Degradable biological magnesium-based amorphous alloy and preparation method thereof

An amorphous alloy and biological technology, which is applied in the field of degradable biological magnesium-based amorphous alloy and its preparation, can solve the problems of unfavorable and controllable degradation, excessive metal content and inability, and achieves reduced degradation rate, high strength and corrosion resistance. , the effect of enhancing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

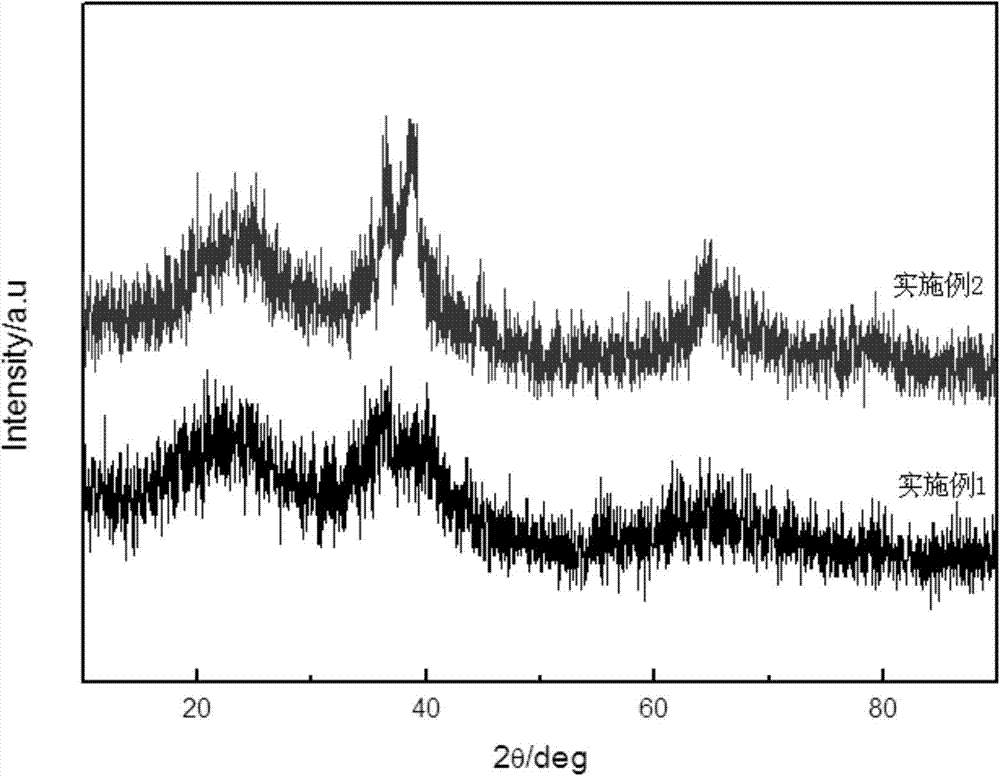

Embodiment 1

[0027] Mg powder, Zn particles, Ca particles, Zr particles, Sr particles and other raw materials with a purity of not less than 99.5% are prepared in an appropriate mass percentage into Mg 66.5 Zn 28 Ca 4 Zr 0.5 Sr 1 masterbatch, 5 kg in total; put the master alloy raw materials with a good ratio into the crucible of the vacuum induction melting furnace, and use the method of intermediate frequency induction melting (700 ℃) to melt the raw materials repeatedly 4 times under vacuum conditions, and then Stir during the process to make the alloy composition uniform, and pour into alloy ingots; break the alloy ingots obtained by smelting, put the broken block alloys into acetone solution and alcohol solution in turn for ultrasonic cleaning, take them out and dry them naturally; Put the bulk alloy ingot into the quartz tube of the vacuum suction casting equipment, and the vacuum degree is 3×10 -4 Pa, induction heating and melting were carried out, and Mg was prepared by vacuum ...

Embodiment 2

[0029]Mg powder, Zn particles, Ca particles, Zr particles, Sr particles and other raw materials with a purity of not less than 99.5% are prepared in an appropriate mass percentage into Mg 65.5 Zn 28 Ca 4 Zr 0.5 Sr 2 masterbatch, 5 kg in total; put the master alloy raw materials with a good ratio into the crucible of the vacuum induction melting furnace, and use the method of intermediate frequency induction melting (750°C) to melt the raw materials repeatedly 4 times under vacuum conditions, and then Stir during the process to make the alloy composition uniform, and pour into alloy ingots; break the alloy ingots obtained by smelting, put the broken block alloys into acetone solution and alcohol solution in turn for ultrasonic cleaning, take them out and dry them naturally; Put the bulk alloy ingot into the quartz tube of the vacuum suction casting equipment, at a vacuum degree of 4×10 -4 Pa, induction heating and melting were carried out, and Mg was prepared by vacuum suct...

Embodiment 3

[0031] Mg powder, Zn particles, Ca particles, Zr particles, Sr particles and other raw materials with a purity of not less than 99.5% are prepared in an appropriate mass percentage into Mg 64.5 Zn 30 Ca 4 Zr 0.5 Sr 1 Masterbatch, 5 kg in total; put the master alloy raw materials with a good ratio into the crucible of the vacuum induction melting furnace, and use the method of intermediate frequency induction melting (800 °C) to melt the raw materials repeatedly 4 times under vacuum conditions. Stir during the process to make the alloy composition uniform, and pour into alloy ingots; break the alloy ingots obtained by smelting, put the broken block alloys into acetone solution and alcohol solution in turn for ultrasonic cleaning, take them out and dry them naturally; Put the bulk alloy ingot into the quartz tube of the vacuum suction casting equipment, at a vacuum degree of 5×10 -4 Pa, induction heating and melting were carried out, and Mg was prepared by vacuum suction cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com