Two-stage dry dust cleaning device and down-hole drilling machine including same

A technology of dry dust removal and secondary dust removal, applied in construction and other directions, can solve the problems of difficult to achieve dust removal effect, endangering the operator's personal health, affecting the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

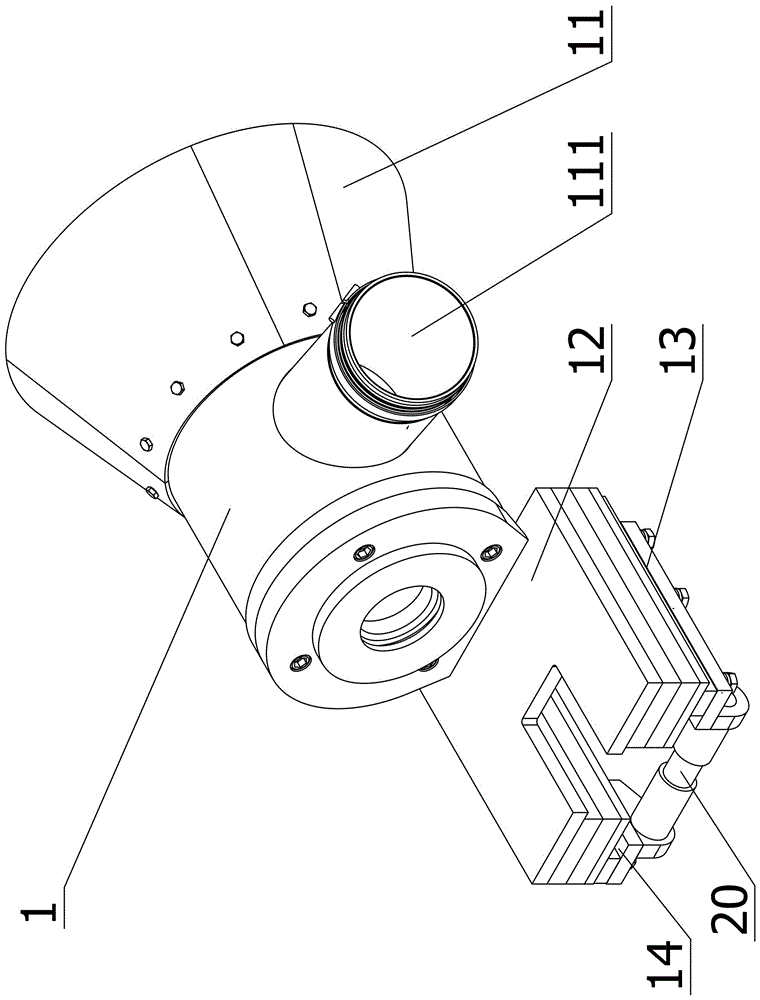

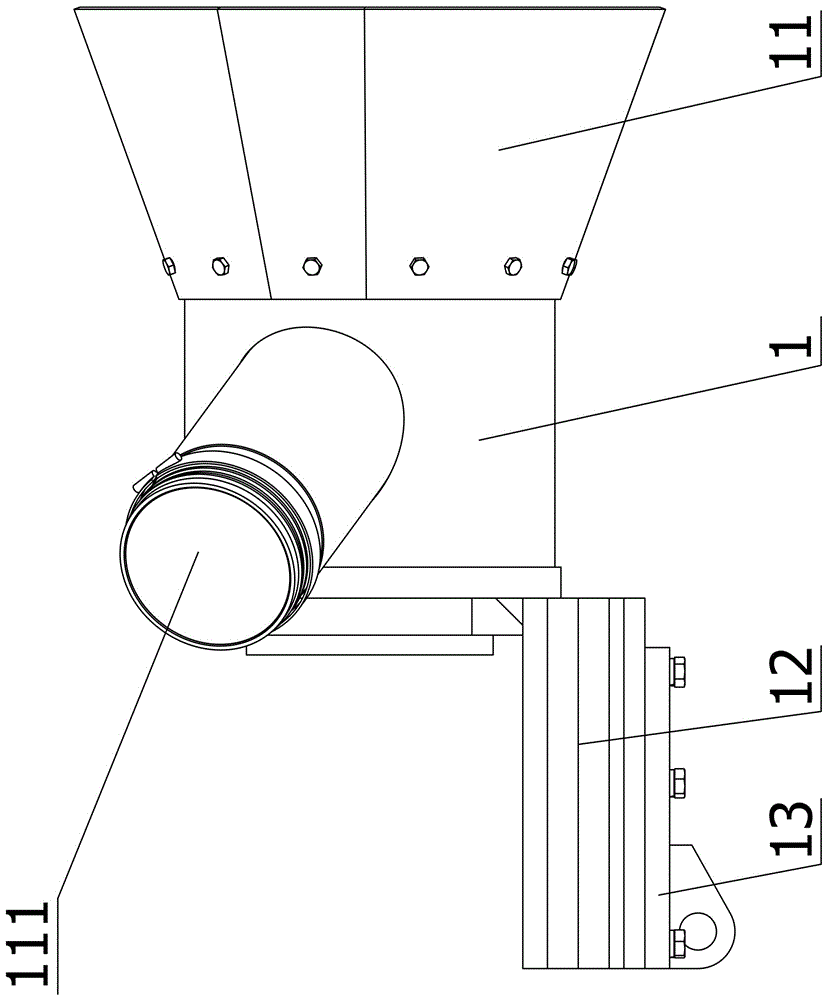

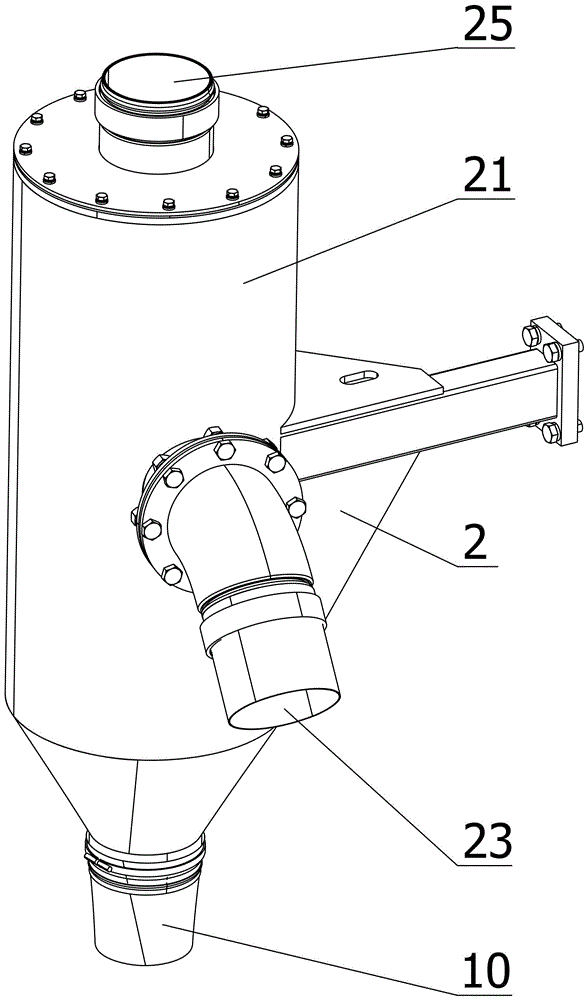

[0031] According to attached Figure 1 to Figure 12 As shown, a two-stage dry dust removal device of the present invention is mainly used in down-the-hole drilling rigs. The two-stage dry dust removal device includes a dust collection part 1, a primary dust removal part 2, and a secondary dust removal part 3. The dust collecting part 1 is adapted to be connected to the front end of the girder 19 , the primary dust removal part 2 is mounted on the girder 19 , and the secondary dust removal part 3 is mounted on the frame 15 . Moreover, the dust collecting part 1 , the primary dust removing part 2 and the secondary dust removing part 3 are sequentially connected with a guide pipe 4 , and the secondary dust removing part 3 is equipped with a centrifugal exhaust fan 5 with an air outlet 51 . The air flow is driven by the centrifugal exhaust fan 5, so that the dust collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com