Silo with breakage lowering devices with L-shaped flow baffles and grain loading method

A technology of crushing device and spoiler, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of loss, difficulty in production and installation, easy breakage and grading, etc., to improve service life, reduce installation cost, and facilitate high and low positions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

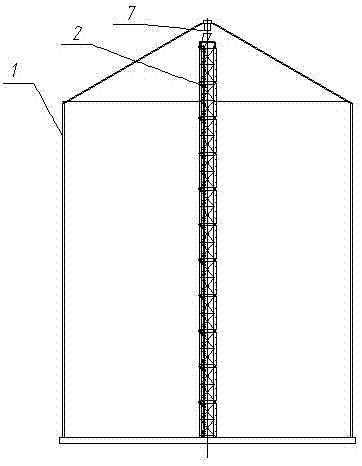

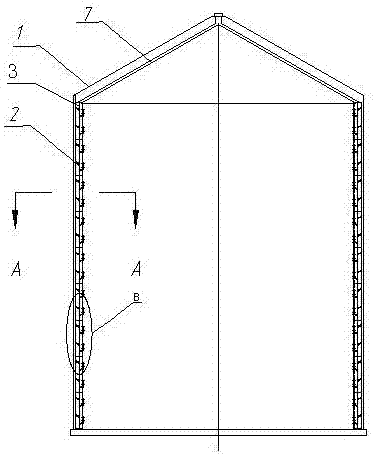

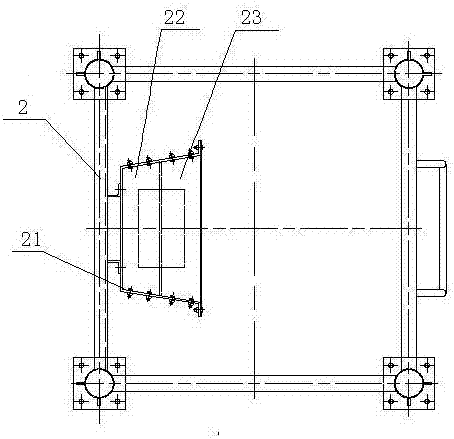

[0032] A silo with a descending crushing device with L rows of baffles, its composition includes: a silo 1, a grain feeding pipe 7 is distributed in the silo, and a group of descending crushing devices 2 are installed in the silo , the upper part of the falling crushing device is the grain inlet 3 corresponding to the grain feeding pipe, the falling crushing device has a trough body 21, and a group of The bluff bodies A22 are arranged in parallel, and a set of bluff bodies B23 are connected to the flanges on both sides of the trough-shaped body. The inclination angle of the bluff bodies A is symmetrical, the bluff bodies B are parallel to each other, and the grain outlet 4 is formed between the bluff bodies B.

Embodiment 2

[0034] According to the silo of the falling crushing device with L rows of baffles described in embodiment 1, there are 1-4 falling crushing devices, there may be a central falling crushing device located in the center of the circle, and the rest are evenly distributed on the circumference, or All mounted on the circumference.

[0035] Each of the falling crushing devices has 3-20 sections, and the length of each section is 1.5-3 meters. There is a socket structure between the sections of the falling crushing device, and the bottom of the previous section is sleeved on the top of the next section, and fixed.

[0036] The section of the bluff body B is L-shaped, Figure 4 or Figure 5 shown.

Embodiment 3

[0038] In the silo of the descending crushing device with L rows of baffles described in Embodiment 1 or 2, the inclination a of the bluff body A and the bluff body B is 31-42°, and the bluff body described after installation The distance L between A is 220-850mm, the distance L1 between the bluff bodies B is 220-850mm; from top to bottom: the distance L2 between the bluff body B and the bluff body A is greater than The distance between the bluff body A and the bluff body B is L3, and the difference between L2 and L3 is 0-400 mm. Generally, it is better to arrange grains at unequal distances.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com