Rotary-cut type integrated central feeding machine

A central feeder and rotary cutting technology, applied in the direction of loading/unloading, containers, packaging, etc., can solve problems such as broken coal, unobvious dredging effect, and downstream equipment stop running, so as to ensure smooth feeding and eliminate blockage Coal factor, effect of balanced continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

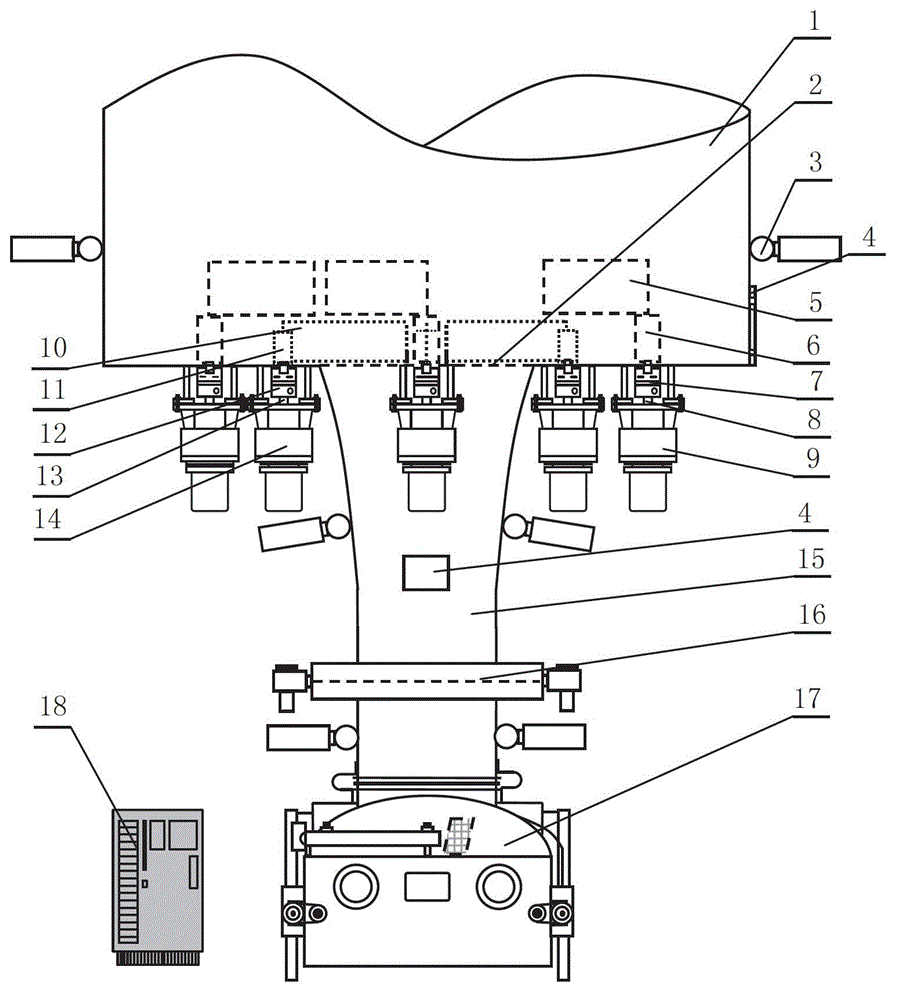

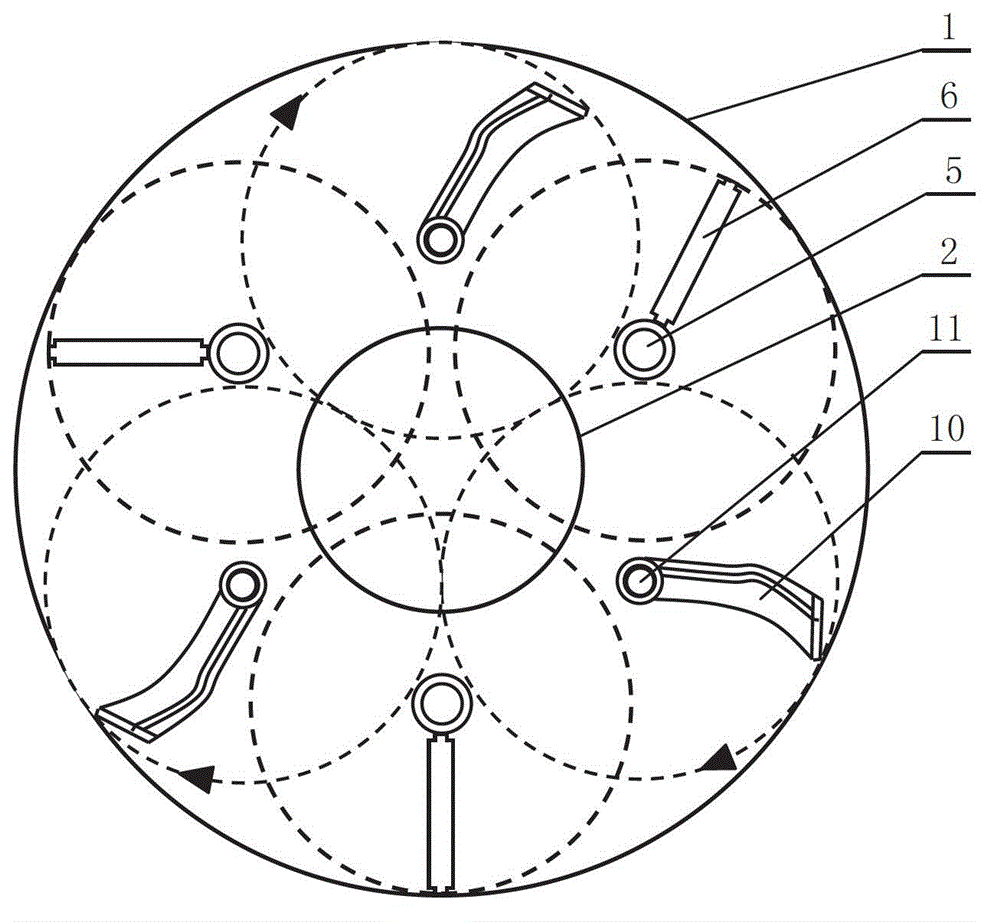

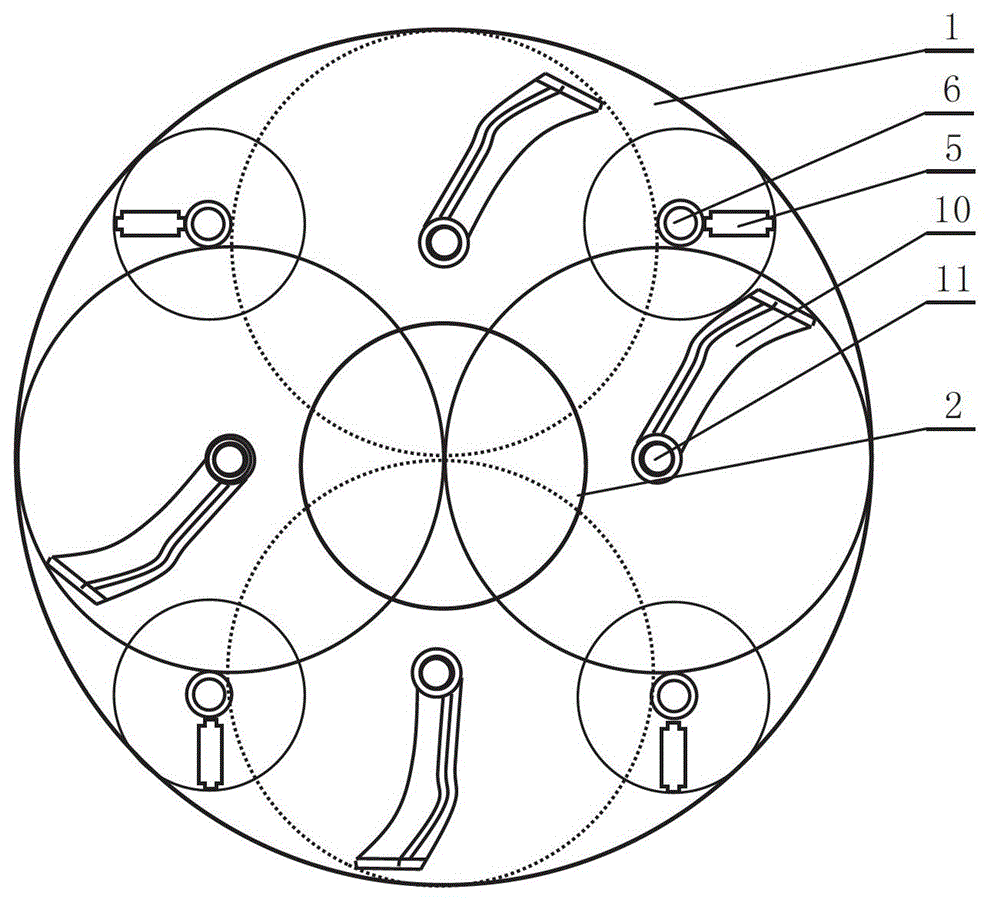

[0027] Such as figure 1 As shown, the present invention includes improved raw coal bunker 1, 3 scraping devices, 3 pushing devices, hyperbolic or shrimp-shaped central feeding hopper 15, flapper door 16, air hammer 3, intelligent electric control box 18 and so on.

[0028] The improved raw coal bunker 1 is preferably cylindrical, with an inner diameter of 3-4 meters, and a height of generally 2-8 meters according to site conditions. It can also be designed as a trumpet-shaped structure with a small mouth. In the middle of the improved raw coal bunker 1, there is a circular discharge opening 2 for raw coal descending, with a diameter of about 1.2-1.5 meters.

[0029] The scraping device, the pushing device, the gate 16 and the air hammer 4 are all controlled by the intelligent electric control box 18. The gate 16 is preferably two-way open. The outer wall of the improved raw coal bunker 1 and the middle or lower part of the hyperbolic or shrimp-shaped central feeding hopper 15 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com