Coated piece and manufacturing method thereof

A manufacturing method and coating technology, applied in chemical instruments and methods, sputtering plating, ion implantation plating, etc., can solve problems such as shedding, discoloration, and inability to effectively prevent electrochemical corrosion of aluminum or aluminum alloy substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

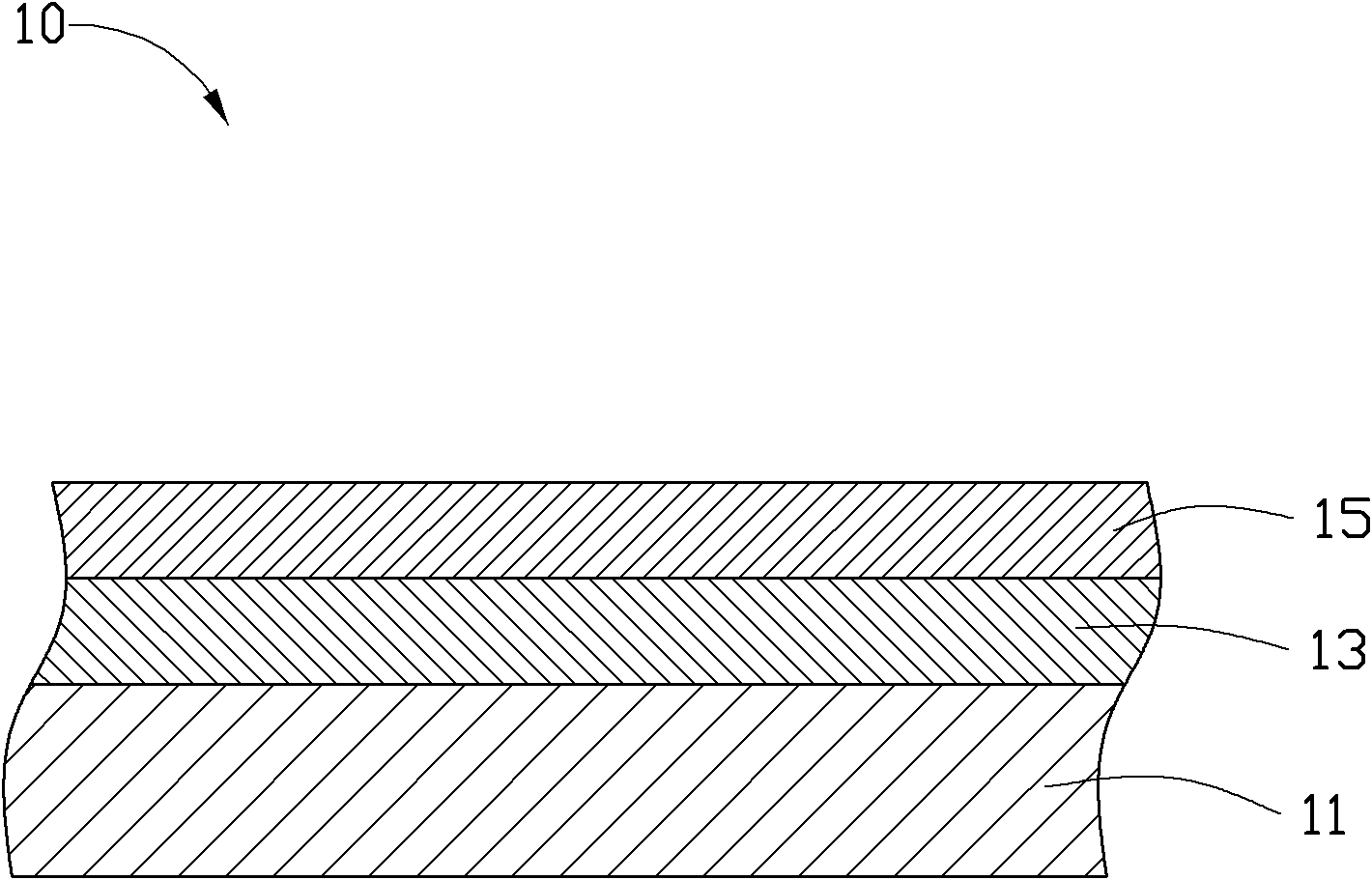

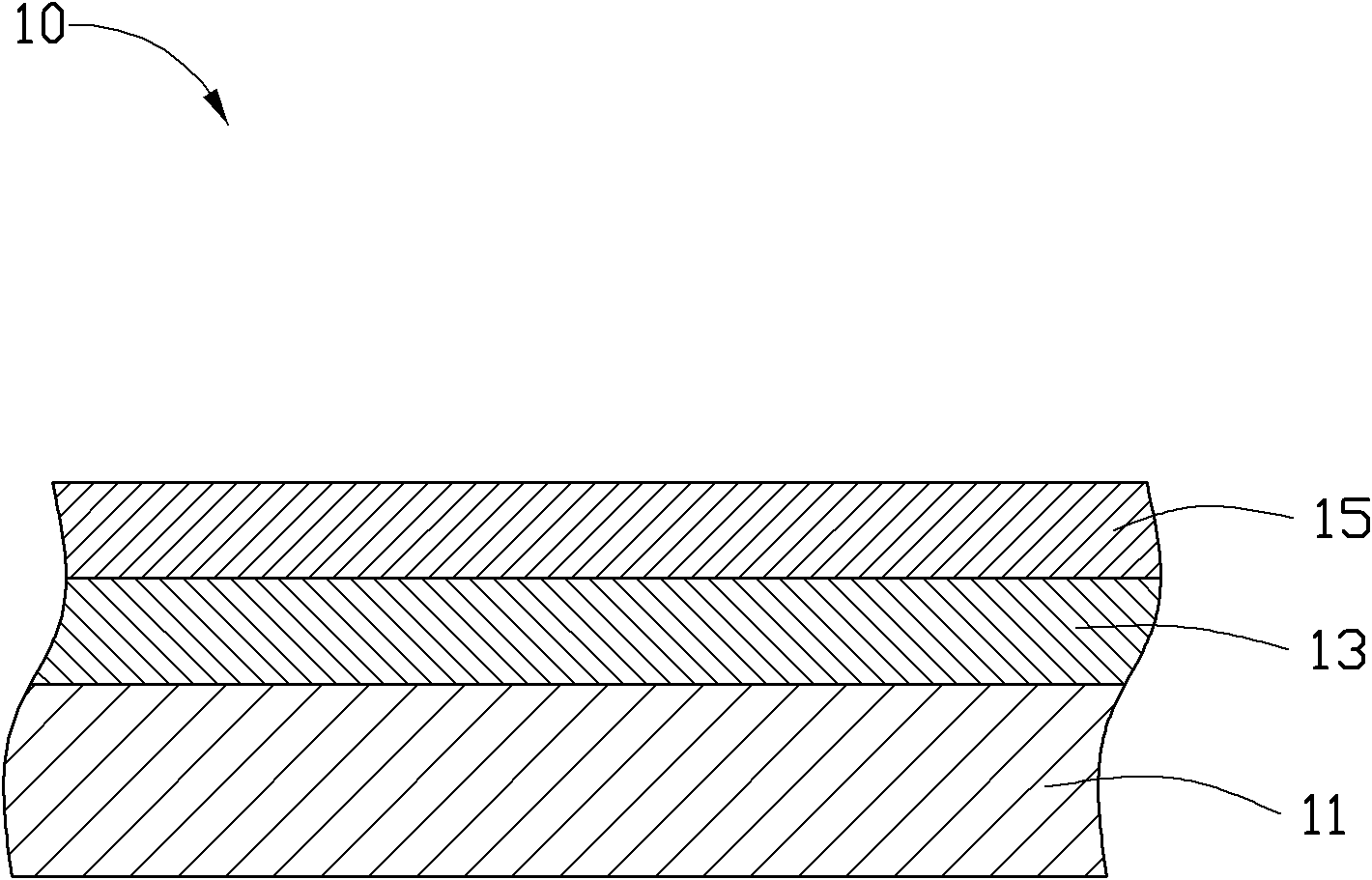

[0019] see figure 1 According to a preferred embodiment of the present invention, the covering member 10 includes an aluminum or aluminum alloy substrate 11 , an amorphous alloy layer 13 and a color layer 15 sequentially formed on the aluminum or aluminum alloy substrate 11 . The covering part 10 may be a covering part of 3C electronic products, and may also be parts of glasses frames, building parts, automobiles and other vehicles.

[0020] The amorphous alloy layer 13 is Fe 70 Cr 10 B 13 x 7 layer, wherein X is selected from any one of phosphorus (P), carbon (C) and silicon (Si). The thickness of the amorphous alloy layer is 2.0-3.0 μm.

[0021] The color layer 15 is a TiN layer with a thickness of 0.5-3.0 μm. It can be understood that the color layer 15 can also be a TiNO layer, a TiCN layer, a CrN layer, a CrNO layer, a CrCN layer or other decorative film layers with an anti-corrosion function.

[0022] Both the amorphous alloy layer 13 and the color layer 15 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com