Patents

Literature

177results about How to "Low corrosion current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of magnesium alloy surface micro-arc oxidation/spray coating compound film

ActiveCN101871119AHigh bonding strengthImprove corrosion resistanceAnodisationLiquid surface applicatorsMicro arc oxidationPlasma electrolytic oxidation

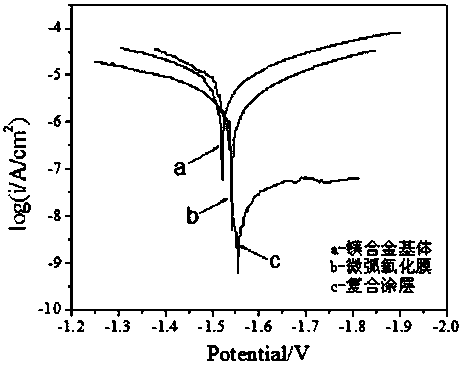

The invention provides a preparation method of a magnesium alloy surface micro-arc oxidation / spray coating compound film, which relates to a preparation method of a magnesium alloy surface compound film. The invention solves the problems that film layers obtained by chemical composition coating, anodic oxidation and vapor deposition in the existing magnesium alloy surface treatment method are thin and have poor corrosion resistance performance, the ion injection has high cost and is difficult to realize large-area processing, the combining force between coating layers and the magnesium alloy is poor, and organic coating layers has the defect of easy aging. The preparation method has the following steps: firstly, using micro-arc oxidation for preparing ceramic films on the surface of the magnesium alloy; then, adopting air spray coating for spraying and coating inorganic paint onto the ceramic films; and then, carrying out heat treatment to obtain the micro-arc oxidation / spray coating compound film. The method is simple, and the cost is low. The air spray coating uses porous structures of the micro-arc oxidation ceramic films, so the combination of the inorganic coating layers and the ceramic films is firm, the thickness of the compound films is between 20 and 40 mum, the self corrosion electric potential is positively moved to -1.02 V, the corrosion current density is lowered by 5 orders through being compared with that of the magnesium alloy, the magnesium alloy surface micro-arc oxidation / spray coating compound film has no damage after 72 to 144h of salt spray tests, and the corrosion resistance performance is good.

Owner:HARBIN INST OF TECH

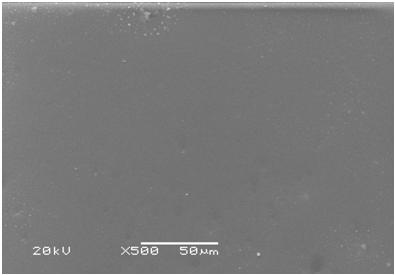

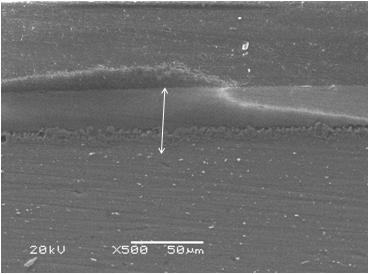

Graphene-doping conductive polymer modified metal bipolar plate of proton exchange membrane fuel cell and preparation method of metal bipolar plate

ActiveCN105552399ADoes not affect other performanceLow corrosion current densityFinal product manufactureCollectors/separatorsConductive polymerPre treatment

The invention relates to a graphene-doping conductive polymer modified metal bipolar plate of a proton exchange membrane fuel cell and a preparation method of the metal bipolar plate, belonging to the technical field of a fuel cell. The bipolar plate comprises a metal plate, a polarity oxide film layer and a graphene-doping conductive polymer film layer, wherein the polarity oxide film layer covers the surface of the metal plate, the graphene-doping conductive polymer film layer covers the surface of the polarity oxide film layer, and the thickness of the graphene-doping conductive polymer film layer is 0.005-0.3 millimeter, the thickness of the polarity oxide film layer is 5-30 nanometers, and the thickness of the metal plate is 0.1-2 millimeters. A graphene-doping conductive polymer film is deposited on the surface of a stainless steel plate after preprocessing by an electrochemical synthesis method, the metal bipolar plate prepared according to the invention has the advantages of relatively low contact resistance, low corrosion current density and high bonding firmness of the metal substrate and the conductive polymer film, moreover, the method is simple, the processing cost is low, and mass production can be achieved.

Owner:HUBEI UNIV +1

Aluminum alloy surface rare earth chemical conversion treatment method

InactiveCN101260521AEasy to operateGolden colorMetallic material coating processesCleaning using liquidsCeriumAccelerant

The invention discloses a method for treating the rare earth chemical conversion on the surface of aluminium alloy. The method comprises a pretreatment procedure on the surface of the aluminium alloy, the preparation of rare earth chemical conversion treating liquid and the treatment of rare earth chemical conversion. The rare earth chemical conversion treating liquid consists of 10 to 30g / L cerium salt, 1 to 5g / L oxidant solution, 0 to 5x10<-2> mol / L film forming accelerant and 1 to 3g / L film forming surface morphology truing agent; the PH value of the treating liquid is 1 to 3; the cerium salt is selected form one or two of hydrous cerium chloride and hydrous cerous nitrate; the film forming accelerant is one or a plurality of transitional metal free ions; the film forming process is completed in 5 to 15 minutes. The method for treating a coating by conversion has high combining intensity with a substrate, good protective performance and simple structure; the coating contains no hexavalent chrome or trivalent chromium which is harmful to the environment and human body.

Owner:SOUTH CHINA UNIV OF TECH

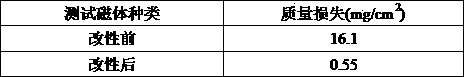

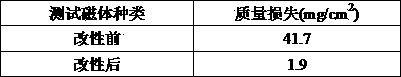

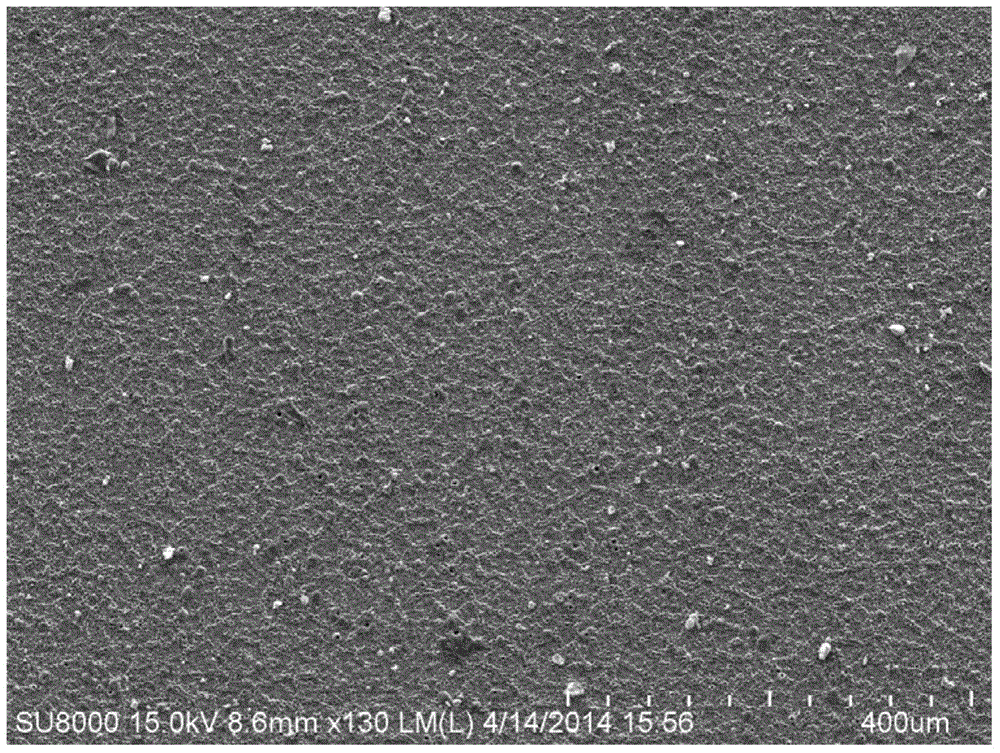

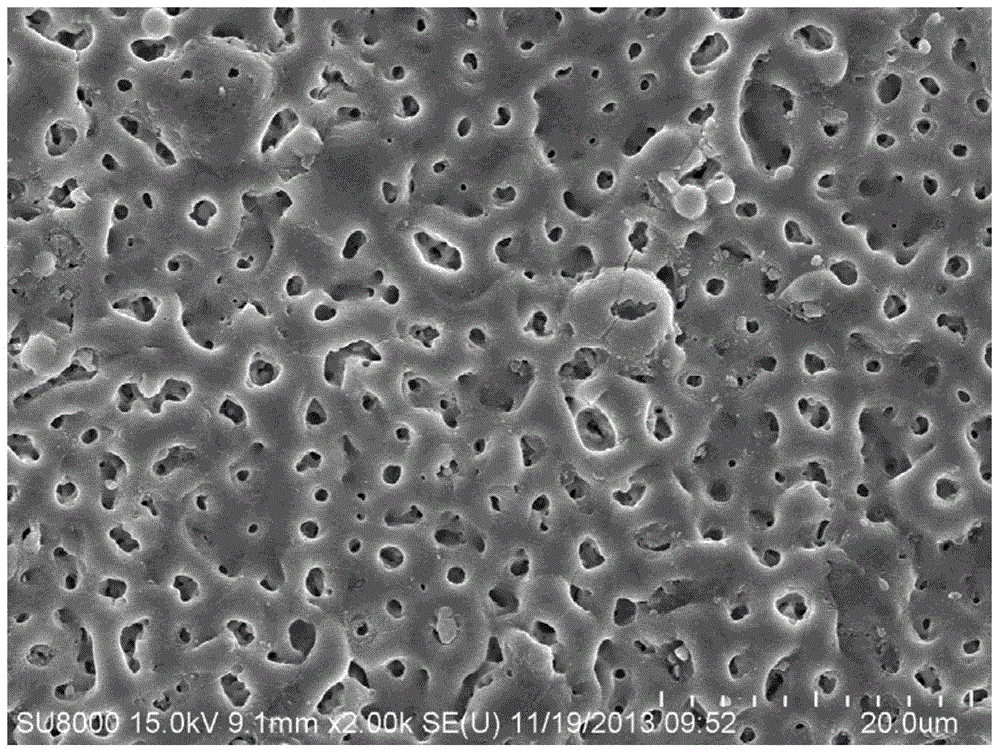

Method for improving corrosion resistance of sintered neodymium iron boron magnet

ActiveCN103668178ALittle influence on magnetic propertiesChange structureInductances/transformers/magnets manufactureMetallic material coating processesIrradiationGrain boundary

The invention discloses a method for improving the corrosion resistance of a sintered neodymium iron boron magnet, and relates to a permanent magnet material surface modification technology. The method mainly comprises the following steps: 1, carrying out sanding, polishing, cleaning and drying pretreatment of a sintered neodymium iron boron magnet surface for processing; 2, clamping the above obtained pretreated sintered neodymium iron boron magnet on a workbench; 3, carrying out laser irradiation of the sintered neodymium iron boron magnet surface for processing under the protection of vacuum or a gas until a grain boundary phase melts to form a micro melting pool; 4, sending metal or compound nano-powder into the grain boundary micro melting pool through a powder sending device for the micro-alloying of the nano-powder and the grain boundary phase; and 5, cleaning up unalloyed nano-powder to obtain a sintered neodymium iron boron magnet with a selectively alloying modified surface grain boundary. The method can effectively change the component and structure of the magnet surface grain boundary phase, can improve the physical and chemical properties of the grain boundary phase, can inhibit the intercrystalline corrosion of the surface of the magnet, and can substantially improve the corrosion resistance of the magnet. The method has the advantages of simple process, easy operation, and suitableness for the large-scale batch production.

Owner:东台城东科技创业园管理有限公司

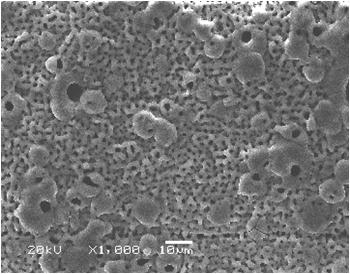

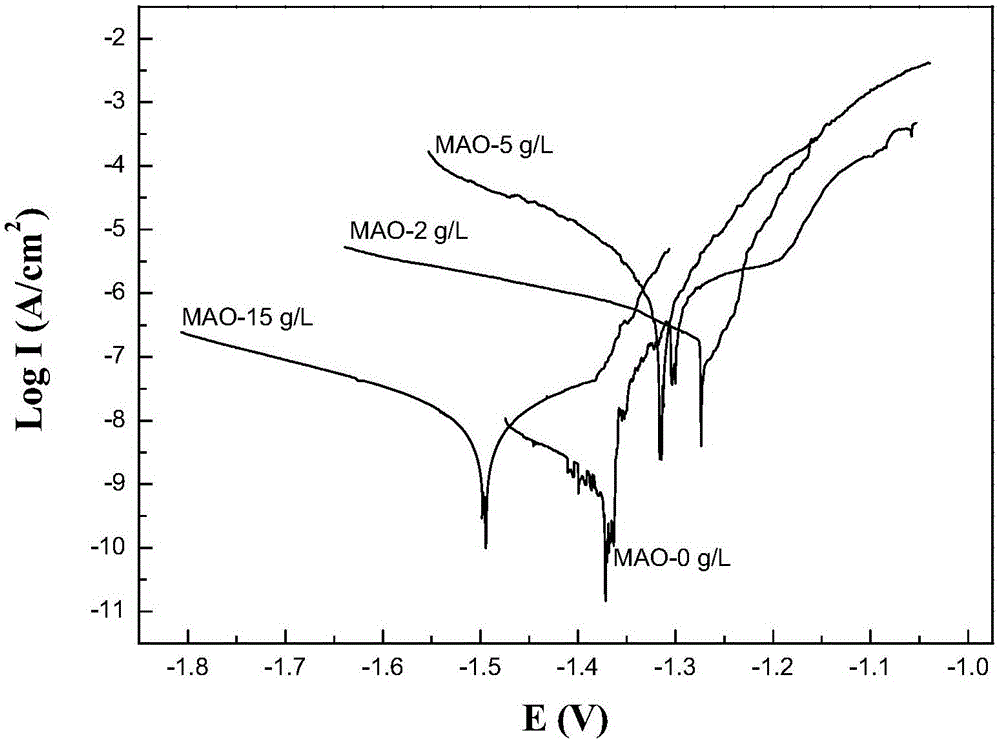

Method for preparing graphene oxide and micro-arc oxidized ceramic composite coating on surface of magnesium alloy

InactiveCN104878377AImprove corrosion resistanceReduce porosityAnodisationMetallic material coating processesPlasma electrolytic oxidationCeramic composite

The invention provides a method for preparing a graphene oxide and micro-arc oxidized ceramic composite coating on the surface of a magnesium alloy and relates to a method of preparing a coating on the surface of the magnesium alloy. The method is used for solving the problem of poor corrosion resistance of the micro-arc oxidized ceramic coating of a porous structure due to large contact area of the coating with a corrosive medium in the corrosion process. The method comprises the following steps: 1, magnesium alloy pre-processing; 2, ultrasonic processing; 3, oil removal; 4, micro-arc oxidization; 5, graphene oxide preparation; 6, application of the graphene oxide solution to the micro-arc oxidized ceramic coating on the magnesium alloy, thereby obtaining the magnesium alloy coated with the graphene oxide and micro-arc oxidized ceramic composite coating. According to the method, the corrosion current density of the graphene oxide and micro-arc oxidized ceramic composite coating is reduced to 14.5nA / cm<2>, which is 1 / 7240 of the corrosion current of the matrix magnesium alloy. The invention relates to the method for preparing the graphene oxide and micro-arc oxidized ceramic composite coating on the surface of the magnesium alloy.

Owner:HARBIN INST OF TECH

Corrosion-resistant self-assembled doped film layer on aluminum alloy surface and preparation method of corrosion-resistant self-assembled doped film layer

InactiveCN104630749ALow corrosion current densityHigh impedanceLiquid/solution decomposition chemical coatingAlloy substrateCorrosion current density

The invention discloses a corrosion-resistant self-assembled doped film layer on an aluminum alloy surface and a preparation method of the corrosion-resistant self-assembled doped film layer. The corrosion-resistant self-assembled doped film layer is composed of a self-assembled film and particles. The preparation method comprises the steps of firstly, carrying out pretreatment, namely grinding, washing, oil removal and the like on an aluminum alloy substrate; then, preparing a self-assembled doped solution; self-assembling the pretreated aluminum alloy to form a film; and taking out the film, drying and curing to obtain the corrosion-resistant self-assembled doped film layer on the aluminum alloy surface. The preparation method is low in cost, simple in preparation process and short in film formation time; the prepared self-assembled doped film is high in resistance and low in corrosion current density; and the film layer is uniform and level in surface, good in binding force on the aluminum alloy substrate, capable of favorably improving the corrosion resistance of the aluminum alloy surface and incapable of polluting the environment and equipment.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

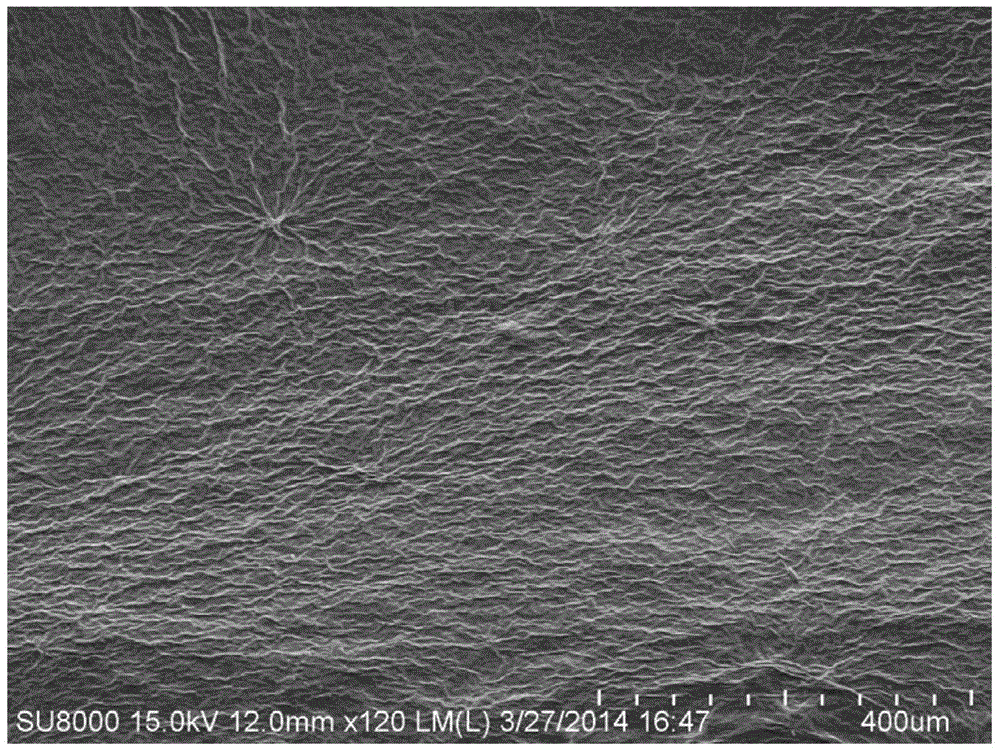

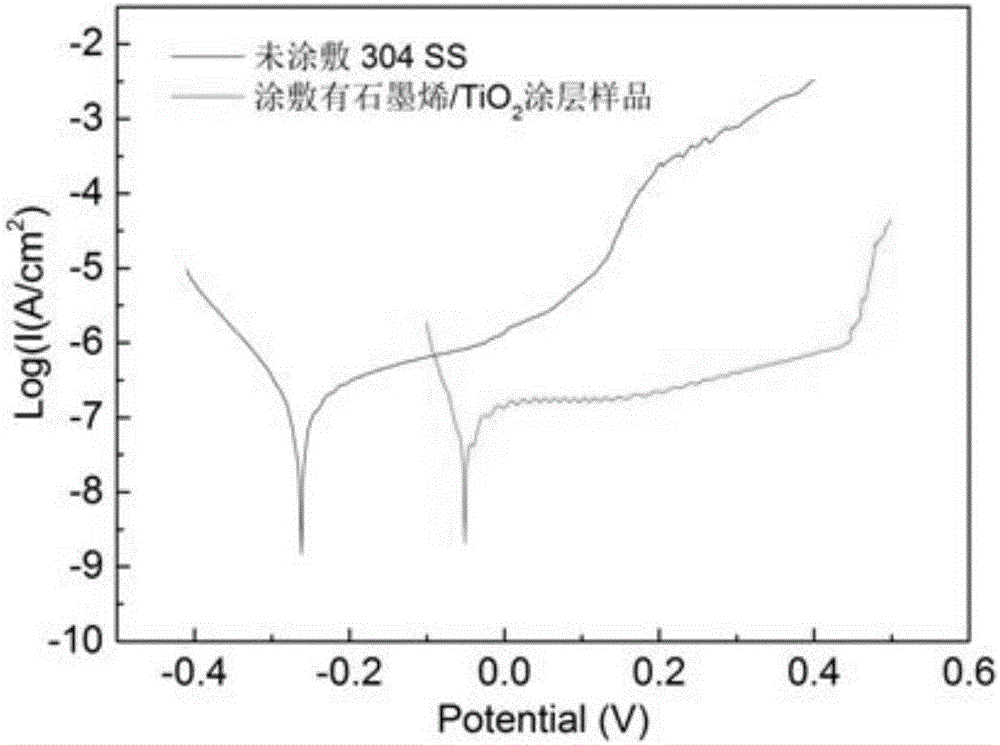

Preparation method of graphene/titanium dioxide transparent anticorrosive coating

InactiveCN106317976AOvercome porosityOvercome crackingLiquid surface applicatorsAnti-corrosive paintsElectrical resistance and conductanceSpray coating

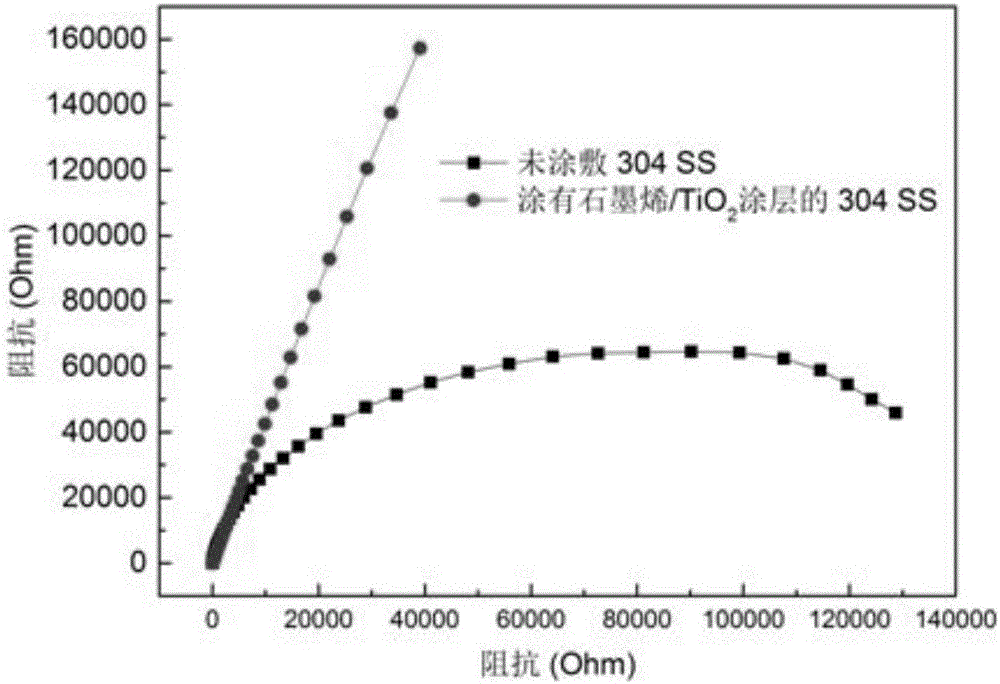

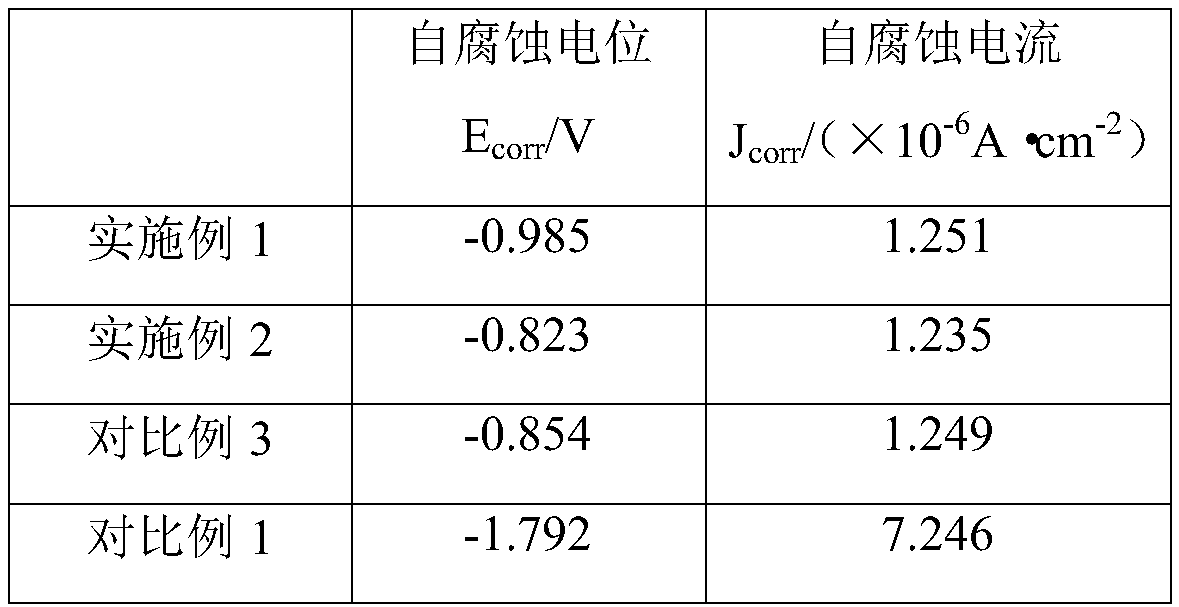

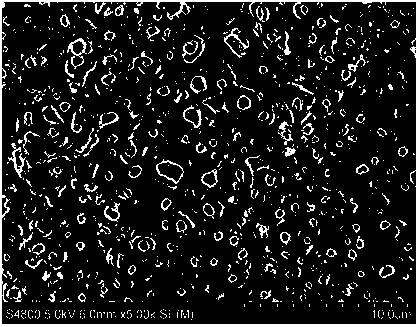

The invention relates to a preparation method of graphene / titanium dioxide transparent anticorrosive coating. The preparation method includes: preparing graphene oxide dispersing liquid; preparing titanium oxide dispersing liquid; preprocessing a stainless steel sample; coating the stainless steel sample with graphene oxide / titanium oxide coating, to be more specific, using a suspension coating or ultrasonic spray coating manner to coat the stainless steel sample with the graphene oxide dispersing liquid, performing blow drying, using a suspension coating or ultrasonic spray coating manner to coat the stainless steel sample with the titanium oxide dispersing liquid, and performing blow drying; or using a suspension coating or ultrasonic spray coating manner to coat the stainless steel sample with the mixed solution of the graphene oxide dispersing liquid and the titanium oxide dispersing liquid; annealing the coated sample at 100-500 DEG C under N2 protective atmosphere for 20-120 minutes to obtain the graphene / titanium oxide anticorrosive coating. Tests show that compared with uncoated stainless steel, the corrosion current density of the polarization curve of the coated stainless steel sample in a sodium chloride solution is lowered by about one magnitude order, the passivation range of the coated stainless steel sample is increased by 2.5 times, and the polarization resistance of the coated stainless steel sample is increased by 8-17 times.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

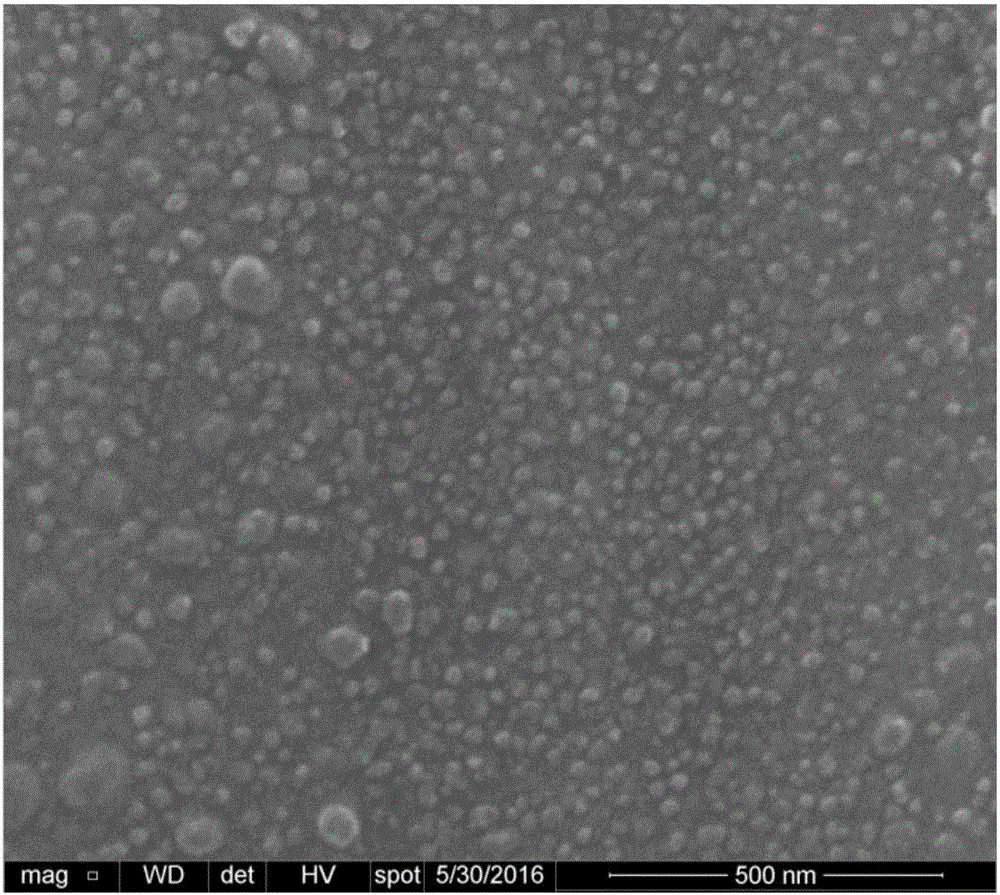

Preparation method of graphene oxide/acrylate-epoxy resin composite anticorrosive paint

InactiveCN111518450AImprove anti-corrosion performanceLow corrosion current densityAnti-corrosive paintsPolymer scienceEpoxy resin composite

The invention discloses a preparation method of graphene oxide / acrylate-epoxy resin composite anticorrosive paint. The preparation method comprises the following steps: preparing graphene oxide, and preparing an acrylic acid modified epoxy resin intermediate from bisphenol A epoxy resin and acrylic acid; then, respectively preparing a nuclear phase monomer pre-emulsion and a shell phase monomer pre-emulsion, and carrying out core-shell reaction polymerization on the nuclear phase monomer pre-emulsion and the shell phase monomer pre-emulsion through an initiator to obtain an acrylate-epoxy resin core-shell emulsion; and finally, mixing the acrylate-epoxy resin core-shell emulsion with graphene oxide to obtain the anticorrosive paint. According to the invention, an epoxy group on the surfaceof the graphene oxide is used as a reaction active point, so the corrosion resistance of the graphene oxide / acrylate-epoxy resin composite anticorrosive paint is greatly improved. Along with the increase of the content of the graphene oxide, the corrosion potential of the paint is increased, and corrosion current density is reduced, so the paint presents excellent metal corrosion resistance.

Owner:JINLING INST OF TECH

Preparation method for corrosion-resistant organic composite coating on surface of magnesium alloy

ActiveCN107855254AImprove corrosion resistanceEasy to operateAnodisationPretreated surfacesEpoxyMicro arc oxidation

The invention discloses a preparation method for a corrosion-resistant organic composite coating on the surface of magnesium alloy. The preparation method comprises the following steps: first, performing pre-treatment, such as grinding, polishing, water washing, oil removing and ultrasonic washing, on a magnesium alloy substrate in sequence; then, preparing micro-arc oxidizing electrolyte, and performing micro-arc oxidizing on the magnesium alloy which is subjected to the pre-treatment to form a micro-arc oxidation film; next, mixing epoxy resin and polyamide in proportion, dip-coating the surface of the micro-arc oxidation film with a mixture, and standing and drying at room temperature; and finally, dipping the micro-arc oxidation film in a polyacrylamide aqueous solution, taking out themicro-arc oxidation film, and frying for 1 to 12 hours at 80 to 150 DEG C to prepare the corrosion-resistant organic composite coating on the surface of the magnesium alloy. The method disclosed by the invention is easy to operate; the prepared organic composite coating on the surface of magnesium alloy can be bonded firmly with a substrate, has a smooth, uniform and dense surface, completely cover micro-pores of the micro-arc oxidation film, has high electrochemical impedance, low corrosion current density and hydrophobic property, and can improve the corrosion resistance of the magnesium alloy well.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

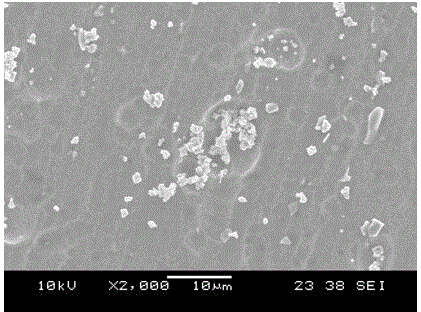

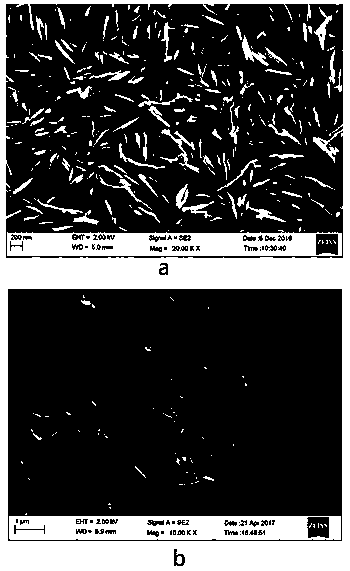

Preparing method for graphene oxide composite coating on surface of magnesium alloy

ActiveCN105350049AImprove corrosion resistanceEasy to operateElectrolytic coatingsElectrolytic agentOxide composite

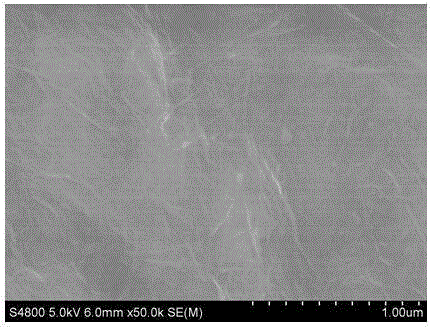

The invention discloses a preparing method for a graphene oxide composite coating on the surface of a magnesium alloy. The preparing method includes the steps that firstly, a magnesium alloy matrix is preprocessed; then, graphene oxide is prepared and dissolved into a 1-5 ml / L triethanolamine water solution and is subjected to ultrasonic dispersing for 2 hours to serve as an electroplating electrolyte; afterwards, a CHI860D type electrochemical workstation is used for assembling a three-electrode system, the preprocessed magnesium alloy serves as a study electrode, a platinum electrode serves as an auxiliary electrode, a saturated calomel electrode serves as a reference electrode, and the chronoamperometry is selected for conducting electrochemical deposition on the magnesium alloy; and finally, the magnesium alloy is taken out to be dried for 1-2 hours at the temperature ranging from 60 DEG C to 70 DEG C, and the graphene oxide composite coating on the surface of the magnesium alloy is obtained. The method is easy to operate, the surface of the obtained composite coating is even and flat, a typical crumple structure of the graphene oxide exists, low corrosion current density and high electrochemical resistance are achieved, and corrosion resistance of the magnesium alloy can be well improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

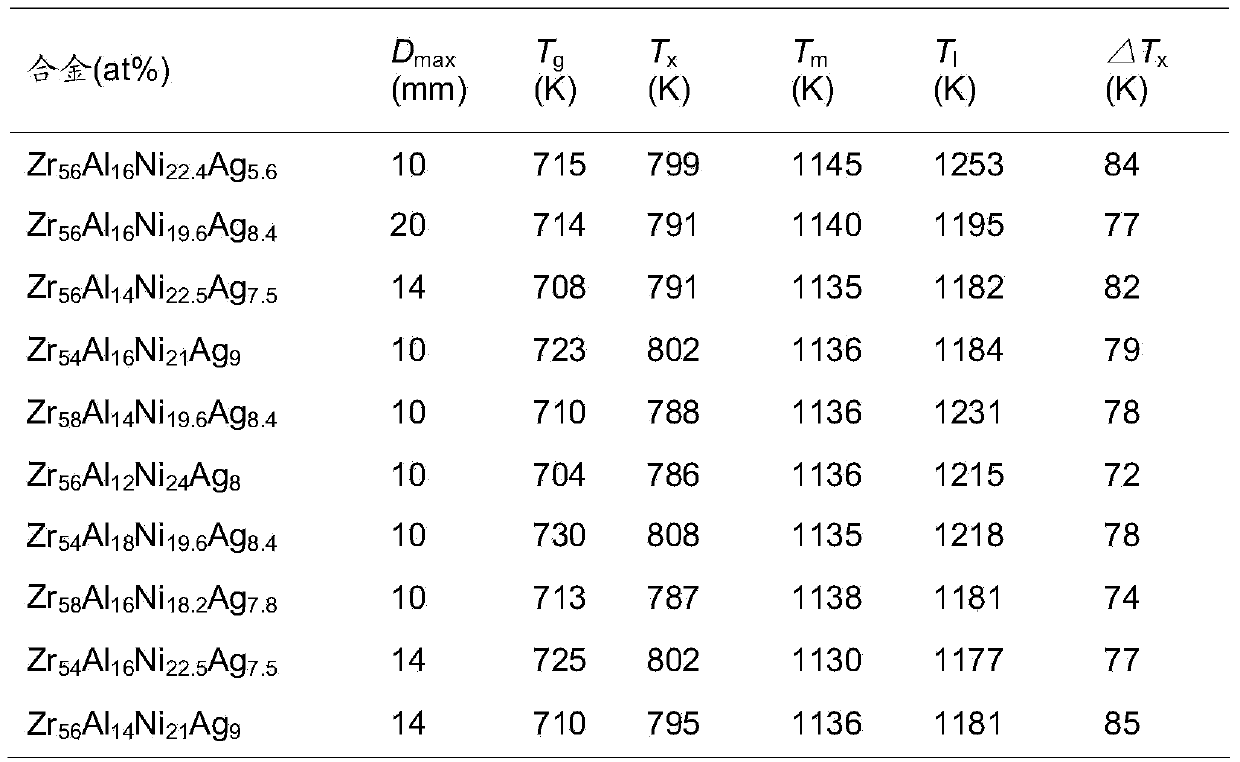

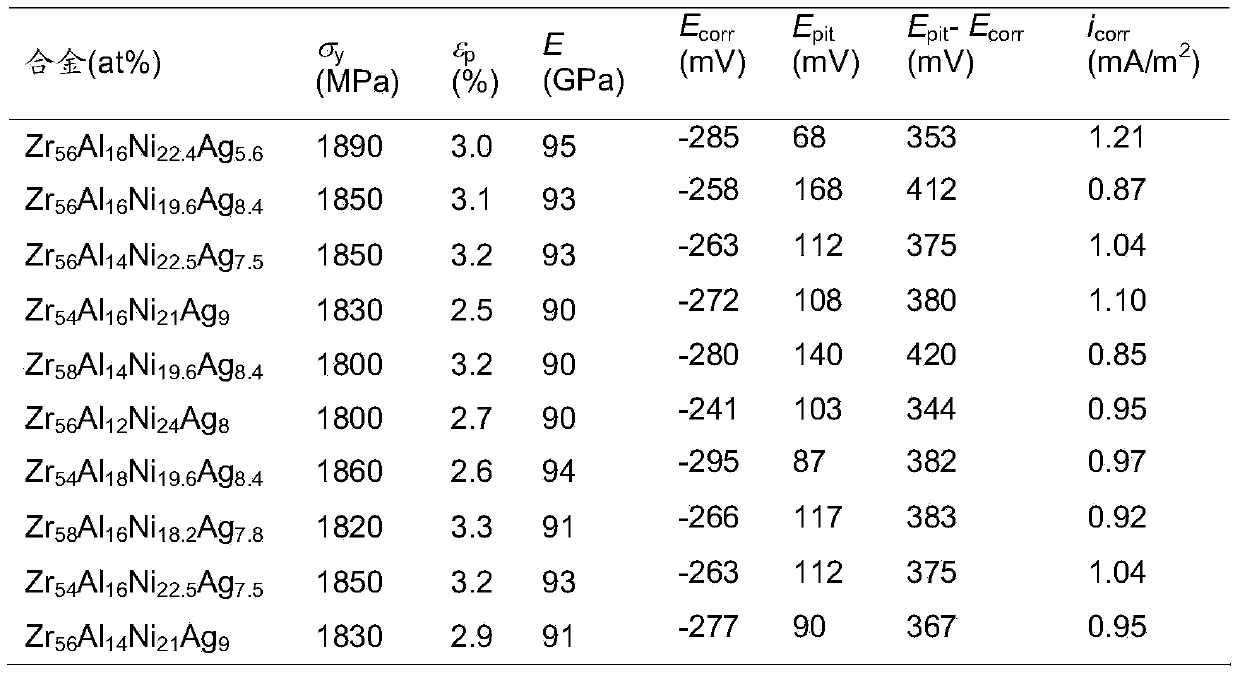

Centimeter-sized Zr-based bulk amorphous alloy, and preparation and application methods thereof

The invention discloses a centimeter-sized high-toughness and high-corrosion resistance Zr-based bulk amorphous alloy, which specifically has a chemical formula ZraAlbNicAgd, wherein a is more than 54 and less than 58 atomic percent, b is more than 12 and less than 18 atomic percent, c is more than 18.2 and less than 24 atomic percent, and d is more than 5.6 and less than 9 atomic percent, and a+b+c+d=100. The invention also discloses a preparation method for the Zr-based bulk amorphous alloy and a method for preparing a thin strip and a rod by utilizing the amorphous alloy. According to the Zr-based bulk amorphous alloy and the methods, elemental Ni and Ag are selected as components of the alloy, so that the corrosion resistance is greatly improved, the amorphous alloy formability of a Zr-Al-Ni alloy is improved, and the prepared bulk amorphous alloy is ultrahigh in formability; the Zr-based amorphous alloy also has the characteristics of high-amorphous alloy formability, high toughness and high corrosion resistance.

Owner:FUJIAN UNIV OF TECH

Method for carrying out electrochemical treatment on surface of biomedical magnesium or magnesium alloy with high biological activity and low degradation rate

InactiveCN104694994AAccelerated corrosionImprove biological activityAnodisationElectrolytic inorganic material coatingCalcium phosphate coatingMicro arc oxidation

The invention relates to a method carrying out electrochemical treatment on the surface of a biomedical magnesium or magnesium alloy with high biological activity and a low degradation rate. The method mainly solves the problem that an existing biomedical magnesium or magnesium alloy is low in biological activity and high in corrosion rate in human body fluid. The method comprises the steps of pretreating a base material, treating the base material in a micro-arc oxidation mode, treating micro-arc oxide magnesium in an electro-deposition mode, and covering the surface of the material with a calcium phosphate coating. The method is used for treating the surface of the biomedical magnesium or magnesium alloy.

Owner:HARBIN INST OF TECH

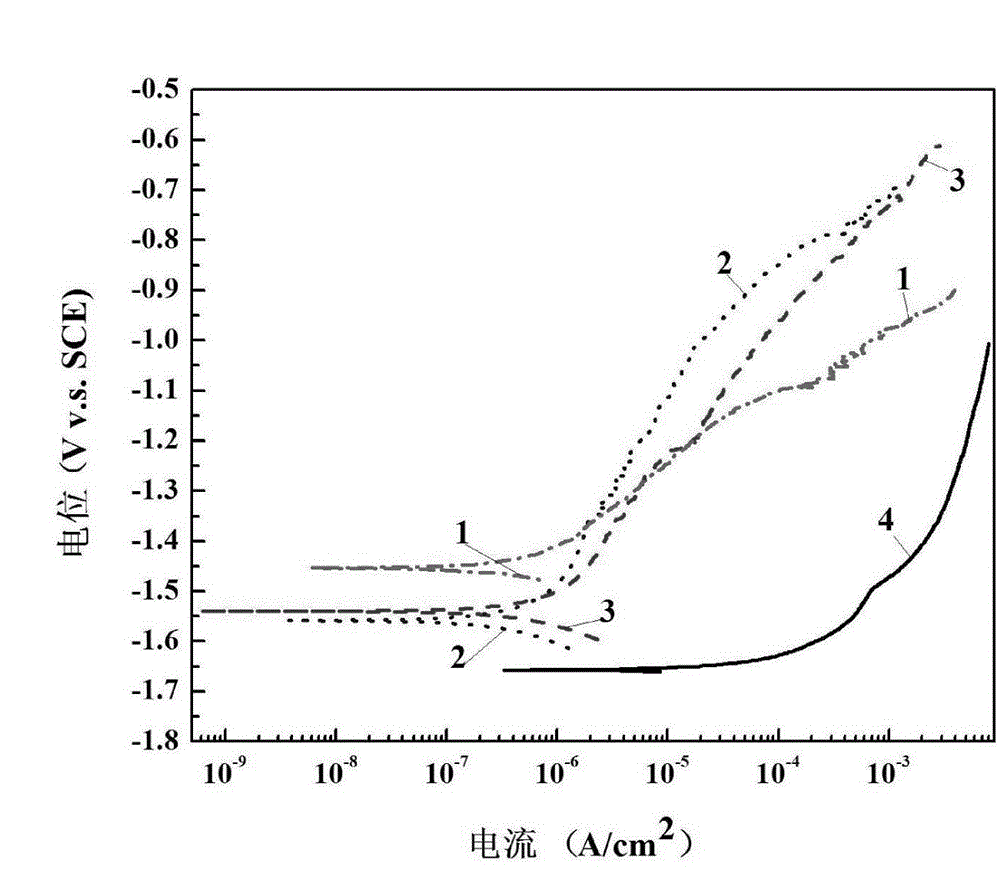

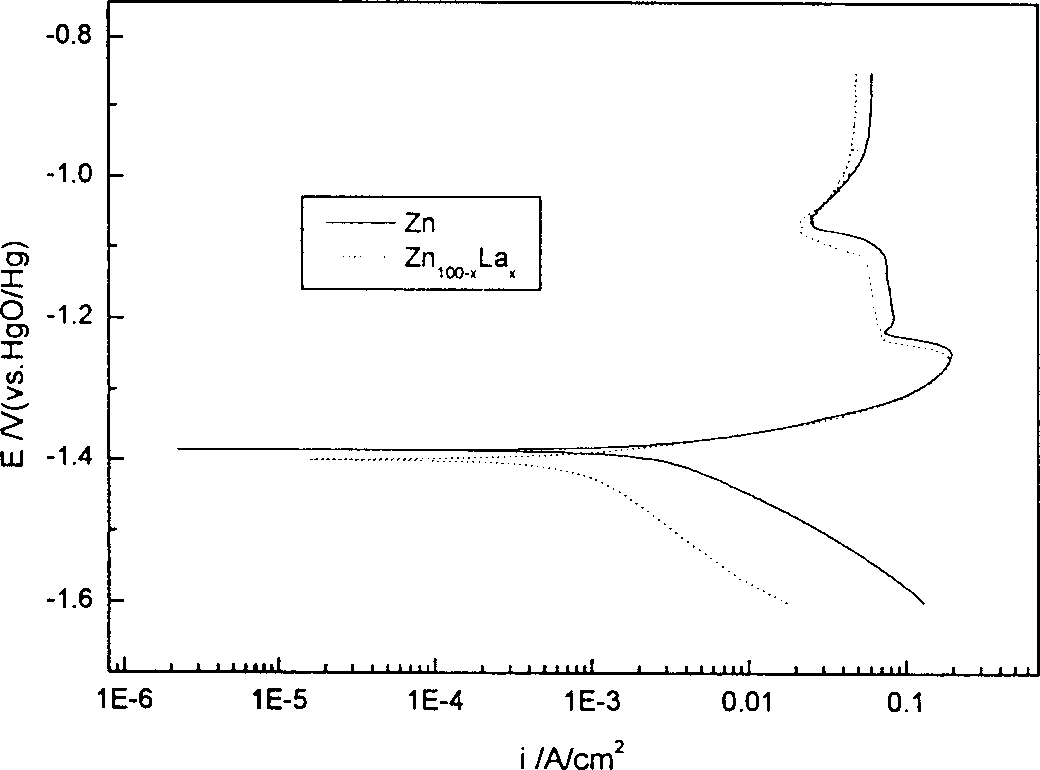

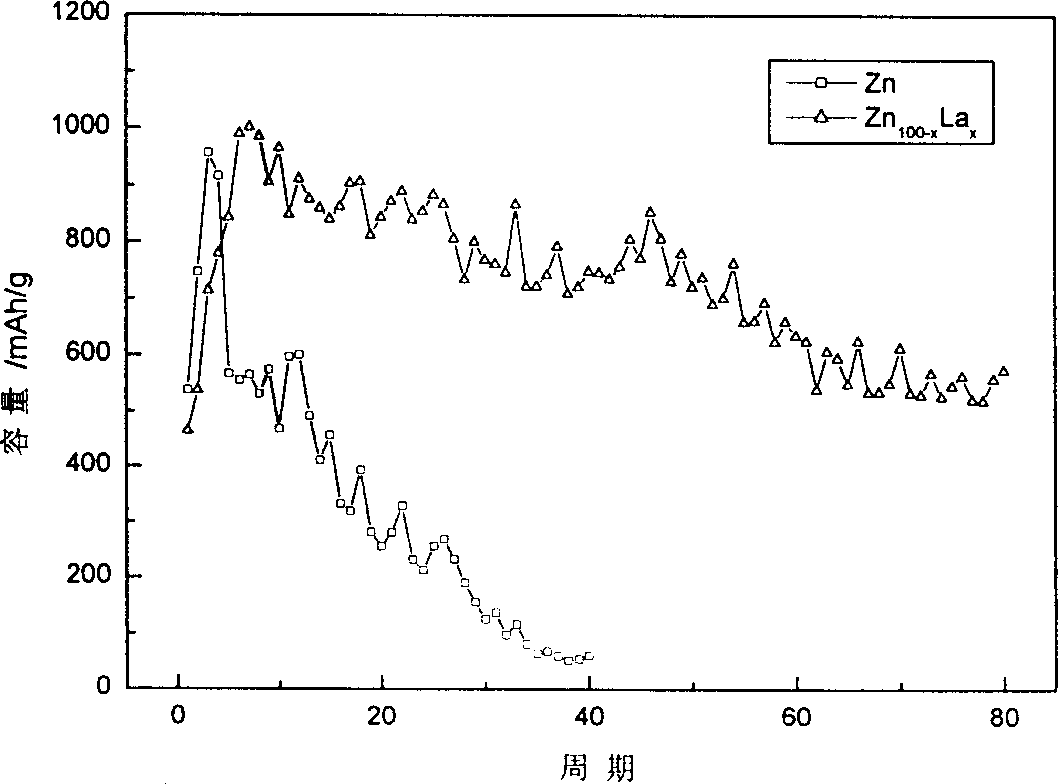

Zinc electrode material for secondary battery using Zn as negative electrode and its preparing process

InactiveCN1396669AImprove performanceImprove the deposition effectElectrode manufacturing processesMischmetalRare earth

A Zn electrode material used as the negative electrode of secondary battery has its chemical formula: Zn100-xMx, where M is one or more kinds of La, Ce, Pu, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yband Lu, and X=0.1-50. Its advantages are excellent electrochemical performance, high discharge capacity, long cyclic life, low cost and no pollution.

Owner:NANKAI UNIV

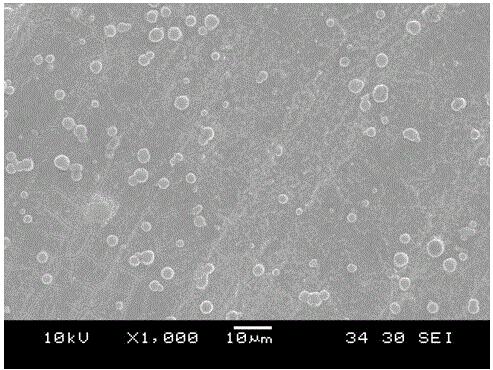

Preparation method of surface composite coating based on metal bipolar plate of proton exchange membrane fuel cell

PendingCN110364749AReduce surface contact resistanceExcellent self-healing performanceElectrolytic coatingsFinal product manufactureMetal substrateCorrosion

The invention relates to the technical field of fuel cells, and specifically relates to a preparation method of a surface composite coating based on a metal bipolar plate of a proton exchange membranefuel cell. The invention adopts an electrochemical method to deposit a conductive polymer intelligent composite coating doped with carbon powder on the metal surface. The metal bipolar plate, which is modified by the conductive polymer intelligent composite coating doped with carbon powder, of the proton exchange membrane fuel cell has the advantages that the corrosion current density is reduced,the long-term corrosion resistance is greatly improved, and the surface contact resistance is low. Meanwhile, the conductive polymer intelligent composite coating doped with carbon powder has strongadhesion, chemical stability and conductivity on the surface of the metal substrate. The preparation method has the advantages of simple operation, low manufacturing cost, safety, environmental protection and simple and easily obtained synthetic raw materials, and is widely applicable to protecting the metal bipolar plate of the proton exchange membrane fuel cell.

Owner:NANJING UNIV OF TECH

Method for one-step in-situ electro-deposition of layered double hydroxide coating on magnesium alloy surface

ActiveCN110484950AHigh security riskReduce security risksElectrolytic inorganic material coatingLayered double hydroxidesMaterials science

The invention provides a method for one-step in-situ electro-deposition of a layered double hydroxide coating on a magnesium alloy surface. The method includes the following steps that firstly, pretreatment is conducted and includes mechanical polishing and oil removing and grease removing, wherein oil removing includes acetone ultrasonic oil removing and alkaline oil removing; secondly, electro-deposition solution preparing and electro-deposition are conducted, wherein an electro-deposition solution of nitrate is prepared through distilled water, and electro-deposition is conducted in the above electro-deposition solution with a magnesium alloy being the work electrode and a platinum sheet being the counter electrode; and thirdly, the distilled water is used for flushing a sample obtainedthrough electro-deposition, the sample is dried in an oven or directly subjected to cold air blowing, and a magnesium alloy sample with an LDH film layer deposited is obtained. The method is achievedat the normal temperature and normal pressure, safety risks of production are lowered, the film forming speed is high compared with tens of hours or several tens of hours of a hydrothermal method, and LDH powder does not need to be prepared in advance or a pulse power source does not need to be used for deposition in multiple steps with various solutions.

Owner:CHINA WEST NORMAL UNIVERSITY

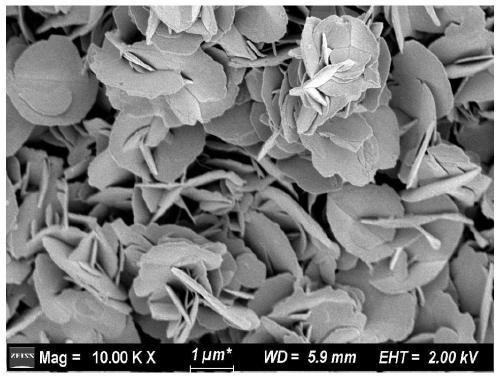

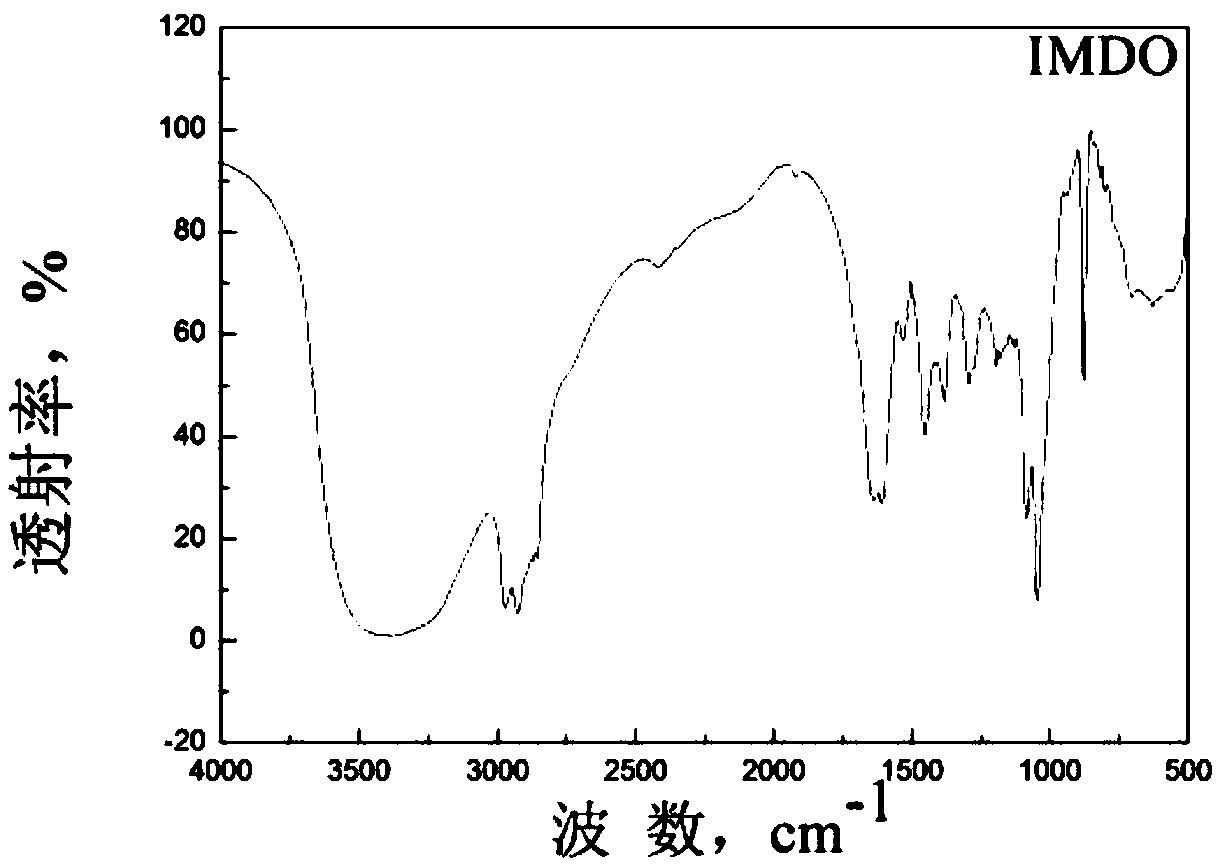

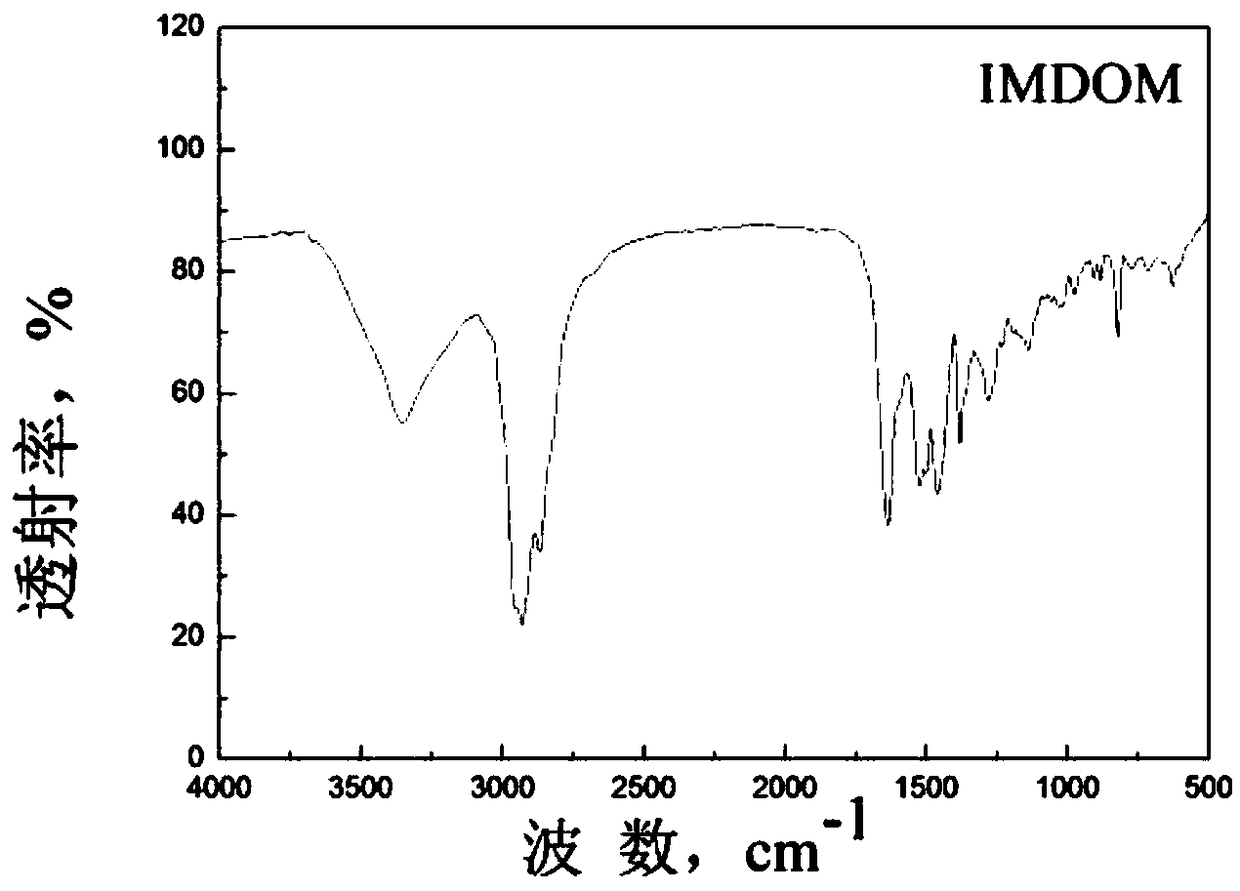

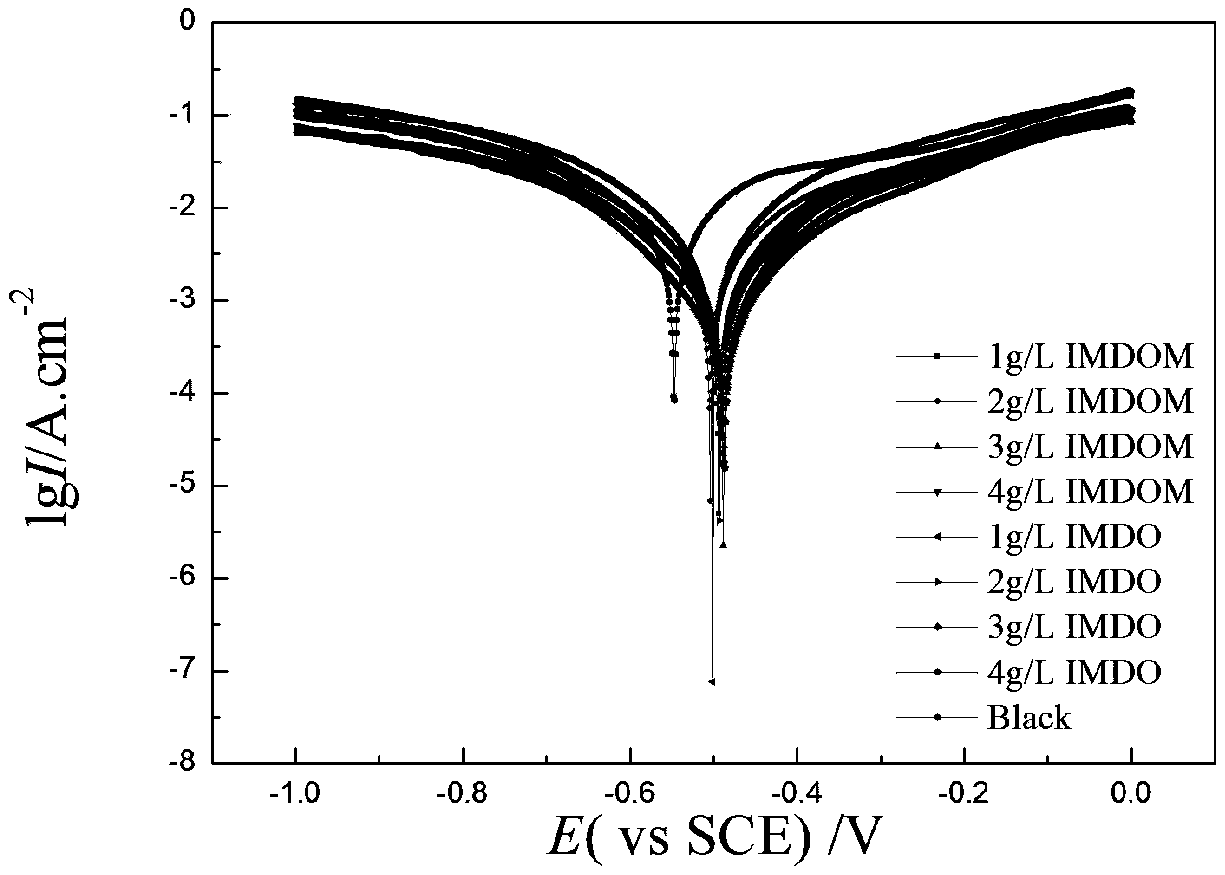

Synthesis method and application of rosin-based imidazoline derivative corrosion inhibitor

ActiveCN108822148ALow corrosion current densityReduce pittingGroup 5/15 element organic compoundsPhosphorous acidMannich reaction

Relating to synthesis and application of metal anticorrosive compounds, the invention specifically discloses a synthesis method and application of a rosin-based imidazoline derivative corrosion inhibitor. In the synthesis process, triethylene tetramine and dehydroabietic acid are adopted as the raw materials to prepare a rosin-based imidazoline derivative corrosion inhibitor intermediate, then phosphorous acid is employed for Mannich reaction modification on the intermediate so as to obtain the rosin-based imidazoline derivative corrosion inhibitor. Structural characterization of the corrosioninhibitor with infrared spectroscopy and analysis by electrochemical process, dynamic weight loss process, energy spectrum analysis, scanning electron microscope and other methods find that the corrosion inhibitor has a good corrosion inhibition effect on metals, and at the same time adding of the corrosion inhibitor can reduce the corrosion current density and decrease the corrosion rate.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

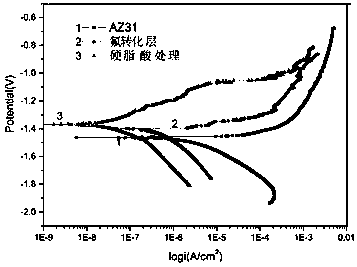

Preparation method of magnesium alloy surface super-hydrophobic fluorine conversion coating

InactiveCN107740083AReduce corrosionLessen the tendency to corrodeMetallic material coating processesNano structuringSimulated body fluid

The invention discloses a preparation method of a magnesium alloy surface super-hydrophobic fluorine conversion coating. The super-hydrophobic fluorine conversion coating of a micro / nano structure isprepared on the surface of a magnesium alloy by the adoption of a liquid-phase growth and hydro-thermal treatment combined method. Through cleaning, polishing, preparation of a fluorine conversion layer and hydrophobization treatment, a porous hydrophobic coating of a micro / nano structure is formed on the film layer. The contact angle of the coating in simulated body fluid reaches 150 degrees, thecontact area between a magnesium alloy sample and the liquid can be reduced, the corrosion current density of the magnesium alloy can be lowered by 3 grades, and the impedance magnitude is increasedfrom 12000 omega.cm<2> to 1400000 Omega.cm<2> and is increased by 100 times. The preparation method of the hydrophobic coating of the nano-structure is simple, equipment is simple and easy to control,cost is low, and the controllability is good.

Owner:CHONGQING UNIV OF TECH

Corrosion-resistant magnesium alloy

InactiveCN104264021ALow corrosion current densityReduce corrosion rateCorrosion resistantMetal alloy

The invention relates to the technical field of metal alloy materials, and particularly relates to corrosion-resistant magnesium alloy. The magnesium alloy comprises the following chemical components in percentage by mass: 6-9wt% of Al, 0.4-1.0wt% of Zn, 0.01-0.3wt% of Mn, 0.001-1.0wt% of V, and the balance of Mg. Due to addition of vanadium, the corrosion potential of the magnesium alloy is improved, the corrosion current density is lowered, the corrosion rate of the magnesium alloy is obviously lowered, and is just 52.81% of original alloy corrosion rate, and the corrosion resistance of the alloy is significantly improved.

Owner:河南德威科技股份有限公司

Micro-arc oxidation self-assembled chemical nickel-plated coating on surface of magnesium alloy and preparation method of micro-arc oxidation self-assembled chemical nickel-plated coating

ActiveCN104152898AImprove bindingImprove corrosion resistanceAnodisationLiquid/solution decomposition chemical coatingMicro arc oxidationMg alloys

The invention discloses a micro-arc oxidation self-assembled chemical nickel-plated coating on the surface of a magnesium alloy and a preparation method of the micro-arc oxidation self-assembled chemical nickel-plated coating. The coating comprises a micro-arc oxidation ceramic layer, a self-assembled layer and a chemical nickel-plated layer which are sequentially attached on the surface of the magnesium alloy. The preparation method comprises the steps of firstly, polishing a magnesium alloy matrix, washing, removing oil and carrying out other pretreatment; then, preparing a micro-arc oxidation solution, and carrying out micro-arc oxidation on the pretreated magnesium alloy to form the micro-arc oxidation ceramic layer; next, immersing the micro-arc oxidation ceramic layer into a prepared self-assembled solution to carry out immersion treatment, and forming the self-assembled layer after drying; and finally, depositing a metal nickel coating on the surface of the micro-arc oxidation self-assembled layer by using a chemical plating method. The method disclosed by the invention is simple in operation; and the prepared composite coating is low in corrosion current density, uniform and smooth in surface, good in bonding strength and capable of favorably improving the corrosion resistance of the magnesium alloy.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

A corrosion-resistant magnesium alloy

InactiveCN104264021BIncreased corrosion potentialImprove corrosion resistanceMetal alloyCorrosion current density

Owner:河南德威科技股份有限公司

Nitrite-free compound type steel bar corrosion inhibitor

InactiveCN102617062AGood corrosion inhibitionCorrosion inhibition slows down and inhibitsRebar corrosionNitrite

The invention discloses a nitrite-free compound type steel bar corrosion inhibitor and relates to the steel bar corrosion inhibitor. The invention provides the nitrite-free compound type steel bar corrosion inhibitor which can prevent steel bars in concrete from being corroded and prevent environmental pollution. The nitrite-free compound type steel bar corrosion inhibitor comprises the following components by weight: 70%-85% of diisooctyl sebacate, 3%-6% of D-sodium gluconate and 12%-27% of zinc sulfate heptahydrate. When the nitrite-free compound type steel bar corrosion inhibitor is sued, 1.5-4.5g of the nitrite-free compound type steel bar corrosion inhibitor is added into per liter of water (the water which is directly used for blending the concrete). The D-sodium gluconate and the zinc sulfate heptahydrate are compounded with the diisooctyl sebacate so as to obtain the nitrite-free compound type steel bar corrosion inhibitor.

Owner:XIAMEN UNIV

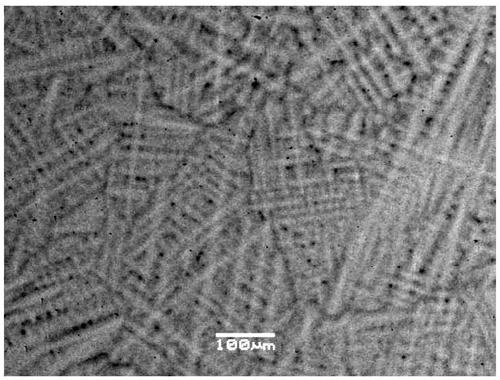

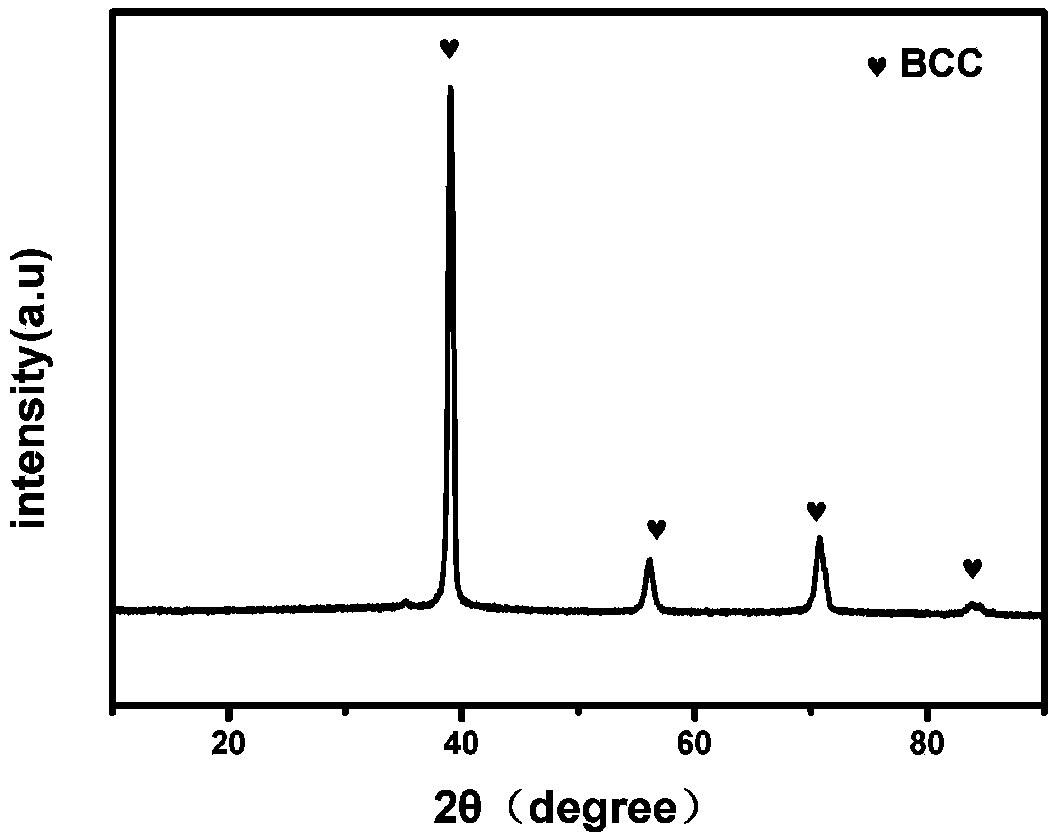

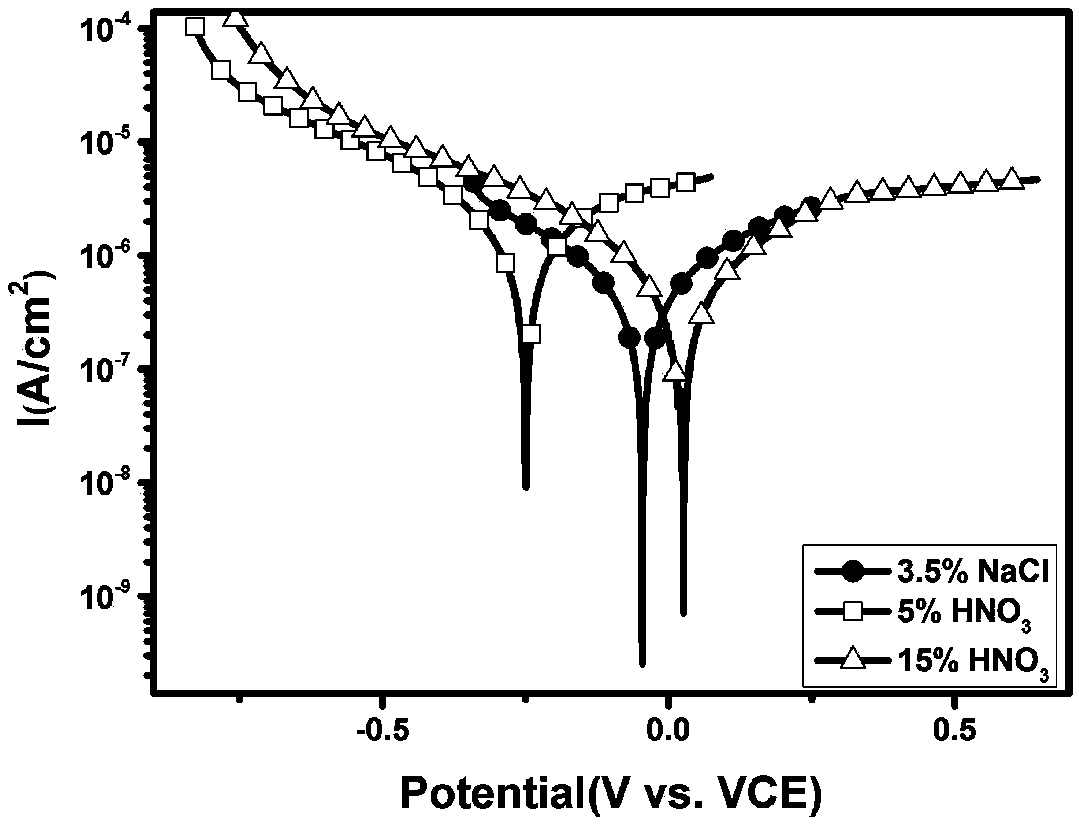

Abrasion-resistant and corrosion-resistant MnNbTaTiV high-entropy alloy material and preparation method thereof

The invention relates to an abrasion-resistant and corrosion-resistant high-entropy alloy material and a preparation method thereof. The preparation process of the MnNbTaTiV high-entropy alloy material includes the following steps that (1) power of all metals is prepared according to the equimolar ratio; (2) the power is mixed uniformly through a powder mixer; (3) the mixed powder is put in a vacuum drying oven to be dried; (4) dried powder is subjected to cold pressing and forming under a press machine; and (5) pressed and blocky samples are smelted through a nonconsumable vacuum arc smeltingfurnace. The prepared MnNbTaTiV high-entropy alloy is of a simplex BCC structure, has the advantages of being high in hardness and corrosion resistance and the like and has excellent application prospects in the field of abrasion resistance and corrosion resistance.

Owner:XIANGTAN UNIV

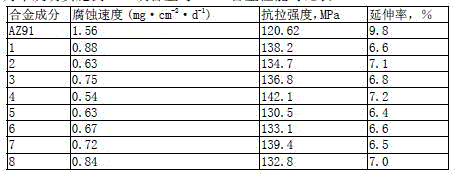

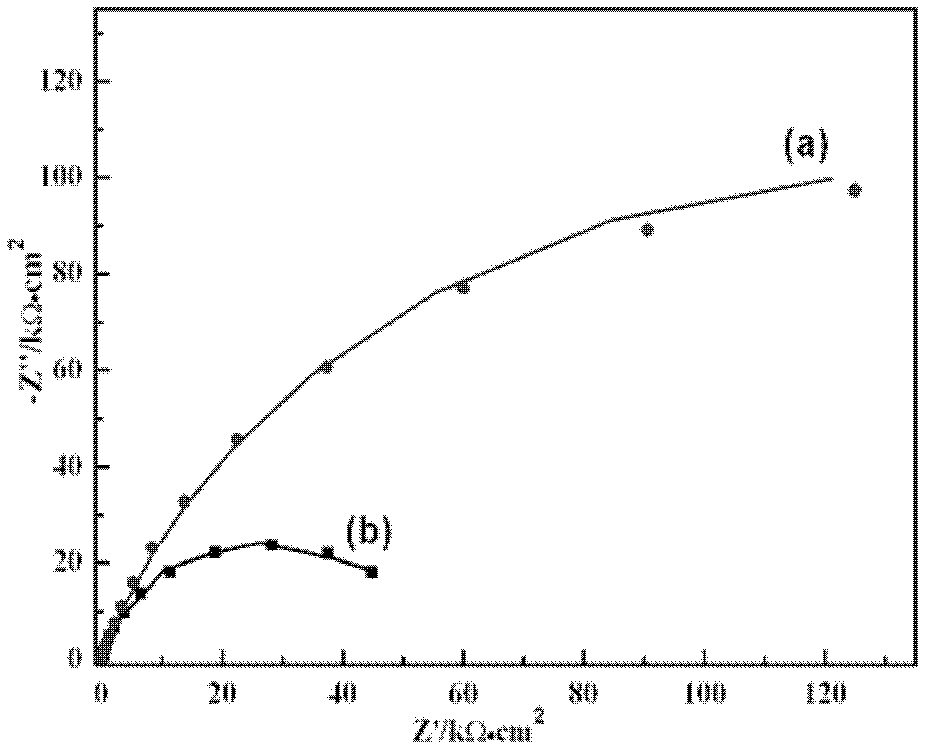

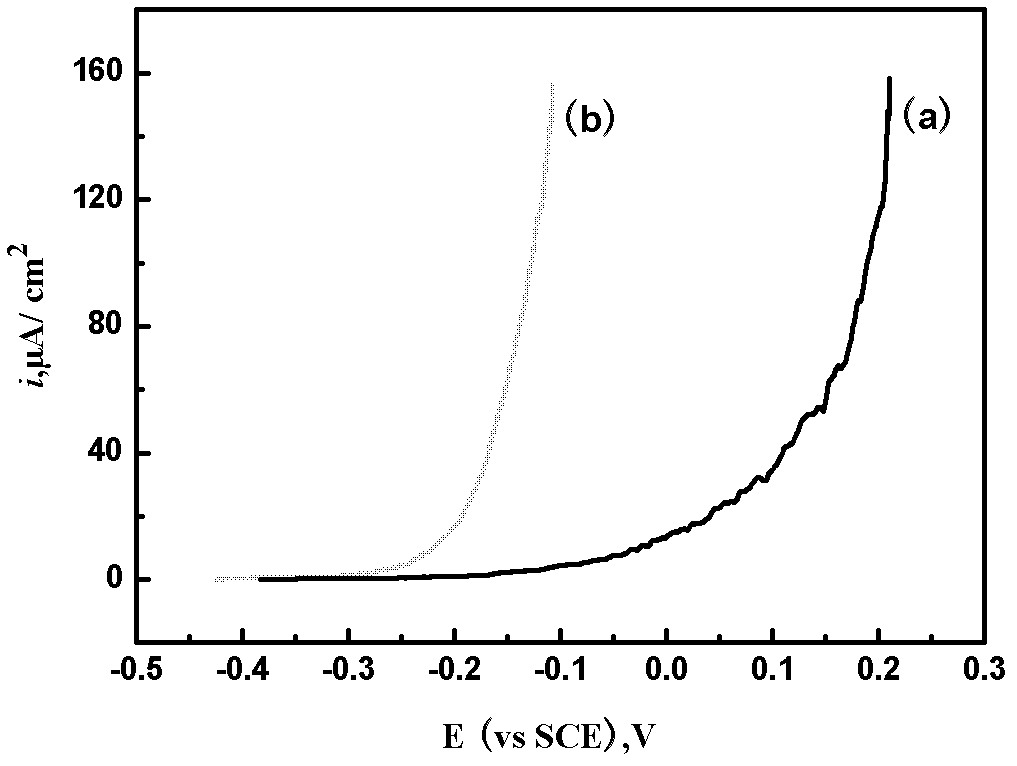

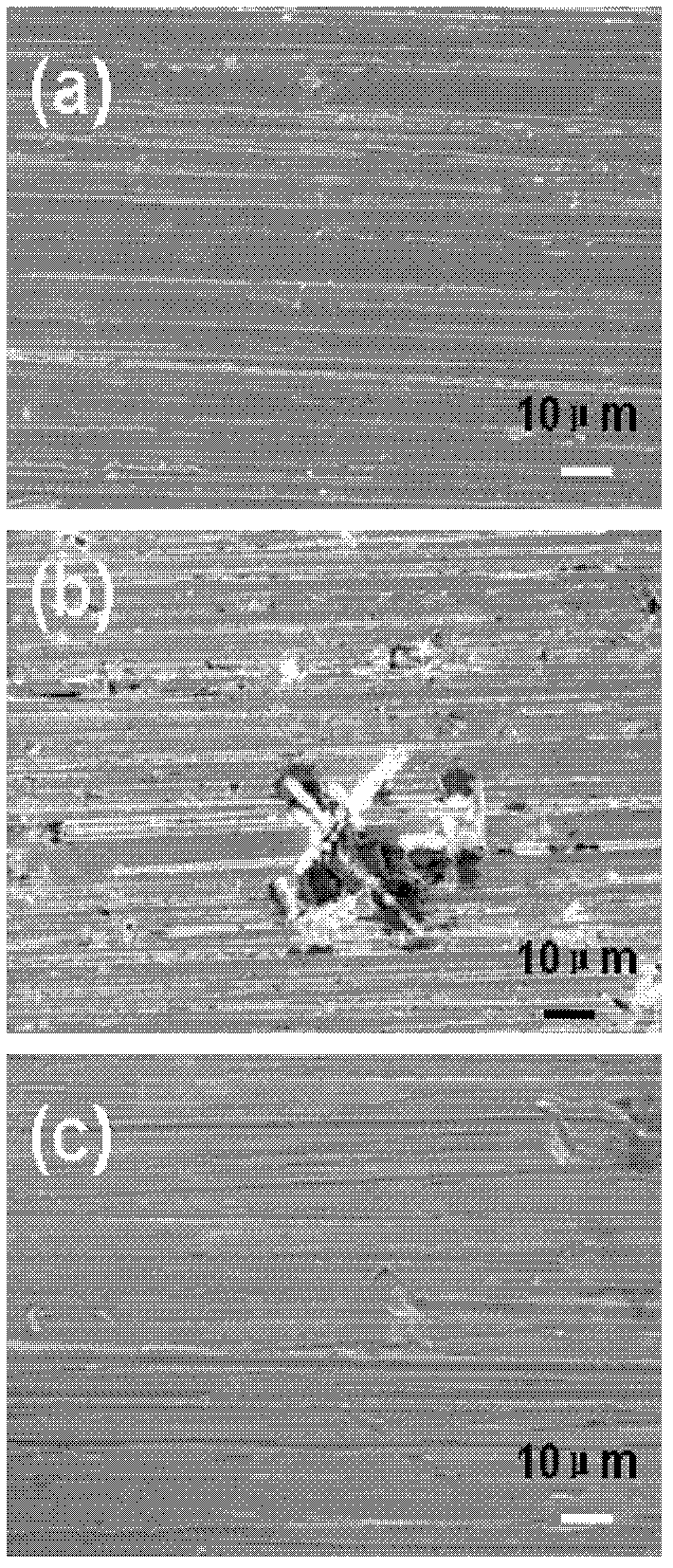

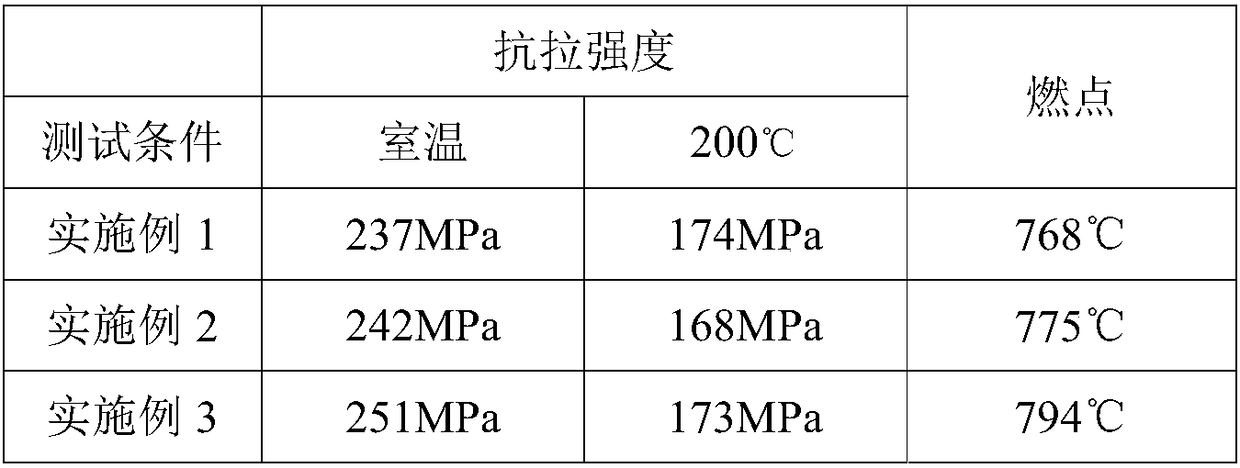

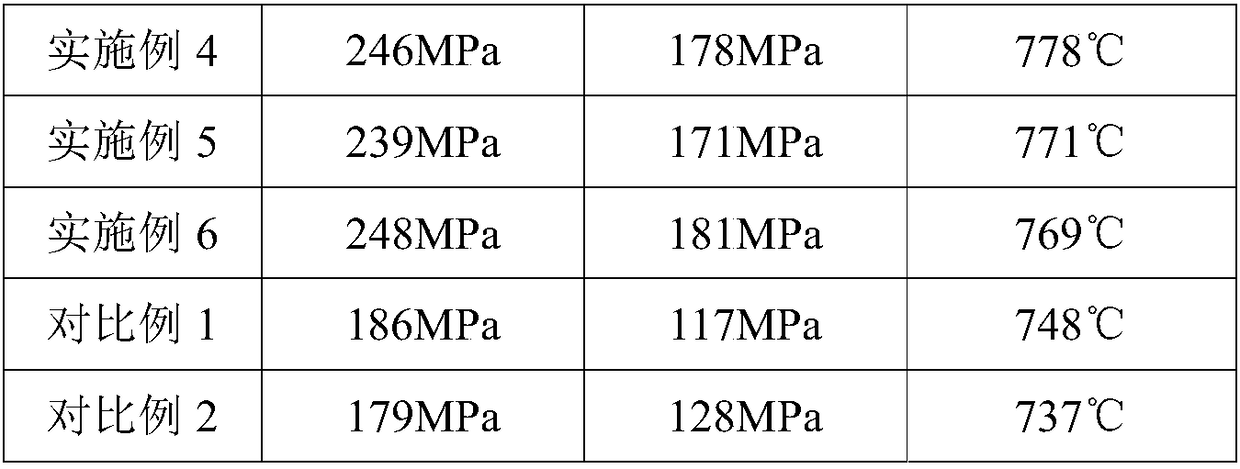

Rare-earth magnesium alloy and preparation method thereof

The invention relates to a rare-earth magnesium alloy and a preparation method thereof, and belongs to the technical field of magnesium-based alloys. The rare-earth magnesium alloy comprises, by mass,5.0-6.0% of Al, 0.8-0.9% of Zn, 0.1-0.3% of Mn, 0.25-0.30% of Nb, 0.45-0.55% of Sm, 0.3-0.4% of Y and the balance Mg and inevitable impurities. According to the rare-earth magnesium alloy, the rare-earth element and the niobium element are added, so that solid solubility of the Al element in a magnesium matrix is improved; and meanwhile, an intermetallic compound is formed in the magnesium alloy,so that stability of a rare-earth magnesium alloy corrosion-resistant surface film is improved, the corrosion current density is reduced, the corrosion rate of the magnesium alloy is obviously reduced, and meanwhile, the mechanical property of the magnesium alloy is remarkably improved.

Owner:HENAN UNIV OF SCI & TECH

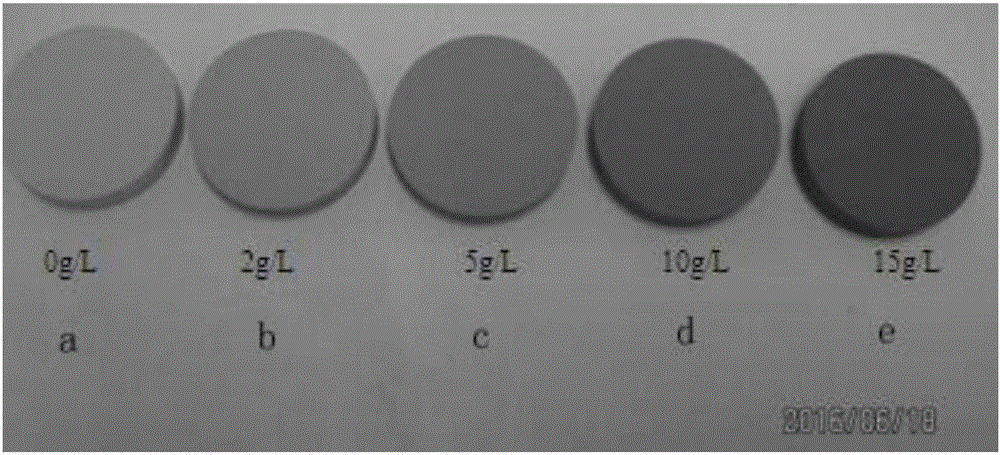

Protective and decorative yellow ceramic layer on magnesium alloy surface and preparation method thereof

InactiveCN106757276AImprove protection performanceGood stabilityAnodisationMicro arc oxidationColoring agents

The invention discloses a protective and decorative yellow ceramic layer on a magnesium alloy surface and a preparation method thereof. The protective and decorative yellow ceramic layer is formed in the way that metal elements in a coloring agent are doped with MgO; and the content of the coloring agent in a micro-arc oxidation electrolyte and electric parameters (mainly including voltage and oxidation time) are regulated and controlled to regulate and control the content of the metal elements doped in a micro-arc oxidation ceramic layer so as to form a MgO yellow micro-arc oxidation ceramic layer with controllable doping content, the doping content of the metal elements is 0.5-10 at.%, the thickness of the ceramic layer is 5-30 [mu]m, and the yellow color is deepened with increase of the doping content. Compared with an existing yellow micro-arc oxidation ceramic layer on the magnesium alloy surface, the protective and decorative yellow ceramic layer on the magnesium alloy surface has the advantages that the process problems of poor solution stability and existence of safety hazards are solved, and particularly, the dark yellow micro-arc oxidation ceramic layer has more excellent protective performance than a traditional white micro-arc oxidation ceramic layer, therefore is more suitable for industrial popularization, and can be applied in the fields of 3C and decoration.

Owner:XIAN TECHNOLOGICAL UNIV

Polyaniline modified sericite heavy-duty anticorrosive paint

InactiveCN106318152AImprove corrosion resistanceGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsDiacetone alcoholEpoxy

The invention discloses a polyaniline modified sericite heavy-duty anticorrosive paint. The paint comprises the following components by weight: 30-50 parts of alkyd resin, 5-15 parts of epoxy resin, 3-10 parts of polyether-ether-ketone, 4-10 parts of terpene resin, 5-10 parts of carboxyl terminated butyronitrile liquid rubber, 2-10 parts of tetraethylenepentamine, 3-10 parts of triethylamine, 3-8 parts of zinc borate, 3-10 parts of red phosphorus, 5-10 parts of modified nano titanium dioxide, 8-20 parts of polyaniline modified sericite, 5-10 parts of glass flake, 3-8 parts of diacetone alcohol, 3-10 parts of propylene glycol butyl ether, 15-20 parts of propylene glycol methyl ether acetate, 3-10 parts of tolyltriazole, 2-8 parts of zinc naphthenate, 5-15 parts of triphenyl phosphate, 20-40 parts of water, and 2-5 parts of an assistant. The polyaniline modified sericite heavy-duty anticorrosive paint provided by the invention has the advantages of good impact resistance, excellent flame retardance and corrosion resistance, and long service life.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

High corrosion resistance magnesium alloy for mechanical shell and preparation method thereof

The invention discloses a high corrosion resistance magnesium alloy for a mechanical shell and a preparation method thereof. The magnesium alloy comprises the chemical components of, by weight percentage, 10.0-15.0% of Al, 0.1-0.9% of Zn, 0.1-0.6% of Cr, 0.05-0.6% of Be, 0.2-0.5% of Mn, and the balance Mg. The preparation method comprises the steps of preheating of raw materials, fusing, casting moulding and the like. The high corrosion resistance magnesium alloy for the mechanical shell and the preparation method thereof have the advantages that the alloy elements of Al, Zn, Cr and Be are added into a magnesium matrix, the corrosion potential of the magnesium alloy is improved through the multi-component function, the corrosion current density of the magnesium alloy is reduced, the corrosion rate of the magnesium alloy is reduced, and the corrosion resistance of the magnesium alloy is remarkably improved; and the magnesium alloy provided by the invention does not contain expensive rare earth metal, the preparation process is simple, the alloy is low in cost, and the application prospects are wide.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

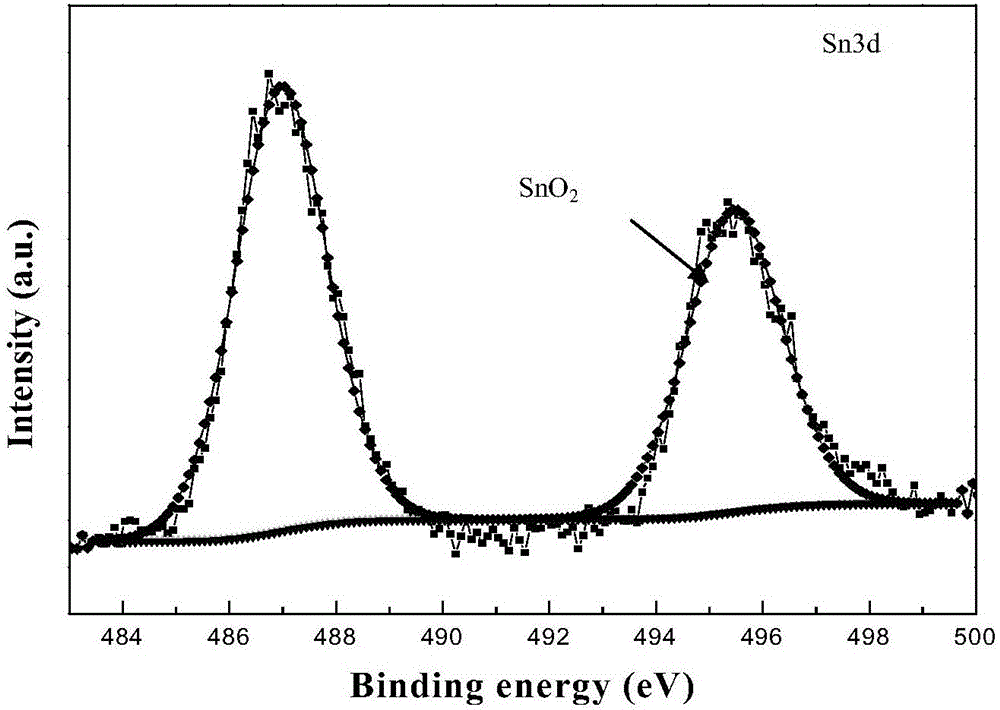

Anti-corrosion rare earth magnesium alloy and preparation method thereof

InactiveCN109457158AReduce corrosion rateImprove mechanical propertiesRare-earth elementMechanical property

The invention relates to an anti-corrosion rare earth magnesium alloy and a preparation method thereof, and belongs to the technical field of magnesium alloy materials. The anti-corrosion rare earth magnesium alloy is prepared from the following components in percentage by mass: 7.0 to 8.0 percent of Al, 0.9 to 1.0 percent of Zn, 0.3 to 0.5 percent of Mn, 0.5 to 0.6 percent of Nd, 0.8 to 0.9 percent of Gd, 0.7 to 0.8 percent of Ag, 0.9 to 1.0 percent of Sn, less than 0.2 percent of the total amount of impurity elements such as Fe, Cu and Ni, and the balance Mg and inevitable impurities. According to the anti-corrosion rare earth magnesium alloy provided by the invention, through adding rare earth elements and other elements, the solid solubility of the Al element in a magnesium matrix is improved, meanwhile, an intermetallic compound is formed in the magnesium alloy, the stability of an anti-corrosion surface film of the rare earth magnesium alloy is improved, the corrosion current density is reduced, the corrosion rate of the magnesium alloy is remarkably reduced, meanwhile, the mechanical property of the magnesium alloy is remarkably improved, and the application range of the magnesium alloy is widened.

Owner:HENAN UNIV OF SCI & TECH

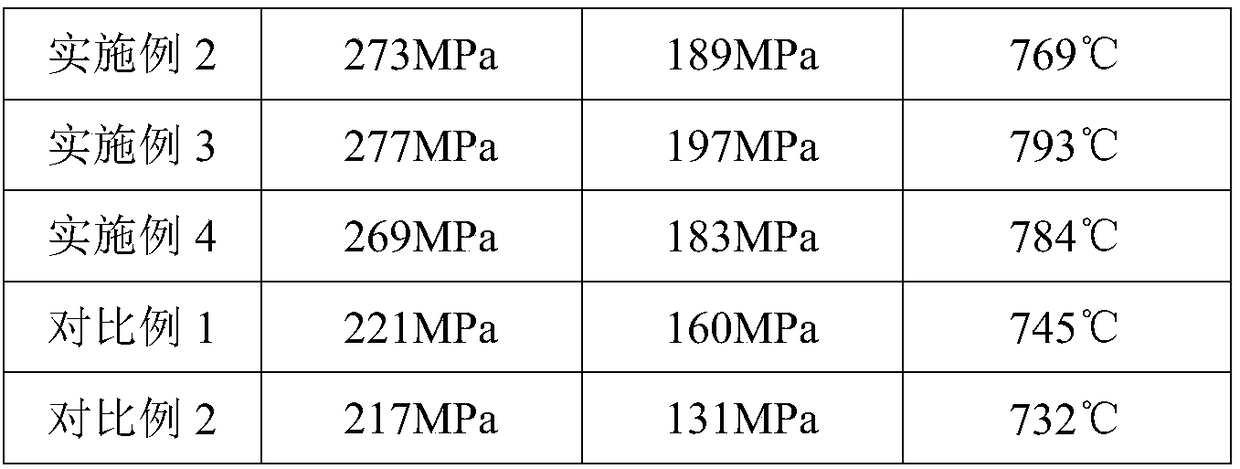

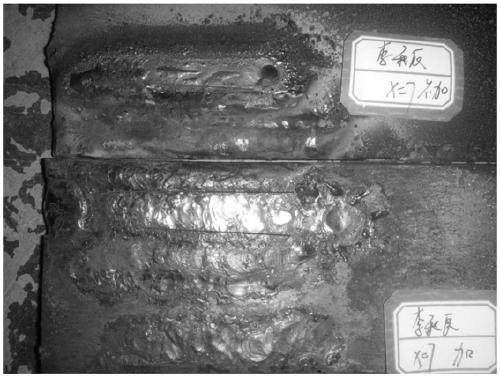

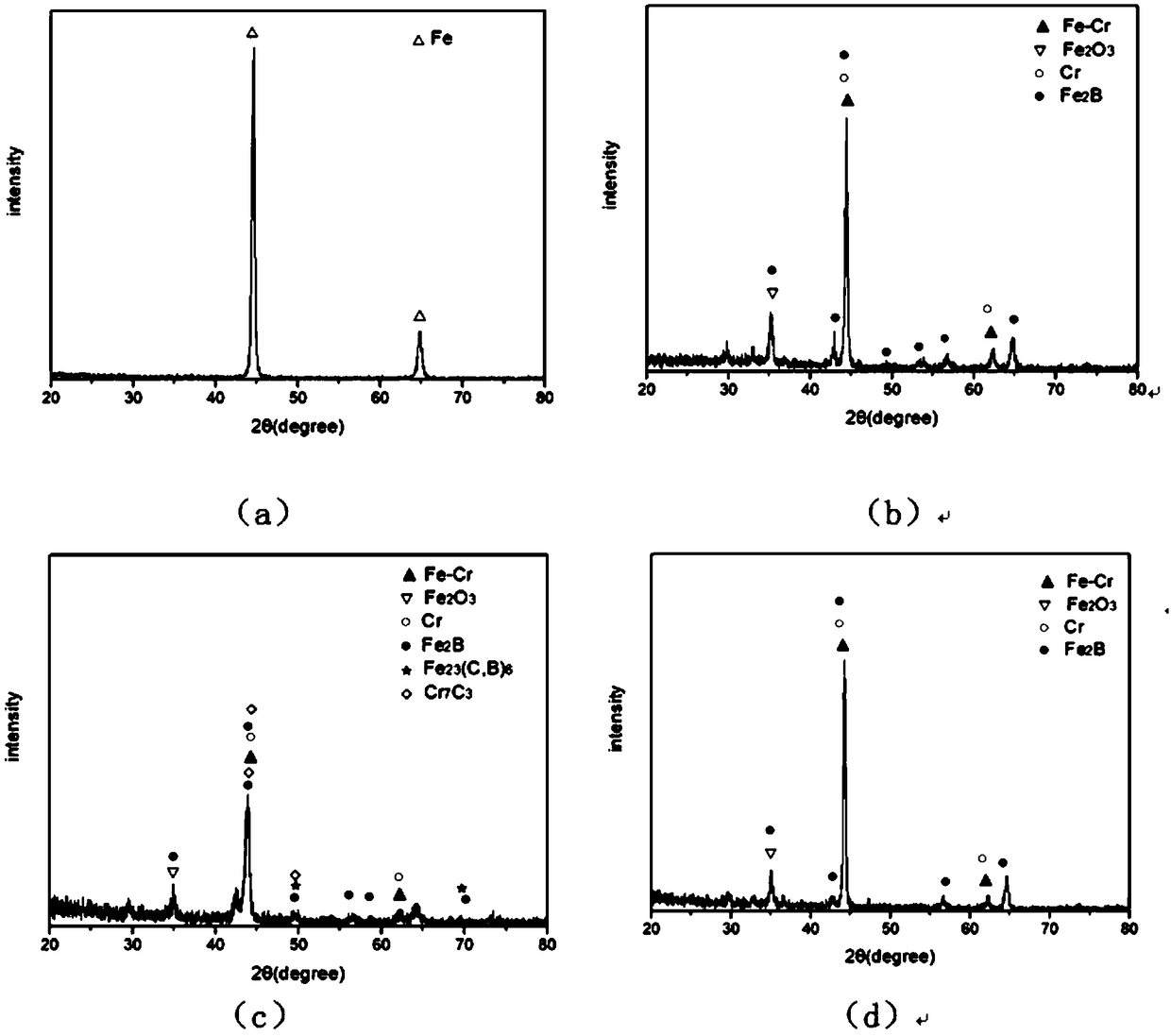

Research for Q235 steel argon arc cladding FeCoCrMoCBY alloy coating

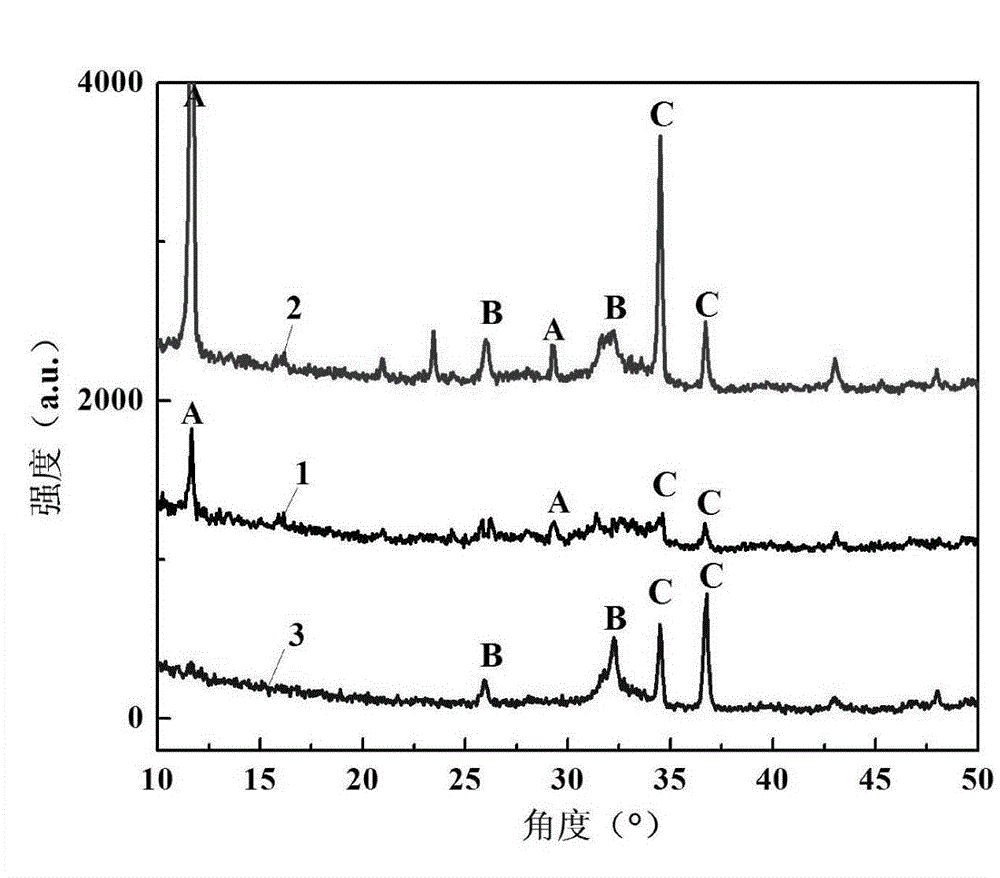

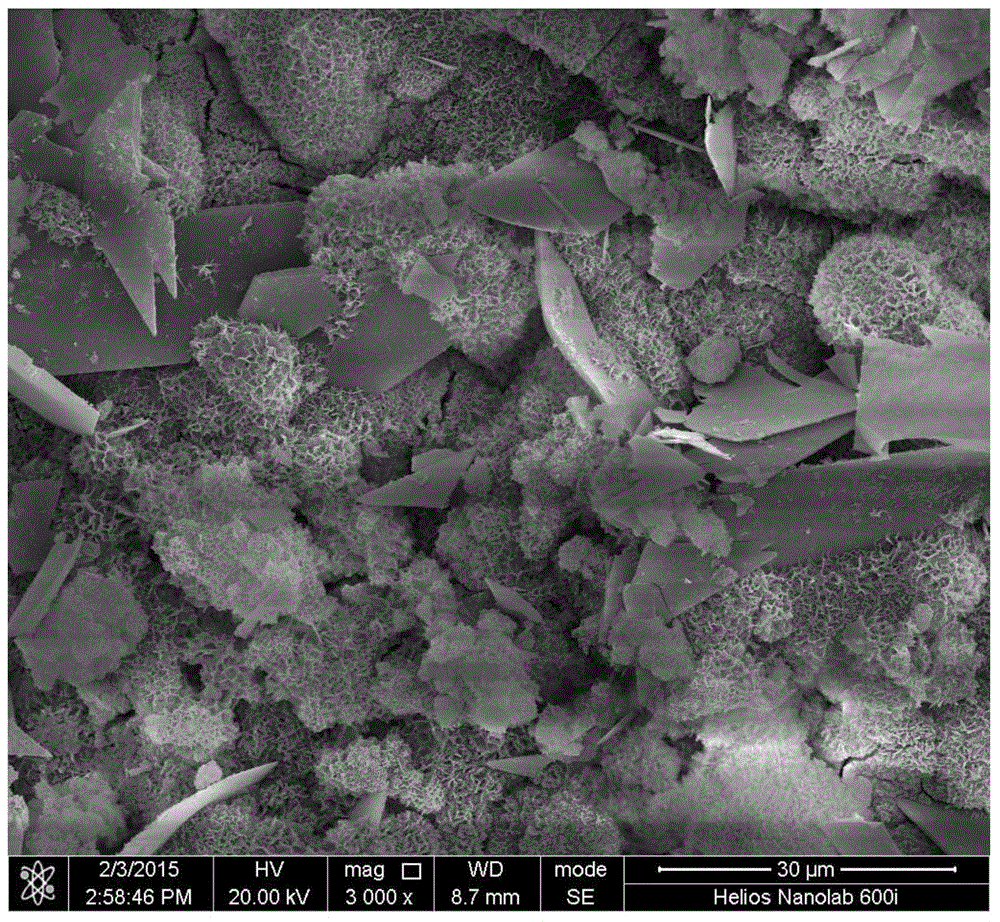

ActiveCN109023356AEasy to shapeThe joint is firmMetallic material coating processesDiffractometerX-ray

The invention relates to a research for a Q235 steel argon arc cladding FeCoCrMoCBY alloy coating. The Fe(48-x)CoxCr15Mo14C15B6Y2 (x=0,7,9) alloy coating is obtained in the manners that a tungsten argon arc welding cladding technology is used and alloy powder in different proportions is prepared to be clad to the Q235 surface. The effects of process parameters such as ball milling time, coating thickness, drying and heat preservation time, welding current, welding voltage and welding speed of the alloy powder on the coating properties are researched. The microstructure, the phase, the Vickershardness and the corrosion resistance of a metallographic microscope, an X-ray diffractometer, a Vickers hardness tester and an electrochemical workstation to the iron-based alloy coating are researched.

Owner:SHANDONG UNIV +1

A surface modified 20Cr steel bipolar plate material and a preparation method thereof

InactiveCN109037708AReduce manufacturing costIncreased corrosion potentialCell electrodesNitrideCarbon steel

The invention relates to a surface modified 20Cr steel bipolar plate material and a preparation method thereof. 20Cr steel is taken as a substrate, that substrate is ground and polis before being treat, and then the substrate is subjected to ion nitriding, electroless nickel plating, nitride coat deposited by PVD technology and the like to prepare a composite multilayer film of 20Cr steel / nitriding / nickel plating / CrN or CrMoN. Under the simulated PEMFC environment, the corrosion resistance and surface contact resistance of the surface modified 20Cr steel bipolar plate meet the American DOE 2020 standard, and the adhesion between the film and the substrate is greater than 45N. The corrosion resistance and surface contact resistance of the surface modified 20Cr steel bipolar plate meet the American DOE 2020 standard. 316L stainless steel material can be replace by a common carbon steel sheet by adopting that method of the invention, and the production cost of the bipolar plate is reduce.

Owner:ZHEJIANG UNIV OF TECH

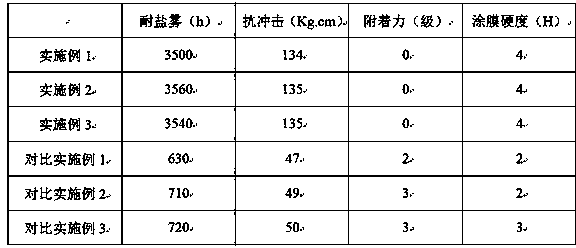

Wheel rim anticorrosion coating material containing basalt scales, and preparation method thereof

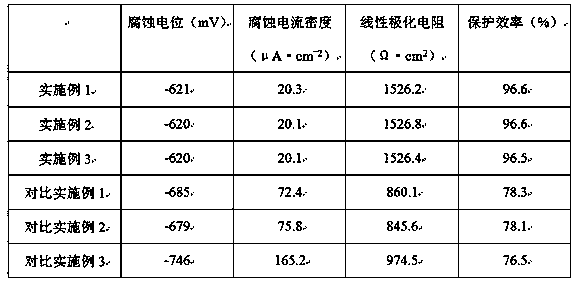

InactiveCN109266162AIncreased corrosion potentialLow corrosion current densityAnti-corrosive paintsEpoxy resin coatingsLinear polarizationCorrosion resistant

The invention discloses a wheel rim anticorrosion coating material containing basalt scales, and a preparation method thereof. According to the present invention, the prepared wheel rim anticorrosioncoating material has advantages of high corrosion potential, high linear polarization resistance, high protection efficiency, low corrosion current density, excellent corrosion resistance, good mechanical property, good salt spray resistance, good impact resistance, good adhesion and high hardness of coating film.

Owner:ANHUI JIANGHUAI WHEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com