Preparation technique of high-density polypyrrole film anticorrosive coating

A technology of anti-corrosion coating and preparation process, applied in coating, electrolytic coating, electrophoretic plating, etc., can solve the problems affecting the adhesion and mechanical properties of polypyrrole film, shorten the effective protection time of polypyrrole film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

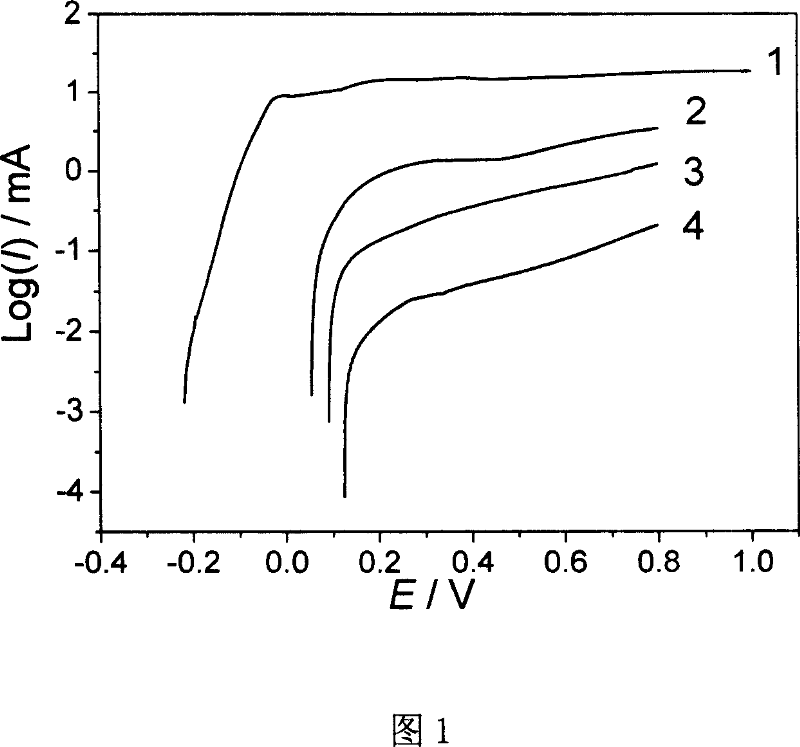

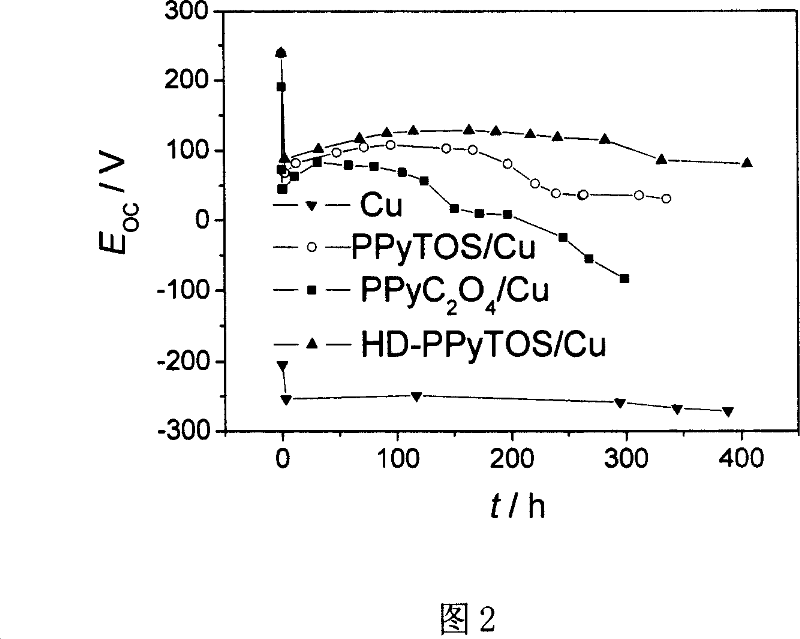

[0009] Example 1, first, use oxalic acid and oxalate to prepare an oxalate solution with a concentration of 0.01mol / L, adjust the pH value of the solution to 7, then add pyrrole monomers to the solution to make the concentration of pyrrole monomers 0.3 mol / L, to obtain solution A; secondly, toluenesulfonic acid is dissolved in the acetocyanide solution containing 1% water and is prepared to be the toluenesulfonic acid solution that concentration is 0.6mol / L, then adds pyrrole in this solution Make the concentration of pyrrole monomer 0.3mol / L to obtain solution B, immerse the copper or copper alloy to be protected in solution A and carry out electrochemical polymerization by cyclic voltammetry to obtain copper or copper alloy modified by polypyrrole film Electrode C; Finally, immerse copper or copper alloy C in solution B for electrochemical polymerization, control the solution temperature between -5 degrees Celsius, and the polymerization current density is 16mA / cm 2 , a laye...

Embodiment 2

[0010] Example 2, first, use oxalic acid and oxalate to prepare an oxalate solution with a concentration of 0.05mol / L, adjust the pH value of the solution to 5, and then add pyrrole monomers to the solution so that the concentration of pyrrole monomers is 0.01 mol / L, to obtain solution A; secondly, toluenesulfonic acid is dissolved in the acetocyanide solution containing 1% water and is prepared as the toluenesulfonic acid solution that concentration is 0.4mol / L, then adds pyrrole in this solution Make the concentration of pyrrole monomer 0.01mol / L to obtain solution B, immerse the copper or copper alloy to be protected in solution A and carry out electrochemical polymerization by cyclic voltammetry to obtain copper or copper alloy modified by polypyrrole film Electrode C; Finally, immerse copper or copper alloy C in solution B for electrochemical polymerization, control the solution temperature between -3 degrees Celsius, and the polymerization current density is 12mA / cm 2 , ...

Embodiment 3

[0011] Example 3, first, use oxalic acid and oxalate to prepare an oxalate solution with a concentration of 0.3 mol / L, adjust the pH value of the solution to 1, then add pyrrole monomers to the solution to make the concentration of pyrrole monomers 0.1 mol / L, to obtain solution A; secondly, dissolving toluenesulfonic acid in the acetocyanide solution containing 1% water and preparing a concentration of 0.2mol / L toluenesulfonic acid solution, then adding pyrrole to the solution Make the concentration of pyrrole monomer 0.1mol / L to obtain solution B, immerse the copper or copper alloy to be protected in solution A and carry out electrochemical polymerization by cyclic voltammetry to obtain copper or copper alloy modified by polypyrrole film Electrode C; Finally, immerse copper or copper alloy C in solution B for electrochemical polymerization, control the solution temperature between 0 degrees Celsius, and the polymerization current density is 8mA / cm 2 , a layer of high-density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com