Ceramic composite pipe for conveying flue gas desulfurization glue size in electric power plant and method for manufacturing same

A ceramic composite, desulfurization slurry technology, applied in separation methods, chemical instruments and methods, pipes, etc., can solve the problems of increasing enterprise costs, poor erosion resistance, affecting the safe operation of power plant flue gas desulfurization devices, etc. Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

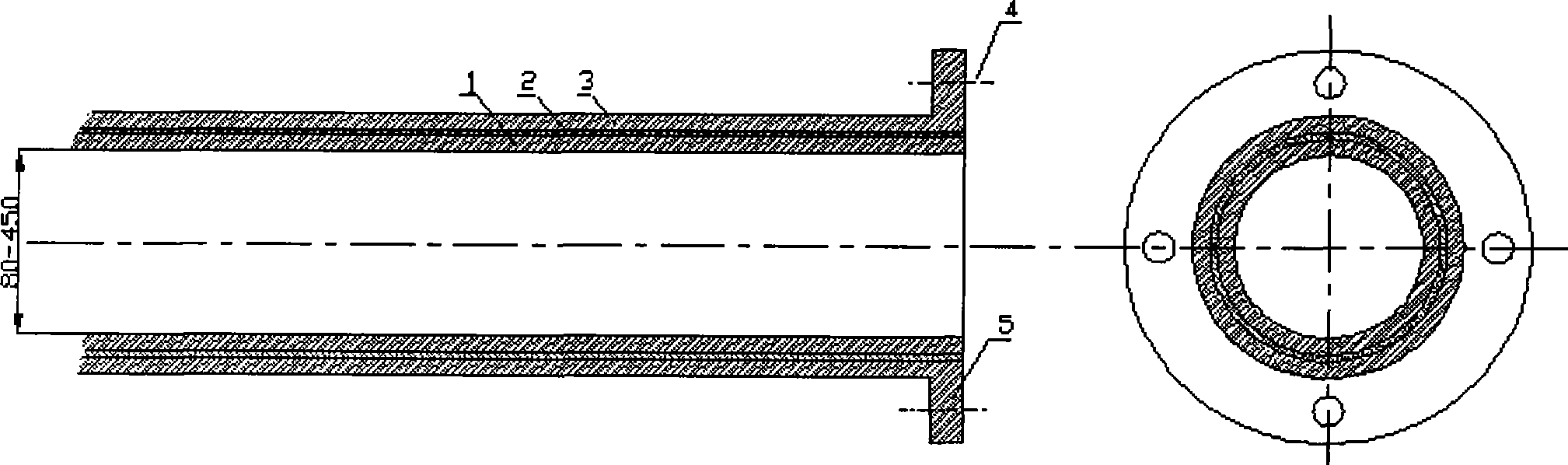

[0023] A ceramic composite pipe for flue gas desulfurization slurry transportation in a coal-fired power plant, characterized in that the inner pipe of the composite pipe is a ceramic pipe 1, the outer pipe is a metal pipe 3, and the middle layer between the inner and outer layers is a plastic pipe 2 . Described ceramic pipe 1 thickness is 5mm, and internal diameter is 180mm; Plastic pipe material is polyethylene (PE) plastics, and plastic pipe thickness is 2mm; Metal pipe selects common metal steel pipe, and the thickness of metal pipe is 4mm. It mainly plays the role of connecting and fixing the pipeline and protecting the inner layer from damage.

Embodiment 2

[0025] A ceramic composite pipe for conveying flue gas desulfurization slurry in a coal-fired power plant is characterized in that the inner layer pipe of the composite pipe is a ceramic pipe, the outer layer pipe is a metal pipe, and the middle layer between the inner layer and the outer layer is a plastic pipe. The ceramic tube has a thickness of 8 mm and an inner diameter of 300 mm. The material of the plastic tube is polyvinyl chloride (PVC) plastic tube, and the thickness of the plastic tube is 1 mm. The metal pipe is made of ordinary metal steel pipe, and the thickness of the metal pipe is 5mm.

Embodiment 3

[0027] (1) Forming of ceramic tube body:

[0028] 60 parts by weight of alumina powder, 6 parts by weight of calcium carbonate, 8 parts by weight of talc powder, 12 parts by weight of spodumene and 3 parts by weight of titanium oxide powder, and 20 parts by weight of kaolin are mixed according to a conventional amount of water and ball milled to prepare The slurry is spray-dried to obtain a mixed powder, and isostatically pressed to form a green body under a pressure of 80 MPa with an isostatic press;

[0029] (2) Place the dried green body at a temperature of 1460°C and fire it for 8 hours to obtain a ceramic tube;

[0030] (3) Select the plastic tube that fits the ceramic tube, put the ceramic tube in the plastic tube, and then put the ceramic tube and the plastic tube in the metal tube, and the metal tube and the plastic tube fit together, layer by layer The layers are glued and connected to form a ceramic composite pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com