Valve block with improved air tightness and air pump

An air tightness and valve plate technology, which is applied to the components of the pumping device for elastic fluid, pump components, variable displacement pump components, etc. 'Arching and other problems, to achieve the effect of reducing airflow velocity, improving performance, and avoiding arching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

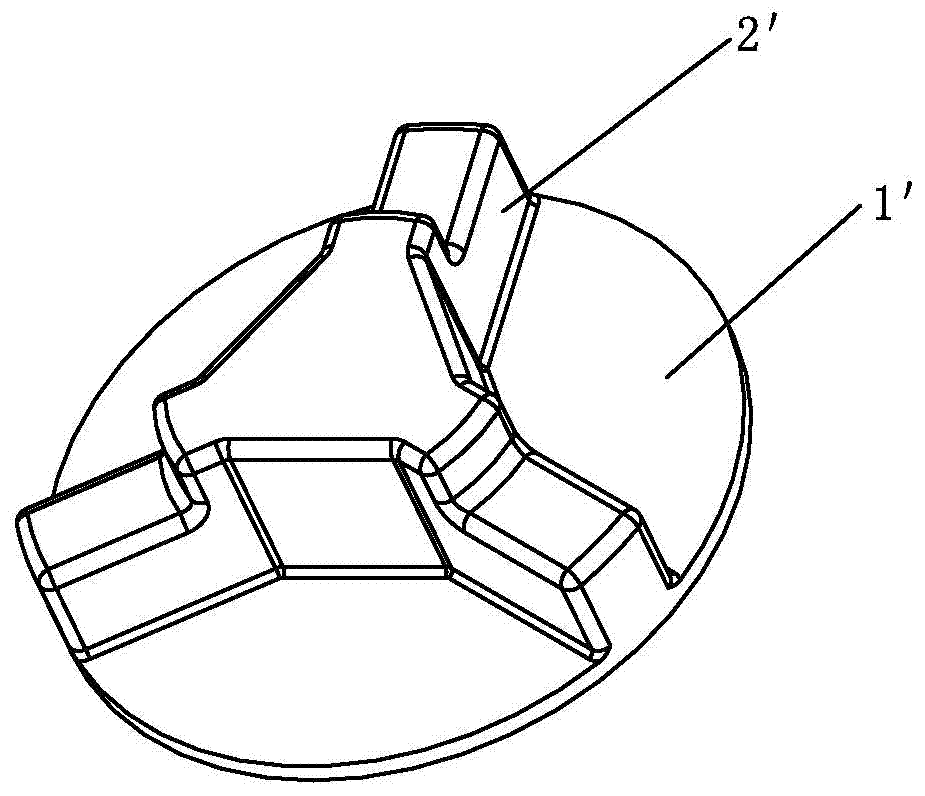

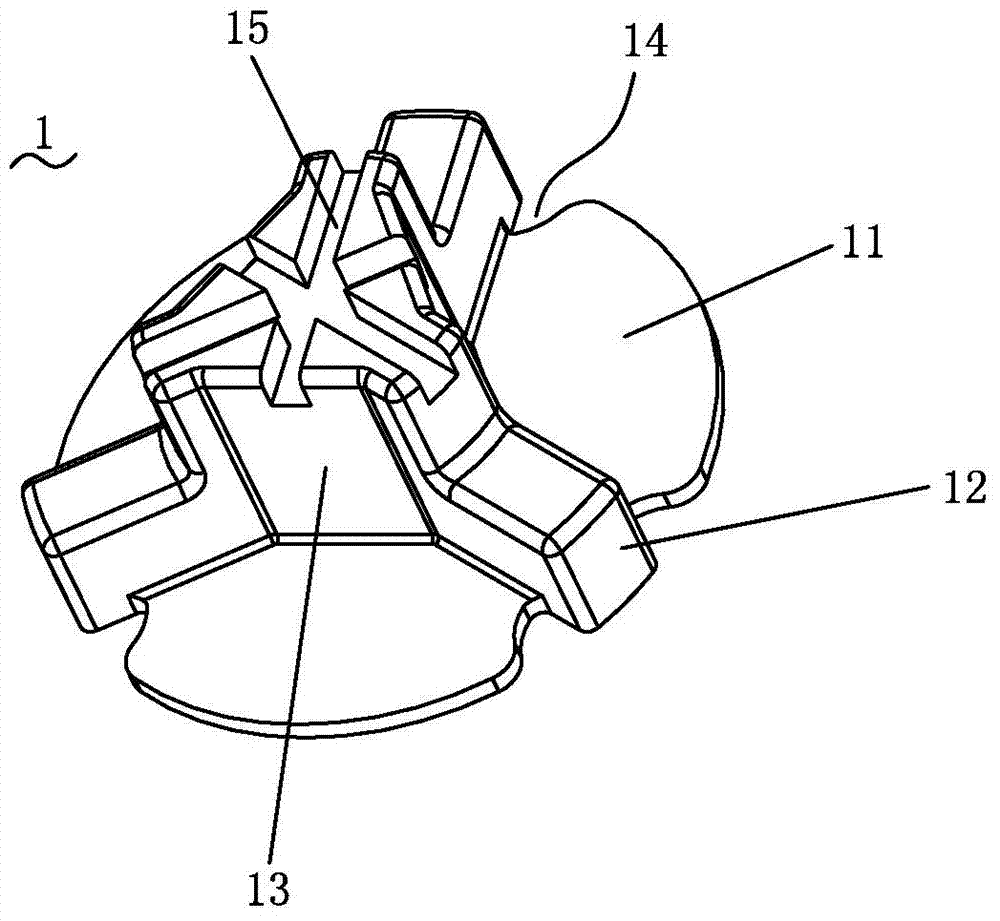

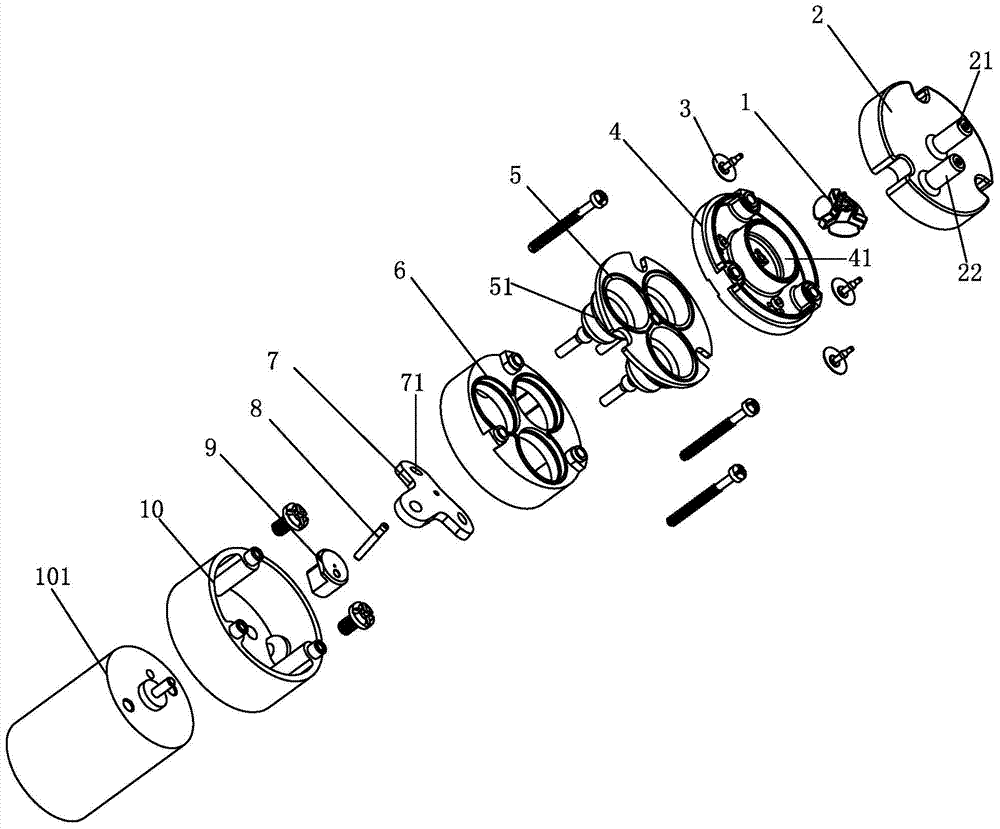

[0025] See figure 2 As shown, a valve plate with improved airtightness of the present invention, the valve plate 1 has three elastically swingable blades 11, three ribs 12 arranged in the radial direction, and a valve plate located at the top of the middle part of the valve plate 1. The mounting column 13 on the surface; the three blades 11 of the valve plate 1 are distributed along the circumferential direction, and are generally similar to a circular structure, and every two adjacent blades 11 are separated by ribs 12; the roots of each blade 11 are respectively connected to the installation The columns 13 are integrally connected. Each blade 11 is provided with a buffer structure at the outer end for connecting with the rib 12 . Here, the buffer structure is a relief gap 14 for providing a deformation buffer space for the assembly and extrusion of each blade 11 .

[0026] The mounting column 13 of the above-mentioned valve plate 1 is in a similar triangular structure, and...

Embodiment 2

[0035] See Figure 5 As shown, a valve plate with improved airtightness of the present invention differs from Embodiment 1 in that: the buffer structure of the valve plate 1 is a film 15, and the film 15 is connected to the circumferential direction of each vane 11 of the valve plate 1. Between the two ends of and the corresponding ribs 12.

[0036] A valve plate with improved airtightness of the present invention adopts the film 15 as a buffer structure. In addition to the above-mentioned advantages, that is, providing a buffer space for the blades 11 to assemble and squeeze deformation, it also has another advantage: it can strengthen each blade. 11 strength, improve the performance of the air pump.

[0037] The valve plate described in the second embodiment can also be applied to an air pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com