Patents

Literature

285 results about "Coal power plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal is mainly used in coal-fired power plants to generate electricity. It is a reliable and low-cost energy source. In the US, about 50% of electricity is generated from coal. The lignite and bituminous coal are largely used for this purpose.

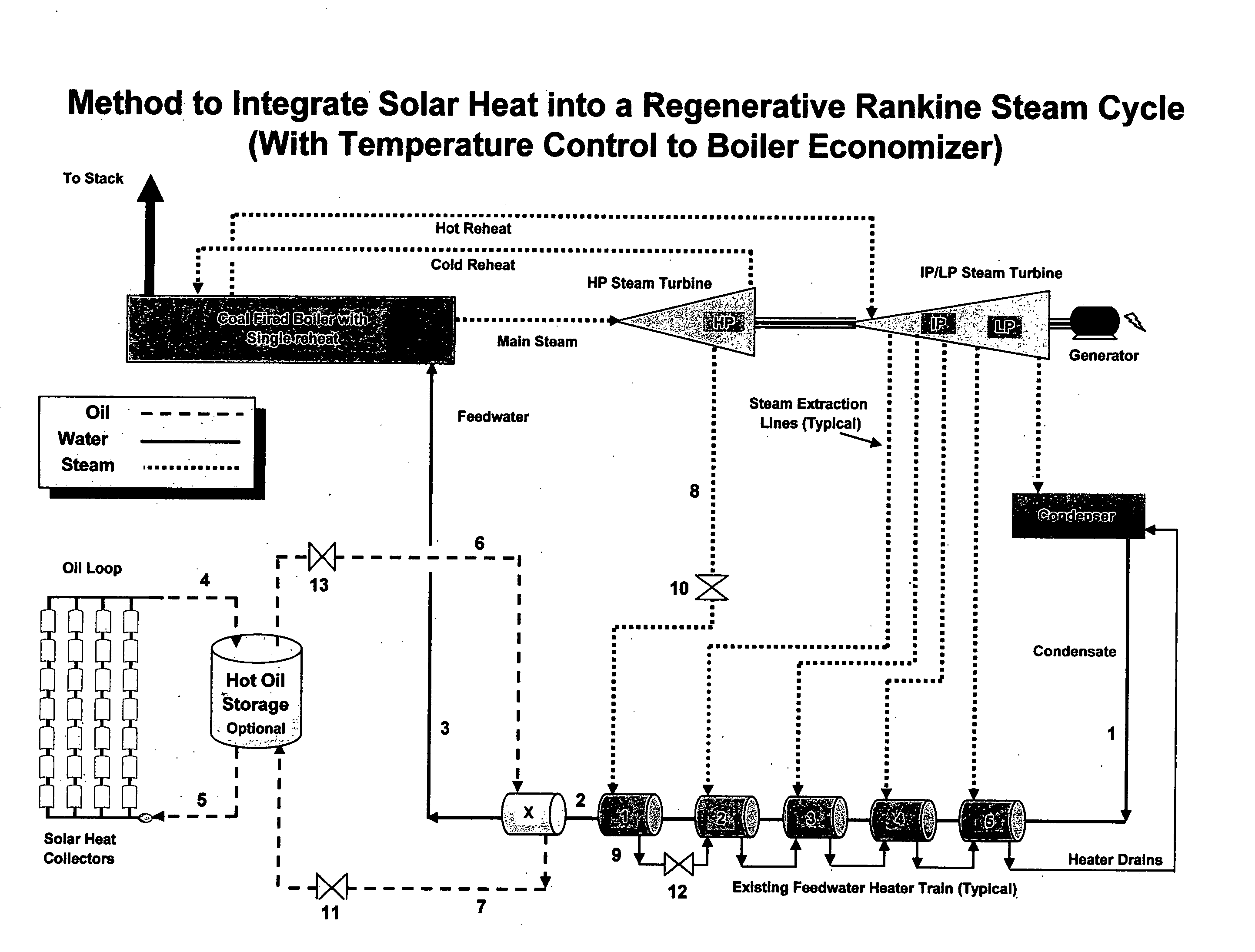

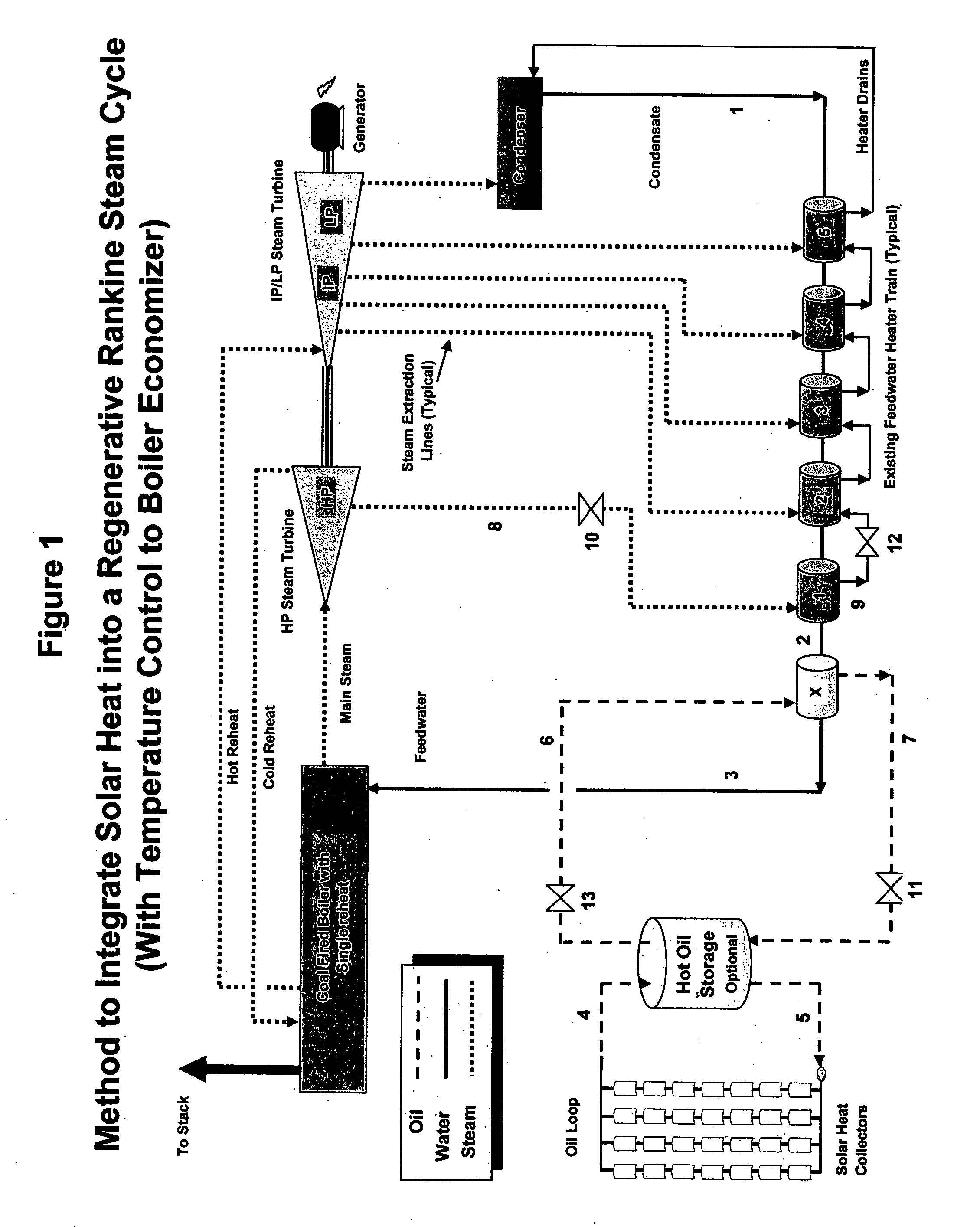

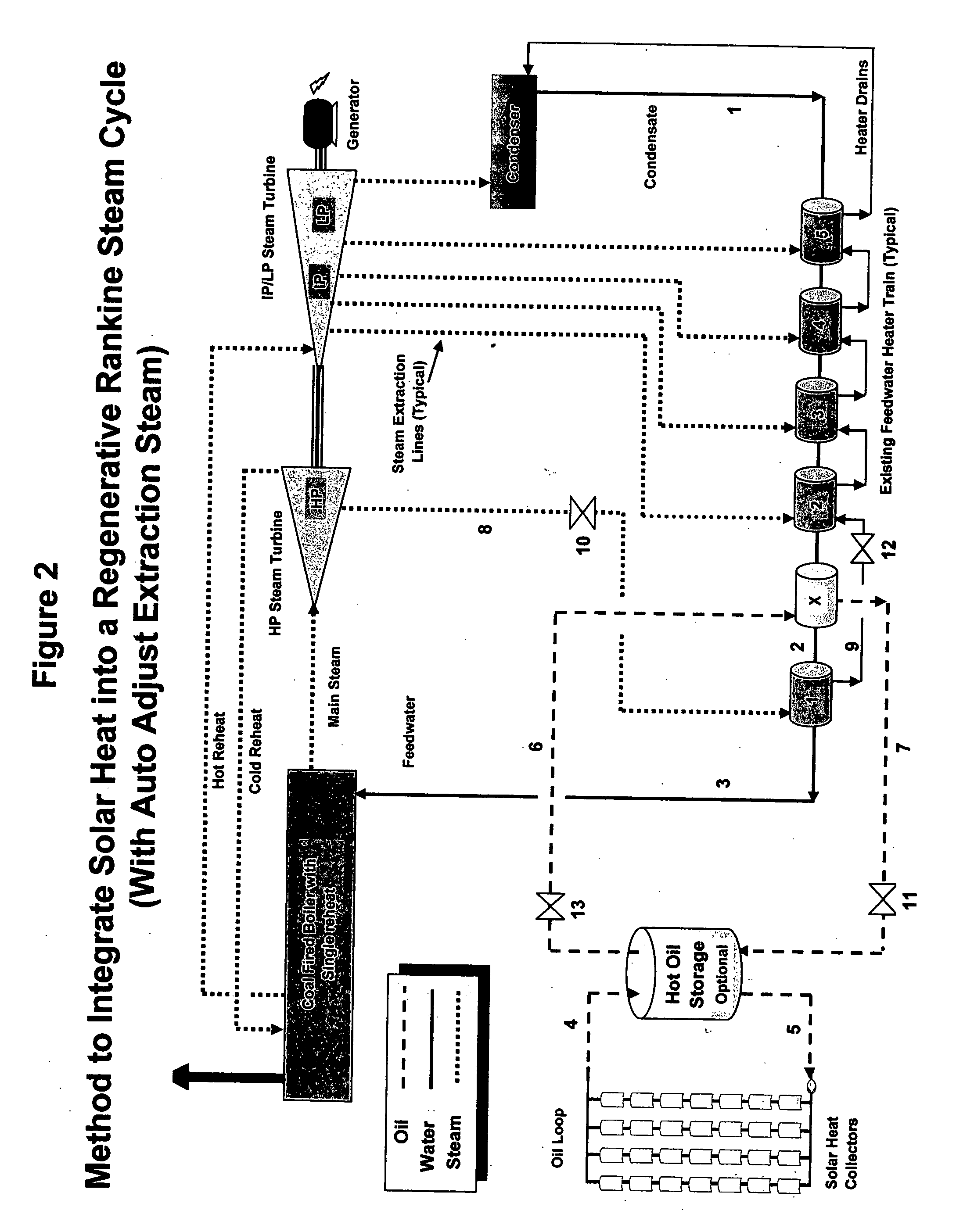

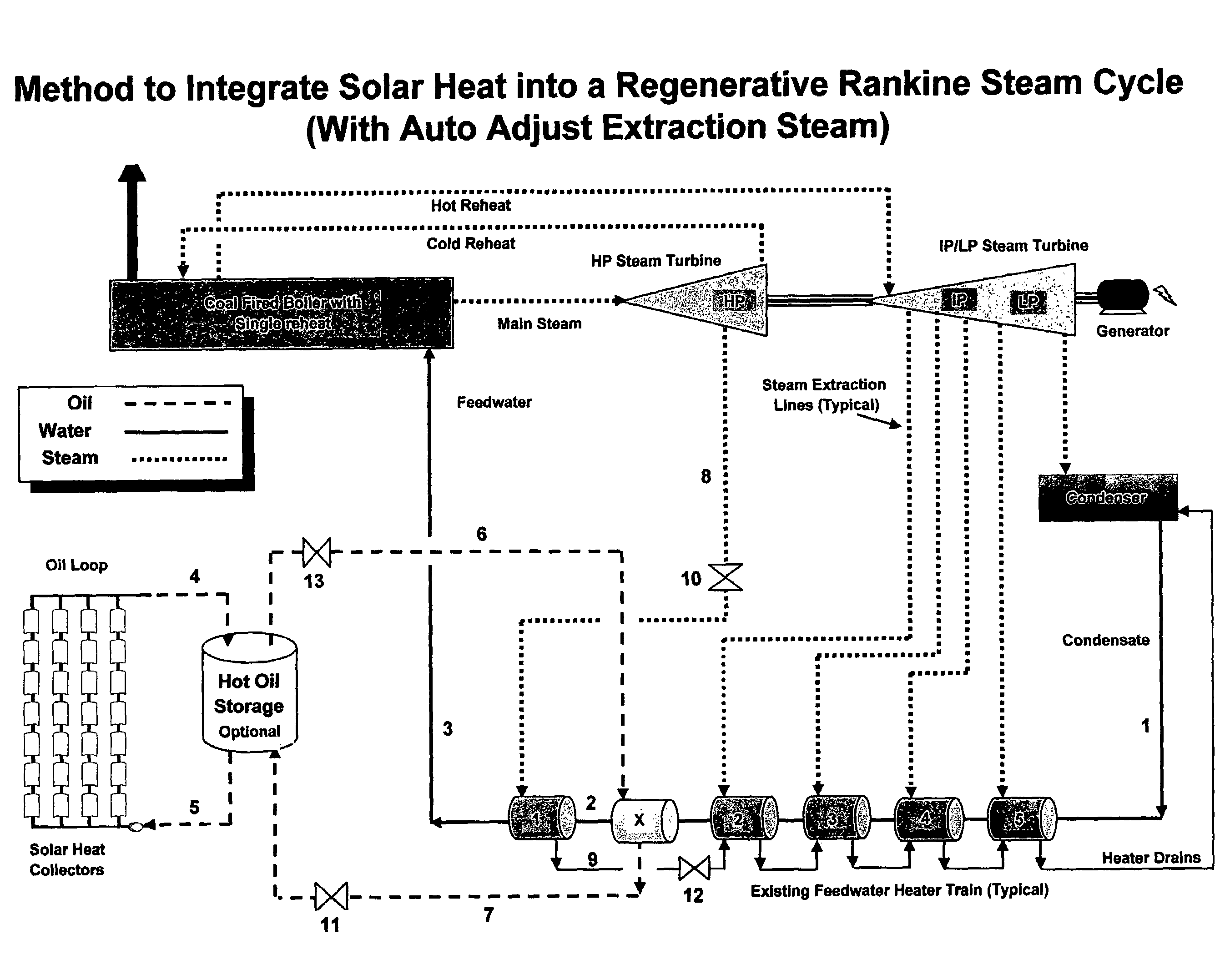

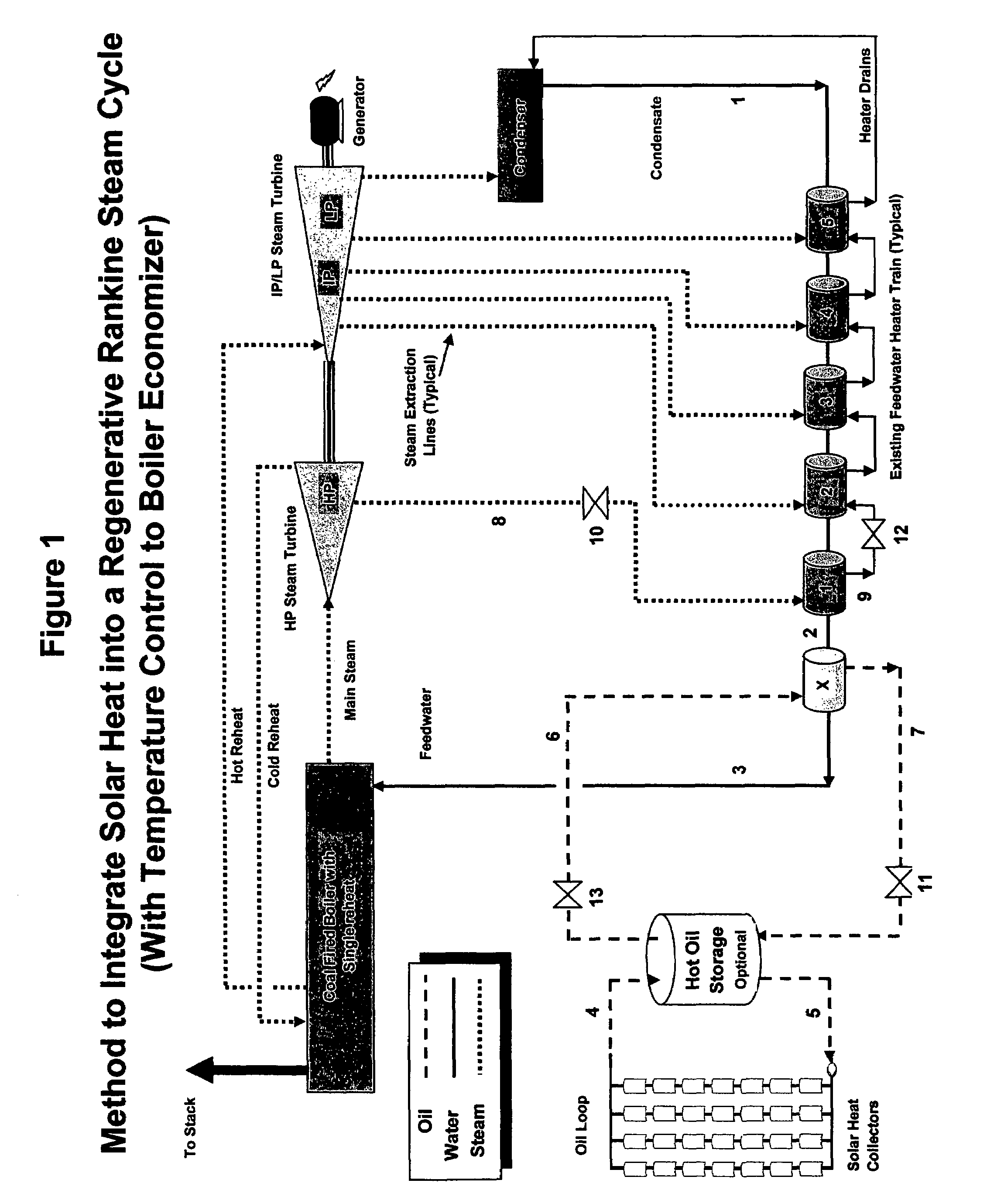

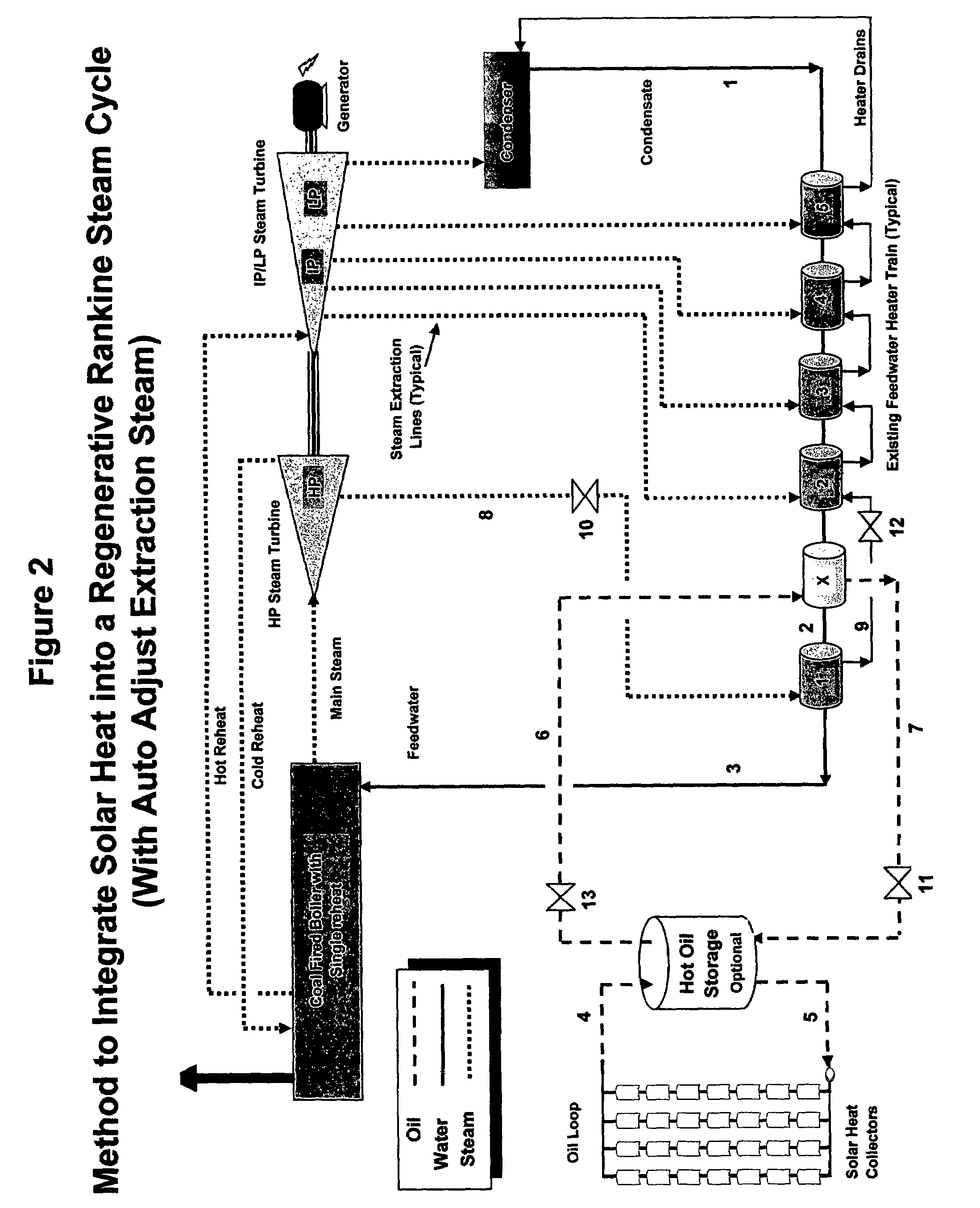

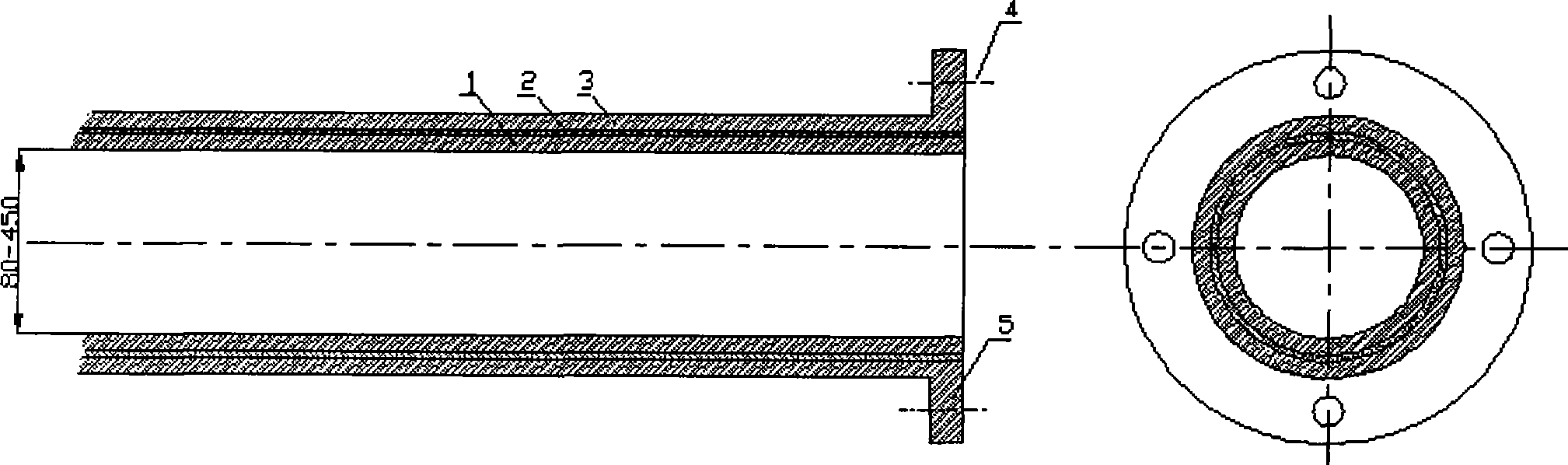

Method and system integrating solar heat into a regenerative rankine steam cycle

InactiveUS20060266039A1High solar system efficiencySmall temperature differenceAuxillary drivesFrom solar energyThermal energyClosed loop

A method to integrate collected solar thermal energy into the feedwater system of a Rankine cycle power plant is disclosed. This novelty uses a closed loop, single phase fluid system to collect both the solar heat and to provide the heat input into the feedwater stream of a regenerative Rankine cycle. One embodiment of this method of integrating solar energy into a regenerative Rankine power plant cycle, such as a coal power plant, allows for automatic balancing of the steam extraction flows and does not change the temperature of the feedwater to the boiler. The concept, depending on the application, allows for the spare turbine capacity normally available in a coal plant to be used to produce incremental capacity and energy that is powered by solar thermal energy. By “piggybacking” on the available components and infrastructure of the host Rankine cycle power plant, considerable cost savings are achieved resulting in lower solar produced electricity costs.

Owner:MARKRON TECH

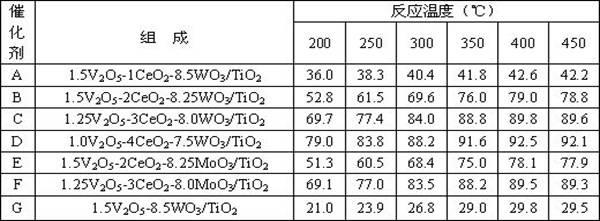

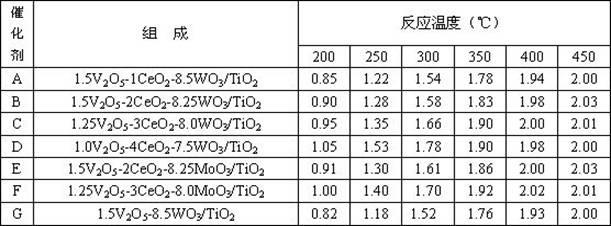

Composite smoke denitration catalyst capable of oxidizing zero-valence mercury

ActiveCN102350340AImprove oxidation capacityRealize collaborative controlDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystVanadate

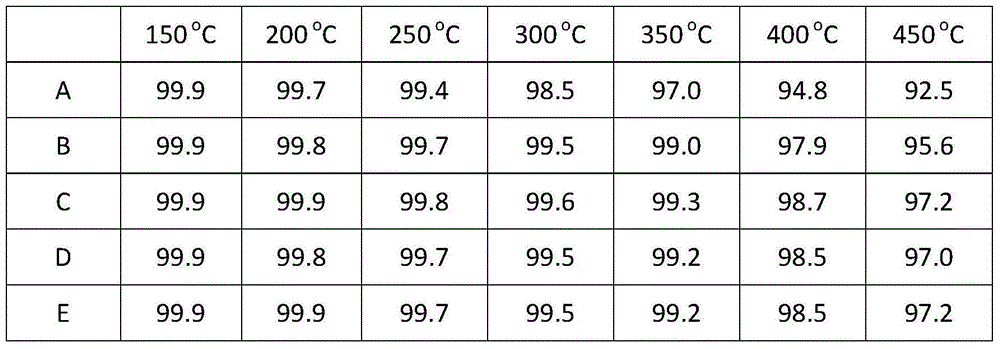

The invention provides a composite smoke denitration catalyst capable of oxidizing zero-valence mercury. The catalyst is composite oxide V2O5-CeO2-WO3 / TiO2 or V2O5-CeO2-MoO3 / TiO2 based on TiO2 as a carrier, wherein the weight proportion is as follows: the weight percent of TiO2 is 75-100, the weight percent of V is 1-1.5, the weight percent of Ce is 1-5, and the weight percent of W or Mo is 7.5-8.5. The preparation method comprises the following steps: depositing Ce(OH)3 on nano TiO2; dipping ammonium vanadate / ammonium molybdate; and drying and roasting so as to obtain the catalyst; or dipping a commercial SCR (selective catalytic reduction) catalyst in a cerous nitrate aqueous solution, and then drying and roasting. The catalyst provided by the invention maintains the denitraiton efficiency of the original SCR catalyst and simultaneously the oxidation rate of zero-valence mercury is obviously improved, and divalent mercury ions are captured in subsequent dedusting equipment and wet desulphurization system; and the application temperature range of the catalyst is wide, the combination control of emission amounts of nitrogen oxides and mercury in smoke of a fuel coal power plant can be achieved on the promise that the smoke purification facility of the fuel coal power plant is not added.

Owner:GUODIAN SCI & TECH RES INST

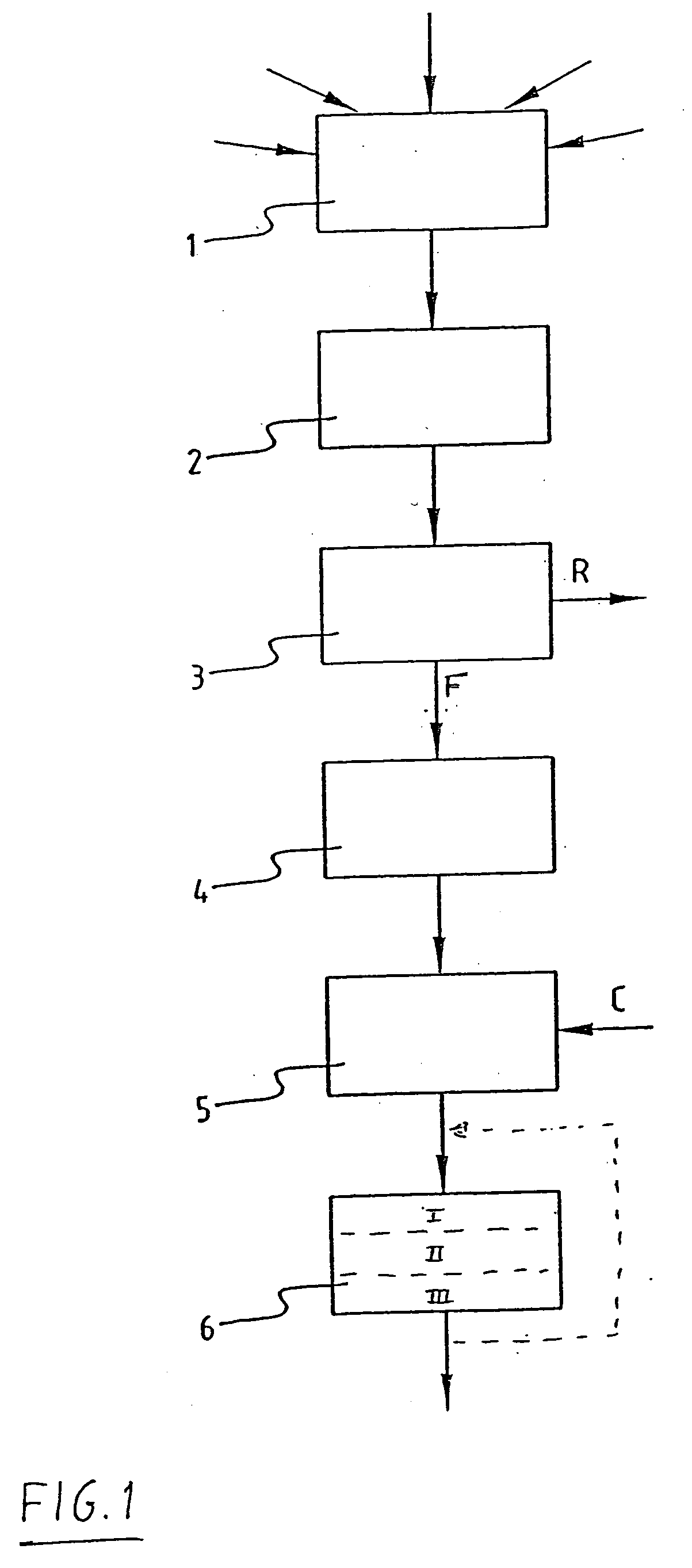

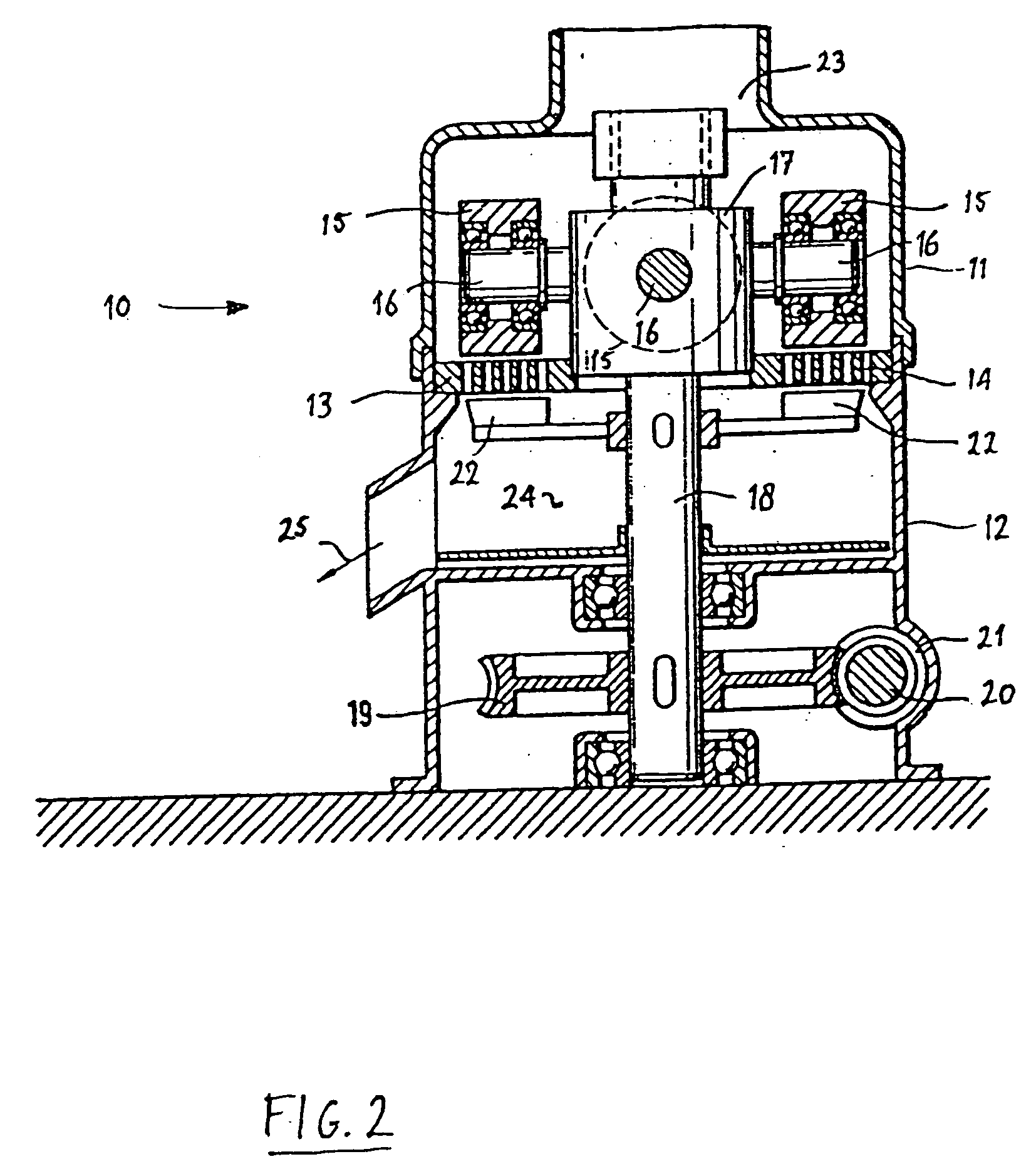

Method and installation for conversion into fuel of organic material originating for instance from domestic waste

InactiveUS20060123697A1Solution value is not highReduce outputBiofuelsSolid fuelsEnvironmental engineeringEngineering

A method is provided for converting organic material from domestic refuse into fuel for use in a pulverized coal power plant, comprising of mixing the organic material with at least one flammable material while adding binder, and pressing the mixture to form hard, relatively brittle agglomerates. Further provided is an installation for converting organic material from domestic refuse into fuel, comprising a device for mixing the organic material with at least one flammable material while adding binder, and device for pressing the mixture to form hard, relatively brittle agglomerates.

Owner:NEDCOAL PATENT IO

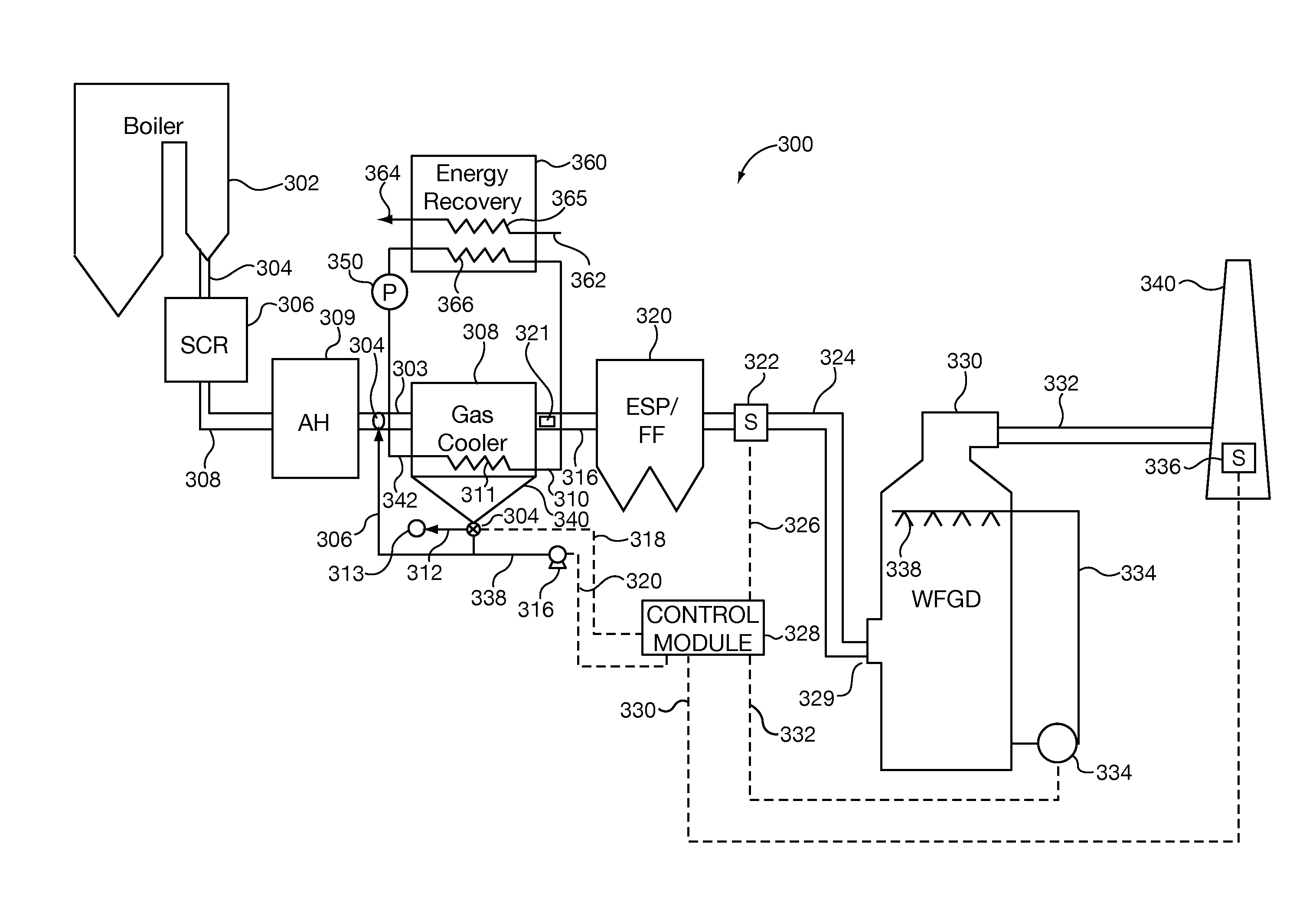

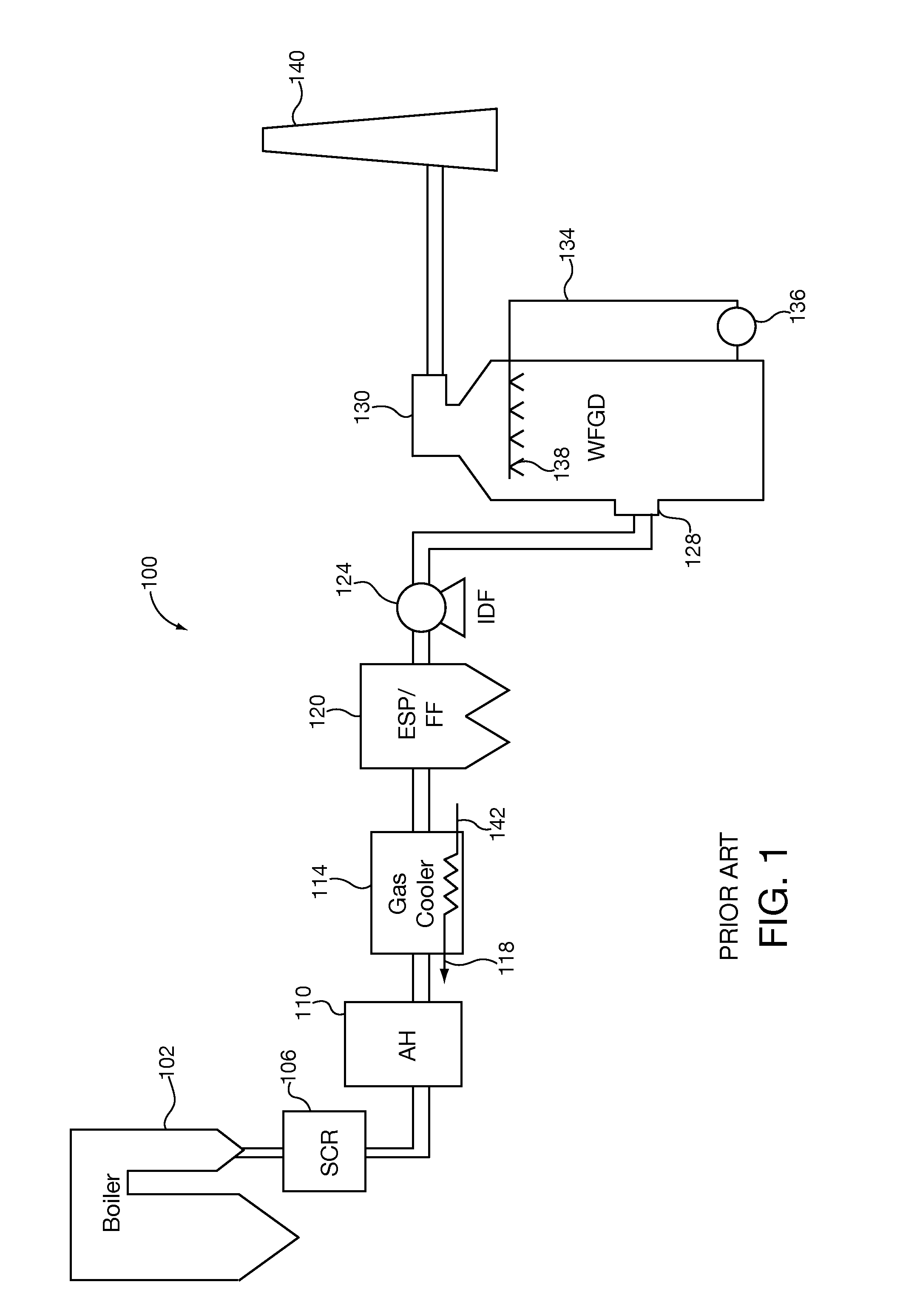

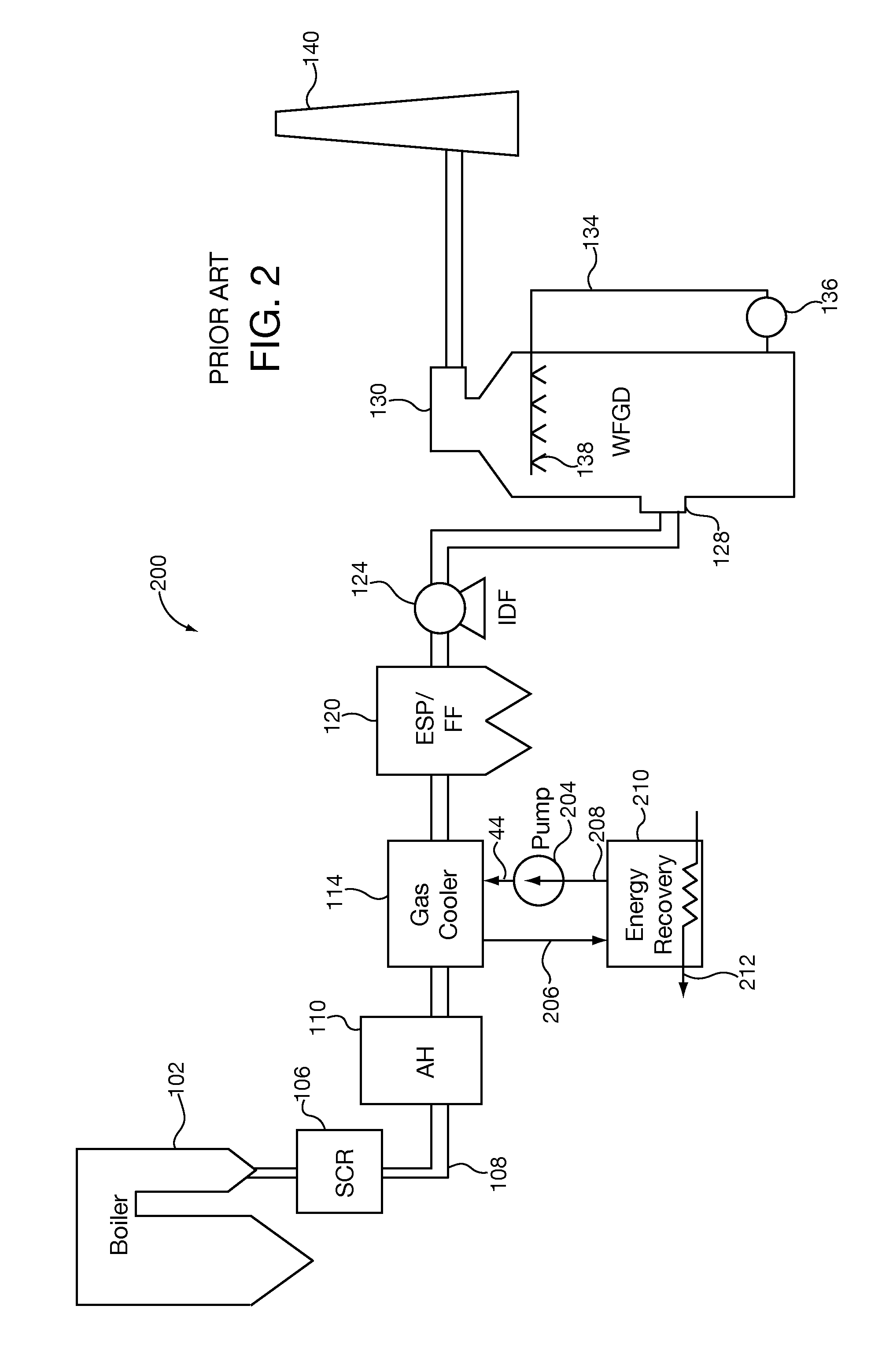

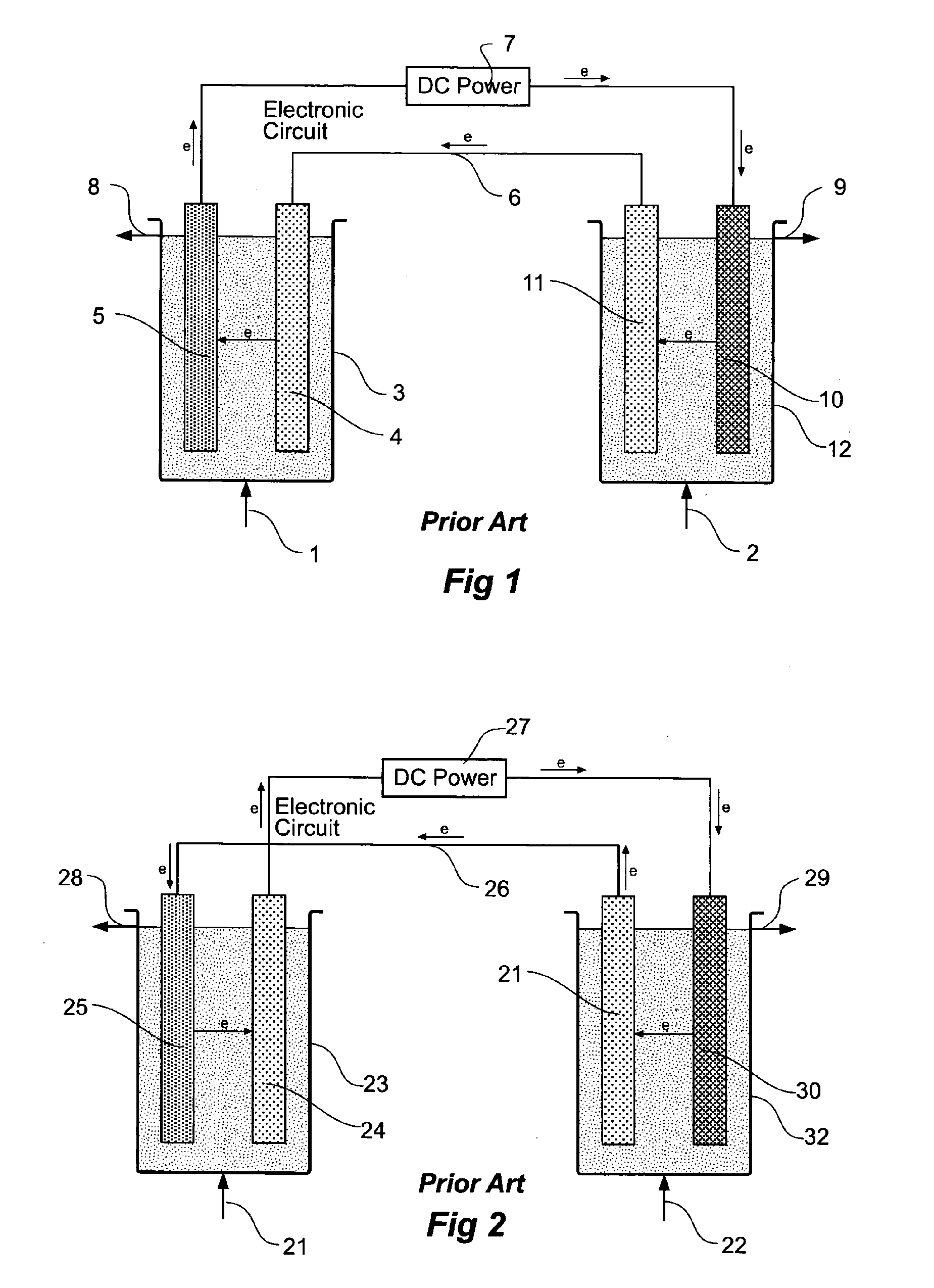

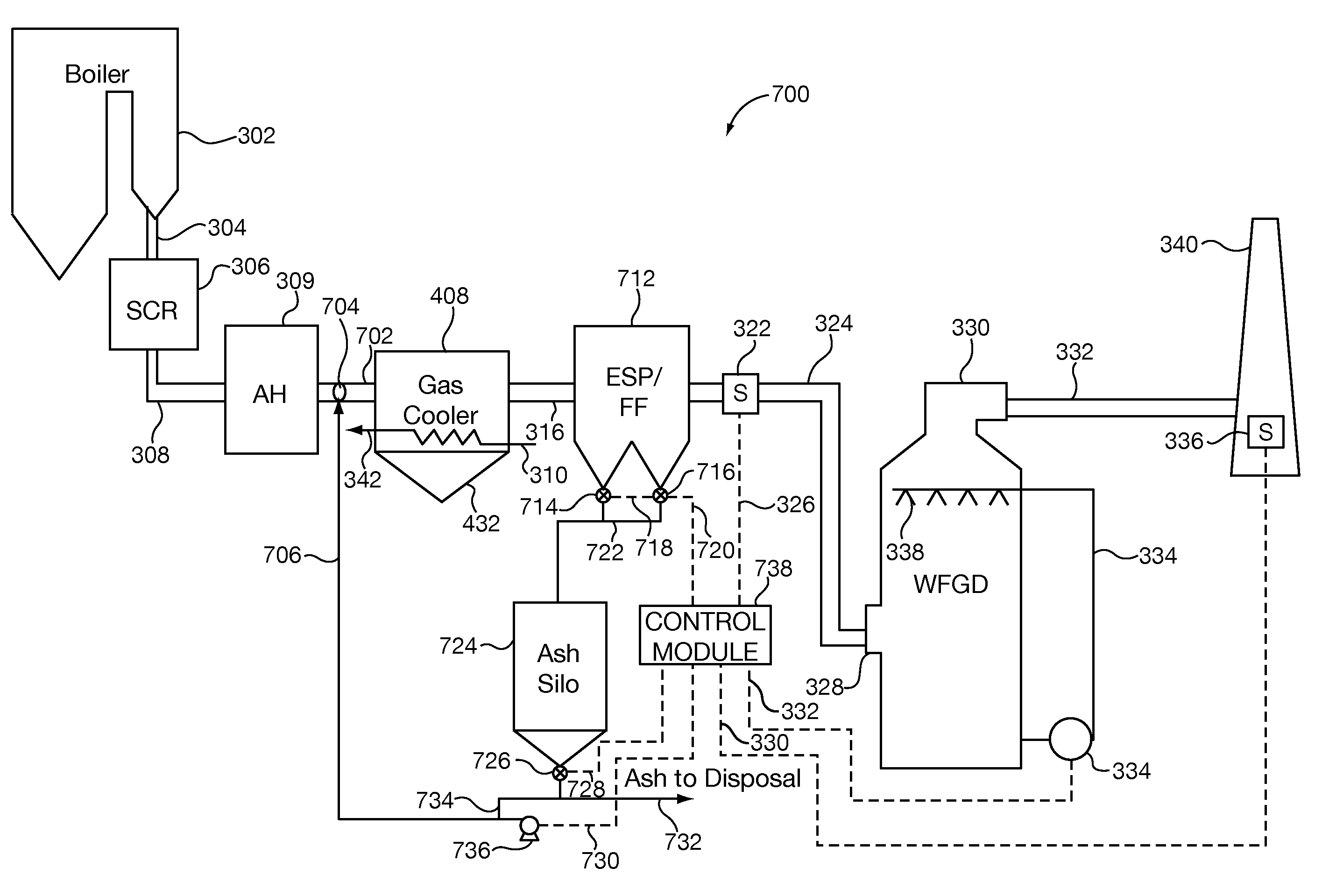

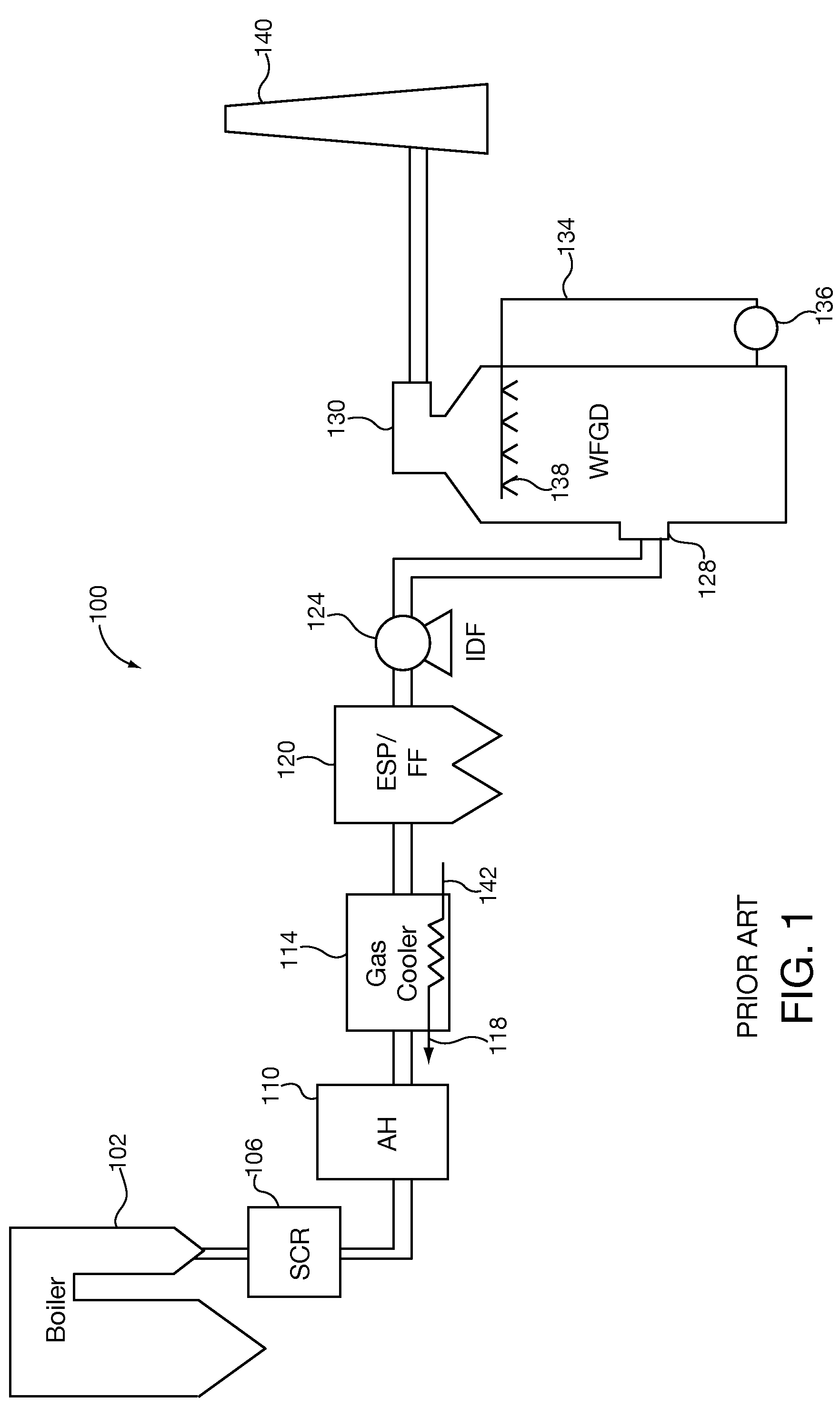

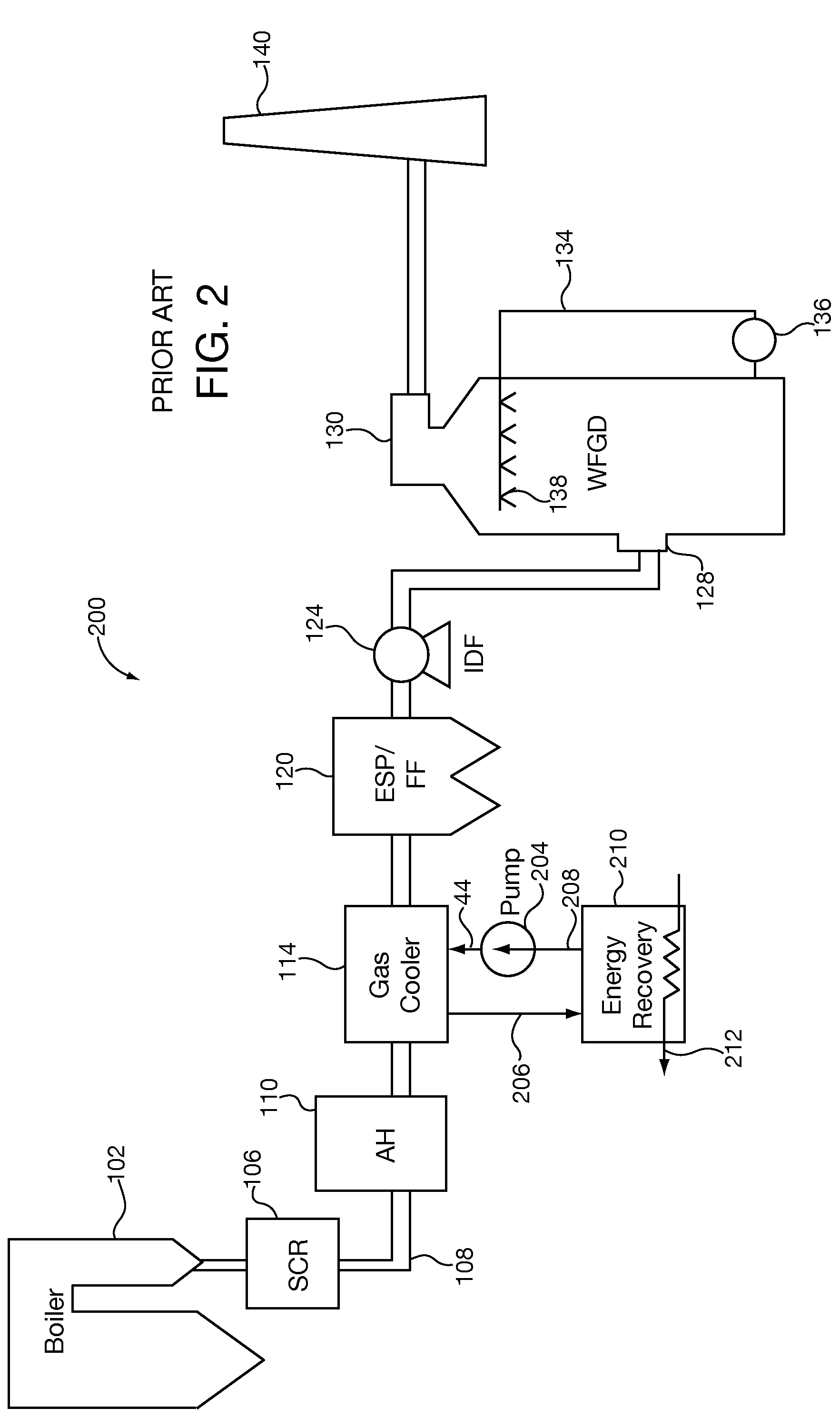

Methods and apparatus for performing flue gas pollution control and/or energy recovery

ActiveUS20090078177A1Improve system efficiencyAvoid and eliminate and reduce any needCombustion using gaseous and pulverulent fuelGas treatmentParticulatesRe introduction

Methods and apparatus for pollution control which are well suited for use in a coal power plant are described. Ash is collected and injected into the flue gas stream at a location upstream of a cooling module. The ash acts as an absorbent and / or reactant material onto which condensate may condense. By re-introducing ash to keep the condensation forming wet areas within the system, lower cost materials which are less corrosion resistant than needed for wet operating conditions can be used. Mercury recovery and SO3 removal is facilitated by the cooling process and re-introduction of collected ash. Activated carbon and / or an alkali absorbent material may be added. Use of a dry ESP and / or fabric filter as opposed to a wet ESP for particulate collection leads to cost benefits. Energy recovered by the cooling of the flue gas may be re-used to heat turbine condensate leading to improved energy efficiency.

Owner:MITSUBISHI POWER AMERICAS INC

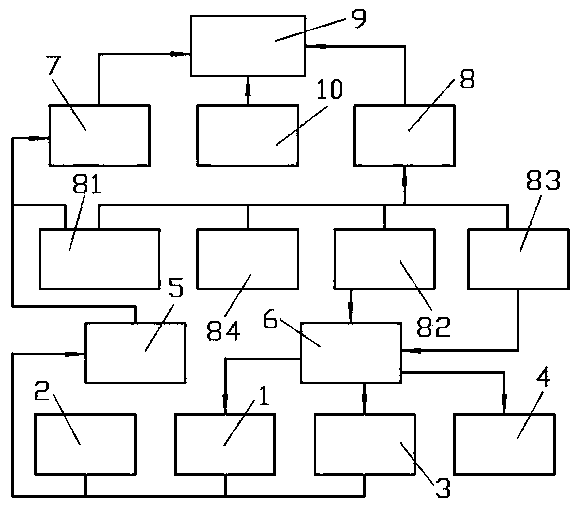

Coal-fired power plant coal yard refined management system and control method thereof

ActiveCN103455901AFast and accurate deliveryAccurate accessSystems intergating technologiesLogisticsInformatizationData acquisition

The invention relates to a coal-fired power plant coal yard refined management system and a control method of the coal-fired power plant coal yard refined management system. The coal-fired power plant coal yard refined management system is characterized by comprising a laser disc coal instrument, an intelligent temperature monitoring meter, a metering device, a stacker-reclaimer, a data acquisition unit, a controller, a data server, an application server and a computer client side. The application server comprises a coal database management module, a real-time stock management module, a coal storage management module and a heat loss evaluation and control module. The control method is characterized by including the following steps that coal pile outline data points and digital signs in a coal yard field are acquired according to the laser disc coal instrument, and three-dimensional reconstruction of coal piles is completed based on a VC++ and OpenGL platform; when coal is transported to a factory, information is input to the coal database management module through an input port in the computer client side. According to the coal-fired power plant coal yard refined management system and the control method, the informatization and intelligentization method is adopted, information is quickly and accurately transmitted, and coal heat loss is reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

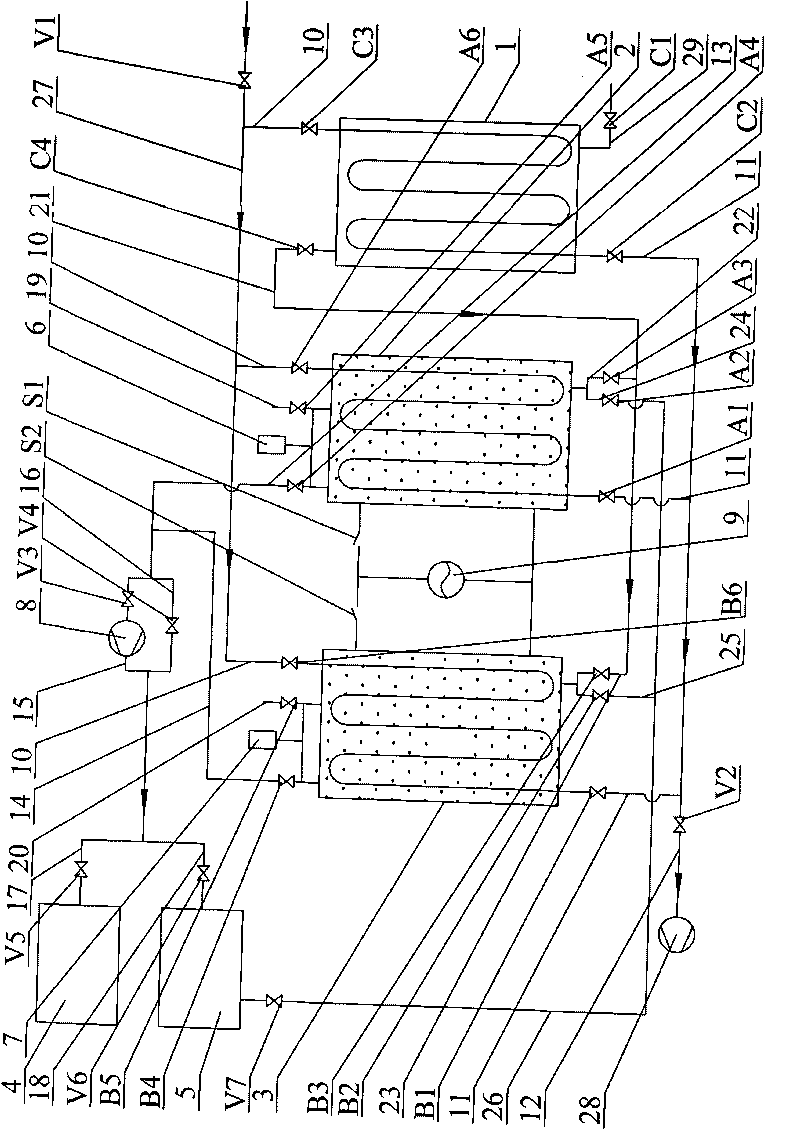

Method and system integrating solar heat into a regenerative rankine steam cycle

A method to integrate collected solar thermal energy into the feedwater system of a Rankine cycle power plant is disclosed. This novelty uses a closed loop, single phase fluid system to collect both the solar heat and to provide the heat input into the feedwater stream of a regenerative Rankine cycle. One embodiment of this method of integrating solar energy into a regenerative Rankine power plant cycle, such as a coal power plant, allows for automatic balancing of the steam extraction flows and does not change the temperature of the feedwater to the boiler. The concept, depending on the application, allows for the spare turbine capacity normally available in a coal plant to be used to produce incremental capacity and energy that is powered by solar thermal energy. By “piggybacking” on the available components and infrastructure of the host Rankine cycle power plant, considerable cost savings are achieved resulting in lower solar produced electricity costs.

Owner:MARKRON TECH

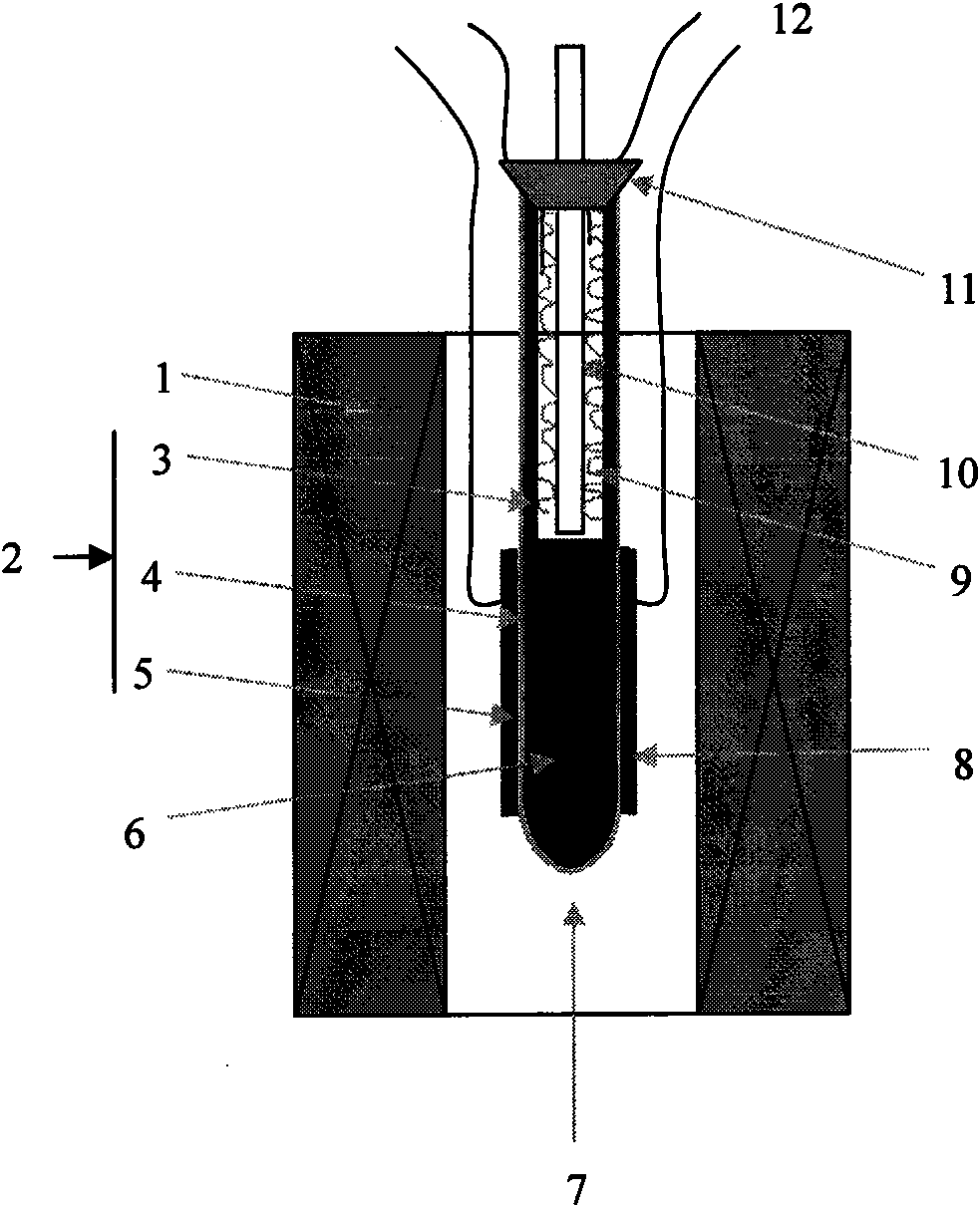

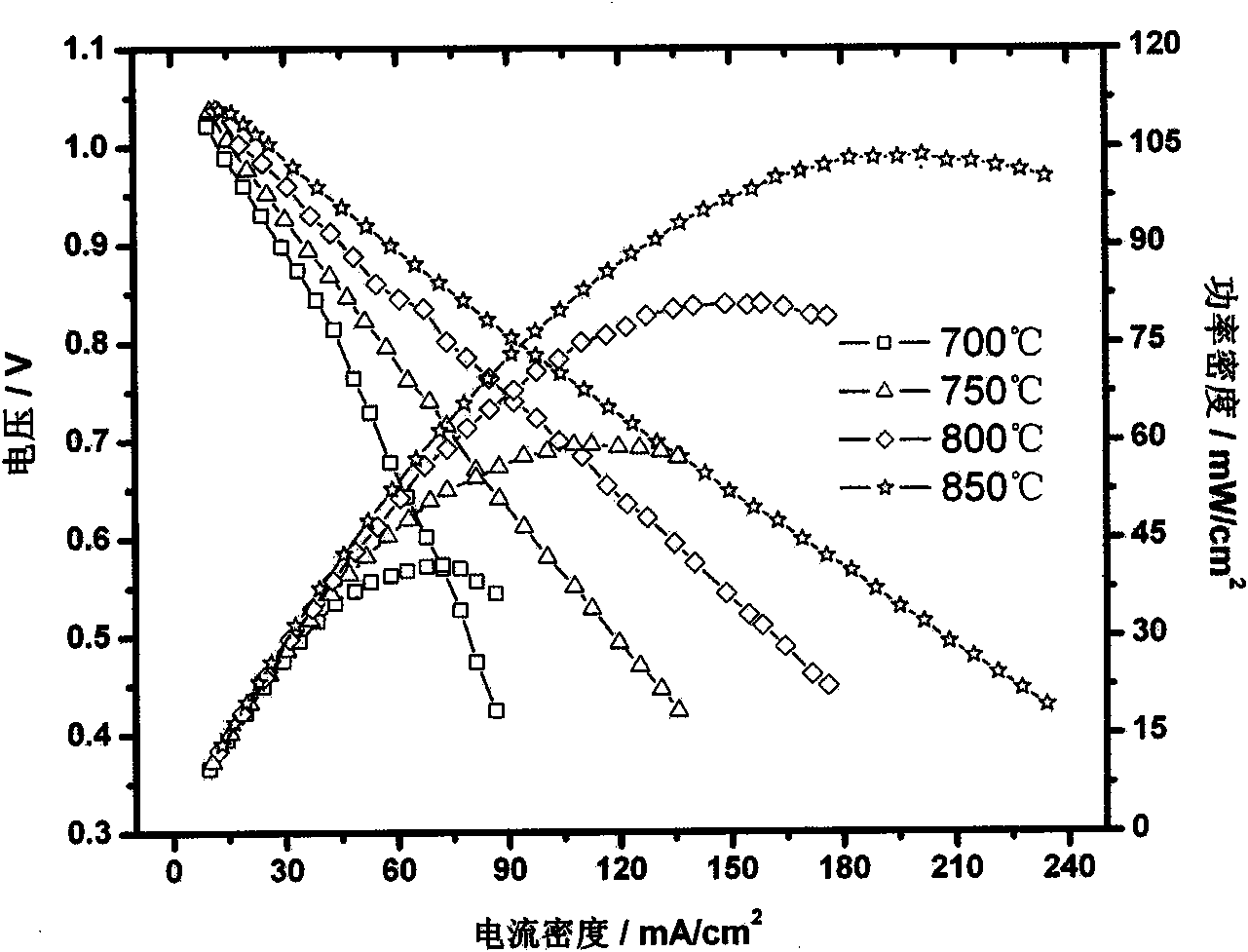

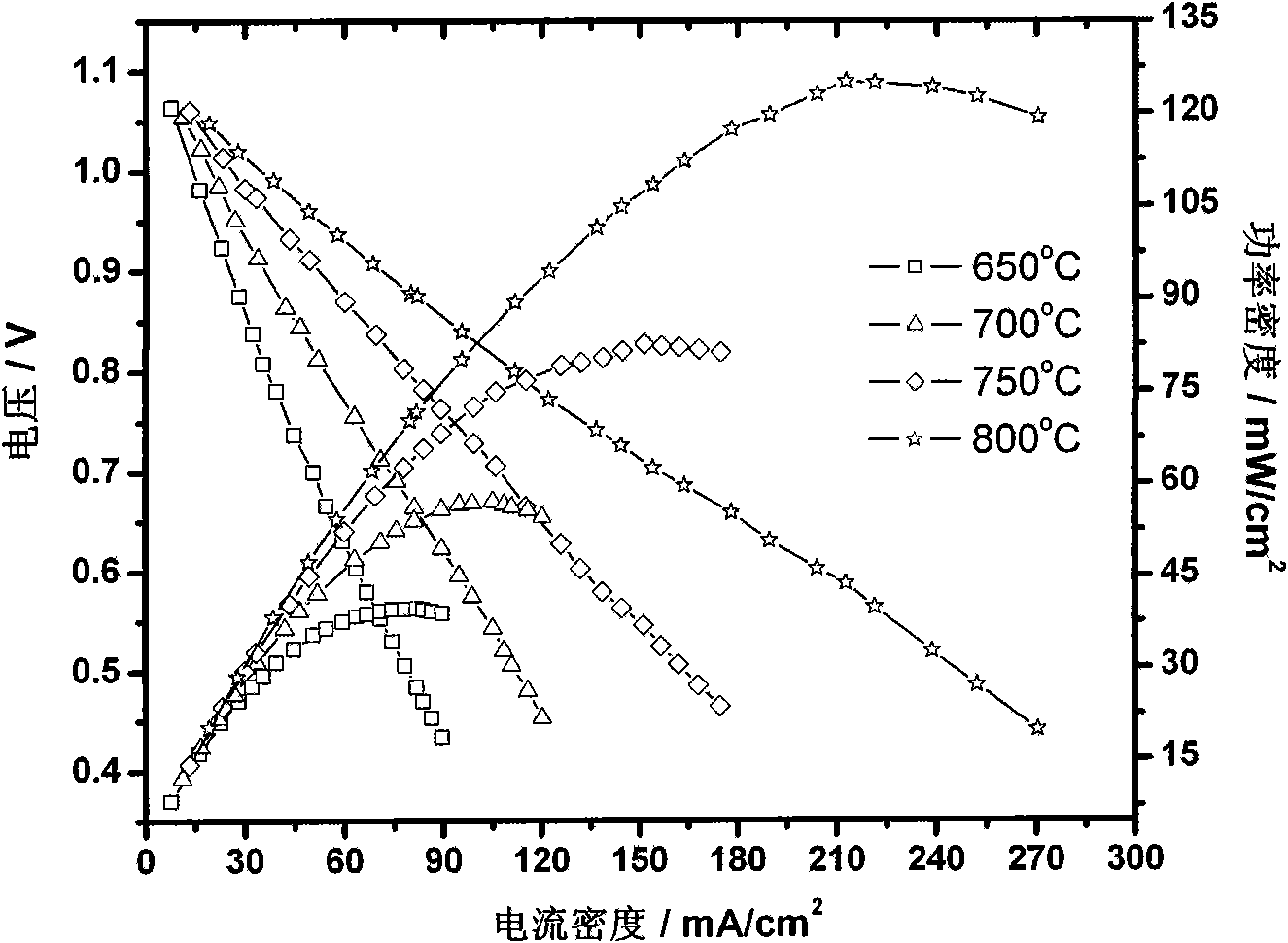

Solid electrolyte direct carbon fuel cell

InactiveCN101540411AEasy to operateImprove energy efficiencySolid electrolyte fuel cellsElectrochemical responseHigh energy

The invention relates to solid electrolyte direct carbon fuel cell. In the invention, tube-type batteries serve as the electrochemical reaction device, the inner layer of the batteries is anode, the intermediate layer is the electrolyte and the outer layer is cathode, carbon fuel is filled in the tube-type batteries. The carbon fuel cell of the invention features high energy efficiency, sound environmental protection property, a theoretic efficiency being 2-3 times of the generating efficiency of the existing coal power plants, reduction of discharge of greenhouse gas CO2, no generation of acidic gases such as nitrogen oxide and sulfide, no possible danger of liquid leakage and gas explosion and fine electrochemistry property.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

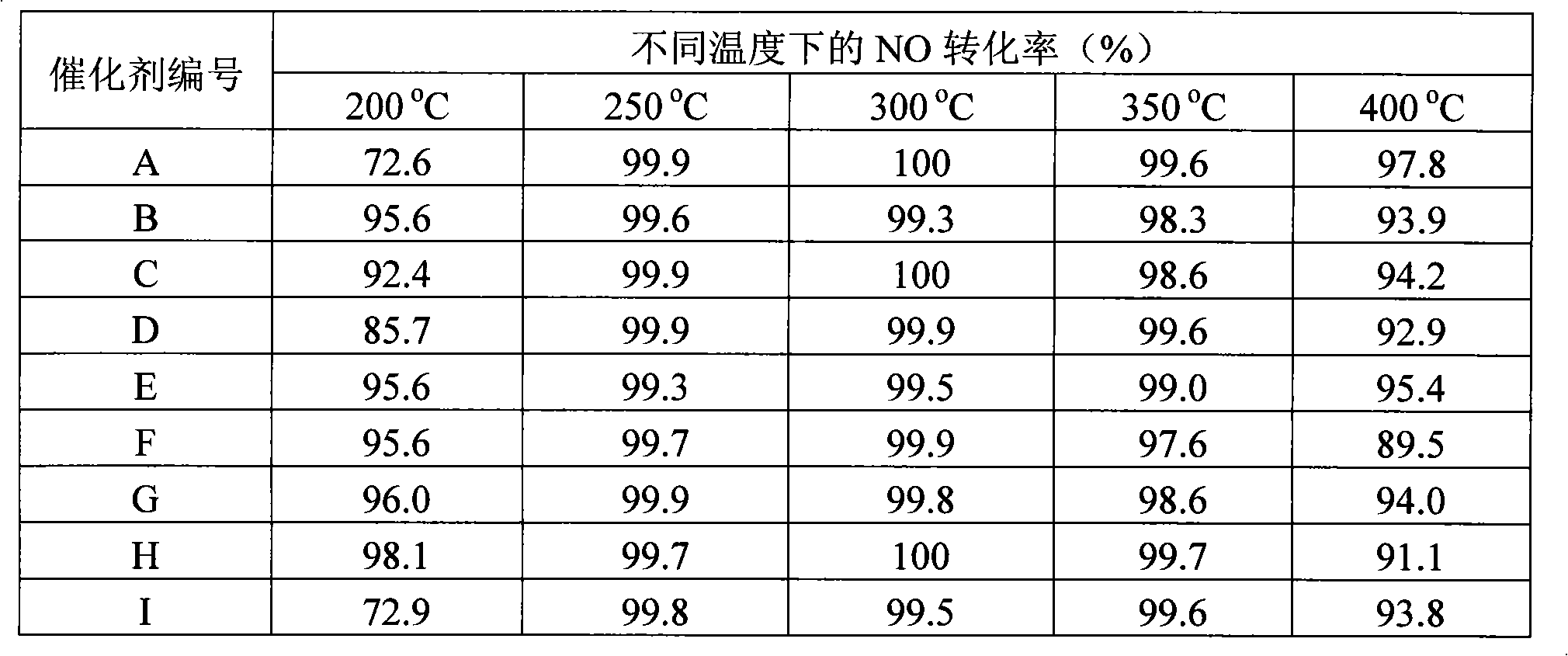

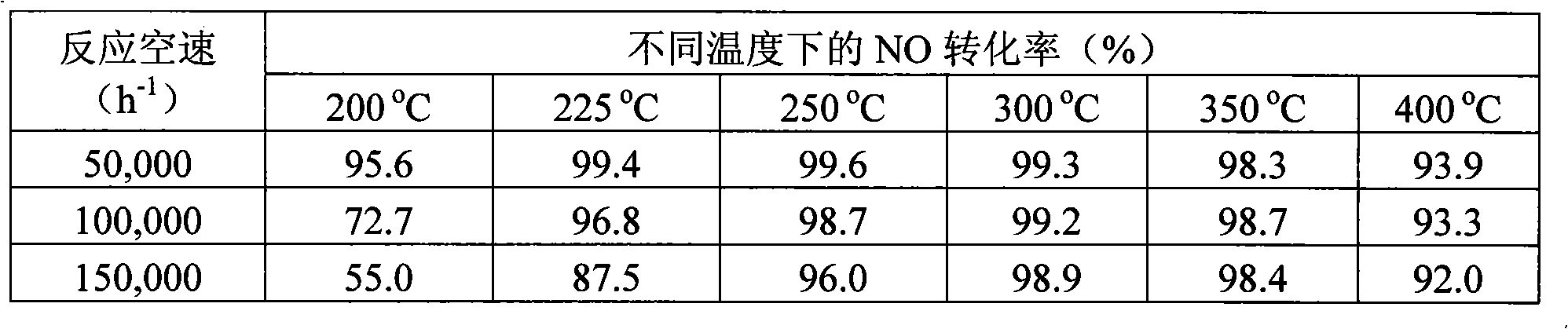

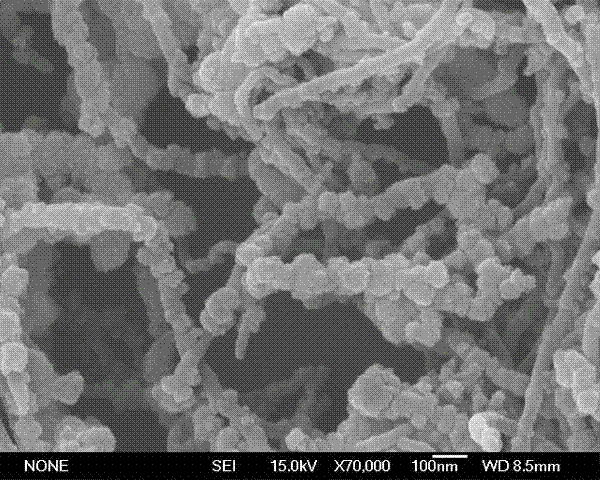

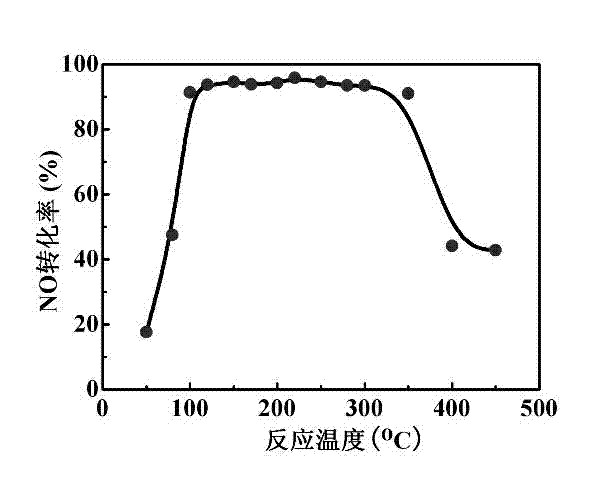

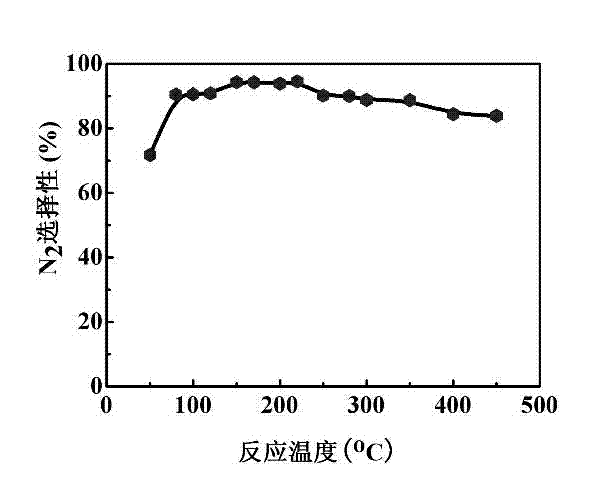

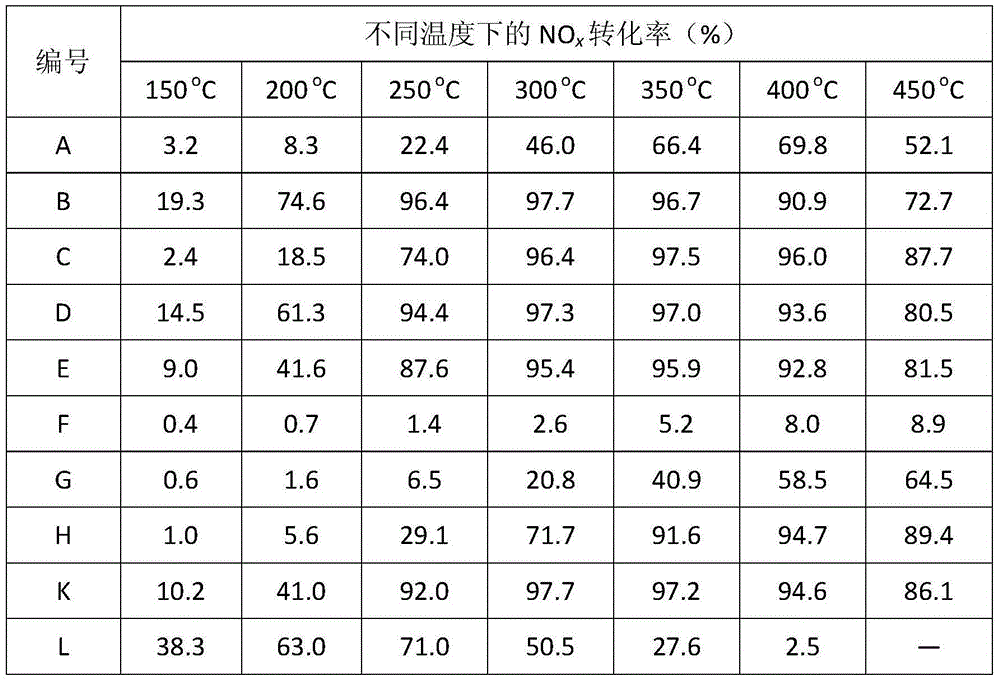

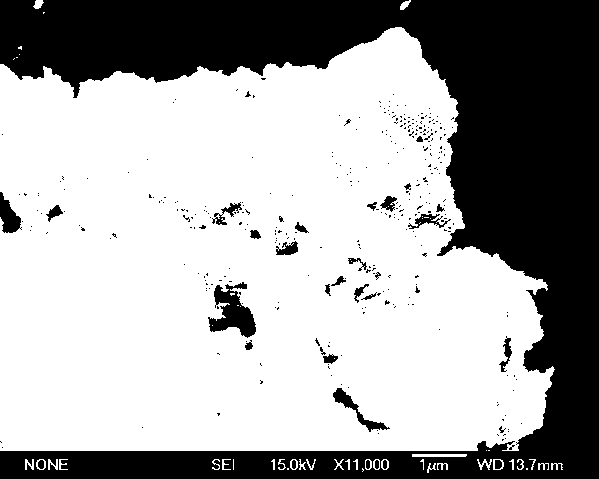

Nanocrystalline Ce-Ti composite oxide catalyst used for selective catalytic reduction of nitric oxide by utilizing ammonia

InactiveCN101785994AExtended service lifeReduce usageDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumNitric oxide

The invention relates to a preparation method of a nanocrystalline Ce-Ti composite oxide catalyst used for the selective catalytic reduction of nitric oxide by utilizing ammonia and an application thereof. The preparation method of the catalyst is the homogeneous precipitation method, namely, the required cerium salt and titanium salt are prepared to mixed solution, and the molar ratio of cerium and titanium is 0.1-1.0; the solution is continuously stirred for 6-10h at the temperature of 90-95 DEG C by taking excessive urea as the precipitator and then is pumped, filtered, washed and dried; and finally, the catalyst is obtained by roasting the processed solution for 4-6h in the air at the temperature of 400-500 DEG C. In the invention, the nanocrystalline Ce-Ti composite oxide catalyst is prepared by taking non-toxic and harmless raw materials and adopting the simple and easy method, which has the characteristics of high catalytic activity, good N2 selection, wide temperature window, good adaptability of high airspeed condition, good SO2 intoxication resistance and the like. The catalyst is applicable to various tail gas sources including fixed combustion devices in an engine of a diesel vehicle, a coal-fired power plant and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

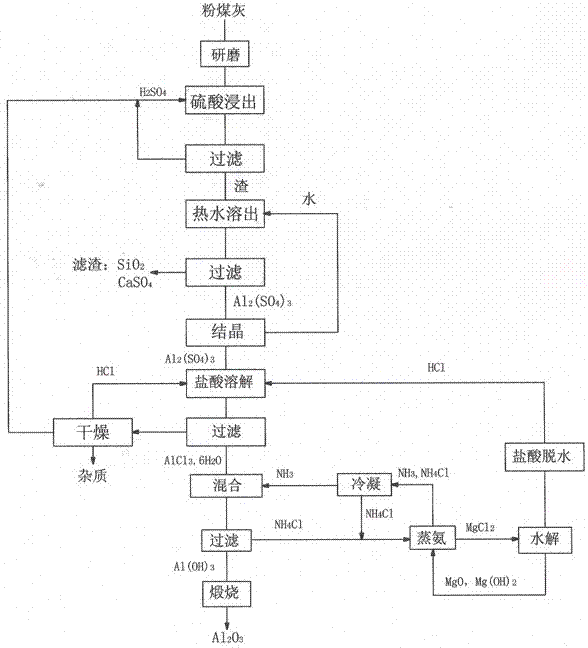

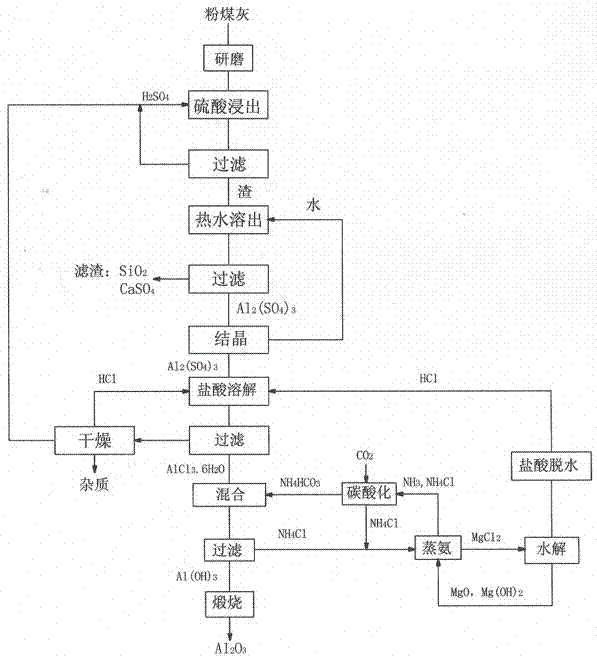

Method for preparing alumina by using power plant fly ash

InactiveCN102849767ASaturated precipitation with high purityThe process steps are simpleAluminium oxide/hydroxide preparationAluminium hydroxideAmmonium chloride mixture

The invention discloses a method for preparing alumina by using power plant fly ash, characterized by: grinding the fly ash, leaching with concentrated sulfuric acid to obtain an aluminum sulfate solution, precipitating aluminum sulfate crystals by concentrating and cooling, dissolving the aluminum sulfate crystals with hydrochloric acid, then letting an HCl gas in the solution to saturate the solution to precipitate AlCl3-6H2O crystals, reacting the AlCl3-6H2O crystals with an ammonium hydroxide solution or liquid ammonia or an ammonium bicarbonate solution or an ammonium carbonate solution to obtain an aluminium hydroxide and ammonium chloride solution, calcining aluminium hydroxide to obtain alumina, displacing ammonium chloride by using magnesium oxide to obtain ammonia gas and magnesium chloride, and hydrolyzing magnesium chloride to obtain magnesium oxide and hydrochloric acid for recycling.

Owner:李景江

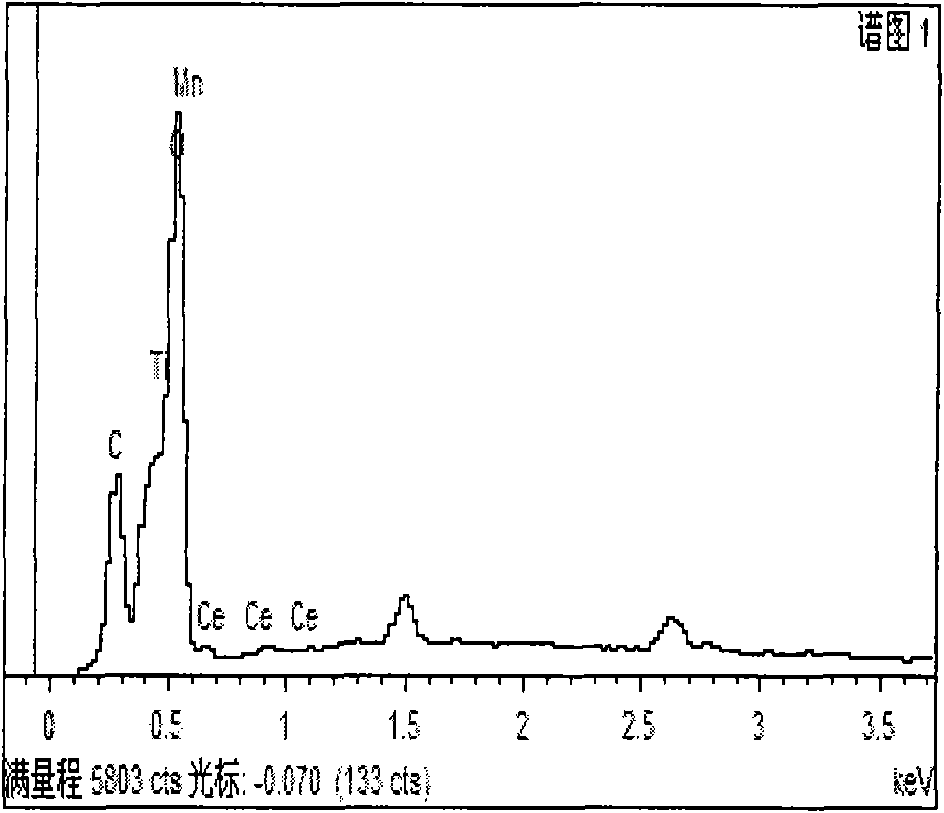

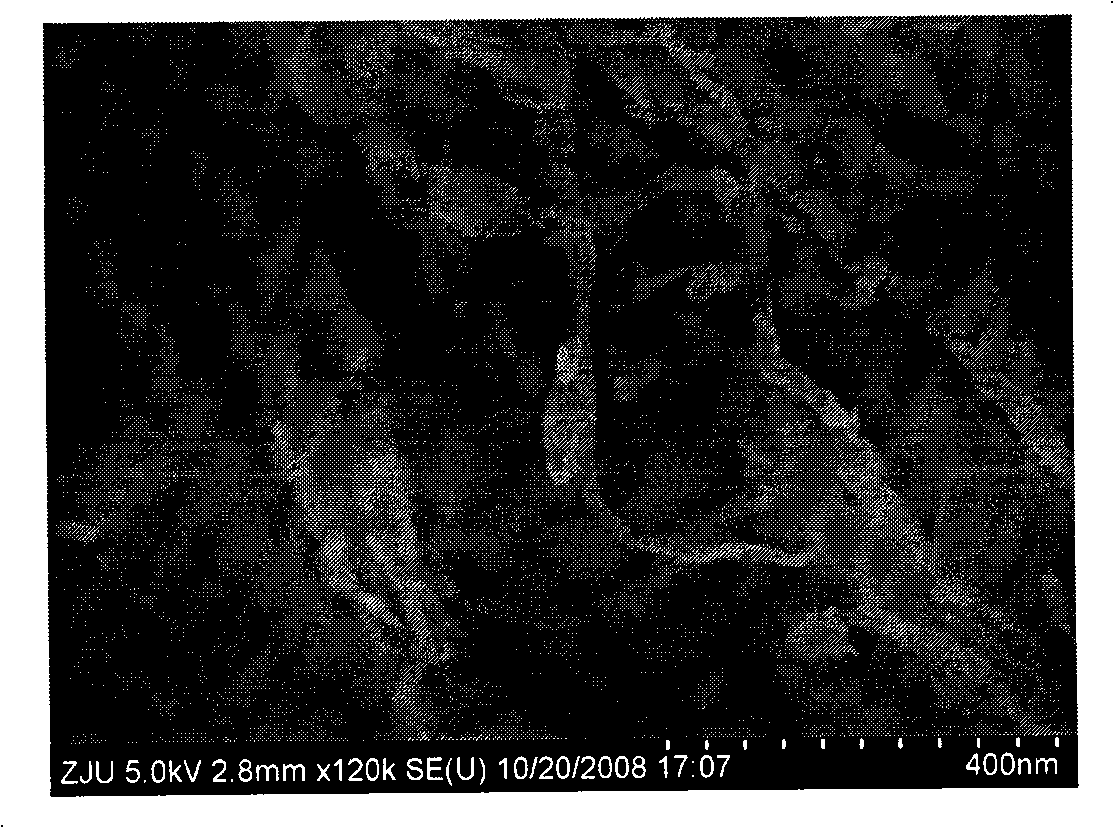

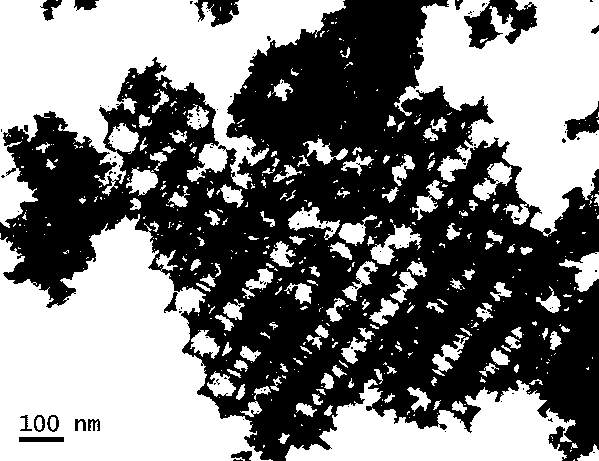

Catalyst for removing NOx in incineration gas and preparation method thereof

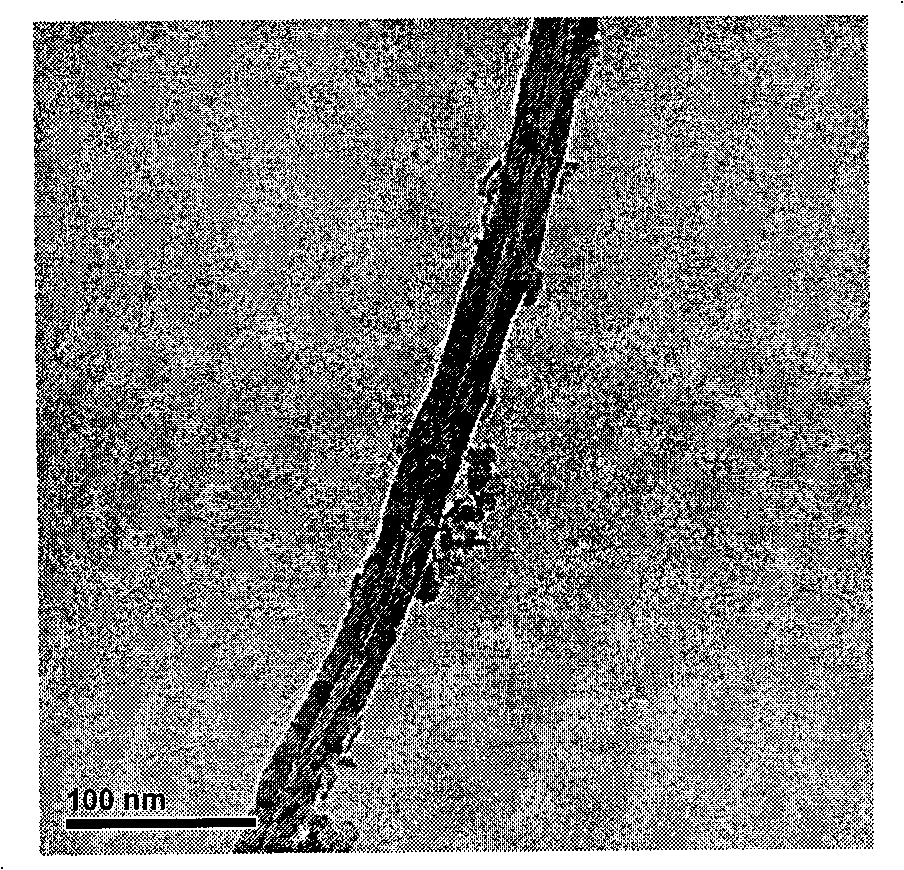

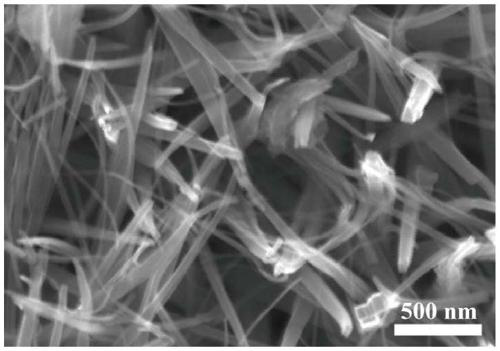

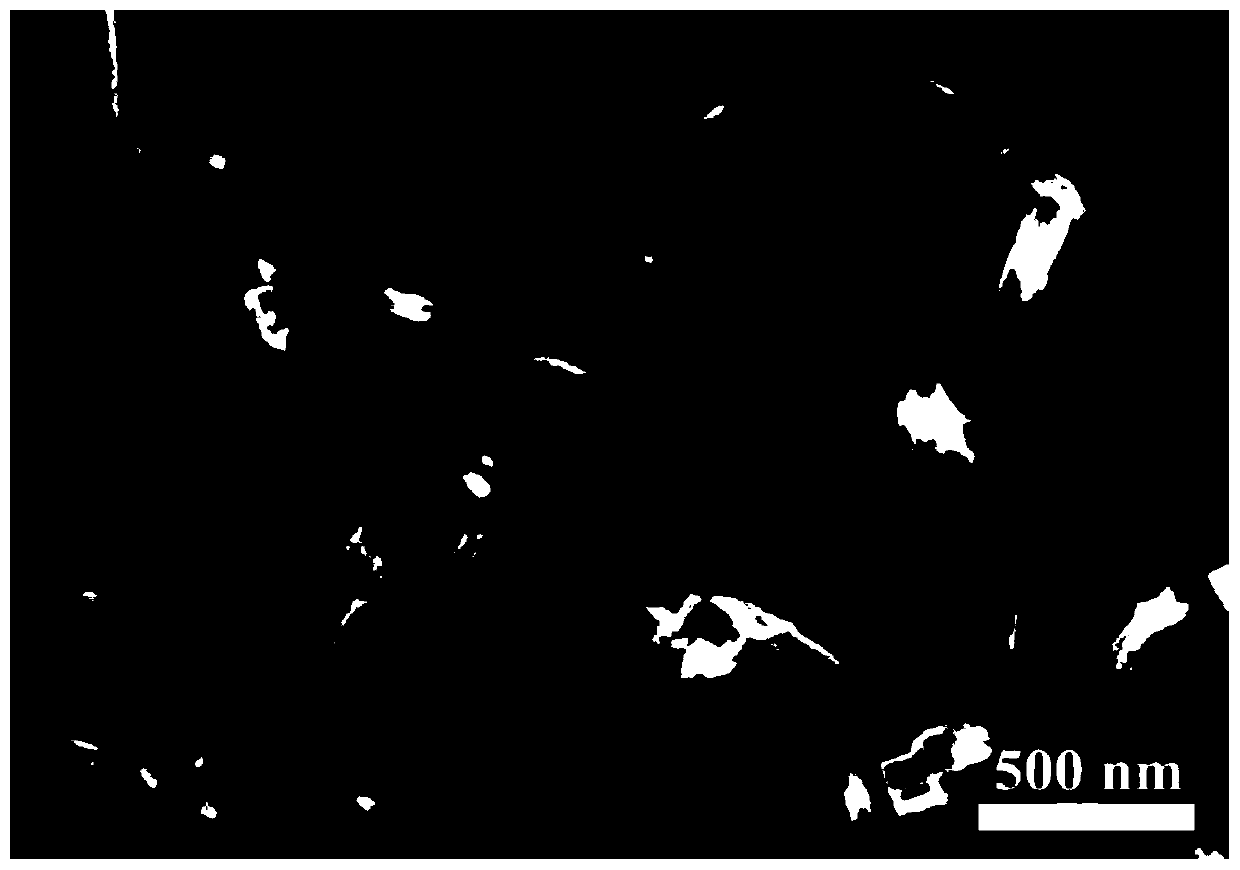

ActiveCN101773824ALarge specific surface areaStrong resistance to poisonDispersed particle separationCatalyst activation/preparationCarbon nanotubeSol-gel

The invention discloses catalyst for removing NOx in incineration gas. The catalyst takes carbon nano tubes and titanium dioxide as carriers and takes manganese oxide and cerium oxide as binary active ingredients. The preparation method can be a sol gel method, a solvothermal method or a coprecipitation method. The catalyst of the invention takes both the carbon nano tubes and the TiO2 as the carriers, the excellent adsorption property of CNTs and the large specific surface area are utilized, the advantages of the TiO2 as traditional carriers are combined and the nontoxic and pollution-free MnOx and CeOx as the binary active ingredients, so the absorption function of the CNTs and the catalytic action of the MnOx and CeOx cooperate with each other, the operating temperature of the selective catalytic reaction is reduced and the NOx removal rate can reach 99.5 percent under 125 DEG C. The catalyst can be used to remove NOx atmospheric pollutants emitted in the high-temperature processes of the coal-fired power plants, the metallurgical industry, the waste incineration and the like.

Owner:ZHEJIANG UNIV

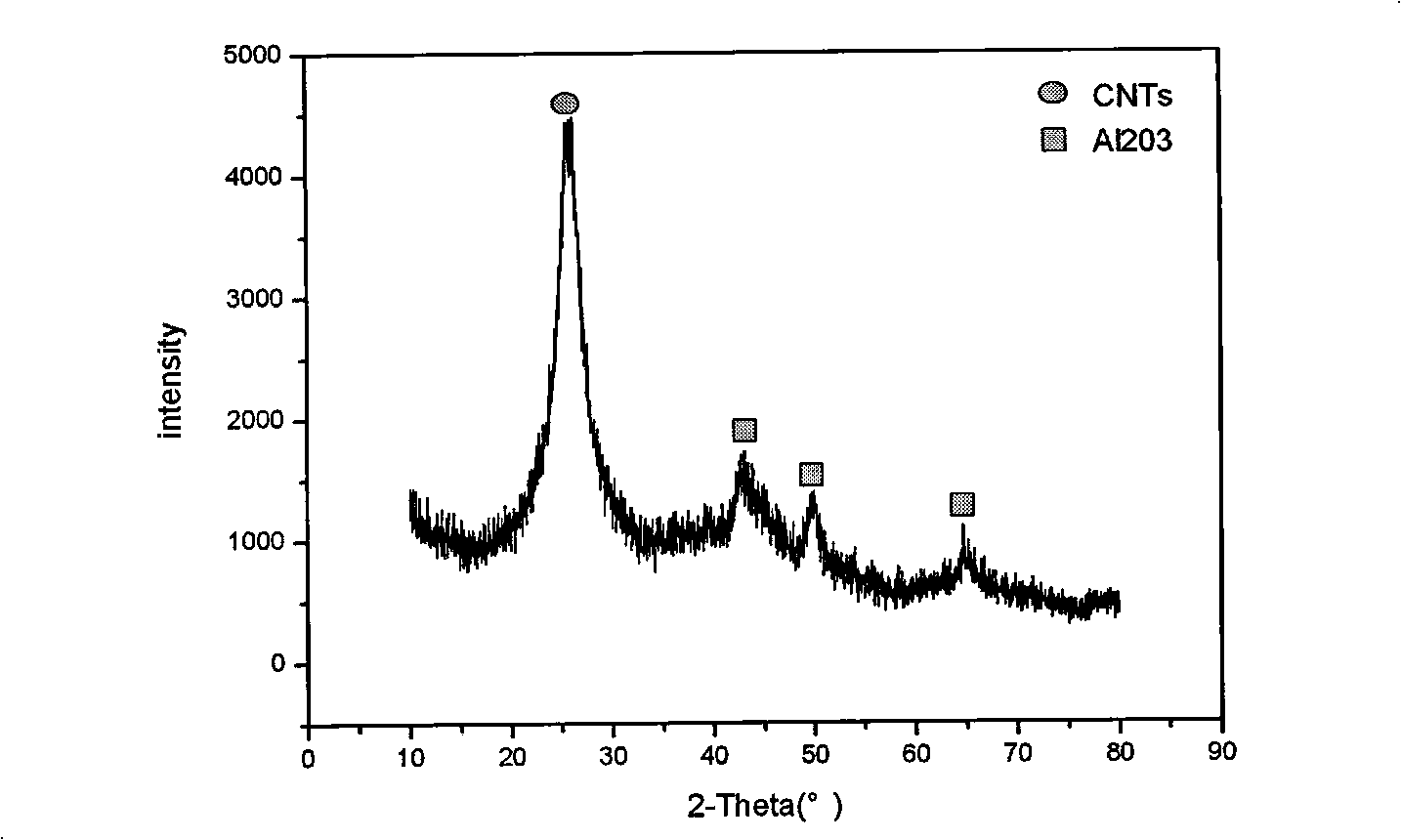

Catalyst for removing nitrogen oxide and organic pollutant discharged in burning and method for preparing same

InactiveCN101513612AGuarantee structureExcellent low temperature SCR characteristicsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsChlorobenzeneCarbon nanotube

The invention discloses a catalyst for removing nitrogen oxide and organic pollutant discharged in burning, comprising carbon nanotube and alumina as the carrier and manganese oxide as the active ingredient, the active ingredient in the catalyst accounts for 1 to 10% of the total catalyst mass. The catalyst is prepared by a solvent-thermal method. In the inventive catalyst, CNTs and Al2O3 are simultaneously used as the carrier for the first time, thus the catalyst has big specific surface area and high mechanical strength, at the same tine the temperature of the selective catalytic reaction is reduced, 94.2% of chlorobenzene removing ratio can be obtained at the temperature of 150 DEG C, 88.8% of NOx removing ratio is obtained at the temperature of 200 DEG C. The catalyst can be used for removing the nitrogen oxide (NOx)and dioxin organic pollutant discharged in the high-temperature process in the fire coal power plant, metallurgy industry, garbage burning and the like.

Owner:ZHEJIANG UNIV

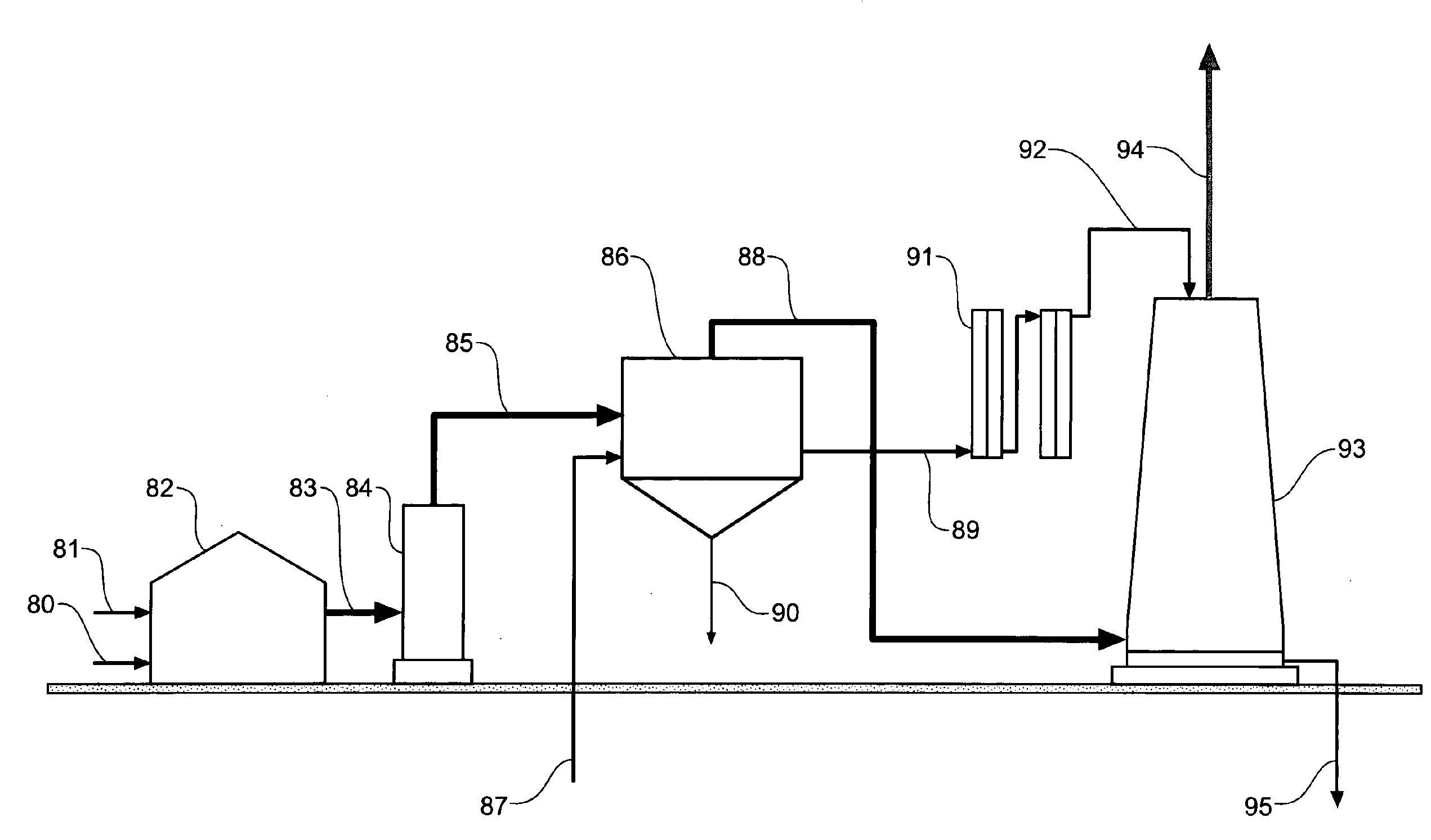

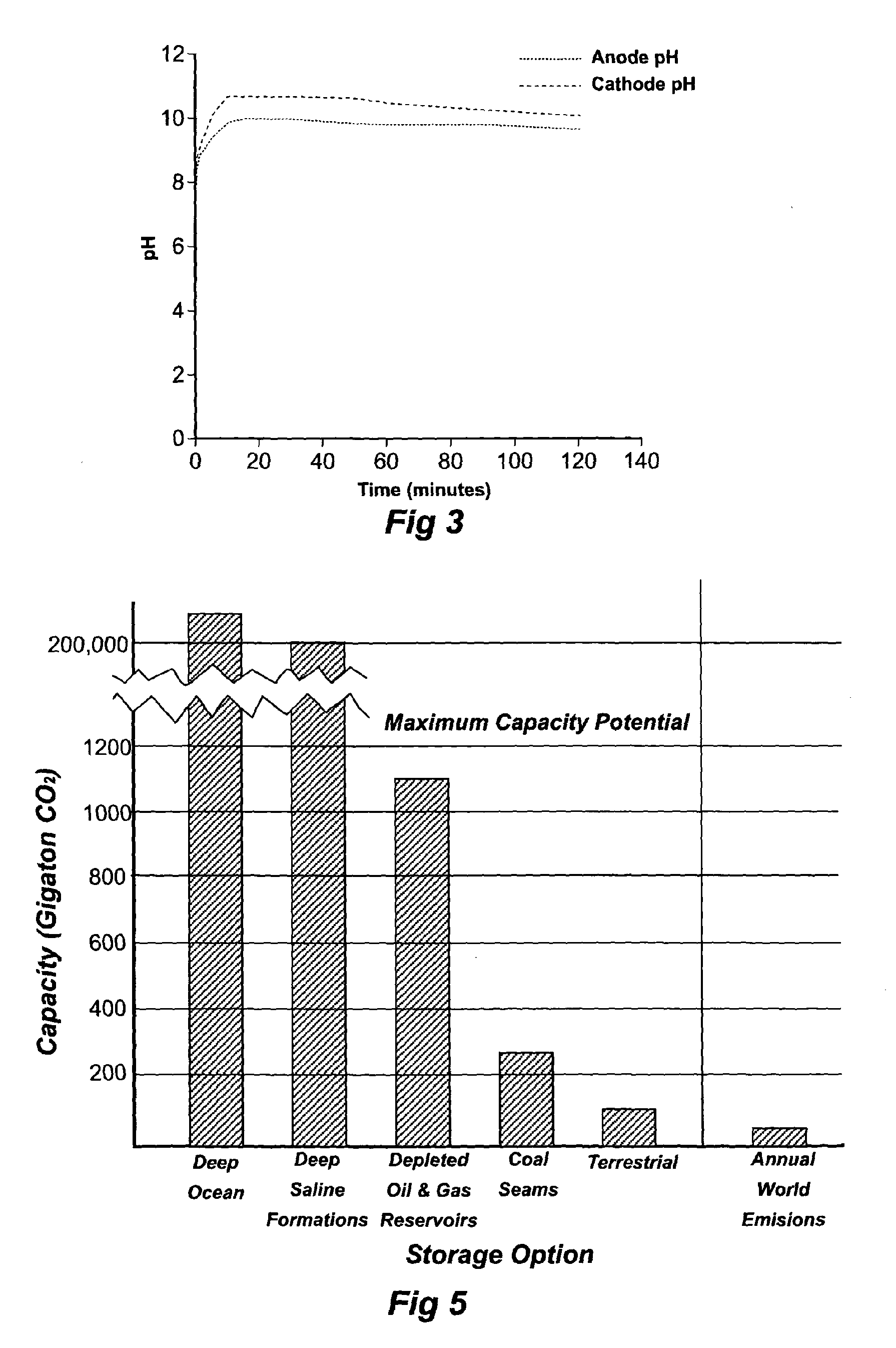

Carbon dioxide sequestration and capture

InactiveUS20100084283A1Calcium/strontium/barium carbonatesCellsCarbon dioxide productionAtmospheric air

A process to convert carbon dioxide into a stable substance with electrolytically activated seawater and use this process to sequester carbon dioxide from coal power plants (82) and similar carbon dioxide producing equipment, and capture and sequester carbon dioxide from the atmosphere. Electrolytically activated seawater (92) is produced using a unipolar electrolytic cell (91) and is sprayed into a contacting tower (93) or into the air.

Owner:GOMEZ RODOLFO ANTONIO M

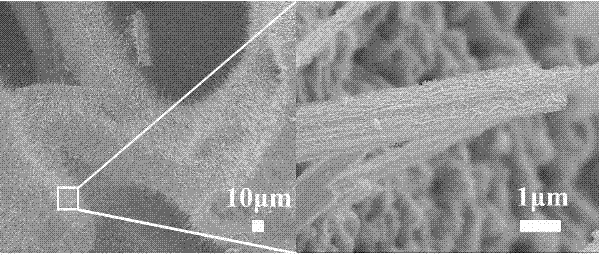

SCR (selective catalyctic reduction) low-temperature denitrification catalyst with nano core-shell structure and preparation method thereof

ActiveCN102335604AImprove low temperature catalytic activityEnhanced anti-toxicityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCarbon nanotube

The invention relates to a SCR (selective catalyctic reduction) low-temperature denitrification catalyst with nano core-shell structure and a preparation method thereof, belonging to the field of environment-friendly catalytic materials. Different from the traditional impregnation method, the method provided by the invention is implemented by carrying out a one-step chemical solvent thermal method on carbon nanotubes (CNTs), manganese salt and cerium salt to obtain the MnOx / CeO2@CNTs nano core-shell structure with high dispersity and high surface area of active components. The catalyst comprises a carrier CeO2@CNTs core-shell composite nano structure, and active components MnO2 and CeO2, wherein the CeO2 is used both as a carrier for further enriching the valence state of MnOx and enhancing the sulfur resistance of MnOx, and as an active component for reinforcing the conversion from NO to NO2 and enhancing the denitrification catalytic activity. The catalyst provided in the invention has excellent oxynitride removal efficiency and high N2 selectivity in fume at 120-250 DEG C. The catalyst provided by the invention can be used for SCR removal of ammonia in oxynitrides in fume discharged by coal-fired power plants, refuse incinerators, boilers and the like.

Owner:SHANGHAI UNIV

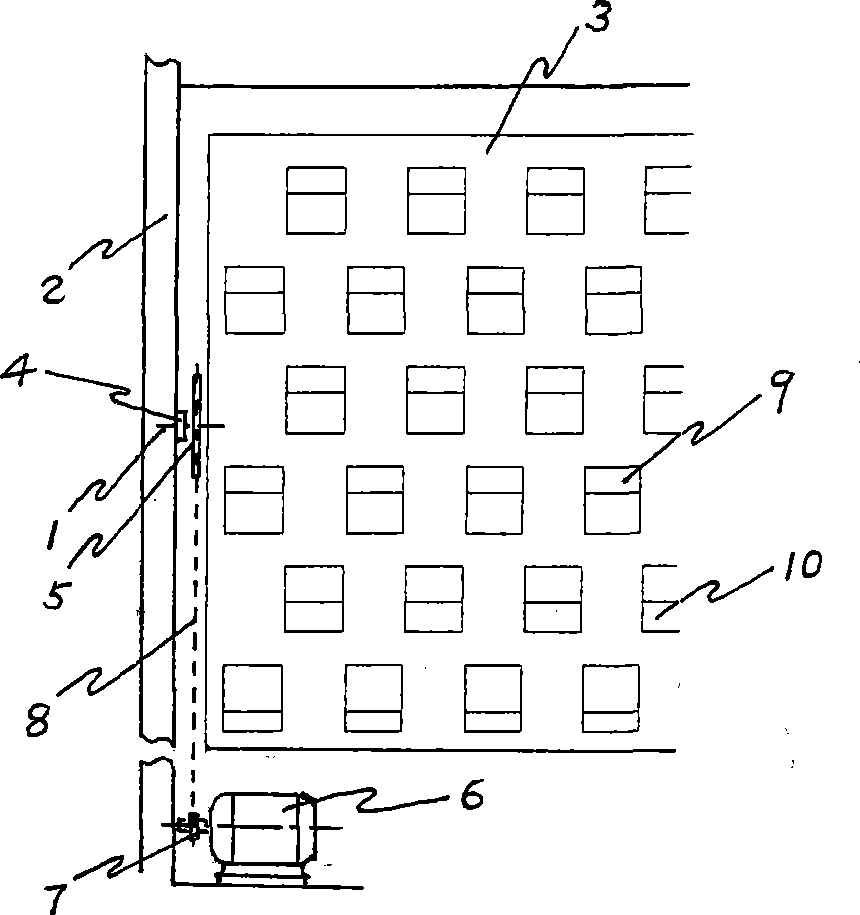

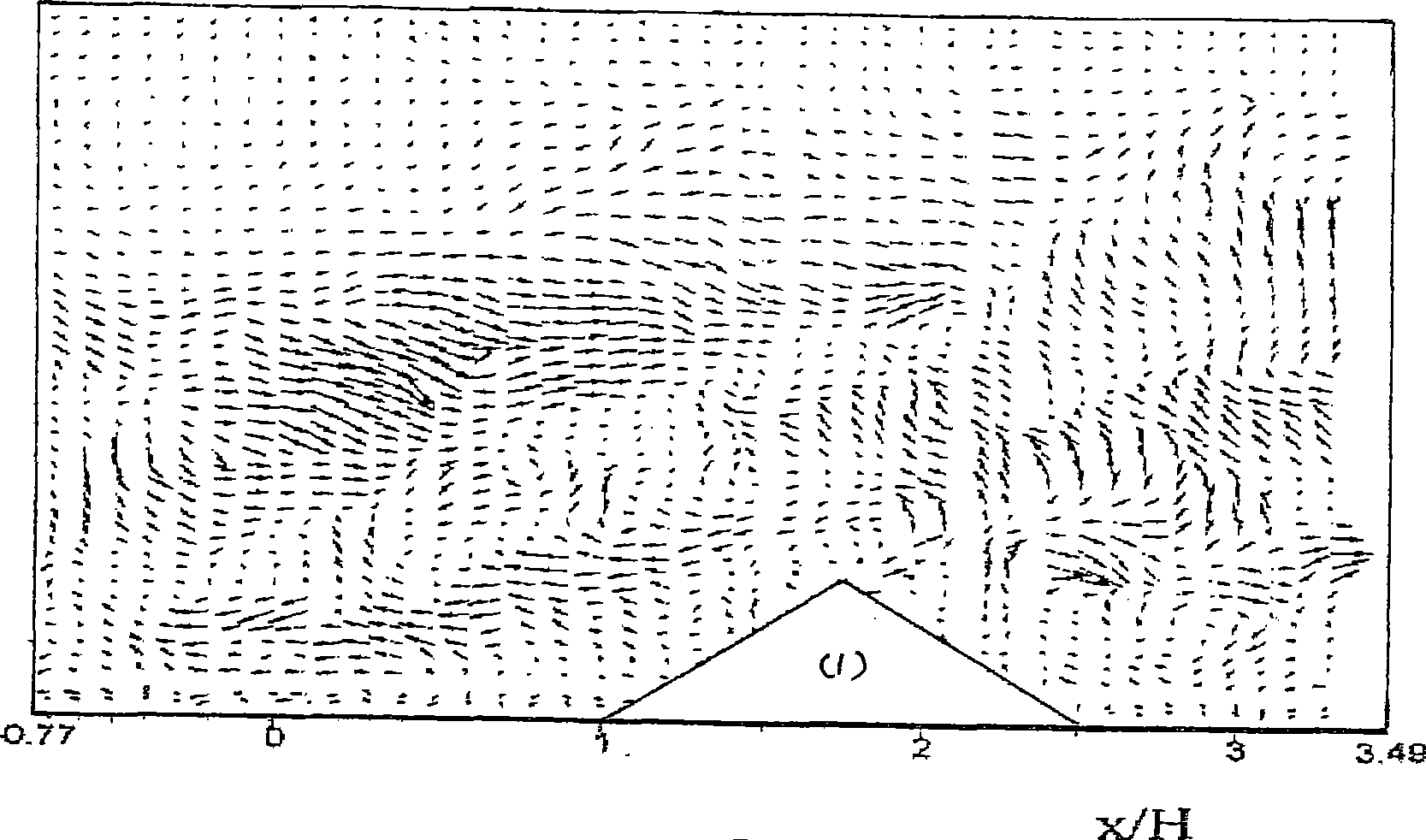

Wind-proof dust-suppression method for open bulk materials stacking field, and its wind-proof dust-suppression net and use

The invention relates to a wind and dust resisting method for an open stacking site of bulk materials, a wind and dust resisting net and the application thereof. The method comprises the following steps: a concrete base is built around the material stacking site; a support steel structure is fixed on the concrete base; the support steel structure is provided with net leaves of the wind and dust resisting net; a main flow wind surface is provided with wind resisting net leaves, and other secondary flow wind surfaces are provided with dust resisting net leaves; the height at which the net leaves are arranged is more than the stacking height of the material stack; the opening ratio of the net leaves is 20 percent to 50 percent and the like. 1 to 3 rows of wind resisting net leaves in the middle of the main flow wind surface are provided with a turnover mechanism. Net holes are long holes or elliptic holes, one side of the net hole is punched into a flanging guide fin which has a certain angle and has guide function. The boundary layer separation, the vortex and the permeation flow are eliminated or reduced effectively, the angle of the dust resisting net can be regulated according to wind directions; and the effect of resisting dust, especially secondary blowing dust can be improved greatly. The invention can be widely applied to the open stacking site of bulk materials in ports, coal mines, coal fired power plants, etc.

Owner:QINGDAO UNIV OF SCI & TECH

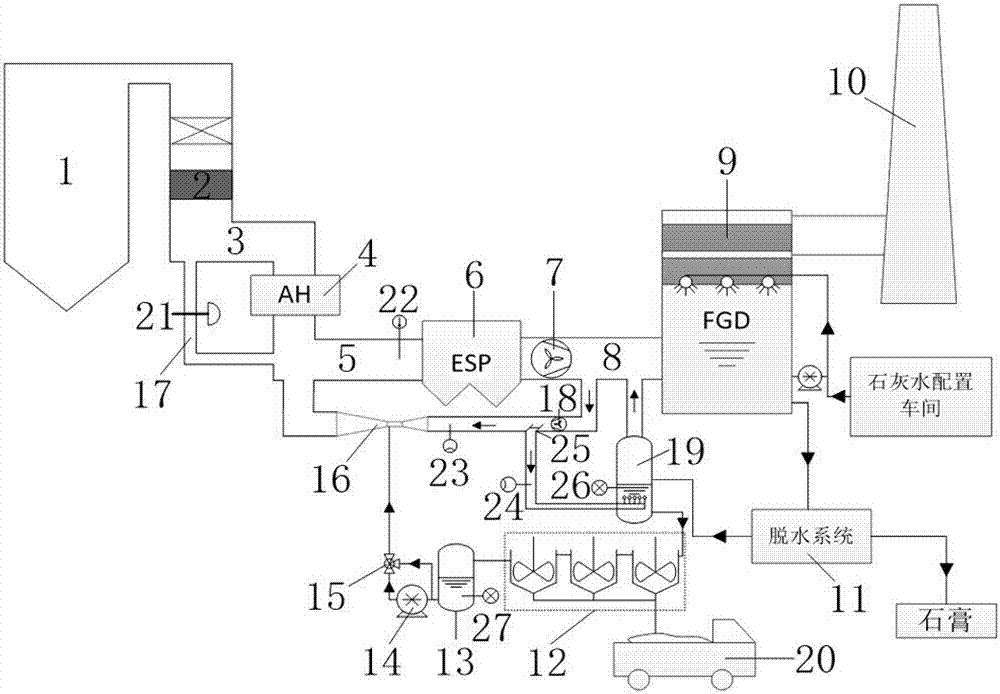

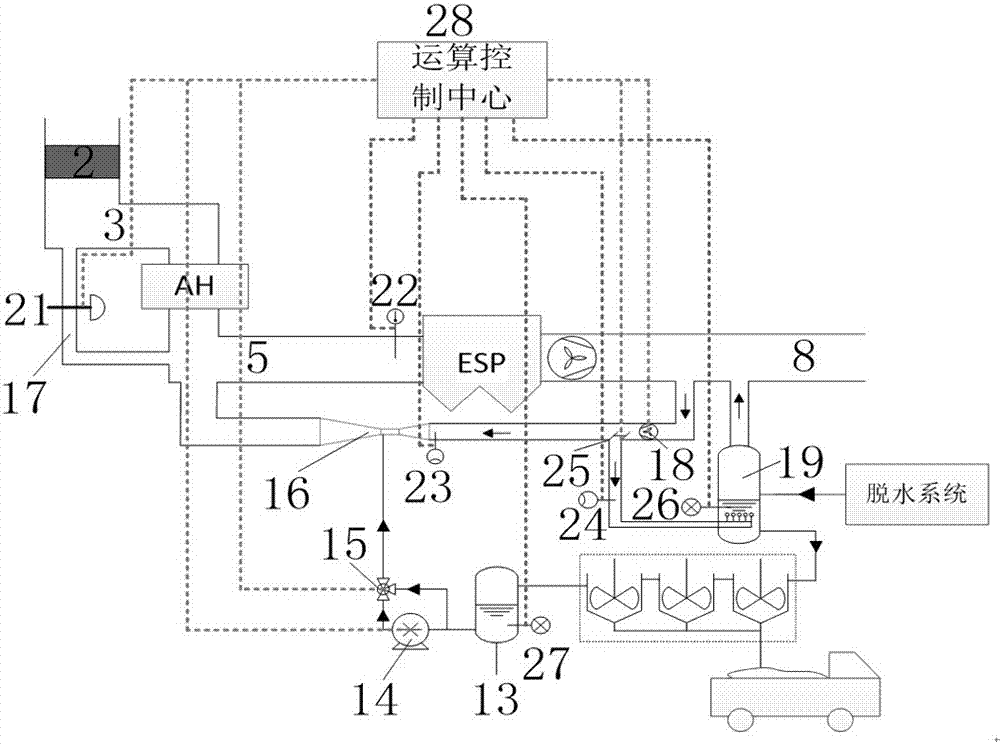

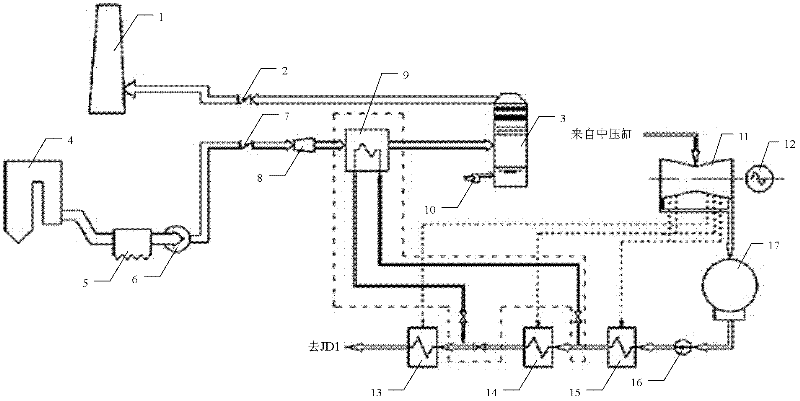

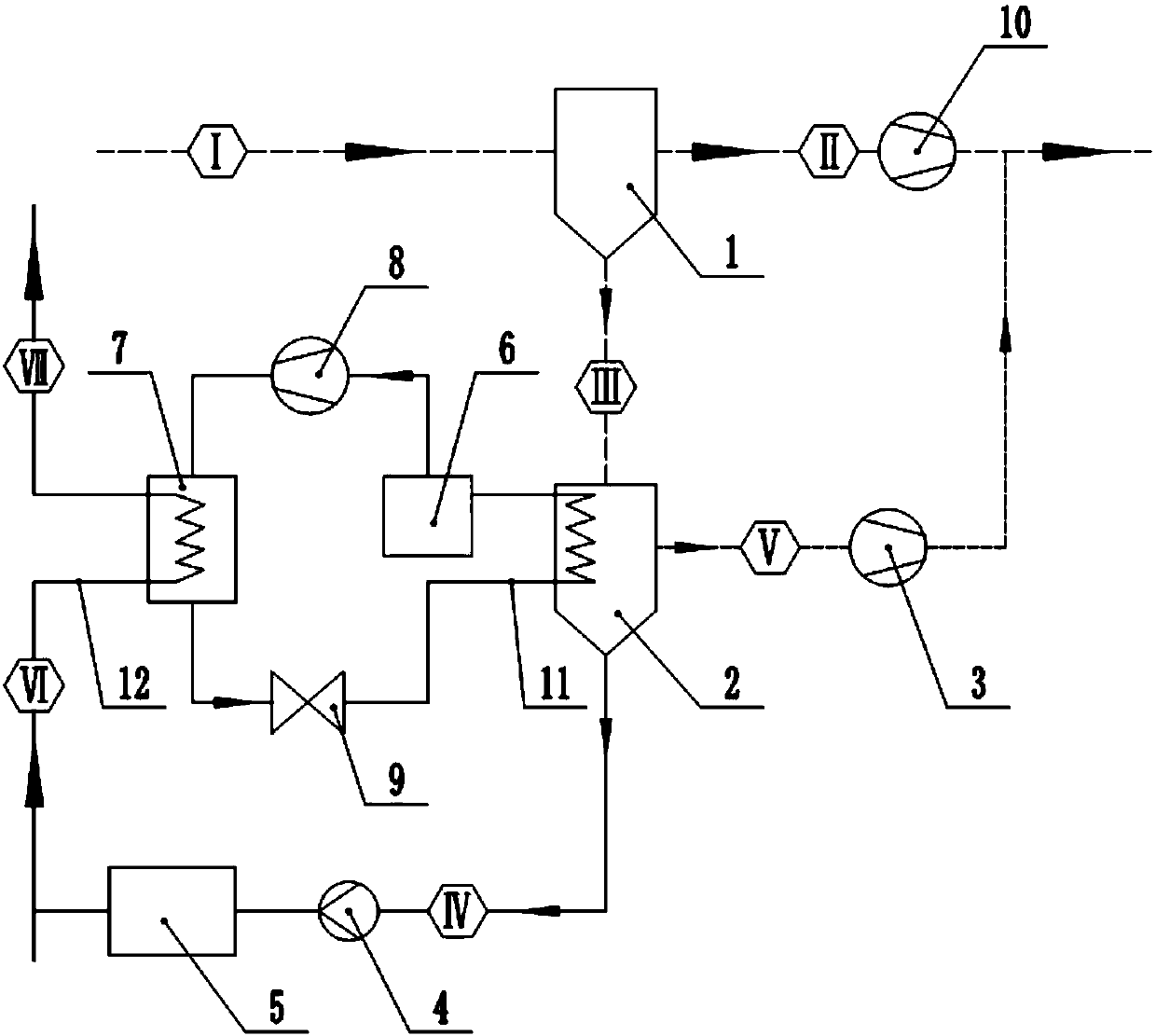

Method and device for achieving desulfurization wastewater zero discharging with full flue gas

PendingCN108006683ATo achieve the effect of reduction treatmentAvoid problems with temperatures below the acid dew pointGas treatmentEmission preventionEvaporationSlurry

The invention discloses a method and device for achieving desulfurization wastewater zero discharging with full flue gas. The method includes the steps that desulfurization wastewater discharged froma coal-fired power plant slurry dewatering system is directly fed into a bypass bubble tower in front of a desulfurizing tower, and then is subjected to reducing concentration with hot flue gas in front of the desulfurizing tower; desulfurization wastewater concentrated water is fed into three connection tanks for charging treatment; settled supernatant liquid is fed into a wastewater tank to be buffered and stored; part of waste heat flue gas is led out behind an electrostatic dust collector and is further pressurized through a high-pressure fan to be fed into an inlet of a Venturi atomizingtube; the desulfurization wastewater stored in the wastewater tank is led into the Venturi tube through negative pressure at a pipe opening of the Venturi tube, high-speed airflow at the throat position of the Venturi tube can impact and atomize the led-in desulfurization wastewater, and meanwhile the waste heat flue gas and liquid drops are subjected to forceful heat transfer so that the pre-evaporation effect on the liquid drops can be achieved; and solid evaporated products are captured by the follow-up electrostatic dust collector or a bag-type dust remover, and therefore low-cost zero discharging of the desulfurization wastewater can be realized.

Owner:HUADIAN ZHENGZHOU MECHANICAL DESIGN INST

Method and system for capturing CO2 by temperature-lowering absorption and low-voltage desorption

InactiveCN101721878AIncrease profitIncrease the adsorption capacityProductsCarbon compoundsChemisorptionCyclic process

The invention relates to a method and a system for acquiring CO2 by temperature-lowering absorption and low-voltage desorption, in particular to a method and a system for captauring CO2 by a method of absorption and desorption, which overcomes the defects of difficult control, large energy consumption of the warming voltage-varying desorption method adopted by power plants to capturing CO2 and the defects of toxic and hazardous gas generated during capturing CO2 by chemisorption method. The method comprises temperature reduction by flue gases, communicating absorption of a first absorption and desorption tower, communicating absorption of a second absorption and desorption tower, and electrified temperature-increasing desorption, purification and temperature reduction of the first the absorption and desorption tower, CO2 gas purging, electrified temperature-increasing desorption, purification and temperature reduction of the second absorption and desorption tower, and communicating absorption of the first the absorption and desorption tower during a next absorption and desorption circulating process. In the system, the first and the second absorption and desorption towers are connected with an alternating current power supply through a first switch and a second switch, and the alternating current power supply is connected with the first and the second absorption and desorption towers. In the utility model, a physical adsorption method is adopted, thereby avoiding the generation of other toxic and hazardous gases by chemical methods. The method and the system are used for capturing CO2 in flue gases in coal industry works and power plants.

Owner:HARBIN INST OF TECH

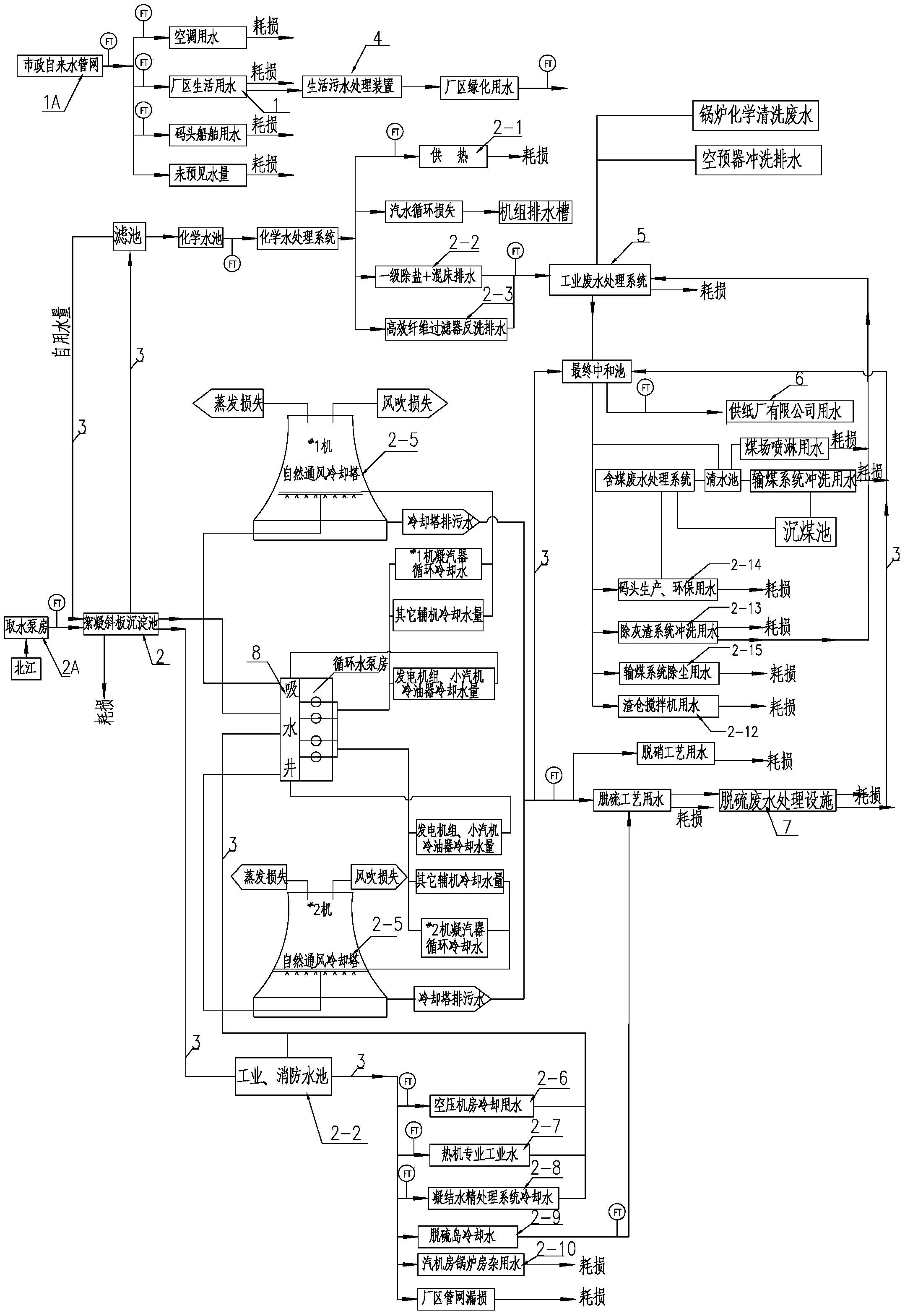

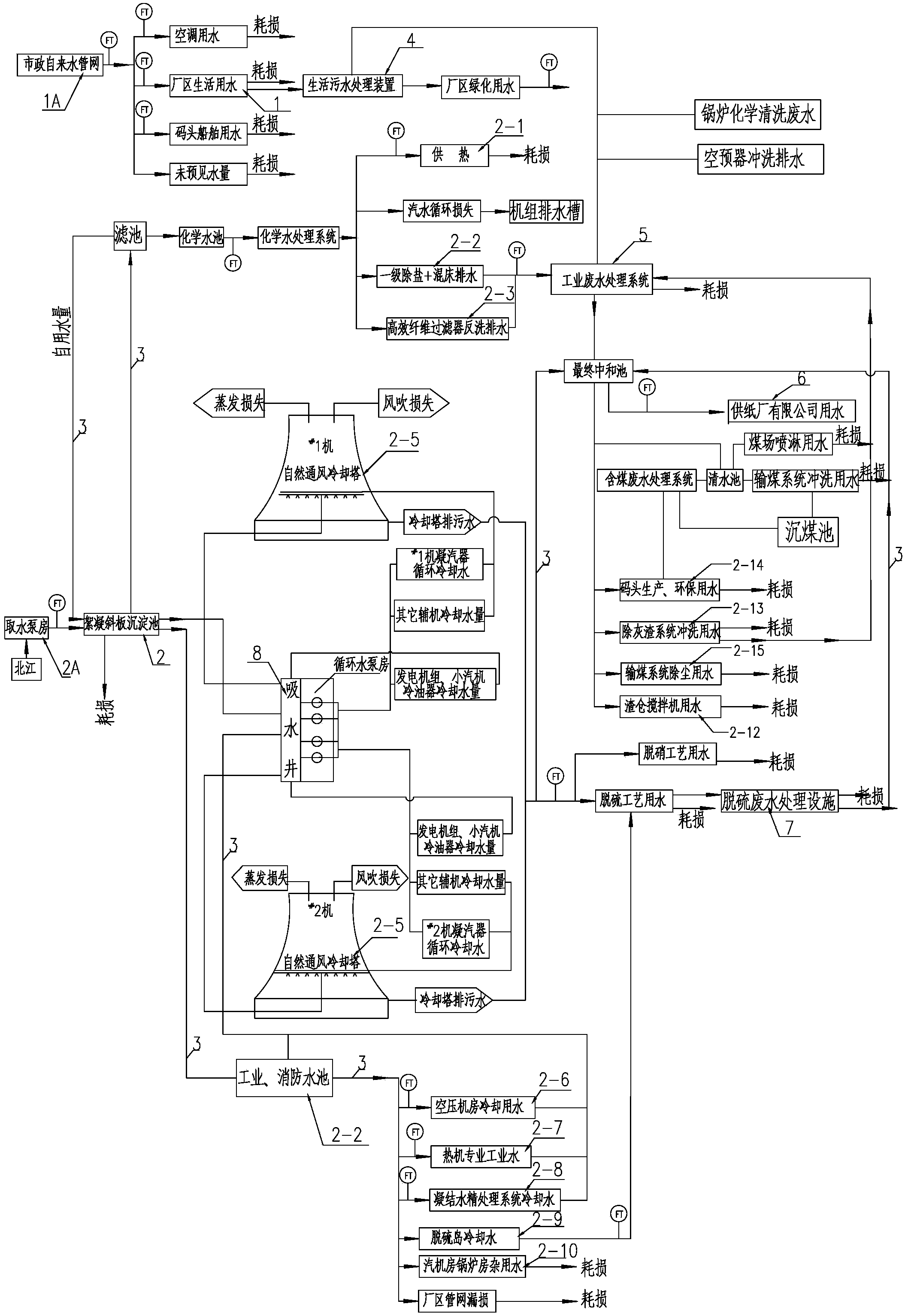

Full-digitalized monitoring method for water for power plants and self-balance water affair system

InactiveCN103853137ARealize full digital real-time monitoringAchieving zero emissionsMultistage water/sewage treatmentProgramme total factory controlWater dischargeEngineering

The invention relates to a monitoring method for a power plant water system and a full-digitalized self-balance water affair system, wherein the method and the system are applicable to an industrial project with a waste water pollution discharge circulation and environment-friendly water utilization system, for example, a coal power plant in an industrial zone. The method includes the steps that first, a water utilization system comprising a control system, a water supply system and a water discharge system is established through a field bus technology, and water quantity balance instruments are arranged on water inlets and water outlets of all water utilization points of the water utilization system; second, the water quantity balance instruments are connected into the control system so as to monitor water inflow and discharge conditions in all places in real time, output data of the water quantity balance instruments are calculated in the control system so as to obtain water utilization volumes and water discharge volumes in all the places, and water inflow and utilization balance is achieved through control of the control system; third, intelligent equipment with field bus connectors are adopted for all kinds of transmitters and analysis instruments related to the power plant water utilization system, and thus full-digitalized real-time monitoring is achieved. The invention further discloses the self-balance water affair system for full-digitalized monitoring on water for power plants. The self-balance water affair system achieves water quantity self-balance and waste water zero discharge.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Dust-removal mercury-removal filter bag for bag-type dust remover and preparation method of filter bag

The invention discloses a dust-removal mercury-removal filter bag for a bag-type dust remover. The dust-removal mercury-removal filter bag is bag which is loaded with a mercury-removal catalyst and made of high-temperature filtration fiber; and the mercury-removal catalyst is a mixture of manganese oxide and cobalt oxide. The invention further discloses a preparation method of the dust-removal mercury-removal filter bag; the filter bag is loaded with the mercury-removal catalyst and applied to the bag-type dust collector; the catalyst can be used for oxidizing elemental mercury in coal-fired flue gas into bivalent mercury (Hg2+), so that absorption or adsorption of a flue gas pollutant purifying device is facilitated. The dust-removal mercury-removal filter bag is applied to controlling mercury emission of a coal-fired power plant, so that adsorbent is substituted by catalytic oxidation; on the basis of keeping the smoke dust removal effect, the removal efficiency of the elemental mercury is bigger than 30%, so that the flue gas mercy removal effect of the coal-fired power plant can be satisfied.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Method and system for efficiently controlling mercury pollution of coal-fired power plant at low cost

InactiveCN102343200ARaise the ratioImprove mercury removal efficiencyDispersed particle separationAir preheaterControl system

The invention discloses a method and system for efficiently controlling mercury pollution of a coal-fired power plant at low cost. The system comprises a primary hot air duct, a secondary hot air duct and a liquid storing tank, wherein the primary hot air duct and the secondary hot air duct are communicated with an air preheater and a hearth; a coal conveying system is communicated with a coal grinding system through a coal feeder; the liquid storing tank is filled with a halide additive solution; and the liquid storing tank is communicated with at least one of the coal conveying system, the coal feeder, the primary hot air duct and the secondary hot air duct. According to the system, the halide additive solution enters a boiler body and participates in a combustion reaction, the oxidation of the mercury in flue gas is promoted and the ratio of mercury oxide in the flue gas is increased, so that the synergetic demercuration effect of flue gas purifying equipment such as denitration equipment, desulfurization equipment, dedusting equipment and the like in a tail flue of a boiler is improved, and the mercury content of flue gas in a chimney is greatly lowered. A mercury pollutant control system has the advantages of small investment and low running cost while the mercury pollutant emission level of the coal-fired power plant can meet stricter environmental standard requirements.

Owner:HUANENG CLEAN ENERGY RES INST

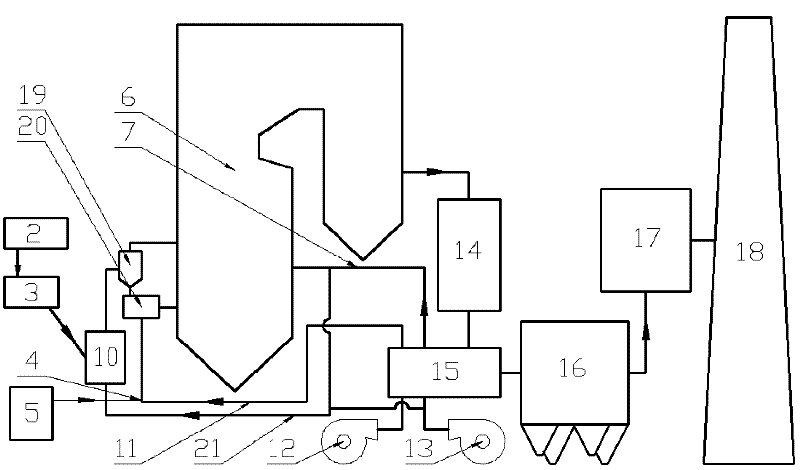

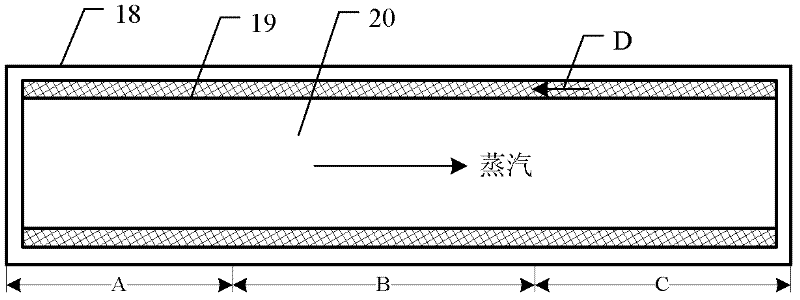

Ceramic composite pipe for conveying flue gas desulfurization glue size in electric power plant and method for manufacturing same

InactiveCN101363560ACorrosion resistantWear-resistantDispersed particle separationPreformed elementsCeramic compositeInterface layer

The invention relates to a ceramic composite pipe used for conveying stack gas desulphurization slurry from electric power plants. An inner layer of the composite pipe is a ceramic pipe and an outer layer is a metal pipe; the interface layer between the inner layer and the outer layer is a plastic pipe; the inner diameter of the composite pipe ranges from 80mm to 450mm. The ceramic composite pipe is characterized by having anti-corrosion and anti-wearing property and long service life.

Owner:JINGANG NEW MATERIALS

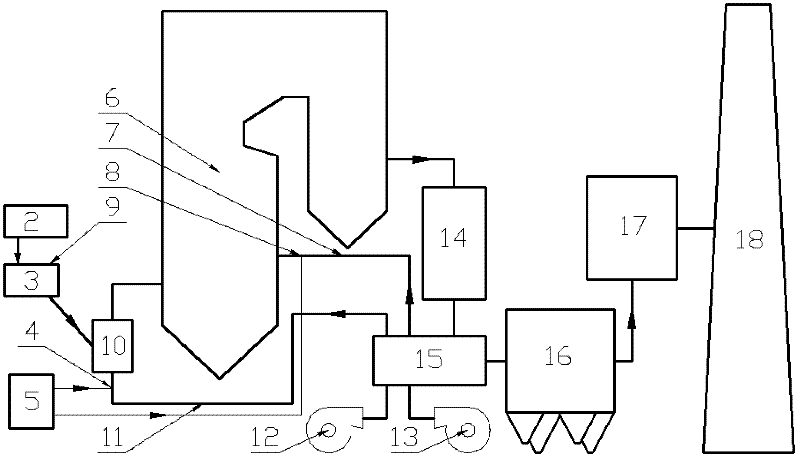

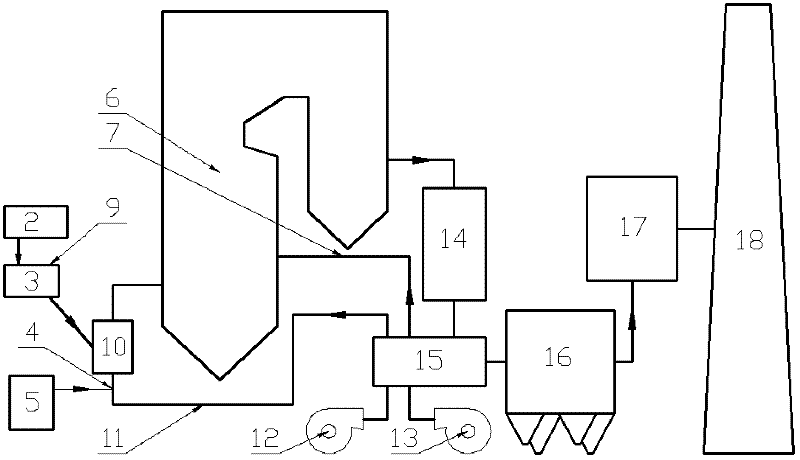

Coal power plant controllable type heat pipe flue gas waste heat recovery system and method

InactiveCN102444900AExcessive heatImprove efficiencyCombustion processIndirect carbon-dioxide mitigationWater vaporFlue gas

The invention discloses a coal power plant controllable type heat pipe flue gas waste heat recovery system and method. The system comprises a boiler, a deduster, a draught fan, a booster fan, a controllable type heat pipe heat exchanger component, a desulfurizing tower and a chimney which are sequentially connected in a cooperation mode through pipelines. The method comprises the following steps: additionally arranging the controllable type heat pipe heat exchanger component in a gas flue system of a coal power plant, and recycling heat and water vapor of the gas flue system; and a bypass gas flue is led out between the draught fan and the booster fan of the gas flue system and is connected between the desulfurizing tower and the chimney of the gas flue system. The coal power plant controllable type heat pipe flue gas waste heat recovery system and method disclosed by the invention can overcome the defects of poor energy conservation performance, poor environmental protection performance, high cost, poor reliability, large occupation space and the like so as to realize the advantages of good energy conservation performance, good environment protection performance, low cost, good reliability, small occupation space and wide application scope.

Owner:辽宁赛沃斯节能技术有限公司

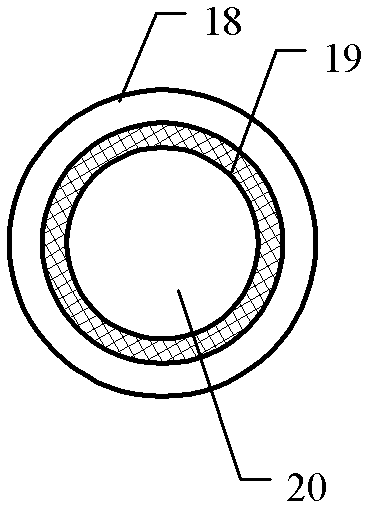

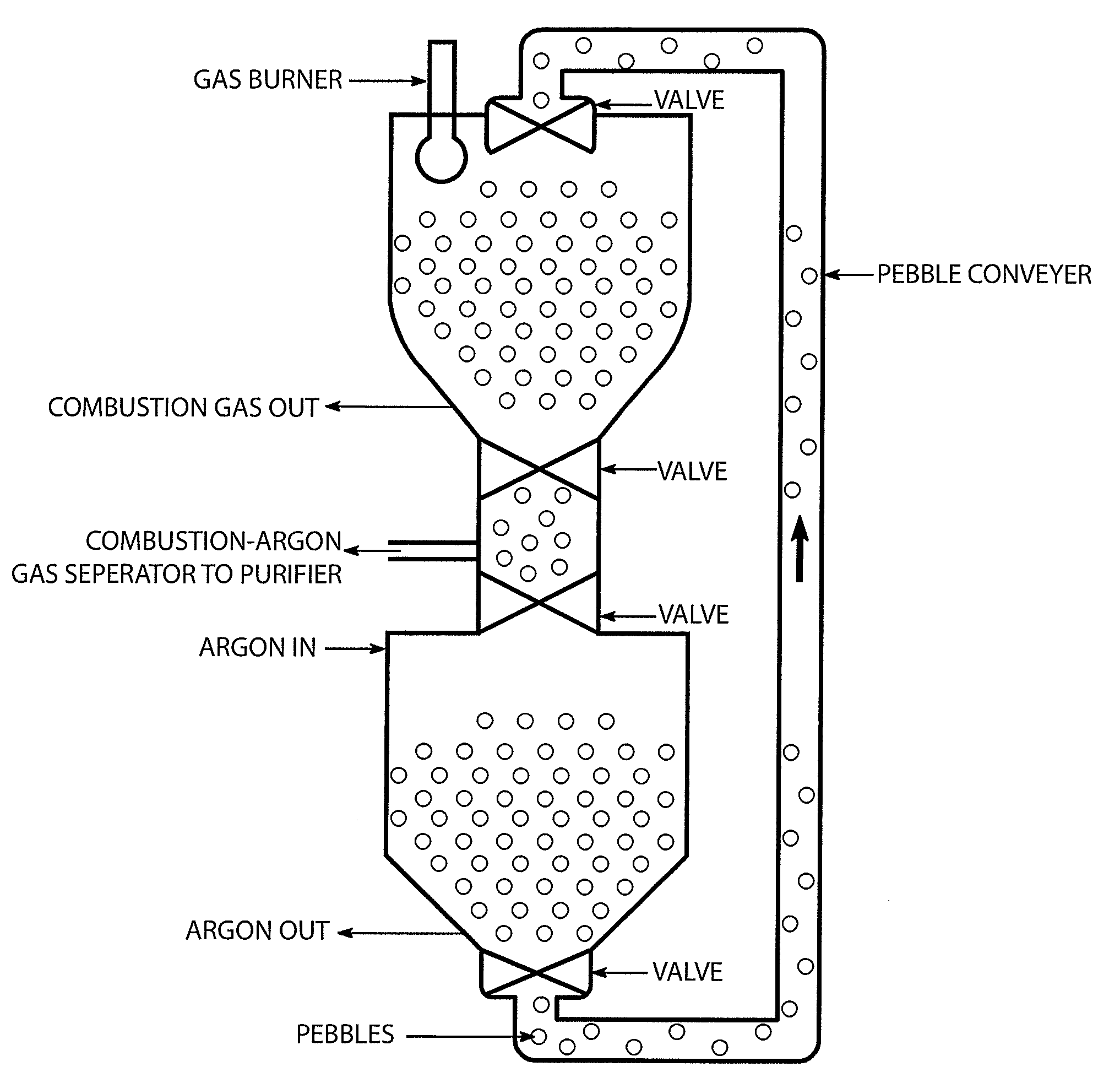

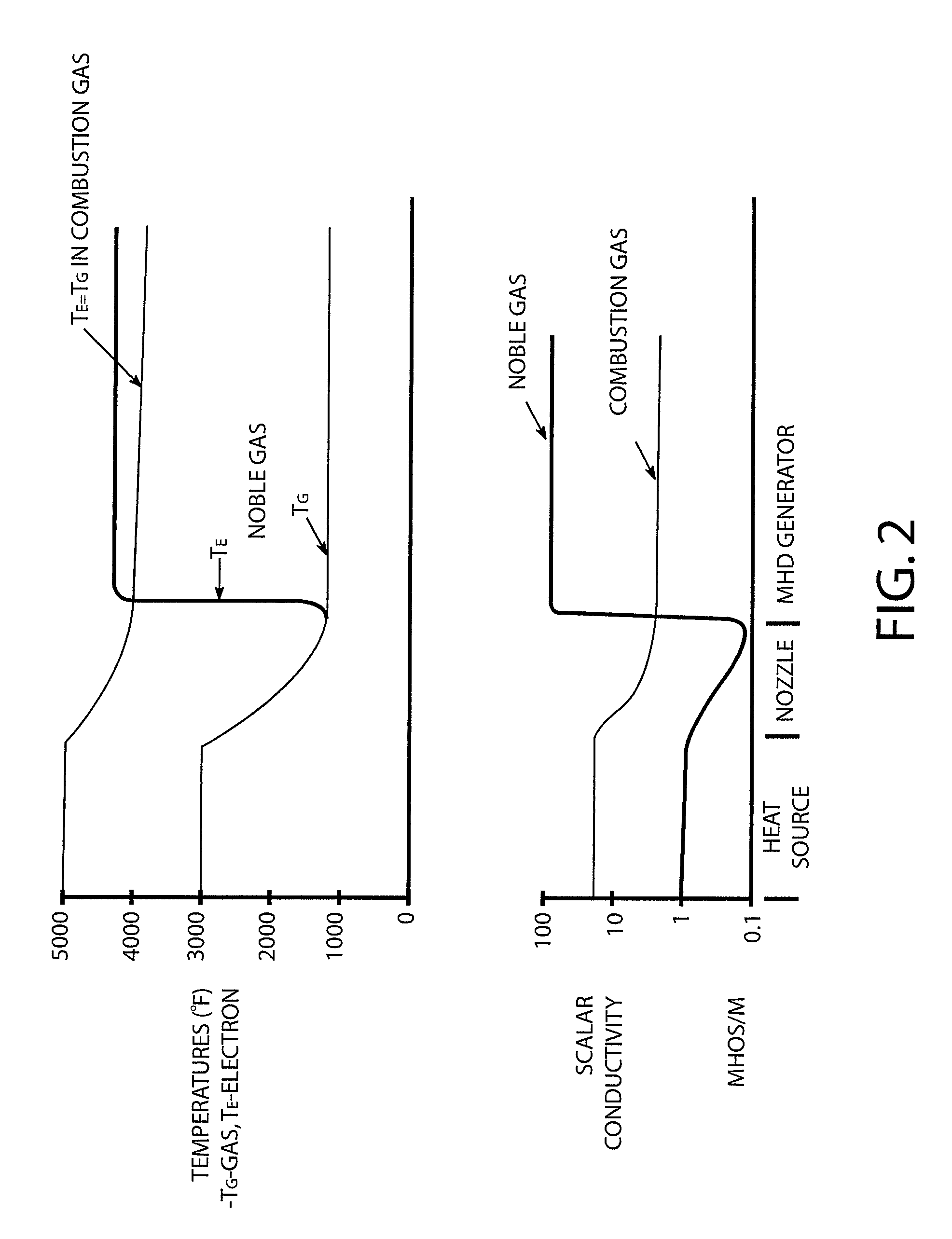

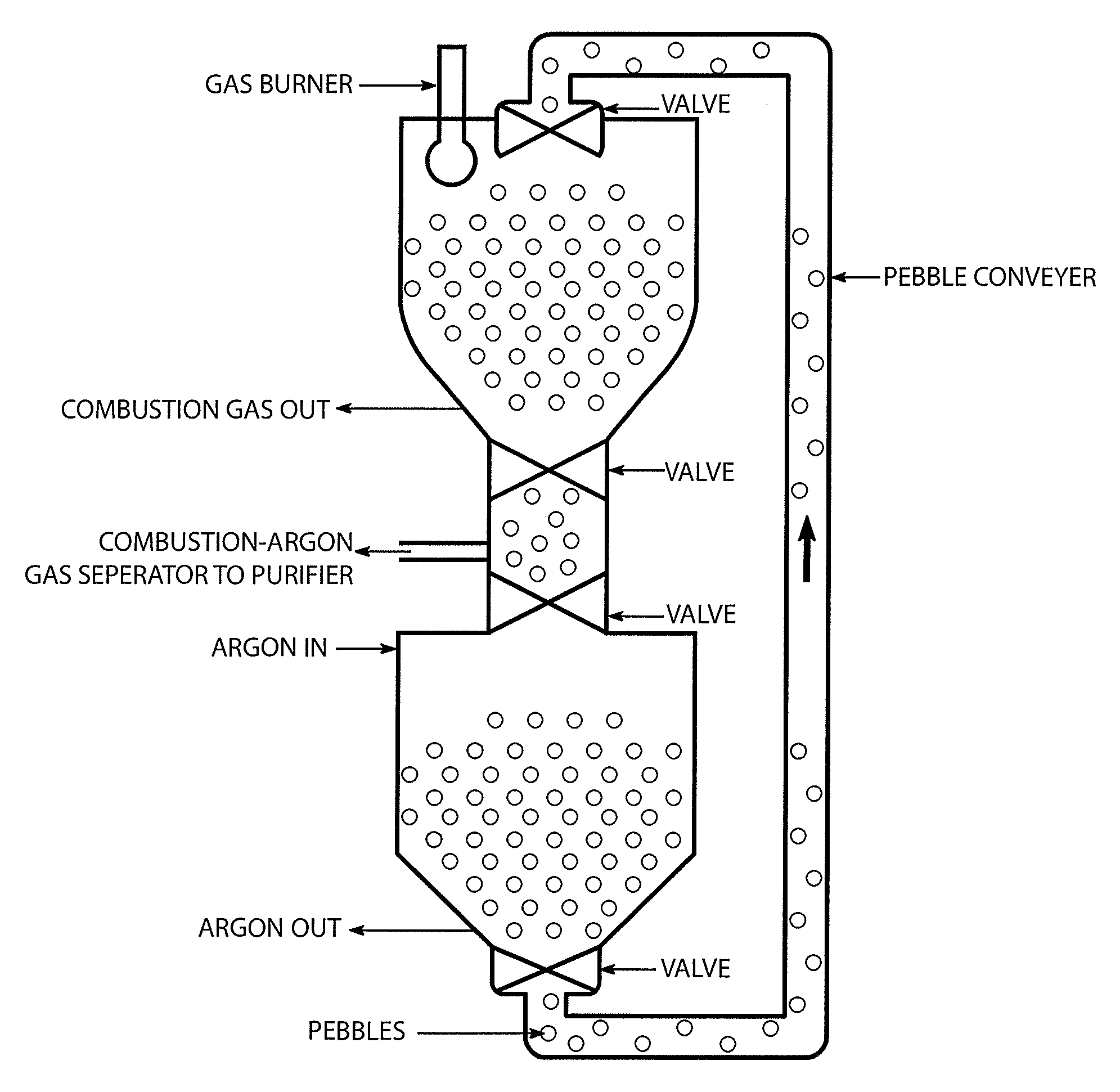

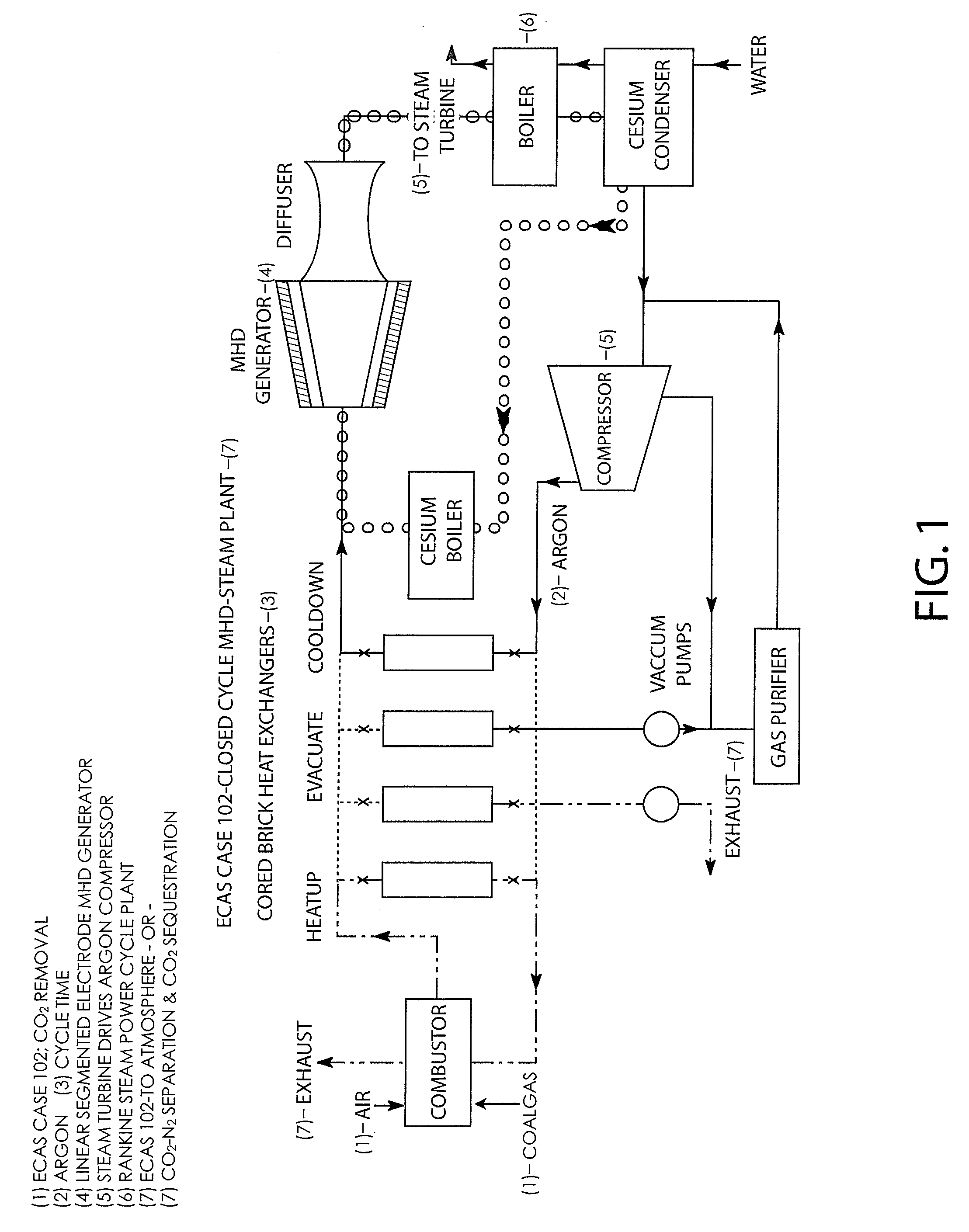

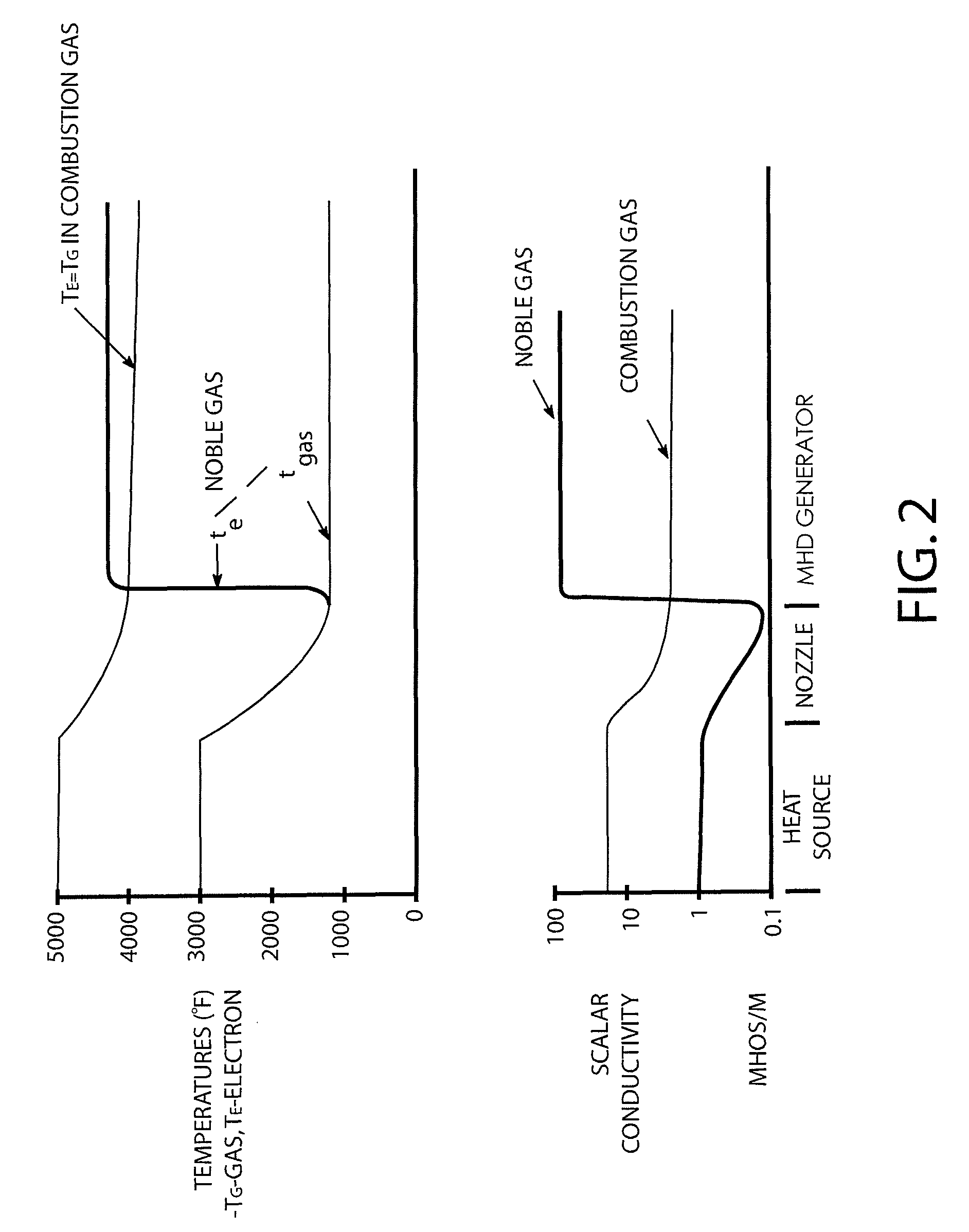

Fossil fuel fired, closed cycle mhd generator in parallel with steam turbine cycle with zero emissions and co2 sequestration

InactiveUS20120137877A1Low costHigh revenue potentialOrganic chemistryNitrogen compoundsNoble gasNuclear engineering

Disclosed is a gaseous fossil fuel fired, indirectly heated, Brayton closed cycle comprising an alkali metal seeded noble gases that is rendered non-equilibrium, electrically conducting in a magnetohydrodynamic (MHD) electric power generator with zero emissions from the combustion products, including physical separation and sequestration of the carbon dioxide (CO2) what is emitted from the fossil fuel, with said cycle combined with a Rankine steam turbine bottoming cycle to compress the noble gas, while another optional new or existing Rankine steam cycle is placed in parallel and separate from the MHD cycle, and it is fired by the solid char remaining if the MHD cycle is fired with the devolatilized coal, and / or with solid coal culm, and / or unburned carbon in coal power plant waste ash, in order to achieve high efficiency at low capital, low operating, and low fuel costs.

Owner:ZAUDERER BERT

Preparation method of copper-foam-based hierarchical composite oxide monolithic denitrification catalyst

ActiveCN103611535AEnhanced mass transferImprove heat transfer performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystPtru catalyst

The invention relates to a preparation method of a copper-foam-based hierarchical composite oxide monolithic denitrification catalyst, and belongs to the field of environment-friendly nano catalyst materials. The catalyst includes main active components of CuO and Fe2O3. The hierarchical composite oxide monolithic denitrification catalyst is prepared by the steps of promoting in-situ growth on the surface of copper foam which is taken as a support carrier through oxidization to form a CuO nano line; under a hydrothermal condition, promoting in-situ deposition on the CuO nano line through hydrolysis of ferrous ions, and washing, drying and calcining to obtain the monolithic denitrification catalyst. The catalyst disclosed by the invention has the advantages of being simple in preparation method, free from molding, uniform in active component distribution, rapid in thermal response speed, good in denitrification performance and the like. The synthesized catalyst is applicable to treatment of nitrogen oxides in tail gas discharged from coal-fired power plants, garbage incinerators, steel mills and the like.

Owner:SHANGHAI UNIV

Methods and apparatus for performing flue gas pollution control and/or energy recovery

ActiveUS7776141B2Improve system efficiencyAvoid and eliminate and reduce any needGas treatmentElectrostatic separationParticulatesRe introduction

Methods and apparatus for pollution control which are well suited for use in a coal power plant are described. Ash is collected and injected into the flue gas stream at a location upstream of a cooling module. The ash acts as an absorbent and / or reactant material onto which condensate may condense. By re-introducing ash to keep the condensation forming wet areas within the system, lower cost materials which are less corrosion resistant than needed for wet operating conditions can be used. Mercury recovery and SO3 removal is facilitated by the cooling process and re-introduction of collected ash. Activated carbon and / or an alkali absorbent material may be added. Use of a dry ESP and / or fabric filter as opposed to a wet ESP for particulate collection leads to cost benefits. Energy recovered by the cooling of the flue gas may be re-used to heat turbine condensate leading to improved energy efficiency.

Owner:MITSUBISHI POWER AMERICAS INC

Method for recycling water and heat in flue gas discharged by coal-fired power plant and system thereof

InactiveCN107551751AAchieve recyclingSolve the phenomenon of white smokeFeed water supplyDispersed particle separationTrappingEngineering

The invention discloses a method for recycling water and heat in flue gas discharged by a coal-fired power plant and a system thereof. The method is realized by two systems, namely a hollow fiber membrane water vapor trapping system and a heat pump system. The hollow fiber membrane water vapor trapping system comprises a membrane assembly, a condenser A, a vacuum pump, a condensate water pump andwater purification equipment; the heat pump system comprises an evaporator, a compressor, a condenser B and an expansion valve connected end to end by a heat exchange circulating pipeline A so as to form a circulation loop, and provides a cold source for the hollow fiber membrane water vapor trapping system by condensing the trapped water vapor into water so as to realize water recovery; the hollow fiber membrane water vapor trapping system provides a heat source for the heat pump system for heating boiler circulating water so as to realize heat recovery. According to the method disclosed by the invention, 20-40% of water and heat in the flue gas discharged by the coal-fired power plant can be recycled, and the aims of saving water and energy can be achieved; meanwhile, the parameters of the flue gas discharged by the power plant are improved, and the white smoke phenomenon and gypsum rain problem can be avoided.

Owner:江苏汇创流体工程装备科技有限公司

Cerium oxide catalyst for catalyzing and purifying nitric oxides, preparation method and application

InactiveCN105233814AWide operating temperature windowImprove catalytic performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTitanium zirconiumFlue gas

The invention discloses a cerium oxide catalyst for catalyzing and purifying nitric oxides, a preparation method and an application, wherein the cerium oxide catalyst for catalyzing and purifying the nitric oxides is a metal oxide catalyst CeOx@ZrO2-TiO2, cerium oxides (CeOx) are uniformly dispersed on the surfaces of composite titanium-zirconium oxides (ZrO2-TiO2). The cerium oxide catalyst for catalyzing and purifying the nitric oxides uses non-toxic harmless raw materials, is prepared through a simple and easy method, has the characteristics of excellent catalytic activity, high N2 generation selective and wide operation temperature window and the like, can be suitable for mobile sources using diesel exhausts as representatives and nitrogen oxide catalytic purification devices of fixed sources using coal burning power plant flue gas as representatives.

Owner:NANJING UNIV OF SCI & TECH

Catalyst for simultaneous denitration, demercuration and dioxin removal and preparation method thereof

ActiveCN111167475AWide active temperature rangeStrong resistance to sulfur poisoningCatalyst carriersGas treatmentPtru catalystEngineering

The invention discloses a catalyst for simultaneous denitration, demercuration and dioxin removal and a preparation method thereof. According to the invention, cerium oxide and niobium pentoxide are used as catalytic active components, a mixture of nickel oxide and platinum nanoparticles is used as a cocatalyst, a titanium dioxide nanoneedle generated by modifying tetrabutyltitanate with hydrochloric acid is used as a main carrier, and the catalyst is used after hydrogen pretreatment. Based on the mass of the carrier, the mass percentage of the active components is 10%-30%, and the mass percentage of the cocatalyst is 0.1%-0.15%. The preparation method comprises the following steps: uniformly stirring the active components, a cocatalyst composite colloidal solution and the optimized and modified catalyst carrier, carrying out aging and extrusion molding, and then performing drying and roasting to obtain the catalyst. The catalyst is environment-friendly, can efficiently remove nitrate,mercury and dioxin at the same time, and has a wide active temperature interval and low SO2 oxidation efficiency. Within 240-500 DEG C, the denitration efficiency and the dioxin removal efficiency ofthe catalyst are both higher than 95%, and the mercury removal efficiency of the catalyst is higher than 99%. The catalyst can be widely applied to the fields of coal-fired power plants, chemical plants and the like.

Owner:南京环福新材料科技有限公司

Fossil fuel fired, closed cycle MHD generator in parallel with steam turbine cycle with zero emissions and CO2 sequestration

InactiveUS8277543B2High revenue potentialEliminate needOrganic chemistryNitrogen compoundsNoble gasNuclear engineering

Disclosed is a gaseous fossil fuel fired, indirectly heated, Brayton closed cycle comprising an alkali metal seeded noble gases that is rendered non-equilibrium, electrically conducting in a magnetohydrodynamic (MHD) electric power generator with zero emissions from the combustion products, including physical separation and sequestration of the carbon dioxide (CO2) what is emitted from the fossil fuel, with said cycle combined with a Rankine steam turbine bottoming cycle to compress the noble gas, while another optional new or existing Rankine steam cycle is placed in parallel and separate from the MHD cycle, and it is fired by the solid char remaining if the MHD cycle is fired with the devolatilized coal, and / or with solid coal culm, and / or unburned carbon in coal power plant waste ash, in order to achieve high efficiency at low capital, low operating, and low fuel costs.

Owner:ZAUDERER BERT

Preparation method of denitration catalyst with nanoscale ordered honeycomb structure

ActiveCN103263911AEnhanced surface acid sitesImprove the activity of medium and low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMicrosphere

The invention relates to a preparation method of a denitration catalyst with a nanoscale ordered honeycomb structure cerium-zirconium oxide skeleton and dispersed tungsten oxide loaded on the surface, belonging to the technical field of preparation technologies of nanometer materials and environment protection. The preparation method is characterized by comprising the following steps of: depositing polrvinyl benzene microspheres into an ordered template, absorbing metal salt solution of cerium and zirconium under the condition that citric acid is taken as a complexing agent, calcining step by step to obtain the catalyst skeleton, and loading tungsten on the surface of the catalyst by means of impregnation and calcined activation to obtain the denitration catalyst with the characteristics. Due to the joint action of the structure and the surface load of the tungsten oxide, the catalyst is provided with a wide catalysis temperature window. Therefore, the catalyst provided by the invention can be used for selective catalytic reduction of nitric oxide in tail gas of a diesel engine and in smoke discharged out of a coal-fired power plant, a steel mill, etc.

Owner:SHANGHAI UNIV

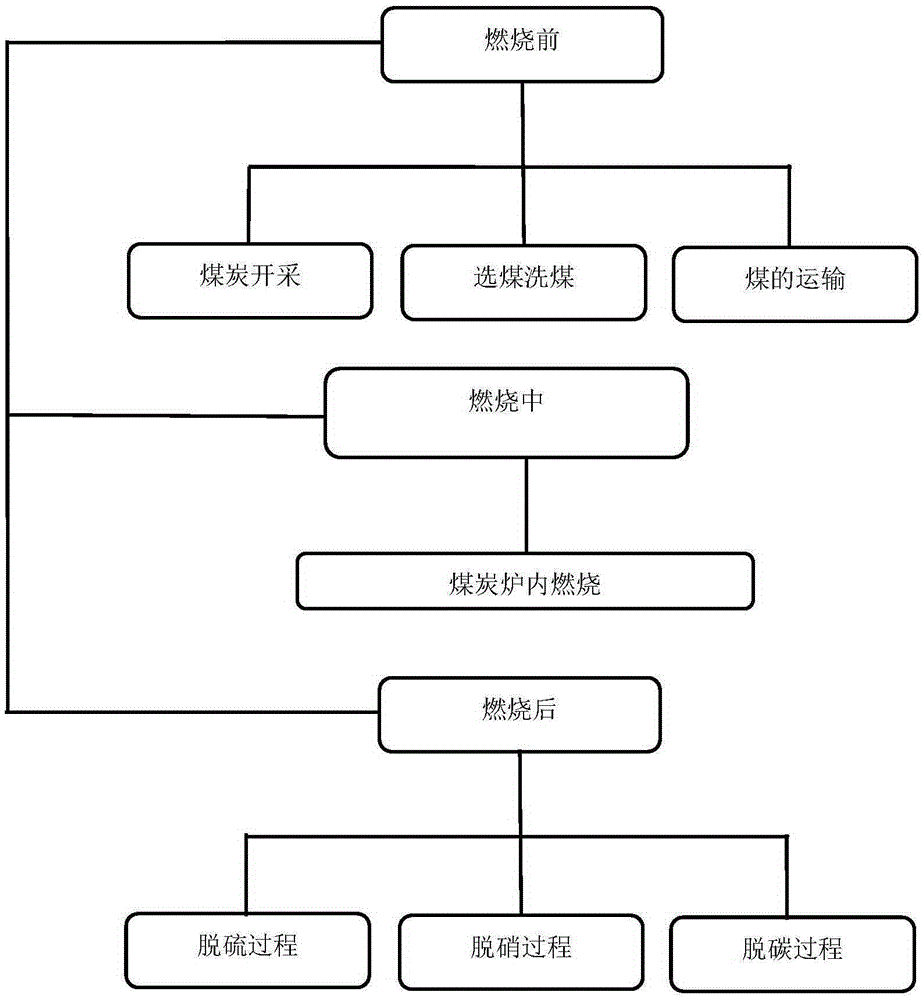

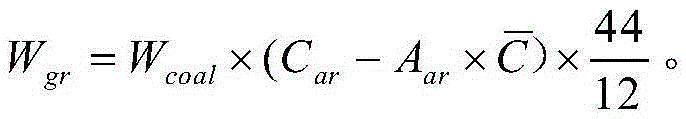

Method for accurate measurement of carbon emission from coal-fired power plant

InactiveCN105242000AHigh measurement accuracyEffective Emissions MonitoringChemical analysis using combustionCombustionCalculation methods

The invention discloses a method for accurate measurement of carbon emission from a coal-fired power plant. The method is used for measuring the carbon emission Wg generated from raw coal in preset consumption Wcoal consumed in a fire coal life cycle by the coal-fired power plant, and comprises the following steps: step S10, measuring the carbon emission W3 produced in the early combustion stage of the fire coal from the coal-fired power plant; step S20, measuring the carbon emission Wgr generated in the middle combustion stage of the fire coal from the coal-fired power plant; step S30, measuring the carbon emission generated in the later combustion stage of the fire coal from the coal-fired power plant, wherein the carbon emission includes carbon emission Ws produced in the desulfurization process, carbon emission Wn produced in the denitrification process and carbon emission Wc generated in the decarburization process; and step S40, calculating the carbon emission (Wg= W3+Wgr+Ws+Wn+Wc) generated from raw coal in preset consumption Wcoal consumed in a fire coal life cycle by the coal-fired power plant. The invention adopts the carbon emission calculation range suitable for coal-fired power plants in China and optimal calculation method for measurement of carbon emission from coal-fired power plants, and has the advantage of high accuracy of measurement.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com