A corrosion-resistant magnesium alloy

A magnesium alloy and corrosion-resistant technology, applied in the field of metal alloy materials, can solve the problems of poor plasticity at room temperature, low mechanical properties, and no corrosion resistance, and achieve the effects of reducing the corrosion rate, improving the corrosion resistance, and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

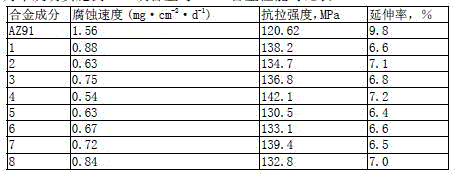

Examples

Embodiment 1

[0020] A corrosion-resistant magnesium alloy, the weight percentage of the chemical composition of the magnesium alloy is: Al is 6wt%, Zn is 0.4wt%, Mn is 0.01wt%, V is 0.001wt%, and the balance is Mg.

[0021] Weigh the materials according to the ratio, preheat each component to 220°C, put aluminum ingots, zinc ingots and manganese ingots into a low-carbon steel crucible with a preheating temperature of 280°C to melt, and pass through SF 6- CO 2 Shielding gas (SF 6 :CO 2 The volume ratio is 1:10), when the components are completely melted and the melt temperature reaches 740°C, vanadium ingots are added, the vanadium ingots are preheated to 200°C, then continuously stirred, and SF 6 -CO 2 Protect the gas until the alloy is completely melted, stir for 5 minutes, stand still for 20 minutes when the temperature reaches 710°C, and pour at 700°C to finally obtain a corrosion-resistant magnesium alloy containing vanadium.

Embodiment 2

[0023] A corrosion-resistant magnesium alloy, the weight percentage of the chemical composition of the magnesium alloy is: Al is 9wt%, Zn is 1.0wt%, Mn is 0.3wt%, V is 1.0wt%, and the balance is Mg.

[0024] Weigh the materials according to the ratio, preheat each component to 220°C, put aluminum ingots, zinc ingots and manganese ingots into a low-carbon steel crucible with a preheating temperature of 280°C to melt, and pass through SF 6- CO 2 Shielding gas (SF 6 :CO 2 The volume ratio is 1:10), when the components are completely melted and the melt temperature reaches 730°C, vanadium ingots are added, the vanadium ingots are preheated to 200°C, then continuously stirred, and SF 6 -CO 2 Protect the gas until the alloy is completely melted, stir for 5 minutes, stand still for 20 minutes when the temperature reaches 710°C, and pour at 700°C to finally obtain a corrosion-resistant magnesium alloy containing vanadium.

Embodiment 3

[0026] A corrosion-resistant magnesium alloy, the weight percentage of the chemical composition of the magnesium alloy is: Al is 7wt%, Zn is 0.5wt%, Mn is 0.03wt%, V is 0.009wt%, and the balance is Mg.

[0027] The method for preparing the corrosion-resistant magnesium alloy is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com