Electric discharging device of rotation electrode

A technology of rotating electrodes and discharge devices, applied in the field of ions, can solve the problems of increasing airflow velocity and energy consumption, short life of cathodes with thin or thin structures, and high ozone yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

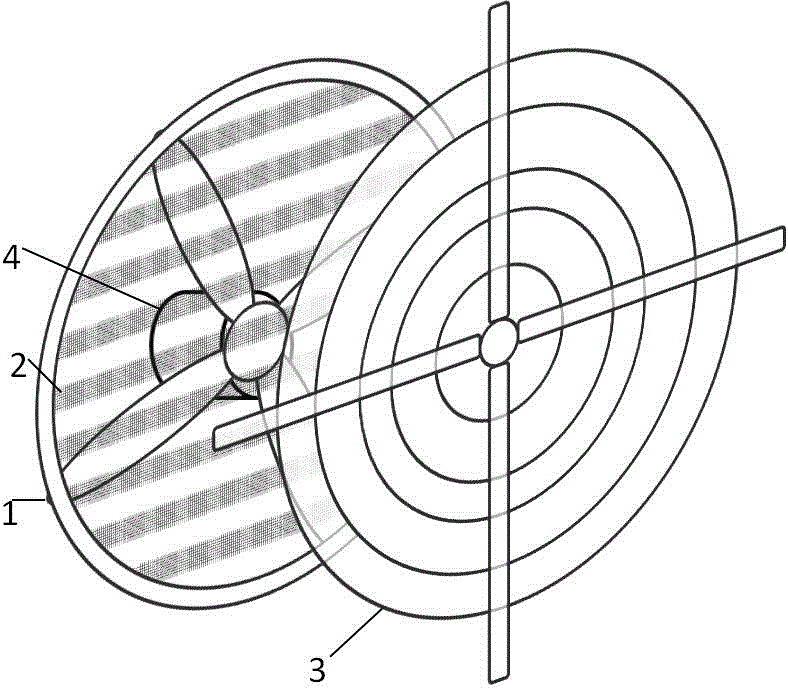

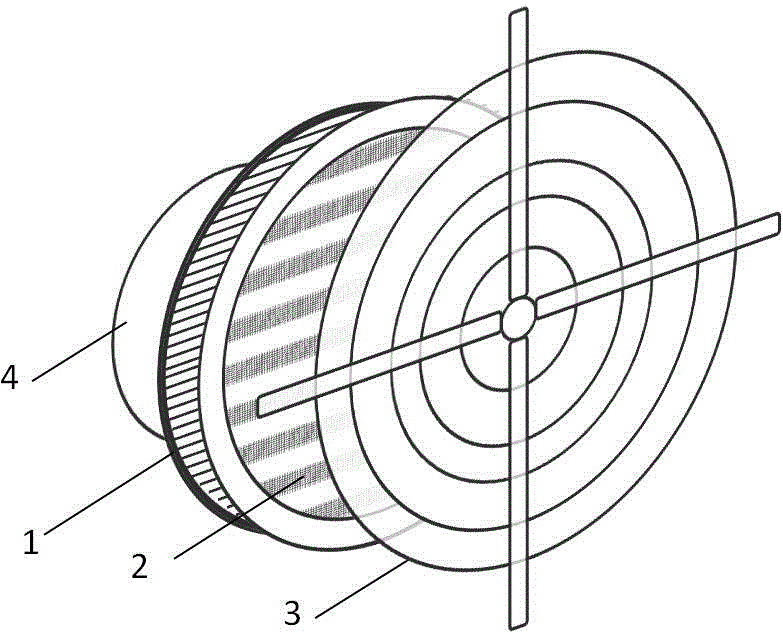

[0030] The discharge device of the centrifugal fan driving the rotating electrode of the specific embodiment 2 of the present invention, its structural diagram is as follows figure 2 shown.

[0031] The rotating electrode 2 is a circular plane structure with 9 strip-shaped wire mesh electrodes arranged in parallel on the metal ring. The circular rotating electrode 2 has the same diameter as the impeller 1 and is fixed on the impeller 1 through the metal ring; The strip wire mesh electrode interval is 10mm, the fixed electrode 3 is a fan metal protective net with a fence structure, the diameter is larger than the impeller diameter; the distance between the rotating electrode 2 and the fixed electrode 3 is 20mm, the driving voltage is 8kV, and the rated power of corona discharge is 10W ;The rated power of motor 4 is 90W, with three gears of high speed, medium speed and low speed, the speed is between 1200-2400r / m, the air supply distance of high speed gear is more than 10 meter...

specific Embodiment approach 3

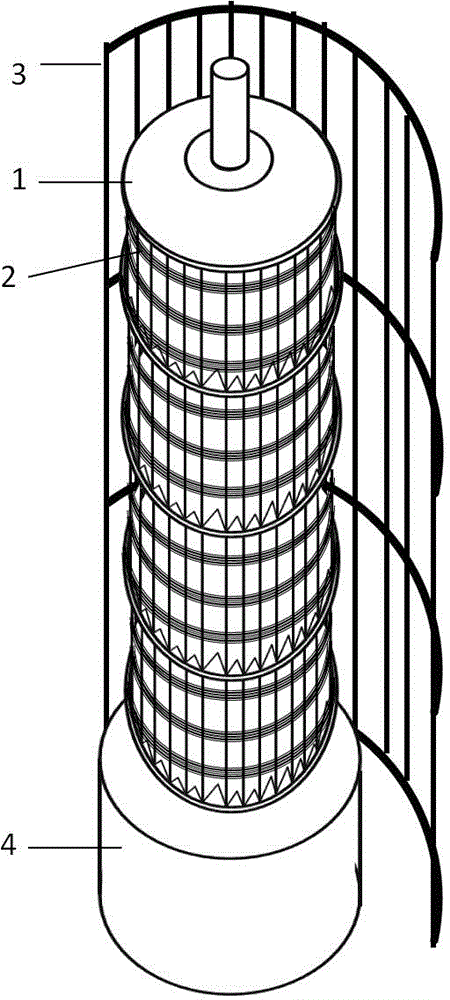

[0032] The specific embodiment 3 of the present invention is to apply the discharge device of the cross-flow fan to drive the rotating electrode in the tower fan. The partial structure diagram of the discharge device is as follows image 3 As shown, the overall schematic diagram of the tower fan is shown in Figure 5 shown.

[0033] The rotating electrode 2 is a wire mesh belt spirally wound on the wind wheel 1 of the cross-flow fan. The distance between the adjacent spiral rings of the metal belt is 10mm. The rotating electrode 2 is in electrical contact with the bearing of the wind wheel 1. The spiral Both ends of the rotating electrode 2 are fixed on the wind wheel 1; the rated power of the motor 4 is 180W, and there are three gears of high speed, medium speed and low speed. More than one meter, air volume 3000m 3 / h, the low speed gear is also more than 10 meters, and the air volume is 1800m 3 / h; the fixed electrode 3 is a two-fifths cylindrical surface dust collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com