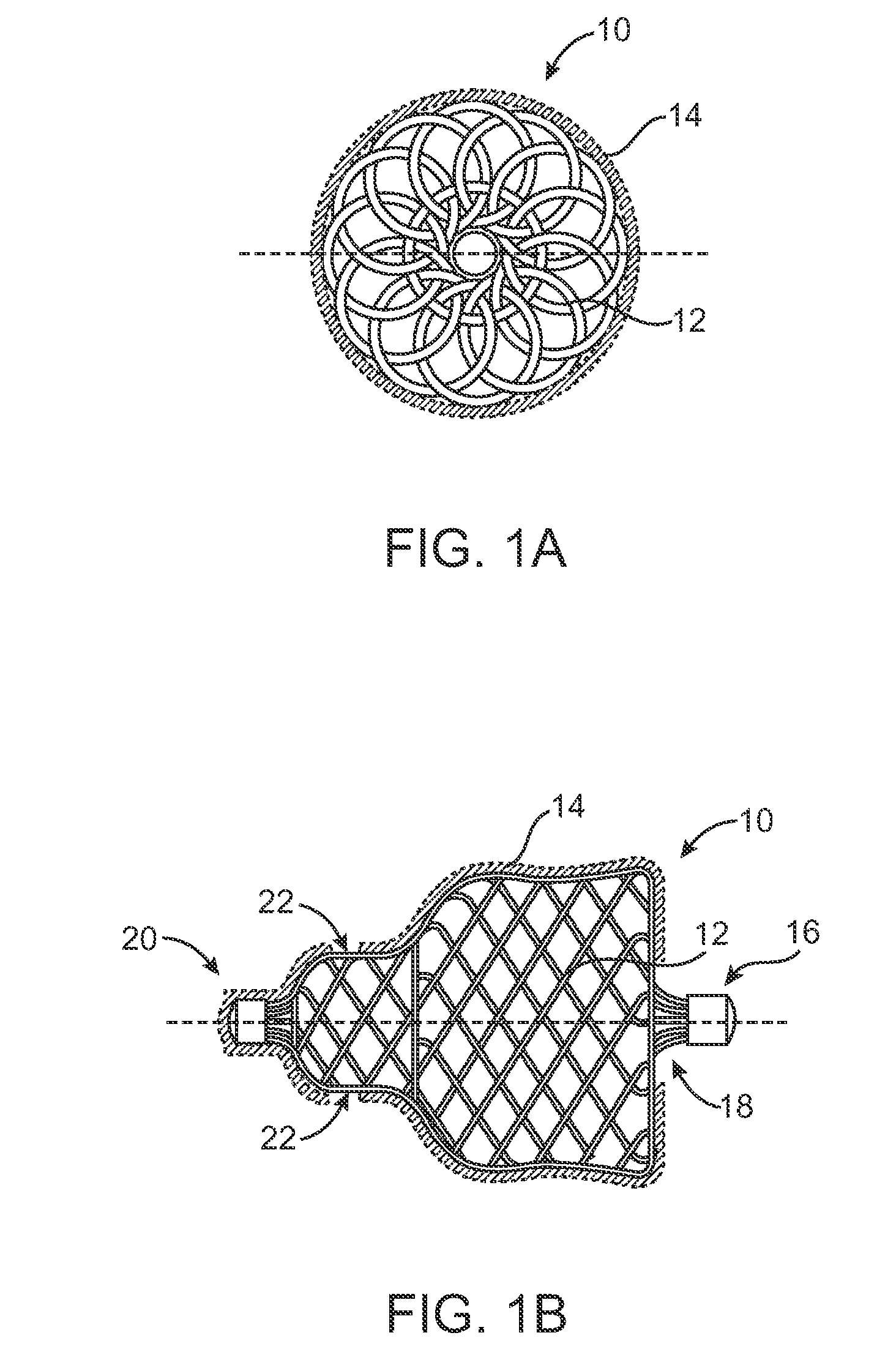

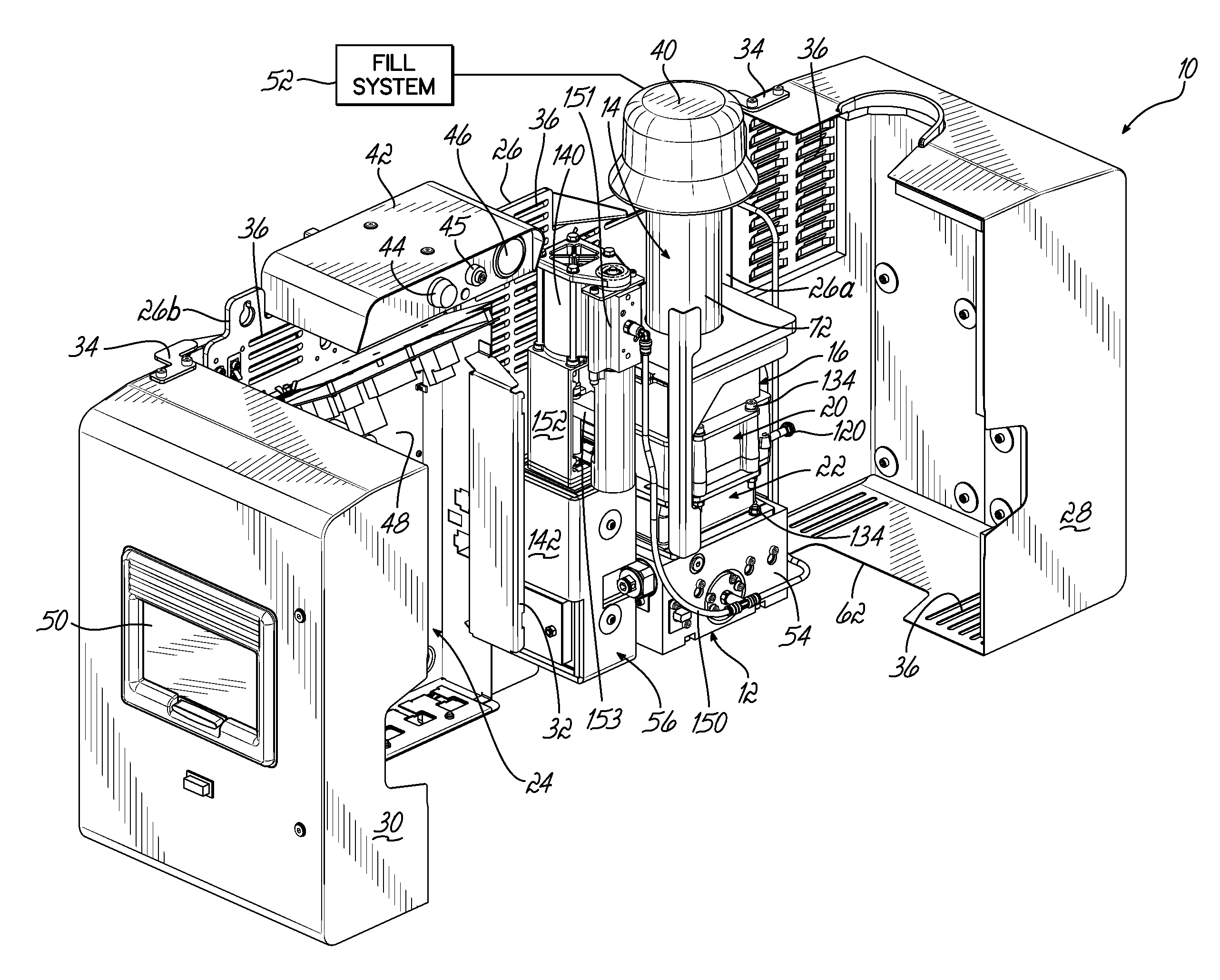

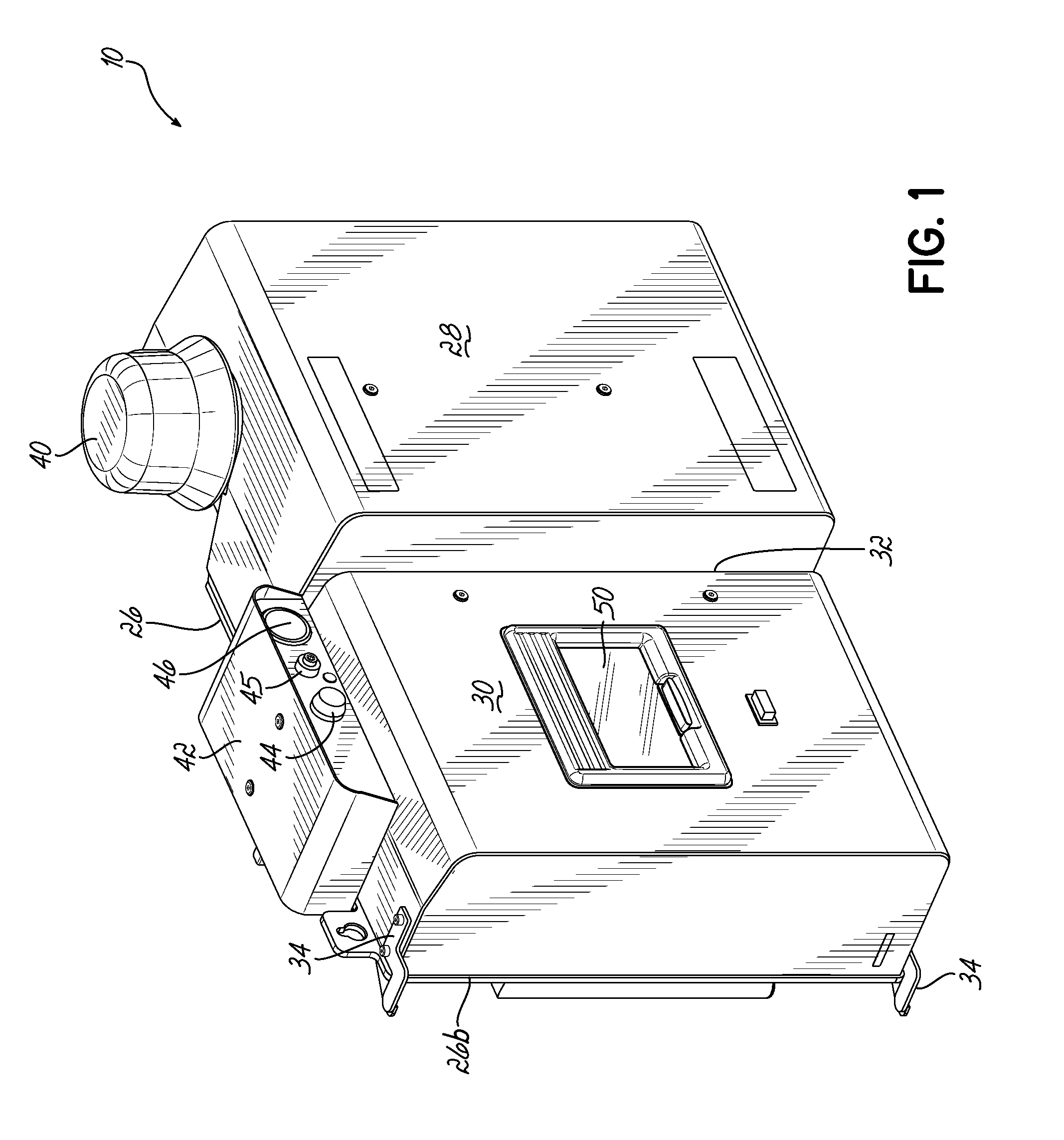

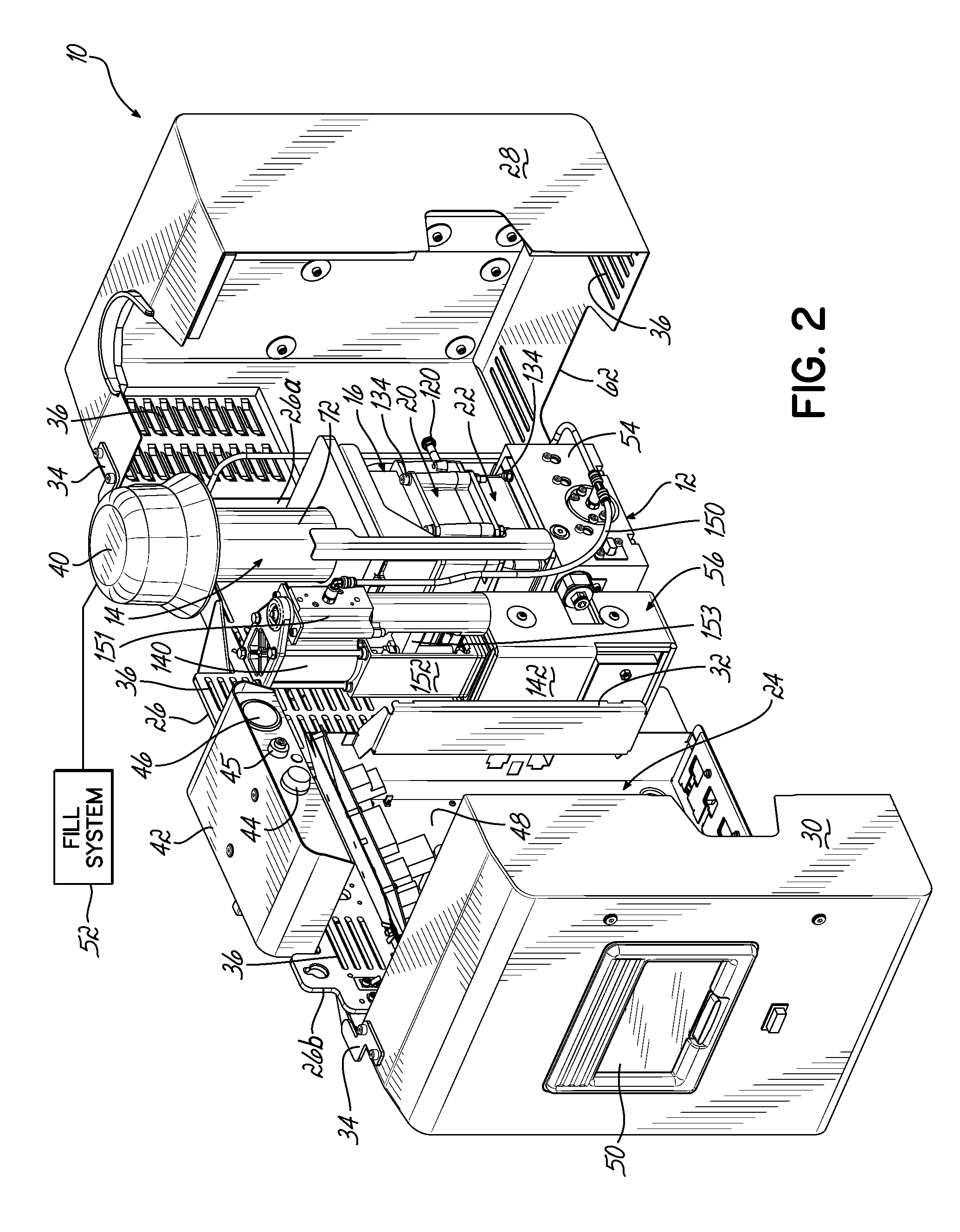

Adhesive dispensing device having optimized cyclonic separator unit

InactiveUS20140079493A1Reduce flow rateAvoid accumulationLiquid surface applicatorsReversed direction vortexMechanical engineeringAdhesive materials

An adhesive dispensing device includes a heater unit for melting adhesive material, a receiving space for feeding the heater unit, and a cyclonic separator unit for delivering adhesive pellets to the receiving space. The cyclonic separator unit includes a tangential inlet pipe proximate to a top end of a generally cylindrical pipe, which is connected to the receiving space at an open bottom end. The tangential or spiral flow of air and adhesive pellets generated through the cyclonic separator unit reduces the speed of the air and adhesive pellets to avoid splashing of molten adhesive material while maintaining enough speed to avoid adhesive build up on the generally cylindrical pipe.

Owner:NORDSON CORP

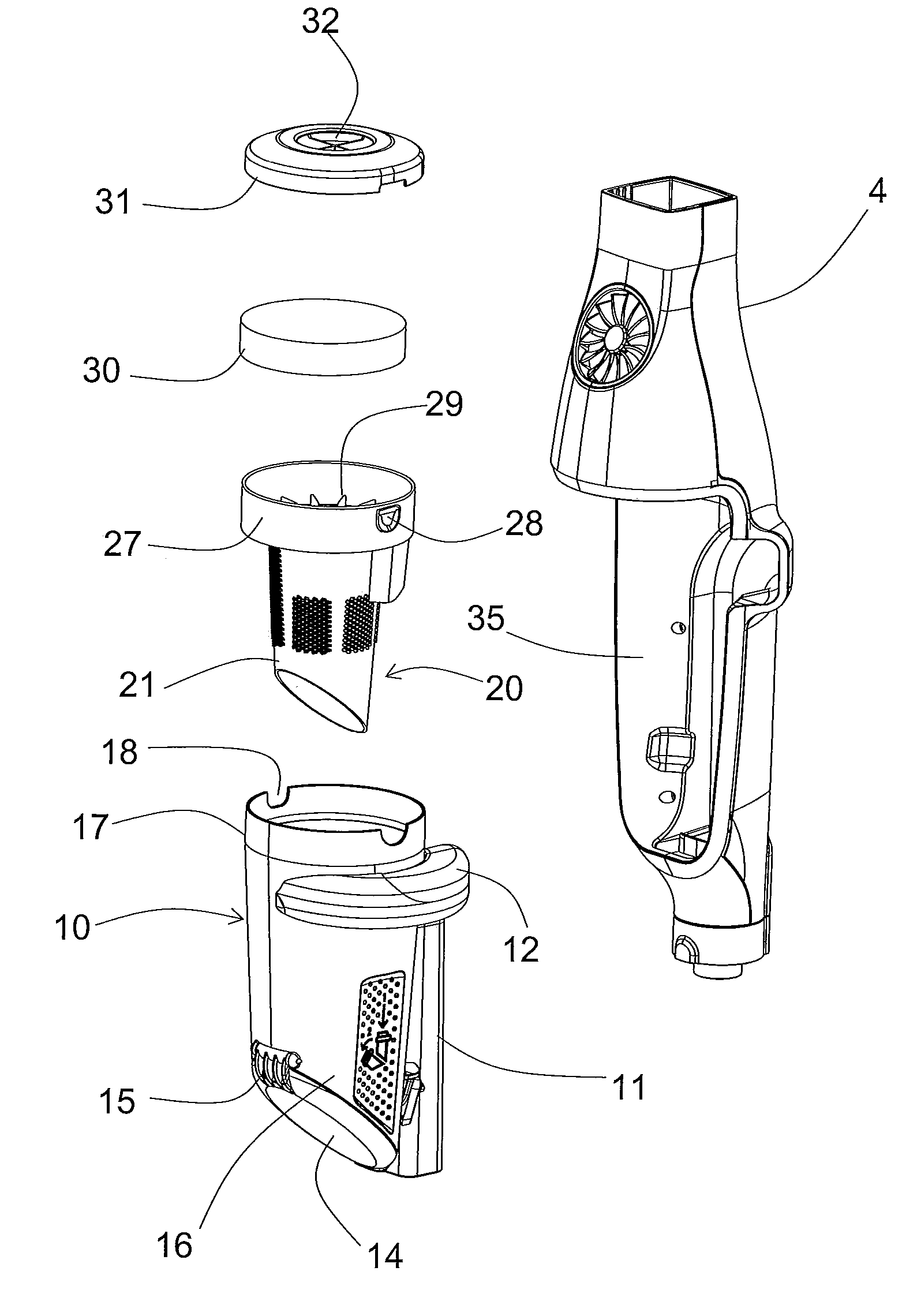

Cyclonic separation device with acceleration ramp

InactiveUS8806707B2Improve efficiencyIncrease speedCleaning filter meansSuction filtersCyclonic separationEngineering

A cyclonic separation device for dust and debris in vacuum cleaners, comprising a roughly cylindrical interior cyclonic chamber connected to an air intake, as well as a separator filter located in the central part of the interior chamber, comprising a tube segment to direct airflow to the air intake with this tube segment located around the roughly cylindrical interior cyclonic chamber, from a starting point to an end point near the air intake, with the cross-section of this tube segment near the end point being smaller than that near the starting point in order to form an acceleration ramp for the airflow between these two points.

Owner:SEB SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com