Patents

Literature

163results about How to "Increased corrosion potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

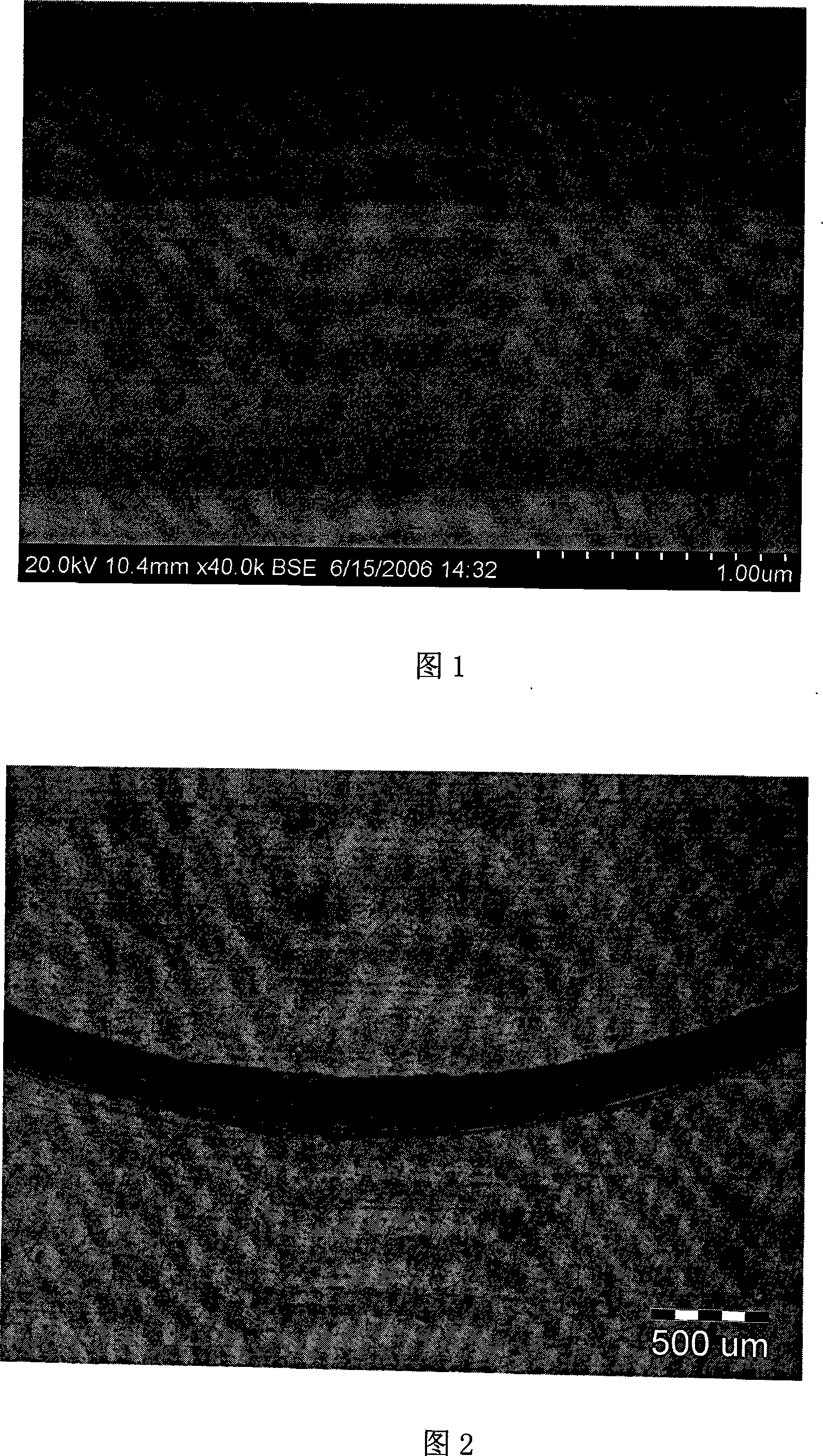

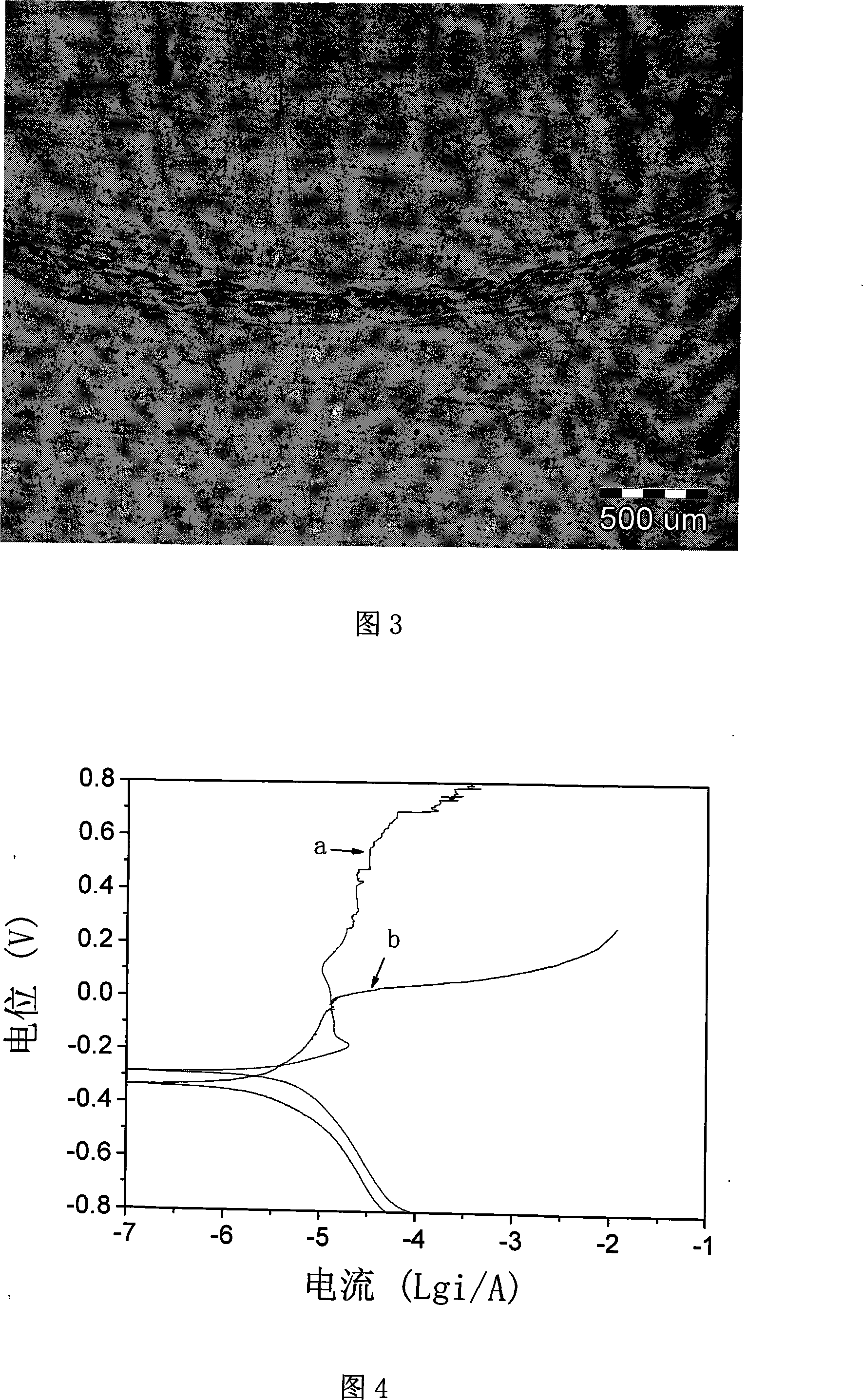

Method for manufacturing surface antimicrobial, abrasion-proof metal/ceramic nano-multilayer film

ActiveCN101220454AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingWear resistantNitrogen gas

The invention which discloses a preparation method for metal / ceramic nanometer multilayer films with antibacterial and wear resistant surfaces relates to a preparation method for nanometer multilayer films and solves the problem of high cost and great difficulty in preparing wholly antibacterial materials and low wear resistance of surfaced treated antibacterial materials. The method comprises the following steps: a magnetron sputtering method is adopted, the background vacuum degree is 10<- 4> to 10<- 2> Pa; sputtering against targets in the conditions of the gas flow ratio of 2 to 17:1 of argon to one gas of the three gases of nitrogen, acetylene or methane, total air pressure of 0.1 - 1.0Pa, magnetron sputtering currents of 0.2 - 50A, voltage of 300 - 600V, substrate bias voltage of minus 50 to minus 400V and deposition temperatures of 80 - 400 DEG C. The nanometer ceramic / metal multilayer films prepared by the invention have good wear resistance and the antibacterial rate of more than 95 percent; the invention has the advantages of no pollution, low cost, easy realization and good industrial application prospects.

Owner:HARBIN INST OF TECH

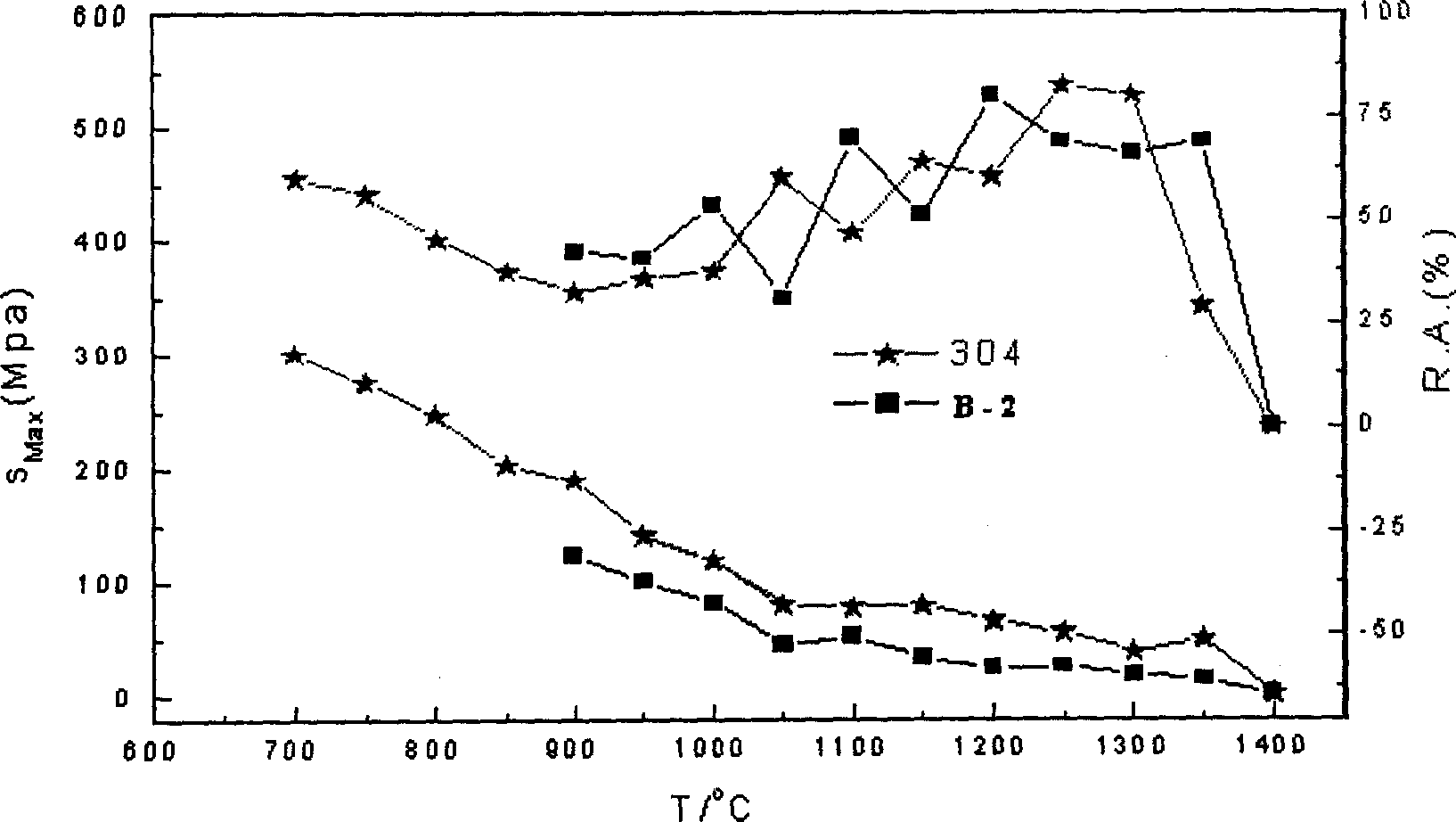

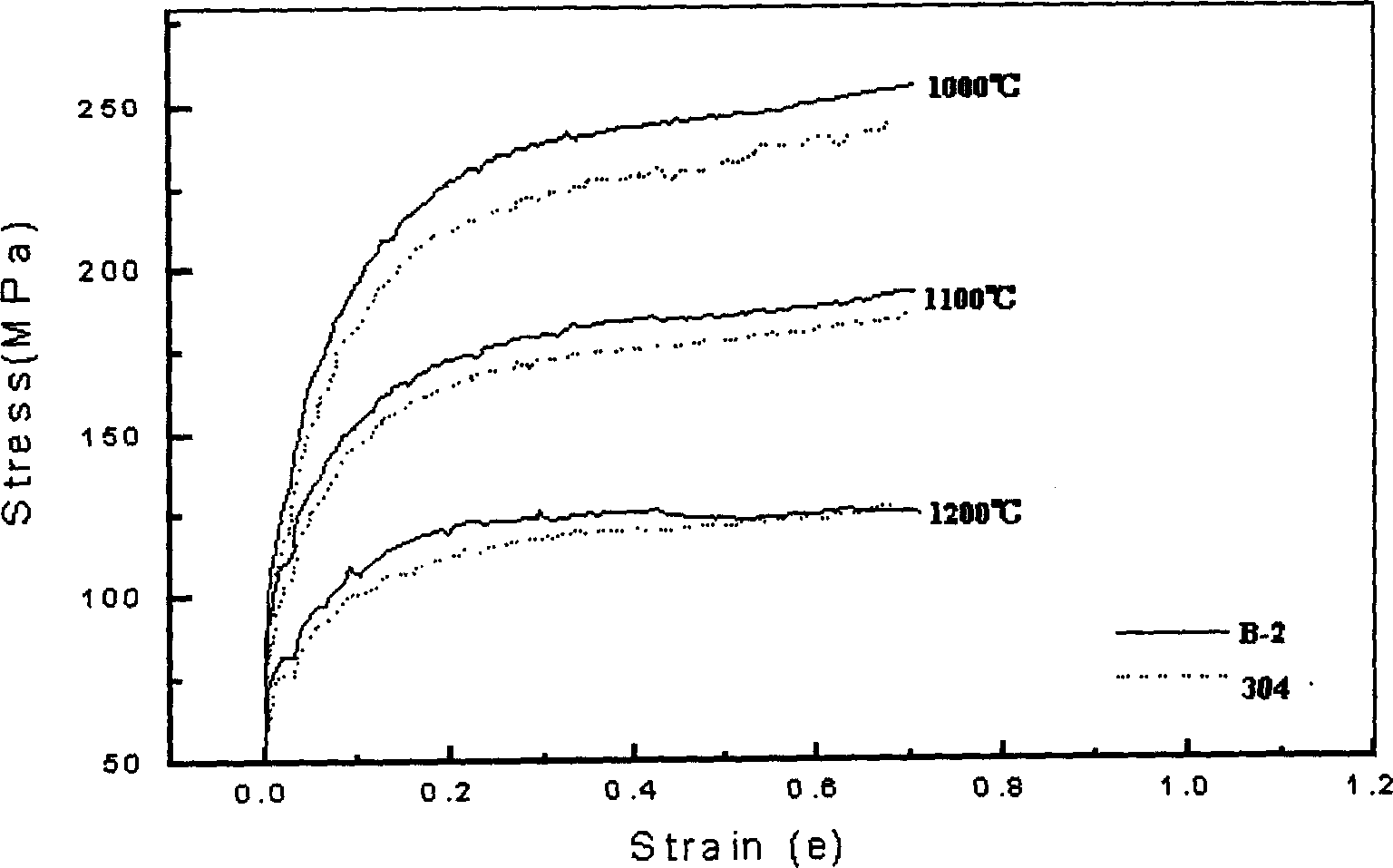

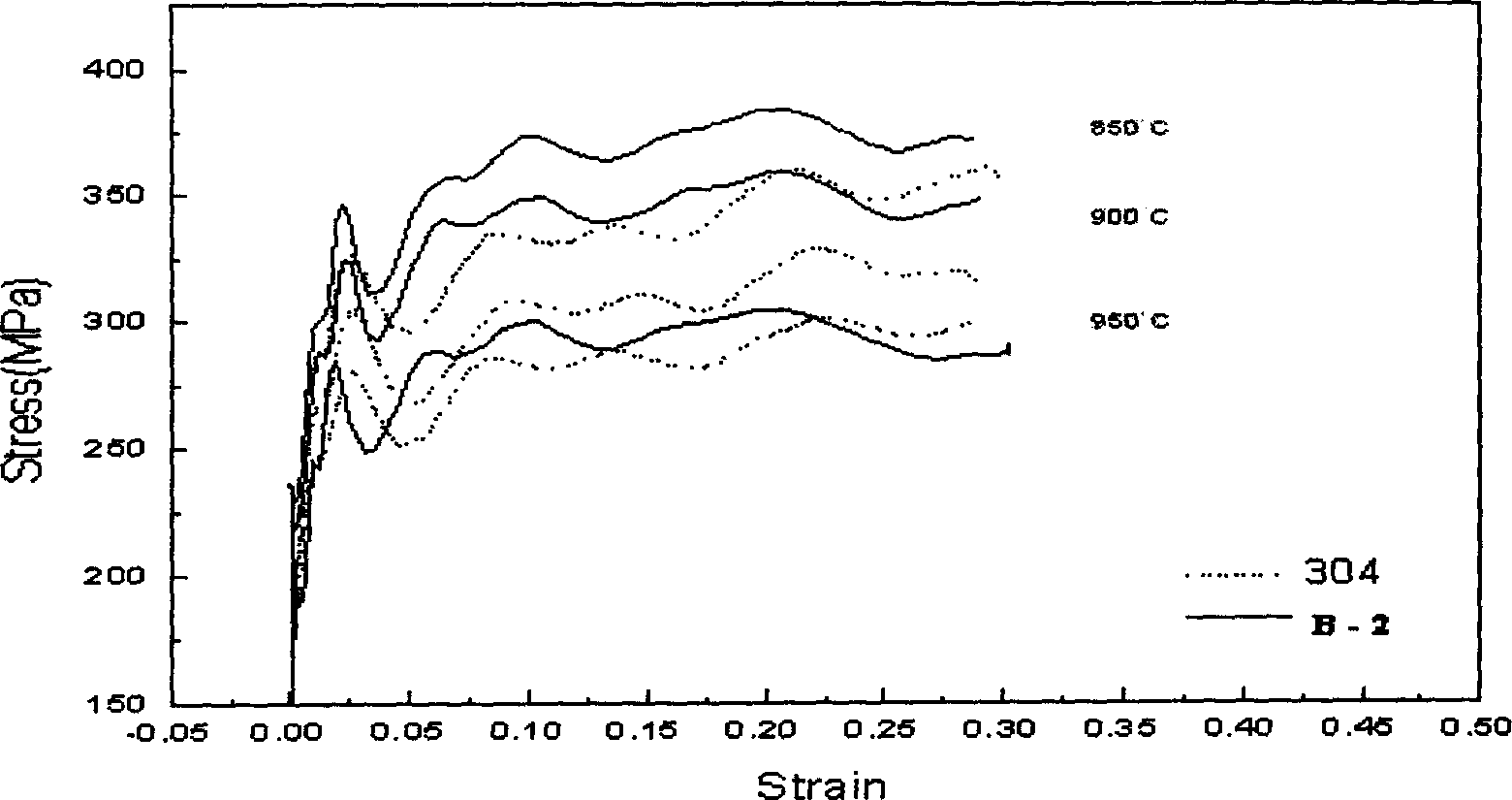

Nickel-saving RE-containing austenitic stainless steel and its prepn

InactiveCN1772942AExcellent overall performanceGood mechanical propertiesTemperature control deviceCasting safety devicesAustenitic stainless steelForging

The present invention belongs to the field of alloy steel, and is nickel-saving RE-containing austenitic stainless steel comprising C not more than 0.08 wt%, Si 0.3-0.8 wt%, Mn 5.0-8.5 wt%, S not more than 0.05 wt%, P not more than 0.04 wt%, Ni 3.0-5.5 wt%, Cr 14-19 wt%, Cu 1.0-4.0 wt%, N not more than 0.20 wt%, total O not more than 0.005 wt%, RE 0.05-0.3 wt% and Fe the rest. The preparation process of the stainless steel includes the technological steps of: smelting, casting at 1500-1650 deg.c, cogging at initial temperature of 1080-1240 deg.c and final forging temperature over 900 deg.c, rolling at initial temperature of 1100-1240 deg.c and final temperature over 900 deg.c, and solution treatment at 1050-1150 deg.c for 20-30 min. During the smelting, the molten steel has oxygen content not more than 50 ppm before RE is added, and RE is added in 30 sec before casting.

Owner:CENT IRON & STEEL RES INST

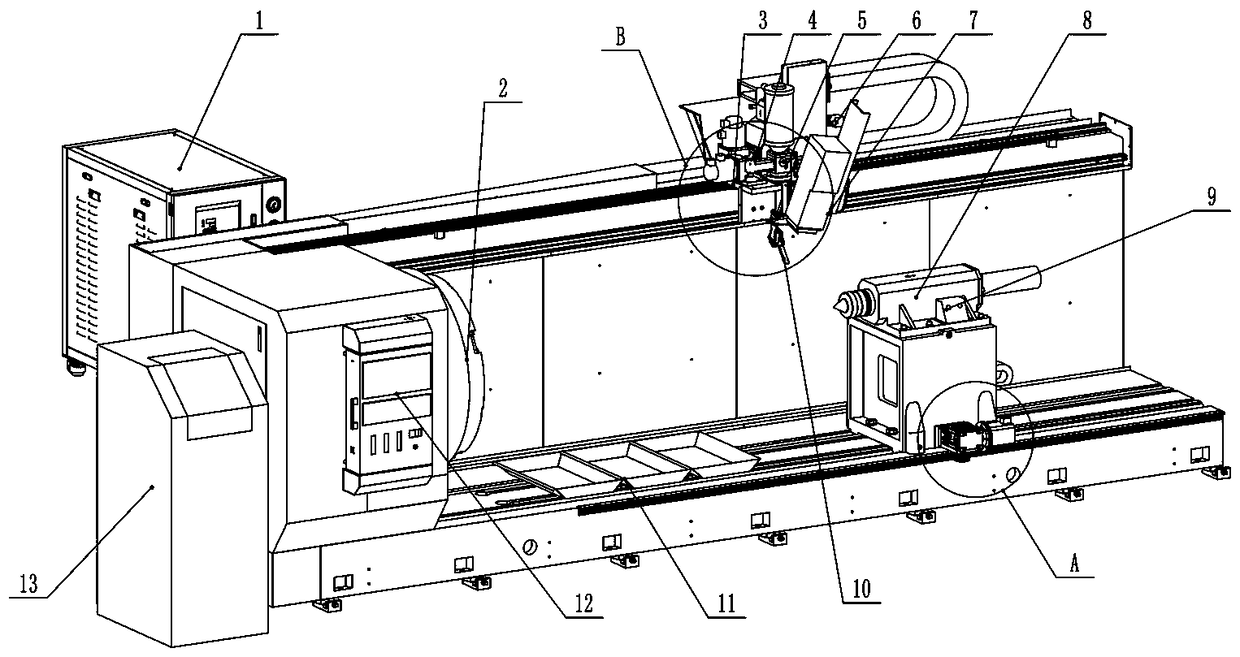

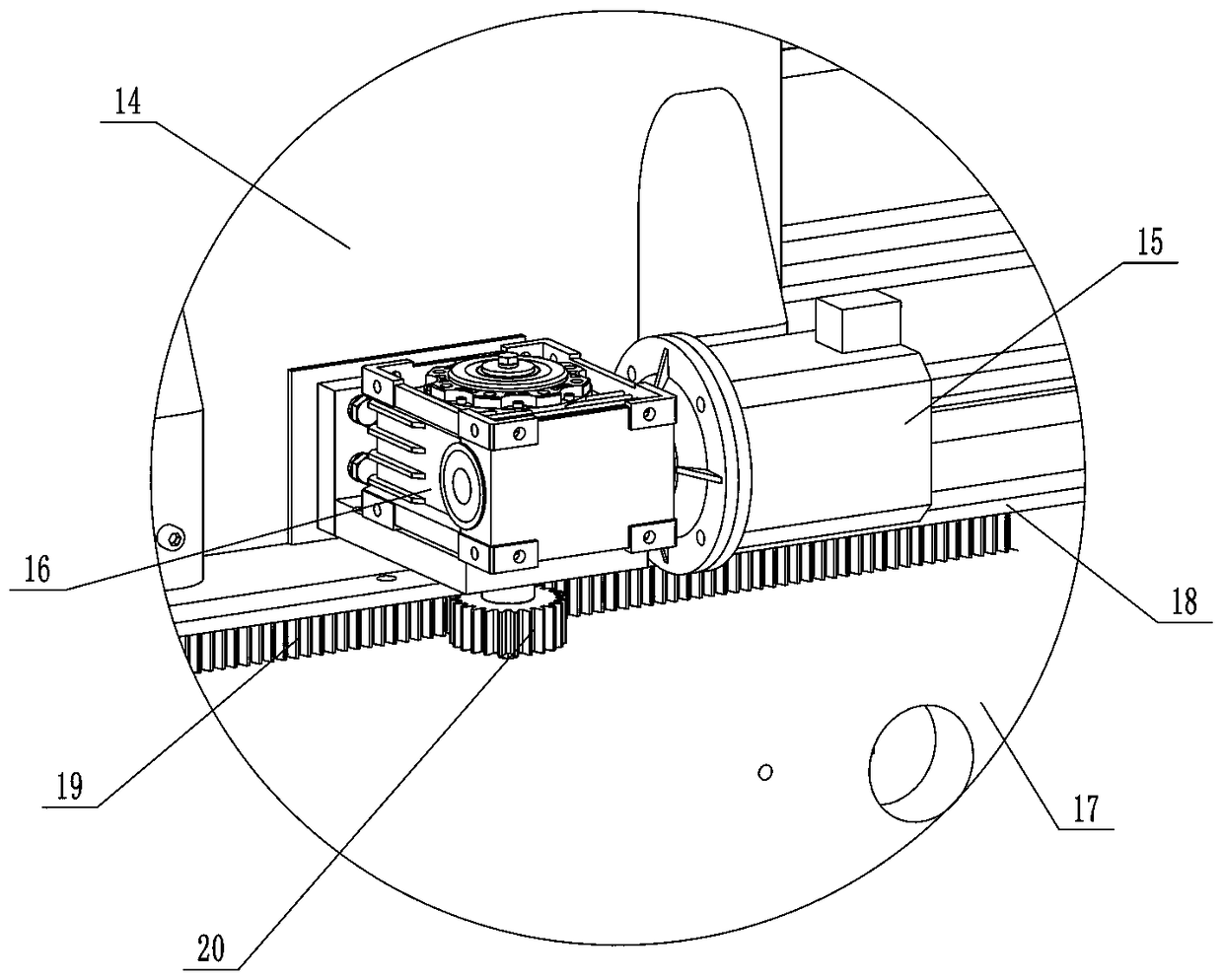

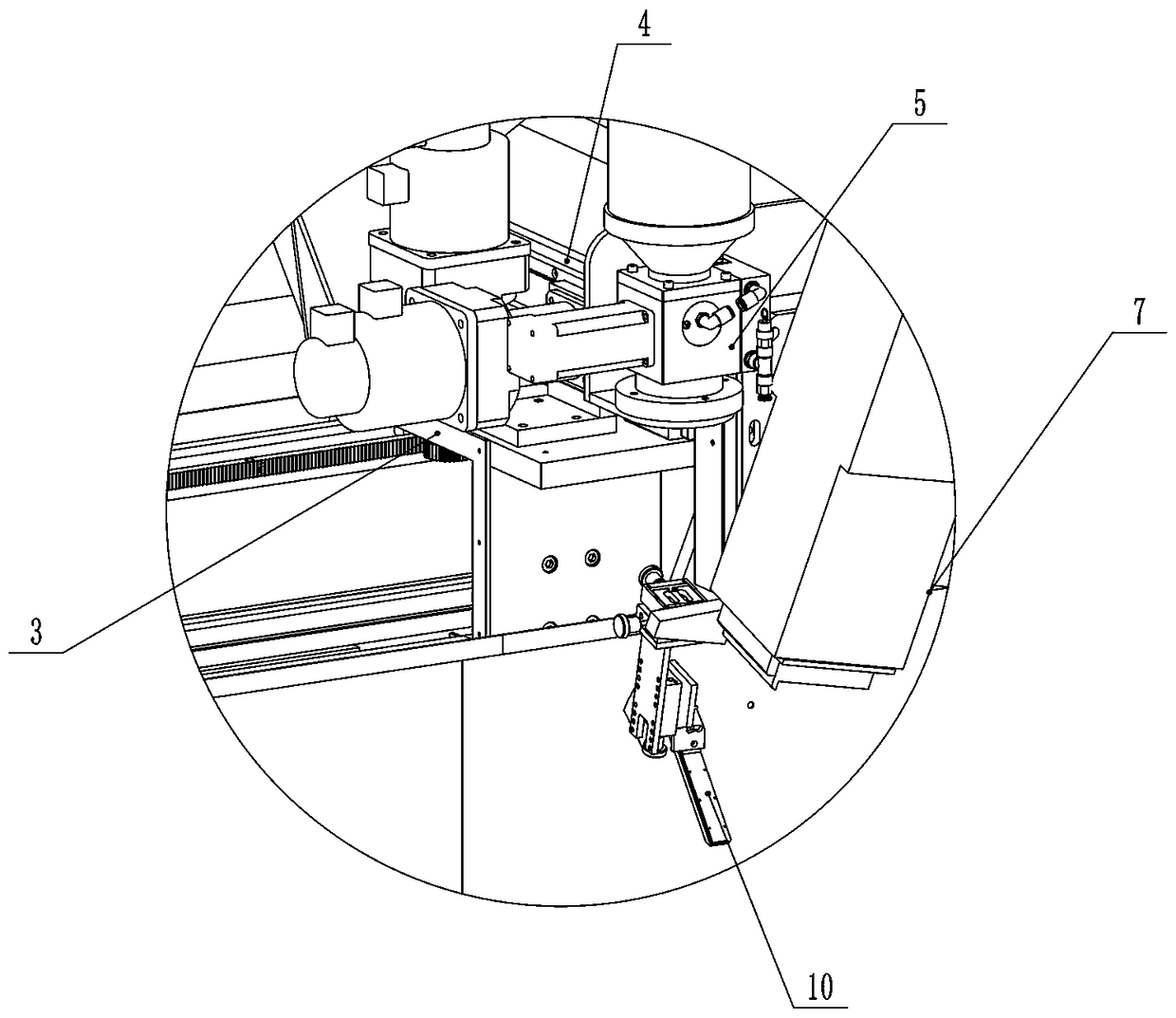

Hydraulic support plunger outer surface laser cladding repairing method

ActiveCN108559996AGuaranteed performanceImprove performanceMetallic material coating processesHardnessOptoelectronics

The invention discloses a hydraulic support plunger outer surface laser cladding repairing method. The hydraulic support plunger outer surface laser cladding repairing method comprises the following steps that firstly, turning is carried out on the outer surface of a hydraulic support plunger to be repaired to remove a fatigue layer and an electroplated layer on the outer surface of the hydraulicsupport plunger, and the outer surface of the hydraulic support plunger is washed; secondly, iron-base alloy powder for laser cladding is put into laser cladding equipment, the laser cladding equipment is used for carrying out laser cladding on the outer surface of the hydraulic support plunger, and a laser cladding layer is formed; thirdly, rough turning is carried out on the hydraulic support plunger which is subjected to laser cladding; fourthly, abrasive machining and polishing treatment are carried out on the hydraulic support plunger which is subjected to rough turning, and the roughnessRa of the outer surface of the polished hydraulic support plunger is smaller than or equal to 0.4; and fifthly, checking and flaw detection are carried out on the outer surface of the polished hydraulic support plunger, and laser cladding repairing of the outer surface of the hydraulic support plunger is completed after it is ensured that no defect exists. The laser cladding layer formed throughthe repairing method is high in hardness, large in thickness and high in corrosion resistance and longer in service life.

Owner:河南省煤科院耐磨技术有限公司

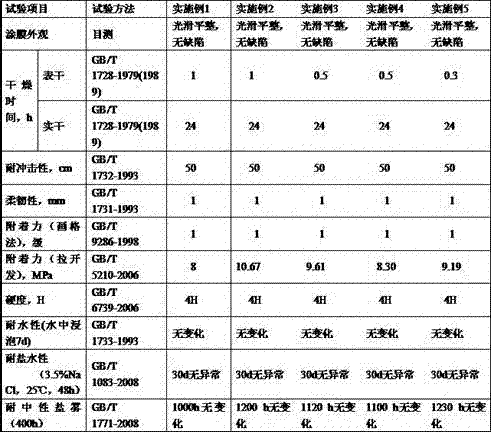

Process for prparing polyaniline corrosion-resistant paint

InactiveCN1358812AIncreased corrosion potentialCorrosion Prevention and MitigationAnti-corrosive paintsEpoxyPolyamide

The present invention discloses a preparation process of polyaniline anticorrosive coating, and includes the following steps: mixing epoxy rsin, polyaniline and diluent uniformly, grinding, then mixing them with phenol aldehide amine, polyamide and diluent uniformly according to the ratio of 10-20:1, cuating on the metal surface and solidifying at room temp. so as to implement said invention. Said anticorrosive coating can form a layer of compact film on the steel surface, can raise corrosion potential of steel, reduce corrosion current and can prevent and relieve corrosion of steel, and said coating layer possesses high harndess and excellent abrasive resistance, after said coating layer is scratched, a passive film can be formed so as to can protect metal from corrosion.

Owner:XI AN JIAOTONG UNIV

Water-based anticorrosive coating and preparation method thereof

ActiveCN107236437ASimple processEasy to operateAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyWater based

The invention relates to the coating field, and particularly discloses a water-based anticorrosive coating and a preparation method thereof. The water-based anticorrosive coating comprises a component A and a component B. The component A comprises the following components by mass: 15-25 parts of a water-based isocyanate curing agent, 15-55 parts of zinc powder, 1-5 parts of a defoaming agent, 1-5 parts of a wetting dispersing agent, 0.9-2 parts of an anti-sinking thixotropic agent, 0.1-5 parts of a conductive macromolecule / fullerene composite material, 0.5-1 part of a flash-rust resistant agent, 0.5-1 part of a flatting agent, 1-3.5 parts of an adhesive force accelerant, and 5-15 parts of a rust resisting pigment; and the component B comprises the following components by mass: 5-13 parts of methyl methacrylate, 15-25 parts of butyl acrylate, 7-16 parts of styrene, 15-30 parts of an epoxy resin, 1-6 parts of a methacrylic acid, 1-5 parts of acrylamide, 1.5-2 parts of hydroxyethyl acrylate, 0.5-5 parts of an emulgator, 0.5-5 parts of an initiator, 80-130 parts of deionized water, and 0.1-1 part of ammonia water. The water-based anticorrosive coating is prepared by stirring and mixing the prepared component A and component B according to the mass ratio of 8-16:1, and has the advantages of strong shielding property, excellent corrosion resistance, environmental protection, good flexibility and strong adhesive force.

Owner:SHIJIAZHUANG TIEDAO UNIV

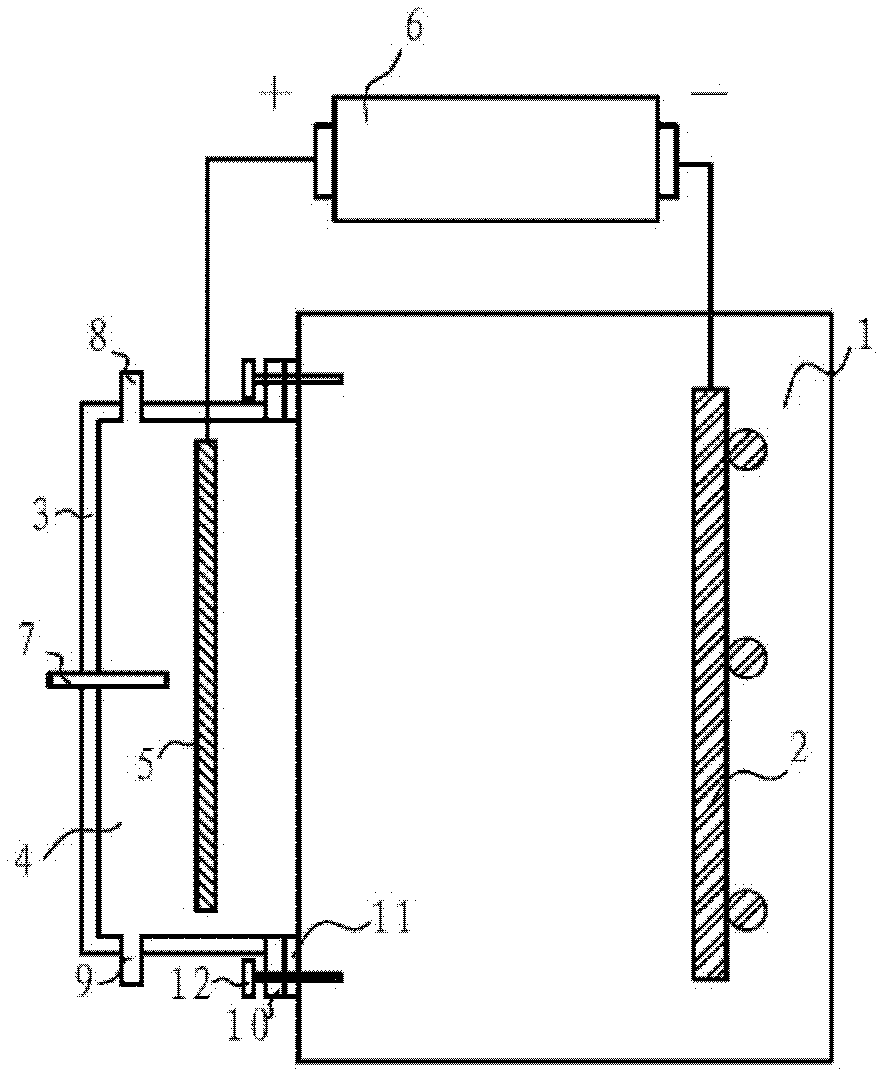

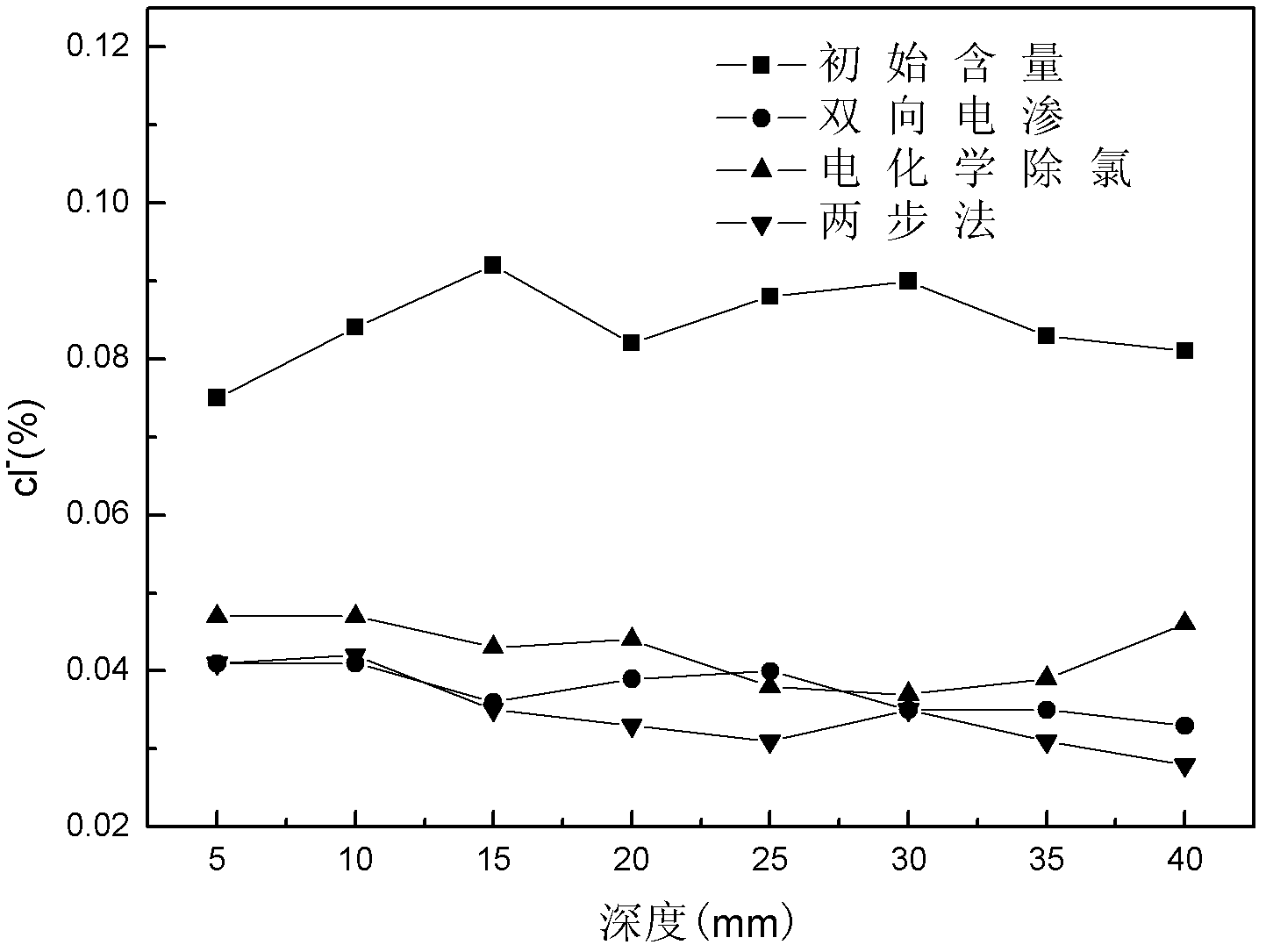

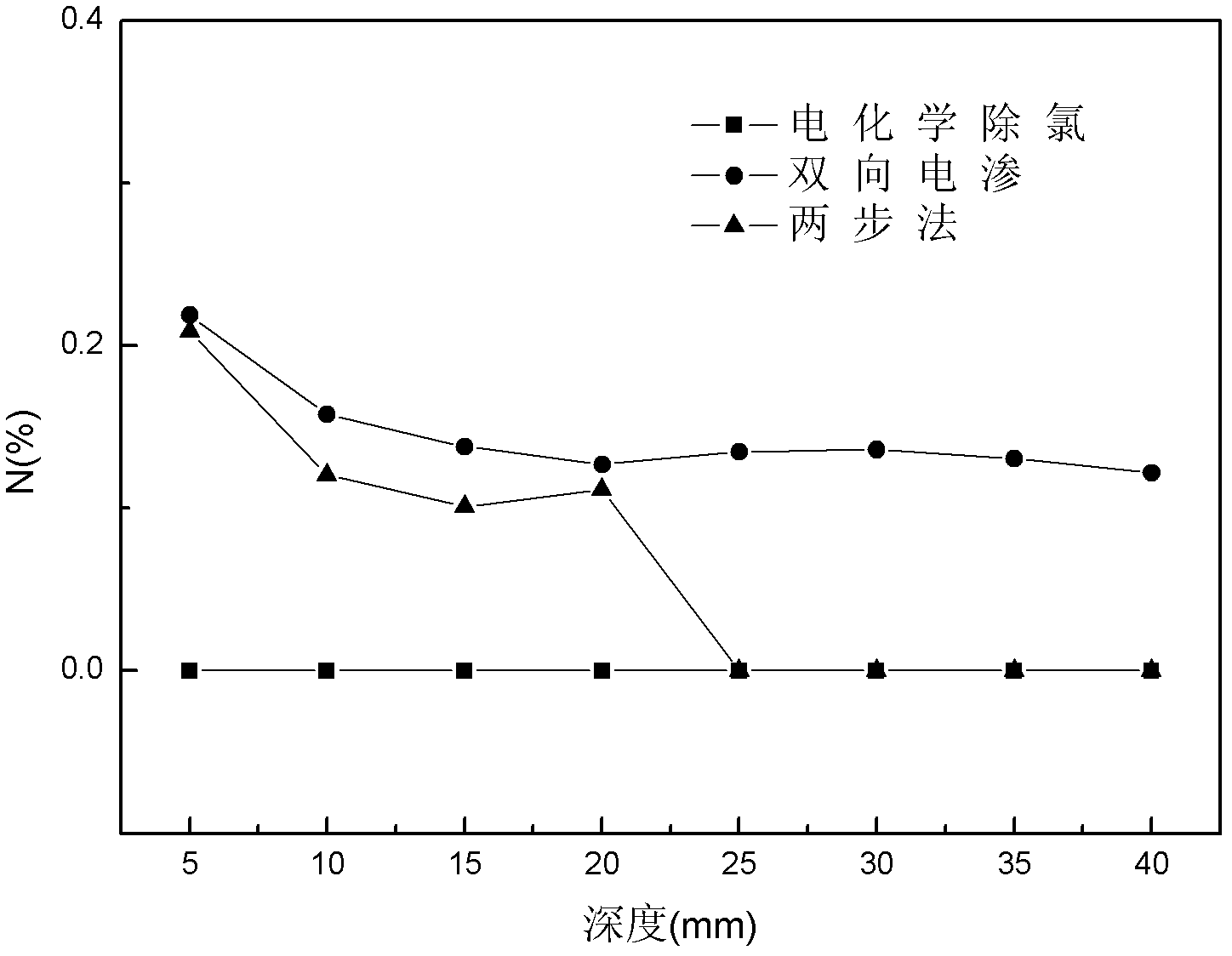

Device and method for repairing concrete structure damaged by salt through two-step process

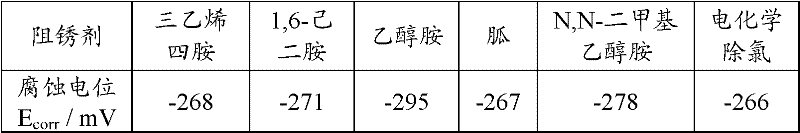

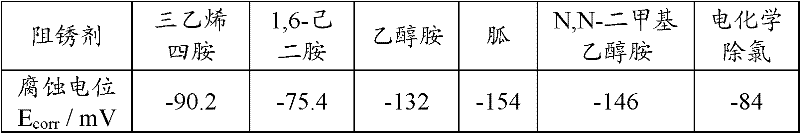

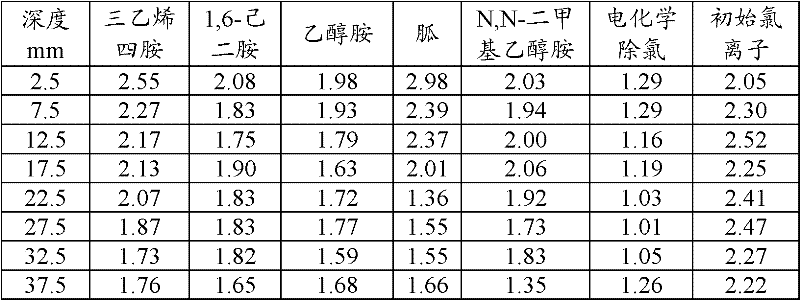

The invention discloses a device for repairing a concrete structure damaged by salt through two-step process, including a steel bar that acts as a cathode and is disposed in concrete, an electrolytic tank whose mouth is in seal seal fit with a surface of the concrete, electrolyte disposed in the electrolytic groove, an anode immersed in the electrolyte and a direct current power supply for providing power to the cathode and the anode, wherein the electrolytic groove is provided with an electrolyte inlet, an electrolyte outlet and a pH indicator, a probe of the pH indicator penetrating througha wall of the electrolytic groove and contacting with the electrolyte. The device provided in the invention is capable of timely replacement of electrolyte which is conducive to full discharge of chloride ions, and is capable of real-time monitoring of the ph value of the electrolyte, being applicable to concrete structures of various kinds of shapes; in addition, the device has the advantages ofsimple structure, convenient operation and effective removal of the chloride ions in a concrete protective layer with the removal efficiency achieving about 60%; further, the device can raise the corrosion potential of a corroded steel bar, decrease corrosion rate, realize the repassivation and maximumly repair a concrete structure damaged by salt.

Owner:浙大宁波理工学院

Cement mortar for repairing corrosion damage of concrete structure and preparation method of cement mortar

ActiveCN103964784AGood adaptability to cementGood compatibilitySolid waste managementSilica fumeCorrosion prevention

The invention relates to cement mortar for repairing corrosion damage of a concrete structure and a preparation method of the cement mortar. At present, a cement-based mortar repair material which is generally used aiming at the concrete corrosion damage lacks pertinence and effectiveness for corrosion damage, and a repair failure problem still exists. The method comprises the following steps: dissolving a water reducing agent and a corrosion inhibitor into mixing water, and stirring and standing without precipitation; putting Portland cement, flyash, silica fume, quartz sand and an expanding agent into a stirring machine in proportion for dry stirring, and then adding the liquid for mixing and stirring for 2-3 minutes; adding the mixing water for stirring to obtain the cement mortar. The compound corrosion inhibitor adopted by the invention is good in cement adaptability, has good compatibility with additives such as the water reducing agent and the expanding agent, has no adverse effect on the strength of materials, and can improve the mobility of mixtures. The mortar has high matrix density, good antiseptic and corrosion-inhibiting capacity and good bonding performance, volume stability and constructability.

Owner:CCCC CIVIL ENG SCI & TECH +1

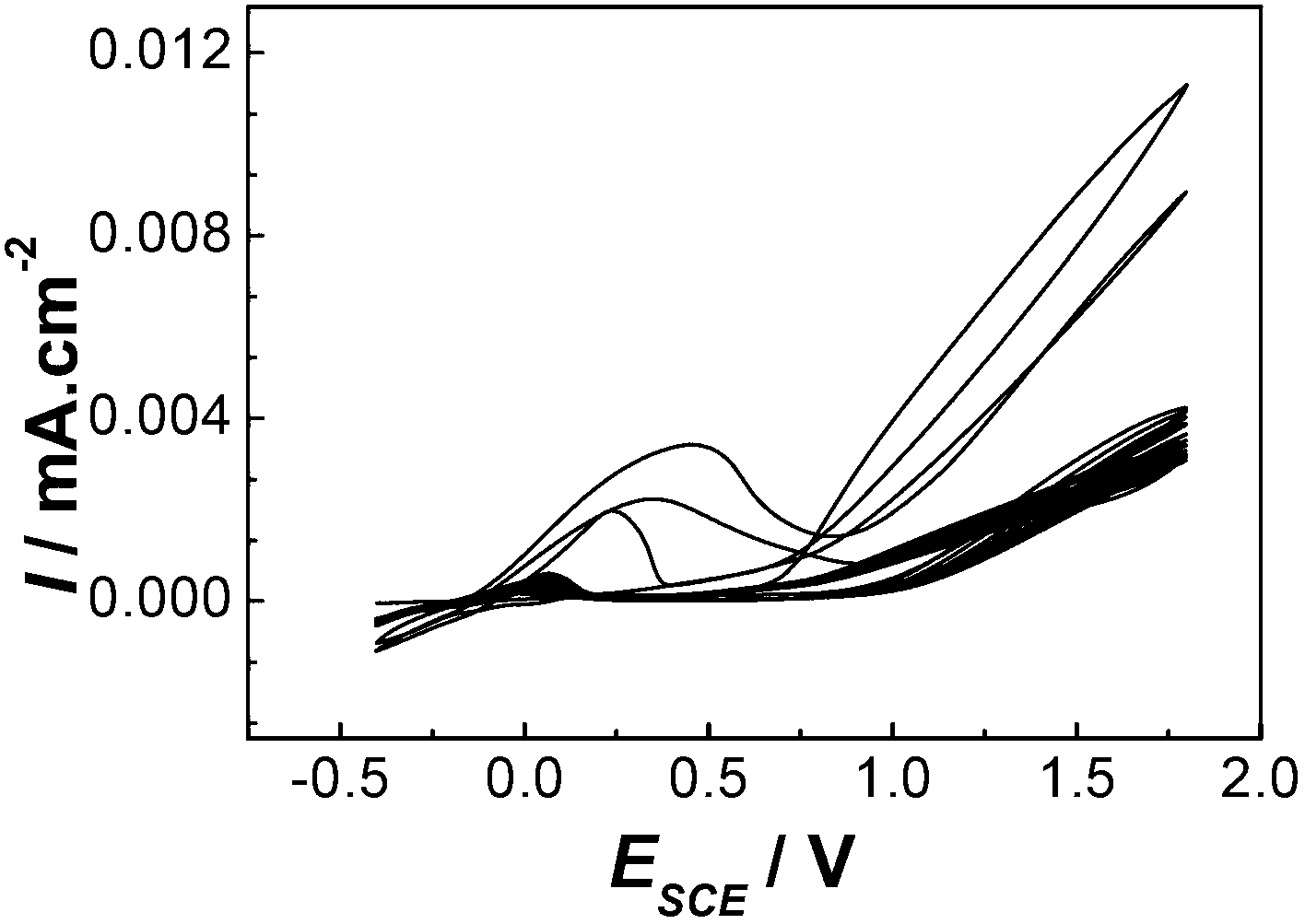

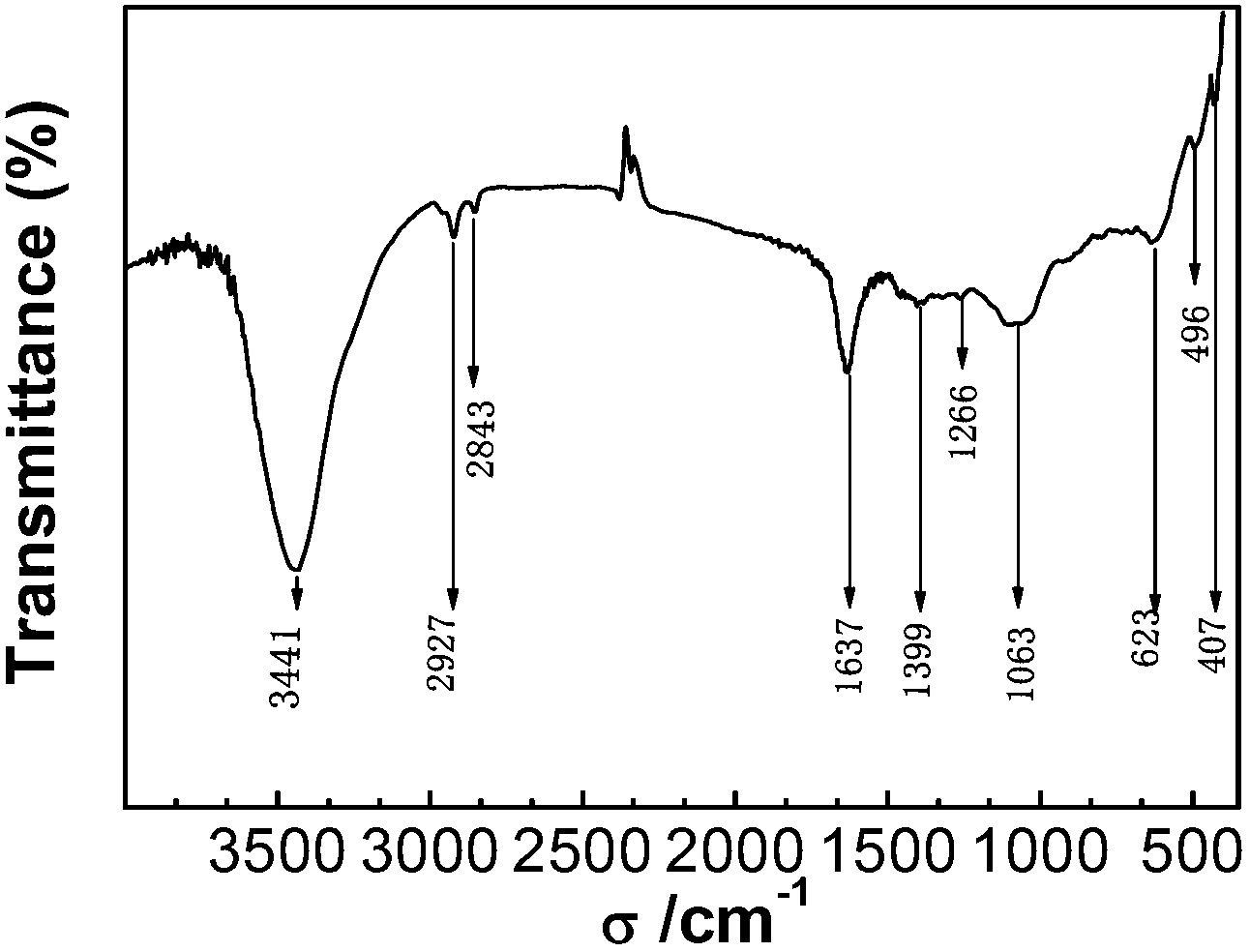

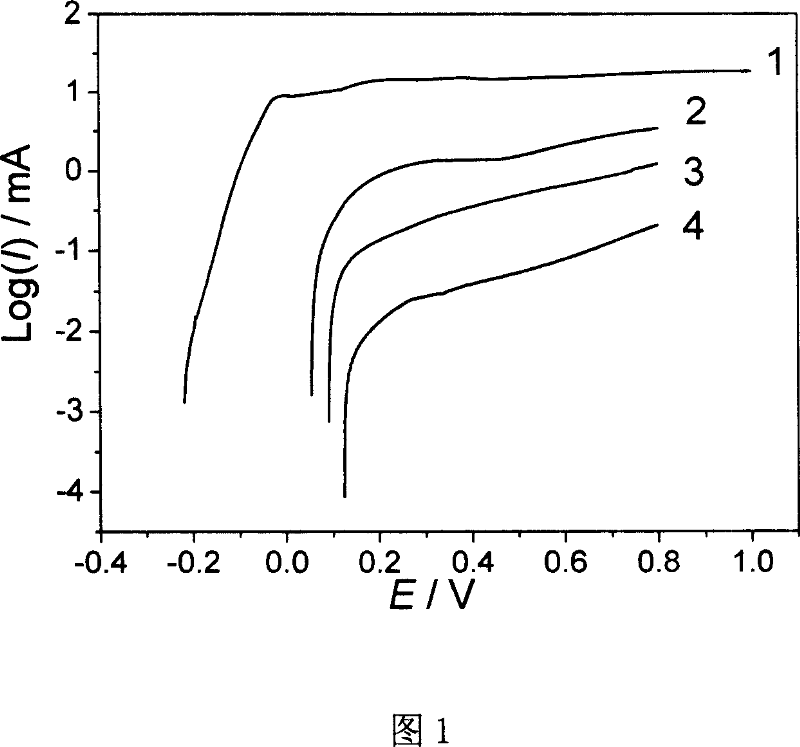

Method for preparing novel conductive composite anticorrosive coating

ActiveCN102703945AIncreased corrosion potentialNo corrosionElectrolytic organic material coatingPolypyrroleCopper electrode

The invention relates to a method for preparing a novel conductive polypyrrole / polyaniline composite anticorrosive coating. The method comprises the following steps of: dissolving p-toluenesulfonic acid into water, regulating the pH value of a solution to be an appropriate value, and adding pyrrole and aniline monomers to obtain a mixed solution; performing electrochemical synthesis by using a three-electrode system, wherein copper is taken as a working electrode, a platinum sheet is taken as an auxiliary electrode, and a reference electrode is a saturated calomel electrode; and performing electrochemical polymerization under certain electrical parameters by cyclic voltammetry to obtain a layer of conductive polypyrrole / polyaniline composite anticorrosive coating on the surface of the copper electrode. The conductive polymer coating generated on the surface of the copper has high adhesion and is uniform and compact; medium corrosion ions can be effectively hindered from penetrating the coating and permeating into the surface of a metal matrix for a long time; the composite coating effectively improves the corrosion potential of a copper matrix and reduces corrosion current; and in addition, after the prepared coating is damaged, a layer of passivating film can be quickly generated on the surface of the matrix so as to ensure that metal is free of corrosion.

Owner:常熟市通顺纺织有限责任公司

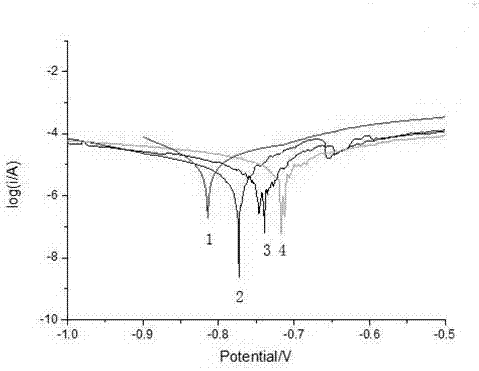

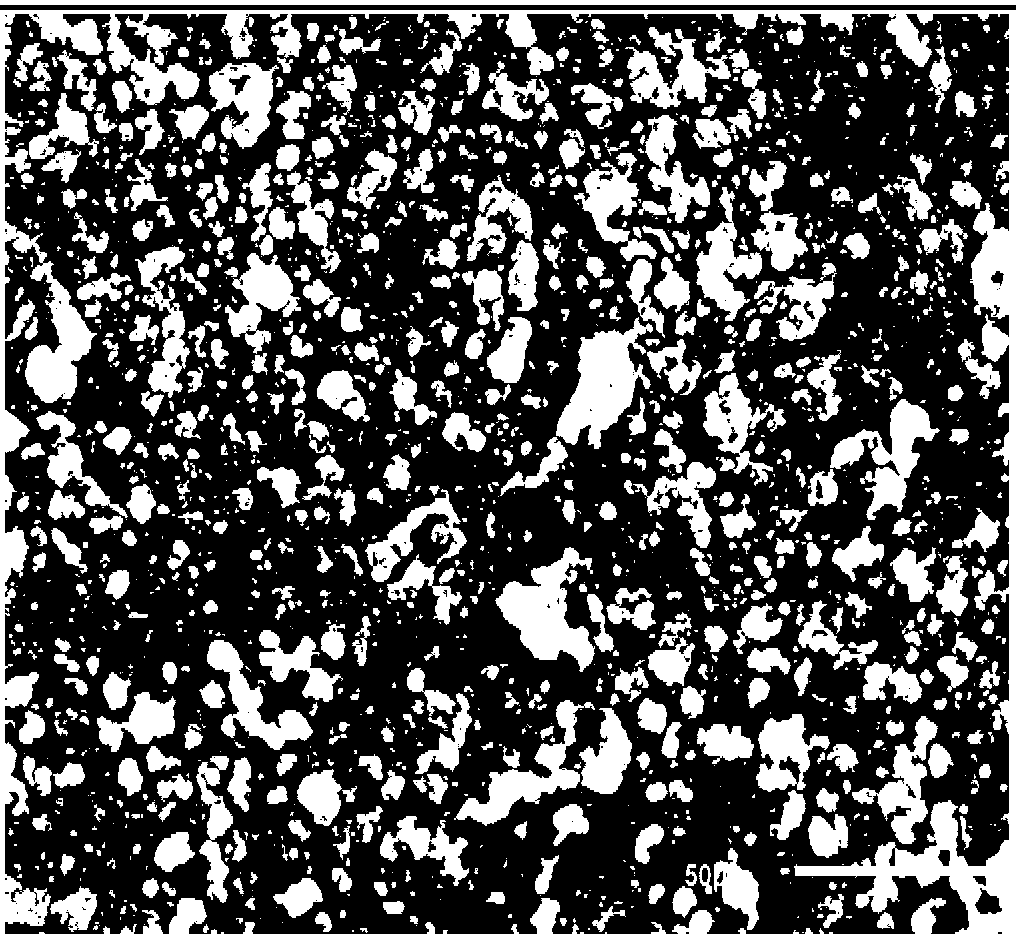

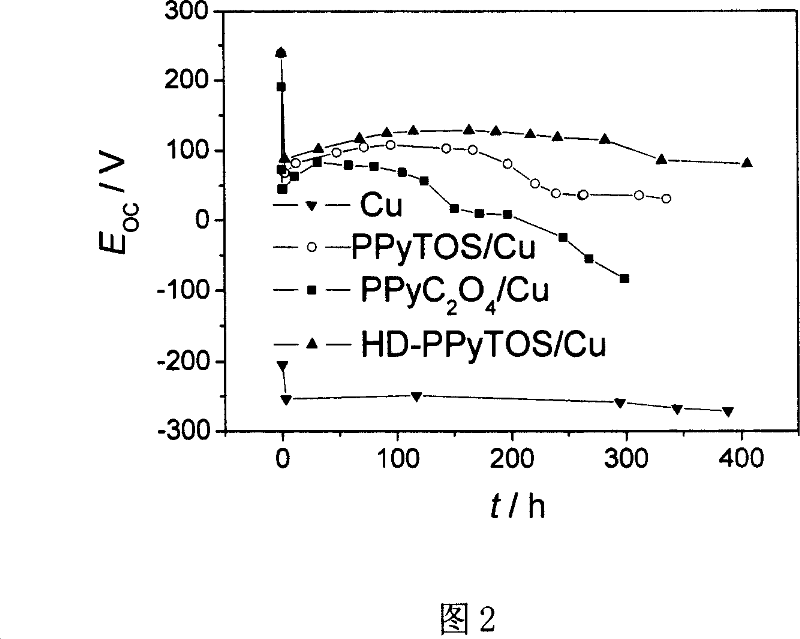

Preparation technique of high-density polypyrrole film anticorrosive coating

InactiveCN101037787AIncreased corrosion potentialNo corrosionElectrophoretic coatingsPolypyrroleMonomer

The invention discloses a process for preparing high density polypyrrole film anti-corrosion coat, wherein the solution A is produced by adding pyrrole monomer into oxalic acid radical solution; the solution B is produced by dissolving methyl benzene sulfonic acid into acetonitrile solution, then the protected copper or copper alloy is immerged into the solution A, and polymerize by an electrochemical process using cyclic voltammetry to produce polypyrrole film-modified copper or copper alloy electrode C; lastly, copper or copper alloy electrode C is immerged into the solution B, and polymerize by an electrochemical process to produce a layer of high density polypyrrole film D on the surface of copper or copper alloy electrode C. The film produced on the surface of copper by the invention is more compact than generally-synthetical polypyrrole film, can efficiently prevent corrosion ion from penetrating through the coat for a long time, and improve the corrosion potential of copper and reduce corrosion current, while the coat has higher adhesivity, but also corrosion of metal can be avoided by producing passivating film after scuffing the coat.

Owner:XI AN JIAOTONG UNIV

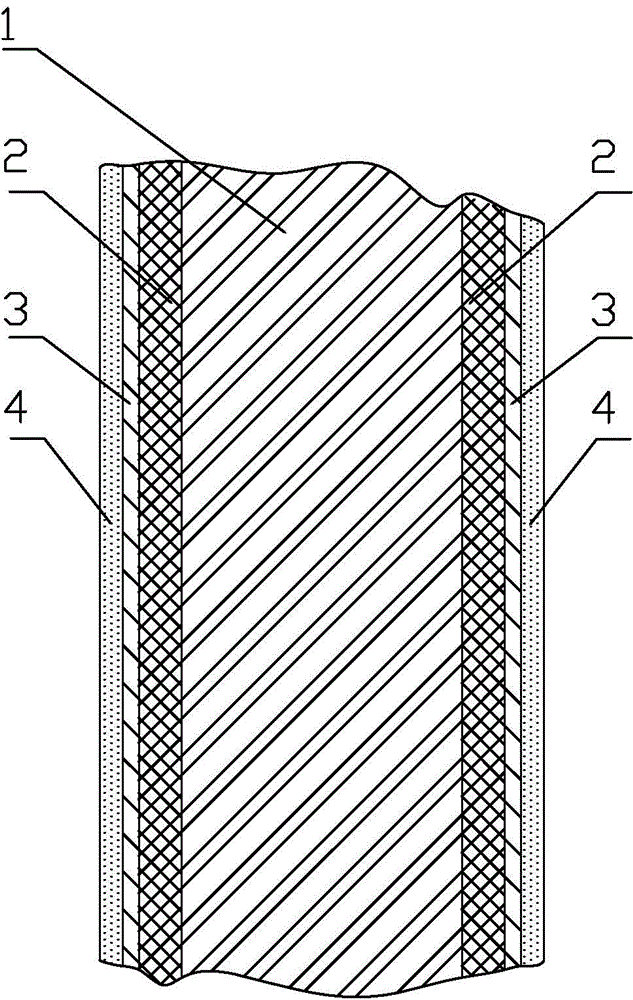

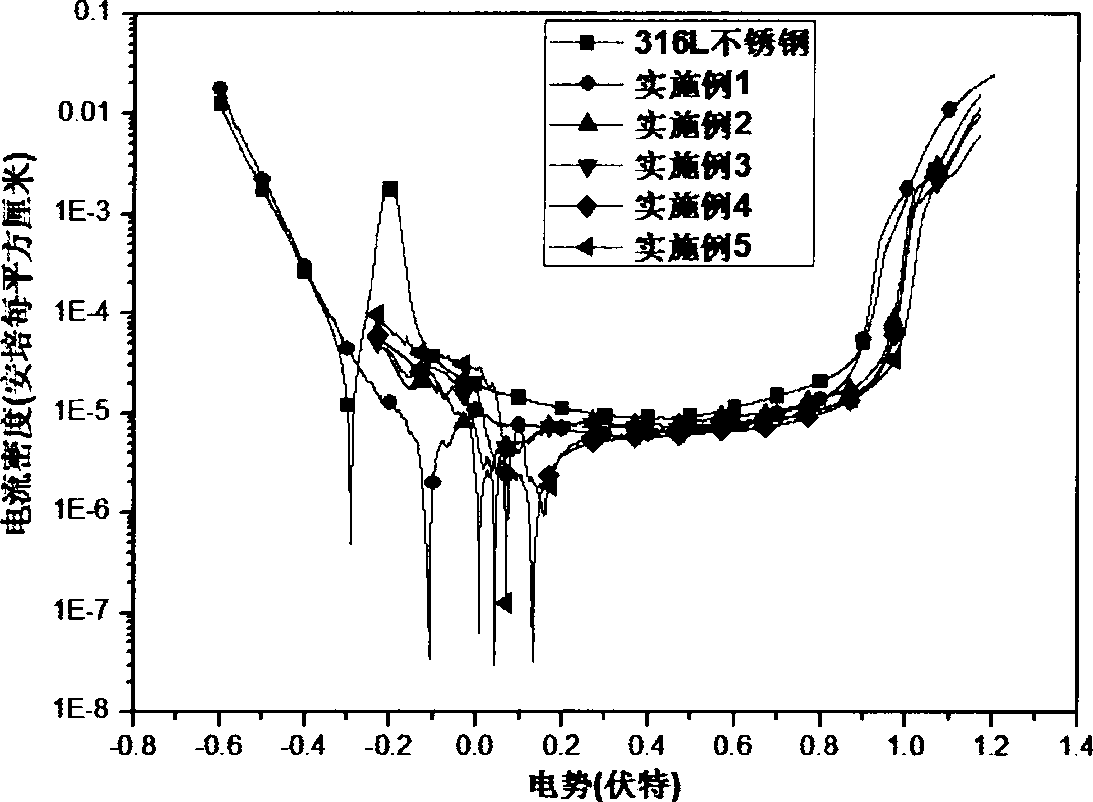

Fuel-cell bipolar plate with nitrified and enhanced surface and preparation method thereof

The invention discloses a fuel-cell bipolar plate with a nitrified and enhanced surface and a preparation method thereof and belongs to the technical field of fuel cells. The bipolar plate is prepared by the following steps of: preparing a nitrified layer, a chromium-nitride thin film and a carbon-based nano composite conductive thin film on the two side surfaces of a matrix of a stainless-steel plate or a titanium-alloy plate in sequence, cleaning and drying the matrix of the stainless-steel plate or the titanium-alloy plate, then putting the matrix in vacuum-arc ion-plating equipment, introducing nitrogen and hydrogen under the vacuum condition, starting bias voltage and hot wires, and preparing the nitrified layer; and introducing argon-nitrogen mixed gas, preparing the chromium-nitride thin film, opening a carbon target and preparing the carbon-based nano composite conductive thin film. The fuel-cell bipolar plate disclosed by the invention has the advantages that an ion nitrification technology is introduced into the field of surface modification of the fuel-cell bipolar plate, and the nitrified layer is prepared on the surface, so that the passivation of the matrix can be avoided, the condition that a coating fails due to corrosion can be effectively prevented; and a stepped transition method is adopted for multi-element composition of the chromium-nitride thin film and the nano composite conductive thin film, so that the peeling of the coating in the use process due to overlarge internal stress and oversmall bonding force is prevented.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

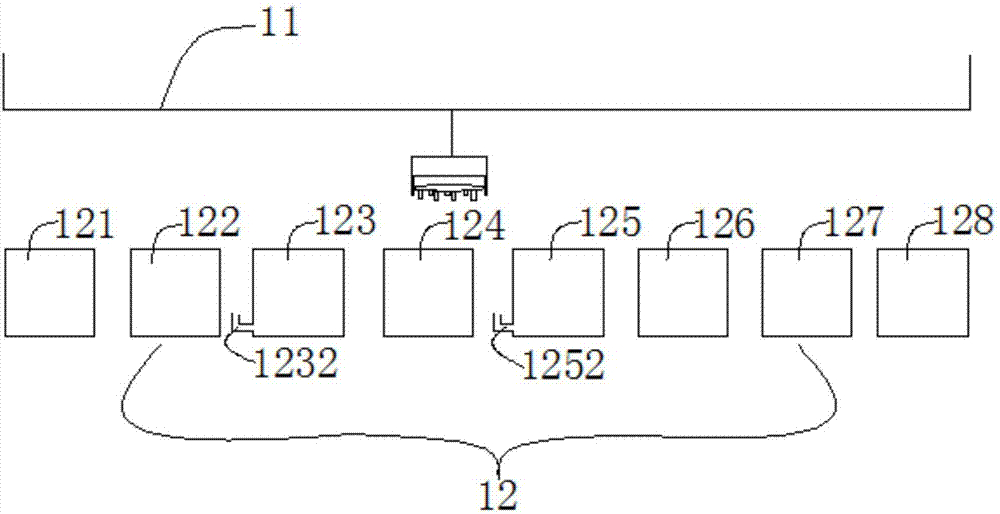

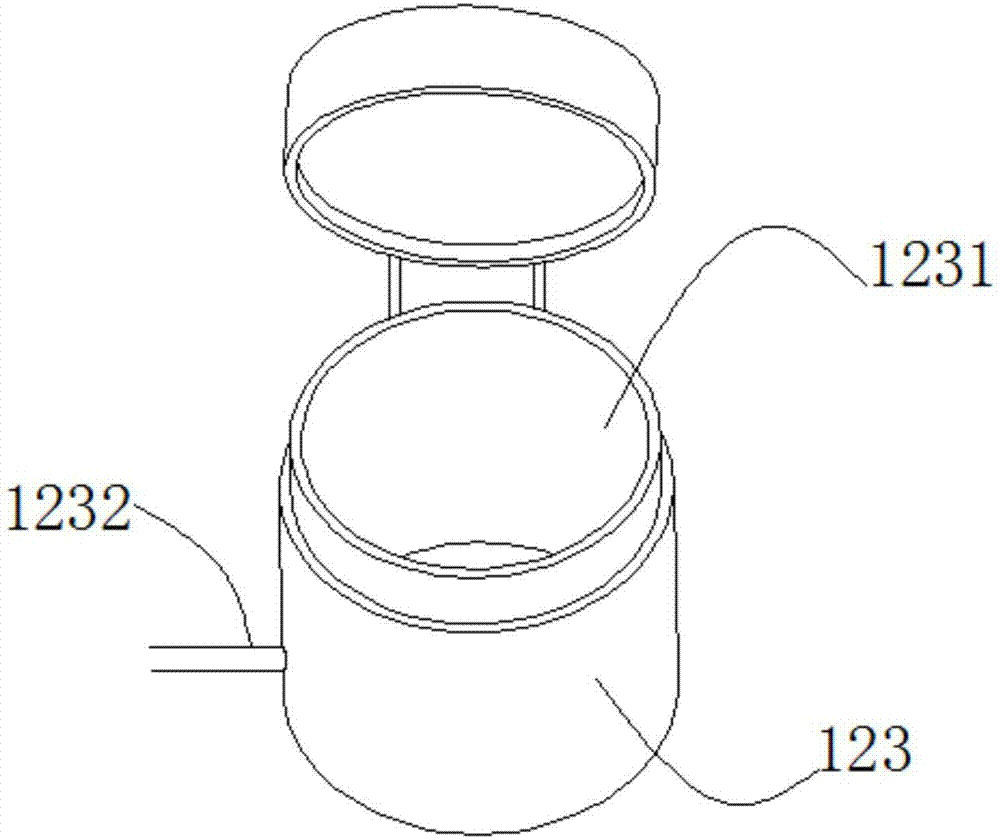

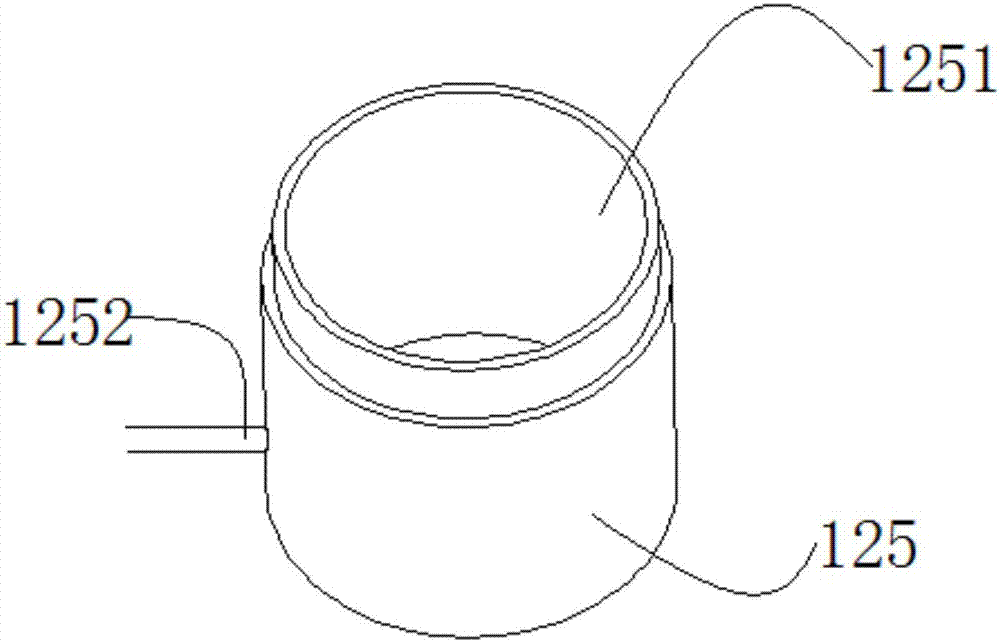

Device and process for surface treatment of parts

ActiveCN107502852ASmall amount of deformationSmall amount of surface deformationSolid state diffusion coatingMachine partsCooling chamber

The invention provides a device and a process for the surface treatment of parts. The device comprises a transportation unit and a treatment unit, wherein the transportation unit is arranged on the upper side of the treatment unit and used for transporting a preliminarily-machined part into the treatment unit; the treatment unit comprises a cleaning pool, an air furnace, a nitriding furnace, an oxidizing furnace, a cooling chamber, an ultrasonic cleaning device, a polishing machine and an oxidation repairing furnace which are arranged in sequence; a first gas transportation pipeline communicates with a nitriding cavity and used for transporting nitrogen gas into the nitriding cavity; and a second gas transportation pipeline communicates with a cooling cavity and used for transporting protective gas into the cooling cavity. By adoption of the device and the process, the nitrogen gas is injected when the surface of the part is subjected to nitriding treatment in the nitriding furnace, thereby facilitating the flow of a nitriding salt solution in the nitriding furnace, improving the nitriding speed, and reducing the deformation; and the part is cooled in the cooling chamber which is fully filled with the protective gas, so that the surface color of the part is uniform and the deformation is little.

Owner:无锡市奕珺金属改性技术有限公司

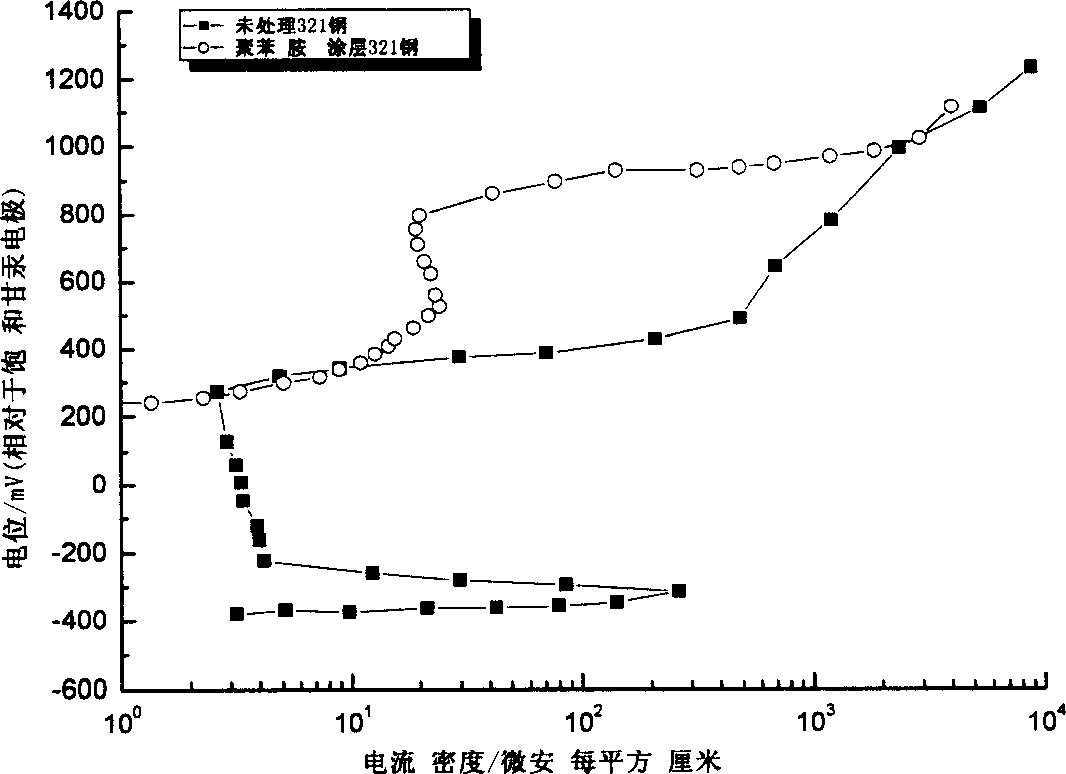

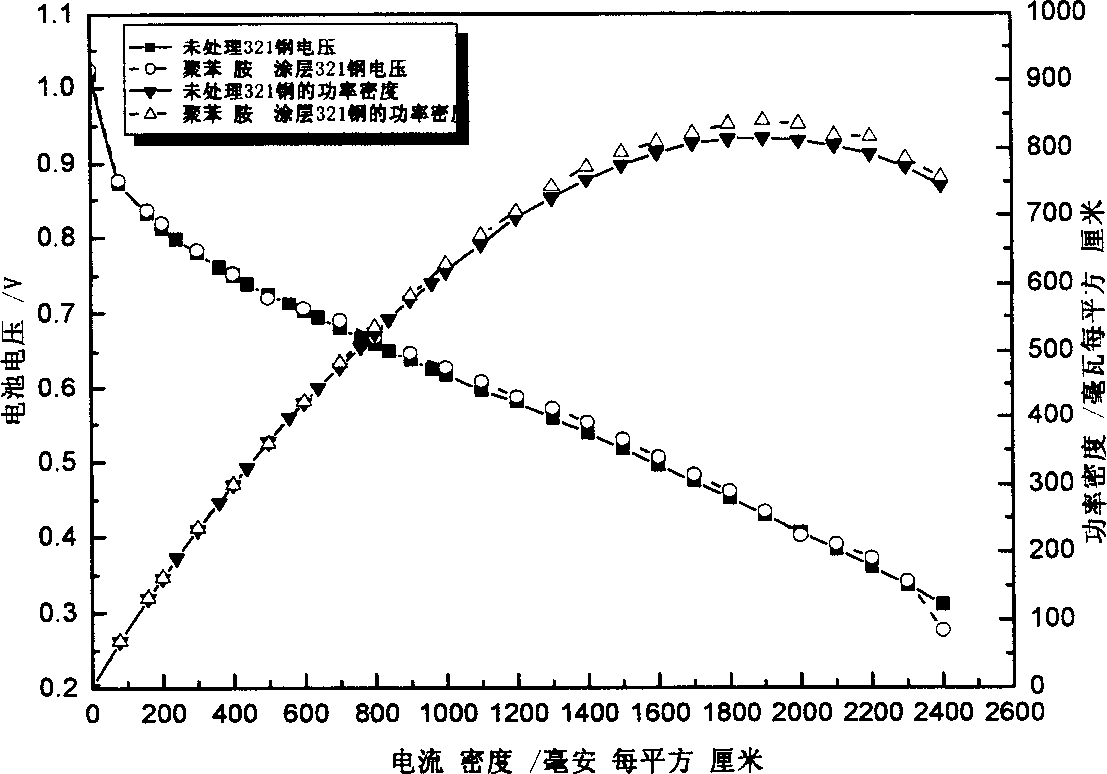

Method for modifying proton exchange membrane fuel cell metal dual-polarity board

ActiveCN1770521APerformance is not affectedIncreased corrosion potentialCell electrodesPolymer scienceConductive polymer

This invention relates to one photon exchange film fuel battery process technique and in detail to one improvement method on the double electrode board, which Adopts three electrode system and integrates into modified electrode board by the electrochemical technique on the metal surface polymer to make the polymer single is ofaniline or thiofuran or pyrrole. The modification process comprises the following steps: putting the metal board into the liquid of oxalic acid, dipping acid or Fraude's reagent and polymer single liquid; using metal board as work electrode and carbon board as couple electrode and saturated calomel electrode as reference electrode. The invention modifies the metal board to realize the metal double board functions of anti-erosion.

Owner:SUNRISE POWER CO LTD

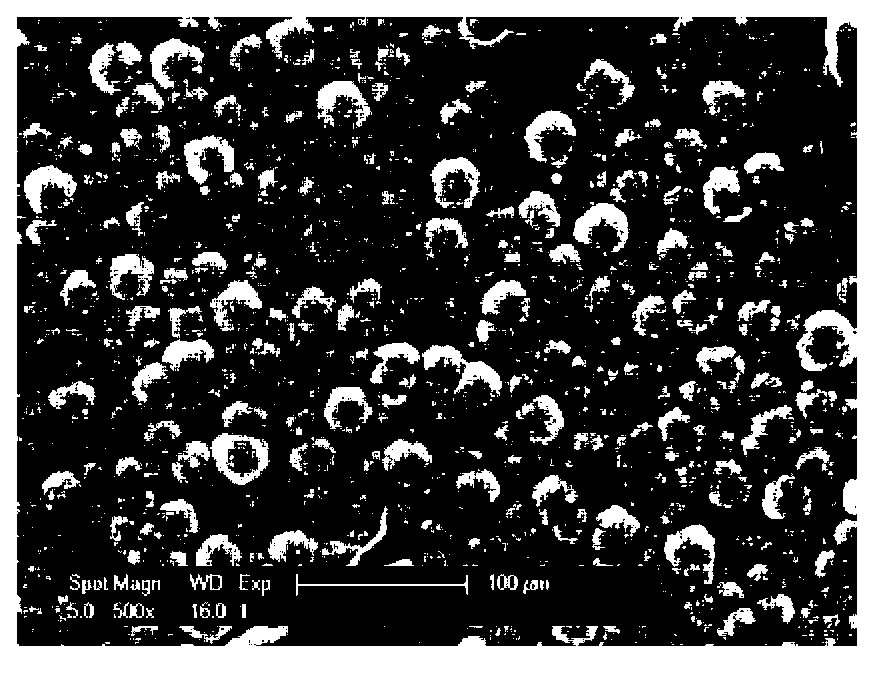

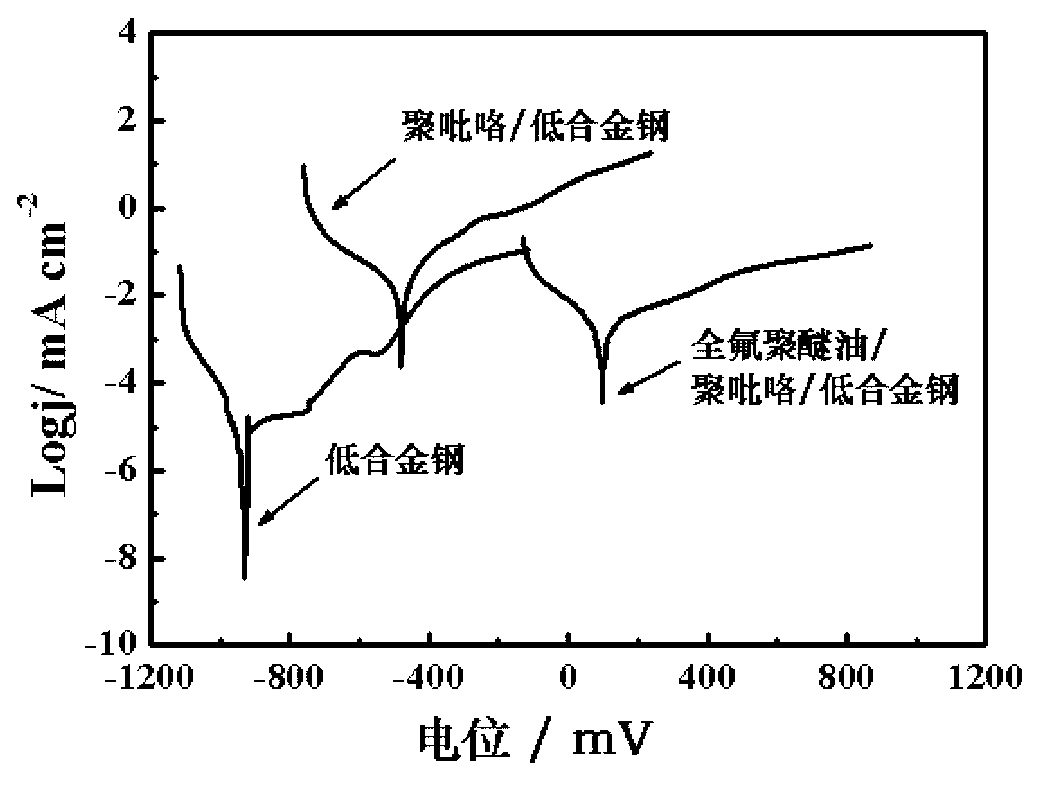

Method for preparing conducting polymer-perfluoropolyether oil complex phase coating

InactiveCN103255465AImprove hydrophobicityImprove anti-corrosion performanceElectrophoretic coatingsPolypyrroleConductive polymer

The invention belongs to the field of conducting polymer anticorrosive coating material preparation and relates to a method for preparing a conducting polymer-perfluoropolyether oil complex phase coating. The method comprises the following steps of: firstly adding distilled water or deionized water to a pyrrole monomer and a surfactant and stirring until the pyrrole monomer and the surfactant are completely dissolved to obtain an electrolyte solution A; then carrying out constant potential polymerization on a working electrode in the electrolyte solution A, taking the working electrode out of the electrolyte solution A, repeatedly washing the working electrode by use of the distilled water or the deionized water, and drying the working electrode to obtain a polypyrrole / low alloy steel composite material B; then after processing the polypyrrole / low alloy steel composite material B by virtue of a fluridizer, standing the polypyrrole / low alloy steel composite material B in a dryer to obtain a composite material C with the hydrophobic surface; and finally carrying out impregnation processing on the composite material C by perfluoropolyether oil to obtain the conducting polymer-perfluoropolyether oil complex phase coating on the surface of the working electrode. The preparation process is simple, the preparation principle is scientific, and the prepared conducting polymer-perfluoropolyether oil complex phase coating has the advantages of high hydrophobic property, good antiseptic property and good environmental stability.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Bidirectional electroosmosis repairing method of corrosive concrete structure

InactiveCN102653990AIncreased durabilityIncrease the precipitation rateBuilding repairsBuilding reinforcementsRebarProtection layer

The invention discloses a bidirectional electroosmosis repairing method of a corrosive concrete structure. The method comprises the following steps of: injecting a corrosion inhibitor into electrolyte; with the steel bar in the concrete as a cathode, paving a stainless steel net on the concrete surface as an anode; immersing the anode into the electrolyte containing the corrosion inhibitor; applying DC (direct current) power between the anode and cathode, and controlling the applied current density to be 1-5A / m<2> based on the total surface area of the steel bar; and cutting off the power 10-20 days later. The method disclosed by the invention is convenient to operate, improves the moving ability of the cationic corrosion inhibitor, and can enable the corrosion inhibitor to enter the steel bar surface through electroosmosis in relatively short time; through the invention, the chloride ions in a concrete protection layer can be effectively removed, and the precipitation rate of chloride ions is high; and moreover, the corrosion potential of the corroded steel bar is increased, the corrosion rate is reduced, re-passivation is realized, the salt-damaged concrete structure is repaired to the greatest degree, and the service life of the structure is prolonged according to the expected requirements.

Owner:GUANGSHA CONSTR GROUP +1

Environment friendly anti-corrosive paint and preparation thereof

InactiveCN101497755AIncreased corrosion potentialCorrosion current reductionAnti-corrosive paintsEpoxy resin coatingsAmmonium sulfateMagnesium

The invention discloses environmental-friendly anti-corrosive polyaniline paint which has high content of polyaniline, good anti-corrosion performance and low cost, causes no pollution and is suitable for preventing steel, magnesium and other metals from being corroded. The environmental-friendly anti-corrosive polyaniline paint contains component A and component B which have the weight ratio of 7:1 to 17:1, wherein the component A contains the following components according to the portion by weight: 40-80 portions of liquid epoxy resin, 4-40 portions of plasticizing agent, 0.1-4 portion(s) of emulsifying agent OP-10, 4-10 portions of small-molecular fatty alcohol, 0.1-15 portion(s) of ammonium persulfate, 0.1-3 portion(s) of distilled water, 0.1-2 portion(s) of 0.4-0.8mol / L camphorsulfonic acid solution, 0.1-16 portion(s) aniline, 0.5-1 portion of defoaming agent and 4-20 portions of reactive diluent.

Owner:SHANDONG UNIV

Method for carrying out electrochemical treatment on surface of biomedical magnesium or magnesium alloy with high biological activity and low degradation rate

InactiveCN104694994AAccelerated corrosionImprove biological activityAnodisationElectrolytic inorganic material coatingCalcium phosphate coatingMicro arc oxidation

The invention relates to a method carrying out electrochemical treatment on the surface of a biomedical magnesium or magnesium alloy with high biological activity and a low degradation rate. The method mainly solves the problem that an existing biomedical magnesium or magnesium alloy is low in biological activity and high in corrosion rate in human body fluid. The method comprises the steps of pretreating a base material, treating the base material in a micro-arc oxidation mode, treating micro-arc oxide magnesium in an electro-deposition mode, and covering the surface of the material with a calcium phosphate coating. The method is used for treating the surface of the biomedical magnesium or magnesium alloy.

Owner:HARBIN INST OF TECH

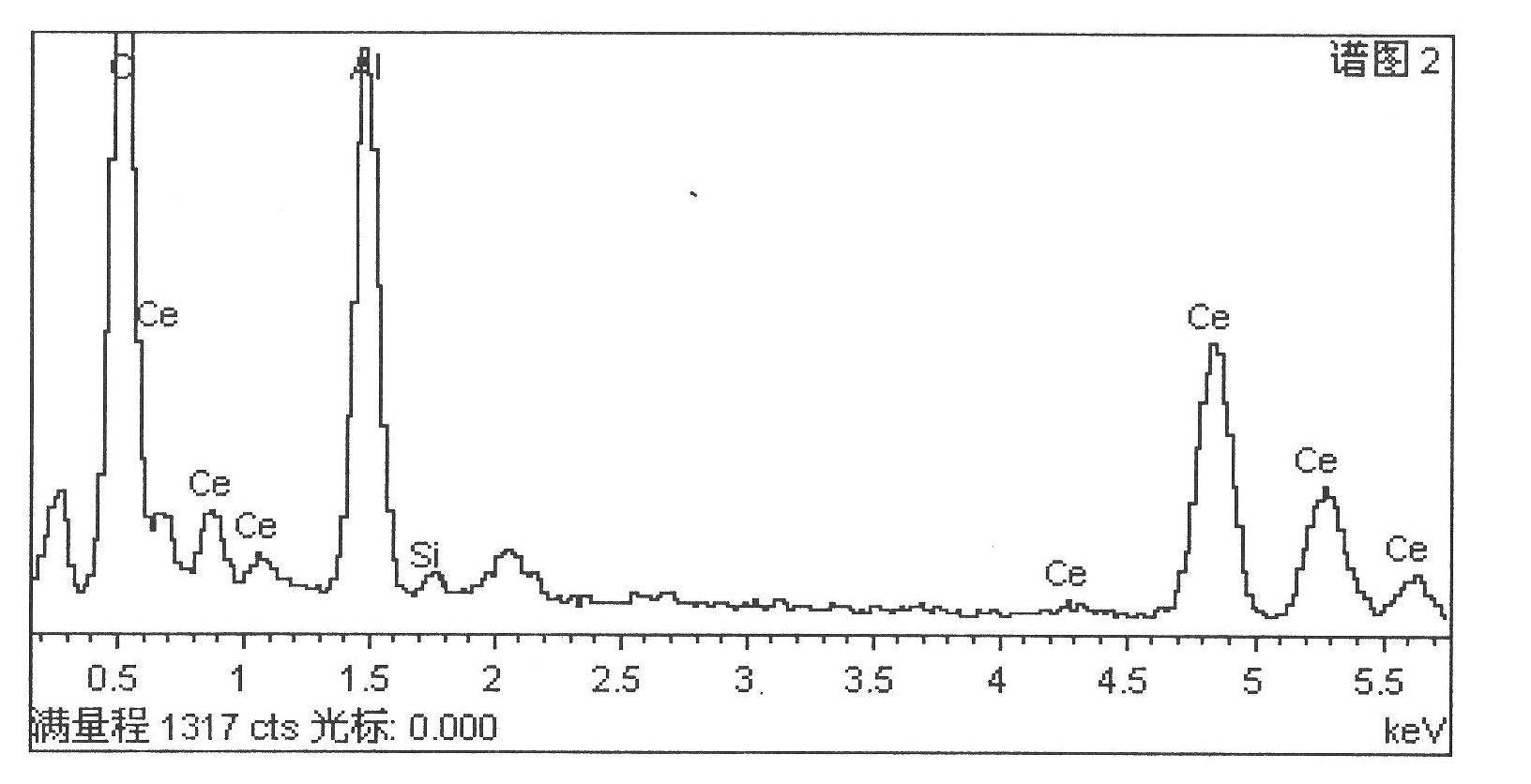

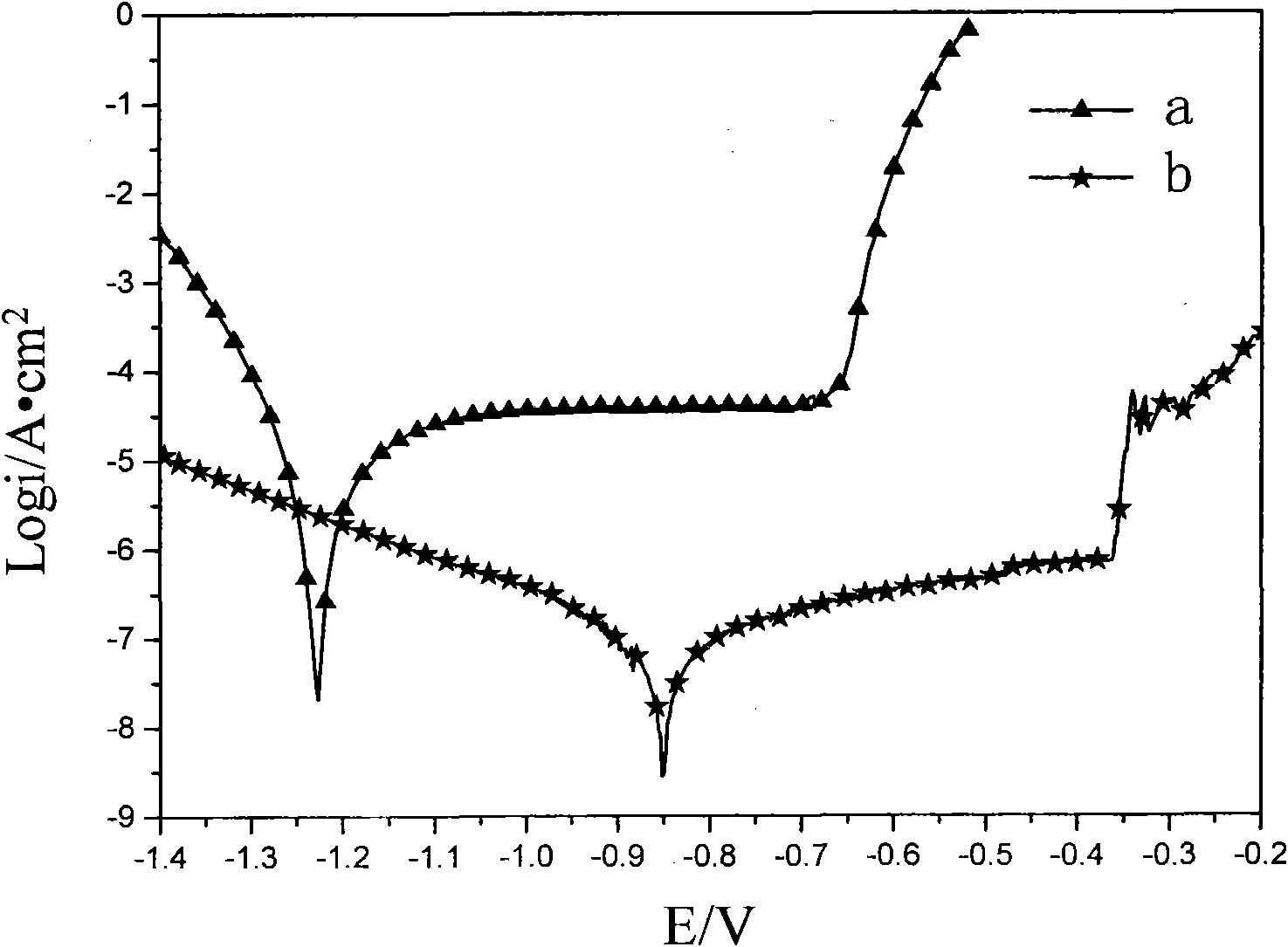

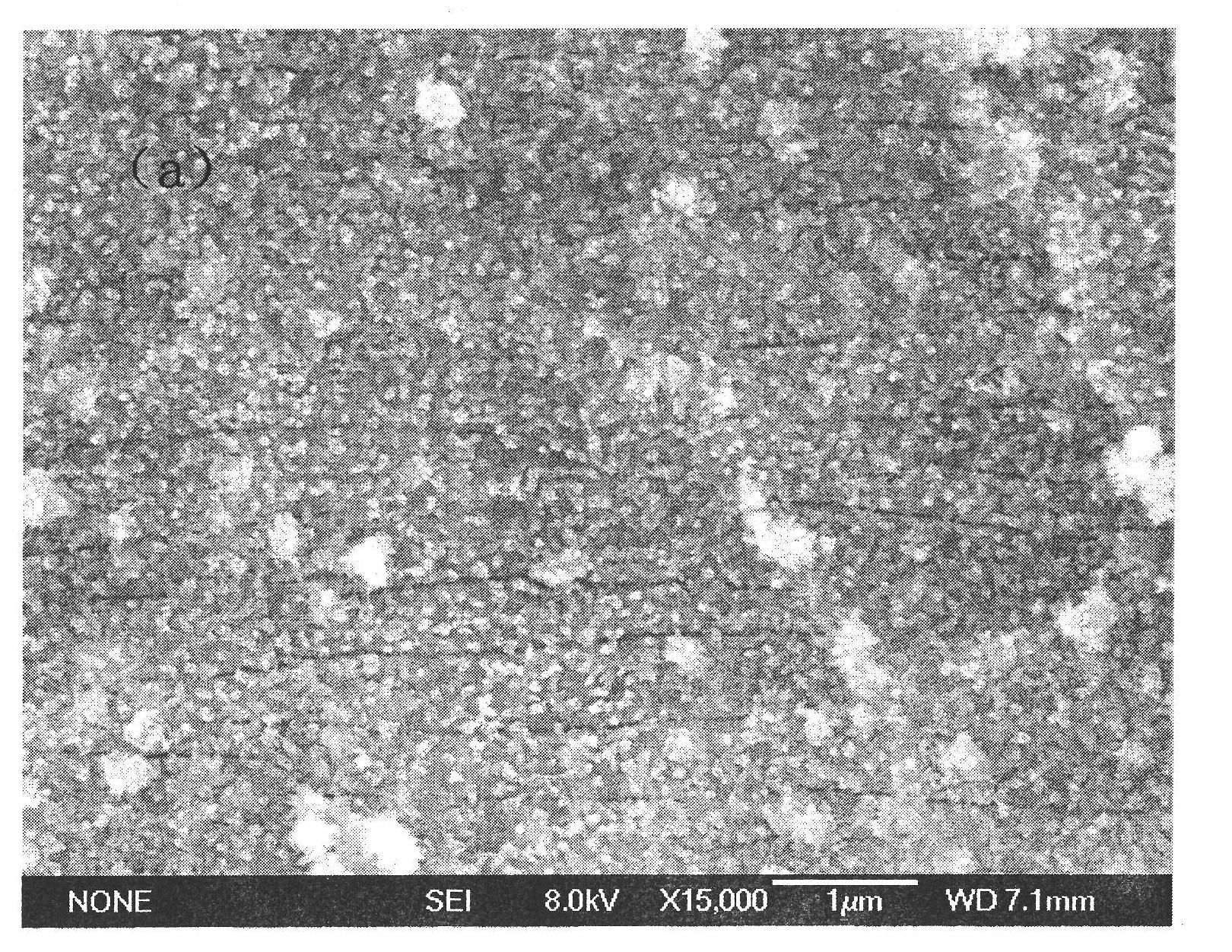

Preparation process of cerium-doped silicon corrosion-resisting membrane on surface of aluminium alloy

InactiveCN102021554AIncreased corrosion potentialImprove corrosion resistanceMetallic material coating processes5052 aluminium alloyCe element

The invention relates a preparation process of a cerium-doped silicon corrosion-resisting membrane on a surface of aluminium alloy. The preparation process is characterized in that surface pretreatment is carried out on aluminium alloy, and then the aluminium alloy is immersed in cerium salt conversion liquid dissolved with organosilicon, so as to carry out membrane formation reaction on the surface of the aluminium alloy, thus the corrosion-resisting membrane is formed; and then the aluminium alloy is taken out, is cleaned by deionized water and is dried. The invention has the advantages that the process is simple, the membrane formation speed is rapid, the preparation time of the corrosion-resisting membrane is shortened, the main constituents of the corrosion-resisting membrane layer are cerium dioxide and hydrated cerium oxide, and the uniformity and compactness of the surface of the membrane are good. After the cerium-doped silicon corrosion-resisting membrane is formed on the surface of the aluminium alloy, the corrosion resistance of the aluminium alloy is improved remarkably.

Owner:OCEAN UNIV OF CHINA

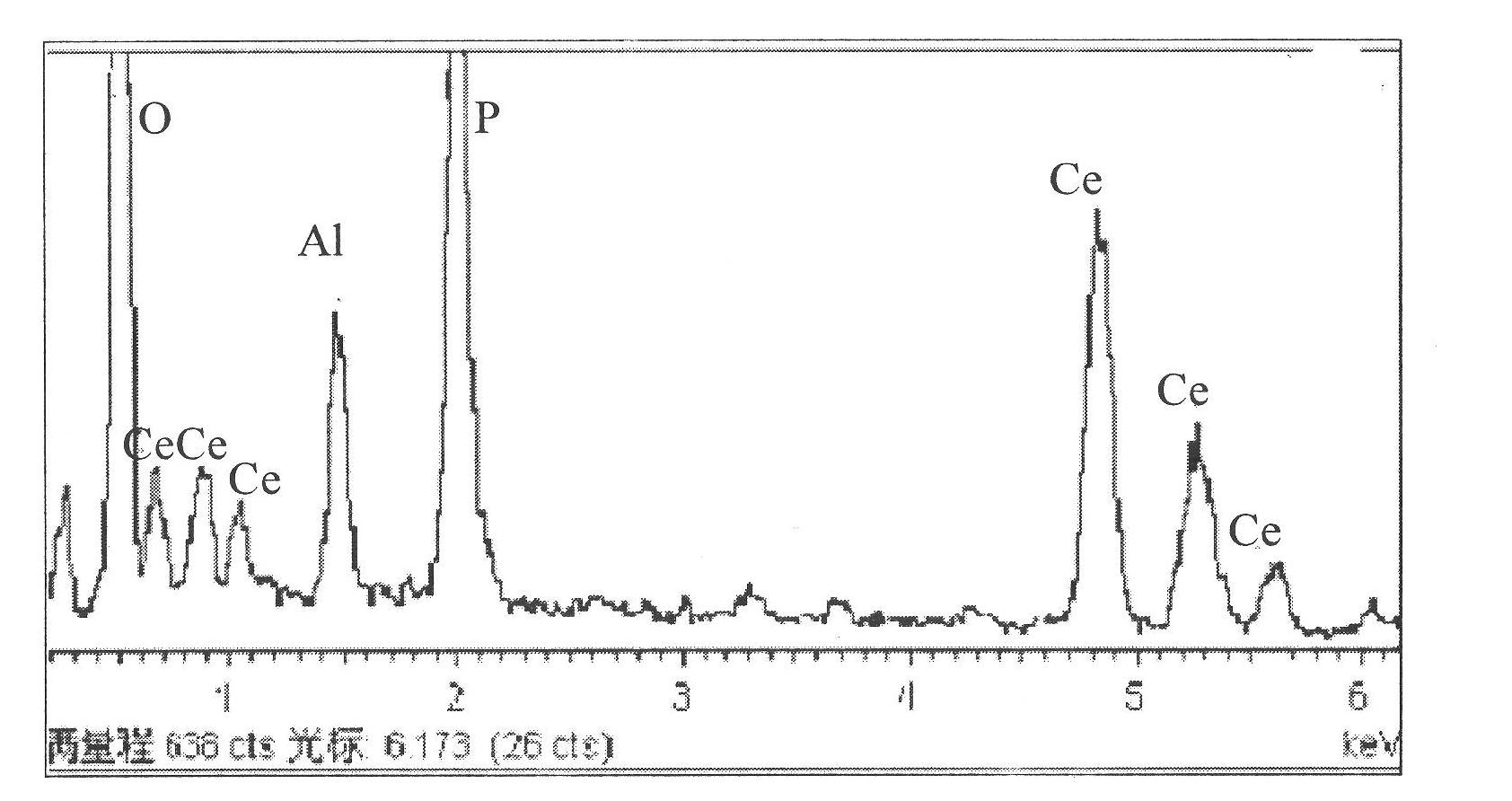

Technique for preparing cerium corrosion-resistant film on surface of aluminum alloy

InactiveCN102108507AImprove corrosion resistanceFast film formationMetallic material coating processesAfter treatmentPhosphate

The invention relates to a technique for preparing a cerium corrosion-resistant film on the surface of aluminum alloy, which is characterized by comprising the following steps: carrying out surface pretreatment on aluminum alloy; immerging the aluminum alloy in a cerium salt conversion liquid to form a film; taking out the aluminum alloy, washing with deionized water, and immerging the aluminum alloy in a phosphate water solution to carry out after-treatment; and washing with deionized water, and drying. The invention has the advantages of high film-forming speed and high deposition rate, and effectively shortens the reaction time. The prepared corrosion-resistant film mainly comprises quadrivalent phosphates of cerium, and the film is uniform and compact; and after the cerium corrosion-resistant film is formed on the surface of the aluminum alloy, the corrosion resistance of the aluminum alloy is obviously enhanced.

Owner:OCEAN UNIV OF CHINA

Biomimetic mineralization method for preparing magnesium alloy-calcium phosphate coating composite material

InactiveCN102776499AAccelerated corrosionGood biocompatibilityMetallic material coating processesAcid etchingCalcium phosphate product

The invention relates to a biomimetic mineralization method for preparing a magnesium alloy-calcium phosphate coating composite material. The method comprises single preprocessing, acid etching preprocessing, bionic solution configuration, immersing in the bionic solution and the like to obtain the magnesium alloy-calcium phosphate coating composite material. Compared with other magnesium alloy-calcium phosphate coating composite materials, a magnesium alloy base body is firstly subjected to acid etching preprocessing, so that the calcium phosphate coating and the surface of the base body can be combined well; and the calcium-phosphate ratio of the bionic solution is 1.67:1, besides, the content of the calcium and the phosphate is higher than that of ordinary bionic solutions in the prior art, the biomimetic mineralization efficiency can be improved remarkably, and the calcium phosphate products are similar to human bone components and have good biocompatibility and corrosion resistance.

Owner:TONGJI UNIV

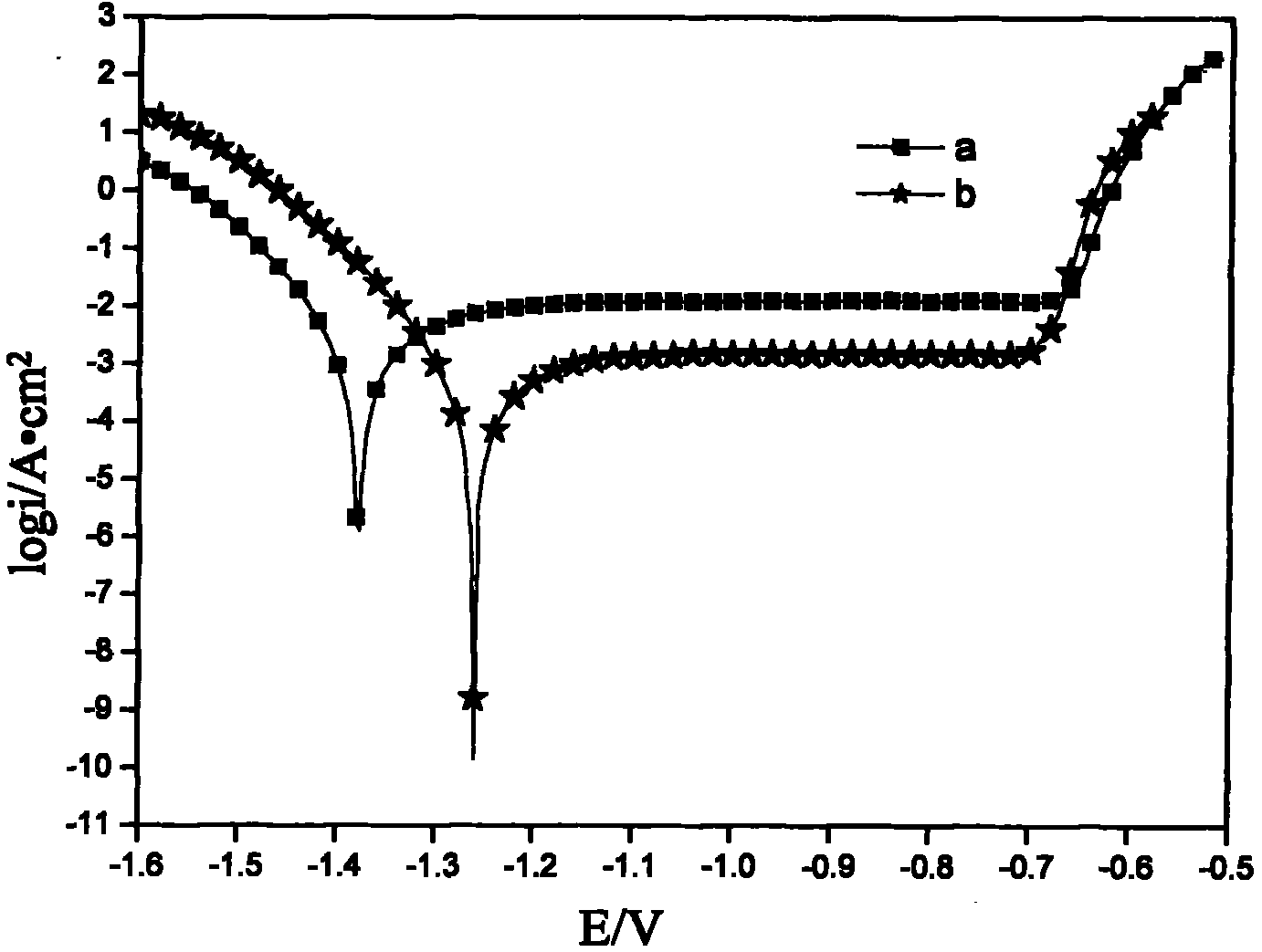

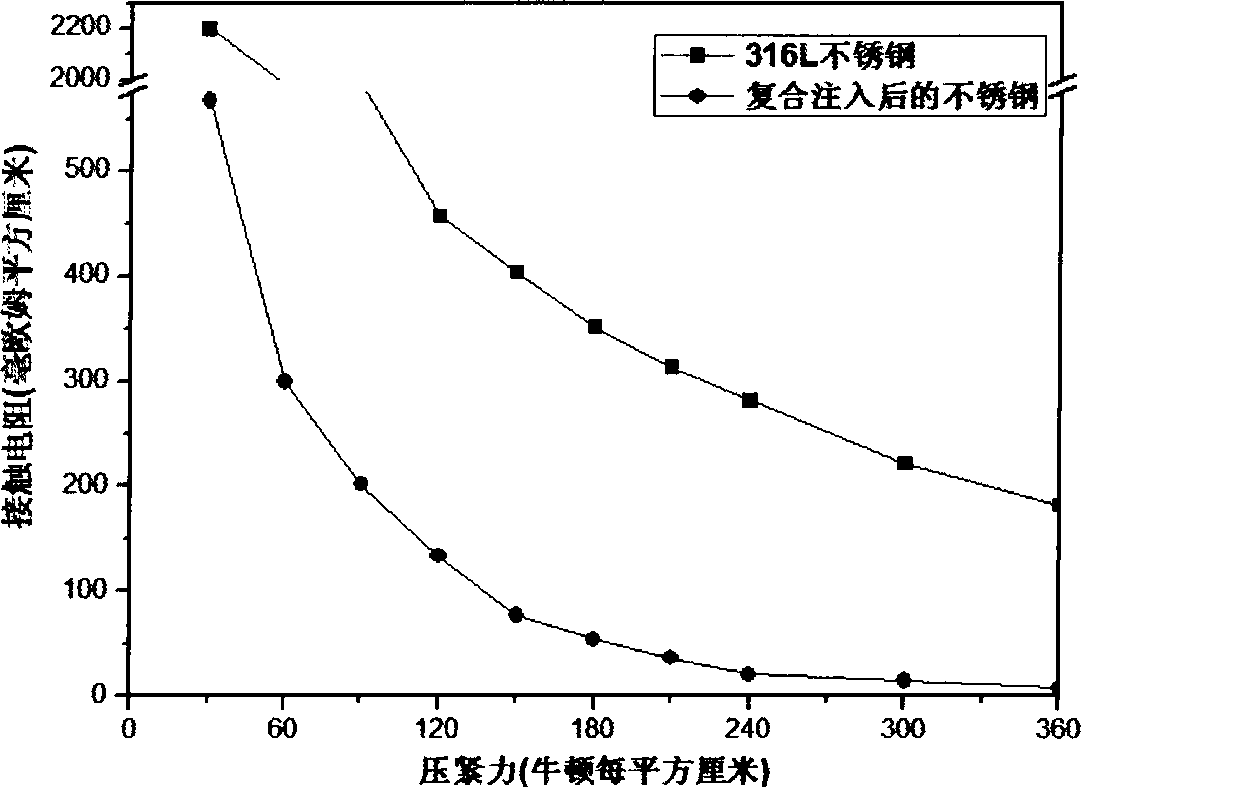

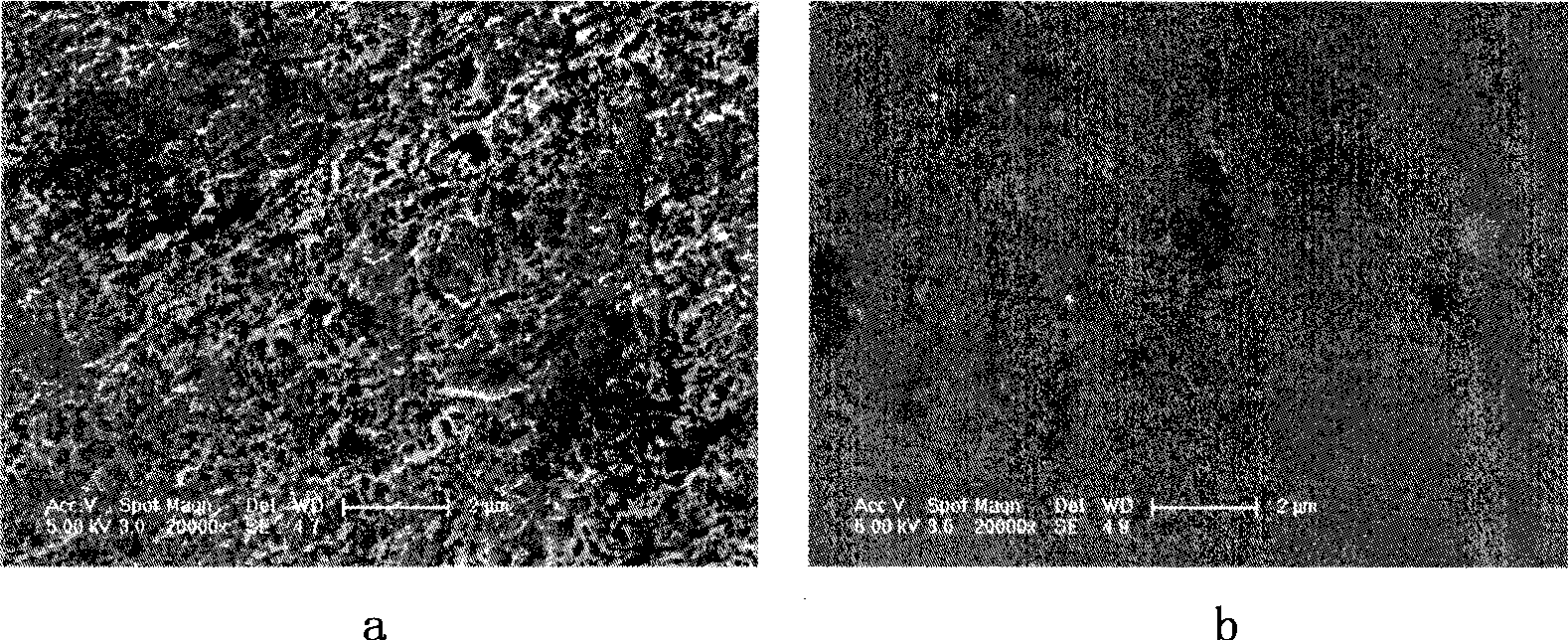

Composite ion injection method for dual polar plates of proton exchange membrane fuel cell

InactiveCN101393990AReduce material costsPrevent thermal reboundCell electrodesCollectors/separatorsCopperIon implantation

The invention relates to a method for injecting compound ions of a bipolar plate of a proton exchange membrane fuel cell in the technical field of fuel cells. The bipolar plate is composed of a surface modification layer and substrate stainless steel. By adopting the method of the ion injection, the ions in arbitrary combination of two elements of nickel, chromium and copper or of all three elements are injected into a stainless steel thin plate, and an injection layer is formed on the surface of the stainless steel thin plate within the range of dozens of nanometer, so as to obtain a modified stainless steel bipolar plate. The invention has the advantages that the corrosion resistance performance of a metallic bipolar plate can be further improved, the contact resistance of the metallic bipolar plate with a gas diffusion layer (carbon paper) can be reduced, a thinner bipolar plate can be produced, and the weight ratio energy and the volume ratio energy of a fuel cell can be increased, so as to satisfy the development requirement on the proton exchange membrane fuel cell.

Owner:SHANGHAI JIAO TONG UNIV

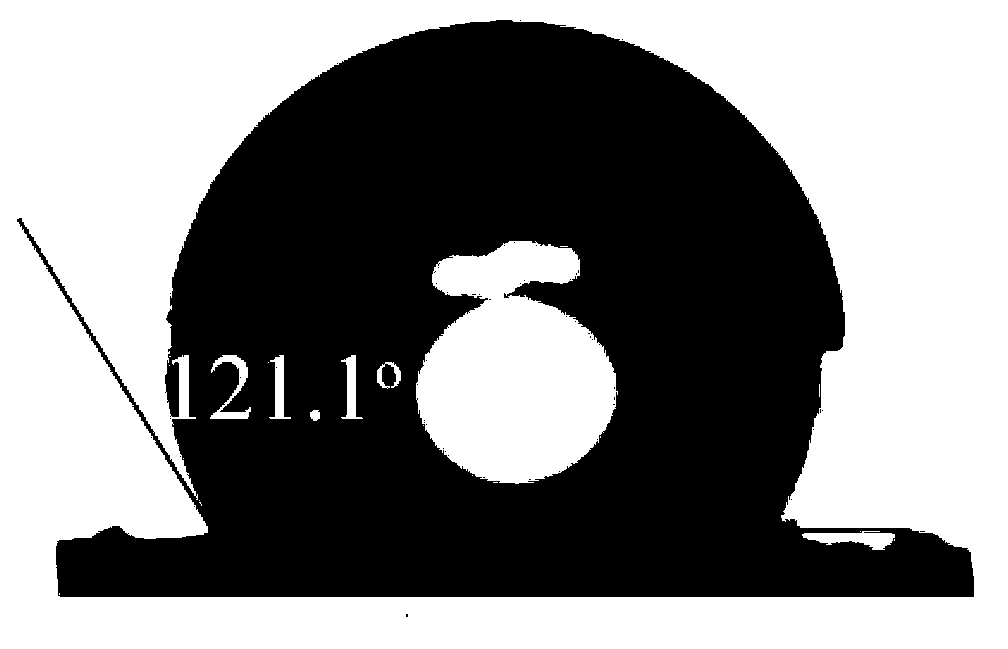

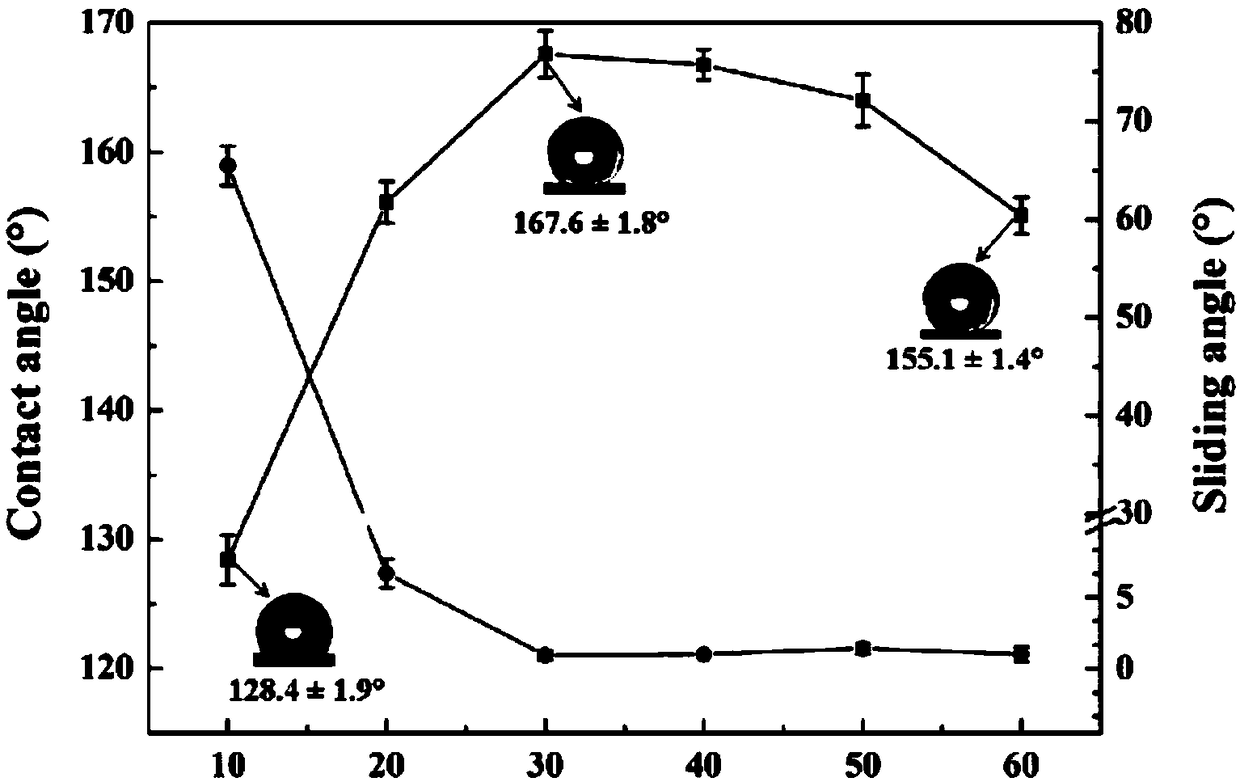

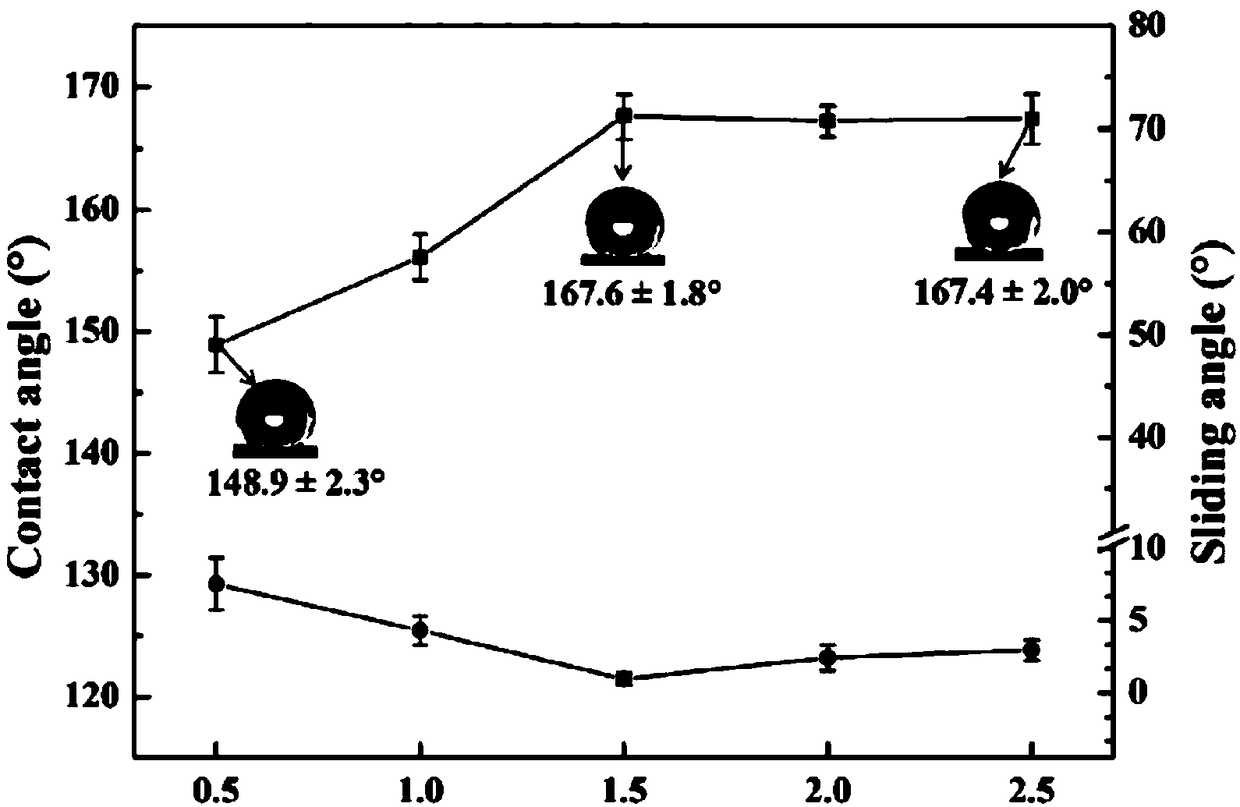

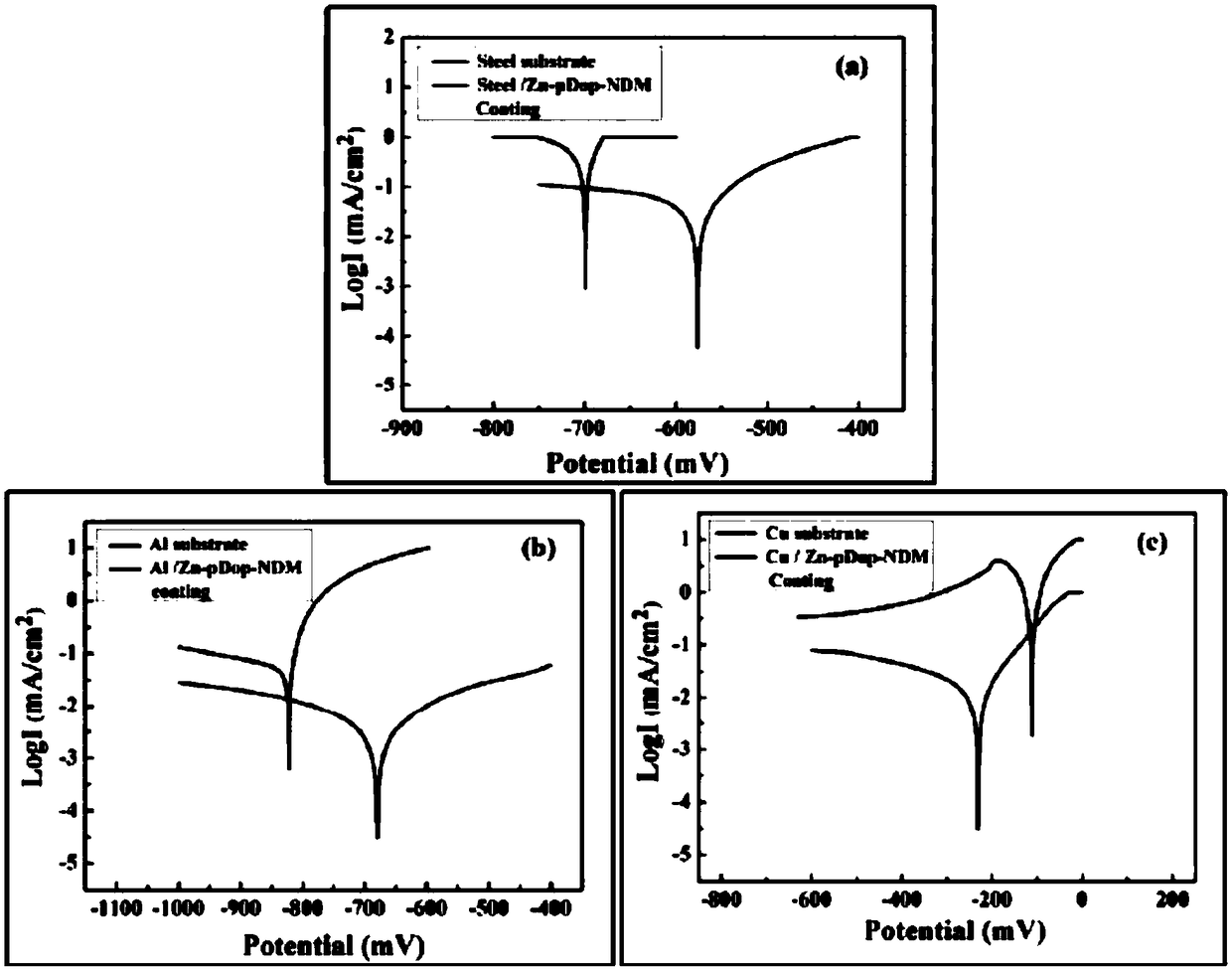

Method for preparing super-hydrophobic coating based on electrodeposition method, and application of super-hydrophobic coating

InactiveCN109355689AIncreased corrosion potentialCorrosion current reductionElectrolytic coatingsTowersAluminium powderPre treatment

The invention relates to a method for preparing a super-hydrophobic coating, in particular to a method for preparing a super-hydrophobic coating based on an electrodeposition method, and the application of the super-hydrophobic coating to the corrosion prevention of a power grid, and belongs to the technical field of super-hydrophobic coatings. The method for preparing the super-hydrophobic coating based on the electrodeposition method comprises the following step I of electrode pretreatment: grinding a steel electrode on abrasive paper, and then cleaning the steel electrode ground properly with deionized water made by a laboratory; then, performing polishing treatment with aluminium powder for further removing large oil stains; and next, rewashing the steel electrode with the deionized water made by the laboratory. The method has the beneficial effects that the super-hydrophobic coating is prepared with the electrodeposition method, and applied to the corrosion prevention of the powergrid; the corrosion potential is increased and the corrosion current is reduced when the super-hydrophobic coating is used; it is proved that the corrosion resistance of the electrode with the coating is better than the corrosion resistance of the electrode without the coating, and the good corrosion resistance effect of the power grid is achieved.

Owner:SHANDONG INST OF BUSINESS & TECH

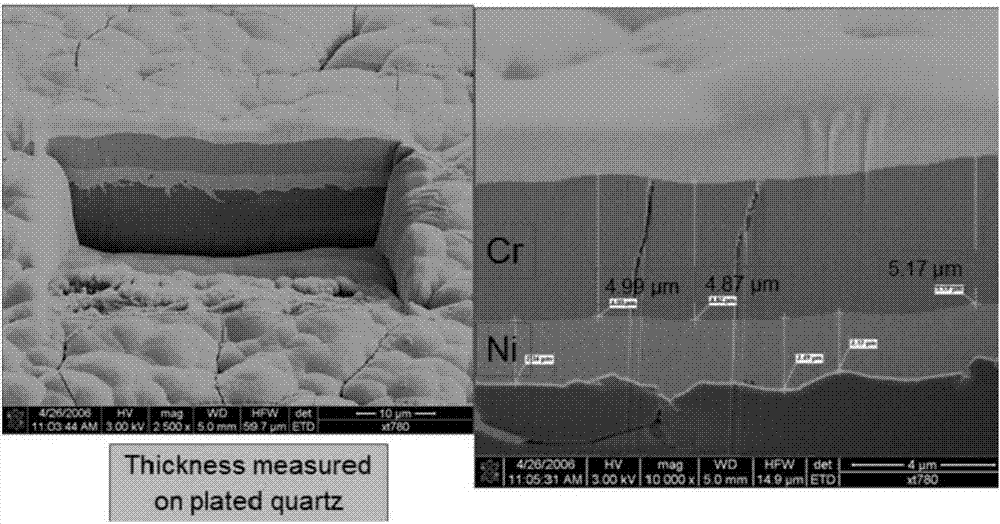

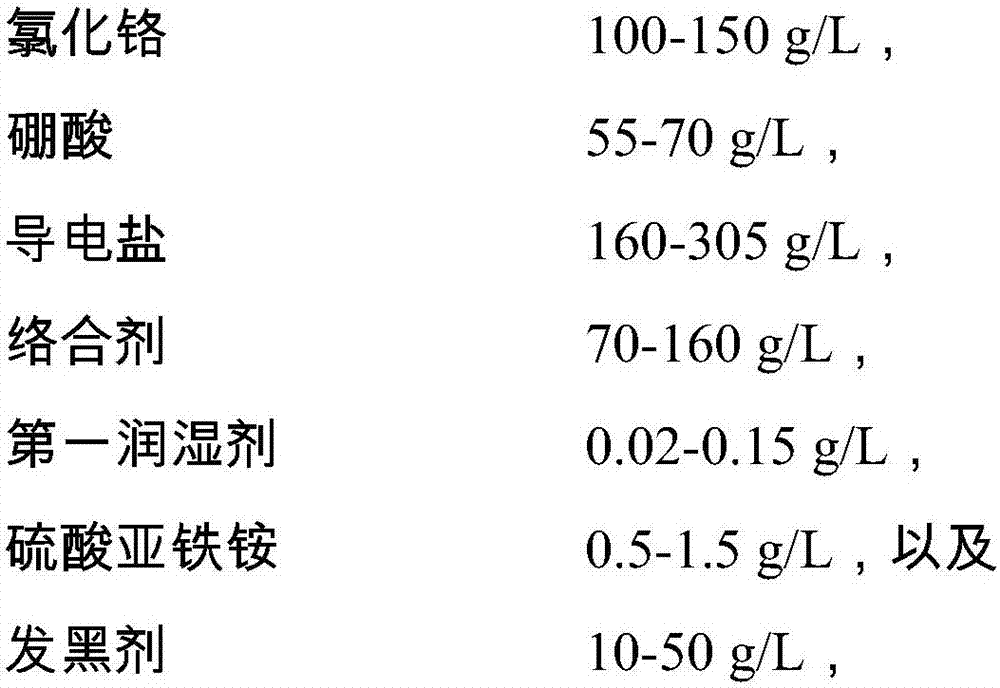

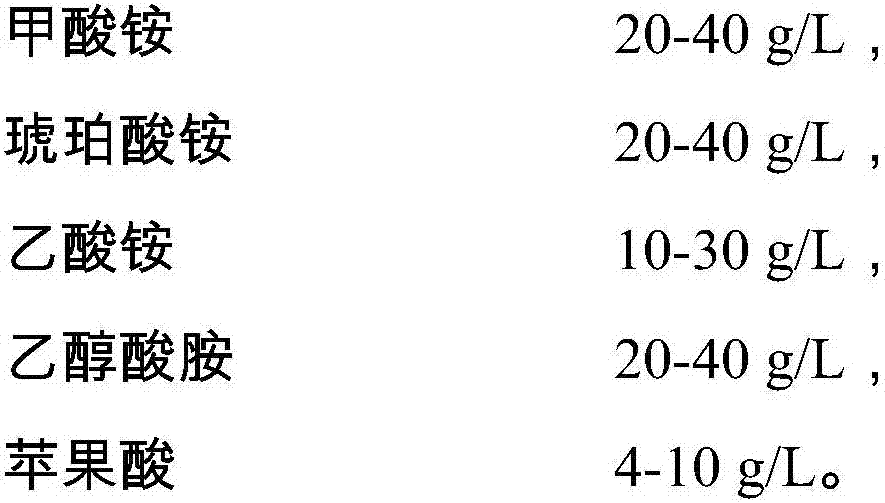

Black chromium plating solution, composite plating layer and preparing method thereof

ActiveCN107099824AUniform colorImprove coverage uniformityAmmonium ferrous sulfatePotassium thiocyanate

The invention relates to a black chromium plating solution, a composite plating layer and a preparing method thereof. The black chromium plating solution comprises water solutions of the following components of 100-150 g / L of chromic chloride, 55-70 g / L of boric acid, 160-305 g / L of conducting salt, 70-160 g / L of complexing agents, 0.02-0.15 g / L of wetting agents, 0.5-1.5 g / L of ammonium ferrous sulfate and 10-50 g / L of blackening agents, wherein the blackening agents are mixtures of methionine, potassium thiocyanate and aspartic acid. The trivalent black chromium plating layer formed by plating through the black chromium plating solution is in deep black, is strong in uniform covering capacity and can be matched with a bright copper layer, a semi-bright nickel layer, a bright nickel layer, a micro-porous nickel layer and a passivation film layer to enable the obtained composite plating layer to have high abrasion resistance and be in uniformly deep black.

Owner:SWELL MARUI GUANGZHOU AUTOMOBILE PARTS

Wear-resisting modified polysulfone coating

InactiveCN105038578ALow costReduce coefficient of frictionAnti-corrosive paintsEpoxy resin coatingsWaxDiethylenetriamine

The invention discloses a wear-resisting modified polysulfone coating which comprises the following components in part by weight: 50 to 60 parts of polysulfone resin, 10 to 20 parts of polytetrafluoroethylene resin, 5 to 15 parts of epoxy resin, 5 to 15 parts of modified polyaniline, 5 to 15 parts of nano silicon dioxide, 2 to 10 parts of kaolin, 1 to 10 parts of ferrotitanium powder, 2 to 10 parts of molybdenum disulfide, 2 to 10 parts of zinc phosphate, 1 to 8 parts of titanium dioxide, 10 to 20 parts of cyclohexanone, 1 to 5 parts of diethylenetriamine, 1 to 5 parts of amino resin, 1 to 5 parts of phenolic resin, 10 to 25 parts of ethanol, 1 to 3 parts of polyethylene wax, 0.3 to 1 part of benzoin, 1 to 2.5 parts of acrylic acid-2-ethylhexyl acrylate, 5 to 15 parts of water and 1 to 5 parts of silane coupling agent. The wear-resisting modified polysulfone coating provided by the invention has the advantages of excellent corrosion resistance, good antistatic property, ageing resistance and long service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Corrosion-resistant magnesium alloy

InactiveCN104264021ALow corrosion current densityReduce corrosion rateCorrosion resistantMetal alloy

The invention relates to the technical field of metal alloy materials, and particularly relates to corrosion-resistant magnesium alloy. The magnesium alloy comprises the following chemical components in percentage by mass: 6-9wt% of Al, 0.4-1.0wt% of Zn, 0.01-0.3wt% of Mn, 0.001-1.0wt% of V, and the balance of Mg. Due to addition of vanadium, the corrosion potential of the magnesium alloy is improved, the corrosion current density is lowered, the corrosion rate of the magnesium alloy is obviously lowered, and is just 52.81% of original alloy corrosion rate, and the corrosion resistance of the alloy is significantly improved.

Owner:河南德威科技股份有限公司

A corrosion-resistant magnesium alloy

InactiveCN104264021BIncreased corrosion potentialImprove corrosion resistanceMetal alloyCorrosion current density

Owner:河南德威科技股份有限公司

Composite protection method for magnesium-lithium alloy surface and special epoxy/nano SiO2 paint

InactiveCN101954348APlay the role of double protectionIncreased corrosion potentialPretreated surfacesMetallic material coating processesEpoxyOrganic film

The invention provides a composite protection method for a magnesium-lithium alloy surface and a special epoxy / nano SiO2 paint. The method comprises the following steps: synthesizing a novel epoxy / nano SiO2 paint; pretreating the surface of the magnesium-lithium alloy; carrying out phytic acid conversion on the surface of the magnesium-lithium alloy to form a phytic acid conversion film on the surface of the magnesium-lithium alloy; and coating and compounding the epoxy / nano SiO2 paint on the phytic acid conversion film of the magnesium-lithium alloy. The introduction of nano SiO2 is beneficial to improving the corrosion resistance of the epoxy paint. At the same time, the unimolecular organic film layer formed by phytic acid conversion and the coating formed from the epoxy / nano SiO2 paint have similar chemical properties, and the cohesive properties of the both are enhanced, thereby being beneficial to forming a stable and compact protective layer on the surface of the magnesium-lithium alloy to have a dual protection effect on the magnesium-lithium alloy and further improving the corrosion resistance of the magnesium-lithium alloy. Thus, the corrosion potential of the magnesium-lithium alloy is increased by 0.8-1.2VSCE, and the corrosion current is reduced by 4-6 orders of magnitude.

Owner:苏州嘉祥树脂有限公司

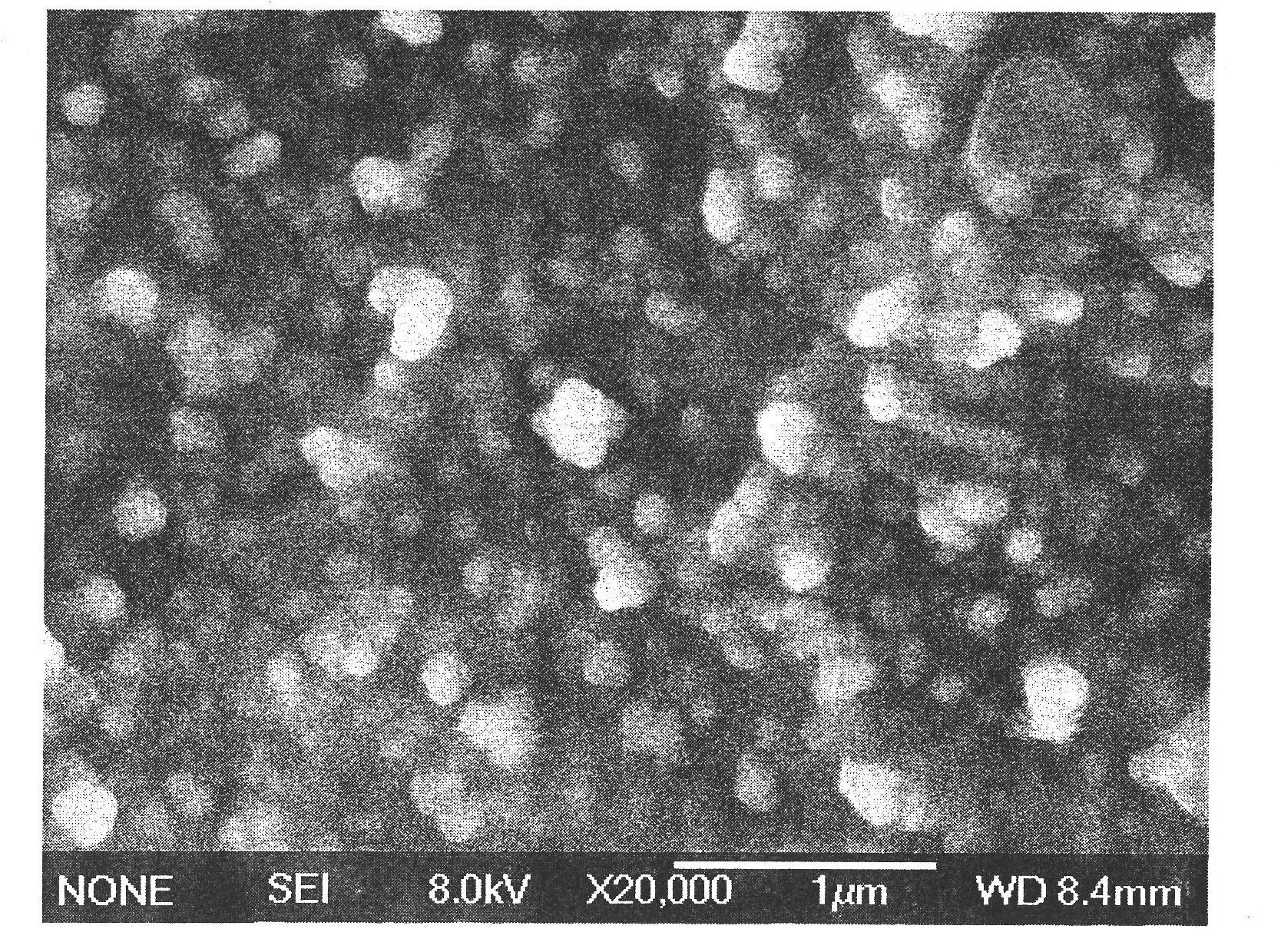

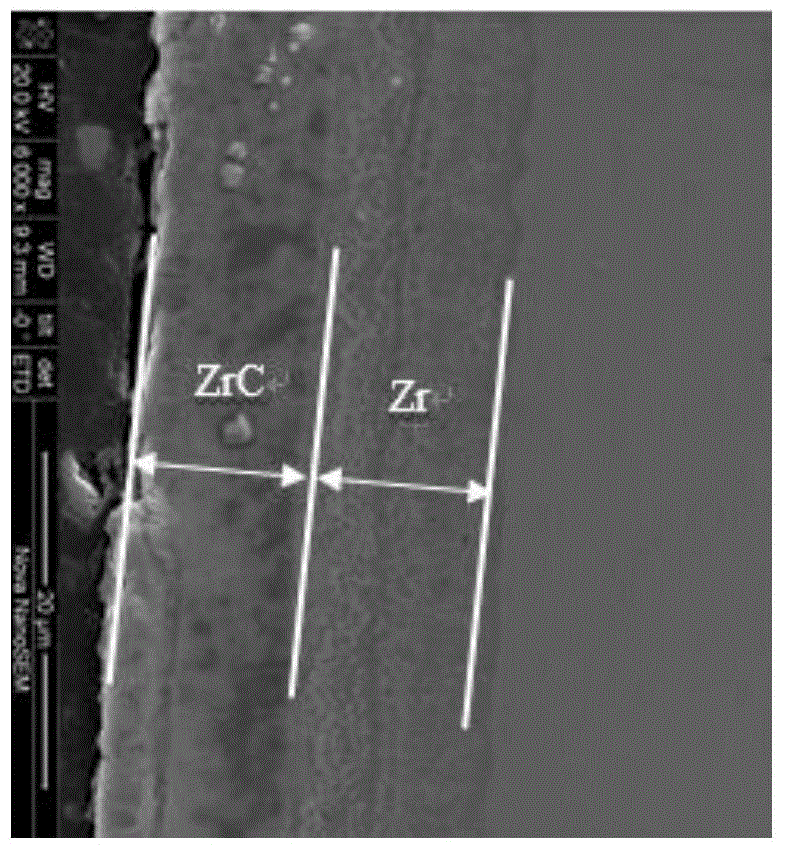

Nanocrystalline ZrC/Zr composite coating of metal bipolar plate of proton exchange membrane fuel cell and preparation method thereof

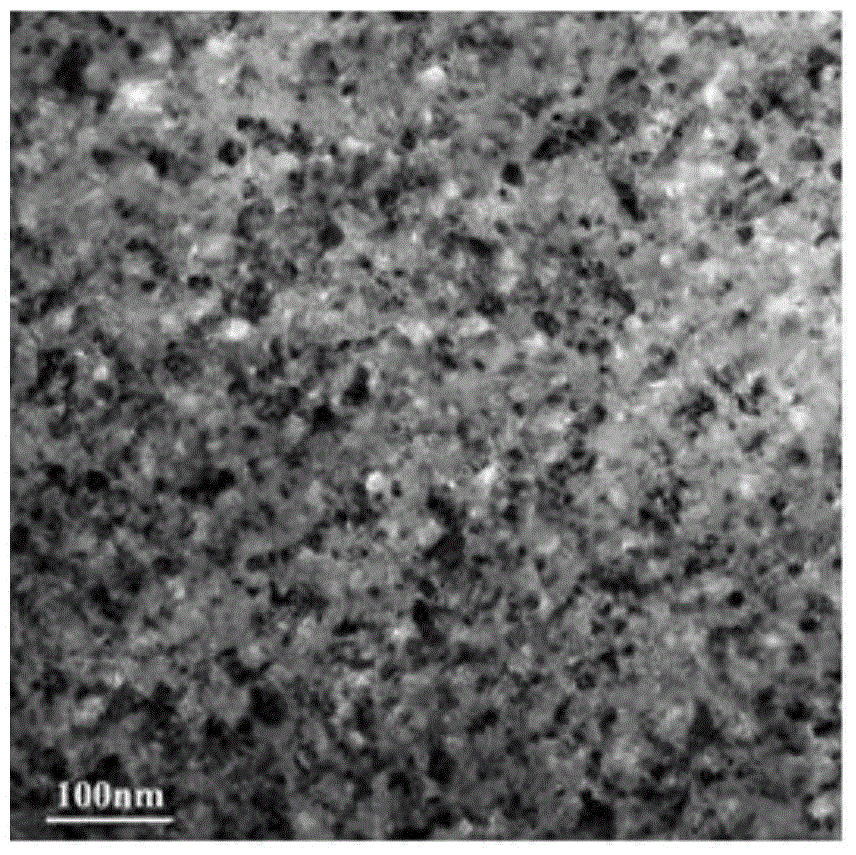

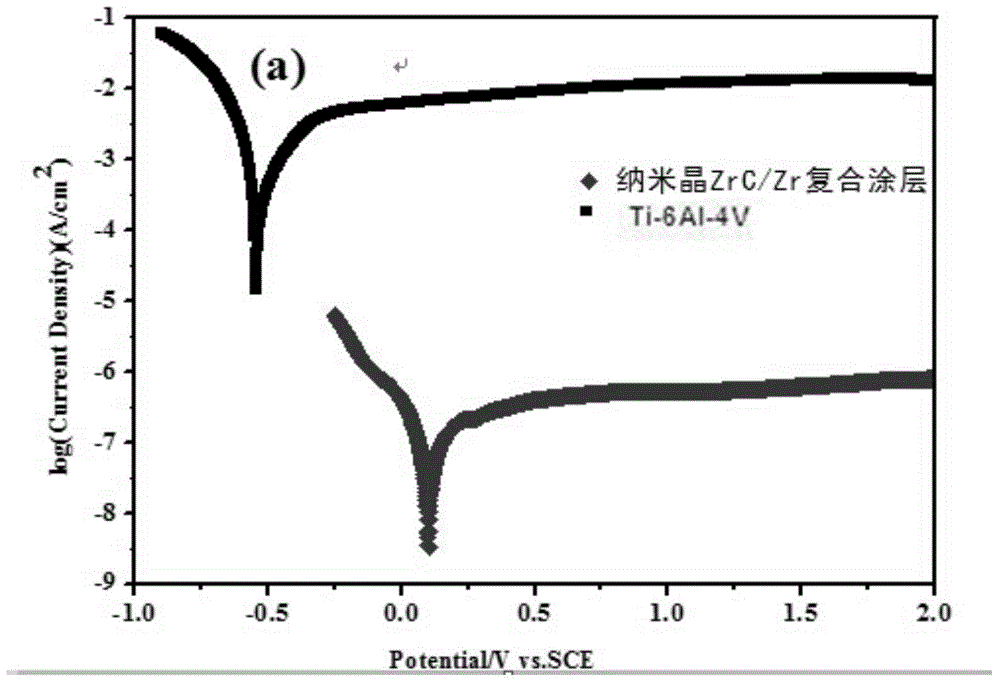

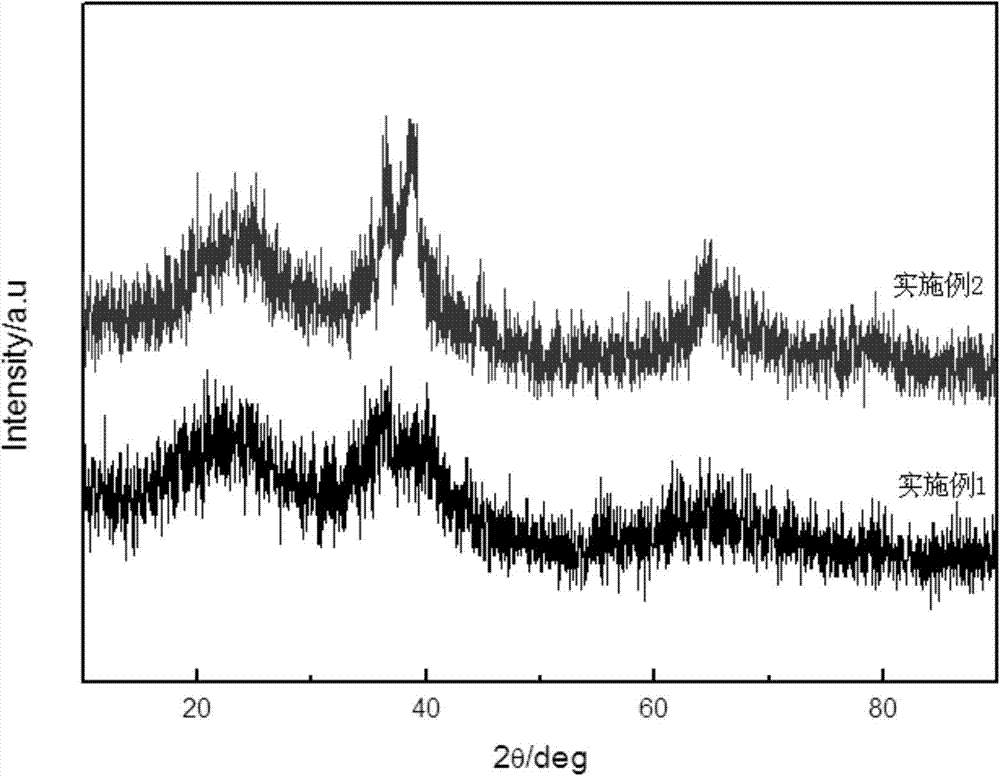

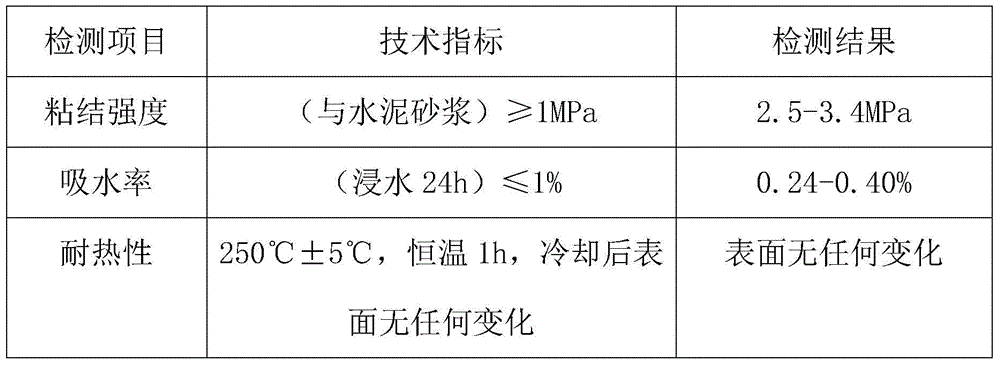

InactiveCN104611679AGood surface conductivityReduce contact resistanceVacuum evaporation coatingSputtering coatingAlloy substrateTitanium alloy

The invention belongs to the field of proton exchange membrane fuel cells, and relates to a nanocrystalline ZrC / Zr composite coating of a metal bipolar plate of a proton exchange membrane fuel cell and a preparation method thereof. Bicathode plasma sputtering deposition equipment is employed for sputtering the nanocrystalline ZrC / Zr composite coating on the surface of a titanium alloy bipolar plate used for the proton exchange membrane fuel cell. The coating is composed of an outer layer ZrC deposition layer and inner layers Zr deposition layer and diffusion layer; and the ZrC deposition layer is composed of equiaxial nanocrystalline ZrC with the average dimension of about 15-20 nm, the diffusion layer is formed by mutual diffusion of alloy elements of the Zr deposition layer and the titanium alloy bipolar plate, and the alloy elements in the diffusion layer show gradient distribution. The nanocrystalline ZrC / Zr composite coating possesses high density, has strong combination force with a titanium alloy substrate, has high corrosion resistance and low contact resistance when being in a proton exchange membrane fuel cell work environment, and is capable of satisfying usage requirements of a fuel cell bipolar plate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

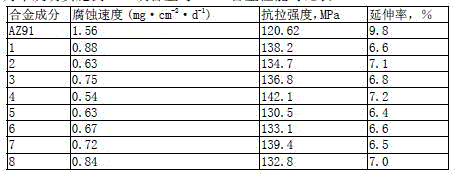

Laser cladding method for improving surface performance of magnesium alloy AZ91D

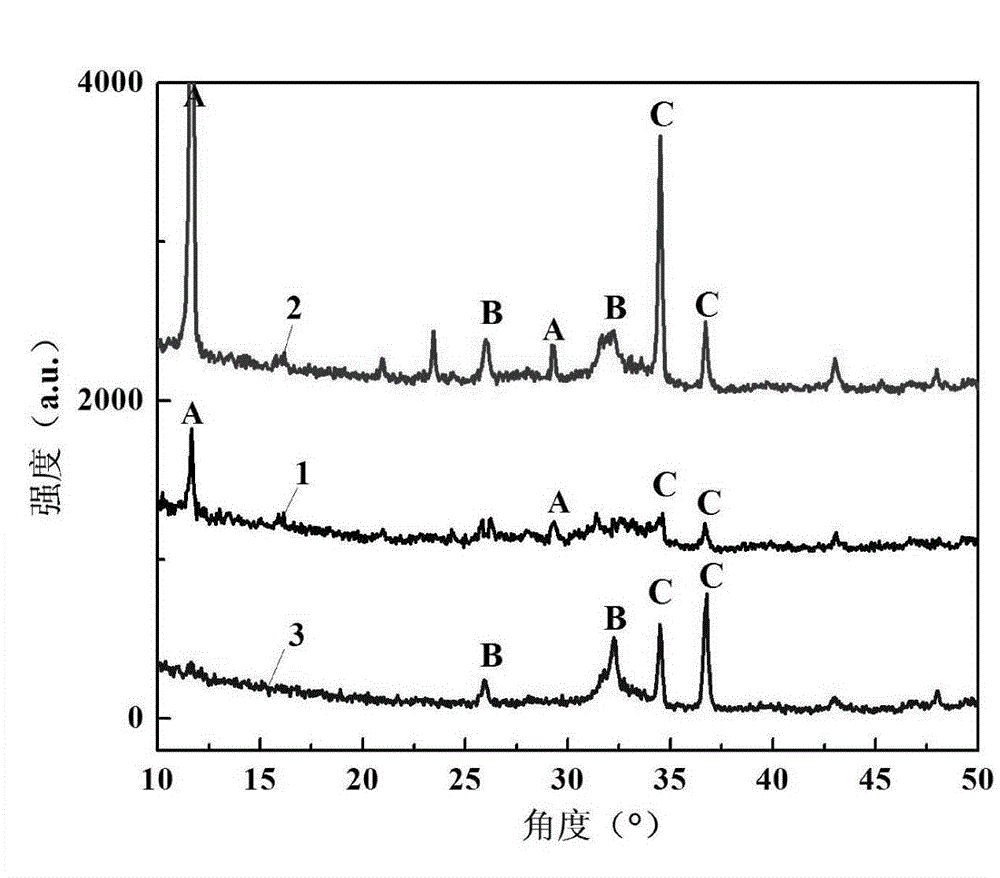

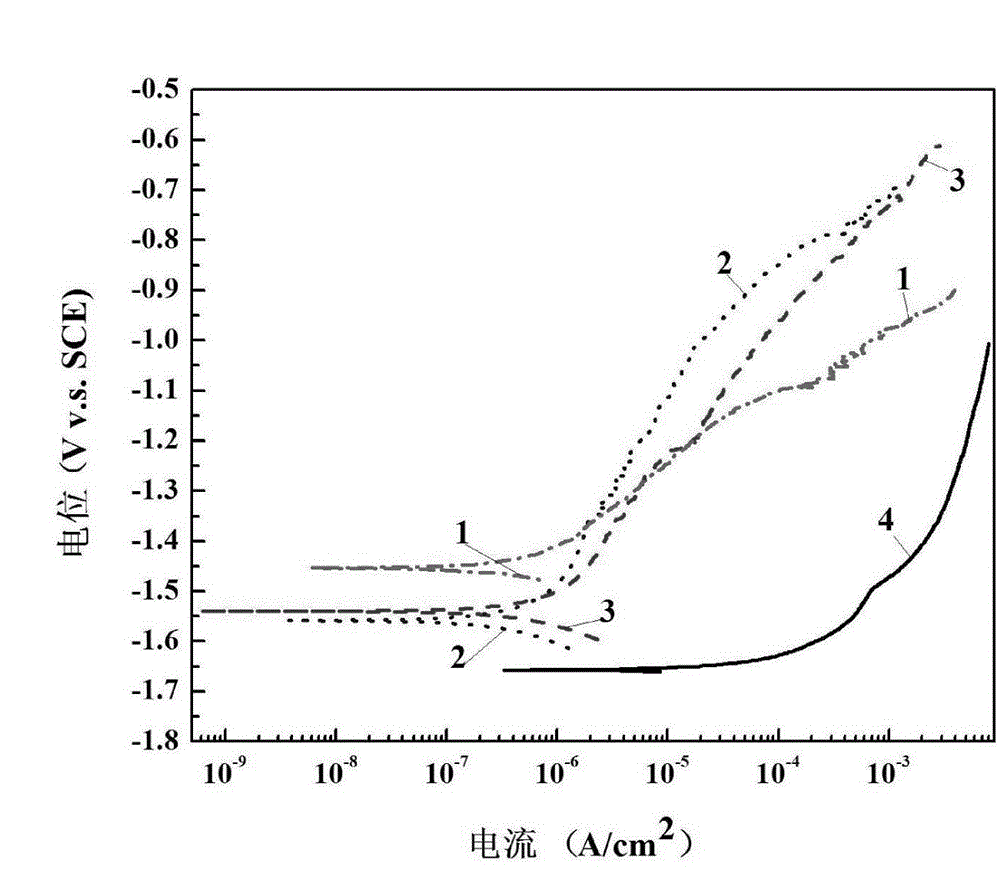

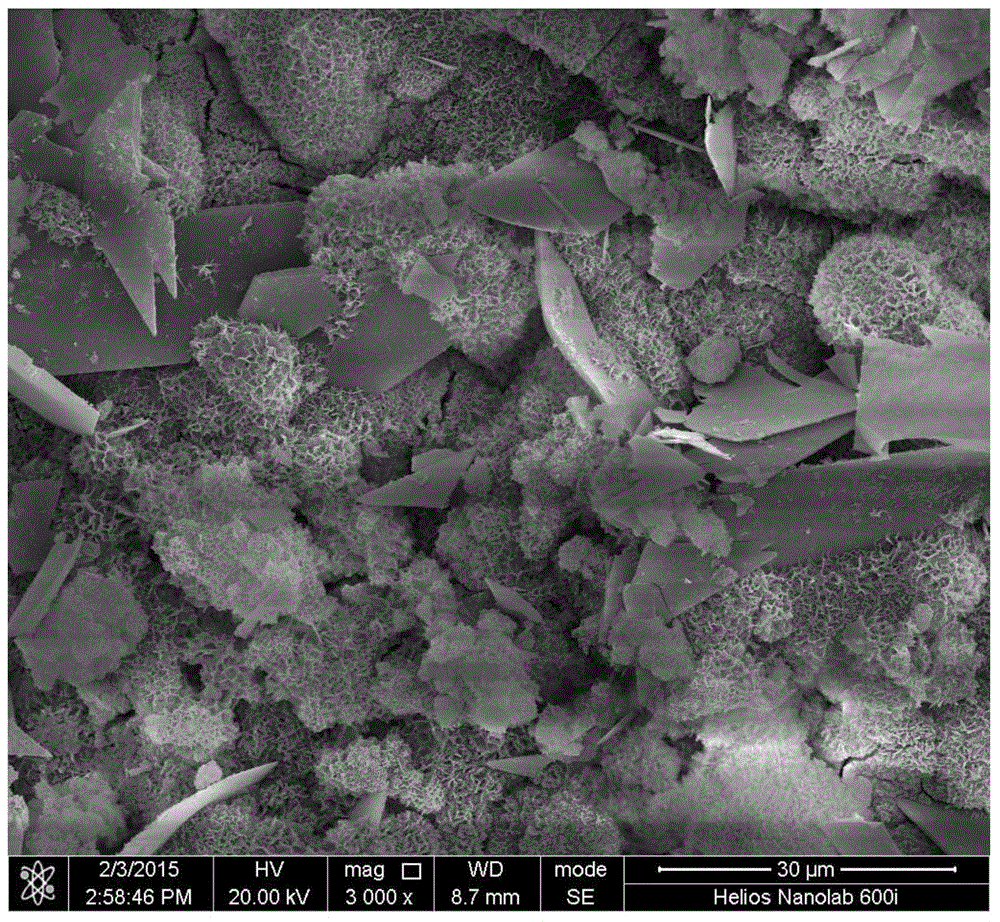

InactiveCN103088339AHigh surface hardnessImprove wear resistanceMetallic material coating processesX-rayScanning electron microscope

The invention provides a laser cladding method for improving the surface performance of magnesium alloy AZ91D. The method adopts Co-Cr alloy powder as a cladding material, and comprises the following steps of 1, pre-treating the surface of a magnesium alloy workpiece; 2, cladding the surface of the magnesium alloy workpiece; 3, obtaining the appearance, composition phase and structure characteristics of the cladding layer by combining a Co-Cr phase diagram and a Co-W-C phase diagram by adopting a SEM (scanning electron microscope) or XRD (X-ray diffraction) analysis means and applying a solidification theory; and 4, testing the mechanical performance and electro-mechanical performance of the surface of the magnesium alloy workpiece according to the composition phase, the appearance and characteristics of distribution, grain size, columnar crystal and dendritic crystal of a solidified tissue. A product fulfilling the requirement can be obtained when the specific surface performance can be achieved. The laser cladding method has the advantages of high hardness of the surface of the magnesium alloy, improved wearing and corrosion resistance, firm combination of effective working layer and matrix, has a certain size and thickness, and is low in cost.

Owner:SUZHOU TIANHONG LASER

Degradable biological magnesium-based amorphous alloy and preparation method thereof

InactiveCN103938125AHigh strengthImprove corrosion resistanceSurgeryProsthesisBiocompatibility TestingAmorphous metal

The invention relates to a degradable biological magnesium-based amorphous alloy. The composition of the alloy is expressed by a chemical formula as follows: Mg100-x-y-z-wZnxCayZrzSrw, wherein x is greater than or equal to 25 and less than or equal to 35, y is greater than or equal to 1 and less than or equal to 5, Z is greater than 0 and less than or equal to 1, and w is greater than 0 and less than or equal to 4; according to the proportions of the various elements in Mg100-x-y-z-wZnxCayZrzSrw, Mg powder, Zn particles, Ca particles, Zr particles and Sr particles, all having the purity of not lower than 99.5%, are prepared into a mother alloy raw material having the nominal composition of Mg100-x-y-z-wZnxCayZrzSrw in appropriate percentage by weight; the prepared mother alloy raw material is smelted repeated more than 3 times under a vacuum condition by use of a medium-frequency induction smelting method and then is cast into an alloy ingot; the alloy ingot is crushed, and the crushed alloy pieces are orderly put in an acetone solution and an alcoholic solution for ultrasonic cleaning; the alloy pieces are prepared into Mg100-x-y-z-wZnxCayZrzSrw amorphous rods by use of a vacuum suction casting method. Compared with the prior art, the magnesium-based amorphous alloy prepared by the preparation method has higher strength and corrosion resistance, and also retains excellent biocompatibility.

Owner:TONGJI UNIV

Polyaniline modified sericite heavy-duty anticorrosive paint

InactiveCN106318152AImprove corrosion resistanceGood flexibilityConjugated diene hydrocarbon coatingsAnti-corrosive paintsDiacetone alcoholEpoxy

The invention discloses a polyaniline modified sericite heavy-duty anticorrosive paint. The paint comprises the following components by weight: 30-50 parts of alkyd resin, 5-15 parts of epoxy resin, 3-10 parts of polyether-ether-ketone, 4-10 parts of terpene resin, 5-10 parts of carboxyl terminated butyronitrile liquid rubber, 2-10 parts of tetraethylenepentamine, 3-10 parts of triethylamine, 3-8 parts of zinc borate, 3-10 parts of red phosphorus, 5-10 parts of modified nano titanium dioxide, 8-20 parts of polyaniline modified sericite, 5-10 parts of glass flake, 3-8 parts of diacetone alcohol, 3-10 parts of propylene glycol butyl ether, 15-20 parts of propylene glycol methyl ether acetate, 3-10 parts of tolyltriazole, 2-8 parts of zinc naphthenate, 5-15 parts of triphenyl phosphate, 20-40 parts of water, and 2-5 parts of an assistant. The polyaniline modified sericite heavy-duty anticorrosive paint provided by the invention has the advantages of good impact resistance, excellent flame retardance and corrosion resistance, and long service life.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com