Patents

Literature

113results about How to "Corrosion current reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

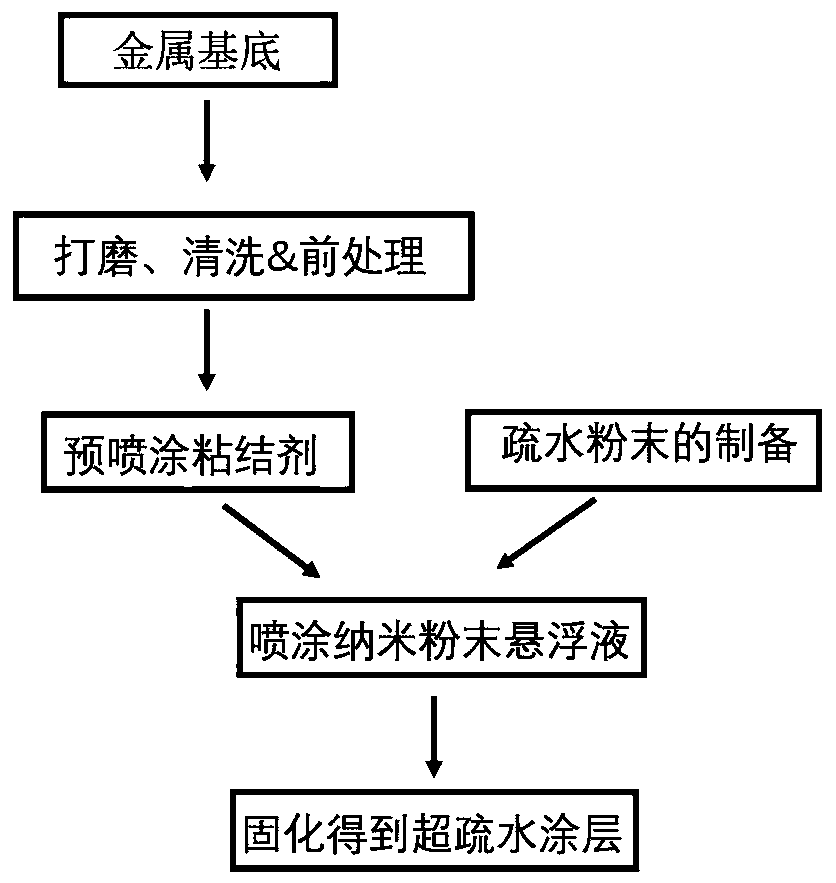

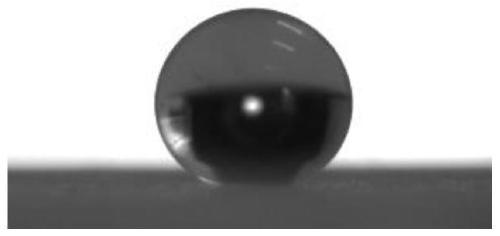

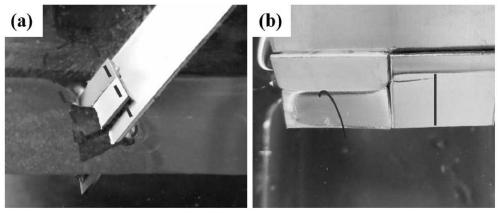

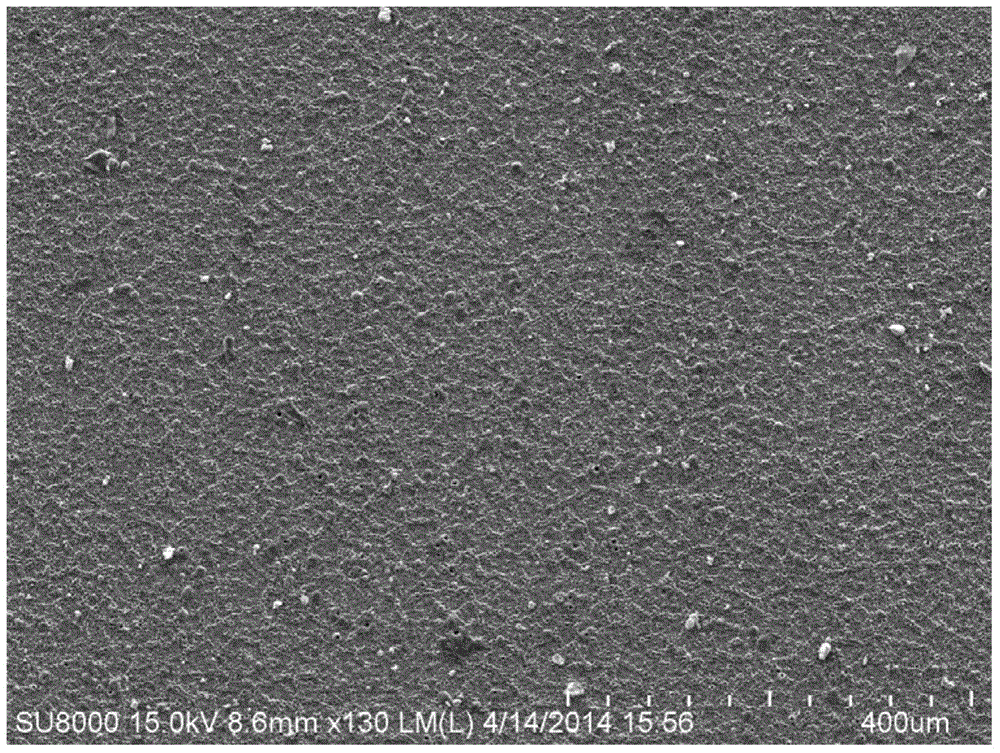

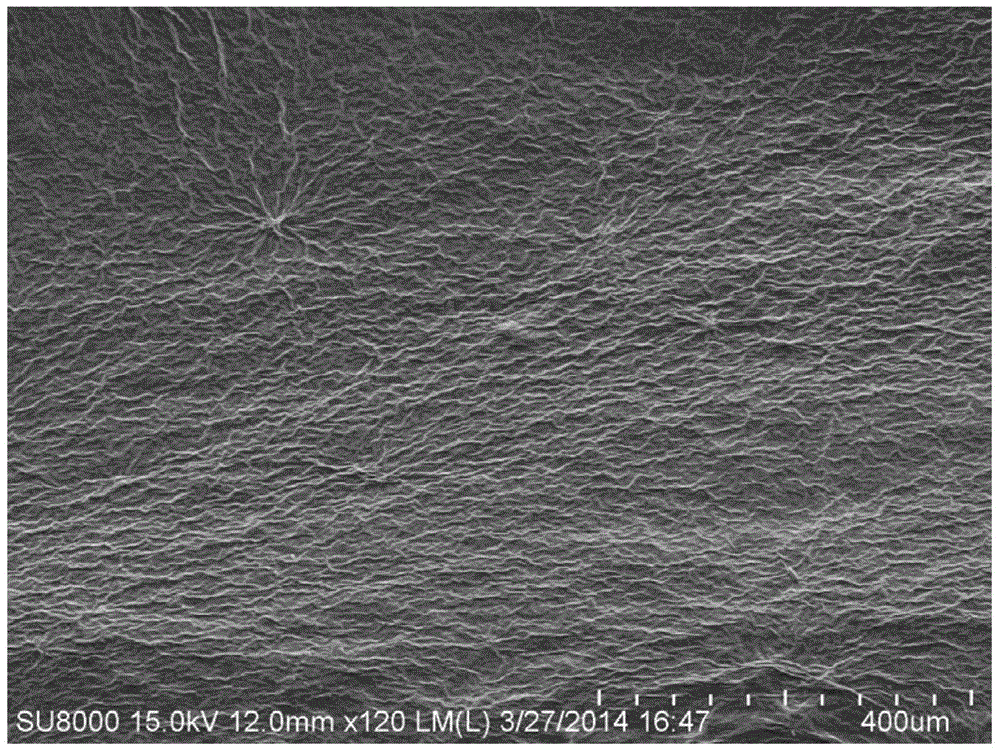

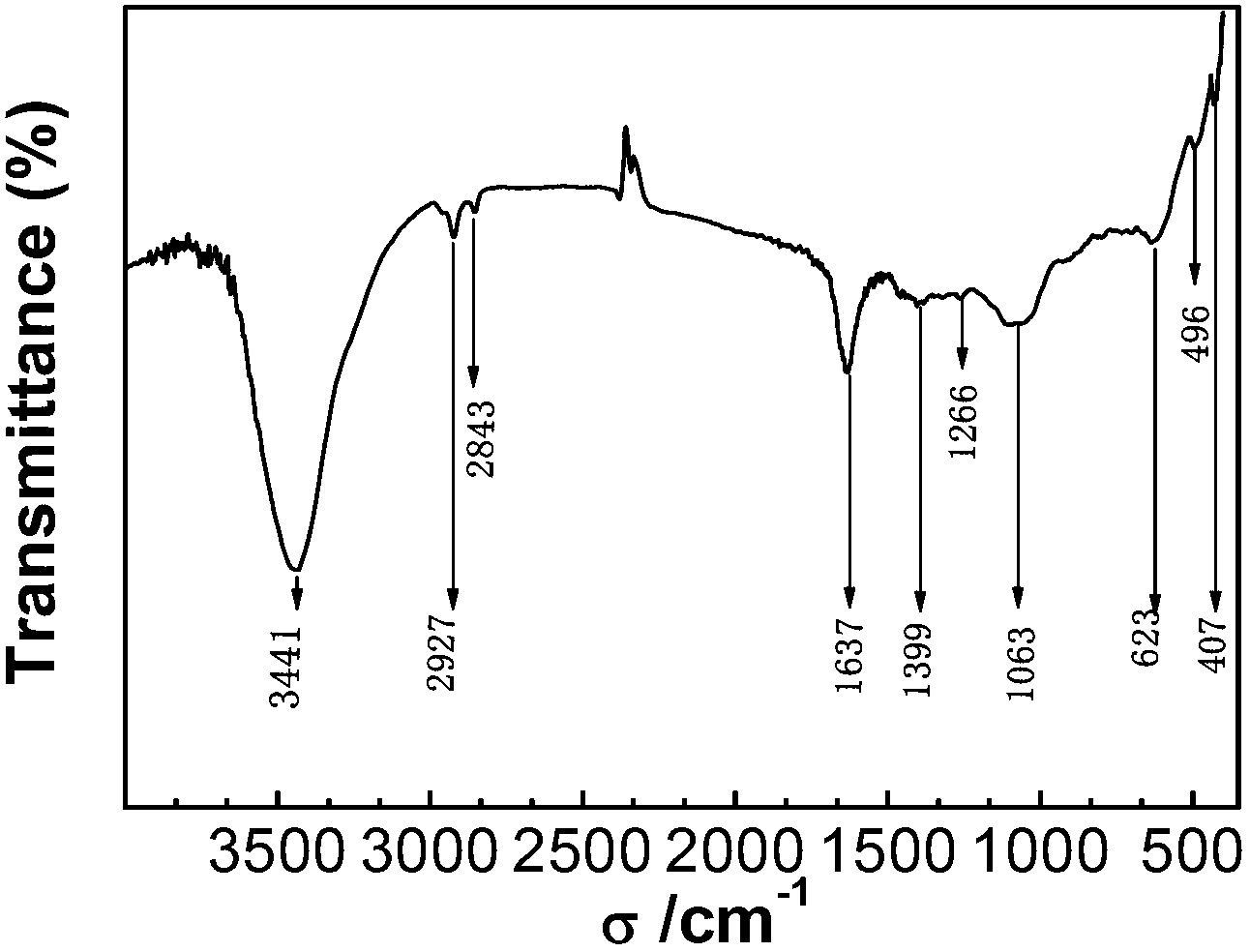

Preparation method of icing-resistant/ corrosion-resistant integrated functional super-hydrophobic coating for aviation

InactiveCN109746172AGood low temperature water repellencyLong freeze delay timeAnti-corrosive paintsSpecial surfacesAviationMicro nano

The invention discloses a preparation method of an icing-resistant / corrosion-resistant integrated functional super-hydrophobic coating for aviation. The method comprises the following steps: preprocessing titanium alloy, aluminum alloy and stainless steel to build a micro-nano structure; pre-spraying an adhering agent; continuously spraying a low-surface-energy nanometer powder coating; and curing to obtain the super-hydrophobic coating with outstanding icing resistance and corrosion resistance. According to the method, the prepared icing-resistant / corrosion-resistant integrated functional super-hydrophobic coating for aviation is good in protection effect. The preparation method is simple in processes, and suitable for massive production; ideas are supplied to solve the problems that anair craft is easily iced and low in corrosion resistance; and the method has a wide application prospect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Process for prparing polyaniline corrosion-resistant paint

InactiveCN1358812AIncreased corrosion potentialCorrosion Prevention and MitigationAnti-corrosive paintsEpoxyPolyamide

The present invention discloses a preparation process of polyaniline anticorrosive coating, and includes the following steps: mixing epoxy rsin, polyaniline and diluent uniformly, grinding, then mixing them with phenol aldehide amine, polyamide and diluent uniformly according to the ratio of 10-20:1, cuating on the metal surface and solidifying at room temp. so as to implement said invention. Said anticorrosive coating can form a layer of compact film on the steel surface, can raise corrosion potential of steel, reduce corrosion current and can prevent and relieve corrosion of steel, and said coating layer possesses high harndess and excellent abrasive resistance, after said coating layer is scratched, a passive film can be formed so as to can protect metal from corrosion.

Owner:XI AN JIAOTONG UNIV

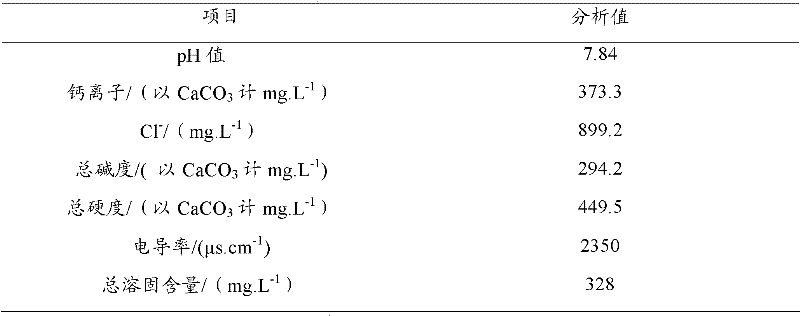

Ascorbic acid phosphorus-free corrosion and scale inhibitor, and preparation method thereof

ActiveCN102225809ADoes not cause eutrophicationWide variety of sourcesScale removal and water softeningGluconatesPollution

The invention discloses an ascorbic acid phosphorus-free corrosion and scale inhibitor which is applicable for treatment of industrial circulating cooling water. The corrosion and scale inhibitor is prepared by compounding a maleic acid compound, an acrylic acid terpolymer, ascorbic acid, a sulfamic acid compound, a zinc salt, a gluconate and distilled water. The ascorbic acid phosphorus-free corrosion and scale inhibitor provided by the present invention provides good corrosion inhibition and scale inhibition effects for carbon steel equipment. The dosage of the phosphorus-free corrosion and scale inhibitor is 20 mg.L<-1> - 50 mg.L<-1> in the industrial circulating cooling water having an alkalinity less than 400 mg.L<-1>, a hardness less than 500 mg.L<-1>, a pH value less than 8.2, a conductance controlled from 0[mu]s.cm<-1>-2400[mu]s.cm<-1>. A plurality of experiment results show that the corrosion and scale inhibitor provides a annual corrosion rate lower than 0.04 mm.a<-1> and a calcium carbonate inhibition rate higher than 98% for the A3 carbon steel. Advantages of the ascorbic acid phosphorus-free corrosion and scale inhibitor and the preparation method are as follows: the discharged waste water during using the corrosion and scale inhibitor does not provide a eutrophic pollution caused by phosphor for water body; the environment is environment-friendly; agent cost for treating each ton of the water is less than 0.12 yuan; the product preparation process is simple.

Owner:WUHAN UNIV OF TECH +1

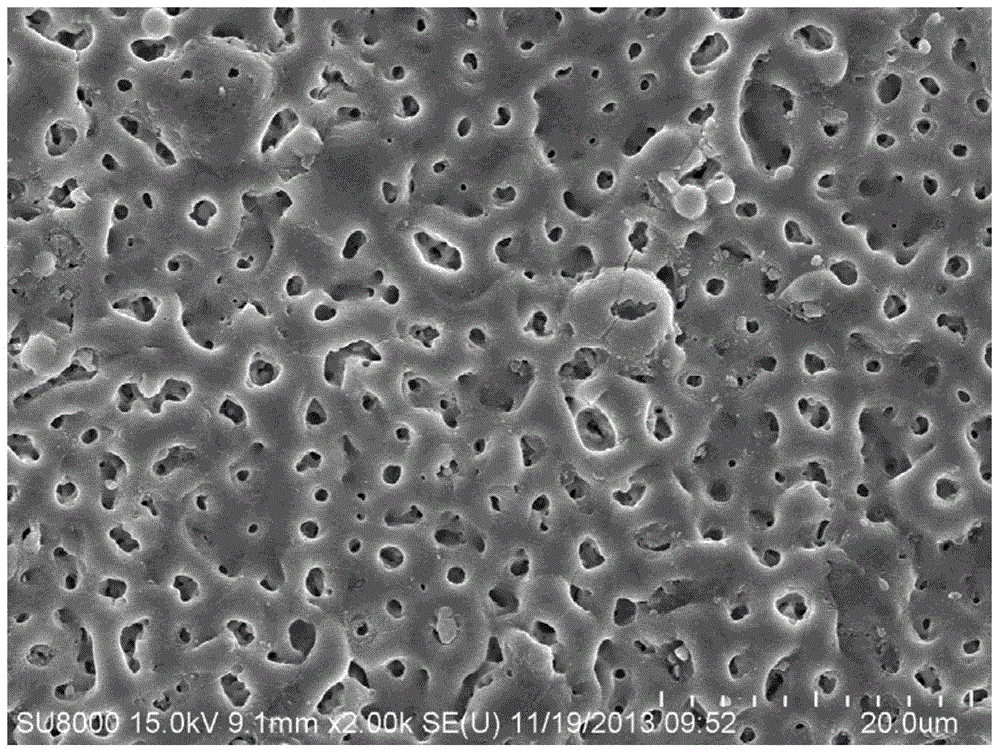

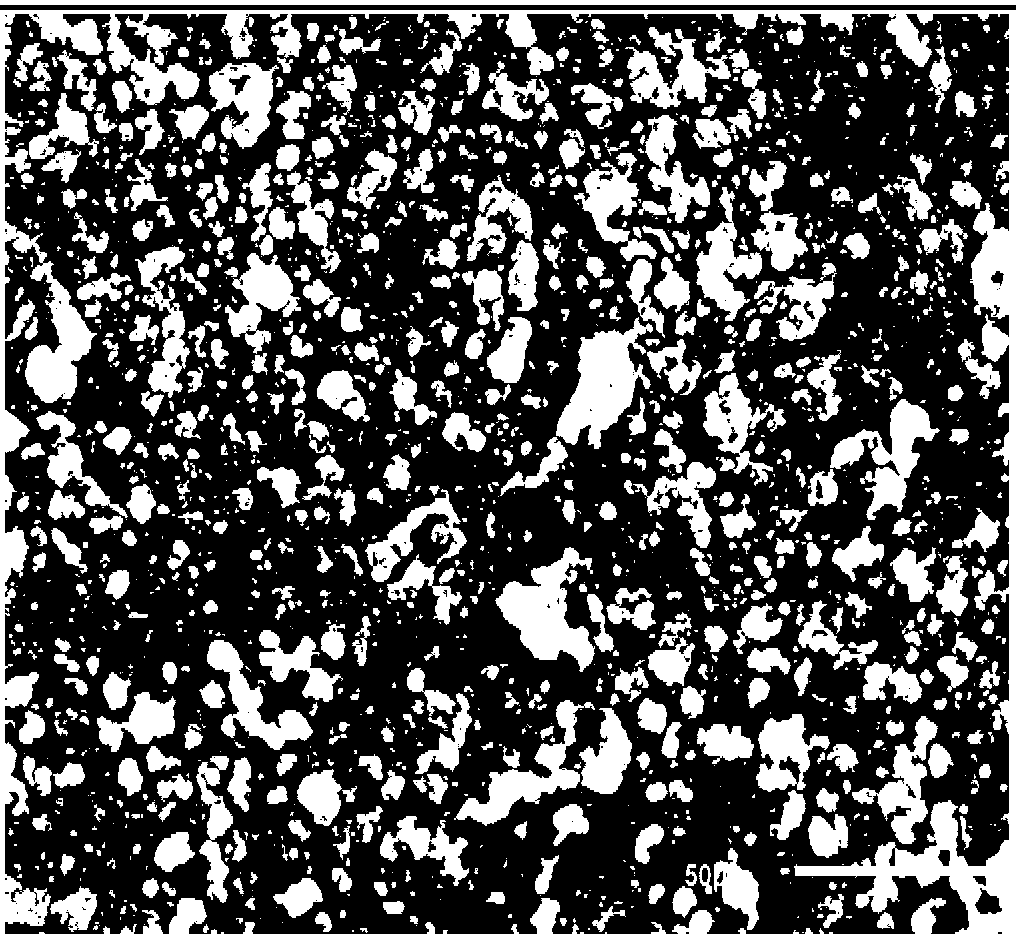

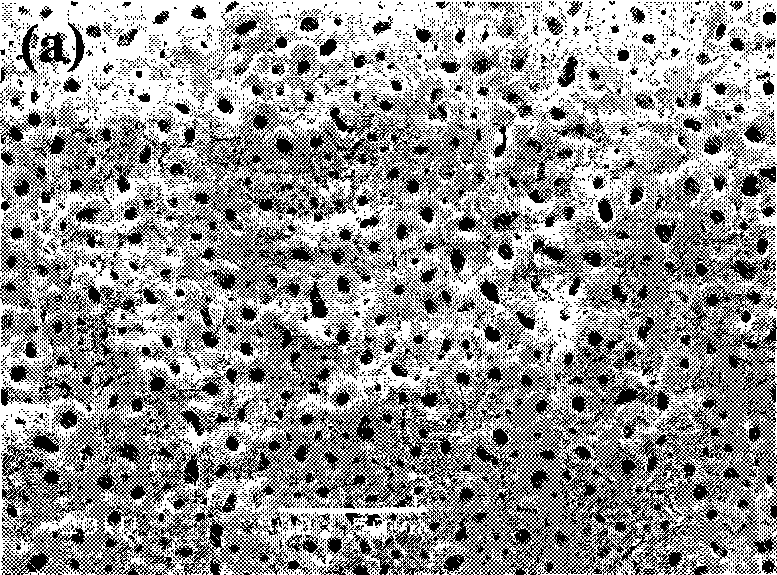

Method for preparing graphene oxide and micro-arc oxidized ceramic composite coating on surface of magnesium alloy

InactiveCN104878377AImprove corrosion resistanceReduce porosityAnodisationMetallic material coating processesPlasma electrolytic oxidationCeramic composite

The invention provides a method for preparing a graphene oxide and micro-arc oxidized ceramic composite coating on the surface of a magnesium alloy and relates to a method of preparing a coating on the surface of the magnesium alloy. The method is used for solving the problem of poor corrosion resistance of the micro-arc oxidized ceramic coating of a porous structure due to large contact area of the coating with a corrosive medium in the corrosion process. The method comprises the following steps: 1, magnesium alloy pre-processing; 2, ultrasonic processing; 3, oil removal; 4, micro-arc oxidization; 5, graphene oxide preparation; 6, application of the graphene oxide solution to the micro-arc oxidized ceramic coating on the magnesium alloy, thereby obtaining the magnesium alloy coated with the graphene oxide and micro-arc oxidized ceramic composite coating. According to the method, the corrosion current density of the graphene oxide and micro-arc oxidized ceramic composite coating is reduced to 14.5nA / cm<2>, which is 1 / 7240 of the corrosion current of the matrix magnesium alloy. The invention relates to the method for preparing the graphene oxide and micro-arc oxidized ceramic composite coating on the surface of the magnesium alloy.

Owner:HARBIN INST OF TECH

Water base non-chrome zinc-aluminium coating and methods for preparing and using same

ActiveCN102911534AMeet the requirements of environmental regulationsHydrogen embrittlement will notLiquid surface applicatorsCoatingsWater basedHazardous substance

The invention relates to a water base non-chrome zinc-aluminium coating and methods for preparing and using the same. The coating is prepared by proportionally mixing a component A and a component B; the component A contains 50-150g / L of lamellar metal powder, 145-290ml / L of organic solvent, 10-200ml / L of deionized water, 10-36ml / L of reducing agent and 5-15ml / L of wetting agent; and the component B contains 60-240ml / L of deionized water, 20-75ml / L of binding agent, 8-22ml / L of thickening agent, 4-8ml / L of silicon compound and the balance of the organic solvent. The method for preparing the water base non-chrome zinc-aluminium coating comprises the steps of: weighing the lamellar metal powder proportionally to be mixed uniformly, and then adding the organic solvent to be mixed uniformly for later use; mixing the reducing agent with the wetting agent, adding an appropriate amount of the deionized water to be mixed uniformly, and then adding the lamellar metal powder liquid to prepare the component A; proportionally weighing the thickening agent, the binding agent and the silicon compound, and adding the organic solvent to be mixed uniformly to prepare the component B; and mixing the prepared component A and the prepared component B according to the ratio of 2:1, and stirring unit uniform, thus obtaining the coating. The method for using the water base non-chrome zinc-aluminium coating is that the coating is coated on a part to be treated, and the baking temperature is increased to 360 DEG C so as to solidify and crosslink the coating to form a dense protective layer. The coating has the corrosion resistance which reaches 840 hours of a neutral salt spray test and over 96 hours of a heat resistance test, the usage amount of harmful substances is greatly reduced, and the working environment is improved.

Owner:翊鹏(湖北)实业有限公司

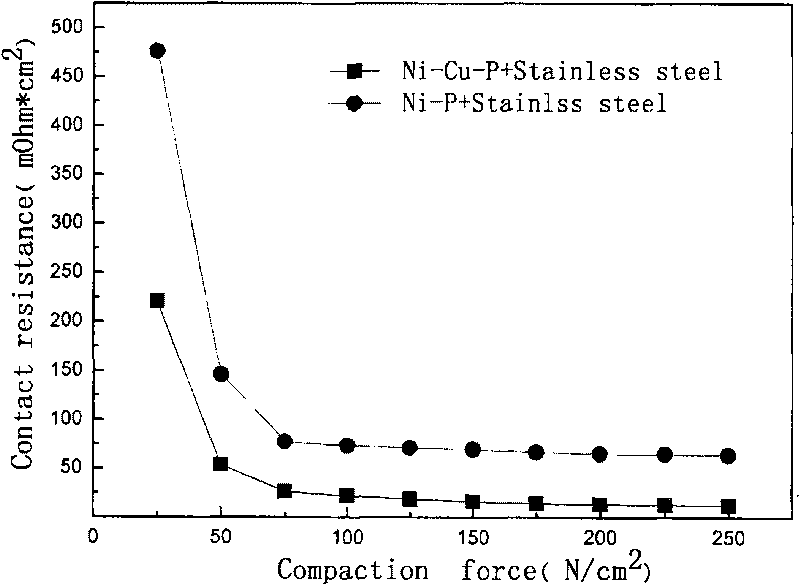

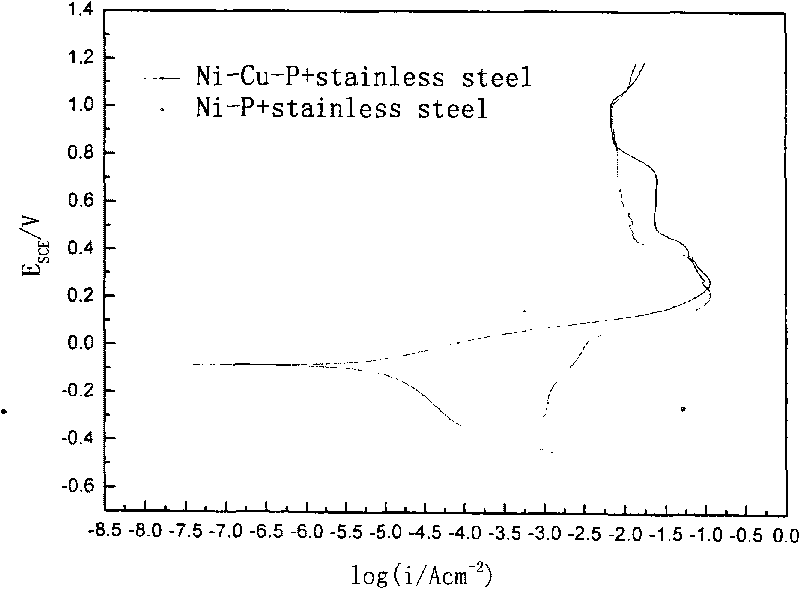

Proton exchange membrane fuel cell stainless steel bipolar plate and modification method thereof

InactiveCN101710620AImprove corrosion resistanceLow priceCell electrodesLiquid/solution decomposition chemical coatingElectrical resistance and conductanceElectroless deposition

The invention relates to an improvement on a surface property of a proton exchange membrane fuel cell metal bipolar plate, which is characterized in that: a substrate surface is plated with a nickel layer and a Ni-Cu-P double-plating layer, wherein Ni-Cu-P adopts electroless deposition. The improvement not only greatly reduces contact resistance of the bipolar plate and a gas diffusion layer, but also improves corrosion resistant. Electrical conductivity and the corrosion resistance can basically reach the level of those of the stainless steel bipolar plate plated with precious metal. The improvement is simple in modification, low in cost and superior in performance after modification.

Owner:江苏新源动力有限公司

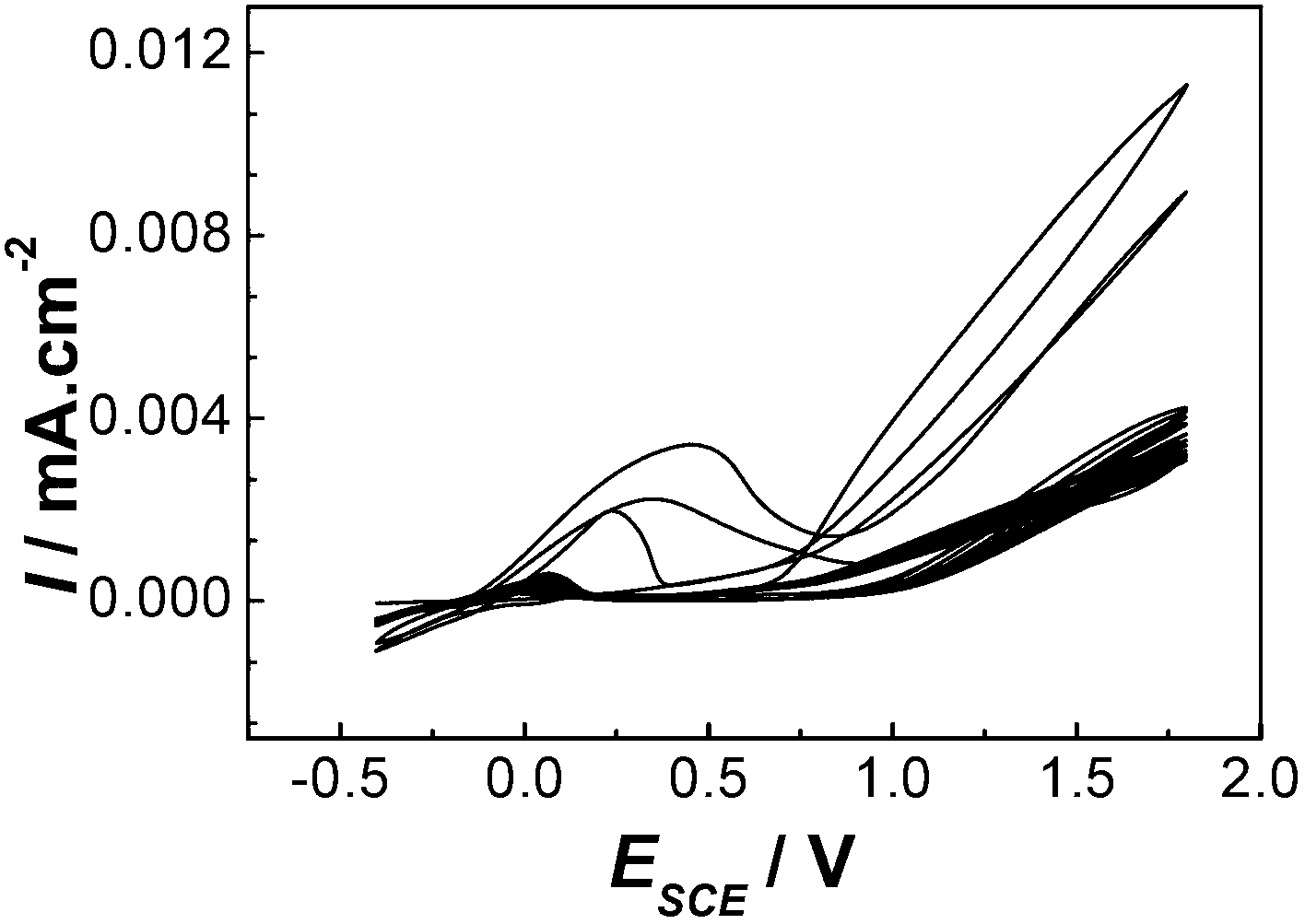

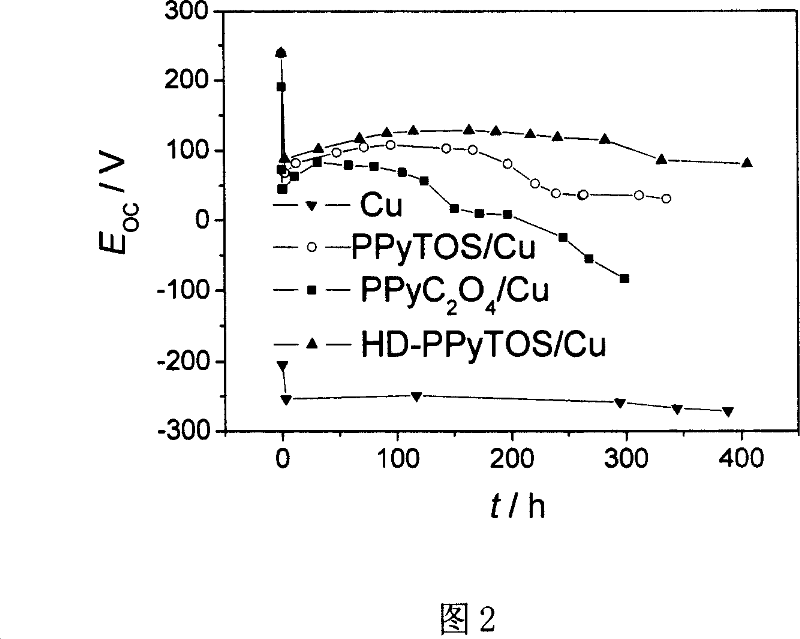

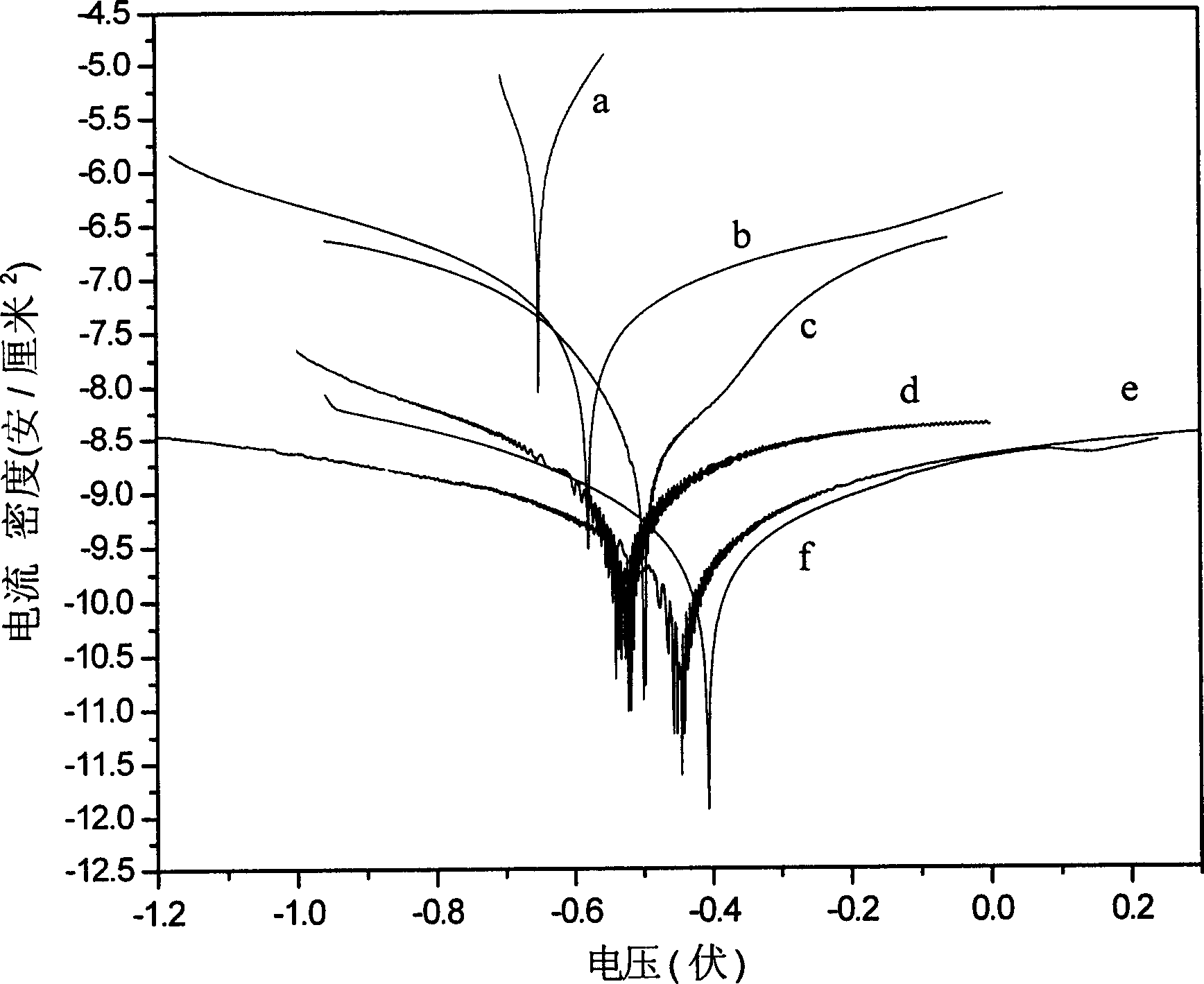

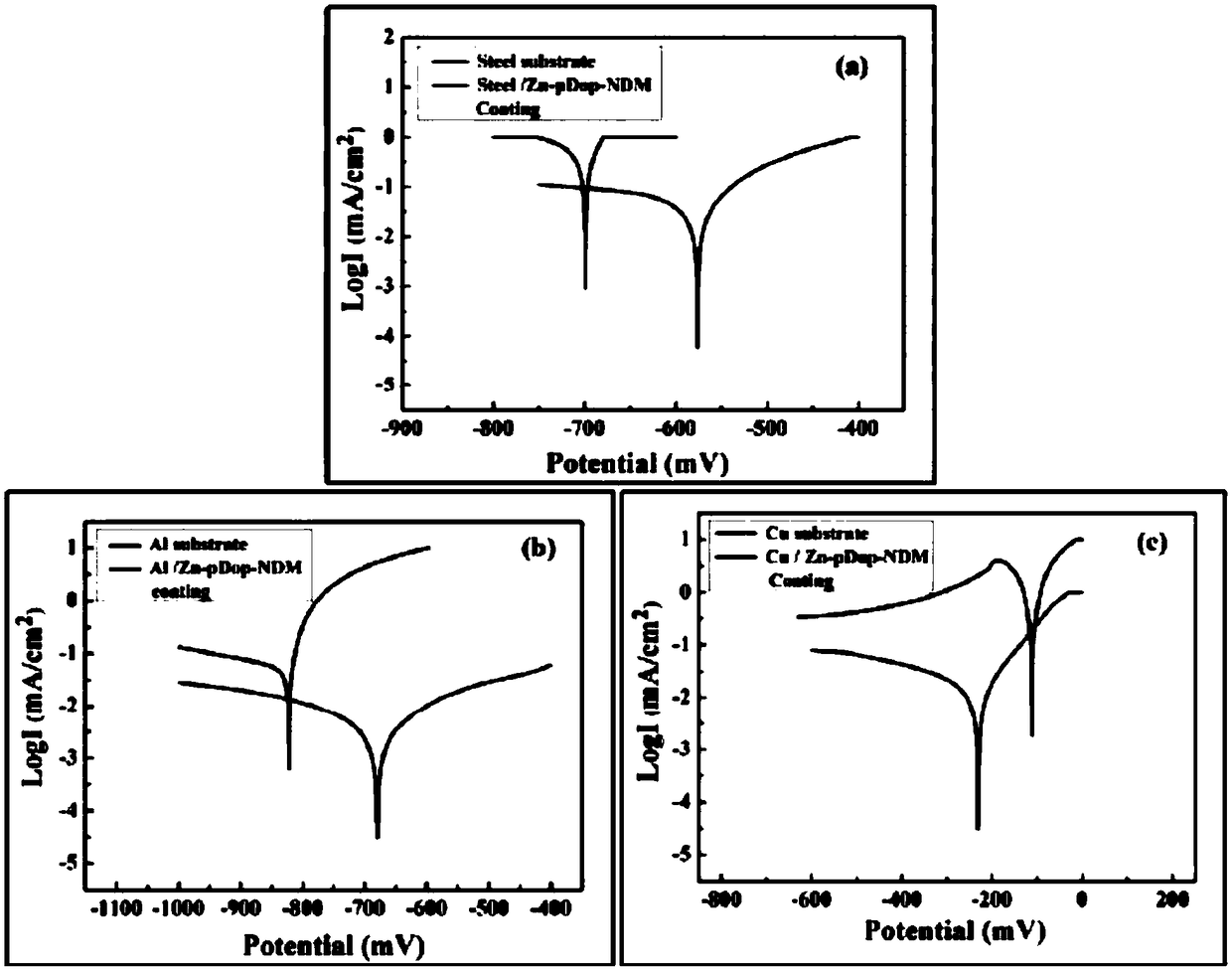

Method for preparing novel conductive composite anticorrosive coating

ActiveCN102703945AIncreased corrosion potentialNo corrosionElectrolytic organic material coatingPolypyrroleCopper electrode

The invention relates to a method for preparing a novel conductive polypyrrole / polyaniline composite anticorrosive coating. The method comprises the following steps of: dissolving p-toluenesulfonic acid into water, regulating the pH value of a solution to be an appropriate value, and adding pyrrole and aniline monomers to obtain a mixed solution; performing electrochemical synthesis by using a three-electrode system, wherein copper is taken as a working electrode, a platinum sheet is taken as an auxiliary electrode, and a reference electrode is a saturated calomel electrode; and performing electrochemical polymerization under certain electrical parameters by cyclic voltammetry to obtain a layer of conductive polypyrrole / polyaniline composite anticorrosive coating on the surface of the copper electrode. The conductive polymer coating generated on the surface of the copper has high adhesion and is uniform and compact; medium corrosion ions can be effectively hindered from penetrating the coating and permeating into the surface of a metal matrix for a long time; the composite coating effectively improves the corrosion potential of a copper matrix and reduces corrosion current; and in addition, after the prepared coating is damaged, a layer of passivating film can be quickly generated on the surface of the matrix so as to ensure that metal is free of corrosion.

Owner:常熟市通顺纺织有限责任公司

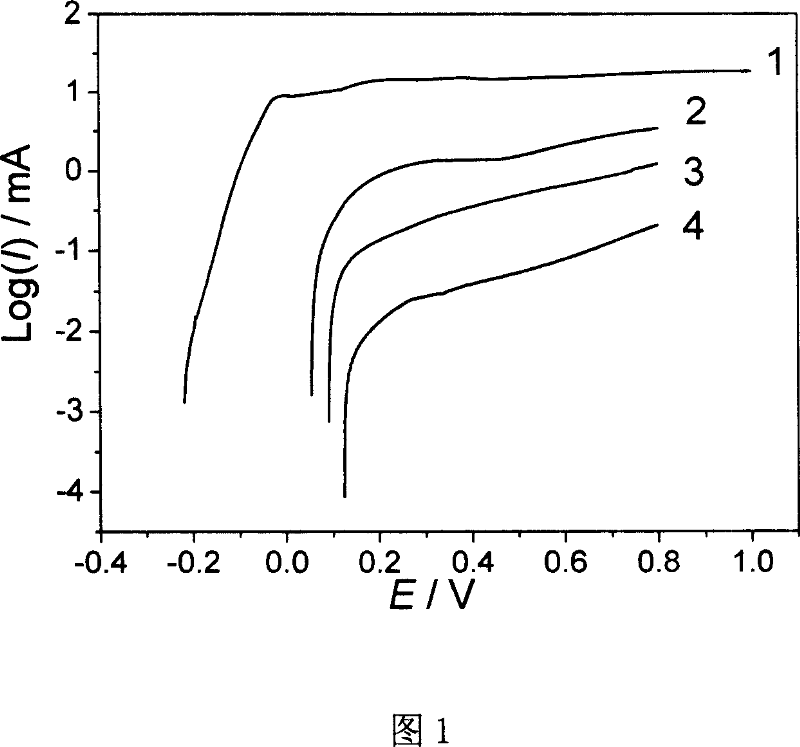

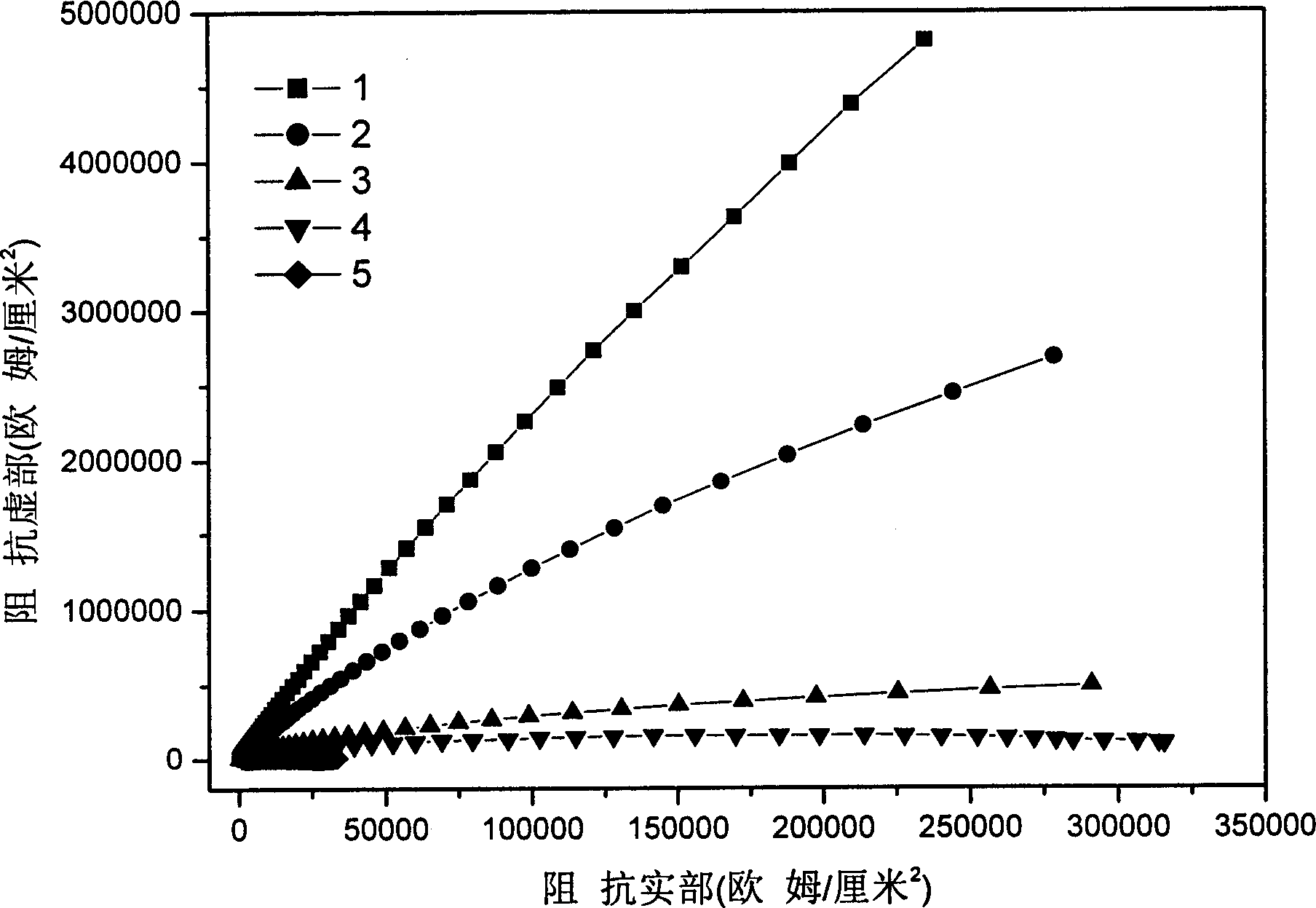

Preparation technique of high-density polypyrrole film anticorrosive coating

InactiveCN101037787AIncreased corrosion potentialNo corrosionElectrophoretic coatingsPolypyrroleMonomer

The invention discloses a process for preparing high density polypyrrole film anti-corrosion coat, wherein the solution A is produced by adding pyrrole monomer into oxalic acid radical solution; the solution B is produced by dissolving methyl benzene sulfonic acid into acetonitrile solution, then the protected copper or copper alloy is immerged into the solution A, and polymerize by an electrochemical process using cyclic voltammetry to produce polypyrrole film-modified copper or copper alloy electrode C; lastly, copper or copper alloy electrode C is immerged into the solution B, and polymerize by an electrochemical process to produce a layer of high density polypyrrole film D on the surface of copper or copper alloy electrode C. The film produced on the surface of copper by the invention is more compact than generally-synthetical polypyrrole film, can efficiently prevent corrosion ion from penetrating through the coat for a long time, and improve the corrosion potential of copper and reduce corrosion current, while the coat has higher adhesivity, but also corrosion of metal can be avoided by producing passivating film after scuffing the coat.

Owner:XI AN JIAOTONG UNIV

Aqueous polyanion metal composite anti-corrosion material and method for preparing the same

InactiveCN1803951AInhibition of Adsorption and GrowthImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsAmmonium sulfateIon

Disclosed is a water-based polyaniline composite metal corrosion-proof material and method for preparation, wherein the material is prepared from the following raw materials (by weight portions): sodium-based montmorillonite 3-8 parts, polystyrolsulfon acid 3-9 parts, deionized water 64-110 parts, phenylamine 1-4 parts, ammonium persulphate 3-9 parts, water-based epoxy resin emulsion 50-60 parts, and water-based epoxy resin curing agent emulsion 20-35 parts.

Owner:NORTHWEST NORMAL UNIVERSITY

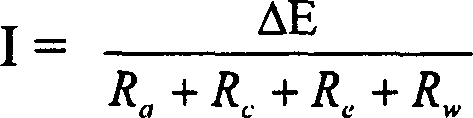

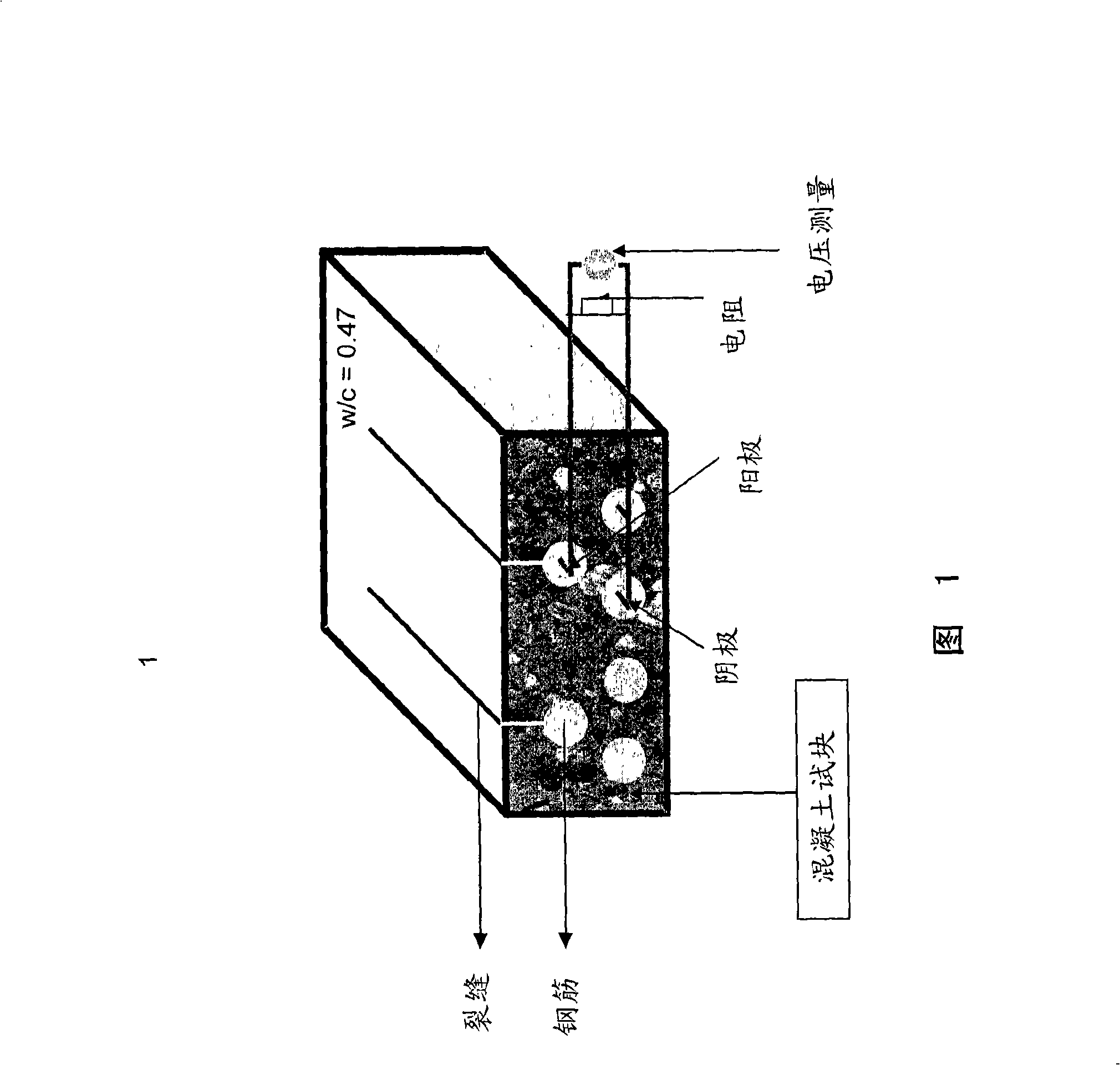

Corrosion inhibitor of steel reinforced concrete

The present invention relates to a reagent containing organosilane and / or organo-silicone, use of the reagent, and a method for using the reagent to reduce the positive corrosion of the steel bar in the concrete. In addition, the present invention also relates to concrete that is produced by the reagent of the present invention.

Owner:GOLDSCHMIDT CHEM CORP

Environment friendly anti-corrosive paint and preparation thereof

InactiveCN101497755AIncreased corrosion potentialCorrosion current reductionAnti-corrosive paintsEpoxy resin coatingsAmmonium sulfateMagnesium

The invention discloses environmental-friendly anti-corrosive polyaniline paint which has high content of polyaniline, good anti-corrosion performance and low cost, causes no pollution and is suitable for preventing steel, magnesium and other metals from being corroded. The environmental-friendly anti-corrosive polyaniline paint contains component A and component B which have the weight ratio of 7:1 to 17:1, wherein the component A contains the following components according to the portion by weight: 40-80 portions of liquid epoxy resin, 4-40 portions of plasticizing agent, 0.1-4 portion(s) of emulsifying agent OP-10, 4-10 portions of small-molecular fatty alcohol, 0.1-15 portion(s) of ammonium persulfate, 0.1-3 portion(s) of distilled water, 0.1-2 portion(s) of 0.4-0.8mol / L camphorsulfonic acid solution, 0.1-16 portion(s) aniline, 0.5-1 portion of defoaming agent and 4-20 portions of reactive diluent.

Owner:SHANDONG UNIV

Preparation method of chromium-free dacromet coating

InactiveCN105348870ACorrosion current reductionHigh stable potentialAnti-corrosive paintsEpoxyChromium free

The invention discloses a preparation method of a chromium-free dacromet coating. The method comprises the following steps: (1) dissolving 3.5g of a thickening agent hydroxyethyl cellulose in a mixed solution of acetone and isopropanol, sequentially adding 4.77g of polyethylene glycol, 1.0g of ethylene glycol, 3.0g of polytetrafluoroethylene and 4.6mL of a surface active agent OP-10, mixing evenly by stirring, and adding 72-80g of flaky zinc powder and 12-13g of flaky aluminum powder to obtain a component A; (2) dissolving 7.5-8.5g of sodium oxalate, 10g of citric acid and 1.3g of boric acid in distilled water, then dropwise adding 0.5mL of an oxidant hydrogen peroxide, and mixing evenly by stirring to obtain a component B; and (3) under stirring condition, adding the component B into the component A, then adding polyurethane modified epoxy resin and KH-570 silane coupling agent, and mixing evenly by stirring to obtain the chromium-free dacromet coating. The method adopts multi-salt mixture as a passivating agent to completely replace chromic anhydride, is more friendly to the environment, and has good environmental benefits.

Owner:HENAN NORMAL UNIV

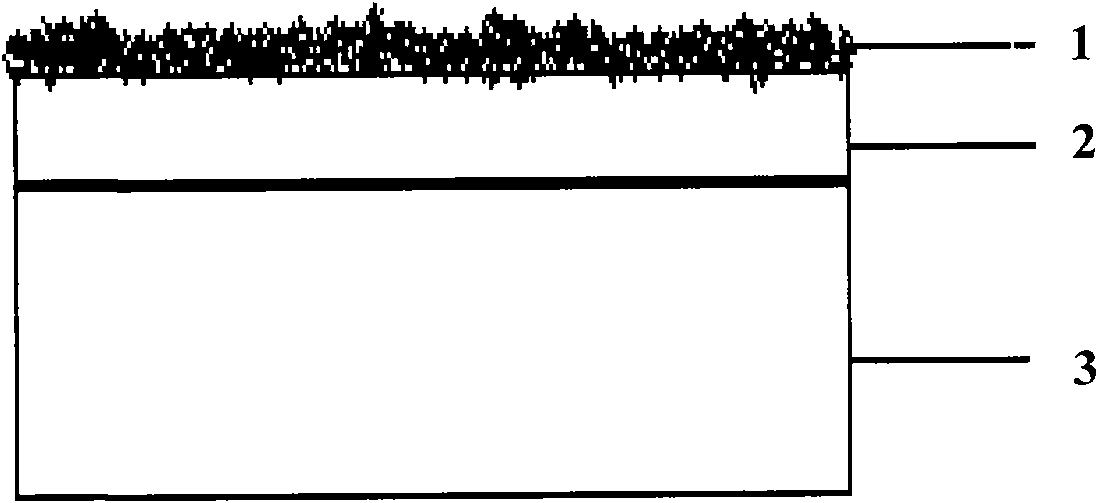

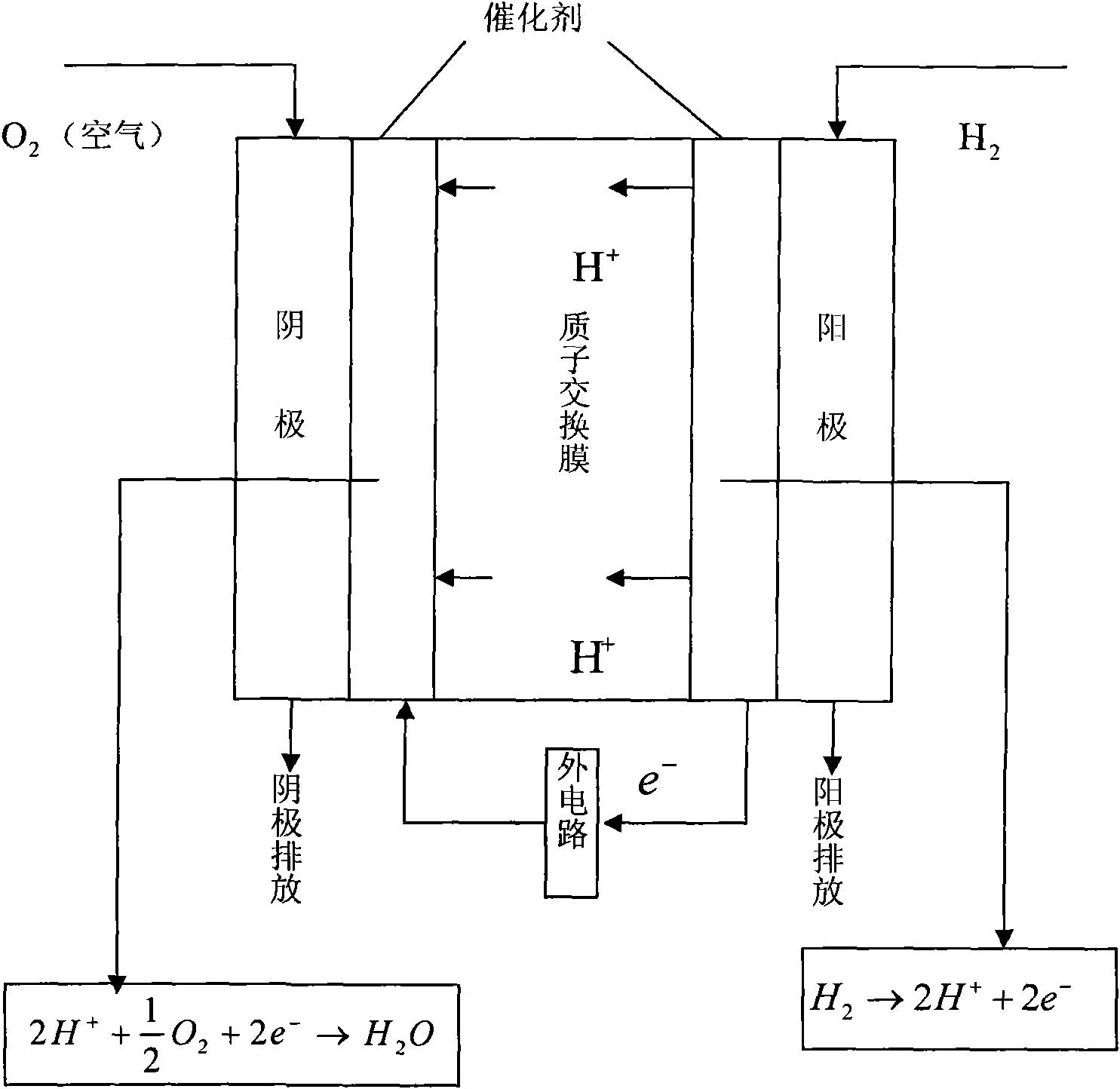

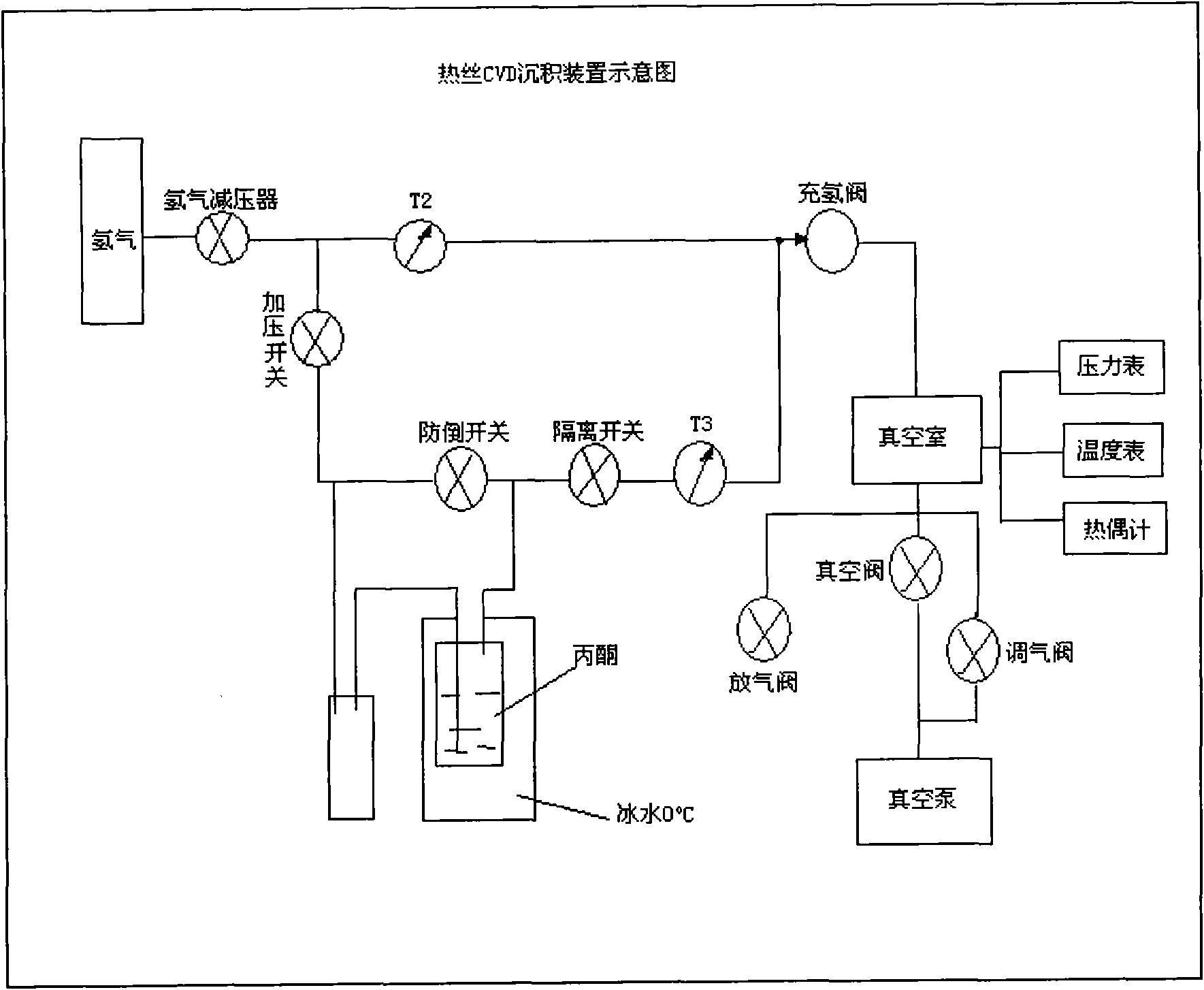

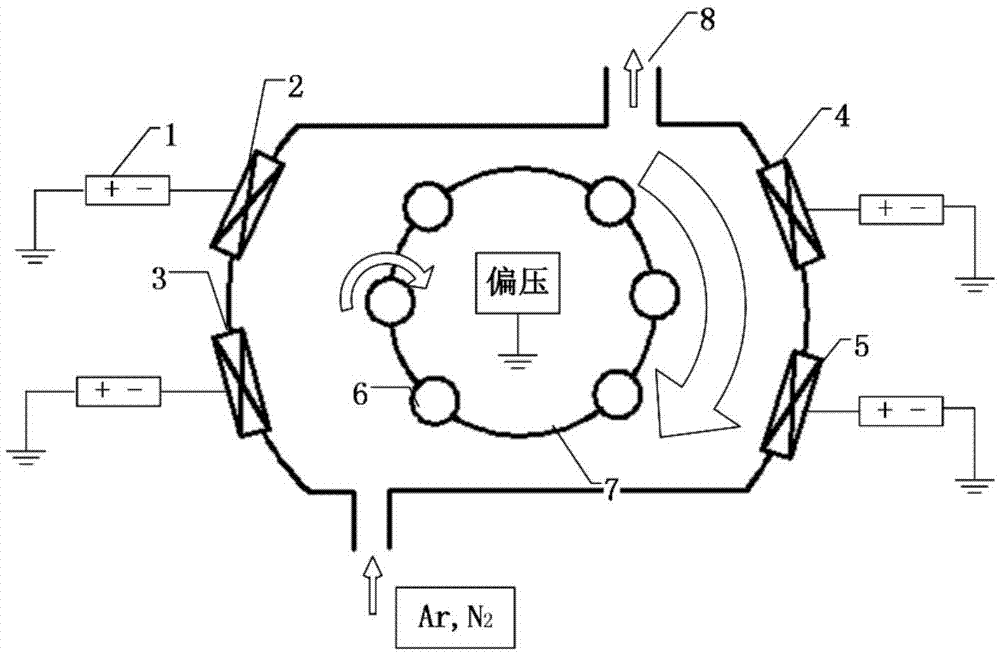

Boron-doping diamond film modification-based PEMFC (Proton Exchange Membrane Fuel Cell) bipolar plate and preparation method thereof

InactiveCN102074708AAccelerated corrosionImprove conductivityCell electrodesSputteringHeat conducting

The invention discloses a boron-doping diamond film modification-based PEMFC (Proton Exchange Membrane Fuel Cell) bipolar plate and a preparation method thereof, belonging to the field of batteries. In the boron-doping diamond film modification-based PEMFC bipolar plate, after a stainless steel plate is subjected to surface pretreatment, a layer of TI film is sputtered on the stainless steel plate by using magnetron sputtering; a boron-doping diamond film is deposited on the TI film by using heat wire CVD (Chemical Vapor Deposition) equipment; and a diamond film and TI film compounded modification layer is formed on the surface of stainless steel. The stainless steel plate treated by the method has high corrosion resistance and a favorable conductive and heat-conducting property; and according to the stainless steel plate, the battery ratio power can be greatly improved and the PEMFC can achieve the aims of prolonging the service life and reducing the weight, the volume and the cost.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Chromium-free passivator as well as preparation method and application thereof

ActiveCN106283014AImprove hydrophobicityAchieving synergistic passivationMetallic material coating processesSolubilityChromium free

The invention relates to a chromium-free passivator as well as a preparation method and an application thereof. The chromium-free passivator is prepared from the following components in percentage by mass: 45%-91.5% of straight-chain fatty acid alcohol amide compound and 9.5%-55% of straight-chain hydrophobic fatty acid. The preparation method comprises steps as follows: raw materials are taken according to the components and are mixed uniformly, and a finished product is obtained; or a mixture of hydrophobic fatty acid and the fatty acid alcohol amide compound is prepared according to the designed components, then an enhancer is added, and the finished product is obtained. The chromium-free passivator is applicable to surface passivation treatment of metal containing manganese. The developed chromium-free passivator has the characteristics of being good in water solubility, non-toxic, pollution-free, good in manganese passivation performance, capable of realizing membrane self-repairing and the like, an existing electrolytic manganese chromate passivation process can be better replaced, and more remarkable environment-friendly benefit and economic benefit are realized.

Owner:CENT SOUTH UNIV

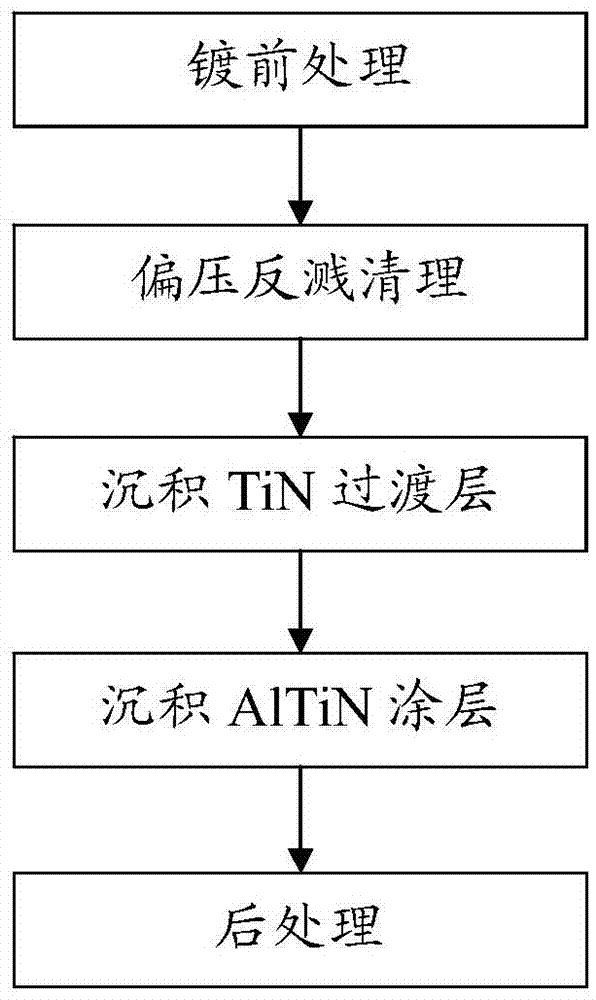

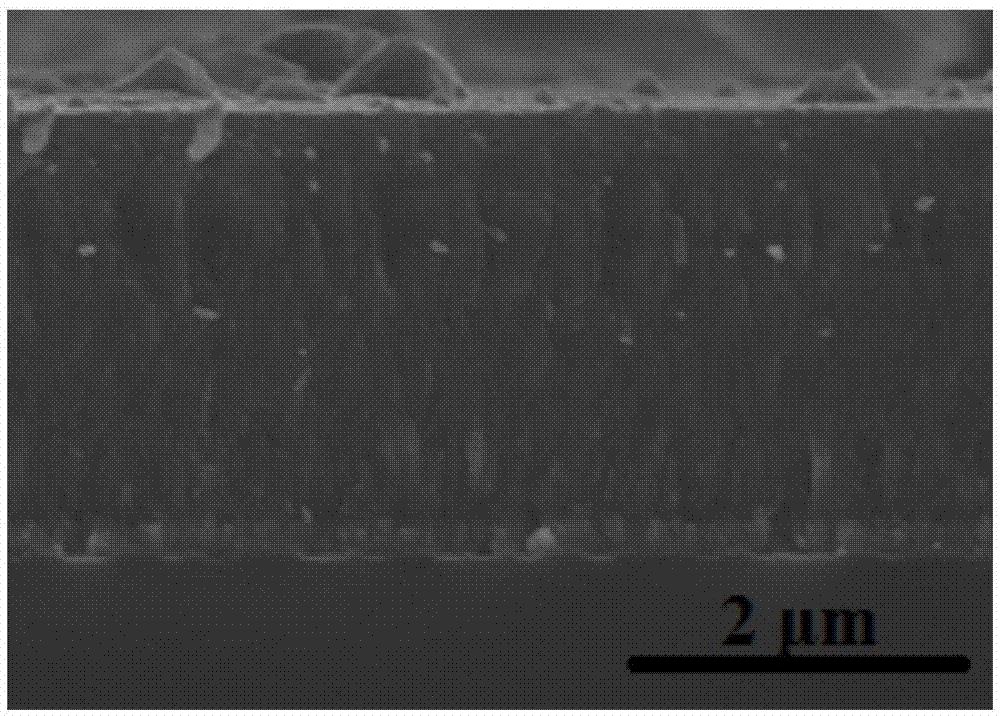

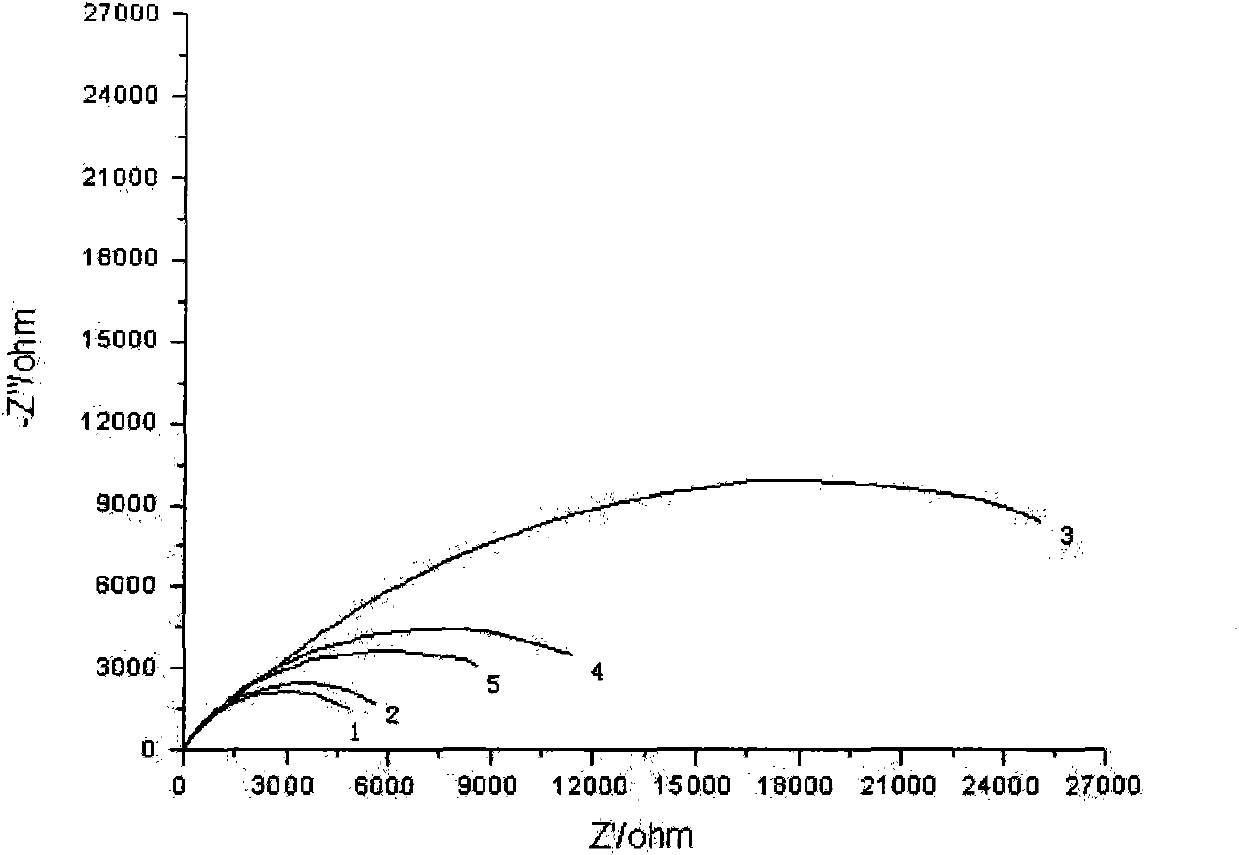

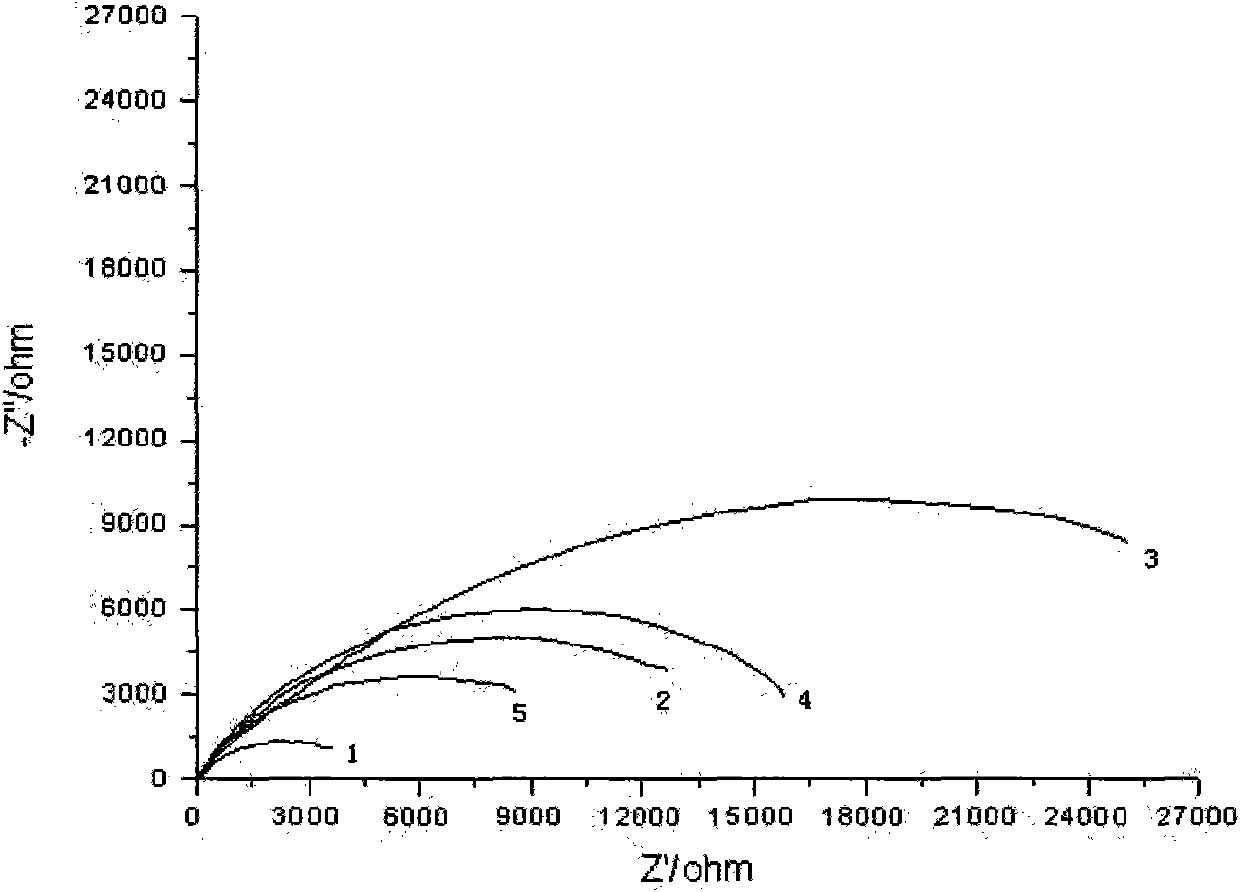

High temperature resistance protective coating and preparing method and application thereof

ActiveCN106929799AImprove high temperature oxidation performanceHigh Al contentVacuum evaporation coatingSputtering coatingOxidation resistantTemperature resistance

The invention discloses a high temperature resistance protective coating and a preparing method and application thereof. The high temperature resistance protective coating comprises a TiN transition layer and an AlTiN coating formed on the TiN transition layer; and in addition, in the AlTiN coating, and the ratio of the Al atom number to the sum of the Ti atom number and the Al atom number is larger than 0.67 and smaller than 0.9. The preparing method includes the steps that a Ti target is selected as a target material, the working atmosphere is N2, an arc ion plating technology is adopted for deposition of the TiN transition layer on the substrate surface; and meanwhile, an Al target and an Al67Ti33 target serve as target materials, and the arc ion plating technology is adopted for deposition of the AlTiN coating on the TiN transition layer continuously. According to the high temperature resistance protective coating, the aluminum content in the AlTiN coating is high, the Al / Ti proportion is adjustable, the oxidation resistance temperature can reach 900 DEG C, the excellent high-temperature oxidation resistant performance and corrosion resistant performance are achieved, and therefore the comprehensive performance of the AlTiN coating, a high-speed cutter and titanium alloy parts is effectively improved, and the service life of the AlTiN coating, the high-speed cutter and the titanium alloy parts is effectively prolonged.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Anti-corrosion method of cupronickel B30

InactiveCN102002701AImprove hydrophobicityIncreased polarization resistanceMetallic material coating processesElectrical resistance and conductanceCupronickel

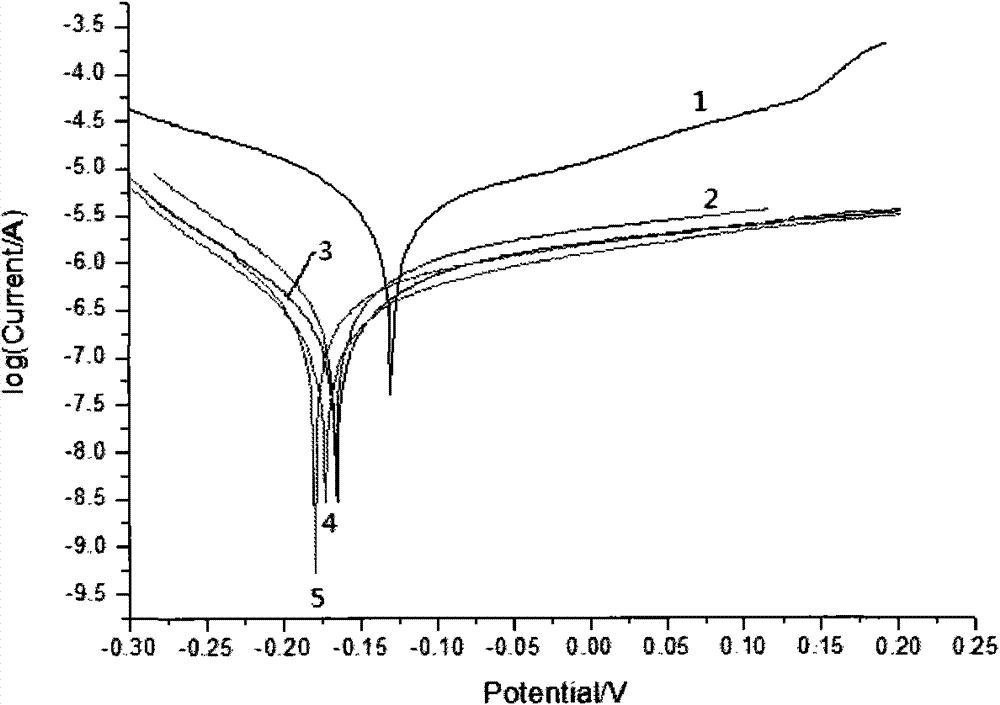

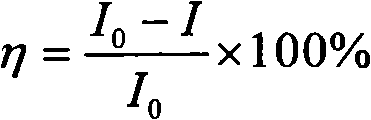

The invention discloses an anti-corrosion method of cupronickel B30, comprising the following steps of: soaking the cleaned cupronickel B30 in a H2O2 solution with the concentration of 5 percent for 30 minutes; then soaking in a stearic acid alcohol solution with the concentration of 0.1 mol / L for 30 minutes; and acquiring an anti-corrosion surface with hydrophobicity on a copper base material, wherein the cupronickel B30 treated through the steps and a Na2WO4 corrosion inhibitor with the concentration of 0.1 g / L are compositely used. Electrochemical tests indicate that the cupronickel B30 subjected to hydrophobic treatment is greatly increased in polarization resistance and reduced in corrosion current in the Na2WO4 corrosion inhibitor with the concentration of 0.1 g / L and can reach the corrosion inhibition efficiency at 88.85 percent and obviously enhance the corrosion resistance; and in addition, the invention has the advantages of low cost without expensive equipment and drugs, simple process, short processing time, safety, reliability and environment protection without pollution.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

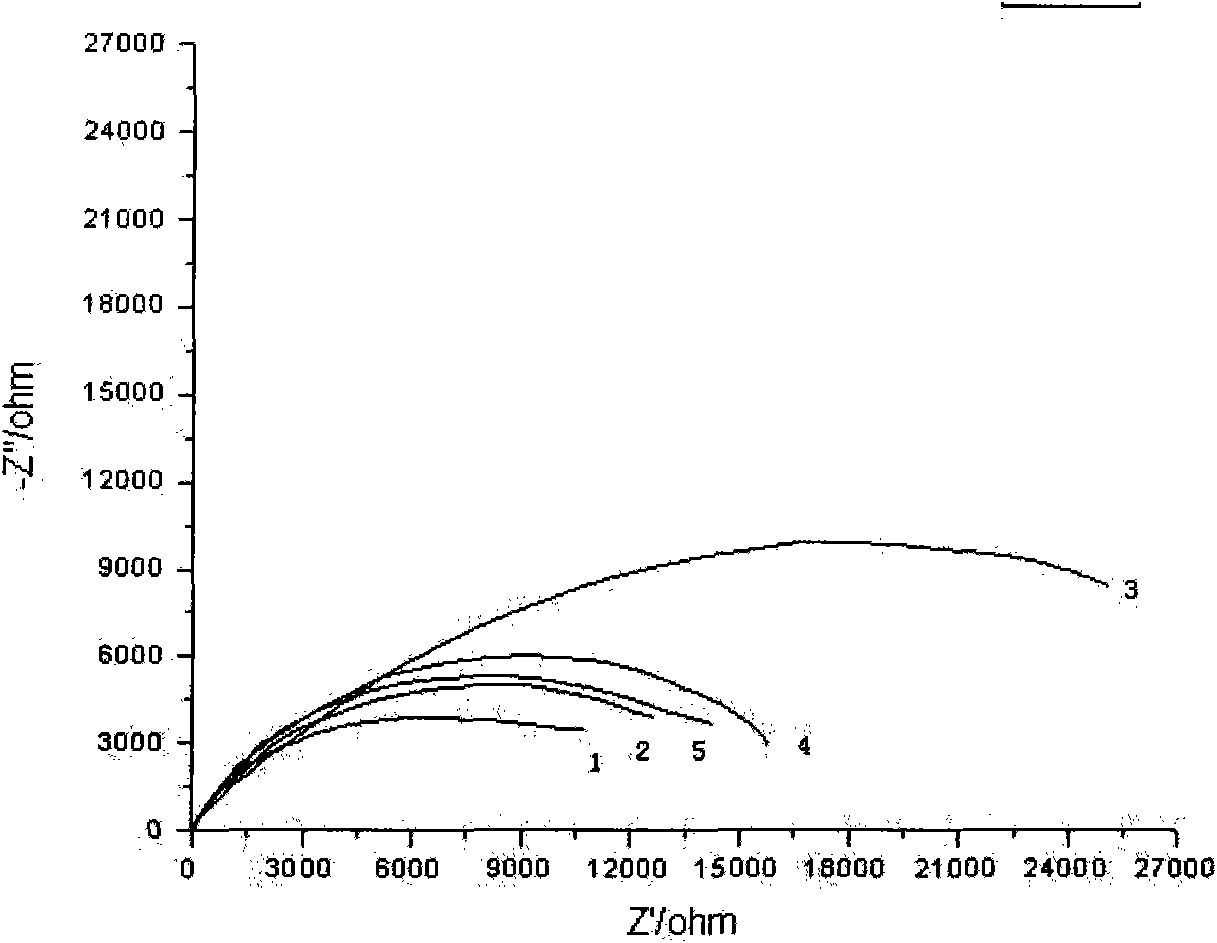

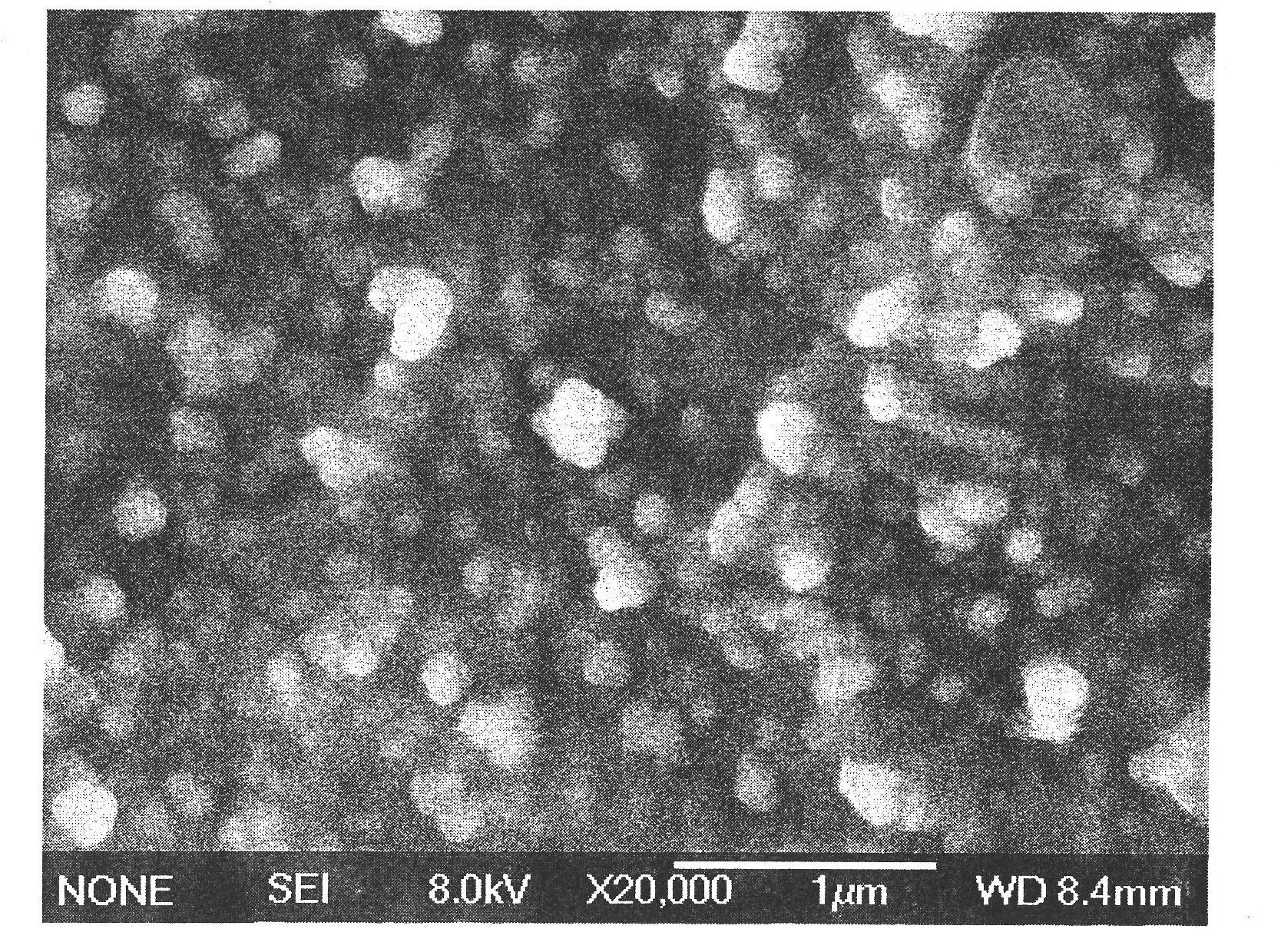

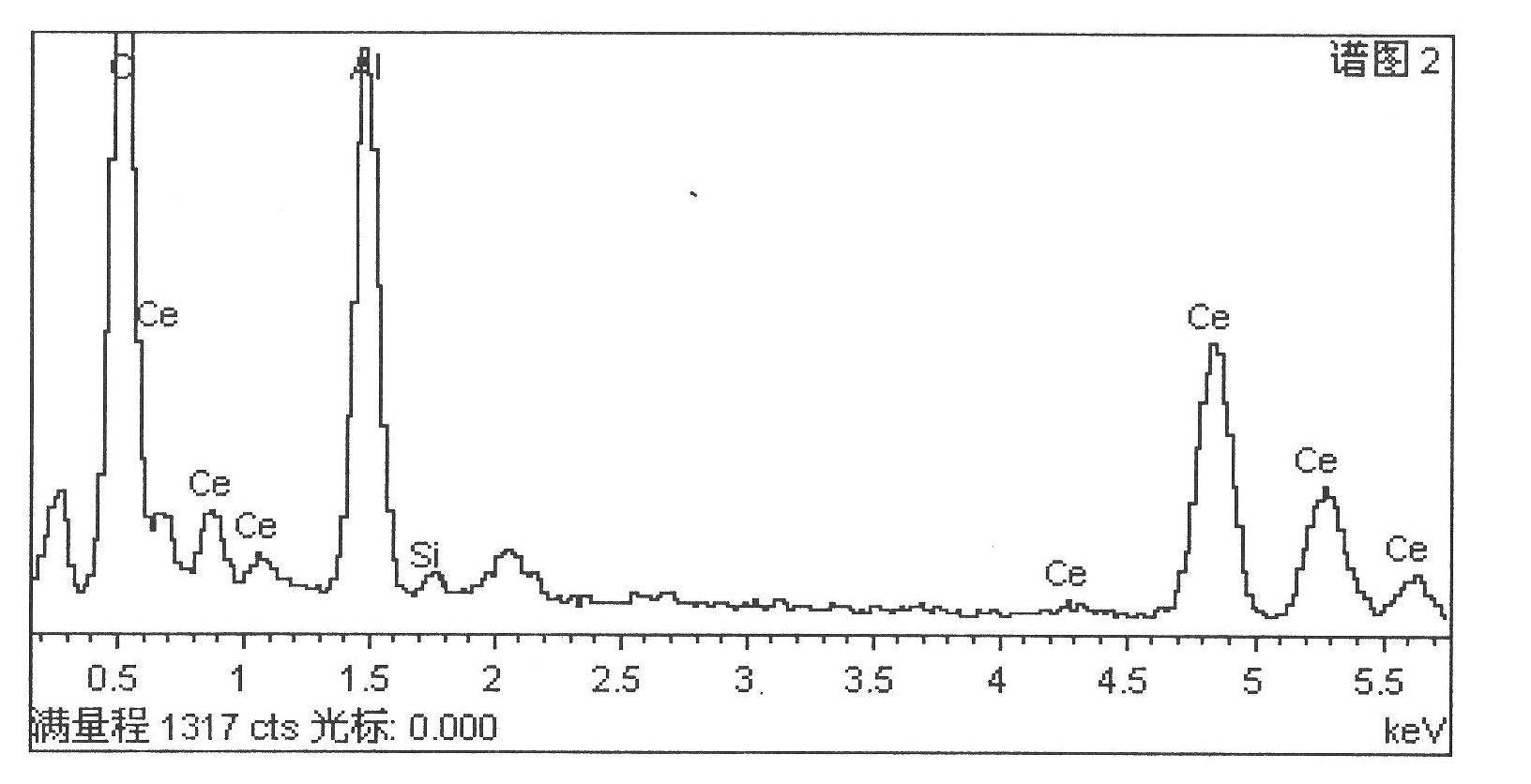

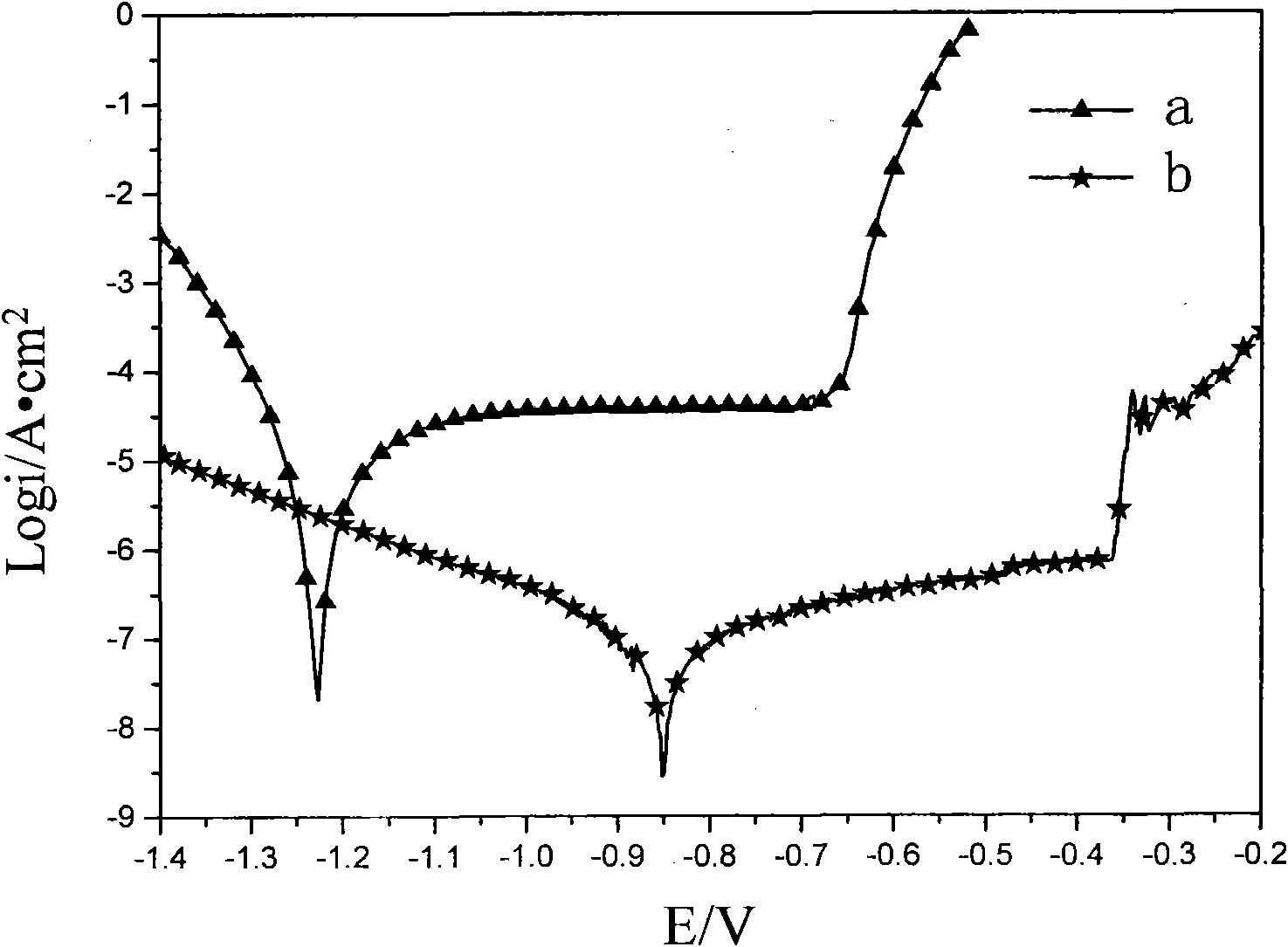

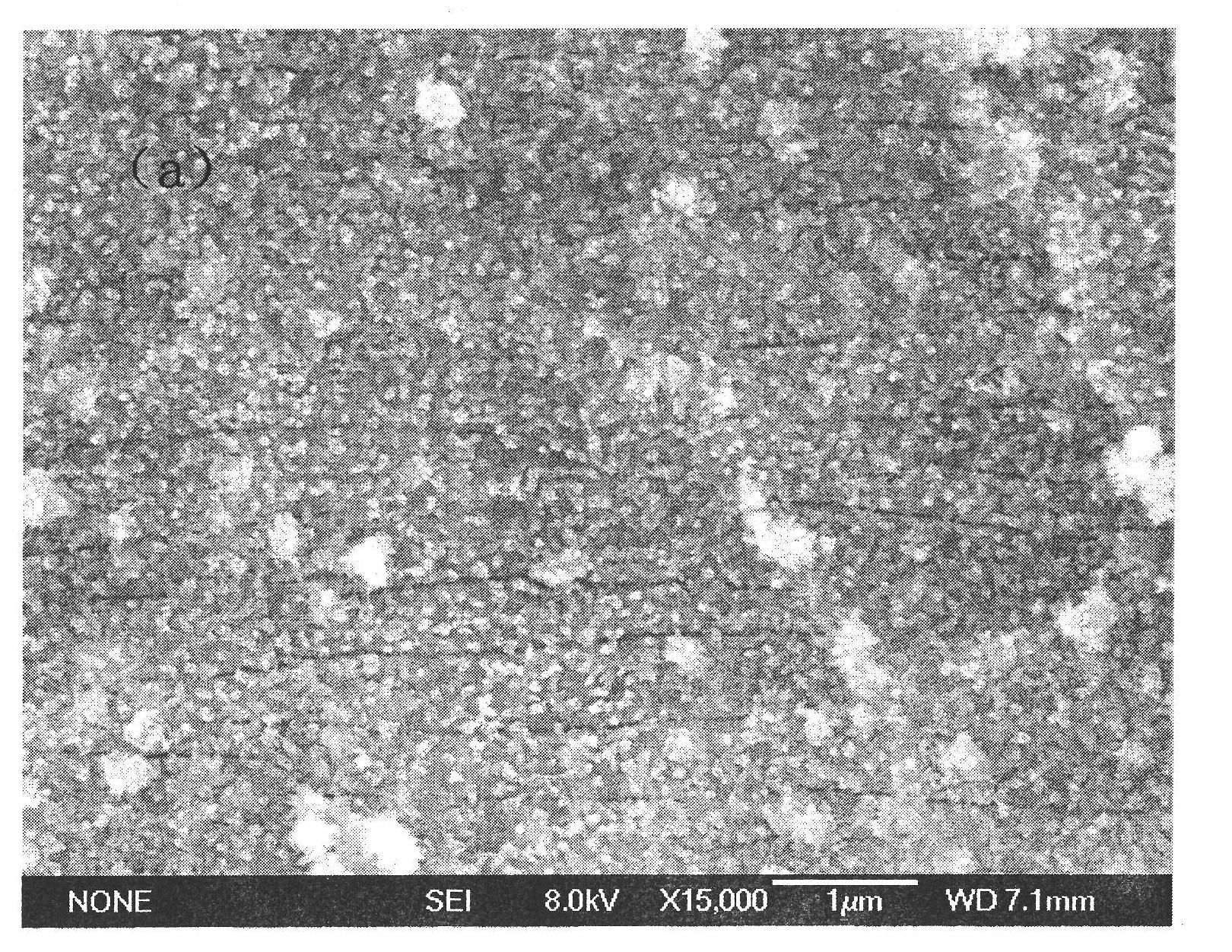

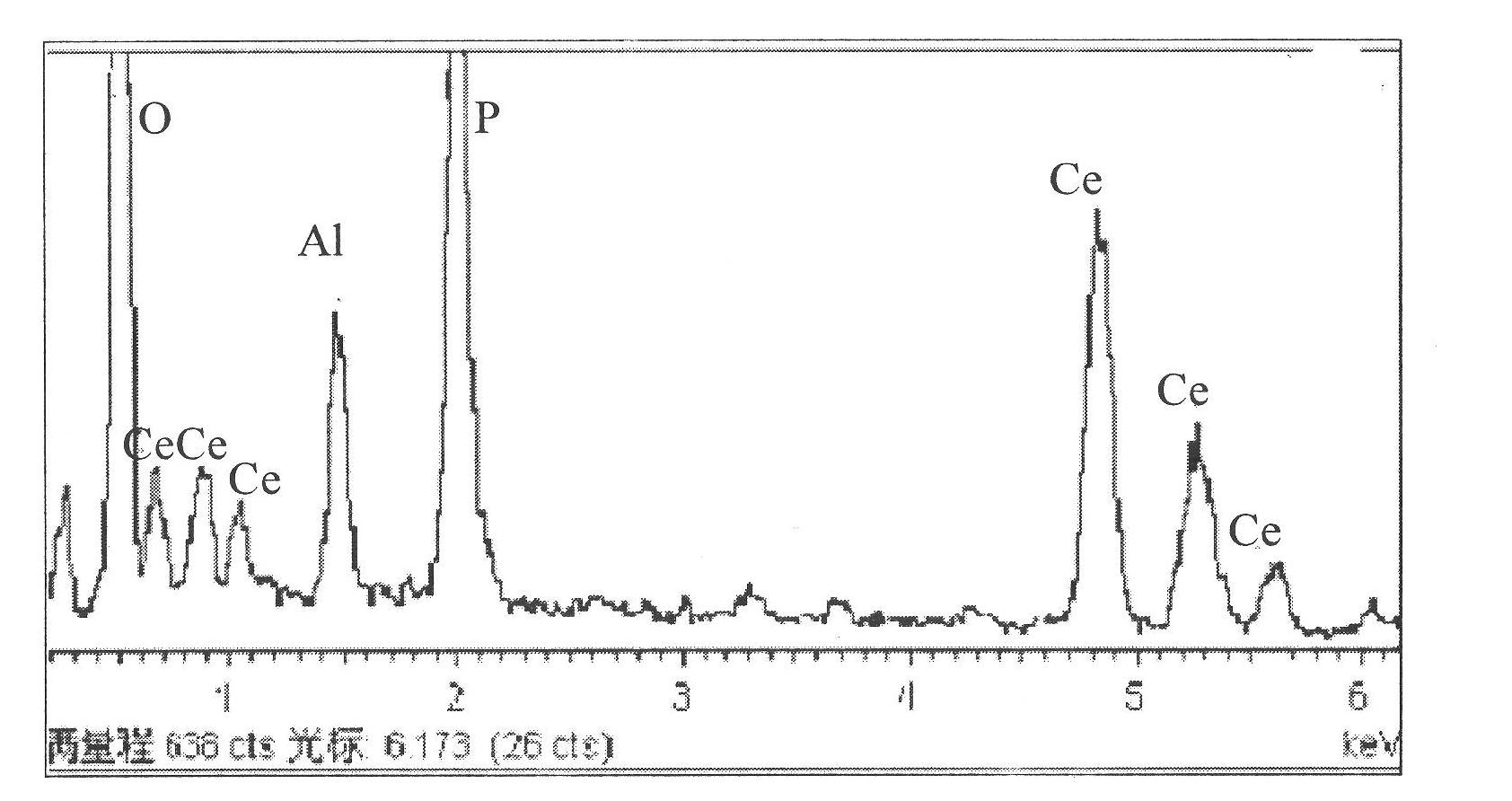

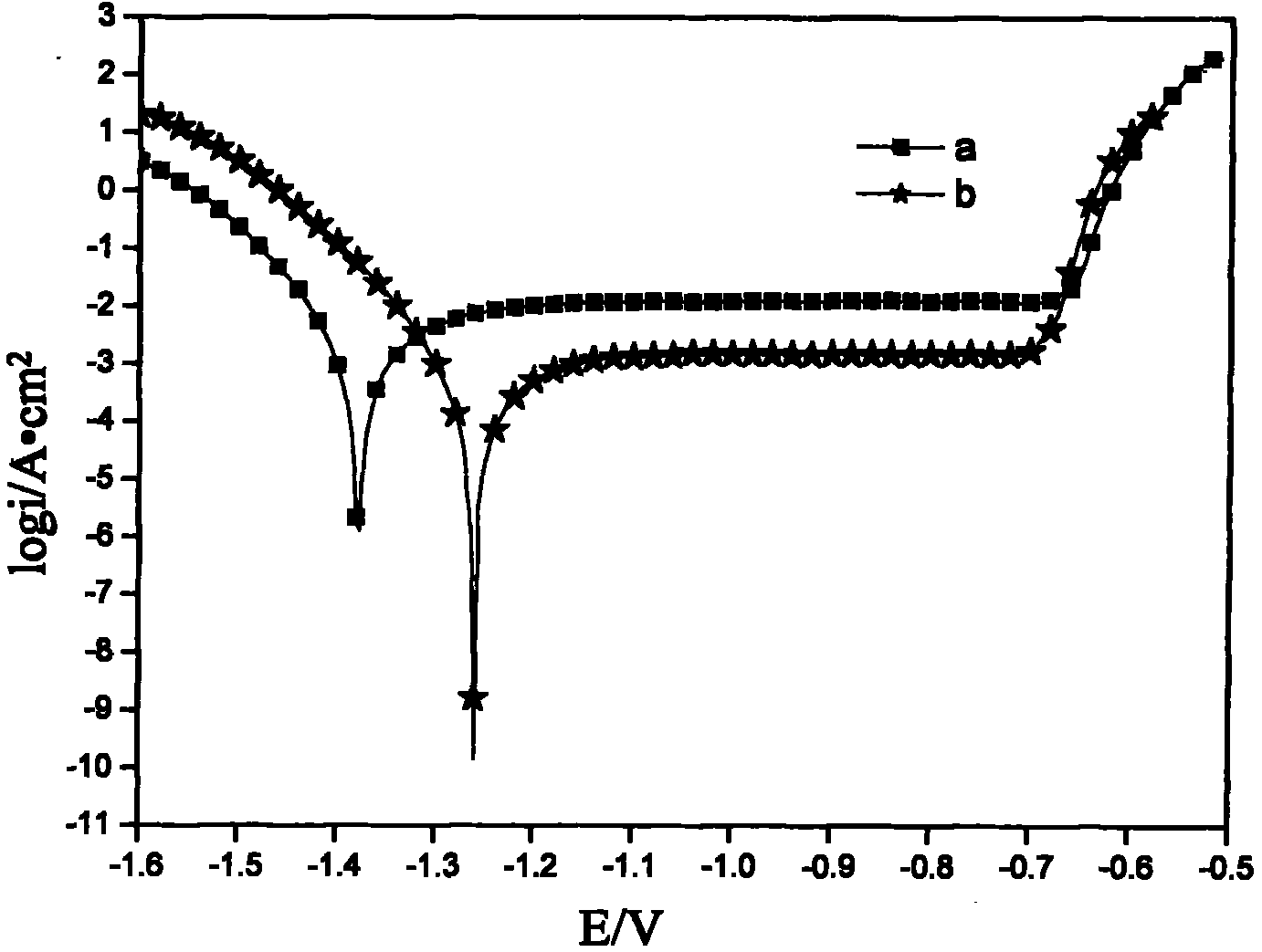

Preparation process of cerium-doped silicon corrosion-resisting membrane on surface of aluminium alloy

InactiveCN102021554AIncreased corrosion potentialImprove corrosion resistanceMetallic material coating processes5052 aluminium alloyCe element

The invention relates a preparation process of a cerium-doped silicon corrosion-resisting membrane on a surface of aluminium alloy. The preparation process is characterized in that surface pretreatment is carried out on aluminium alloy, and then the aluminium alloy is immersed in cerium salt conversion liquid dissolved with organosilicon, so as to carry out membrane formation reaction on the surface of the aluminium alloy, thus the corrosion-resisting membrane is formed; and then the aluminium alloy is taken out, is cleaned by deionized water and is dried. The invention has the advantages that the process is simple, the membrane formation speed is rapid, the preparation time of the corrosion-resisting membrane is shortened, the main constituents of the corrosion-resisting membrane layer are cerium dioxide and hydrated cerium oxide, and the uniformity and compactness of the surface of the membrane are good. After the cerium-doped silicon corrosion-resisting membrane is formed on the surface of the aluminium alloy, the corrosion resistance of the aluminium alloy is improved remarkably.

Owner:OCEAN UNIV OF CHINA

Technique for preparing cerium corrosion-resistant film on surface of aluminum alloy

InactiveCN102108507AImprove corrosion resistanceFast film formationMetallic material coating processesAfter treatmentPhosphate

The invention relates to a technique for preparing a cerium corrosion-resistant film on the surface of aluminum alloy, which is characterized by comprising the following steps: carrying out surface pretreatment on aluminum alloy; immerging the aluminum alloy in a cerium salt conversion liquid to form a film; taking out the aluminum alloy, washing with deionized water, and immerging the aluminum alloy in a phosphate water solution to carry out after-treatment; and washing with deionized water, and drying. The invention has the advantages of high film-forming speed and high deposition rate, and effectively shortens the reaction time. The prepared corrosion-resistant film mainly comprises quadrivalent phosphates of cerium, and the film is uniform and compact; and after the cerium corrosion-resistant film is formed on the surface of the aluminum alloy, the corrosion resistance of the aluminum alloy is obviously enhanced.

Owner:OCEAN UNIV OF CHINA

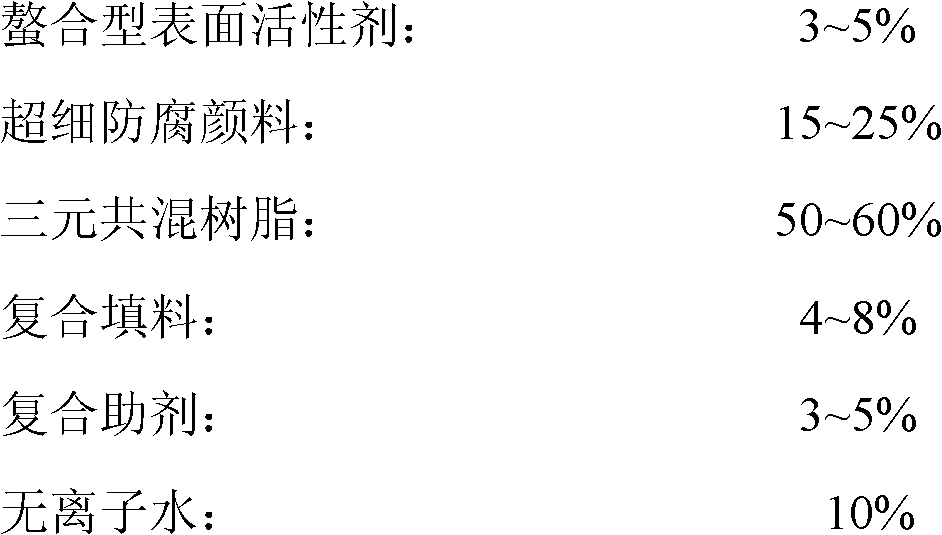

Chelate type flashing erosion-resistant water-based metal anticorrosion coating and preparation method thereof

InactiveCN102153930AHigh resistance to flash corrosionHigh surface resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedEmulsion

The invention relates to a chelate type flashing erosion-resistant water-based metal anticorrosion coating and a preparation method thereof. A chelate type surfactant is used as a flashing erosion-resistant component. Being stirred, the chelate type surfactant, composite assistant and deionized water are added and blended and then continually stirred with composite filler added. Being stirred, superfine anticorrosion pigment is added uniformly and then is stirred continuously for a certain time. Color paste obtained is dispersed and homogenized by a high-shear emulsion machine and then sent to a horizontal sand mill to be ground into pigment filler color paste with the particle size being less than or equal to 10mum. Being stirred at high speed, ternary blending resin is slowly added in the pigment filler color paste and stirred continuously for a certain time so that polyvalent metal oxide formed by flashing erosion and the chelate type surfactant form complex. Under the migration action of the surfactant, the complex can be easily stripped from a metal substrate, so that the substrate remains smooth. Therefore, the anticorrosion ability of the water-based anticorrosion coating is improved and the adhesion of the coating on the substrate is not affected.

Owner:大连市轻化工研究所有限公司

Biomimetic mineralization method for preparing magnesium alloy-calcium phosphate coating composite material

InactiveCN102776499AAccelerated corrosionGood biocompatibilityMetallic material coating processesAcid etchingCalcium phosphate product

The invention relates to a biomimetic mineralization method for preparing a magnesium alloy-calcium phosphate coating composite material. The method comprises single preprocessing, acid etching preprocessing, bionic solution configuration, immersing in the bionic solution and the like to obtain the magnesium alloy-calcium phosphate coating composite material. Compared with other magnesium alloy-calcium phosphate coating composite materials, a magnesium alloy base body is firstly subjected to acid etching preprocessing, so that the calcium phosphate coating and the surface of the base body can be combined well; and the calcium-phosphate ratio of the bionic solution is 1.67:1, besides, the content of the calcium and the phosphate is higher than that of ordinary bionic solutions in the prior art, the biomimetic mineralization efficiency can be improved remarkably, and the calcium phosphate products are similar to human bone components and have good biocompatibility and corrosion resistance.

Owner:TONGJI UNIV

Method for preparing super-hydrophobic coating based on electrodeposition method, and application of super-hydrophobic coating

InactiveCN109355689AIncreased corrosion potentialCorrosion current reductionElectrolytic coatingsTowersAluminium powderPre treatment

The invention relates to a method for preparing a super-hydrophobic coating, in particular to a method for preparing a super-hydrophobic coating based on an electrodeposition method, and the application of the super-hydrophobic coating to the corrosion prevention of a power grid, and belongs to the technical field of super-hydrophobic coatings. The method for preparing the super-hydrophobic coating based on the electrodeposition method comprises the following step I of electrode pretreatment: grinding a steel electrode on abrasive paper, and then cleaning the steel electrode ground properly with deionized water made by a laboratory; then, performing polishing treatment with aluminium powder for further removing large oil stains; and next, rewashing the steel electrode with the deionized water made by the laboratory. The method has the beneficial effects that the super-hydrophobic coating is prepared with the electrodeposition method, and applied to the corrosion prevention of the powergrid; the corrosion potential is increased and the corrosion current is reduced when the super-hydrophobic coating is used; it is proved that the corrosion resistance of the electrode with the coating is better than the corrosion resistance of the electrode without the coating, and the good corrosion resistance effect of the power grid is achieved.

Owner:SHANDONG INST OF BUSINESS & TECH

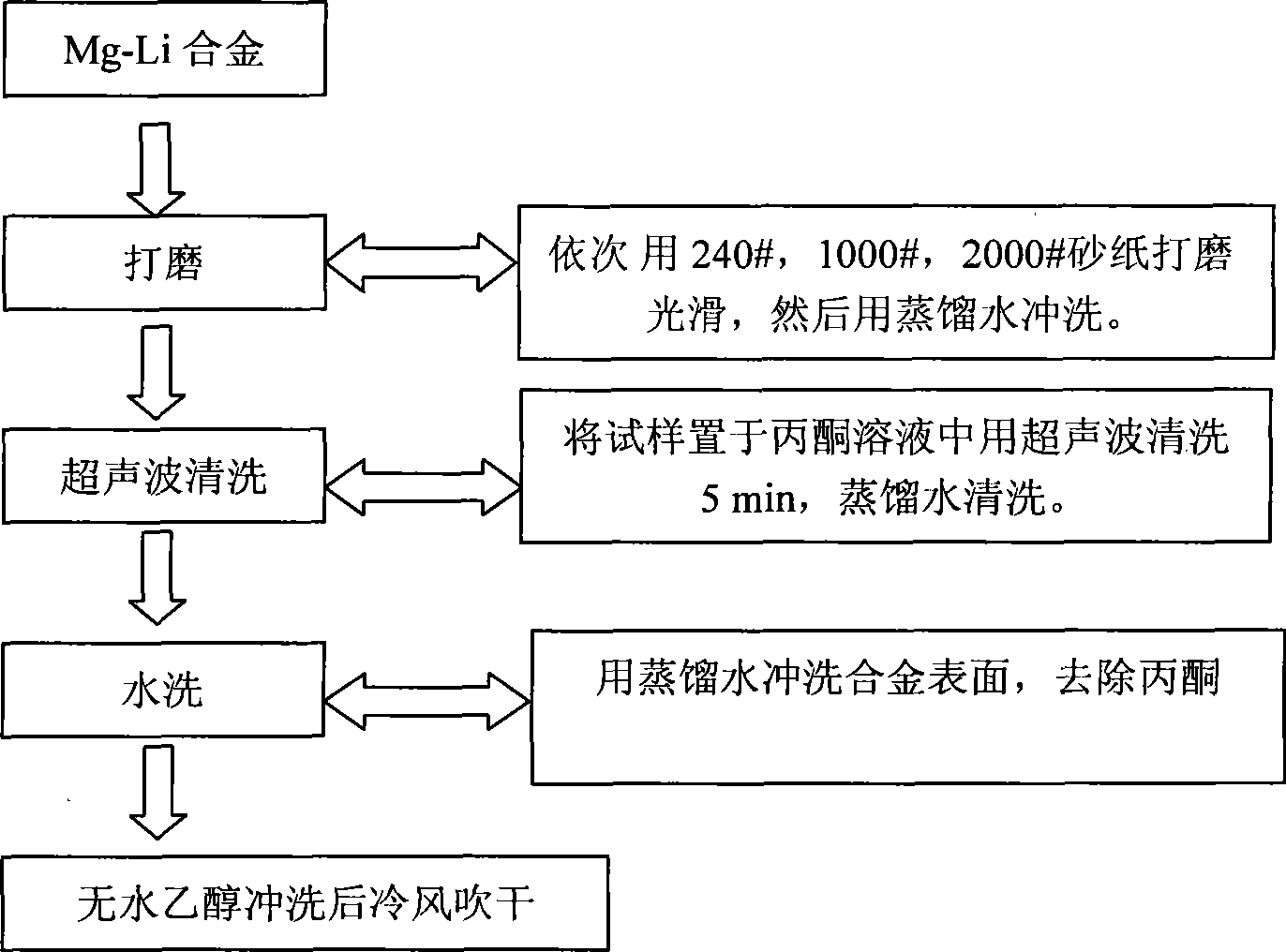

Composite protection method for magnesium-lithium alloy surface and special epoxy/nano SiO2 paint

InactiveCN101954348APlay the role of double protectionIncreased corrosion potentialPretreated surfacesMetallic material coating processesEpoxyOrganic film

The invention provides a composite protection method for a magnesium-lithium alloy surface and a special epoxy / nano SiO2 paint. The method comprises the following steps: synthesizing a novel epoxy / nano SiO2 paint; pretreating the surface of the magnesium-lithium alloy; carrying out phytic acid conversion on the surface of the magnesium-lithium alloy to form a phytic acid conversion film on the surface of the magnesium-lithium alloy; and coating and compounding the epoxy / nano SiO2 paint on the phytic acid conversion film of the magnesium-lithium alloy. The introduction of nano SiO2 is beneficial to improving the corrosion resistance of the epoxy paint. At the same time, the unimolecular organic film layer formed by phytic acid conversion and the coating formed from the epoxy / nano SiO2 paint have similar chemical properties, and the cohesive properties of the both are enhanced, thereby being beneficial to forming a stable and compact protective layer on the surface of the magnesium-lithium alloy to have a dual protection effect on the magnesium-lithium alloy and further improving the corrosion resistance of the magnesium-lithium alloy. Thus, the corrosion potential of the magnesium-lithium alloy is increased by 0.8-1.2VSCE, and the corrosion current is reduced by 4-6 orders of magnitude.

Owner:苏州嘉祥树脂有限公司

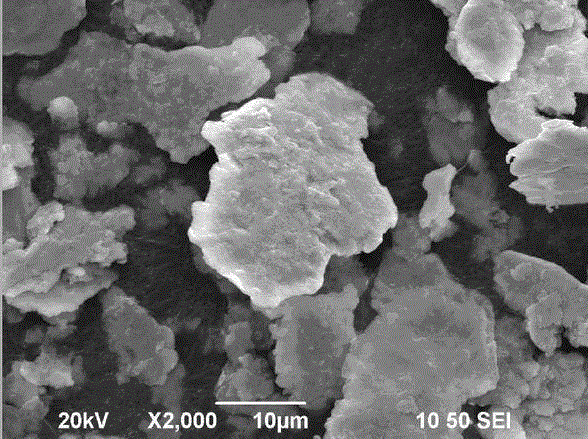

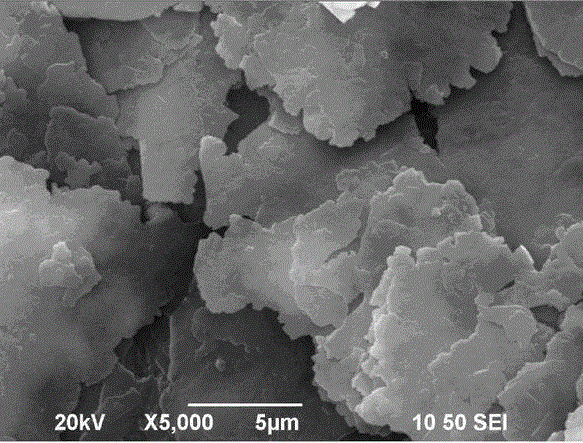

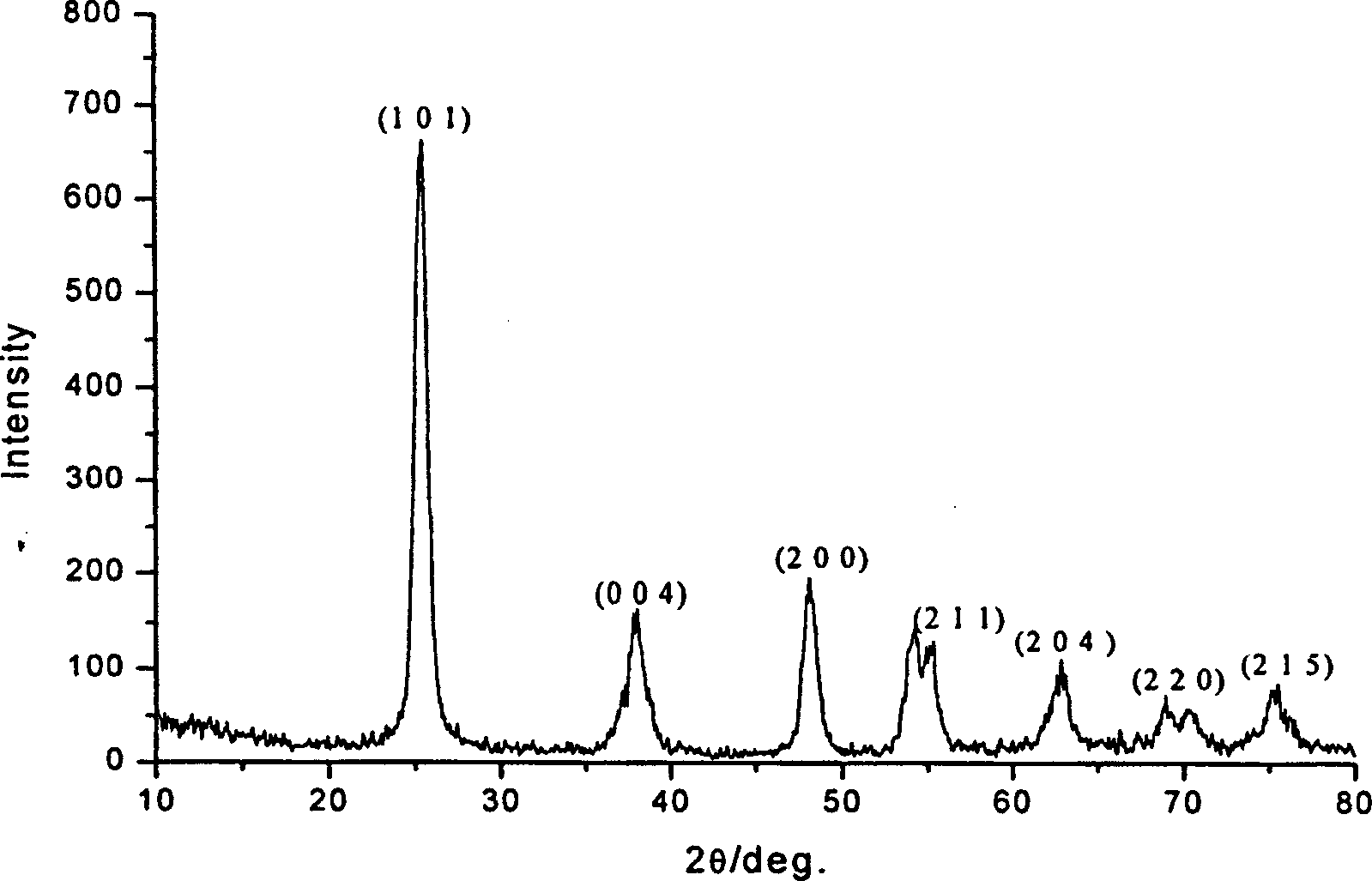

Laser cladding method for improving surface performance of magnesium alloy AZ91D

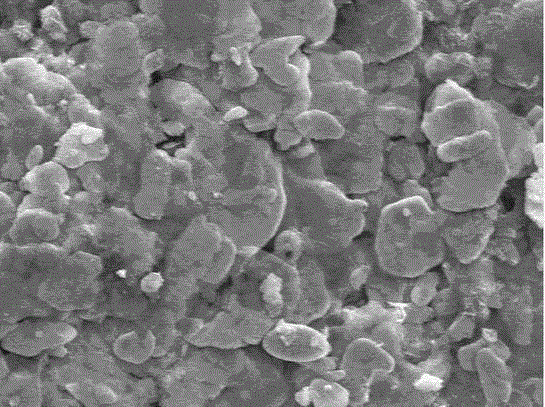

InactiveCN103088339AHigh surface hardnessImprove wear resistanceMetallic material coating processesX-rayScanning electron microscope

The invention provides a laser cladding method for improving the surface performance of magnesium alloy AZ91D. The method adopts Co-Cr alloy powder as a cladding material, and comprises the following steps of 1, pre-treating the surface of a magnesium alloy workpiece; 2, cladding the surface of the magnesium alloy workpiece; 3, obtaining the appearance, composition phase and structure characteristics of the cladding layer by combining a Co-Cr phase diagram and a Co-W-C phase diagram by adopting a SEM (scanning electron microscope) or XRD (X-ray diffraction) analysis means and applying a solidification theory; and 4, testing the mechanical performance and electro-mechanical performance of the surface of the magnesium alloy workpiece according to the composition phase, the appearance and characteristics of distribution, grain size, columnar crystal and dendritic crystal of a solidified tissue. A product fulfilling the requirement can be obtained when the specific surface performance can be achieved. The laser cladding method has the advantages of high hardness of the surface of the magnesium alloy, improved wearing and corrosion resistance, firm combination of effective working layer and matrix, has a certain size and thickness, and is low in cost.

Owner:SUZHOU TIANHONG LASER

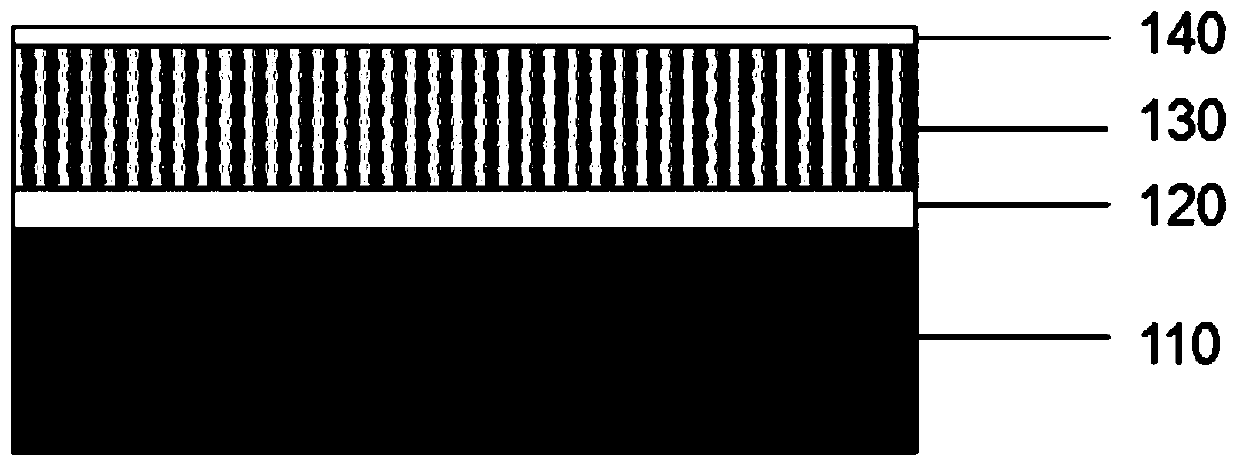

Composite multi-layer hydrophobic and anti-corrosion film as well as preparation method and application thereof

ActiveCN110551975AImprove hydrophobic propertiesImprove corrosion resistanceVacuum evaporation coatingSputtering coatingFilm structureElectrically conductive

The invention discloses a composite multi-layer hydrophobic and anti-corrosion film as well as a preparation method and an application thereof. The film comprises a first metal adhesion layer, a hydrogen-containing amorphous carbon film layer and a hydrogen-free amorphous carbon film layer from bottom to top and is prepared through magnetron sputtering with control on the ratio of argon to hydrogen. Physical and chemical characteristics of different hybridization composition types of carbon are considered, the amorphous carbon film adopting the dual-layer structure is designed, the a-C:H filmis used as a conductive substrate, and thin-layer a-C with the surface covered is used as the anti-corrosion and hydrophobic medium. Through the structural design, the amorphous carbon film can effectively improve the anti-corrosion performance of the film structure on the basis that the conductivity is guaranteed. The design concept has the great prospect for application in the field of metal corrosion resistance and bipolar plates and has the very positive promotion significance for application of metal bipolar plates to hydrogen cells.

Owner:FOSHAN UNIVERSITY

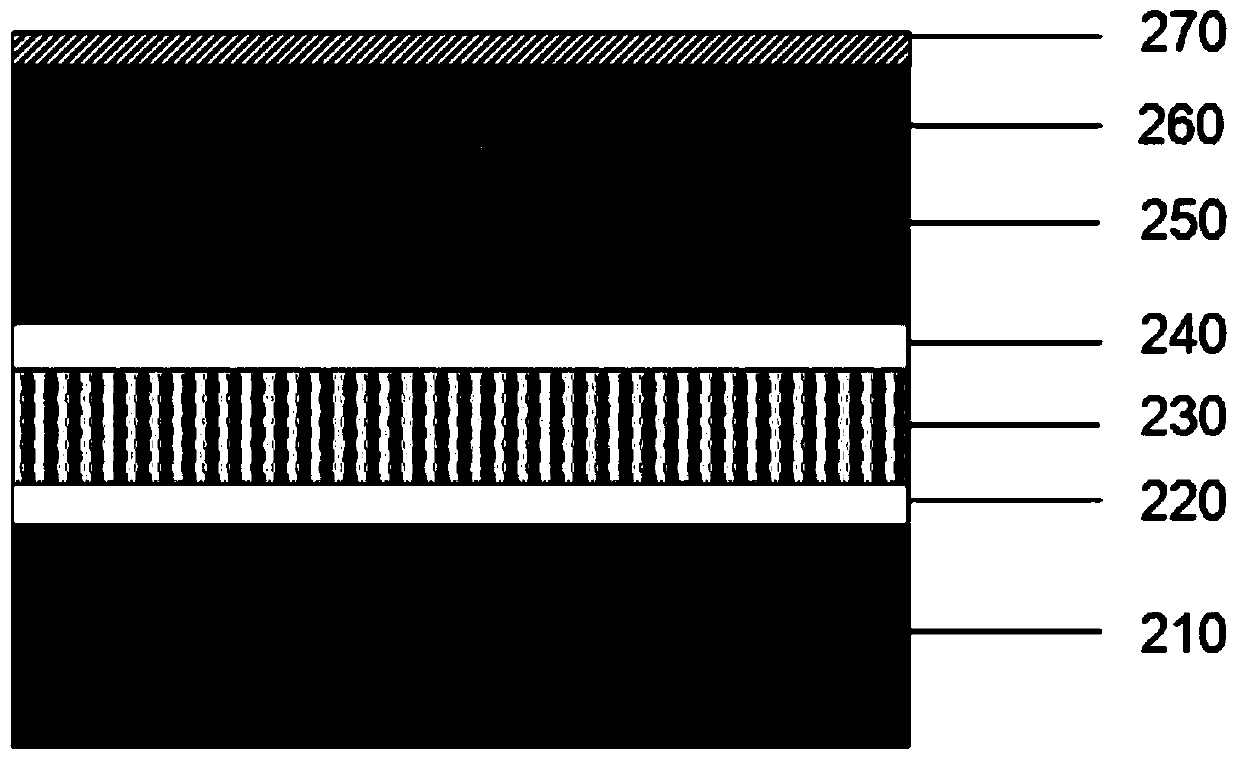

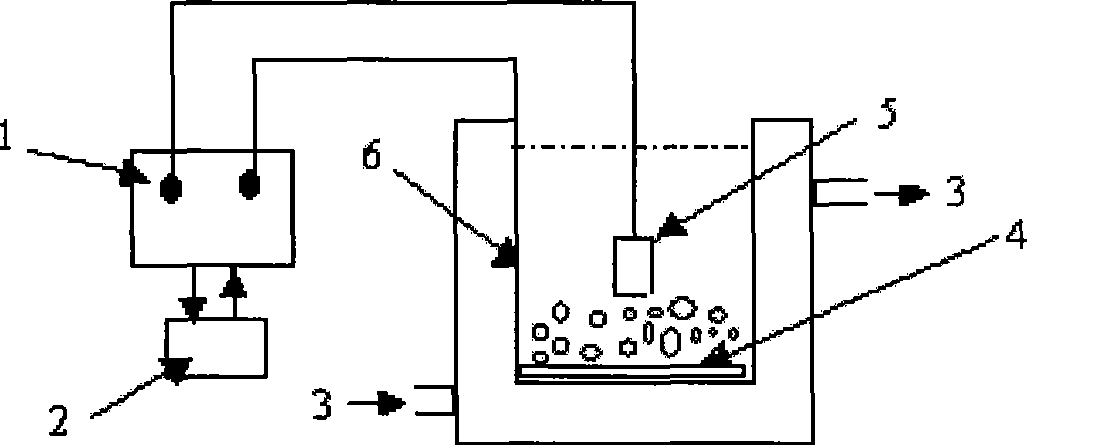

Method for preparing composite coating by surface differential arc oxidation/chemical conversion of Mg-Li alloy

InactiveCN101418460AImprove corrosion resistanceImprove densification performanceAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention provides a method for preparing a micro-arc oxidized / chemically converted composite coating on the surface of Mg-Li alloy. The method comprises the following steps: in an electrolyte consisting of 3 to 30 grams of silicate per liter, 1 to 10 grams of sodium hydroxide per liter, 10- 30 milliliters of triethanolamine per liter and 1 to 3 liters of distilled water, pretreated Mg-Li alloy is subjected to micro-arc oxidation for 4 minutes by use of a constant-current micro-arc oxidation mode, at the pulse frequency of 2,000 Hz, with the duty cycle of 15 percent and the current density of 5 A / dm<2>; the Mg-Li alloy subjected to the micro-arc oxidation is completely placed in a chemical conversion solution; the conversion solution consists of 5 to 40 grams of molybdate per liter, 1 to 10 grams of sodium fluoride per liter and 1 to 15 milliliters of hydrogen peroxide with the concentration of 30 percent; the reaction temperature of chemical conversion is 45 DEG C; the reaction time of chemical conversion is 0.5 to 3 hours; and after the chemical conversion treatment, the film-covered Mg-Li alloy is taken out and dried with cold air. The method has the advantages of high efficiency, low cost, simple process and no pollution on environment, and can improve the corrosion resistance of the Mg-Li alloy and widen the application range of the Mg-Li alloy.

Owner:HARBIN ENG UNIV

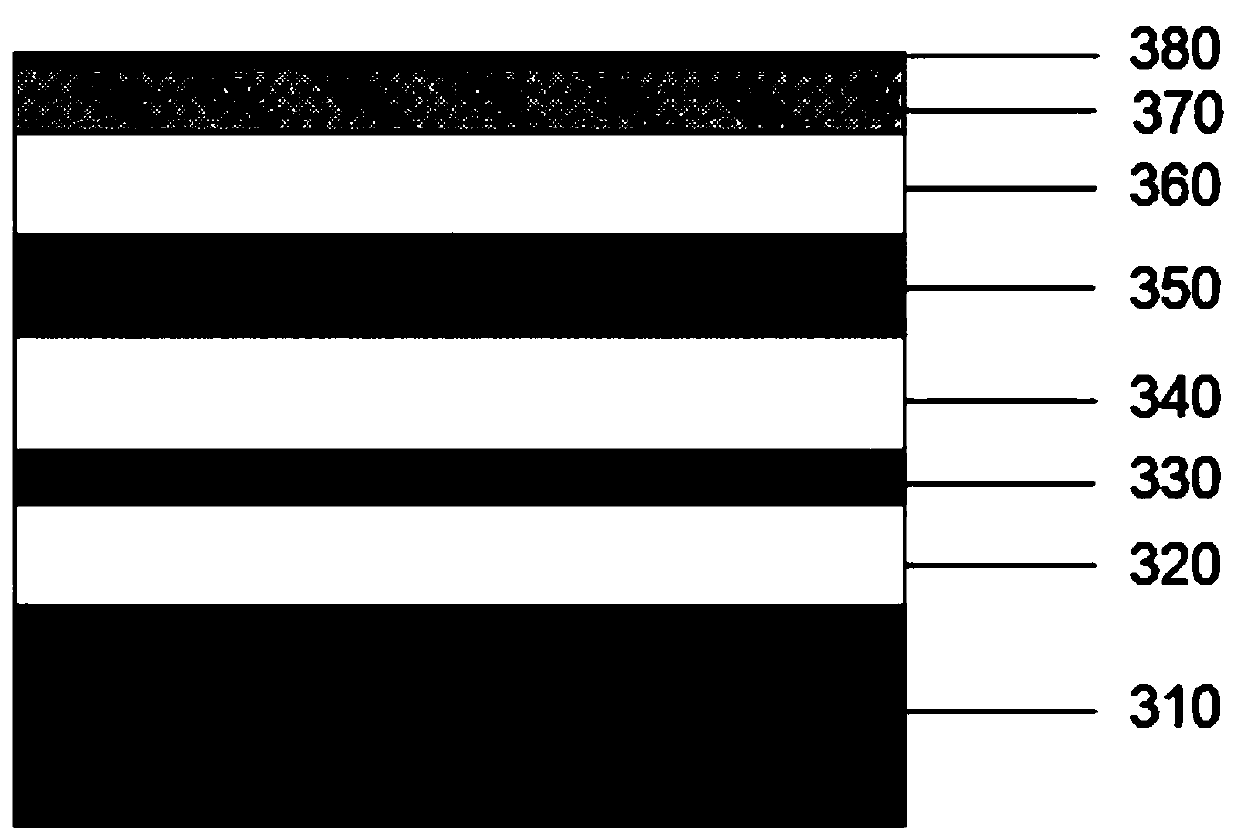

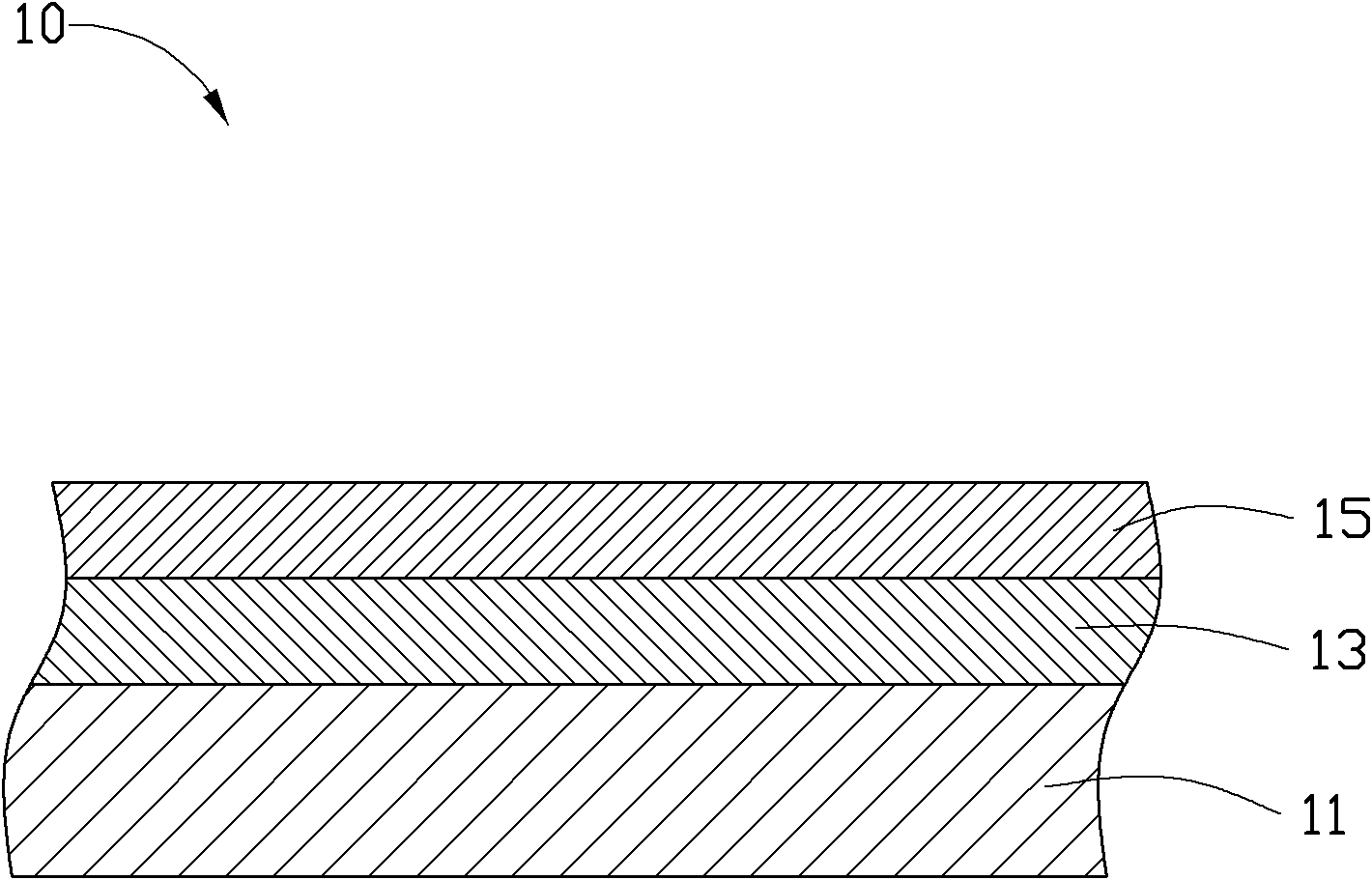

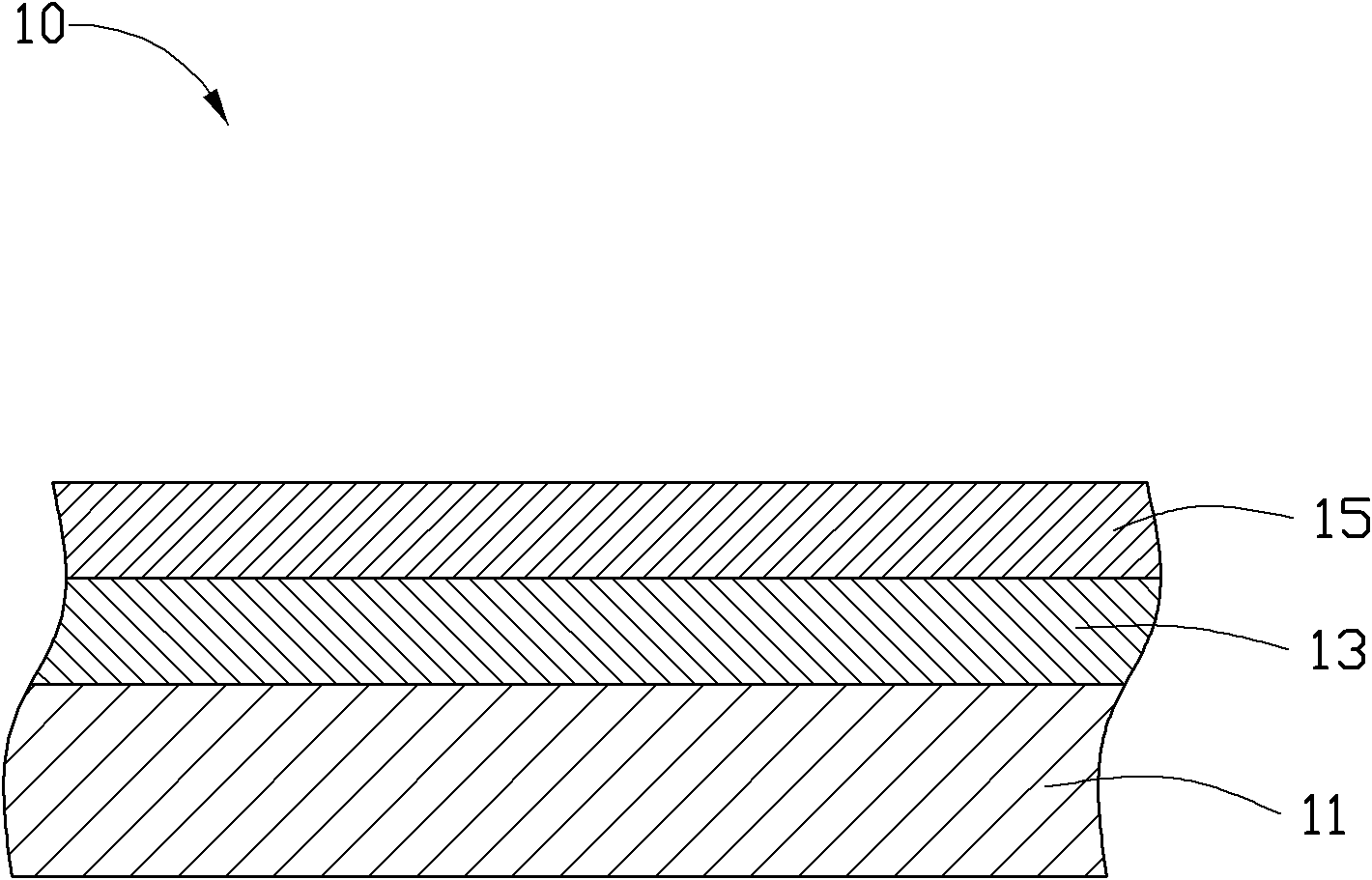

Coated piece and manufacturing method thereof

InactiveCN102465251AImprove corrosion resistanceCorrosion current reductionVacuum evaporation coatingSputtering coatingAlloy substrateSilicon

The invention provides a coated piece which comprises an aluminum or aluminum alloy substrate, an amorphous alloy layer and a colored layer with an anti-corrosion function, wherein the amorphous alloy layer and the colored layer are formed on the aluminum or aluminum alloy substrate in turn; the amorphous alloy layer is Fe70Cr10B13X7; and X is any one selected from phosphorus, carbon and silicon. The coated piece has excellent corrosion resistance and decorative appearance. The invention also provides a manufacturing method for the coated piece.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

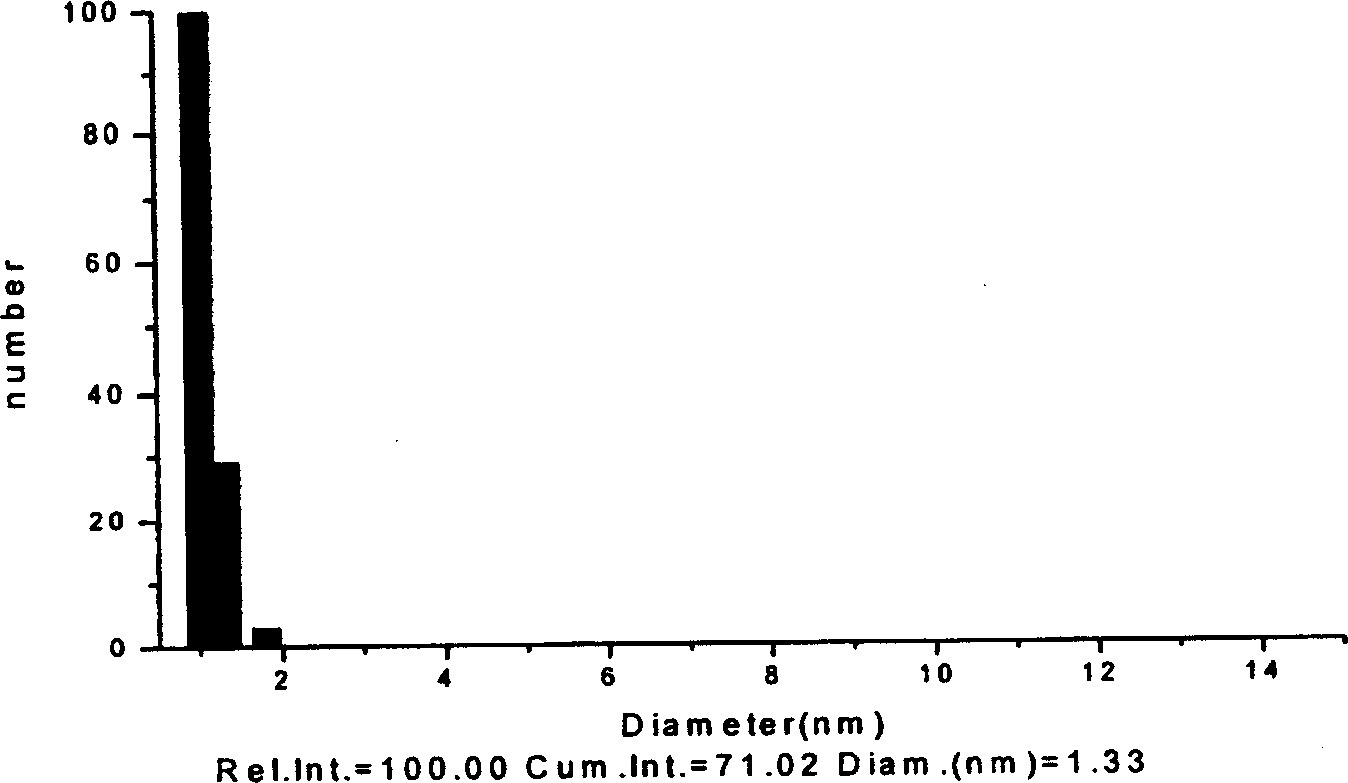

Metal surface anti-corrosion method based on surface nanometer construct

InactiveCN1211500CCorrosion current reductionImprove corrosion resistanceSolid/suspension decomposition chemical coatingAlcoholMetal

An anticrossion treating process for the metal surface includes such steps as preparing ultrafine (nano-class) TiO2 sol by adding EAcAC and tetrabutyl titanate to alcohol and dropping water, preparing a decorative nano TiO2 film layer on the metal surface by pull method, hydrothermal treating, and fluorosilalkylating to obtain a hydrophobic film. Its advantages are high anticorrosion effect and easy control.

Owner:XIAMEN UNIV

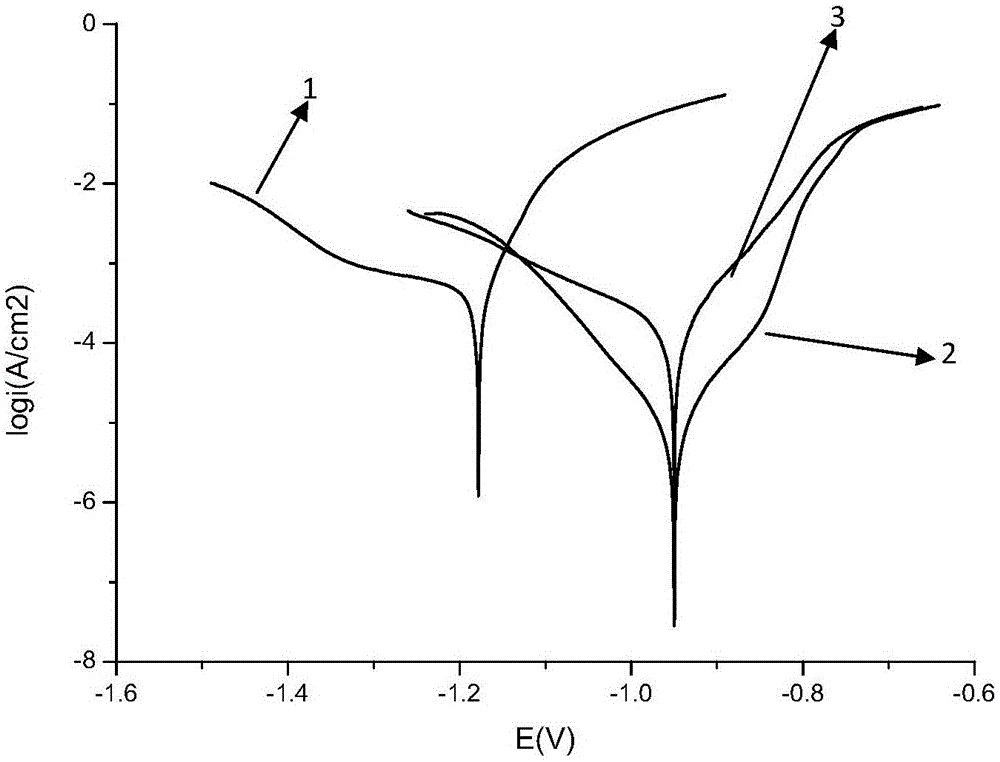

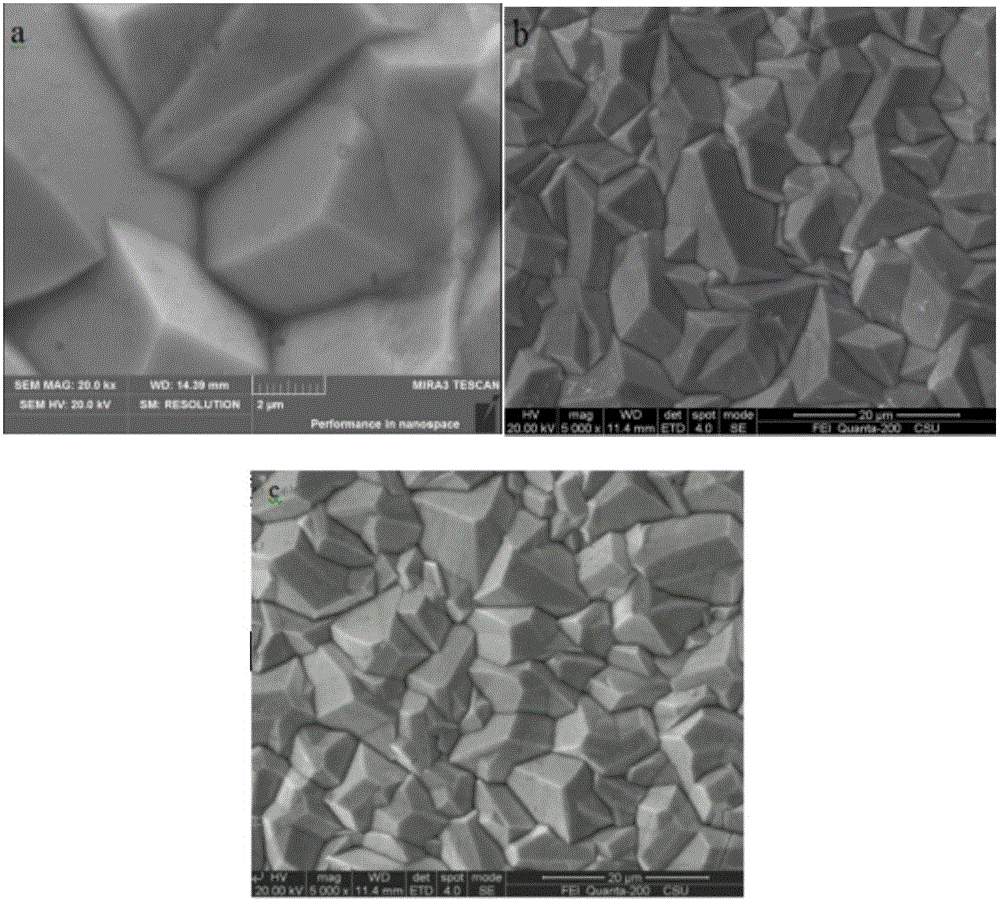

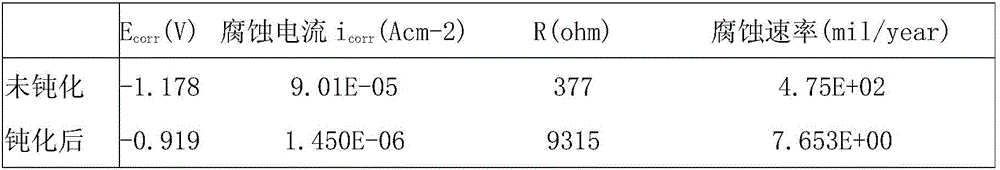

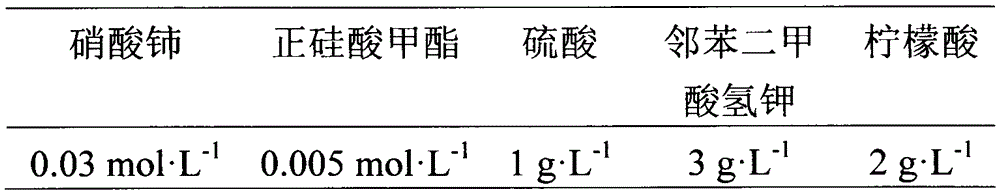

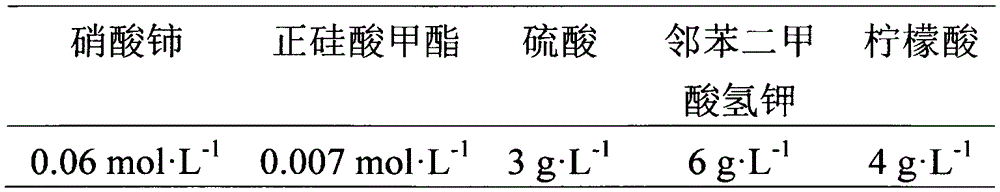

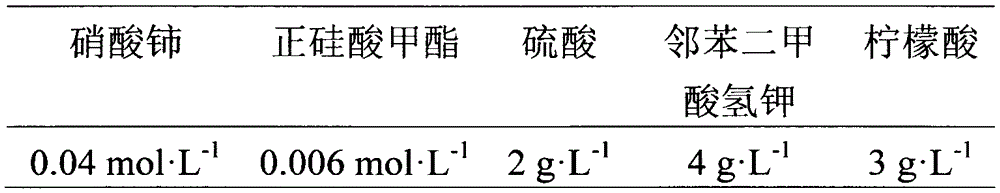

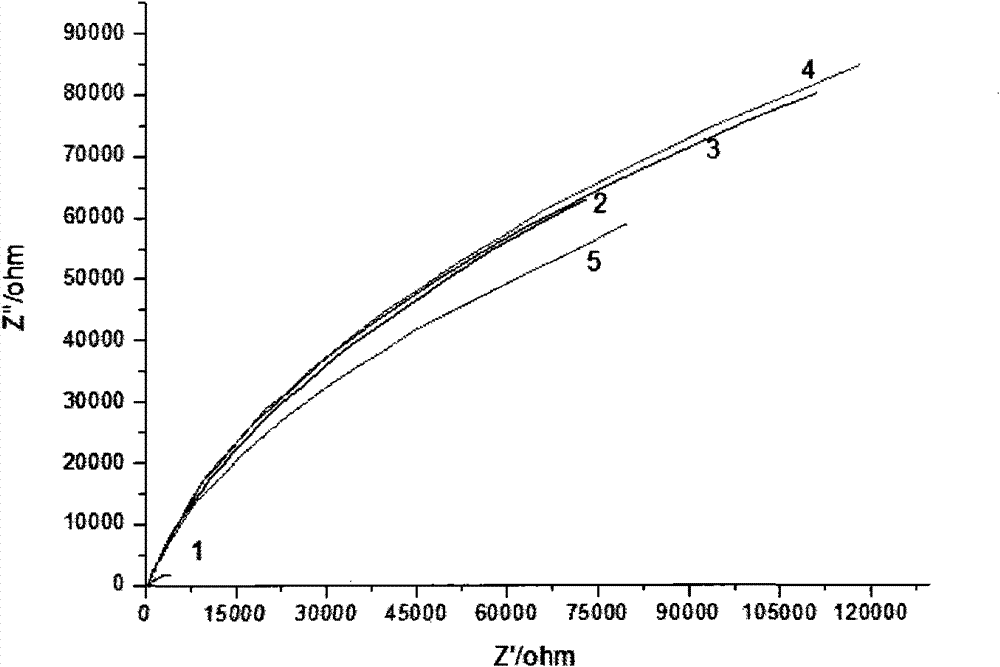

Copper alloy passivation solution and passivation layer preparation method

InactiveCN105256359AImprove corrosion resistanceExtended service lifeAnodisationSolventAnodic oxidation

The invention provides a copper alloy passivation solution and a passivation layer preparation method, and belongs to the field of metal material surface treatment. Each liter of the copper alloy passivation solution comprises 0.03-0.06mol of cerium nitrate, 0.005-0.007mol of ethyl orthosilicate, 1-3g of sulfuric acid, 3-6g of potassium biphthalate and 2-4g of citric acid; and a solvent is water. A passivation layer preparation method comprises the following steps: taking a copper alloy as a working electrode in a three-electrode system; putting the working electrode into the passivation solution; enabling the working electrode, a reference electrode and a counter electrode to form the conducing tri-electrode system; and carrying out anode oxidization on the working electrode under constant-current density to form the passivation layer. The passivation layer preparation method is simple and low in cost; and the prepared passivation layer can be applied to surface treatment of copper and a copper alloy product, so that the corrosion resistance of the copper alloy can be obviously improved, and the service life of the copper alloy is prolonged.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Application of 3-amino-1,2,4-trizole as bronze corrosion inhibitor

The invention discloses an application of 3-amino-1,2,4-trizole as a bronze corrosion inhibitor, belonging to the technical field of corrosion and protection of metal materials. The 3-amino-1,2,4-trizole has a concentration of 10-40mg / L in a simulated atmospheric solution and the electrochemistry data show that the 3-amino-1,2,4-trizole used as the bronze corrosion inhibitor has good corrosion inhibiting effect. Particularly, after adding 30mg / L 3-amino-1,2,4-trizole corrosion inhibitor in the simulated atmospheric solution, the bronze corrosion current is greatly reduced from 6.886uA / cm2 to 0.2684uA / cm2 and the corrosion inhibition efficiency is 96.1%, thereby proving that the 3-amino-1,2,4-trizole can be used as the bronze corrosion inhibitor, is environmental-friendly, and has good corrosion inhibiting effect to the bronze in the system after used.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

Environment-friendly polyaniline anti-corrosion and anti-shedding coating

InactiveCN104341960AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyEthylene glycol bis

The invention discloses an environment-friendly polyaniline anti-corrosion and anti-shedding coating. The coating comprises a component A and a component B, wherein the weight ratio of the component A to the component B is (10 to 1)-(20 to 1); the component A is prepared from the following components: (1) 53g of liquid epoxy resin E56, (2) 6g of diethylene glycol dibenzoate, (3) 0.5g of OP-10, (4) 10g of n-amyl alcohol, (5) 3g of ammonium persulfate, (6) 1.5g of distilled water, (7) 1g of 0.4mol / L camphorsulfonic acid water solution, (8) 10g of aniline, (9) 0.5g of methyl silicone oil and (10) 7g of neopentyl glycol diglycidyl ether; the component B comprises the following components: 110g of liquid fatty polyamine, 30g of polyaniline, 5g of quartz sand, 10g of ethylene glycol phenyl ether, 5g of talcum powder and 5g of rosin glycerin ester. The coating has the advantages of high polyaniline content, good anti-corrosion property, no pollution, low cost, and the like.

Owner:QINGDAO YIQUN PANT GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com