Patents

Literature

37results about How to "Improve decorative appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Headgear

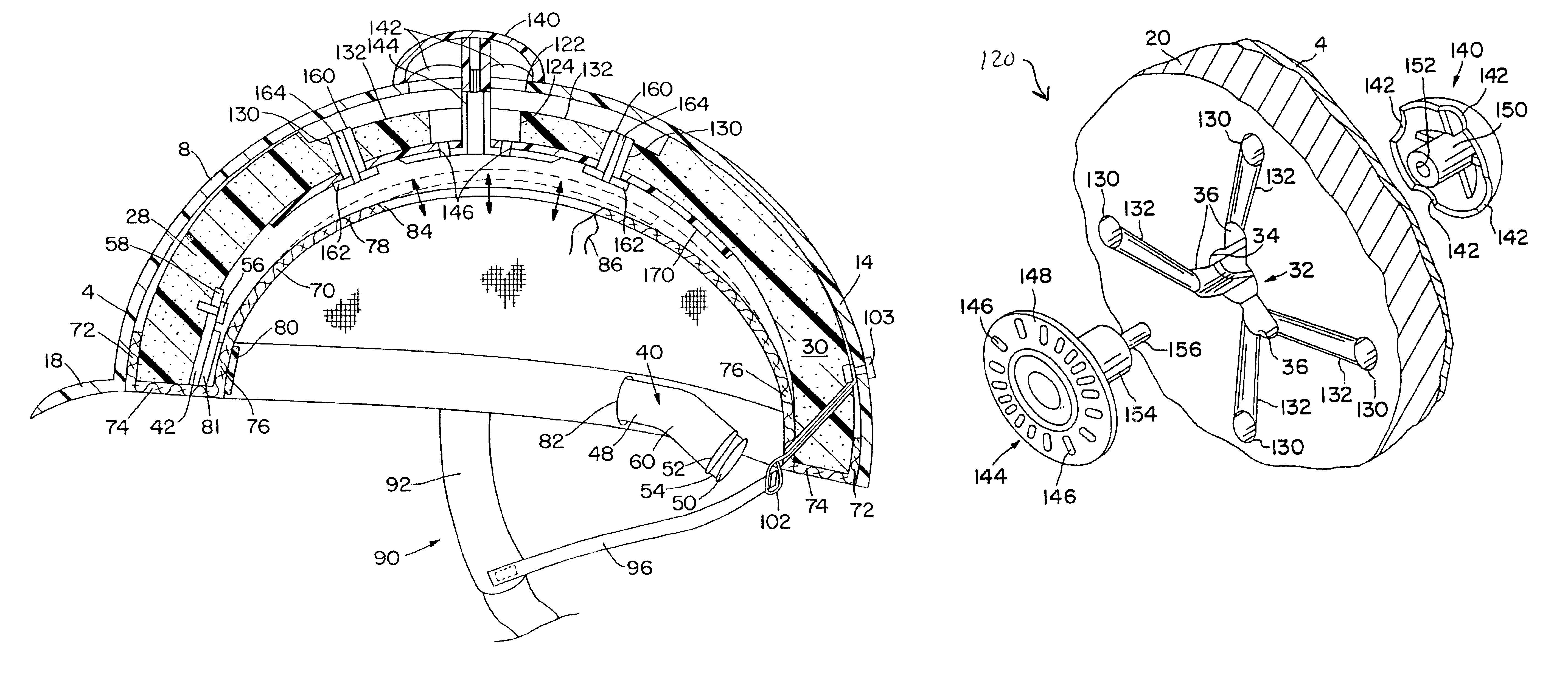

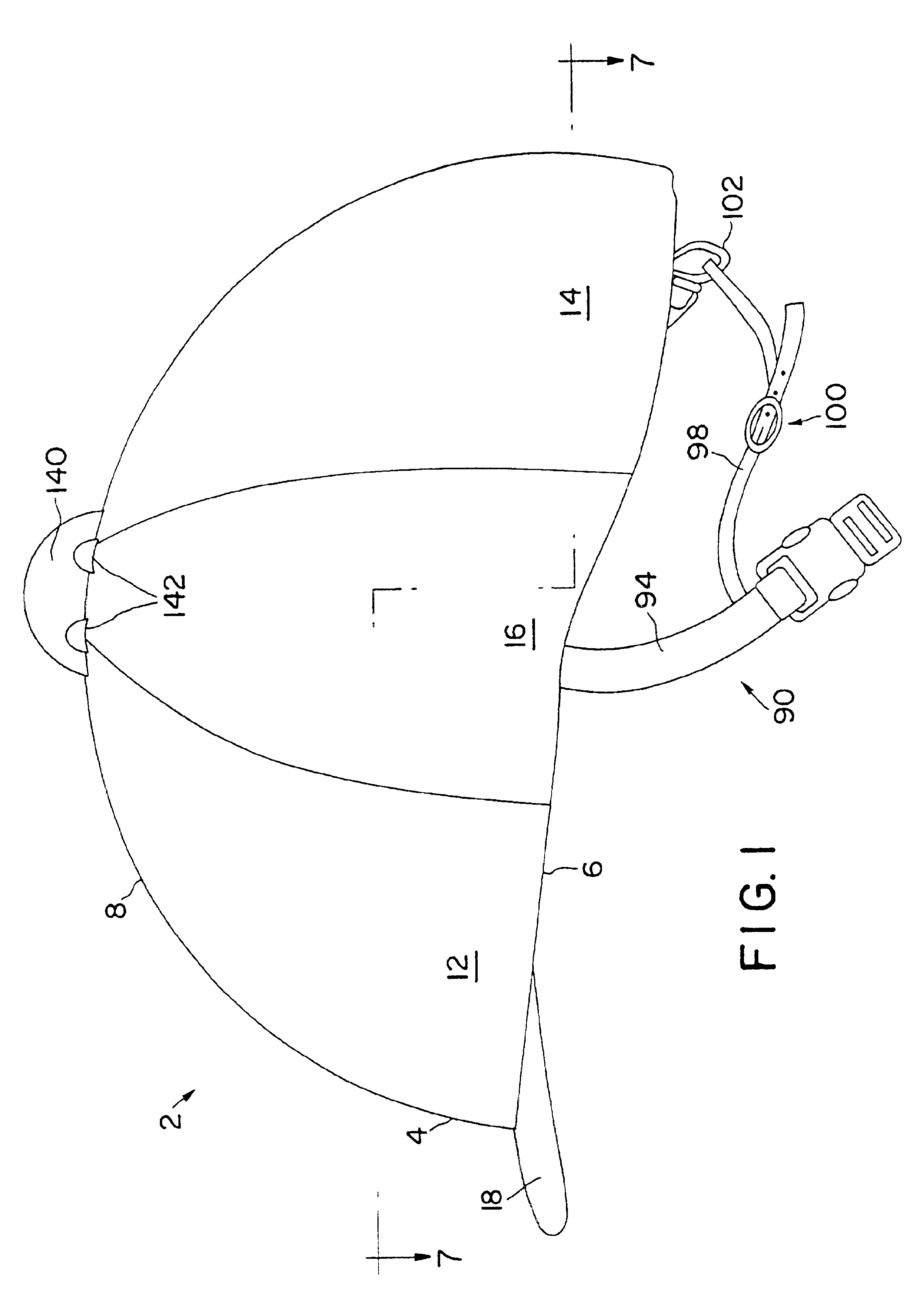

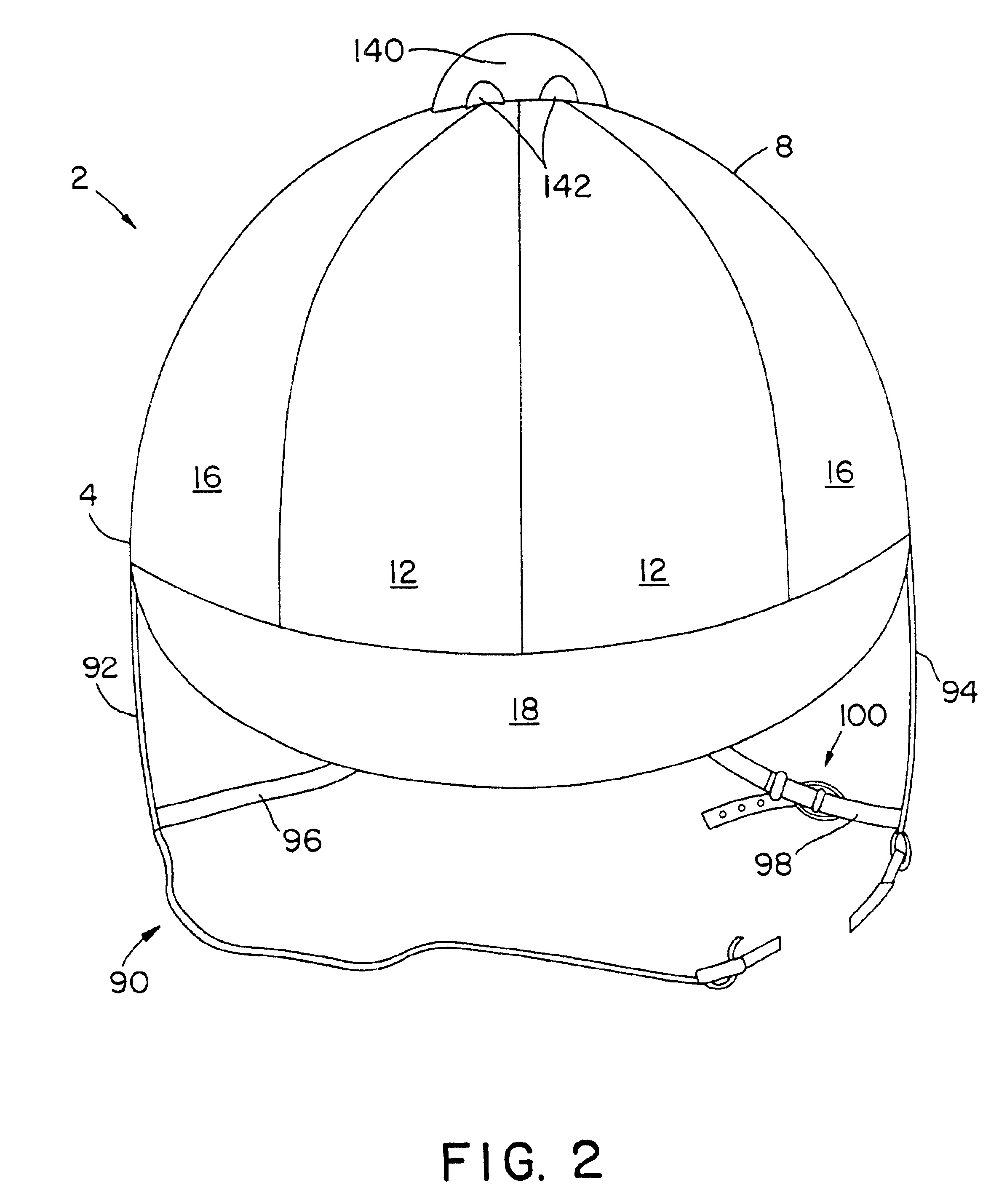

InactiveUS6880176B2Reduce shockEasy vertical adjustmentHatsSport apparatusEngineeringMechanical engineering

Owner:TROXEL CYCLING & FITNESS

Closure

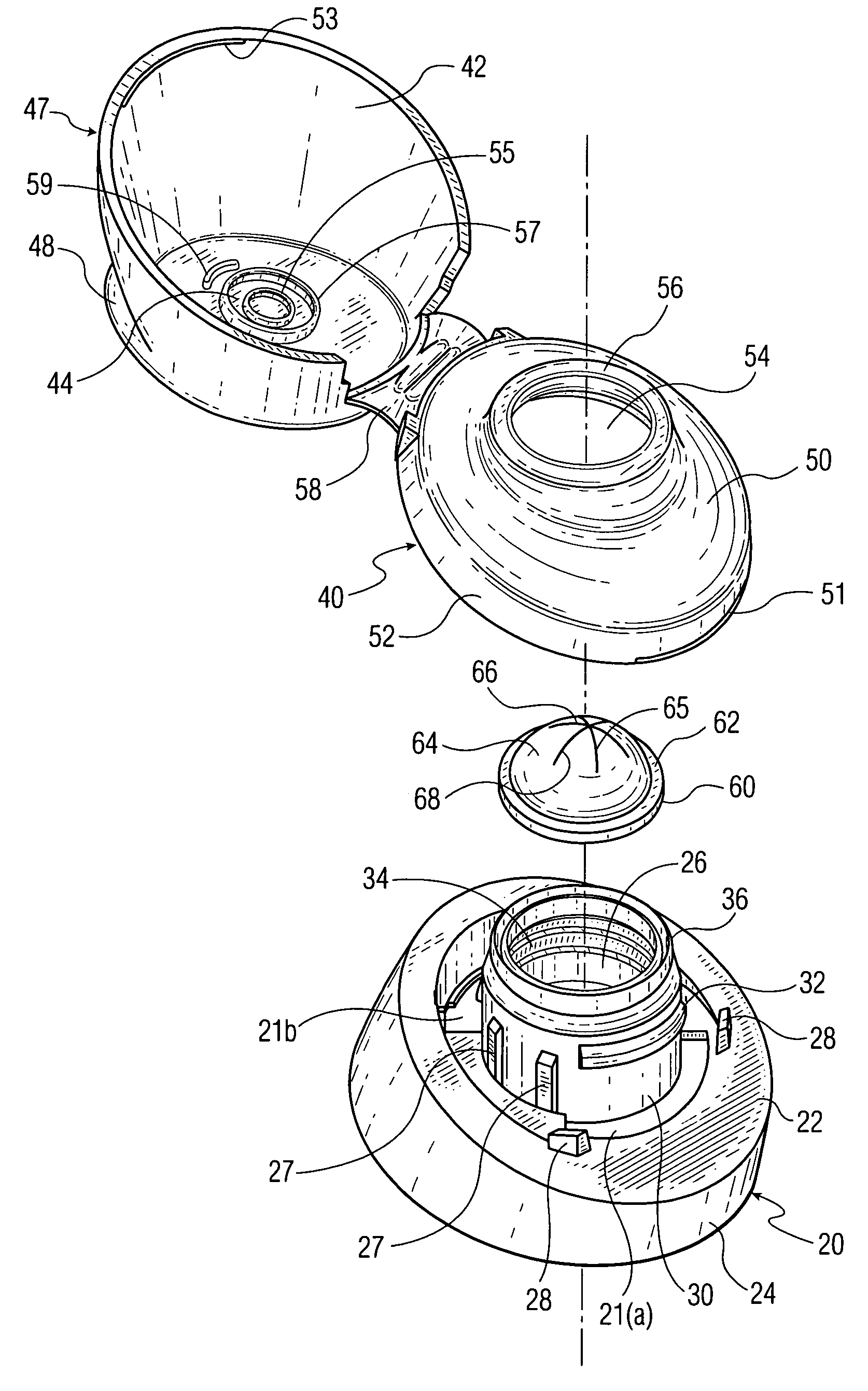

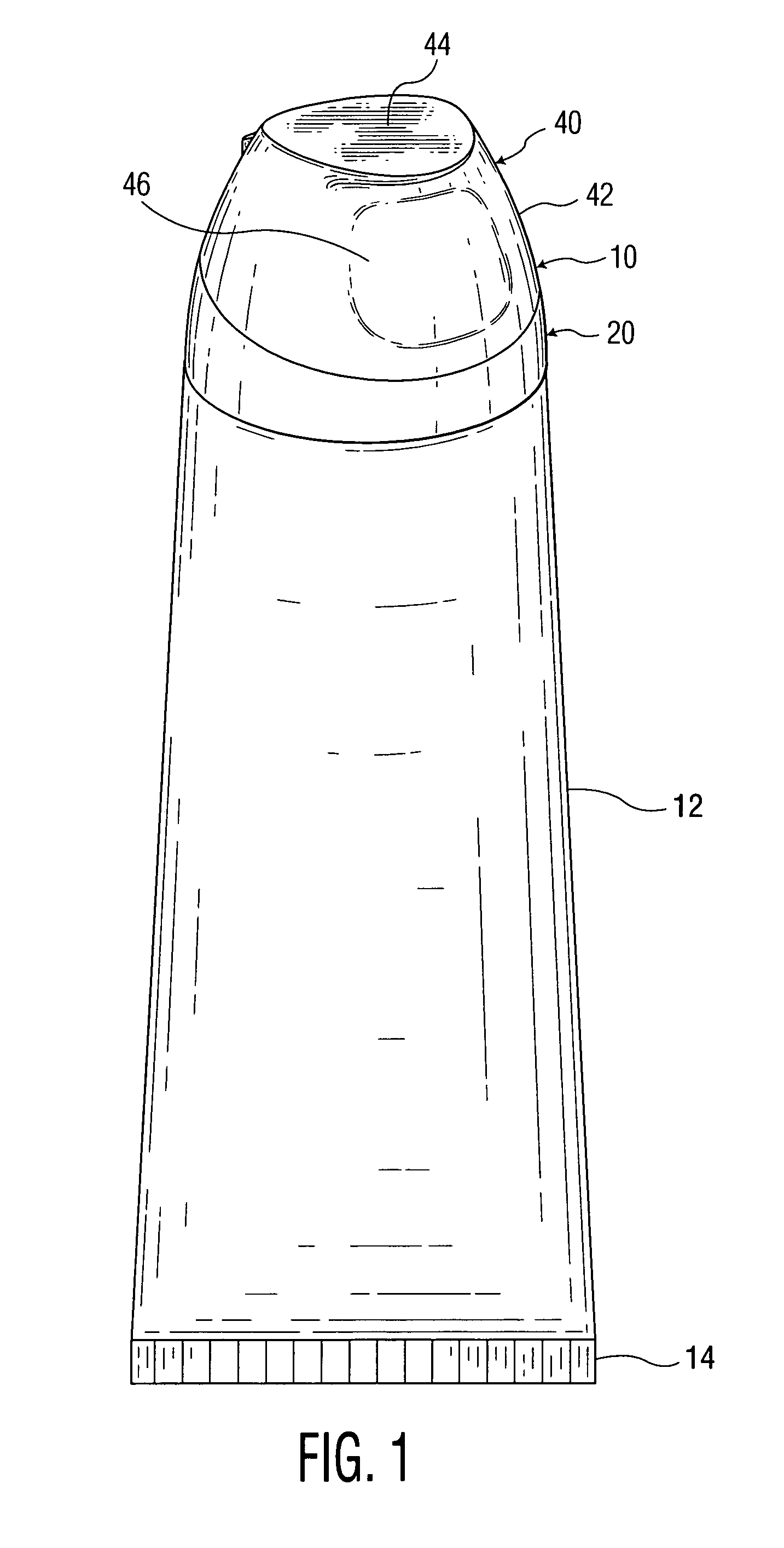

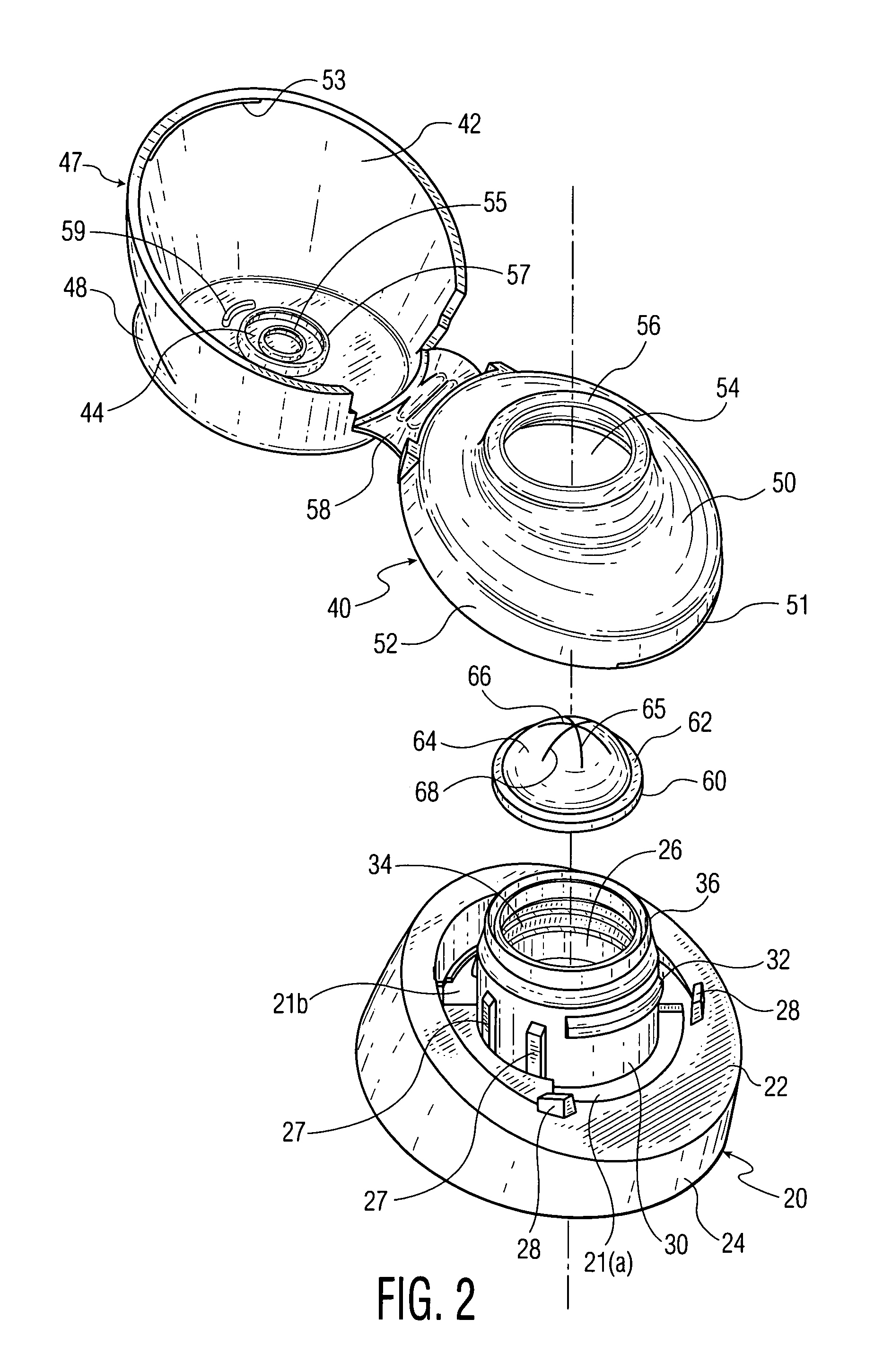

InactiveUS7731066B2Prevent escapeImprove decorative appearanceClosuresLiquid flow controllersMechanical engineeringPolymer

There is disclosed a closure comprised of a valve, a base unit and an upper unit. The base unit has a base surface with a peripheral skirt. The base surface has an aperture with a cylindrical section extending above and below the base surface. The cylindrical section has an aperture therethrough. The upper unit has an upper surface and an aperture adapted to align with the aperture of the cylindrical section of said base unit. The upper unit has a lid to cover the apertures in the base unit cylindrical section and the upper unit. A lid inner top surface has two projecting seals, one to maintain the valve closed when the lid is closed and the other to provide a seal when the lid is closed. and a latch mechanism attaches the base unit to the upper unit. A preferred latch mechanism comprises a projection and an interfitting recess, one being on the base section and the other on the upper section. The lid top surface preferably has an essential horizontal top surface. In a preferred embodiment the valve is a polymeric valve located in the aperture between the base unit and the upper unit and held in place by contact with both the base unit and the upper unit. The rheology of the product in the container and the characteristics of the valve are coordinated so that the product will be fully contained by the valve regardless of the orientation of the container, including being inverted.

Owner:SEAQUIST CLOSURES FOREIGN +1

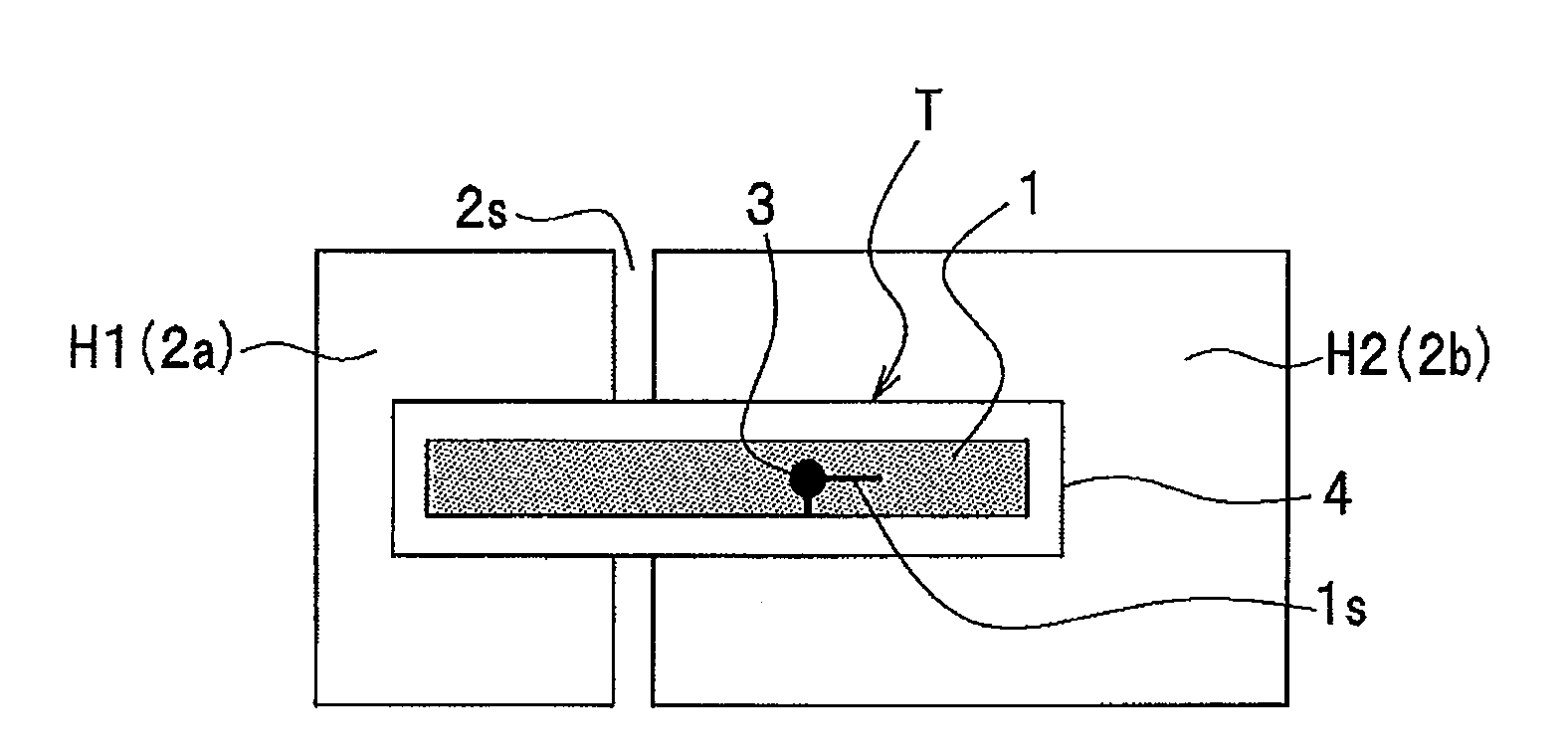

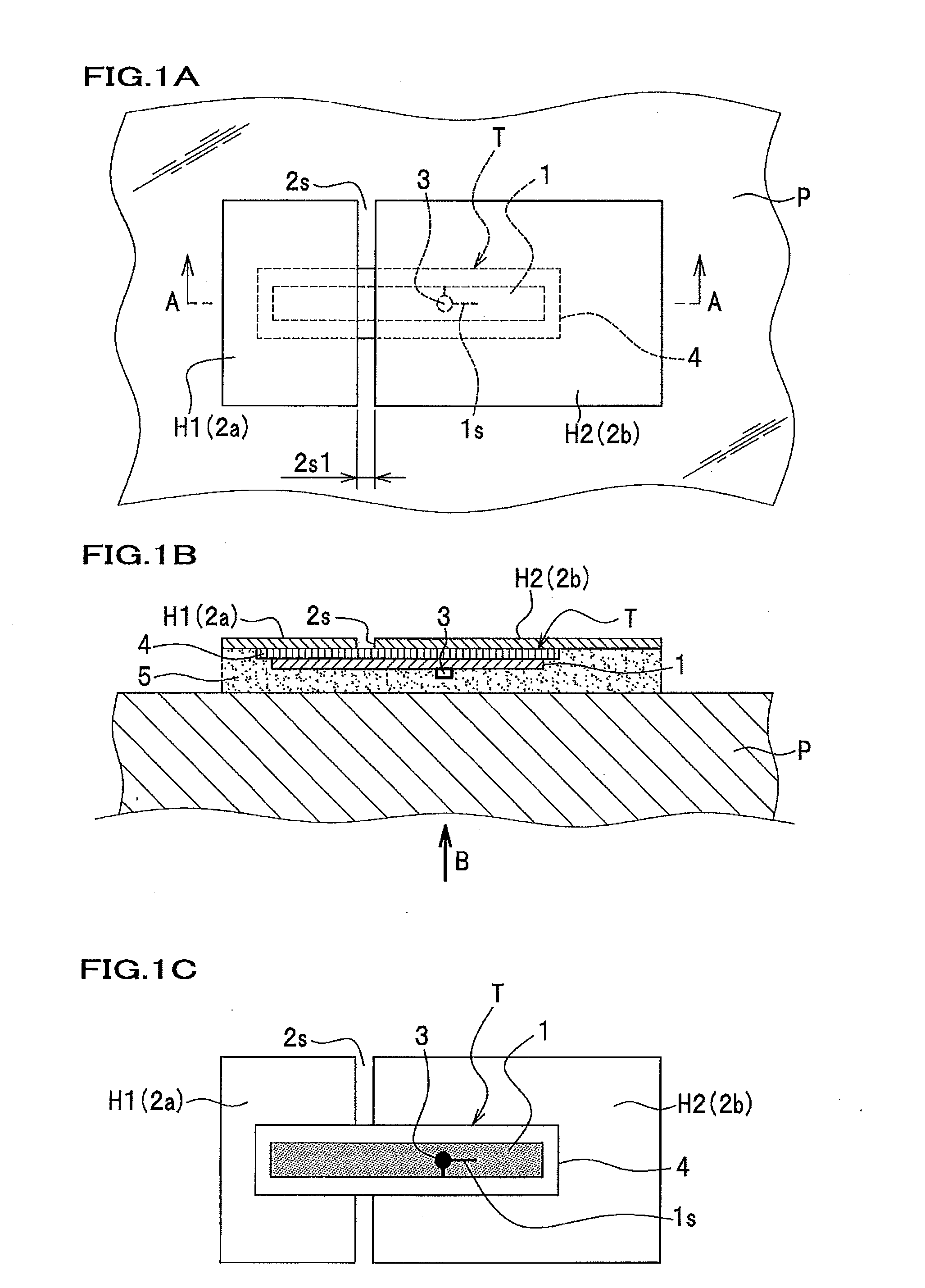

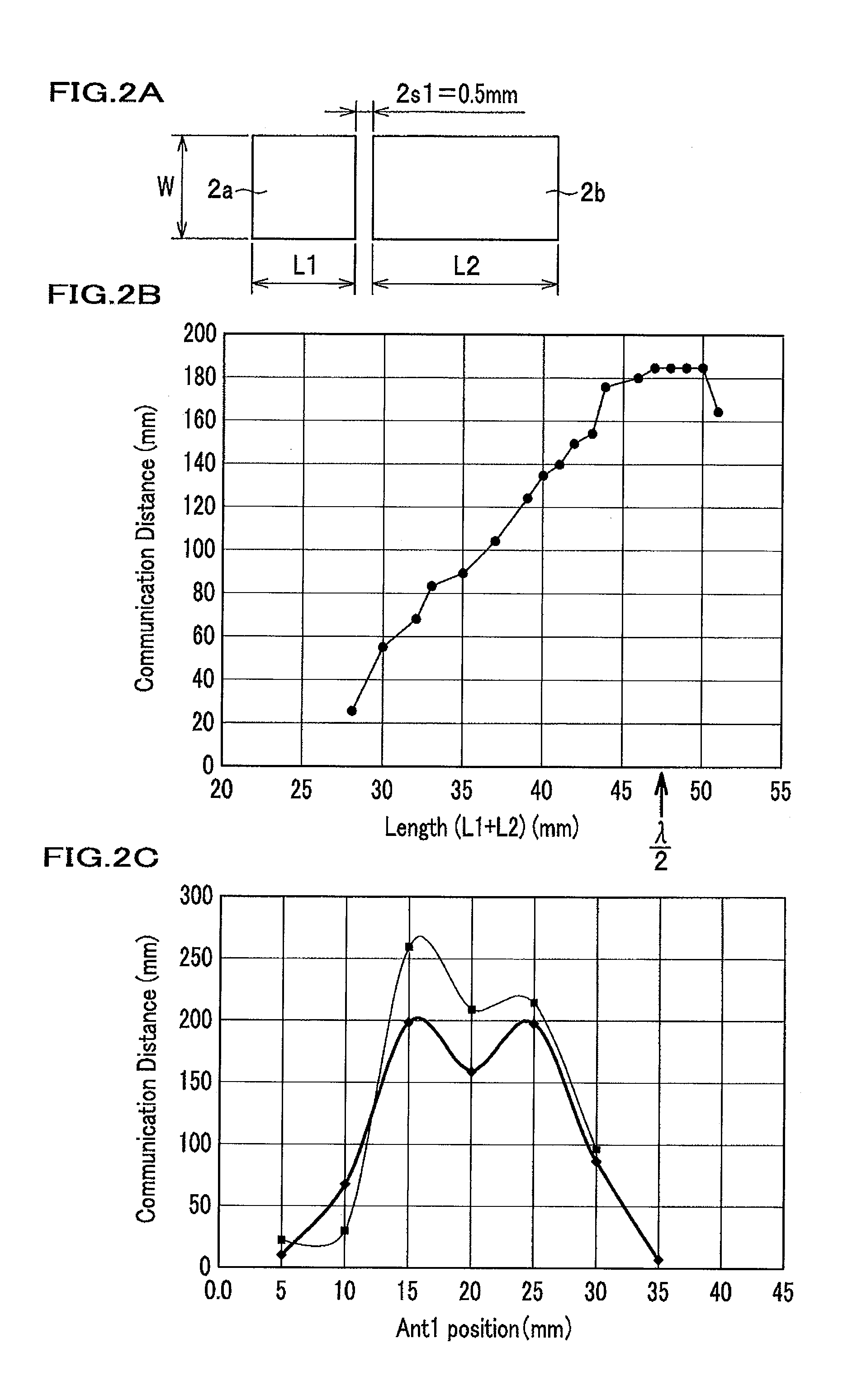

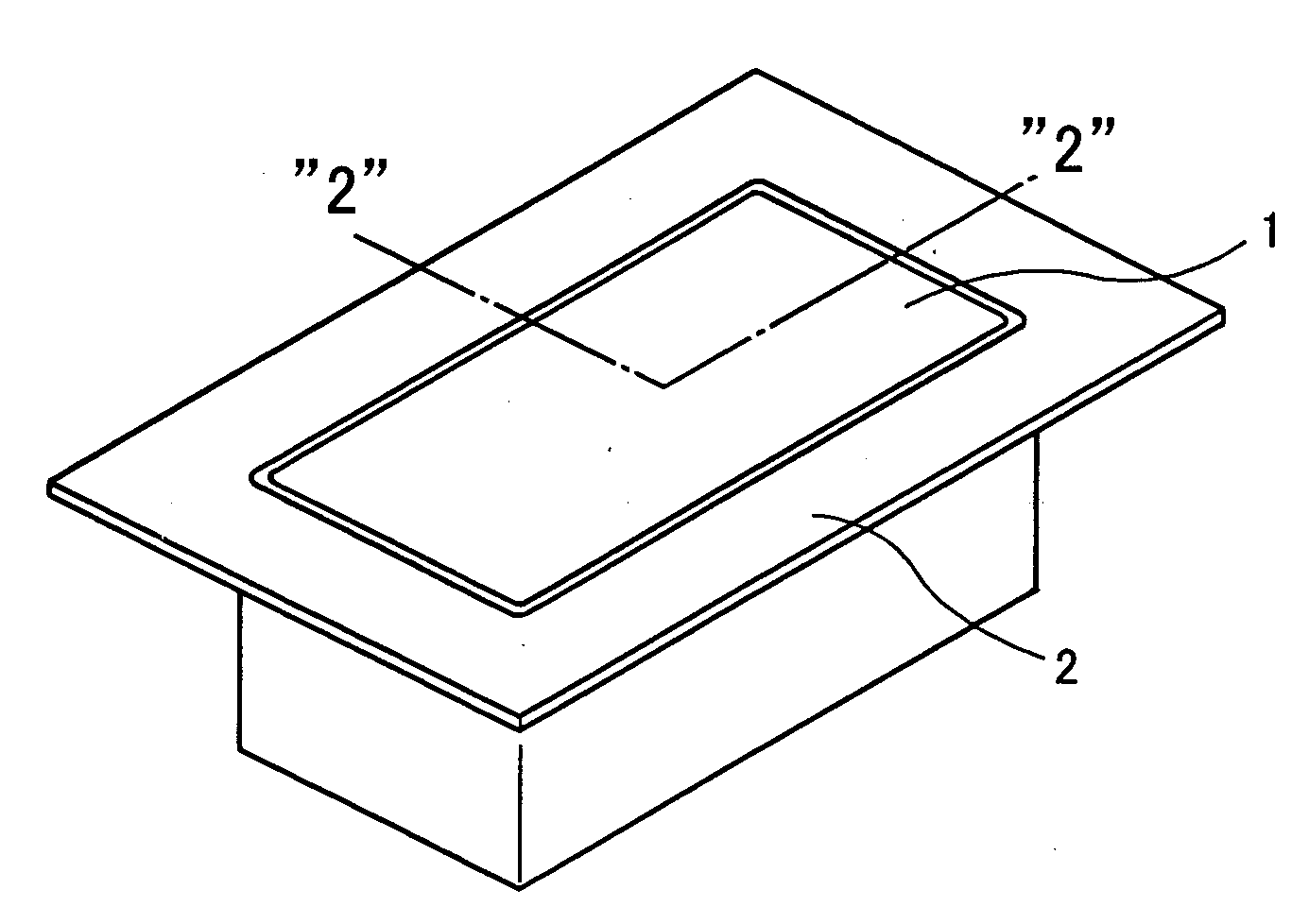

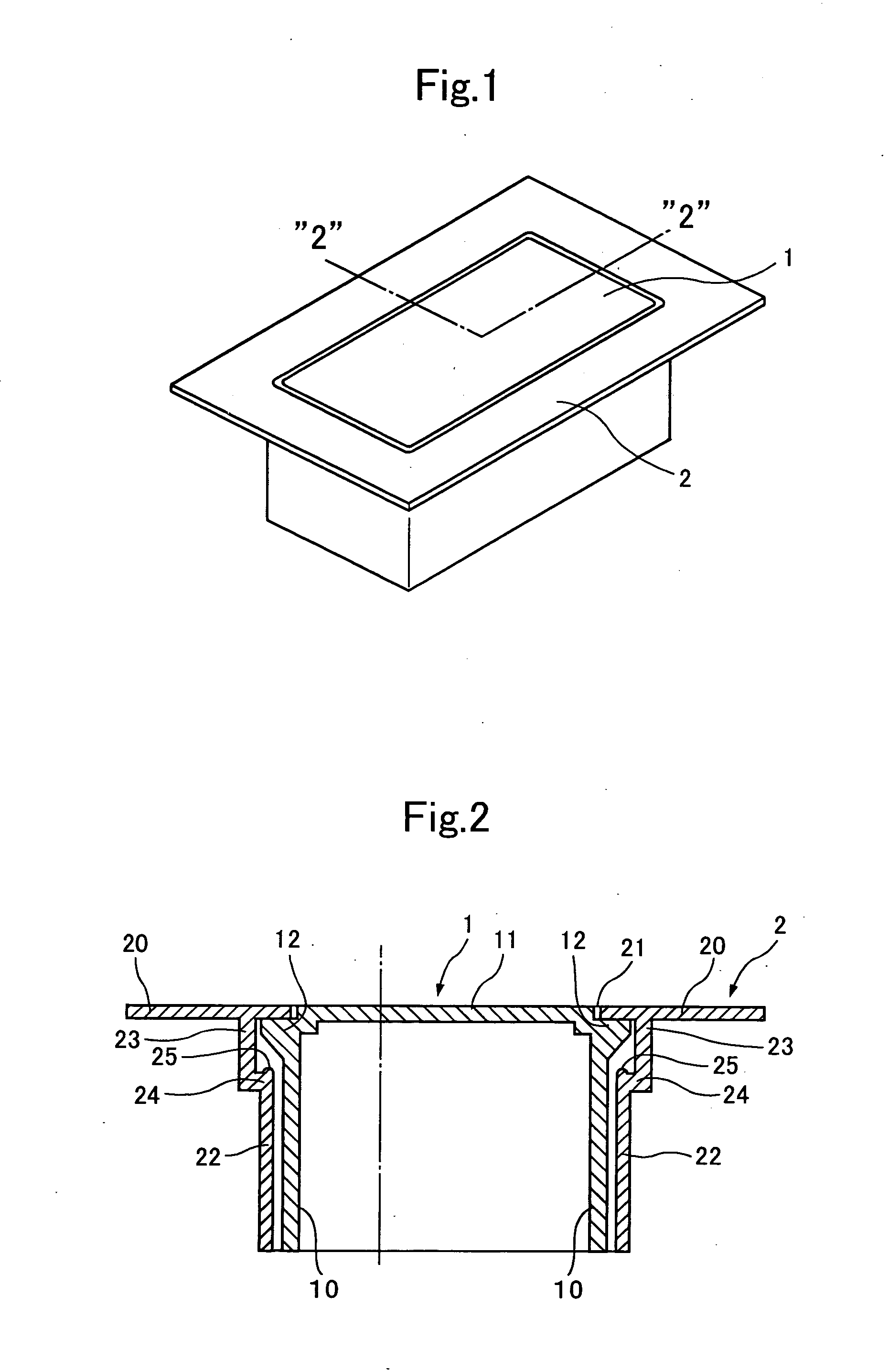

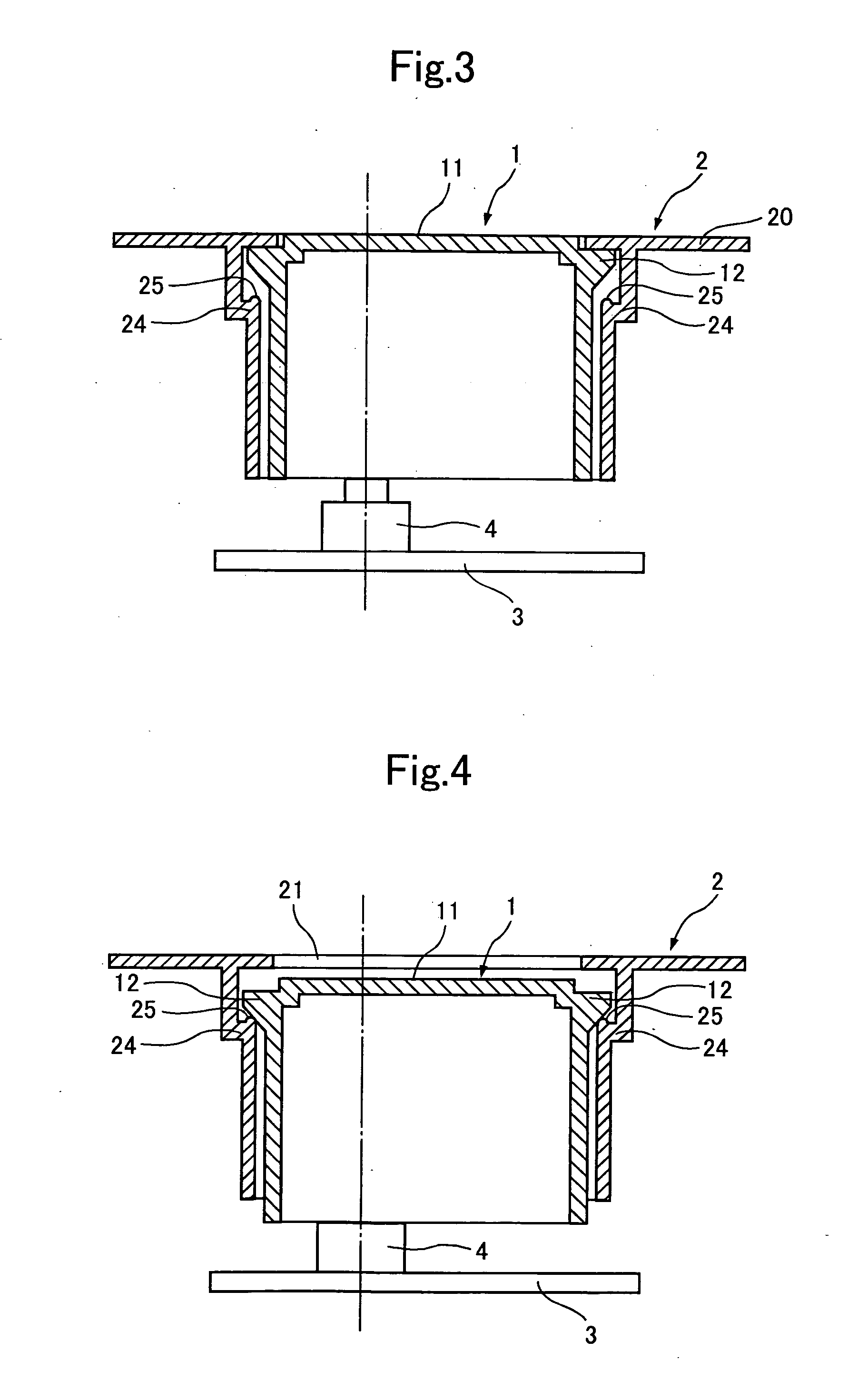

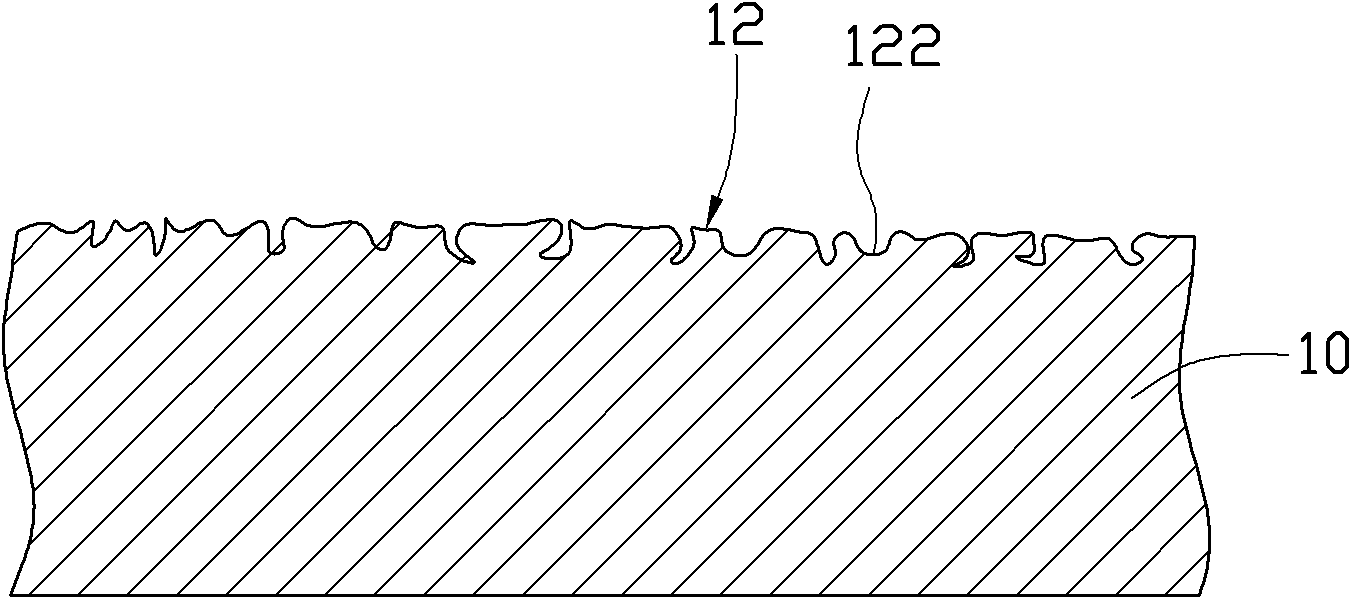

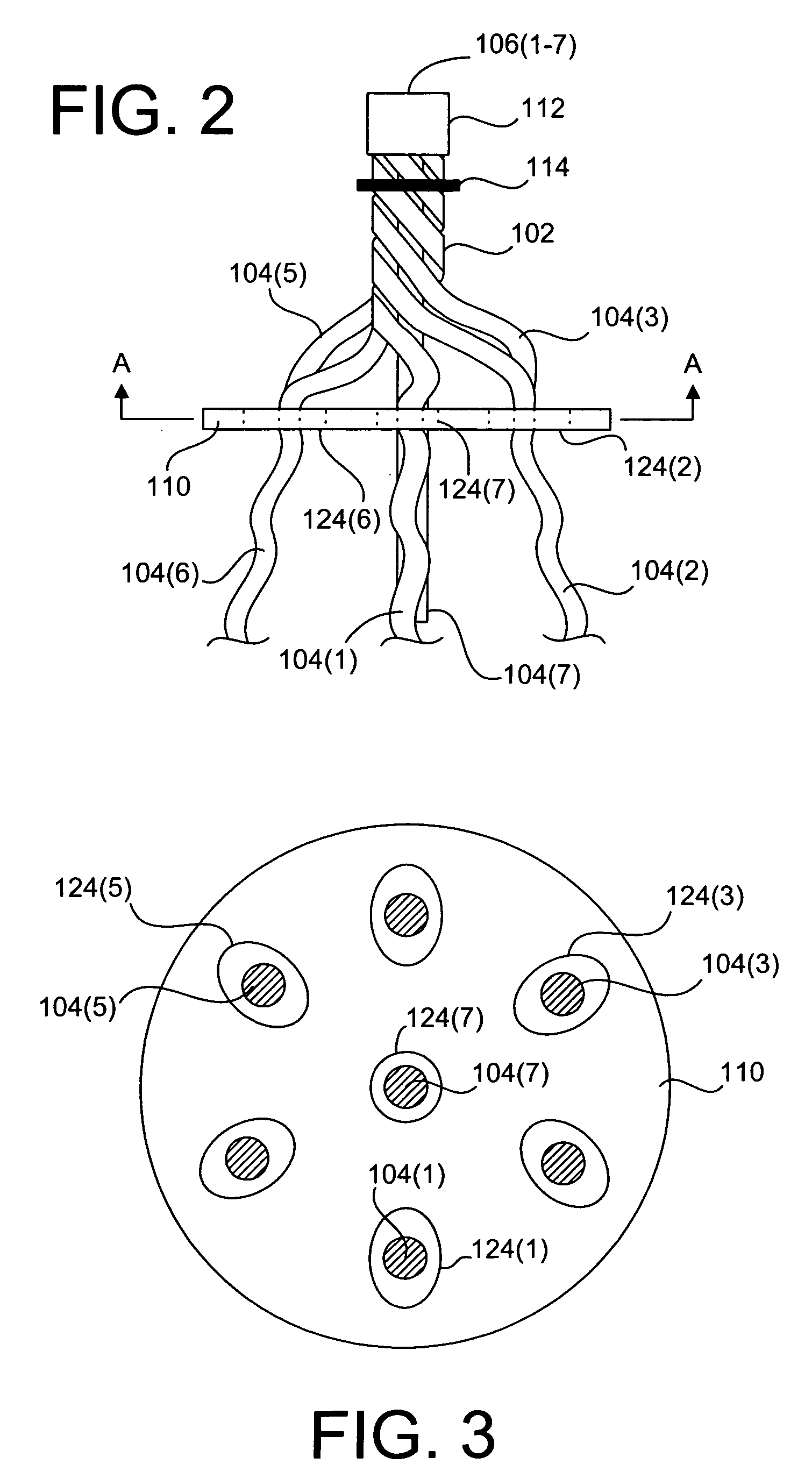

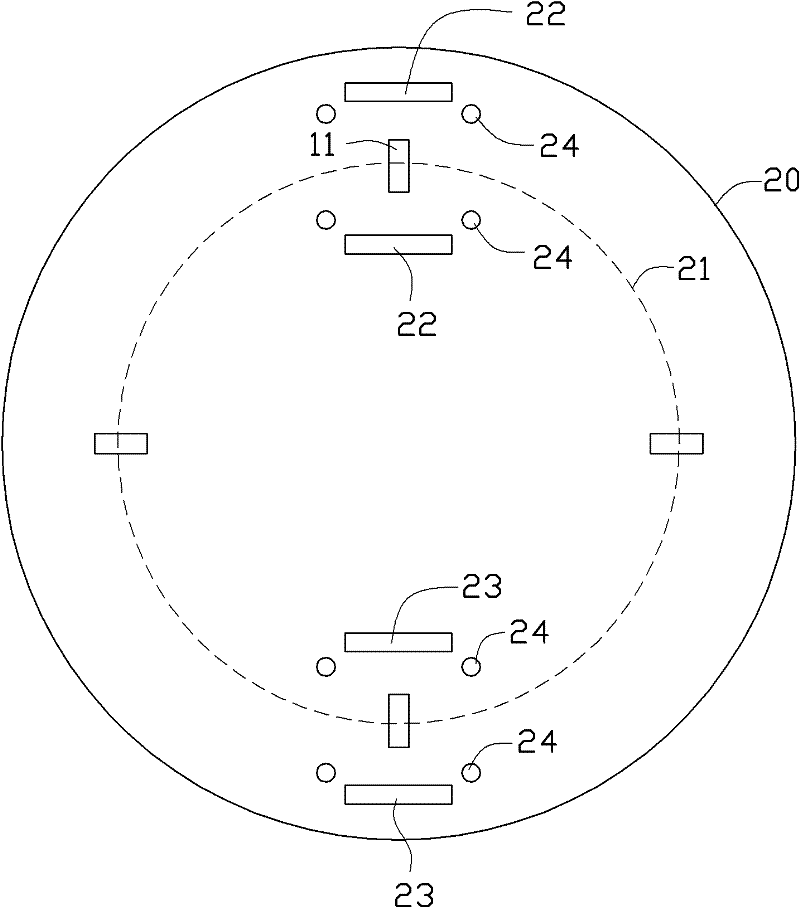

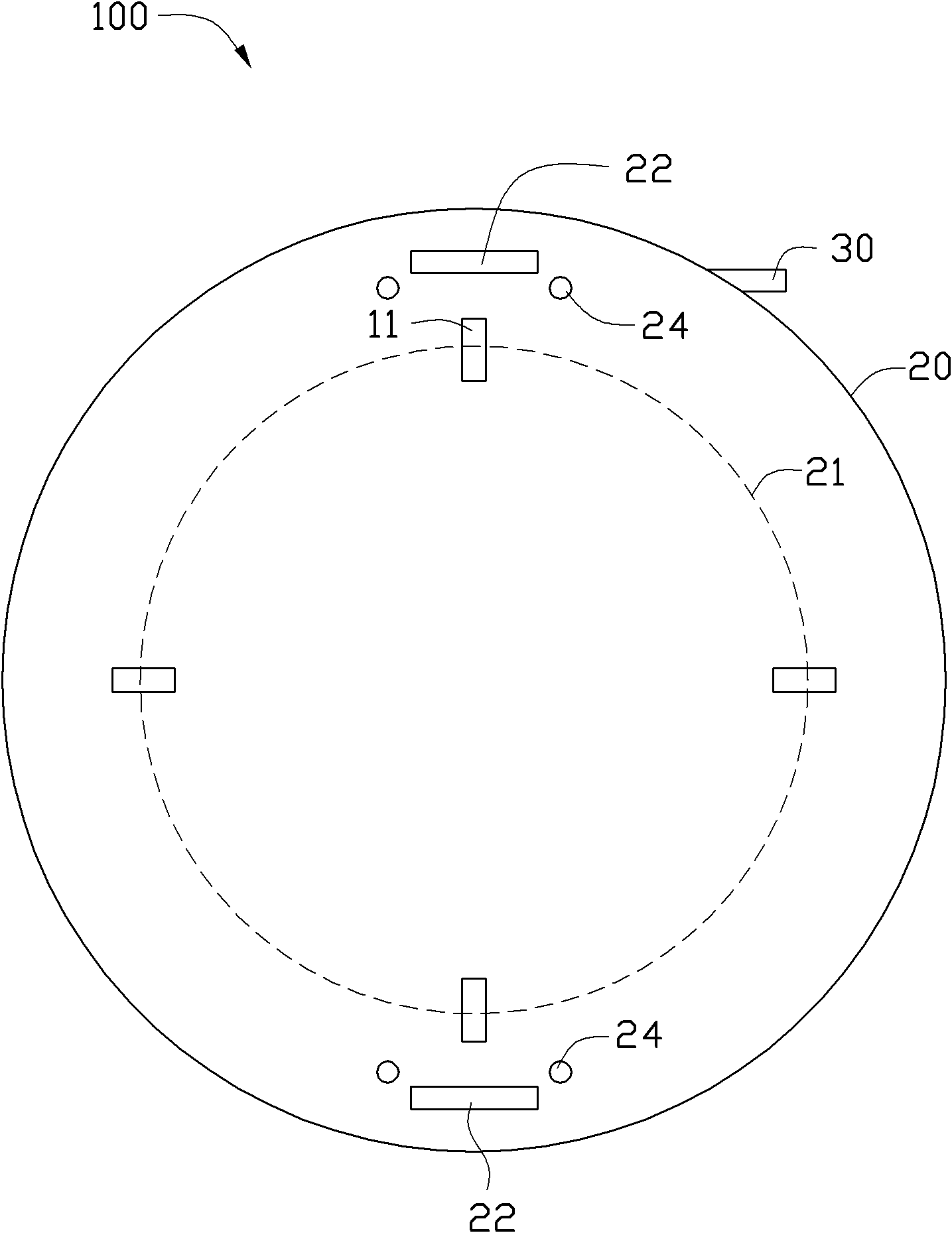

Assembling structure of radio IC tag

InactiveUS20100123010A1Improve decorative appearanceIncreased Design FreedomAntenna equipments with additional functionsRecord carriers used with machinesImpedance matchingEngineering

In an assembling structure of a radio IC tag, the radio IC tag includes an IC chip for recording information therein and a first antenna connected to the IC chip for wirelessly transmitting or receiving information. The first antenna has a first gap for performing impedance matching. A conductive second antenna having a second gap is arranged over the IC chip, the first gap, and the first antenna.

Owner:HITACHI LTD

Push button

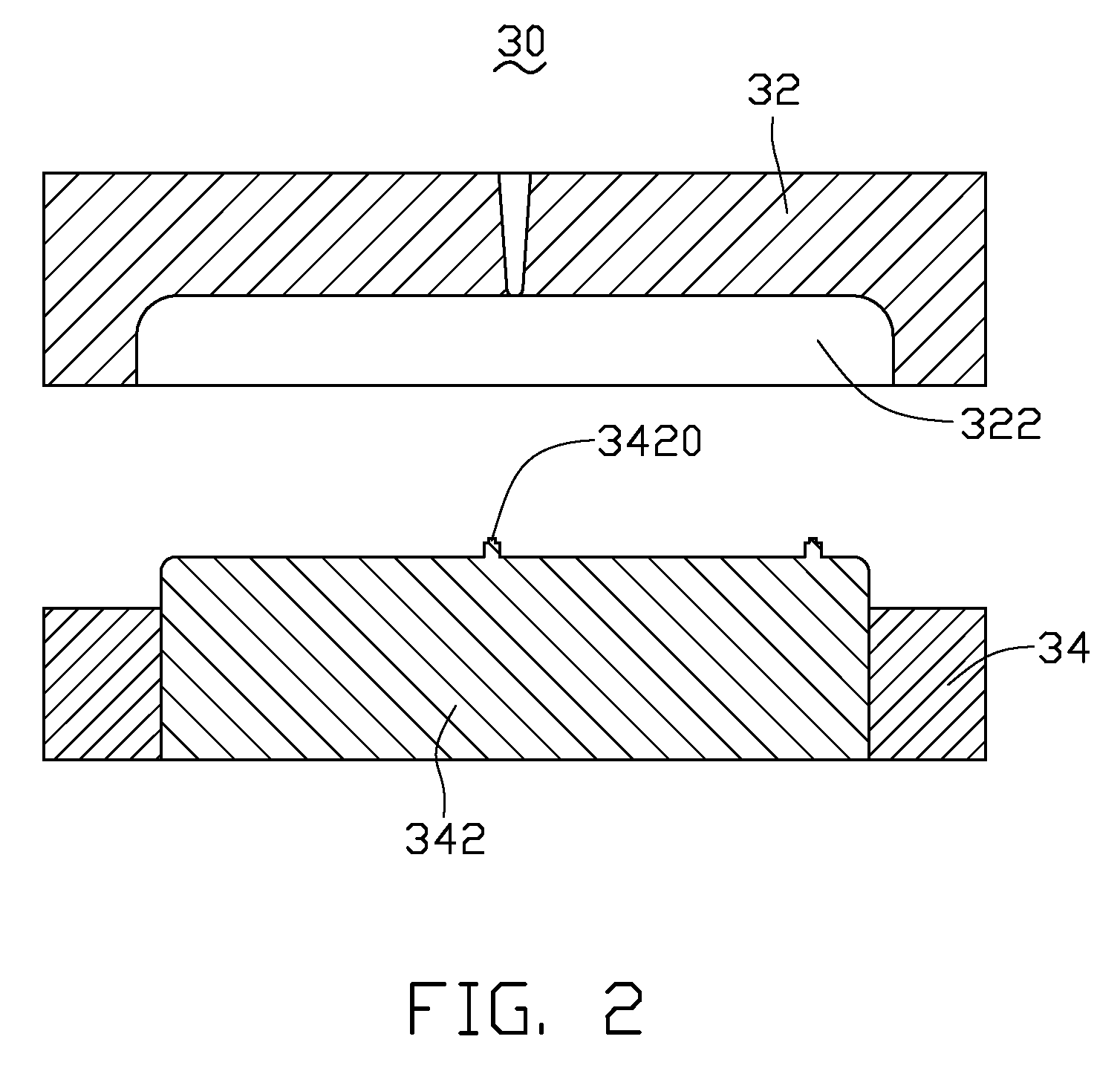

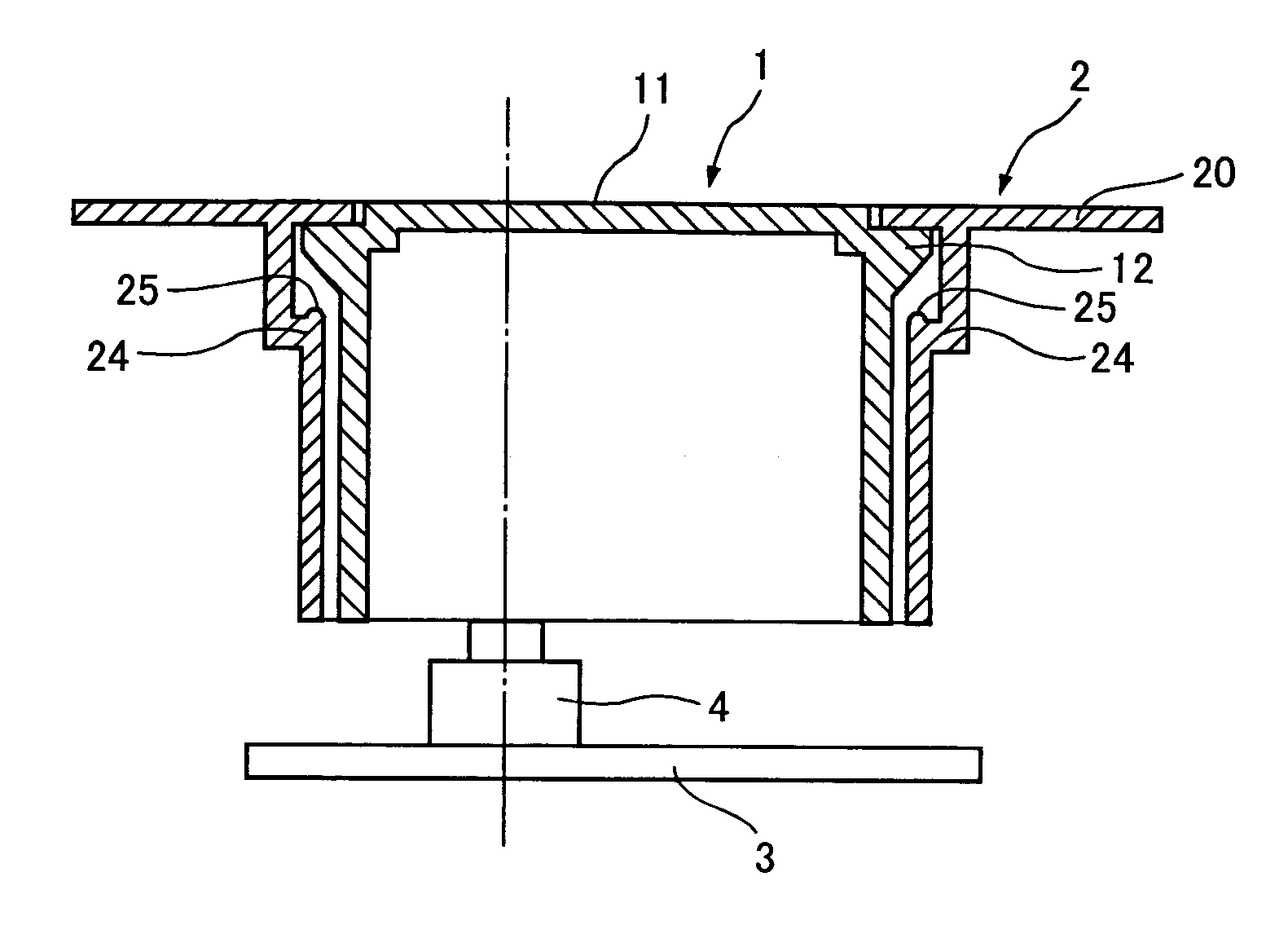

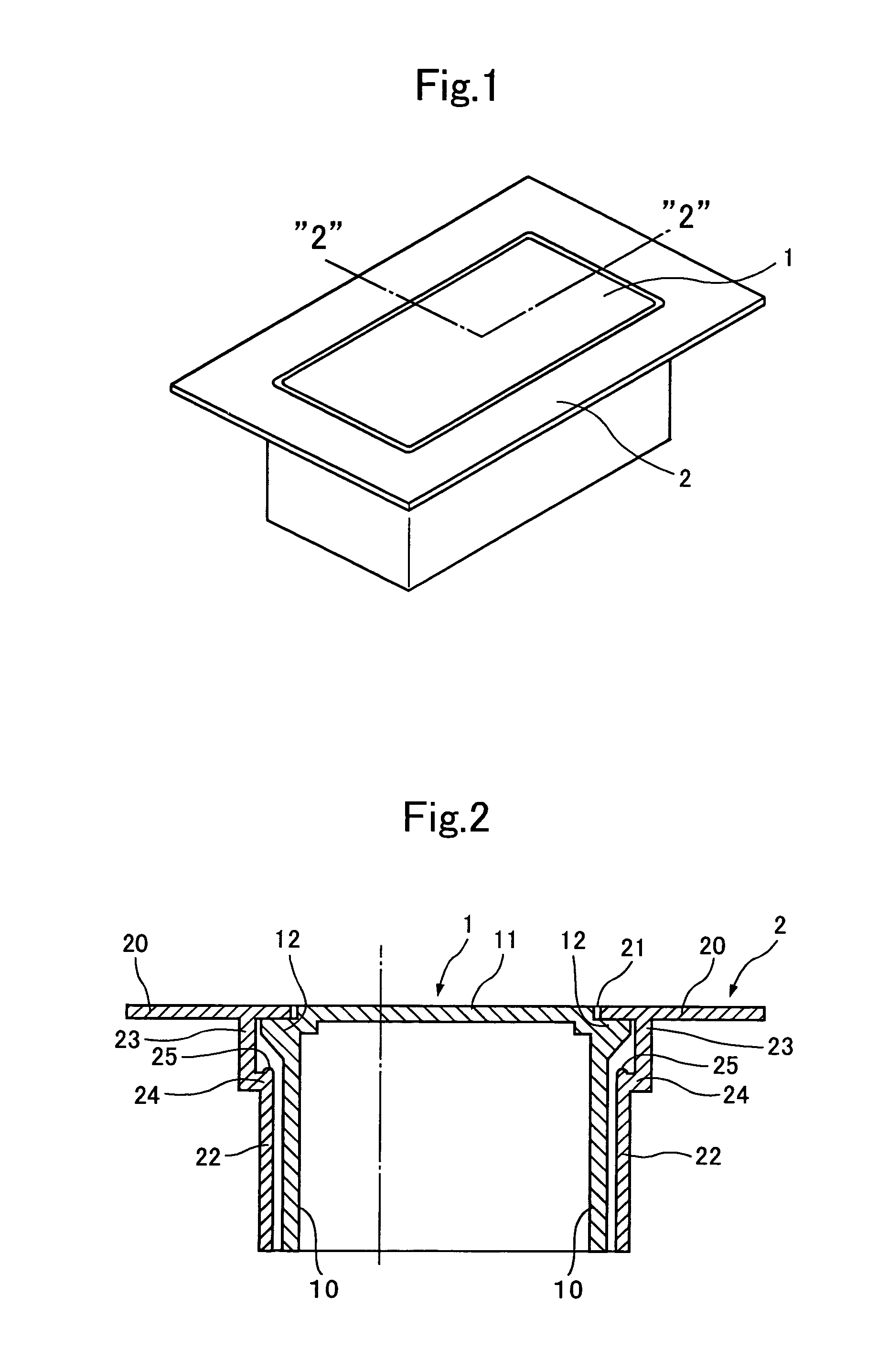

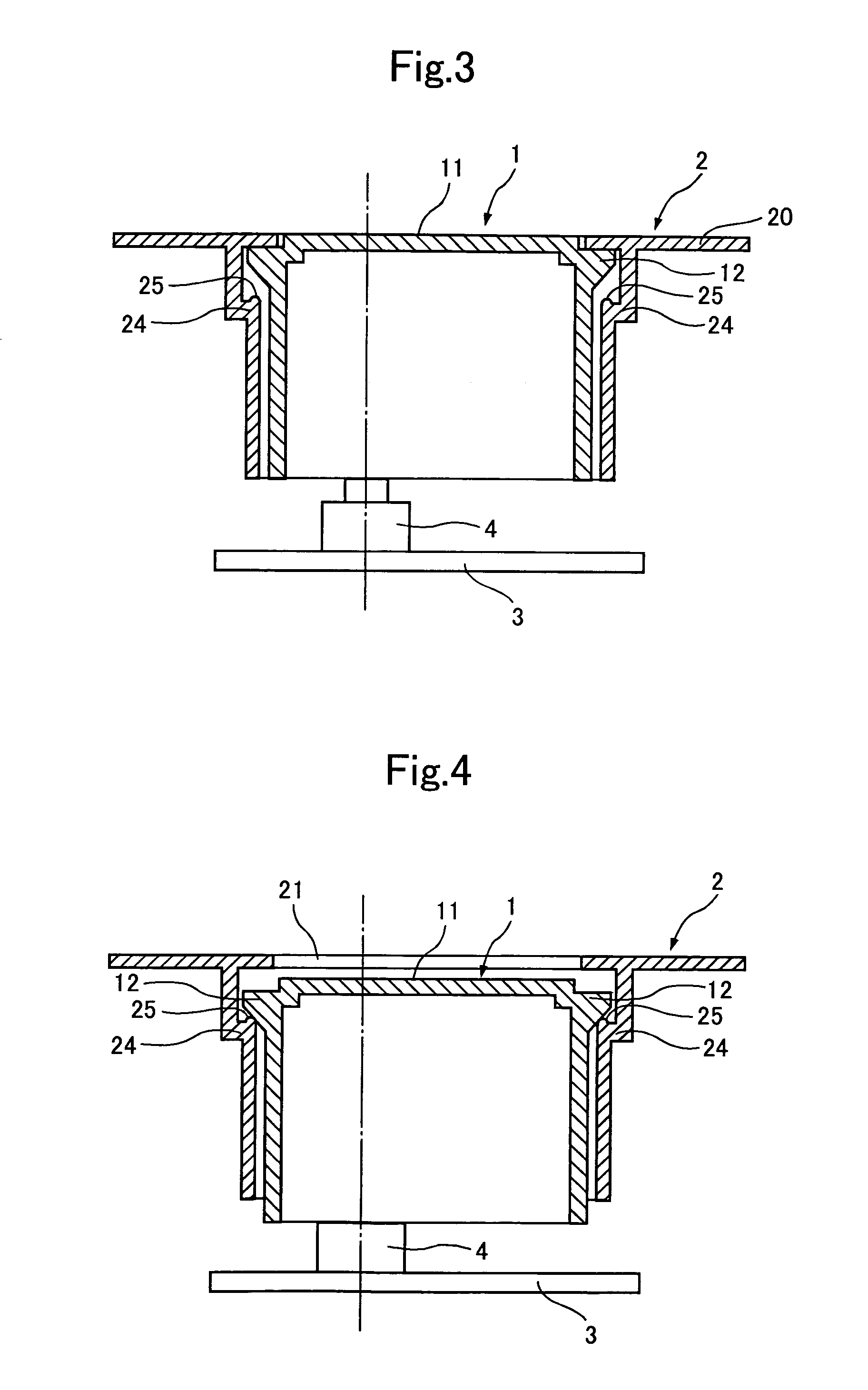

InactiveUS20050072661A1Regulates the displacement of the button bodyImprove decorative appearanceEmergency actuatorsContact operating partsReciprocating motionPush-button

A push button includes a button body, and a panel body. The button body includes a cylinder, a presser, and a rim. The cylinder has opposite ends, and an outer peripheral shape. The presser is disposed at one of the opposite ends of the cylinder, and forms a pressing surface. The rim protrudes beyond the outer peripheral shape of the cylinder, and has a rear surface facing the pressing surface back-to-back. The panel body includes a cylinder-shaped holder, a main body, and a flange. The cylinder-shaped holder holds the button body therein so as to enable the button body to reciprocate in an axial direction of the cylinder, and has an opening. The main body demarcates the opening of the cylinder-shaped holder. The flange protrudes radially inward, and has a leading end to be brought into contact with the rear surface of the rim.

Owner:TOYODA GOSEI CO LTD

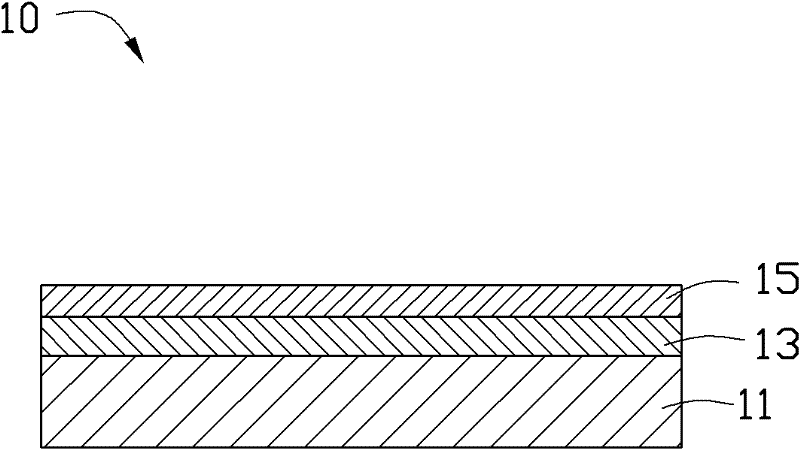

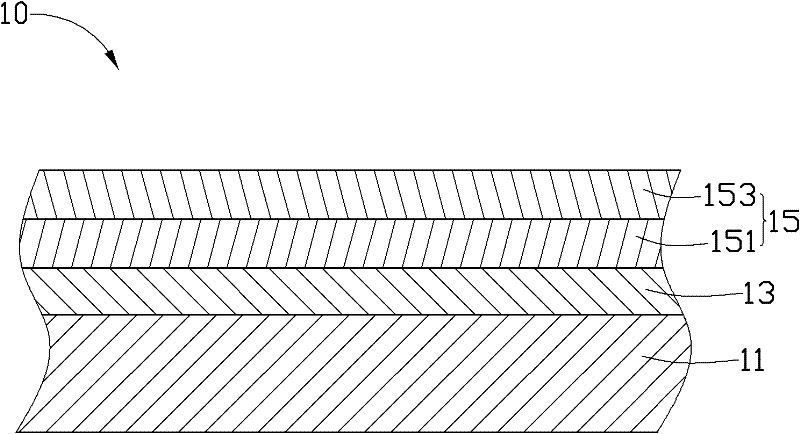

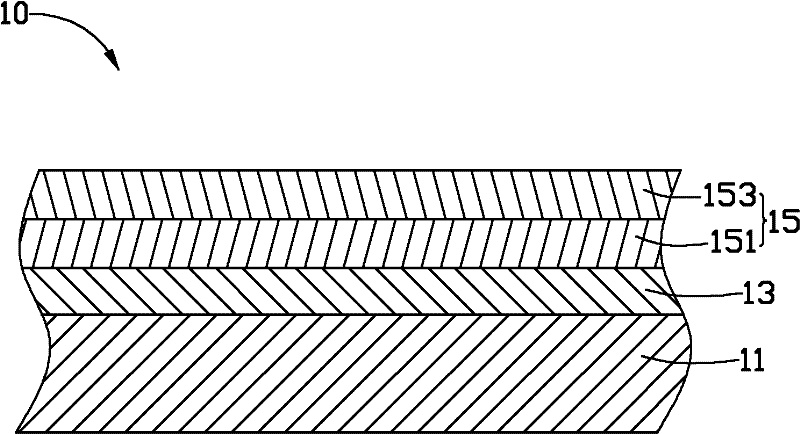

Aluminum product and preparation method thereof

ActiveCN102691080AImprove corrosion resistanceImprove decorative appearanceAnodisationSuperimposed coating processOptoelectronicsElectrochemistry

The invention discloses an aluminum product. The aluminum product comprises an aluminum matrix, an anode oxide film and a color layer, wherein the anode oxide film and the color layer are orderly arranged on the aluminum matrix. The aluminum matrix comprises a porous surface formed by electrochemical etching. Multiple nano-pores are distributed on the porous surface. Sizes of the nano-pores are in a range of 8 to 20nm. The anode oxide film and the color layer are orderly arranged on the porous surface. The color layer is formed by vacuum coating. The invention also provides a preparation method of the aluminum product.

Owner:GUANGDONG GUANGYUN NEW MATERIAL TECH CO LTD

Housing for an electronic device and method for making the housing

InactiveUS20090009935A1Improve decorative appearanceDiminish metal lusterCasings/cabinets/drawers detailsCeramic shaping apparatusEngineeringInjection moulding

Owner:FIH (HONG KONG) LTD +1

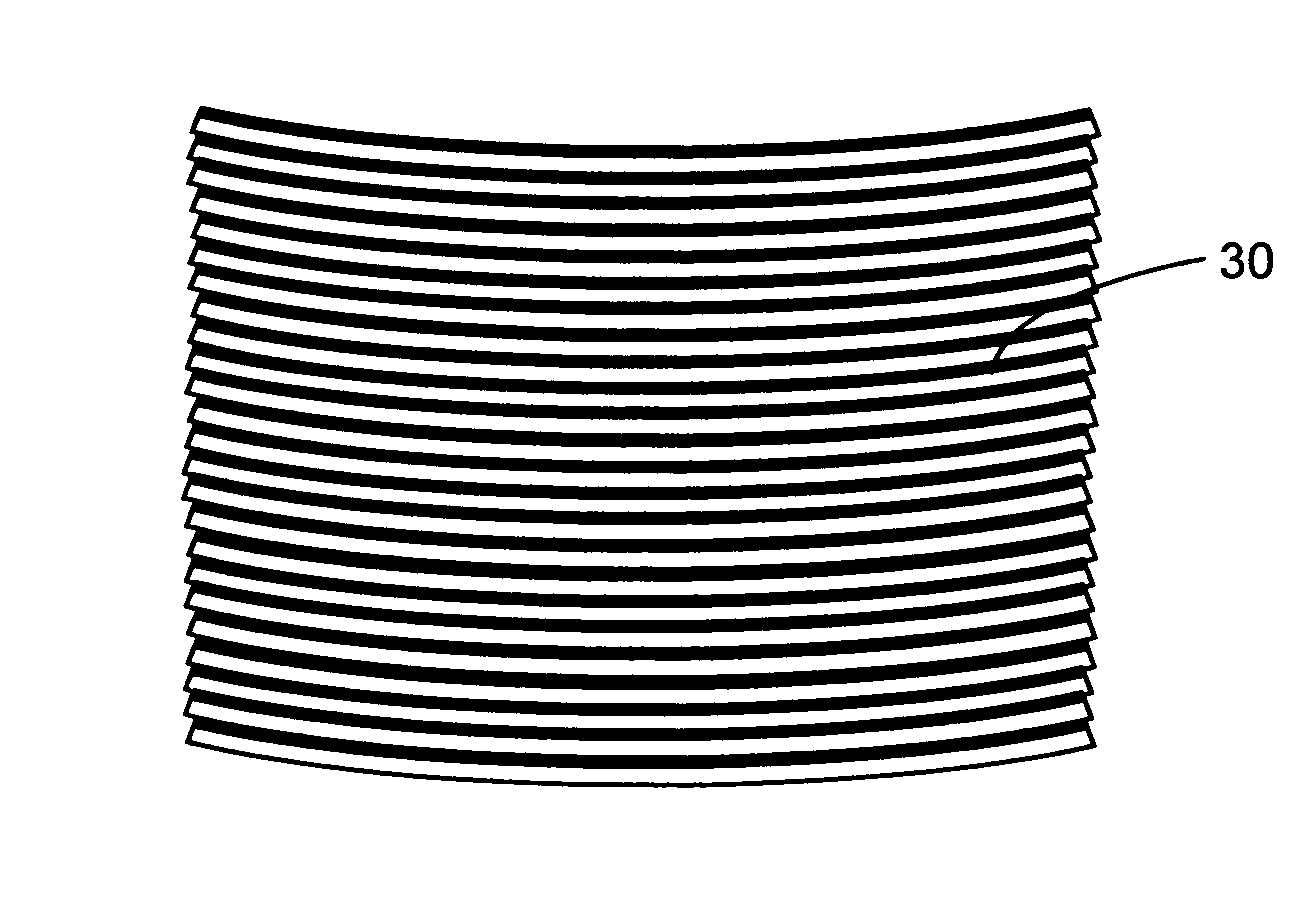

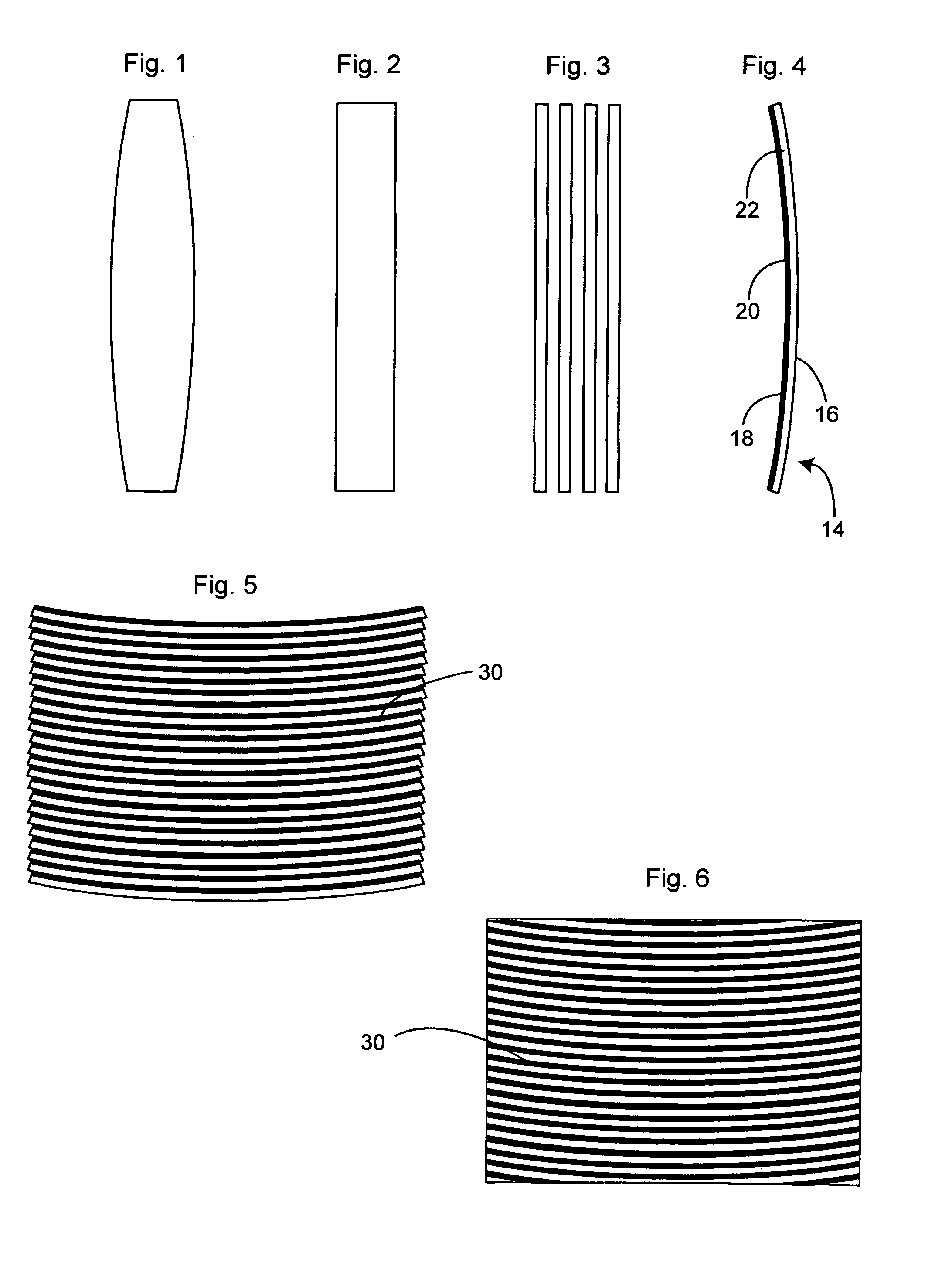

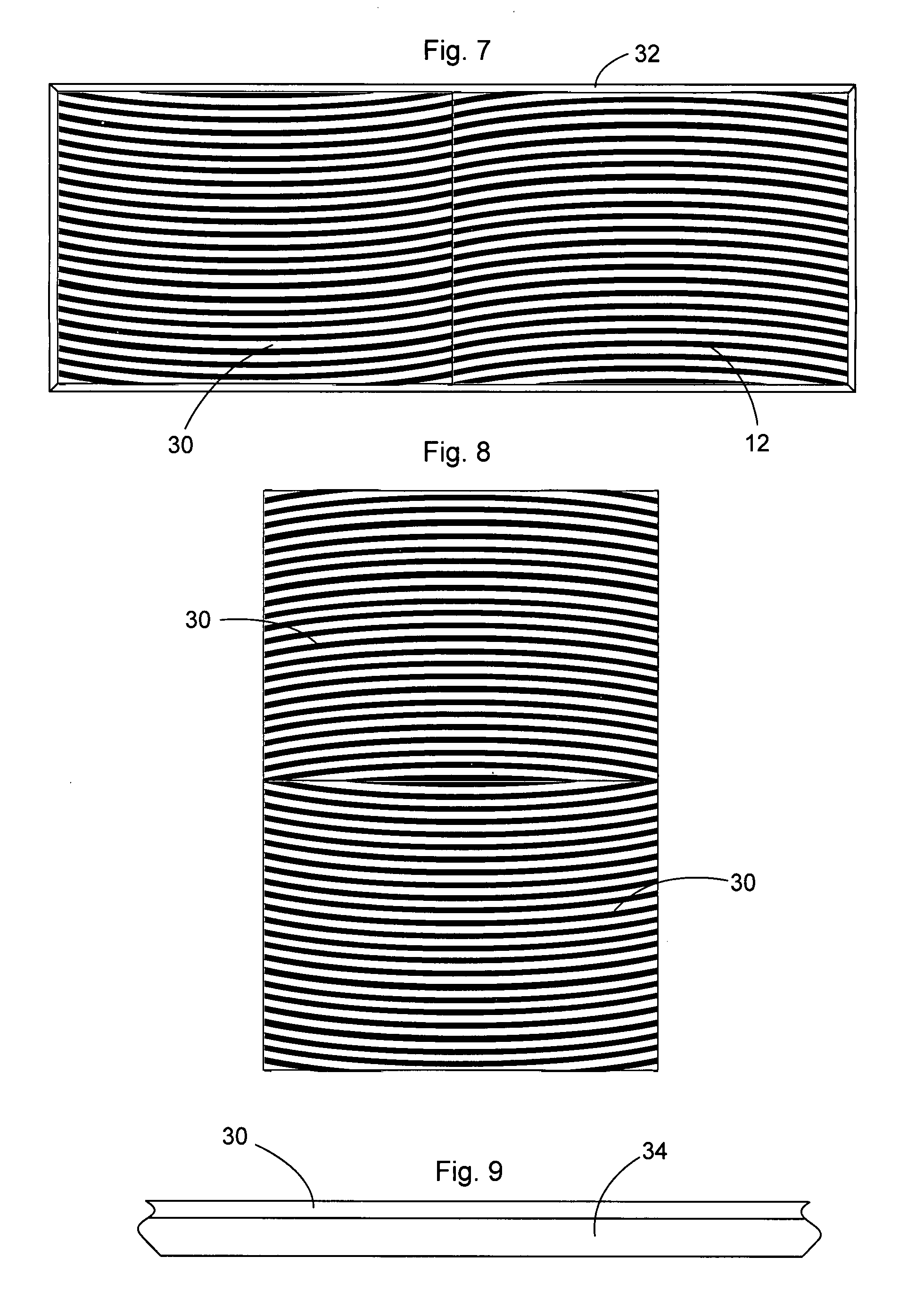

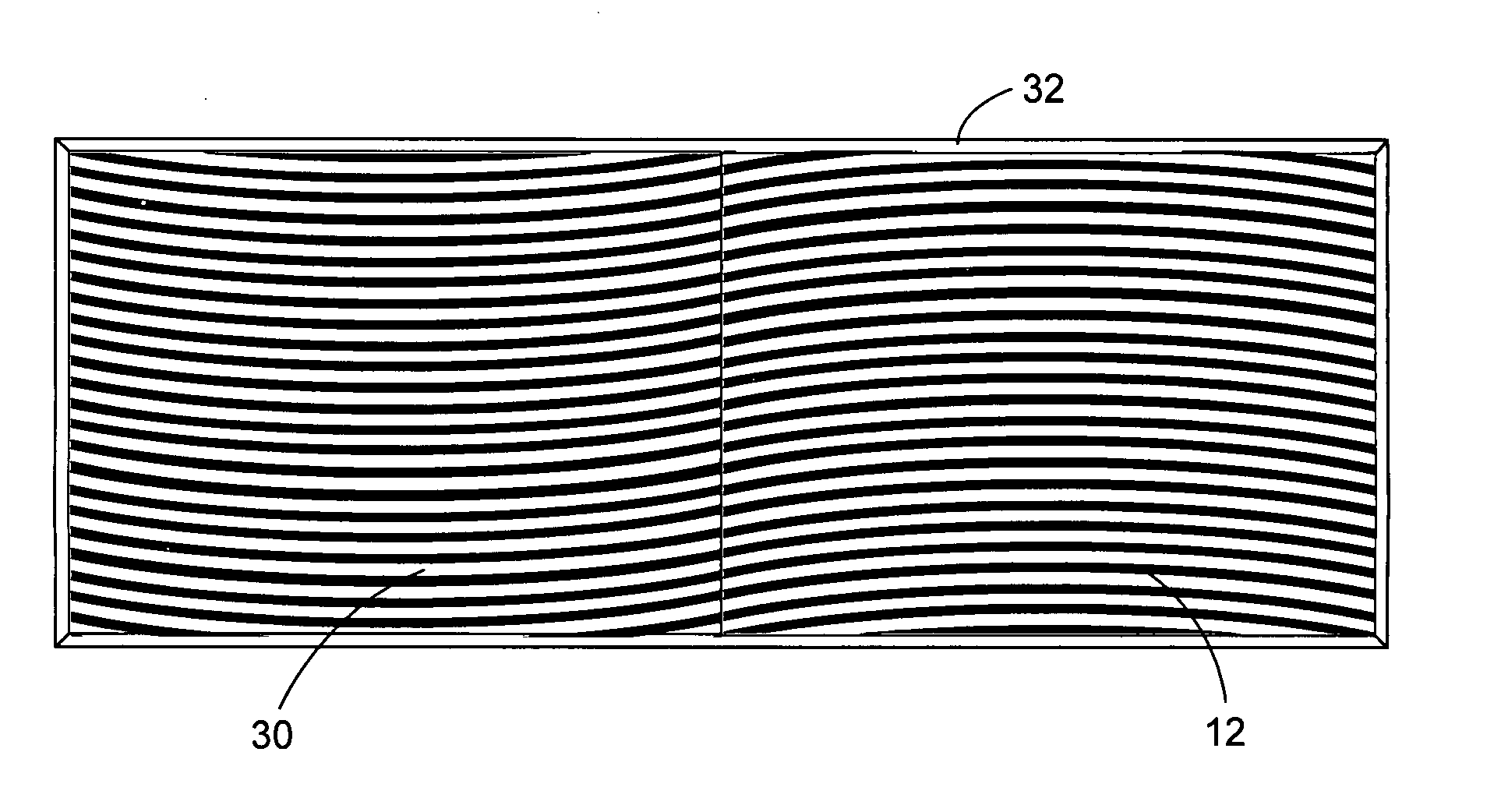

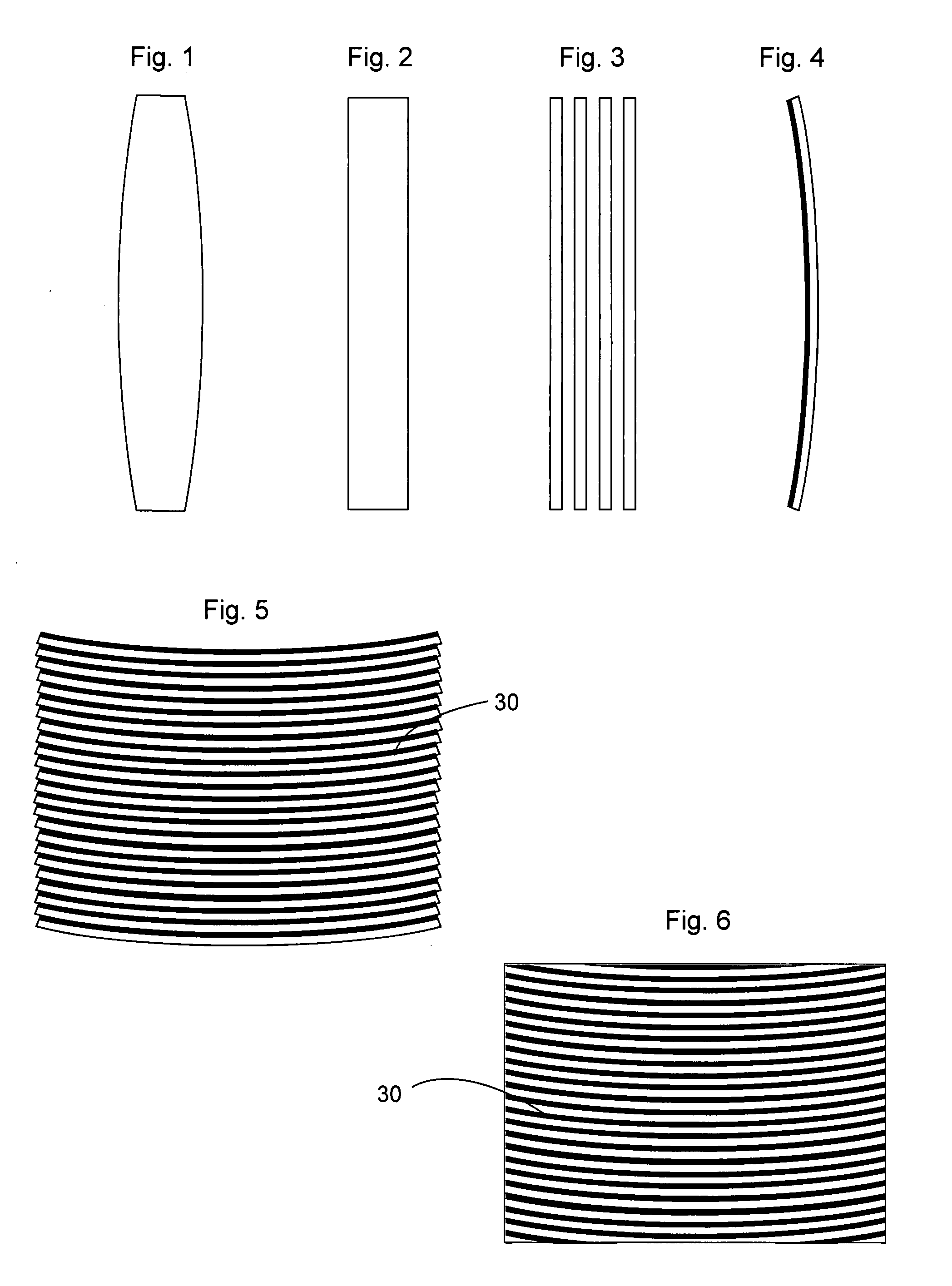

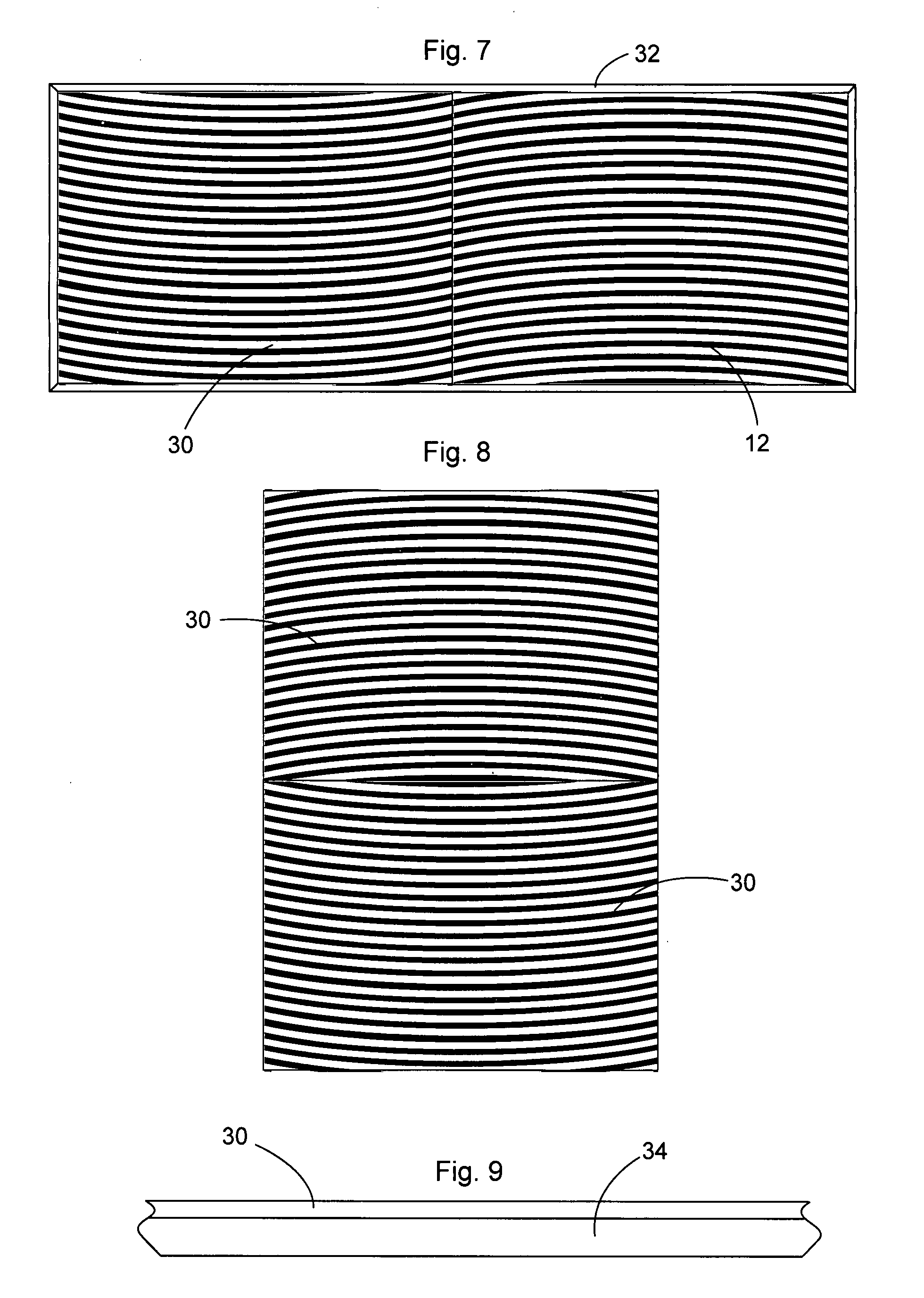

Laminated furniture component and method

InactiveUS7572495B2Good for scrollingSlight frictionSpecial ornamental structuresWood veneer joiningBarrel ShapedEngineering

Decorative wooden laminated panels are made from barrel staves previously forming parts of barrels used to age wine and other alcoholic beverages, each stave having inner and outer segments, with the inner segment being different in appearance from the outer due to penetration of alcoholic beverage components. The sides of said staves are first trimmed so that the sides are straight and parallel, and the staves are then cut into a plurality of strips. The strips are then formed into a panel with the inner surface of each strip being adjacent the outer surface of an adjacent strip, providing a decorative pattern of alternating contrasting stripes.

Owner:ATKINSON JESSICA S

Push button

InactiveUS7119297B2Regulates the displacement of the button bodyImprove decorative appearanceEmergency actuatorsContact operating partsReciprocating motionEngineering

Owner:TOYODA GOSEI CO LTD

Laminated furniture component and method

InactiveUS20080199648A1Improve decorative appearanceIncreased durabilityLayered productsSpecial ornamental structuresBarrel ShapedEngineering

Decorative wooden laminated panels are made from barrel staves previously forming parts of barrels used to age wine and other alcoholic beverages, each stave having inner and outer segments, with the inner segment being different in appearance from the outer due to penetration of alcoholic beverage components. The sides of said staves are first trimmed so that the sides are straight and parallel, and the staves are then cut into a plurality of strips. The strips are then formed into a panel with the inner surface of each strip being adjacent the outer surface of an adjacent strip, providing a decorative pattern of alternating contrasting stripes.

Owner:ATKINSON JESSICA S

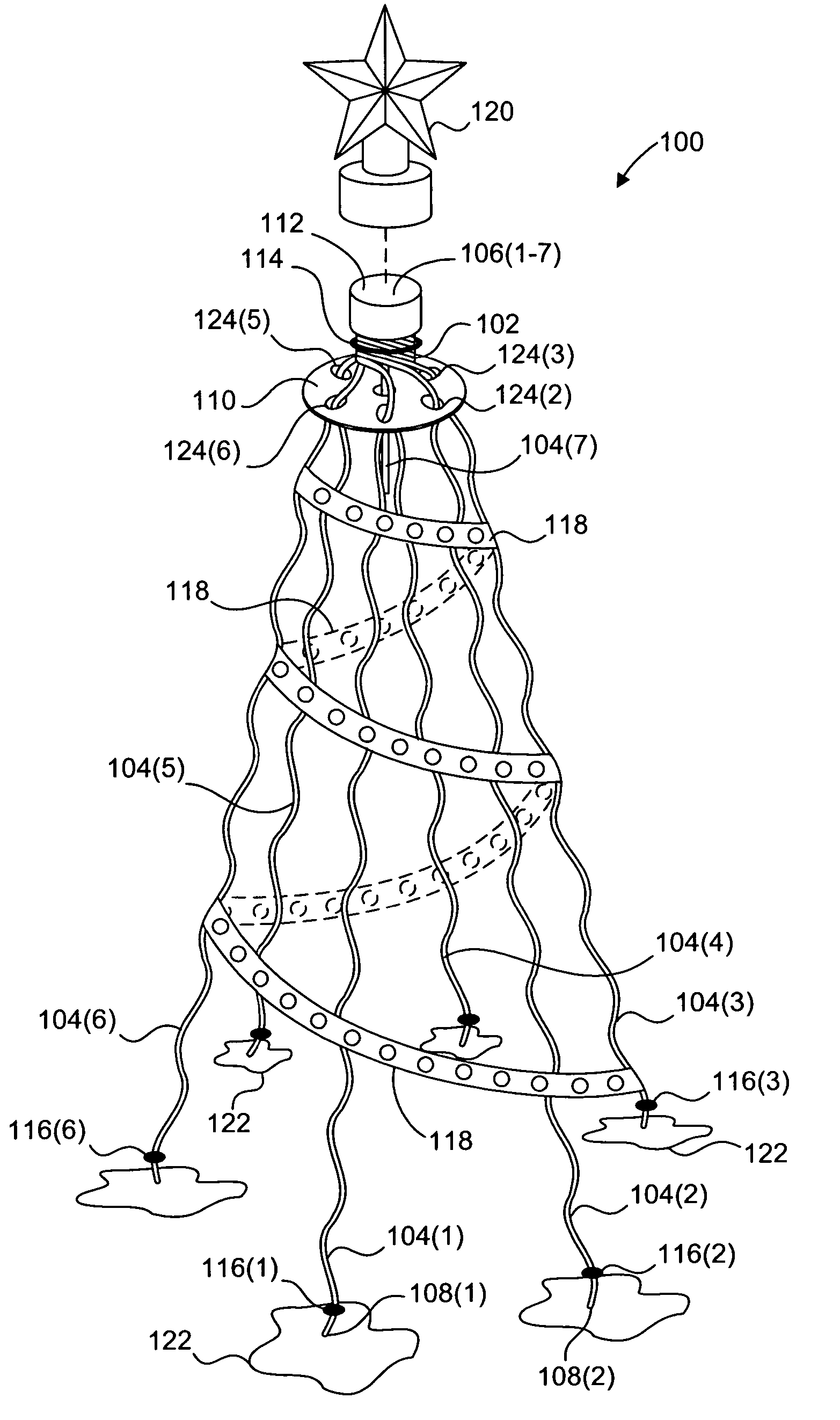

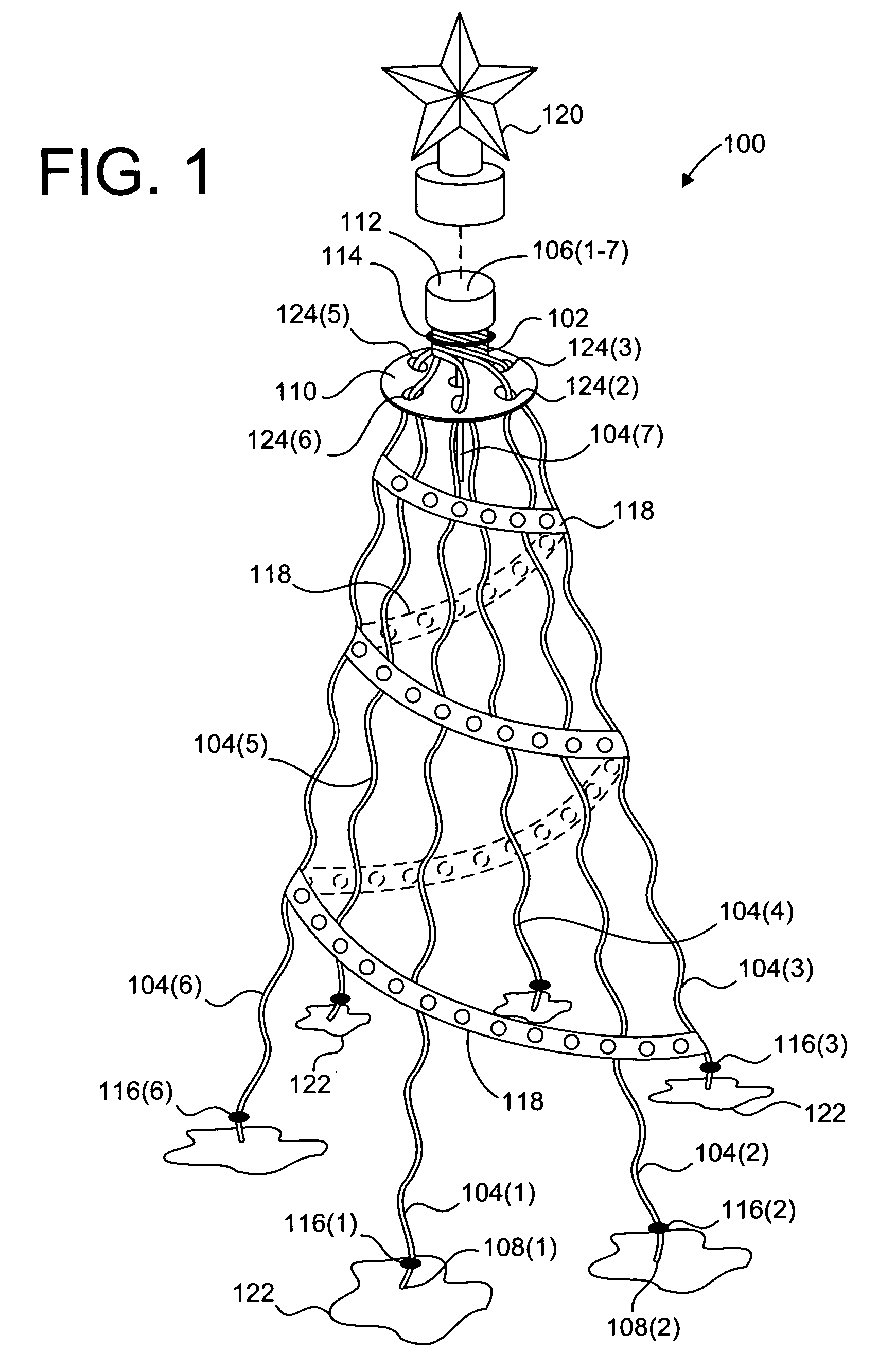

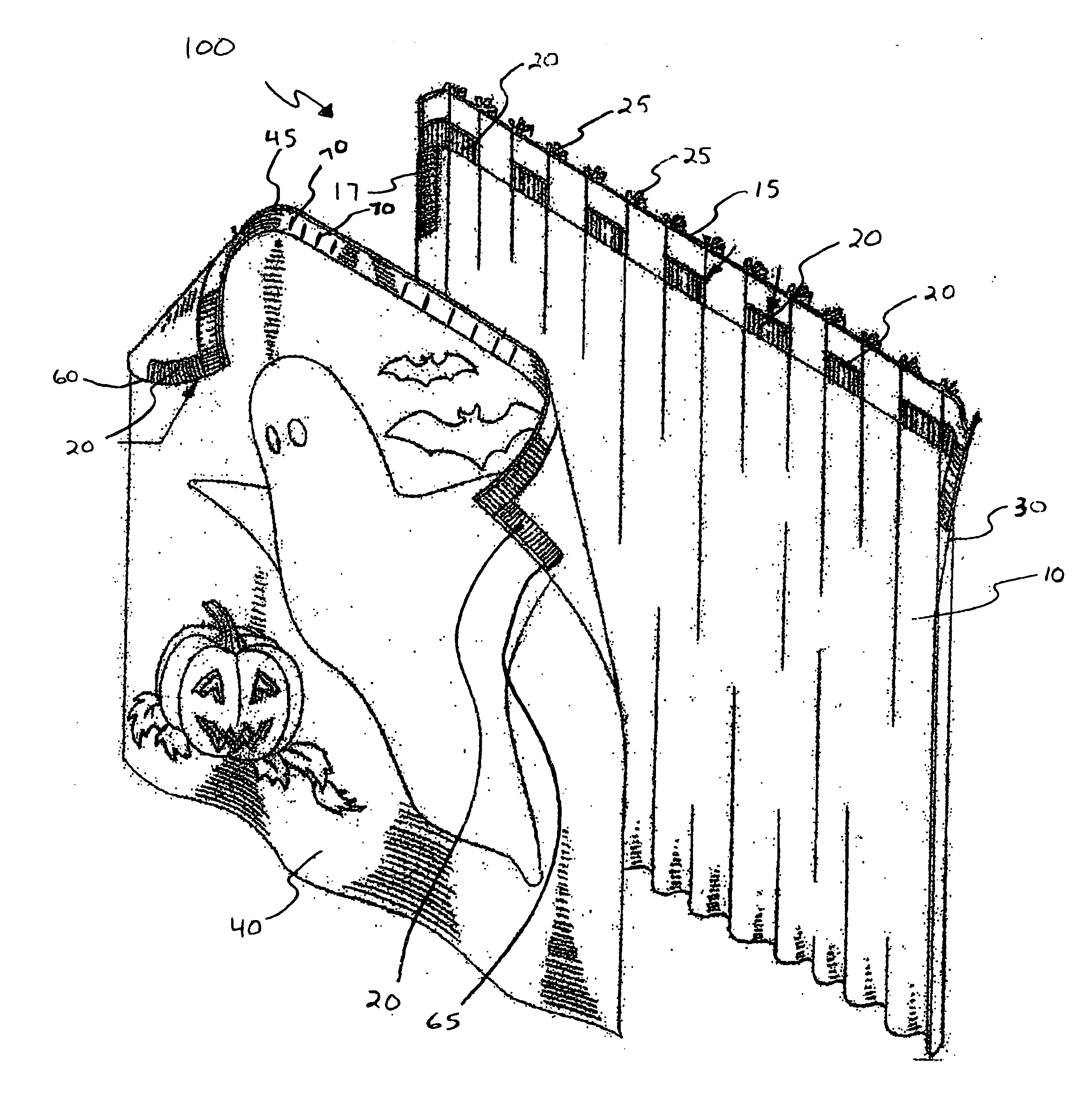

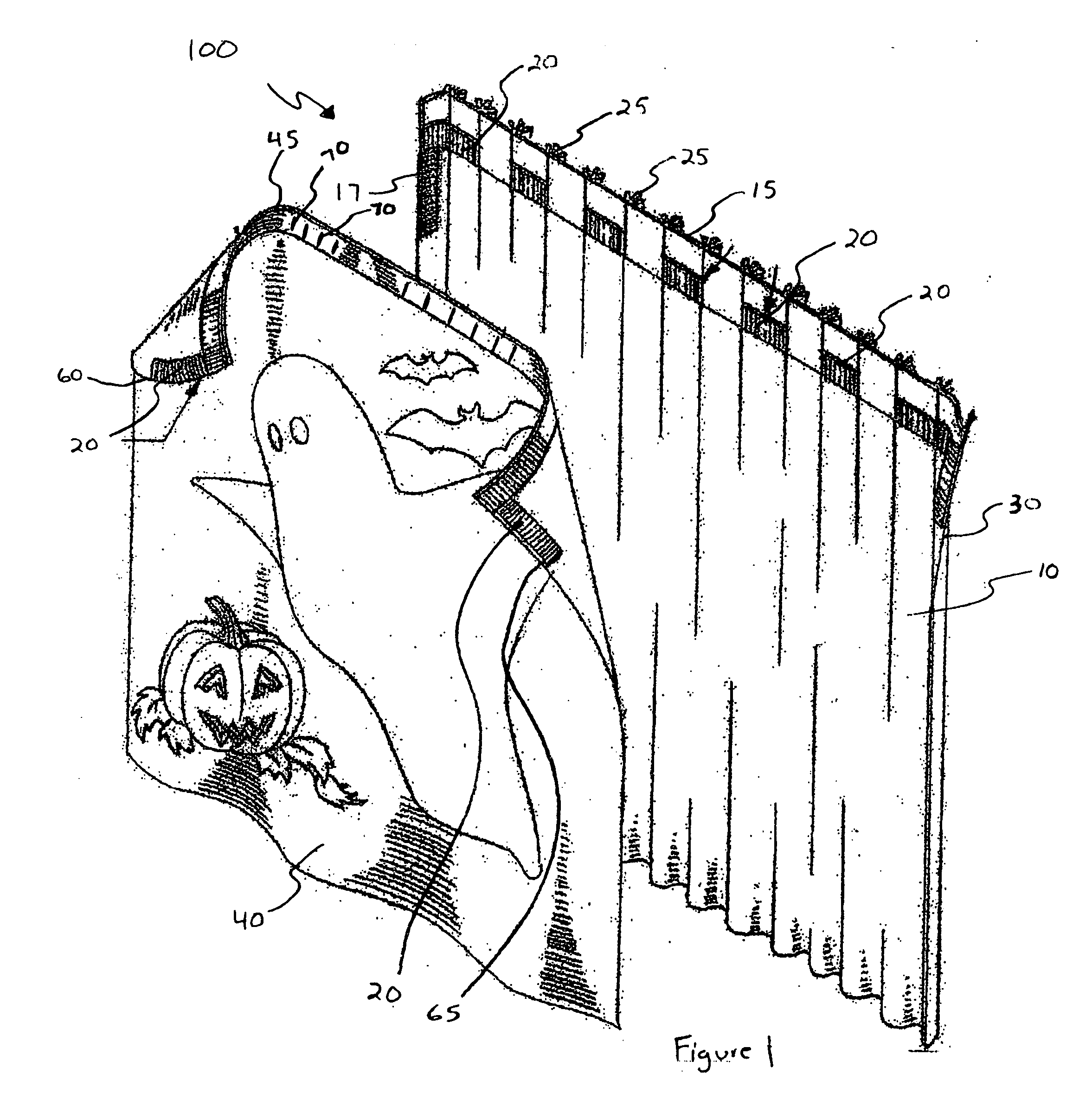

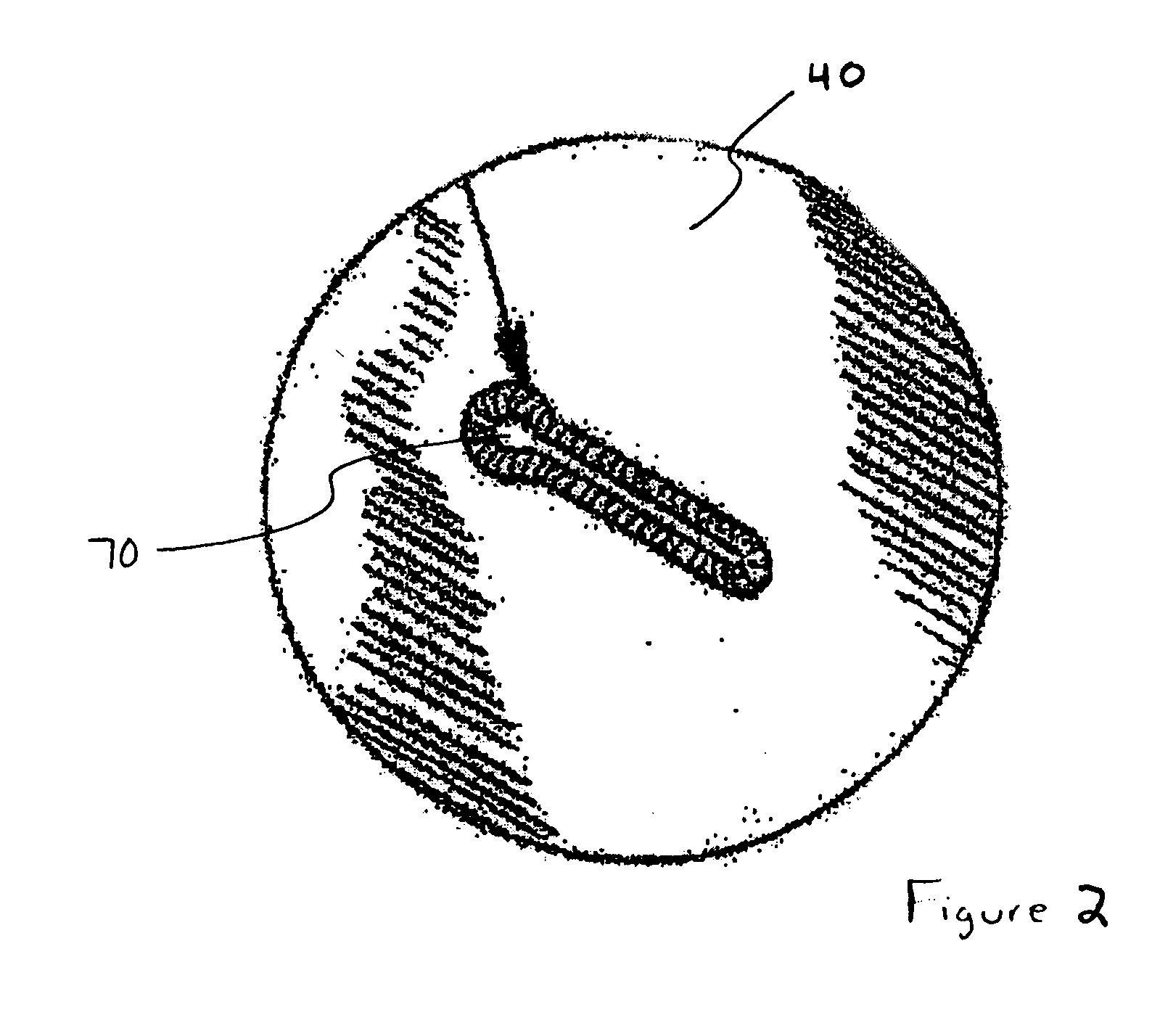

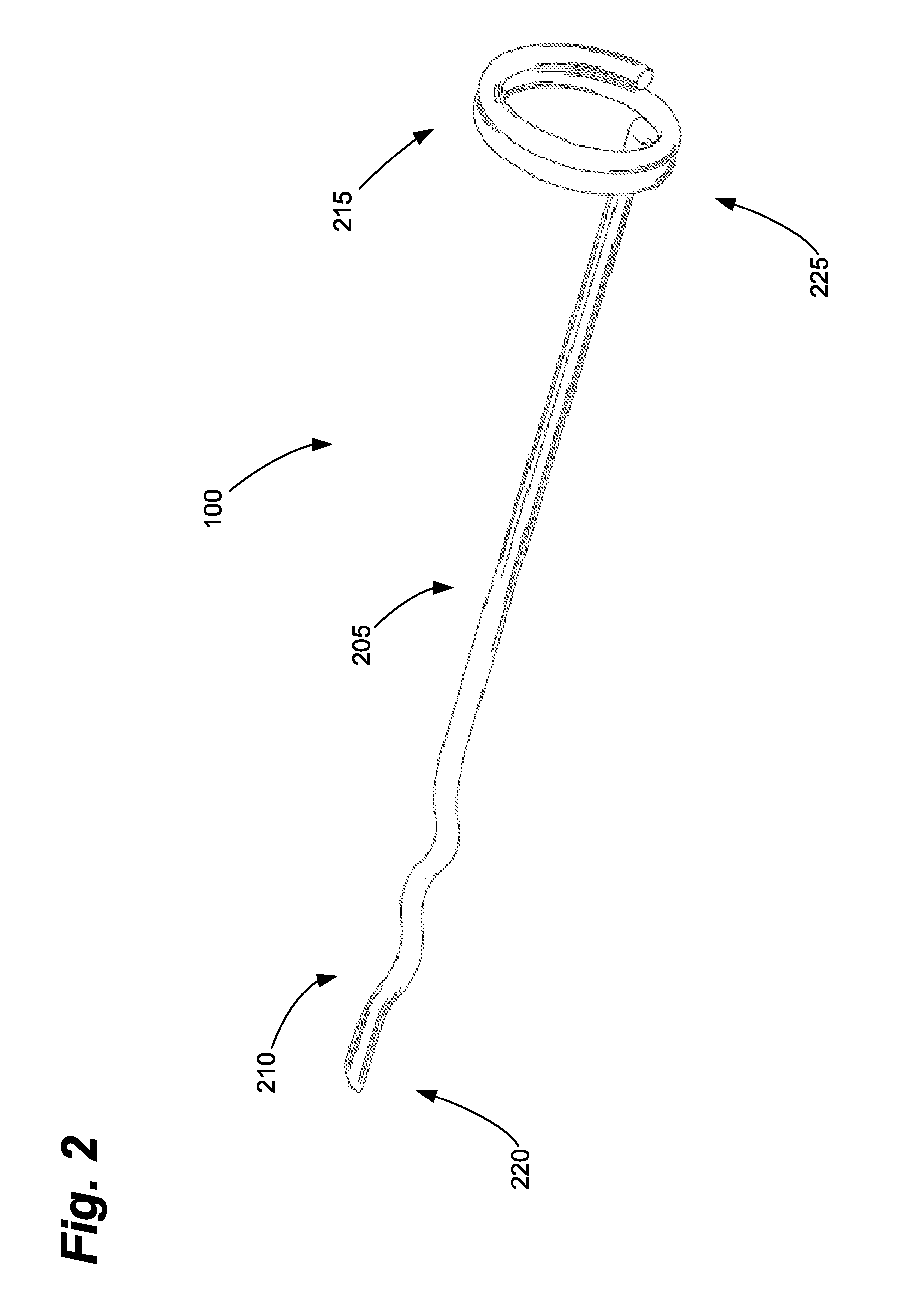

Collapsible decorative structure

InactiveUS7320816B2Easy to collapseEasy erectionDead plant preservationUmbrellasBiomedical engineeringSupport surface

A novel decorative structure includes a length of strand material, having a plurality of individual strands twisted with respect to one another and fixed with respect to one another near a first end of the strands, a twisting member having a plurality of apertures formed therein, each adapted to receive a respective one of the individual strands therethrough, and an anchoring member adapted to support the decorative structure on a support surface. In a particular embodiment the twisting member is a disc, such that when the twisting member is advanced from a second end of the strands to the first end, the strand material is caused to unwind. Similarly, when the twisting member is advanced from the first end to the second end of the strands, the strand material is caused to wind up. When unwound, the strands can support a container within the unwound ends of the strand material.

Owner:QUIGEL CAMERON F

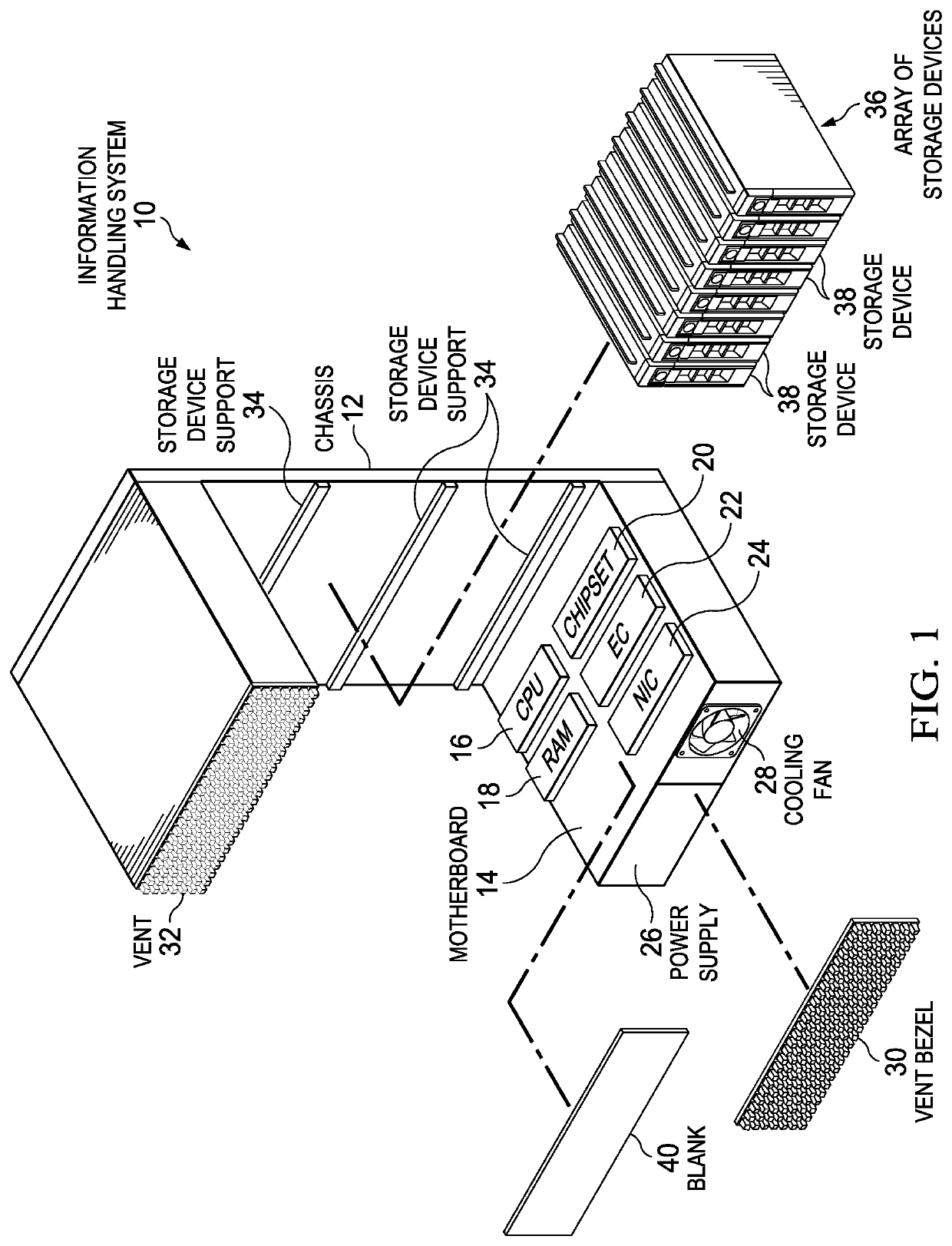

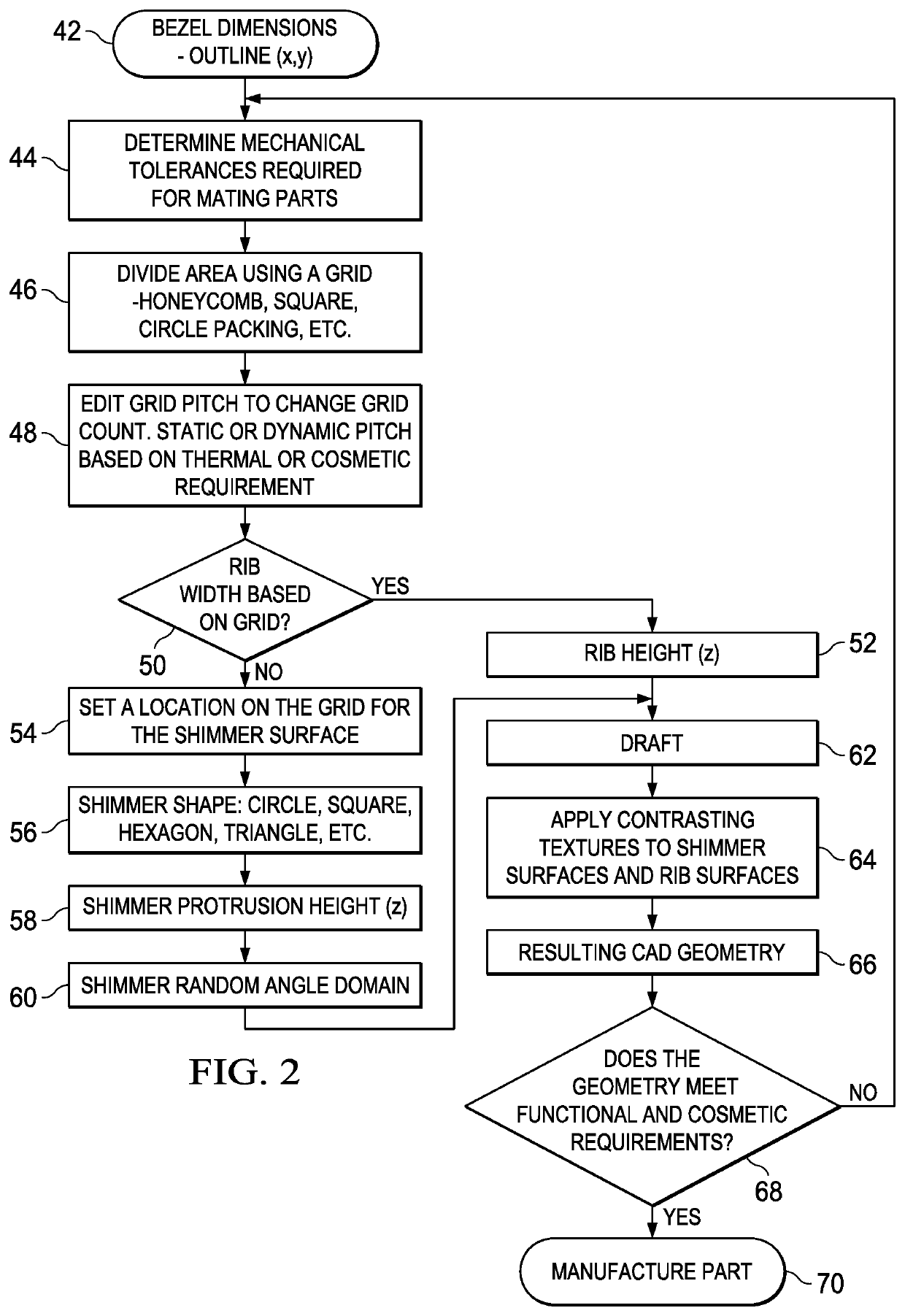

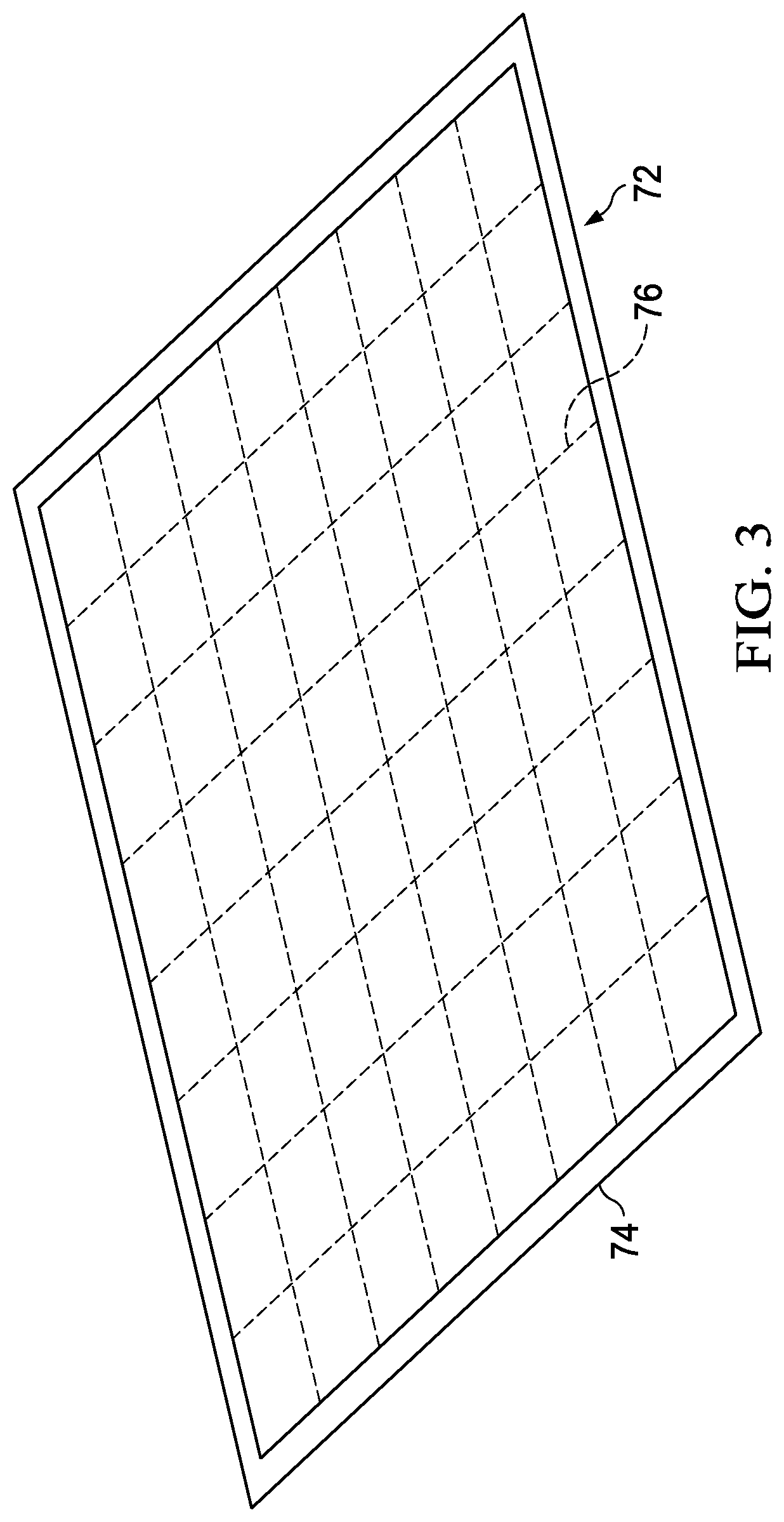

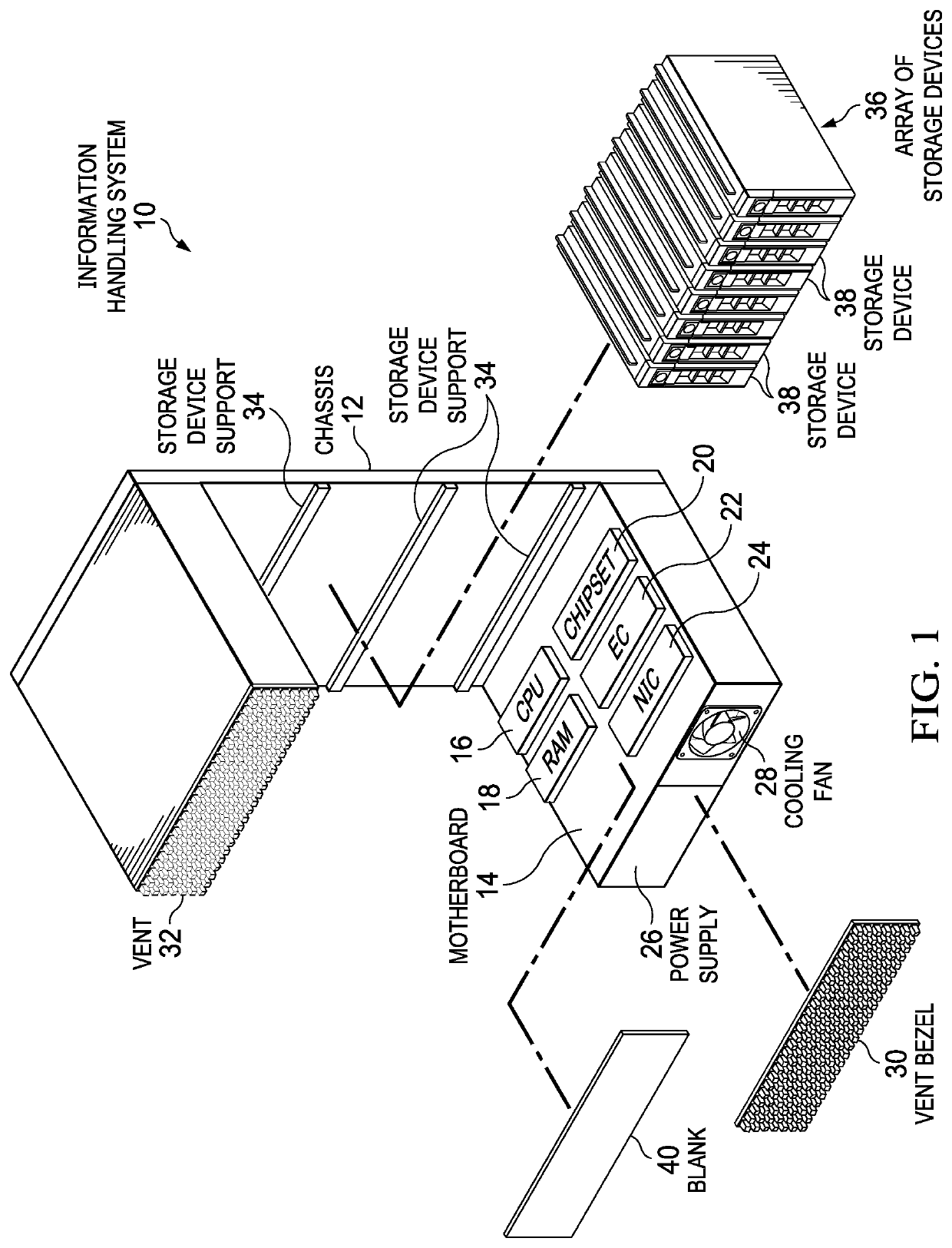

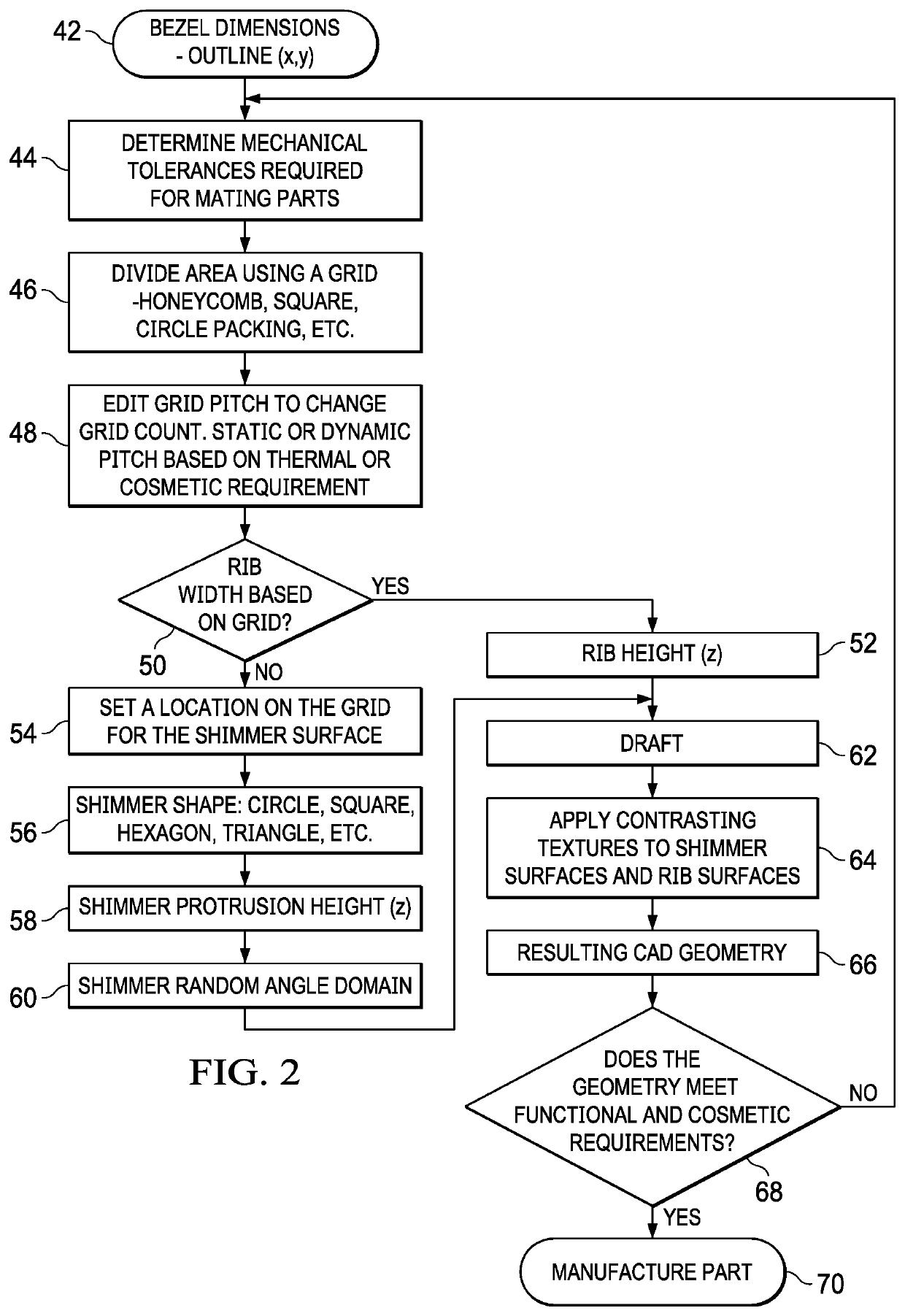

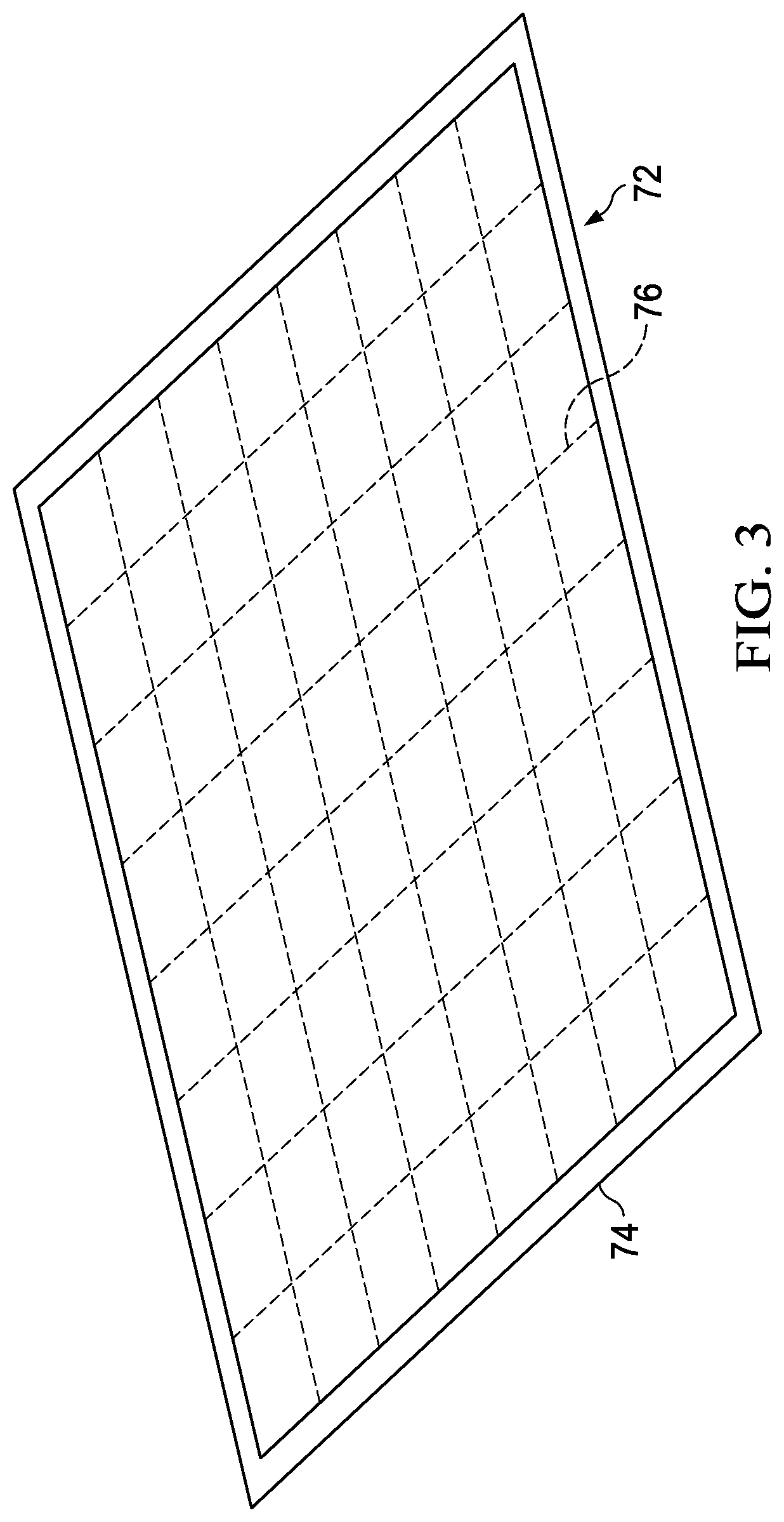

Information handling system reflective outer housing

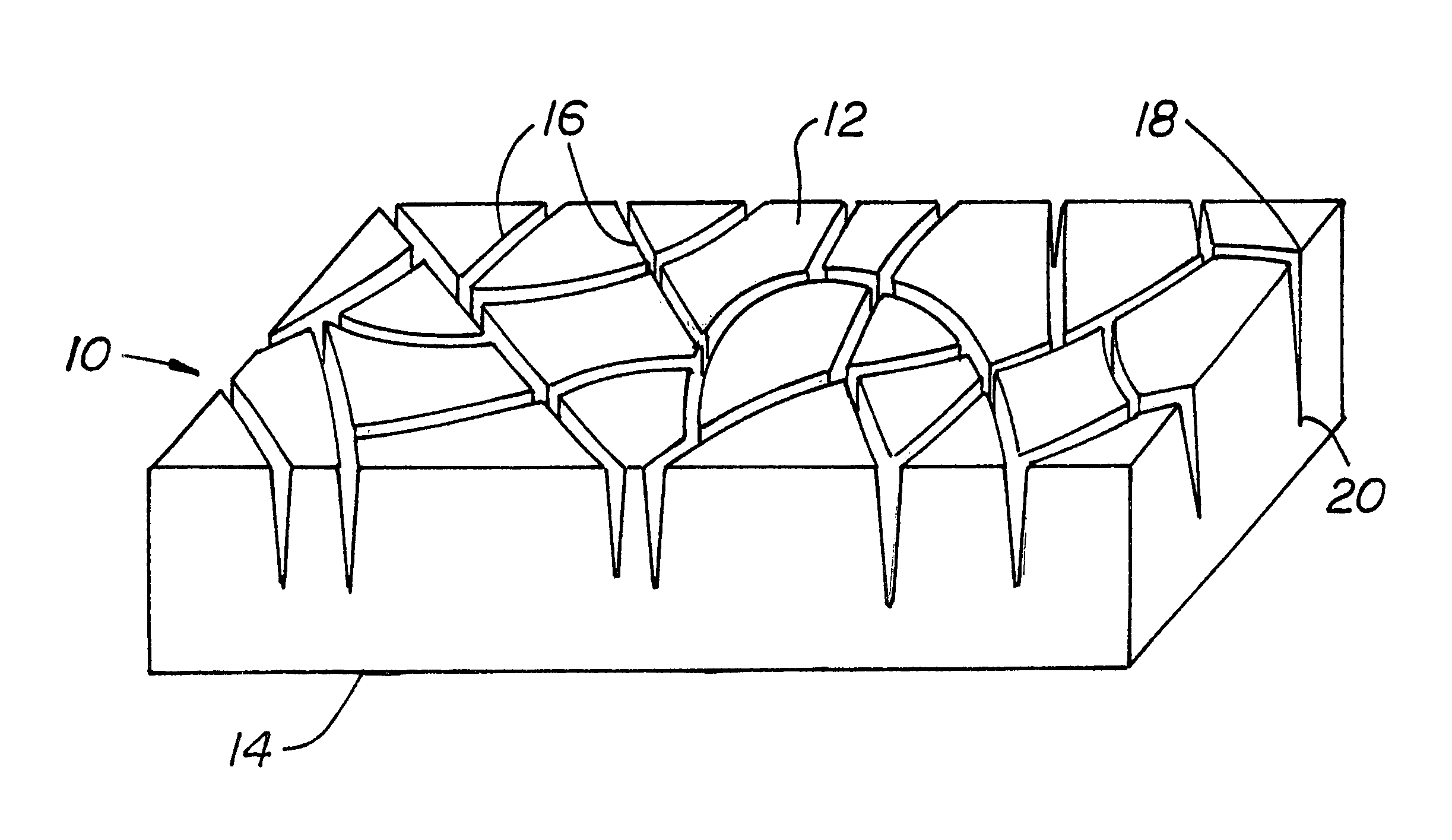

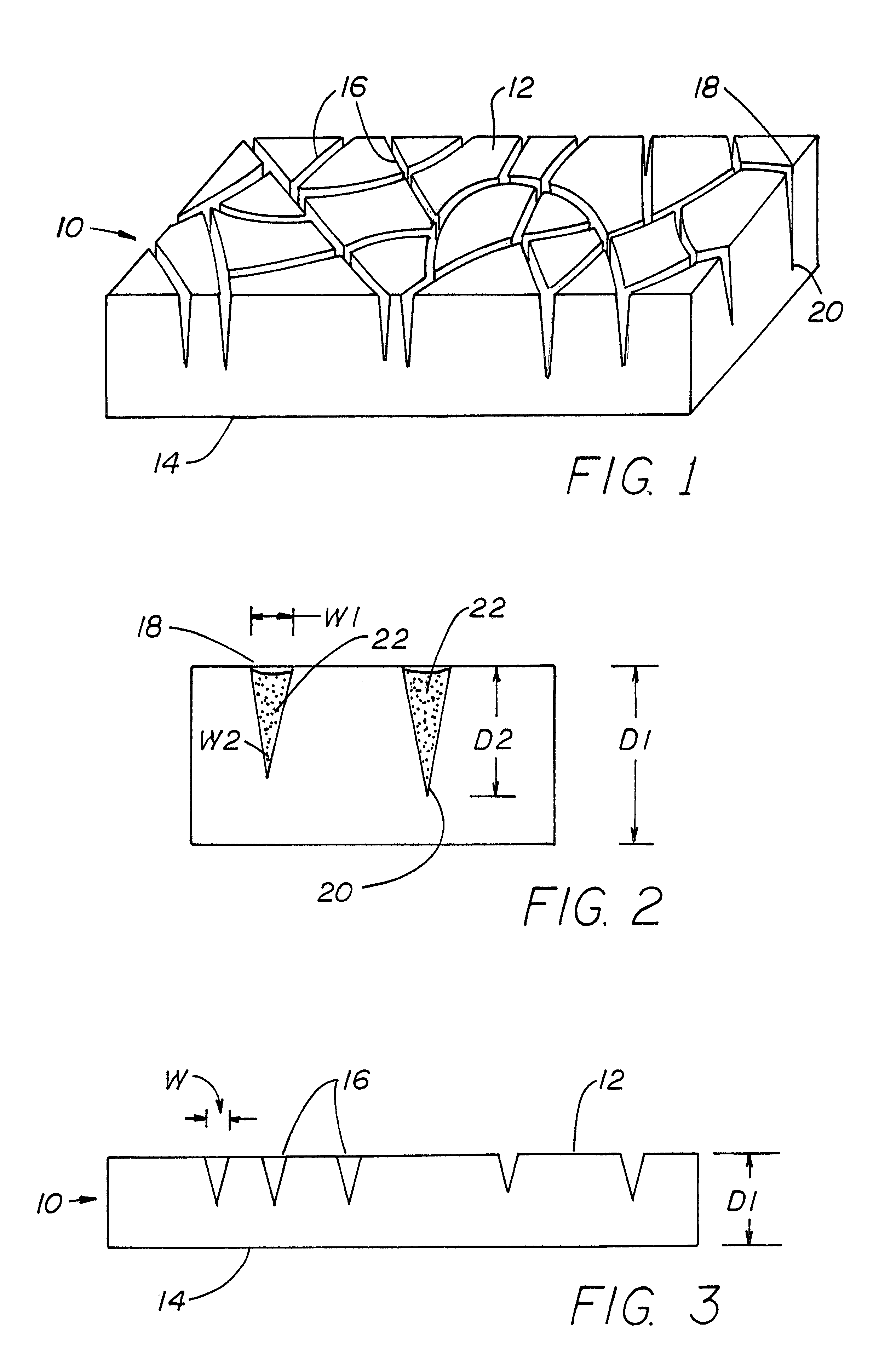

ActiveUS10788868B1Improve decorative appearanceGreat mechanical toleranceDigital processing power distributionLight reflectionEngineering

An information handling system housing vents air at a grid of openings formed in a wall with a member extending outward from each intersection of the grid to define air channels. Each member terminates with a polished planar surface that reflects light against a flat underlying material. Variable angles of the polished planar surface relative to the plane of the wall creates a presentation of isolated reflections against the flat background that vary based upon a viewing angle of the housing wall.

Owner:DELL PROD LP

Curtain system with removable layer

InactiveUS20060248641A1Easy to replaceImprove decorative appearanceBathsDouchesEngineeringSecondary layer

A curtain designed to have at least two layers to be suspended from a suitable horizontal support structure adjacent to a window, shower or bathtub. The curtain includes a first layer that is configured in a substantially vertical an planar manner and a second layer that is adjacent thereto. The second layer is configured to be releasably secured to the first layer using a plurality of fasteners, such as hook-loop fasteners proximate the upper edges of the first layer and second layer. The first layer further includes a plurality of hooks proximate to the upper edge to facilitate suspension of the curtain from a horizontal support structure. The second layer further includes a plurality of apertures designed to receive decorative objects therein.

Owner:KINSTLE TRINDA L +1

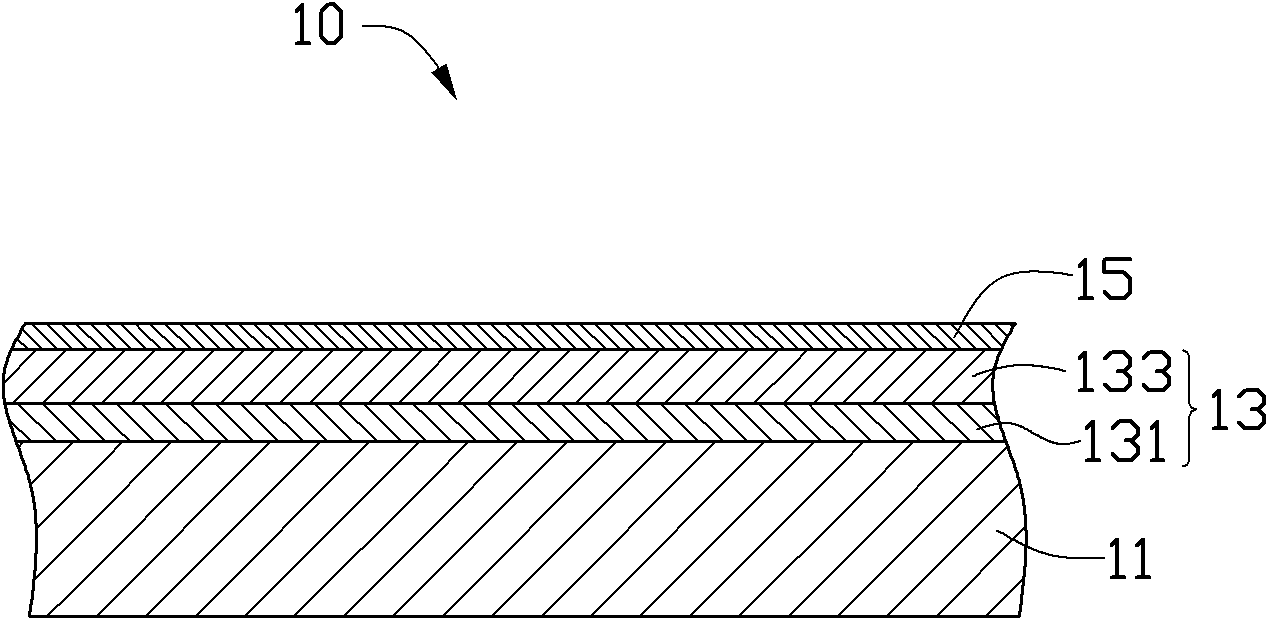

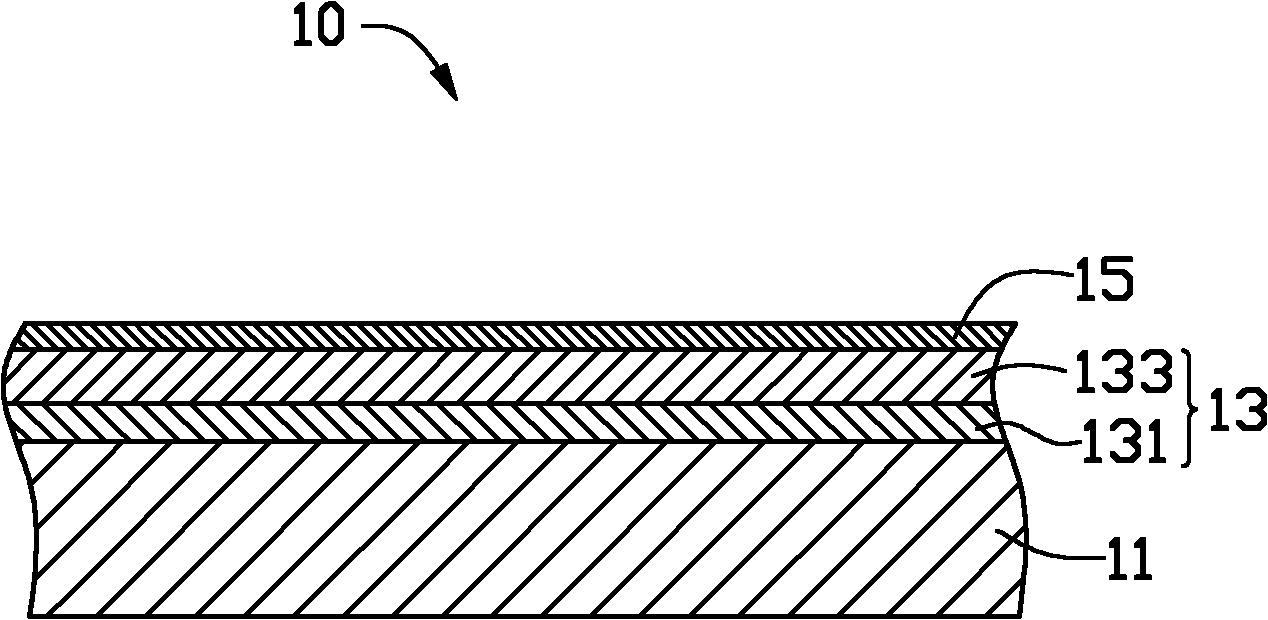

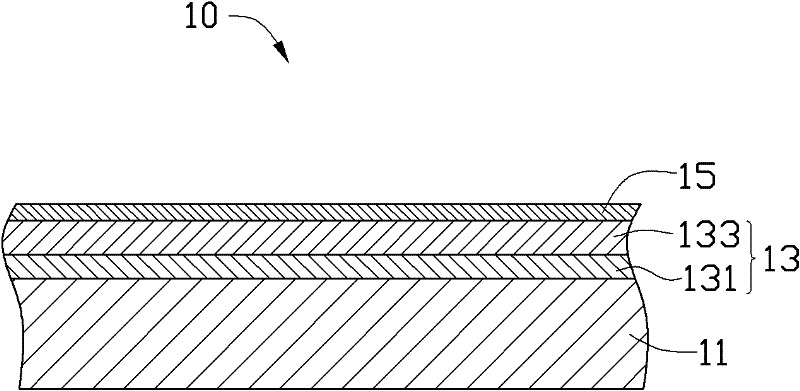

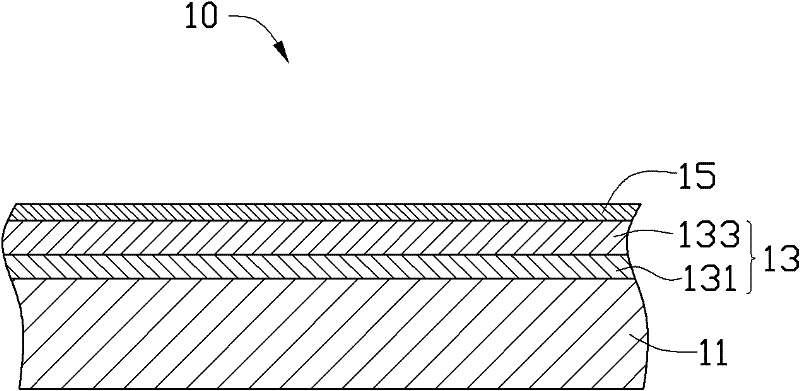

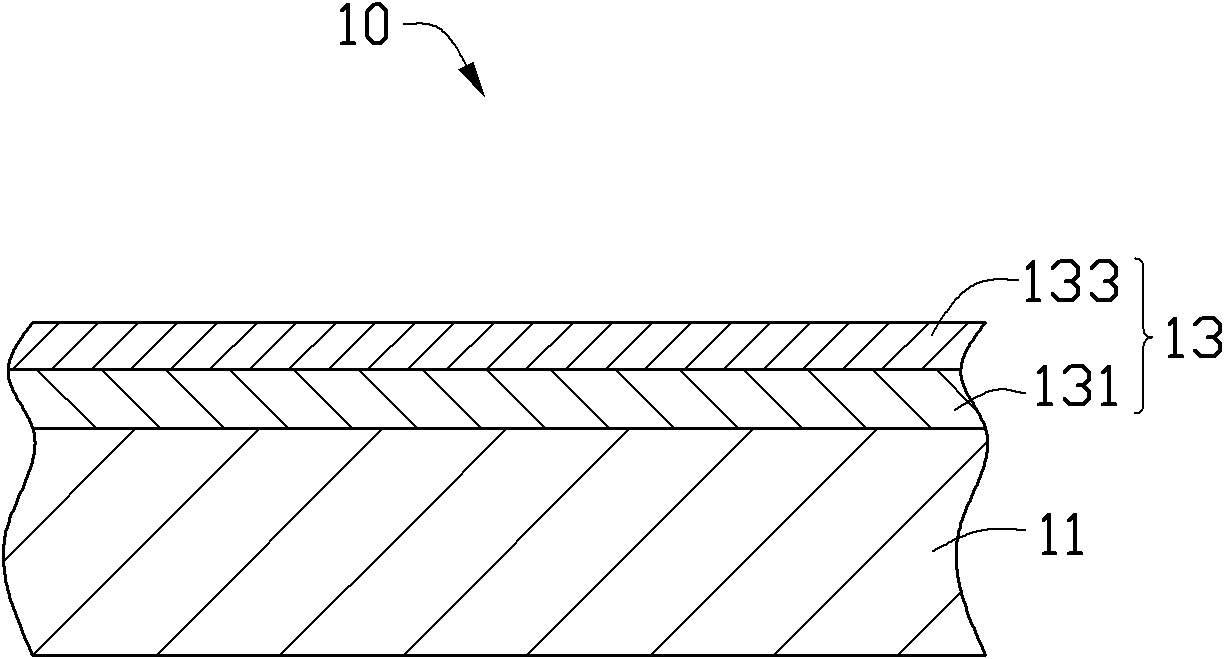

Shell and manufacturing method thereof

InactiveCN102534504AImprove corrosion resistanceImprove decorative appearanceVacuum evaporation coatingSputtering coatingSputteringMetal

The invention provides a shell which comprises a metal base, an anticorrosion layer formed on the metal base, and a decorative color layer, wherein the anticorrosion layer is an aluminum-manganese layer. The shell has favorable corrosion resistance and good decorative appearance. The invention also provides a manufacturing method of the shell, which comprises the following steps: providing the metal base; carrying out magnetron sputtering on the metal base to form the anticorrosion layer; and carrying out magnetron sputtering on the anticorrosion layer to form the decorative color layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

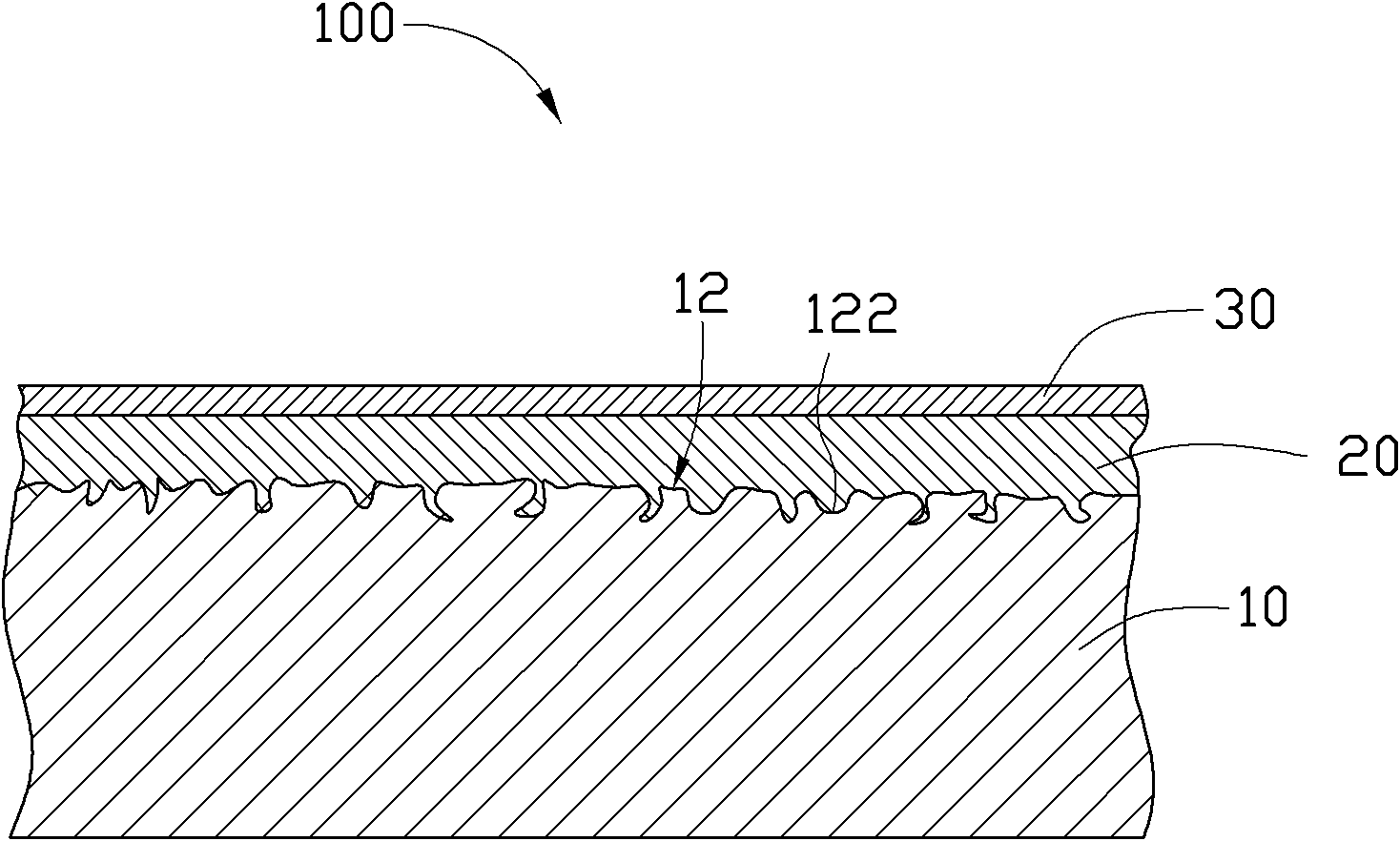

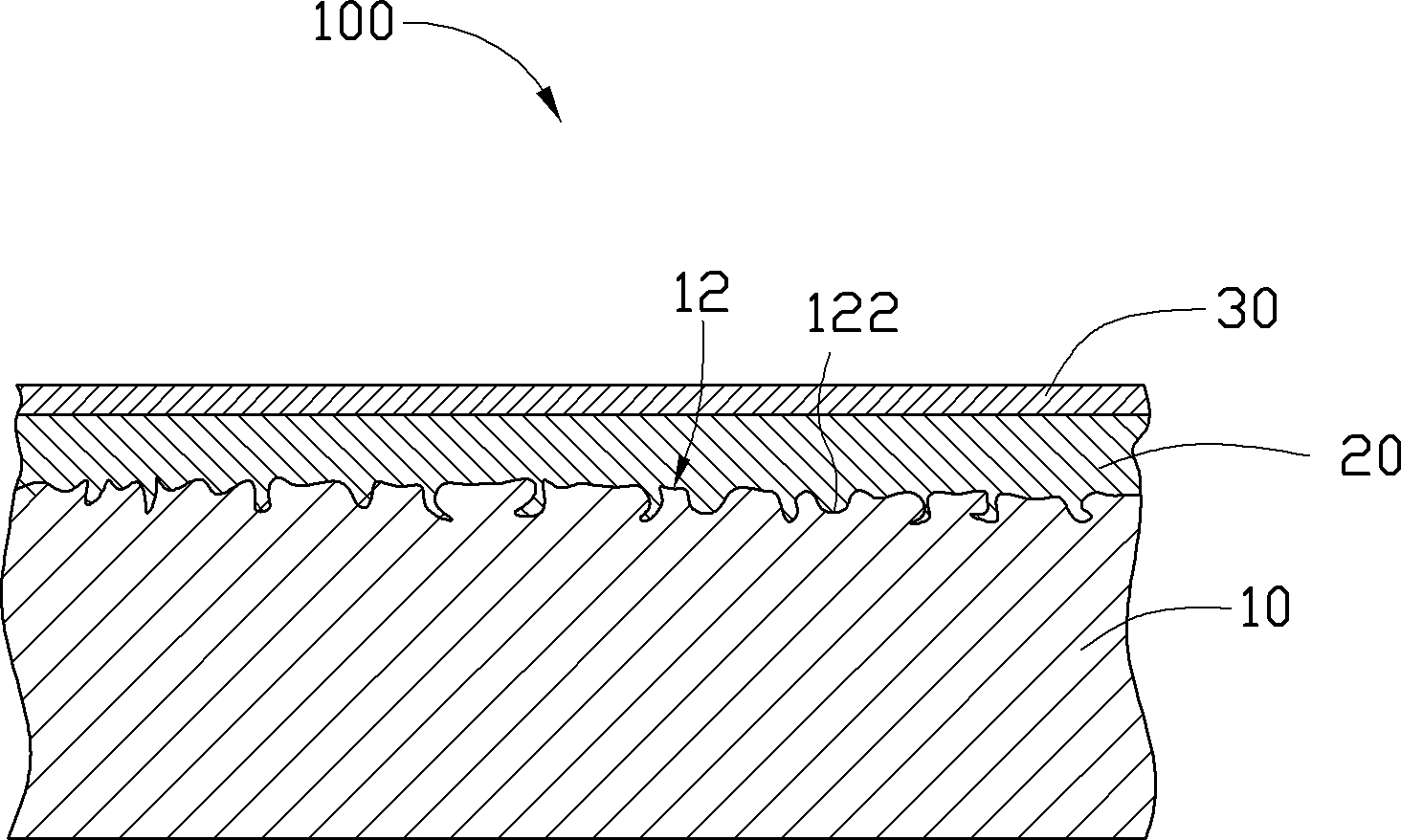

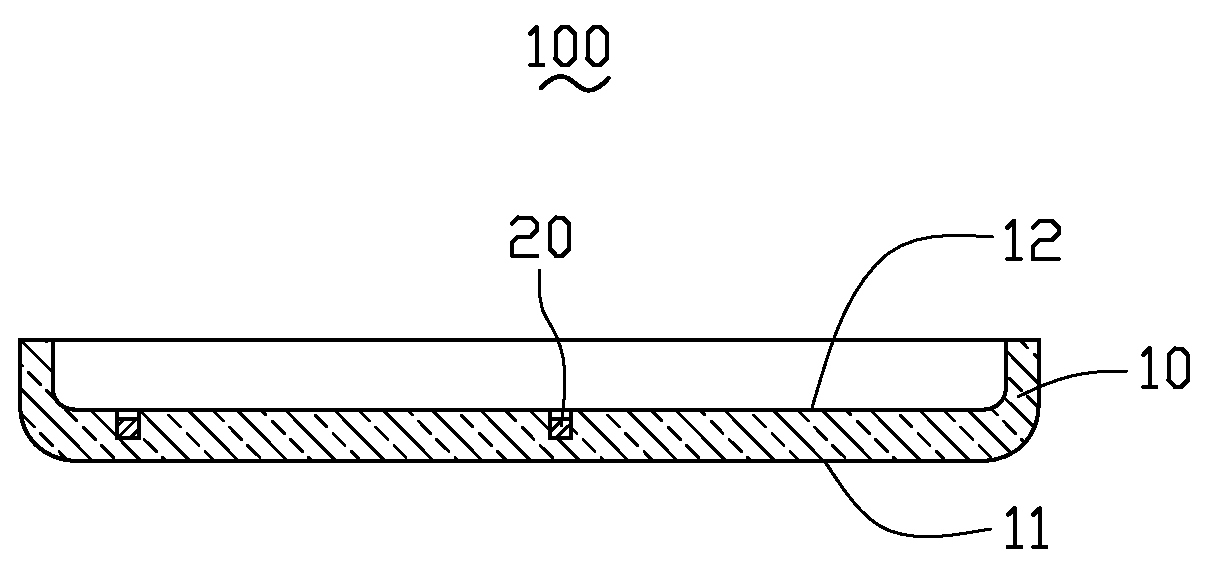

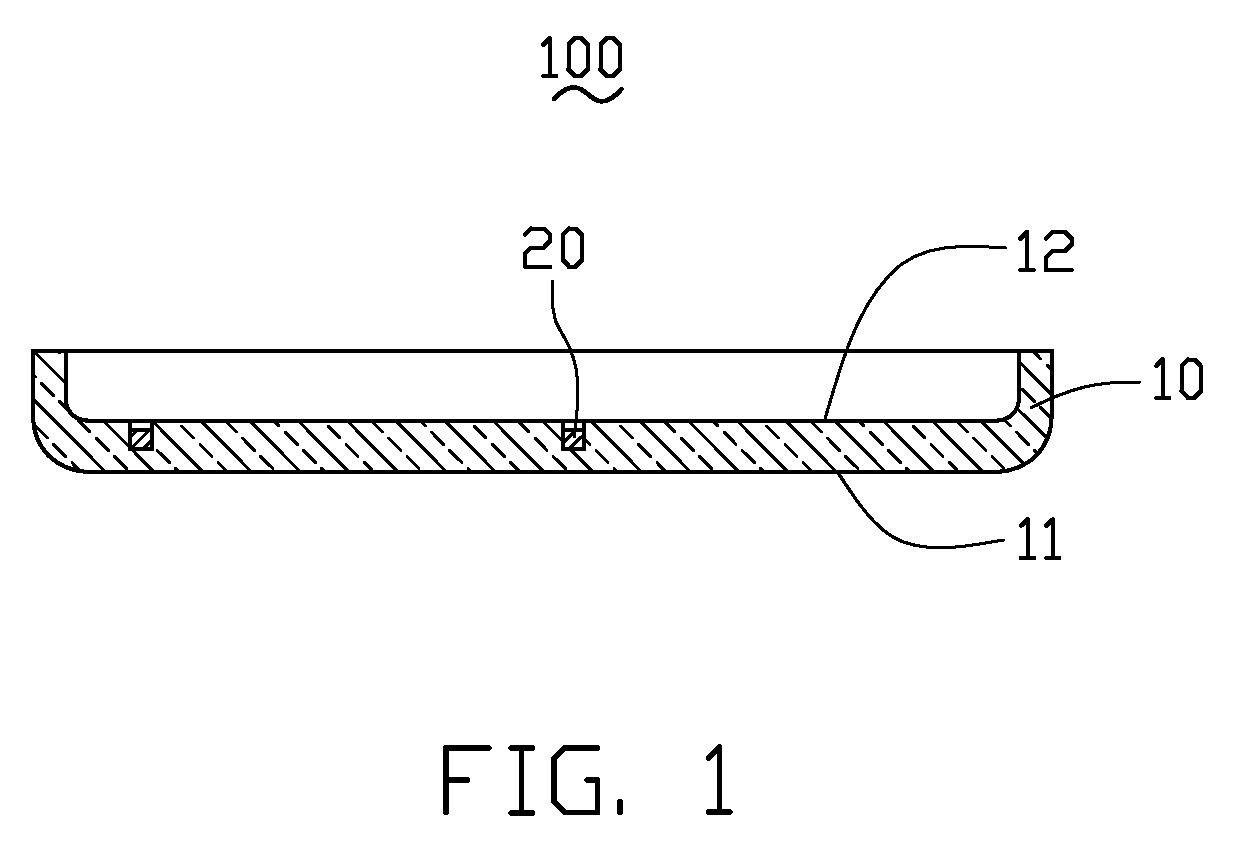

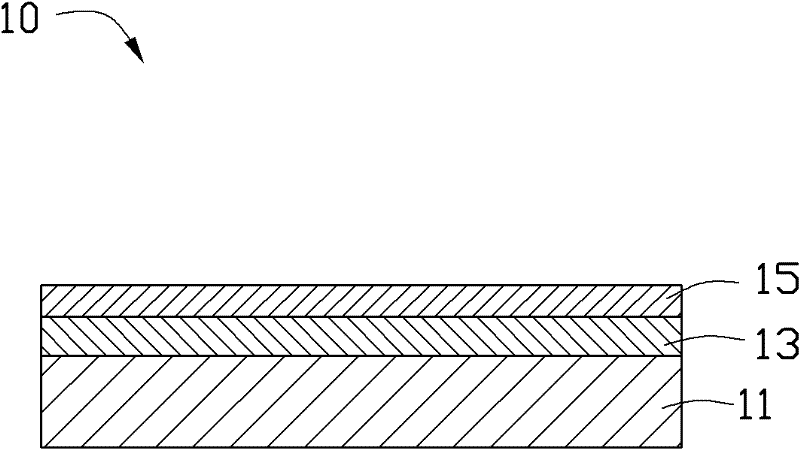

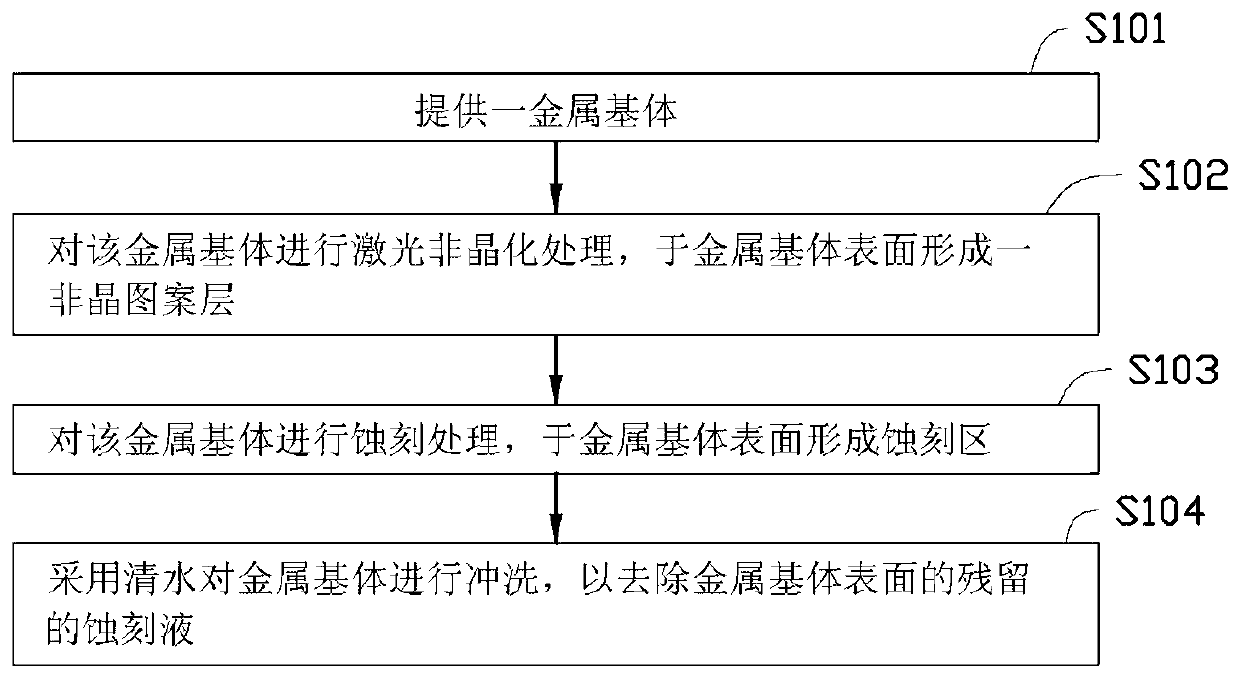

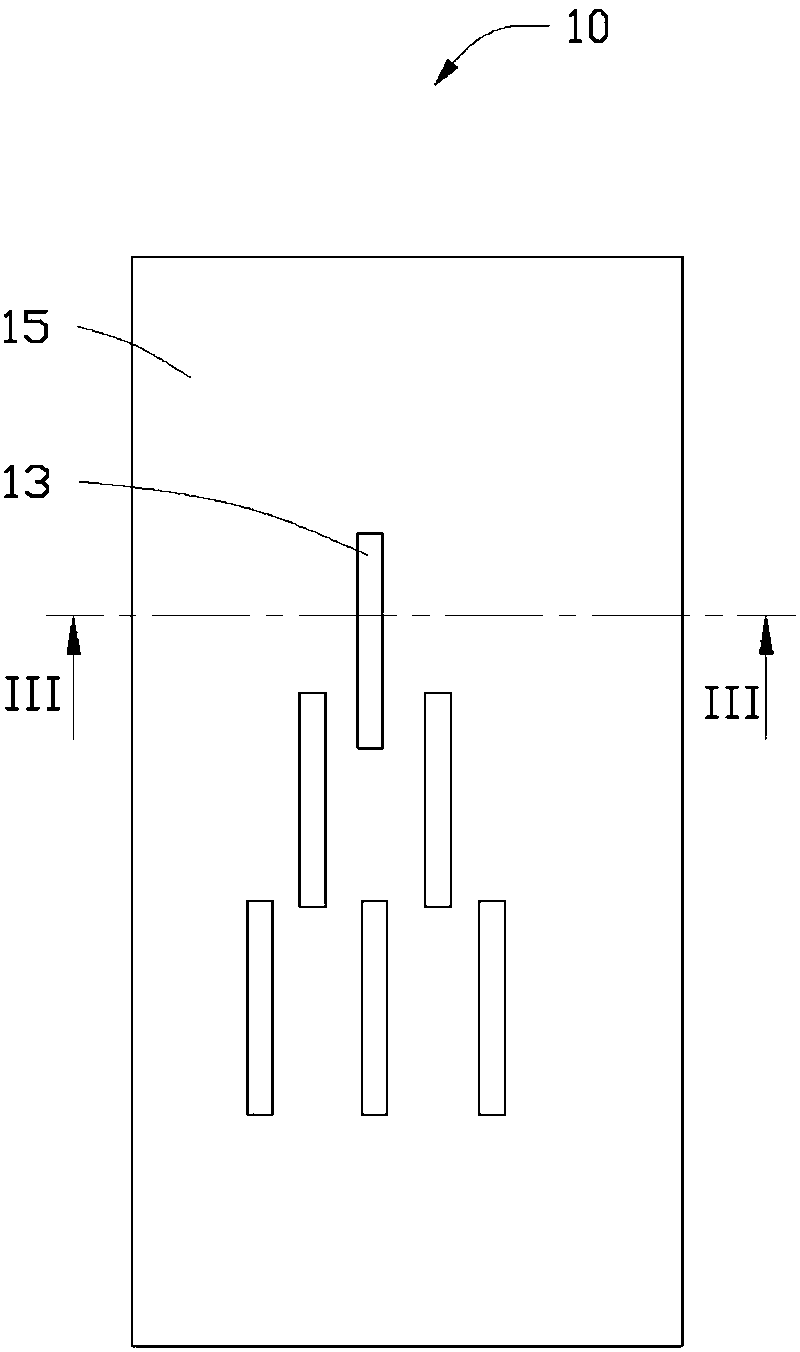

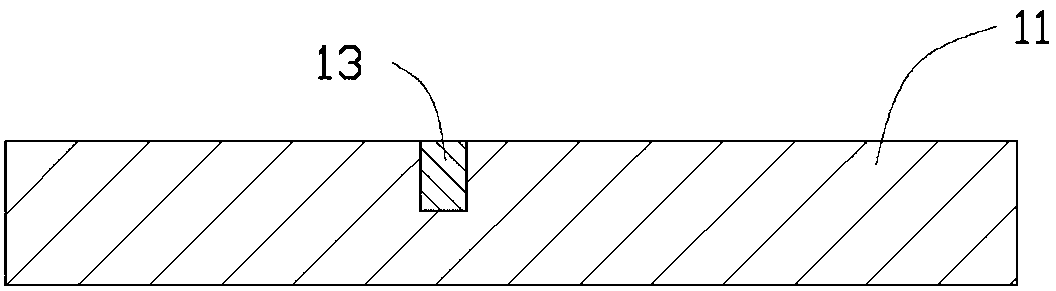

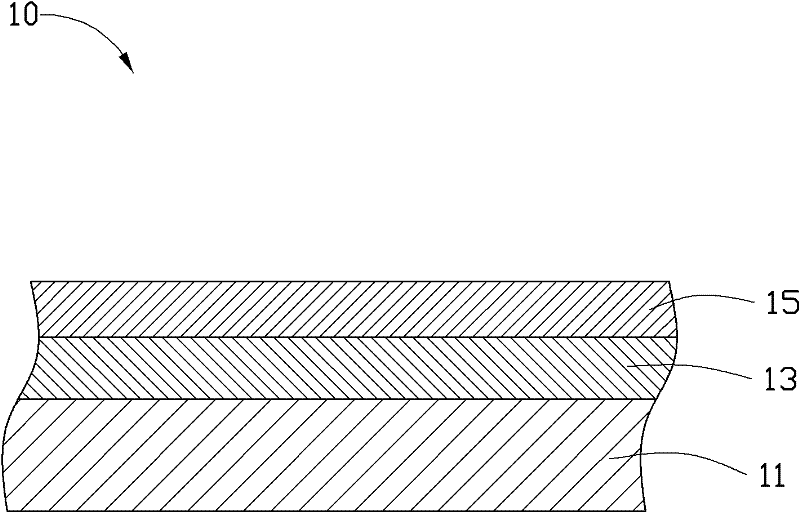

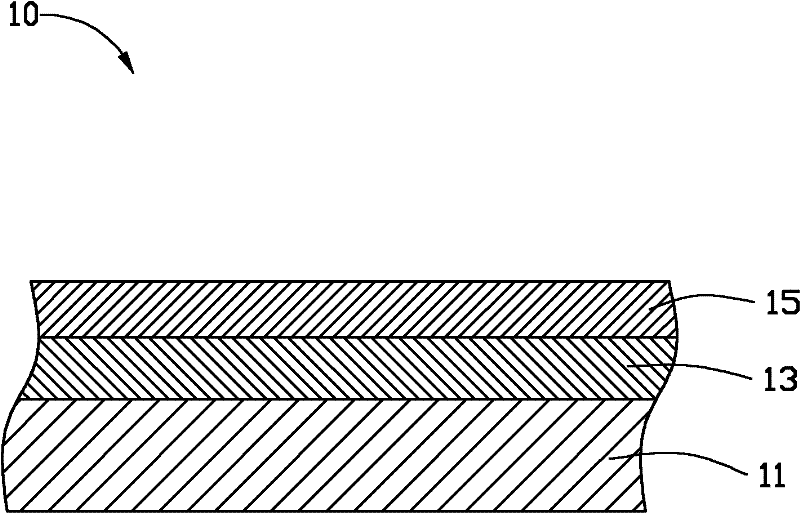

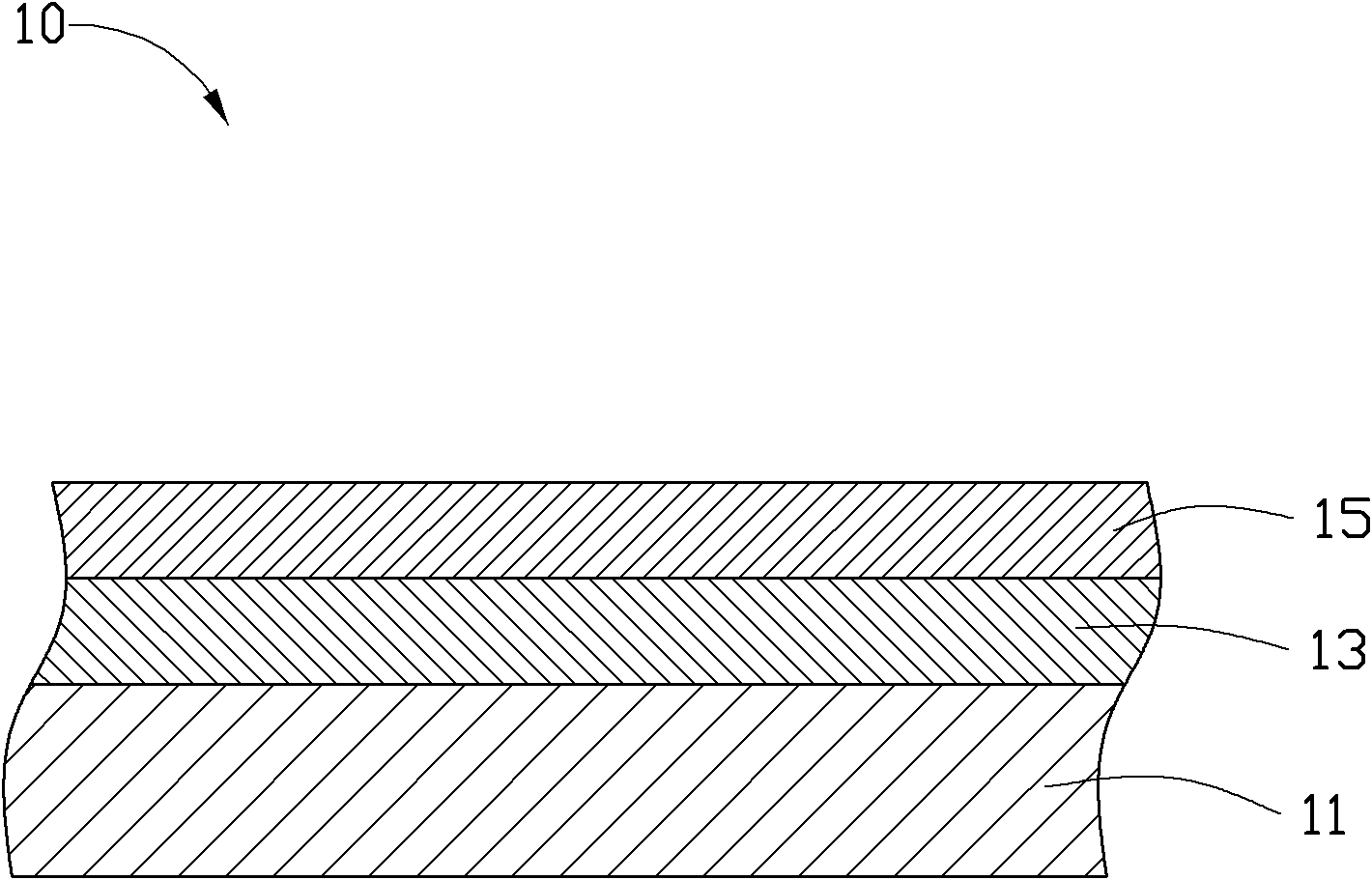

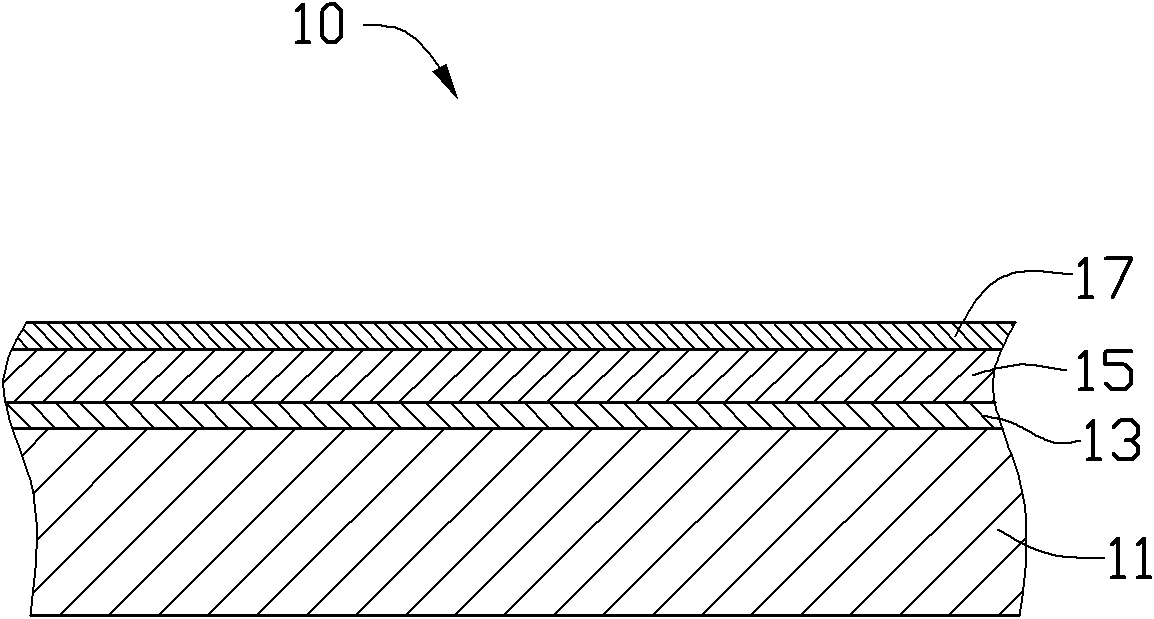

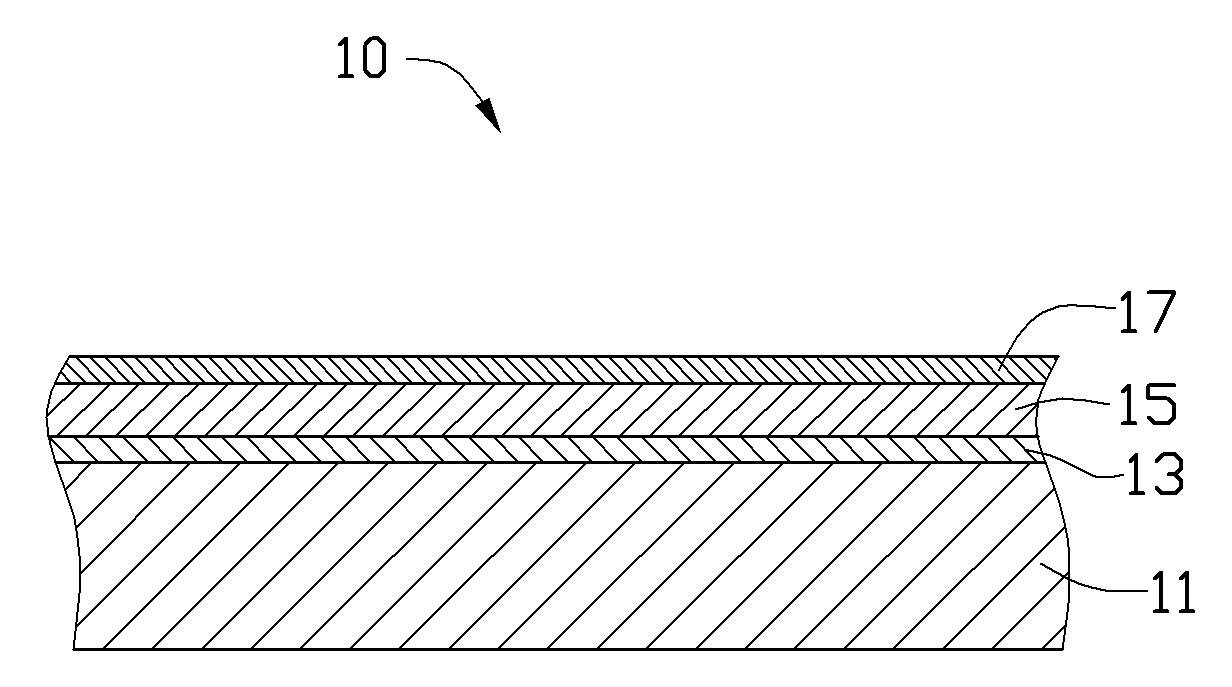

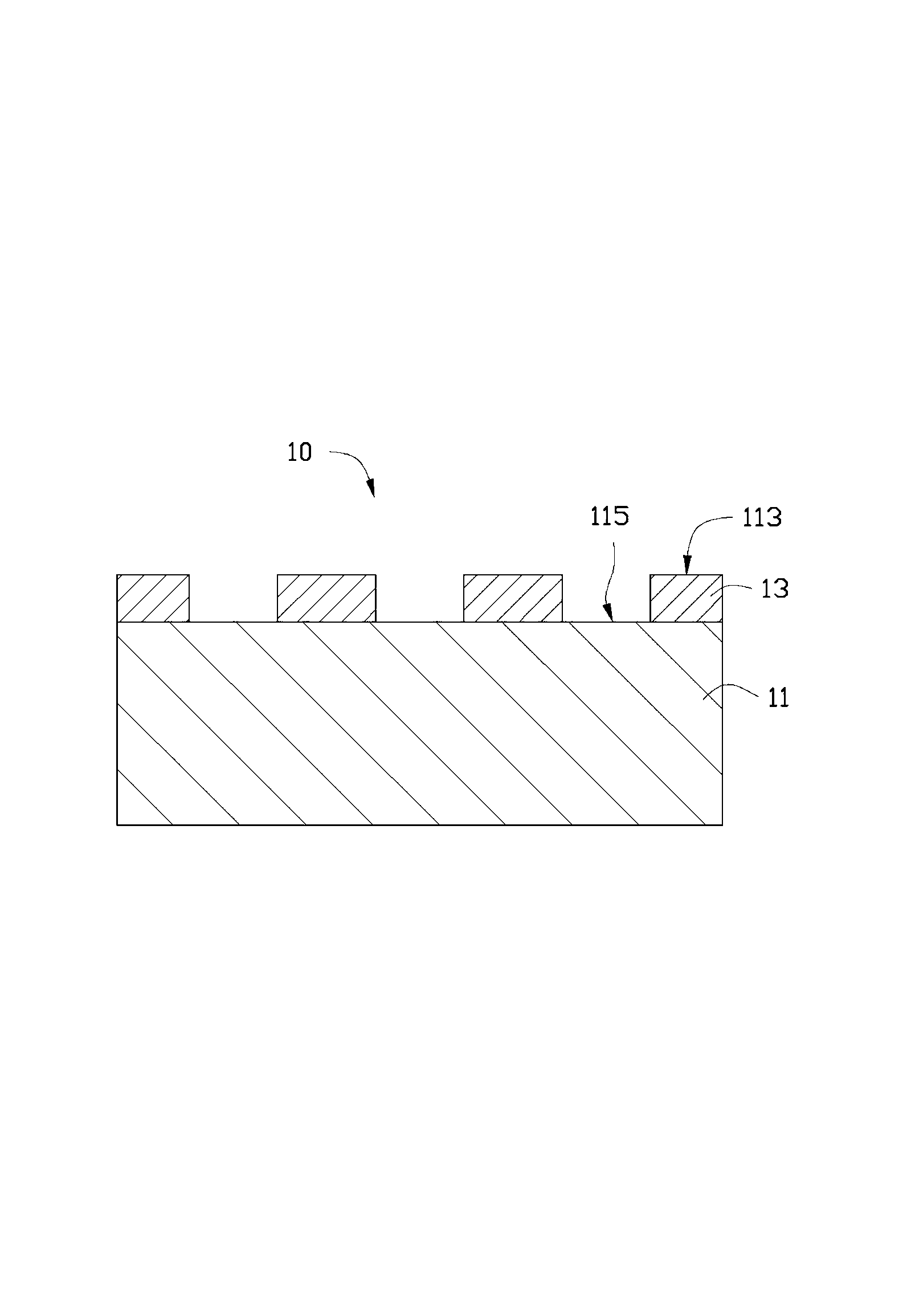

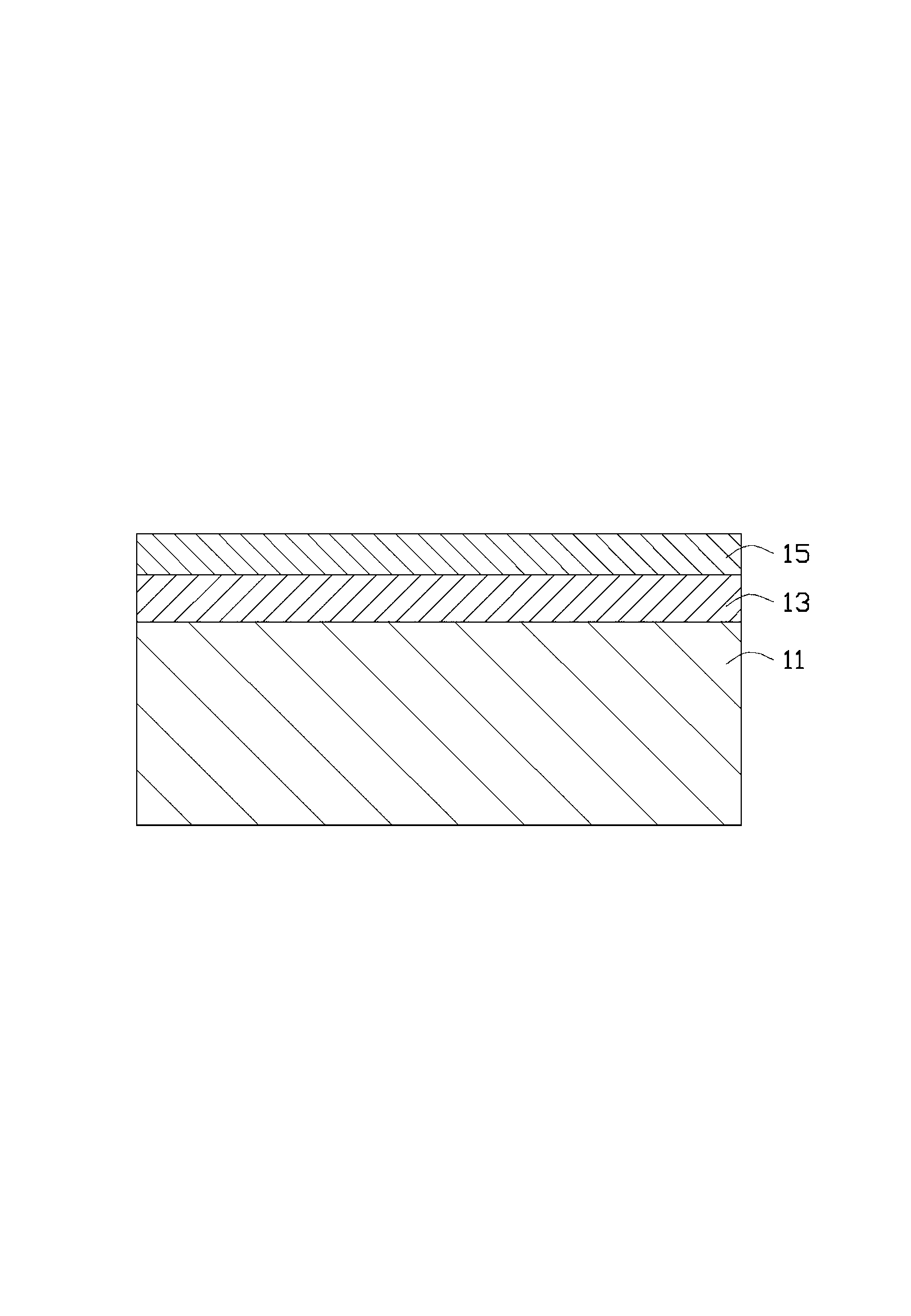

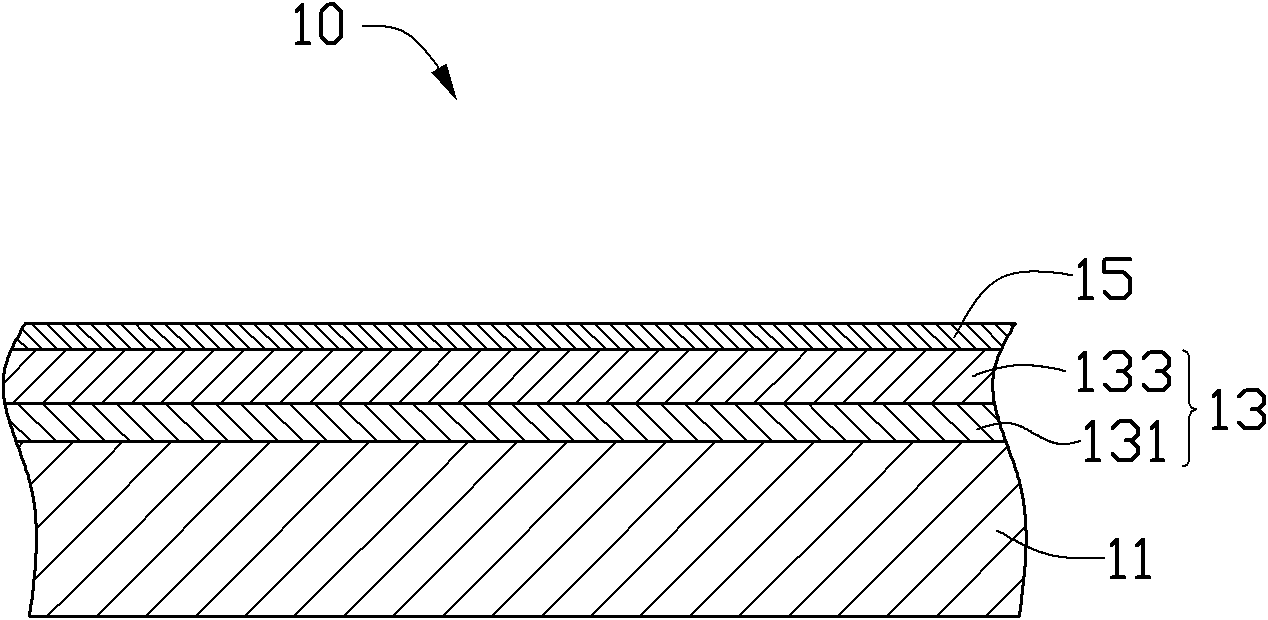

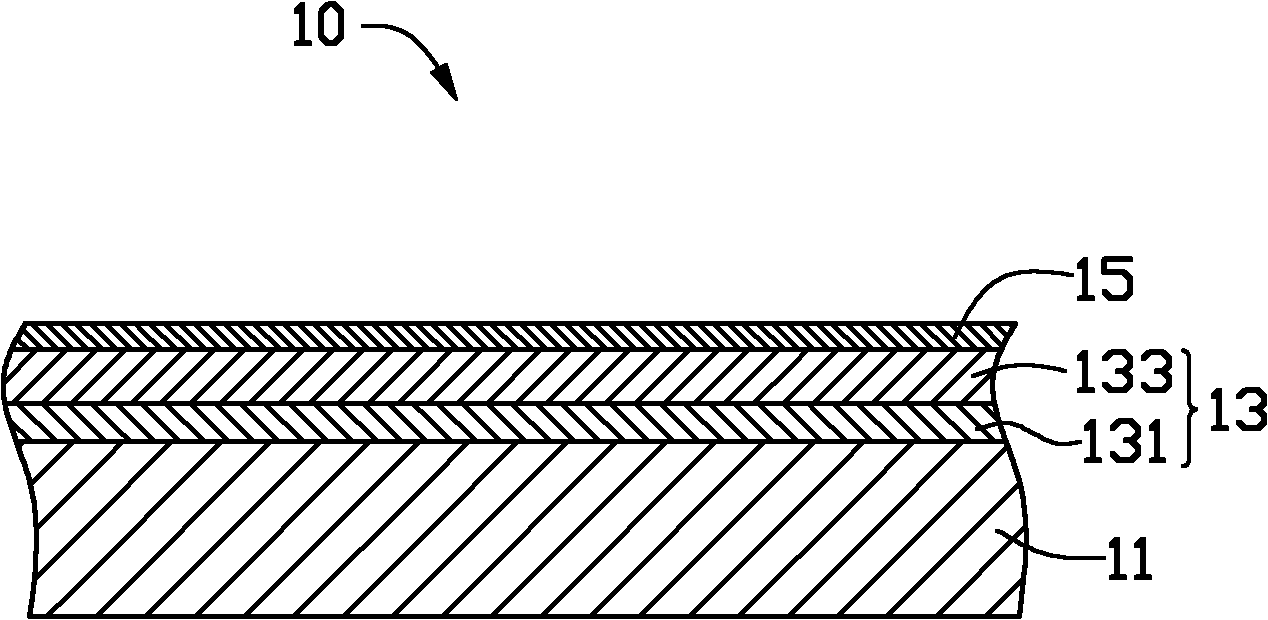

Substrate surface pattern production method and product thereof

ActiveCN103317932AImprove wear resistanceImprove decorative appearanceDecorative surface effectsThin material handlingSubstrate surfaceMetal substrate

The invention relates to a substrate surface pattern production method, which comprises the following steps: providing a metal substrate; carrying out a laser amorphization treatment on the metal substrate to form an amorphous pattern layer on the surface of the metal substrate; and carrying out an etching treatment on the metal substrate to form an etching region on the surface of the metal substrate, wherein no amorphous pattern layer is formed on the surface of the metal substrate. The present invention further provides a product produced by using the substrate surface pattern production method.

Owner:FIH PRECISION ELECTRONICS LANG FANG CO LTD

Shell and manufacturing method thereof

InactiveCN102453855AImprove corrosion resistanceImprove decorative appearanceVacuum evaporation coatingSputtering coatingSputteringAlloy substrate

Owner:金机虎精密机械(武汉)有限公司

Coated piece and manufacturing method thereof

InactiveCN102465251AImprove corrosion resistanceCorrosion current reductionVacuum evaporation coatingSputtering coatingAlloy substrateSilicon

The invention provides a coated piece which comprises an aluminum or aluminum alloy substrate, an amorphous alloy layer and a colored layer with an anti-corrosion function, wherein the amorphous alloy layer and the colored layer are formed on the aluminum or aluminum alloy substrate in turn; the amorphous alloy layer is Fe70Cr10B13X7; and X is any one selected from phosphorus, carbon and silicon. The coated piece has excellent corrosion resistance and decorative appearance. The invention also provides a manufacturing method for the coated piece.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Shell and manufacturing method thereof

InactiveCN102469728AImprove corrosion resistanceImprove decorative appearanceVacuum evaporation coatingCasings/cabinets/drawers detailsSputteringAlloy

A shell comprises a magnesium or magnesium alloy substrate. The shell is formed on an anti-corrosion coating which is on the surface of the magnesium or magnesium alloy substrate and is formed on a color layer which is on the surface of the anti-corrosion coating. The anti-corrosion coating comprises a magnesium layer and a magnesium oxide layer which are successively formed on the surface of the magnesium or magnesium alloy substrate. The shell possesses good corrosion resistance and a decorative appearance. The invention also provides the manufacturing method of the shell. The method comprises the following steps: providing the magnesium or magnesium alloy substrate; performing magnetron sputtering of the anti-corrosion coating on the magnesium or magnesium alloy substrate, wherein the anti-corrosion coating comprises the magnesium layer and the magnesium oxide layer which are successively formed on the surface of the magnesium or magnesium alloy substrate; performing magnetron sputtering of the decorative color layer on the anti-corrosion coating.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

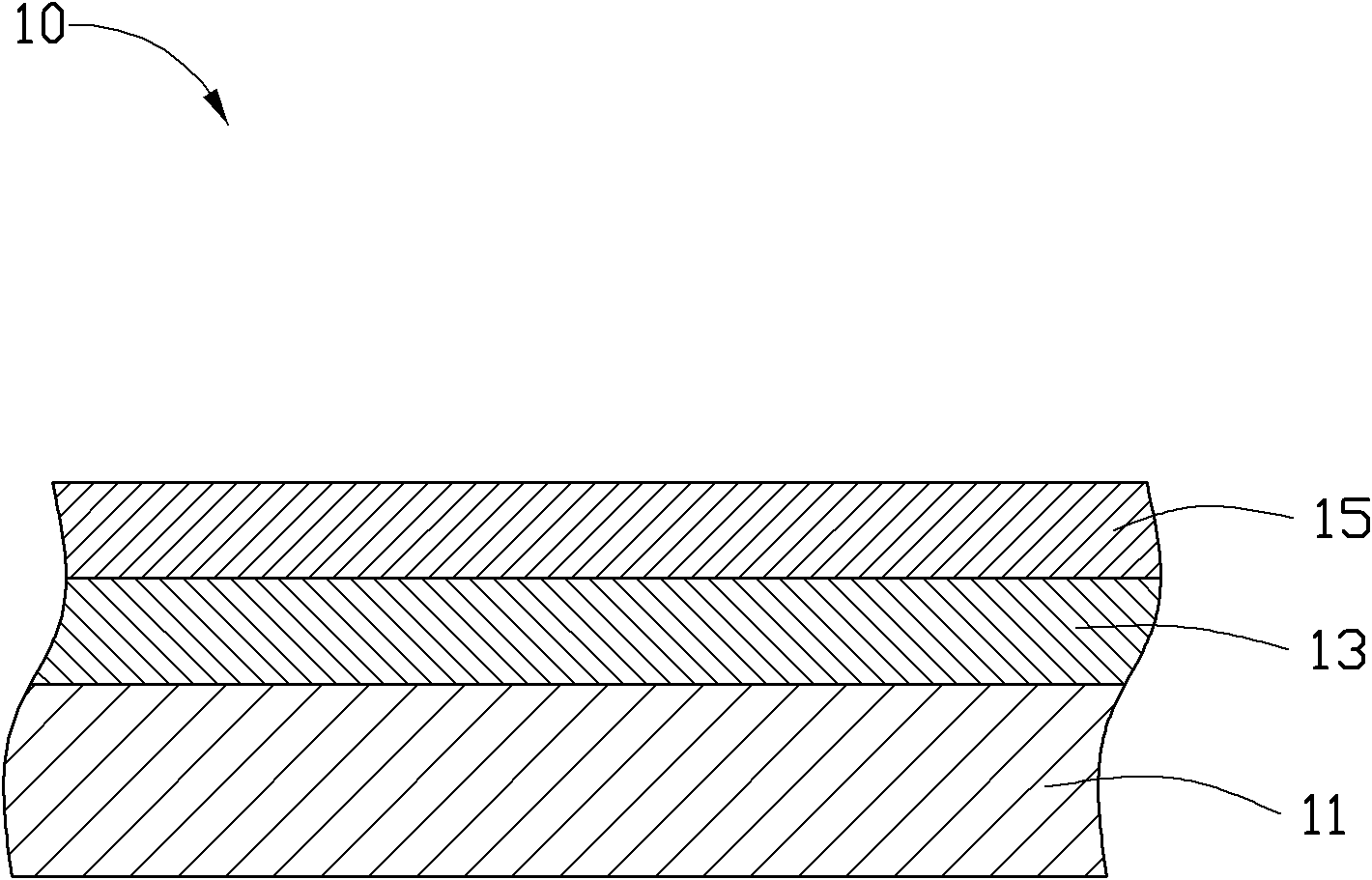

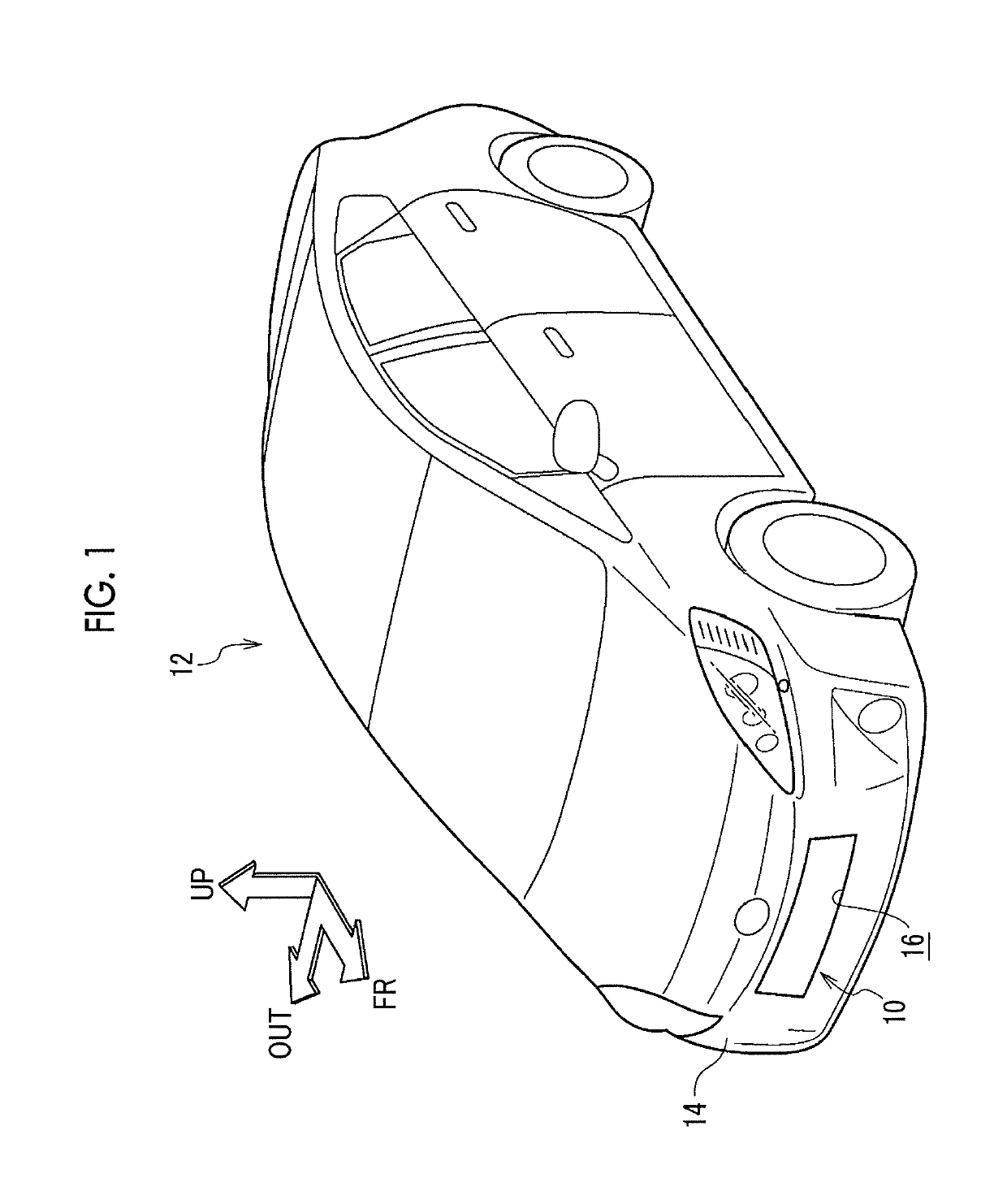

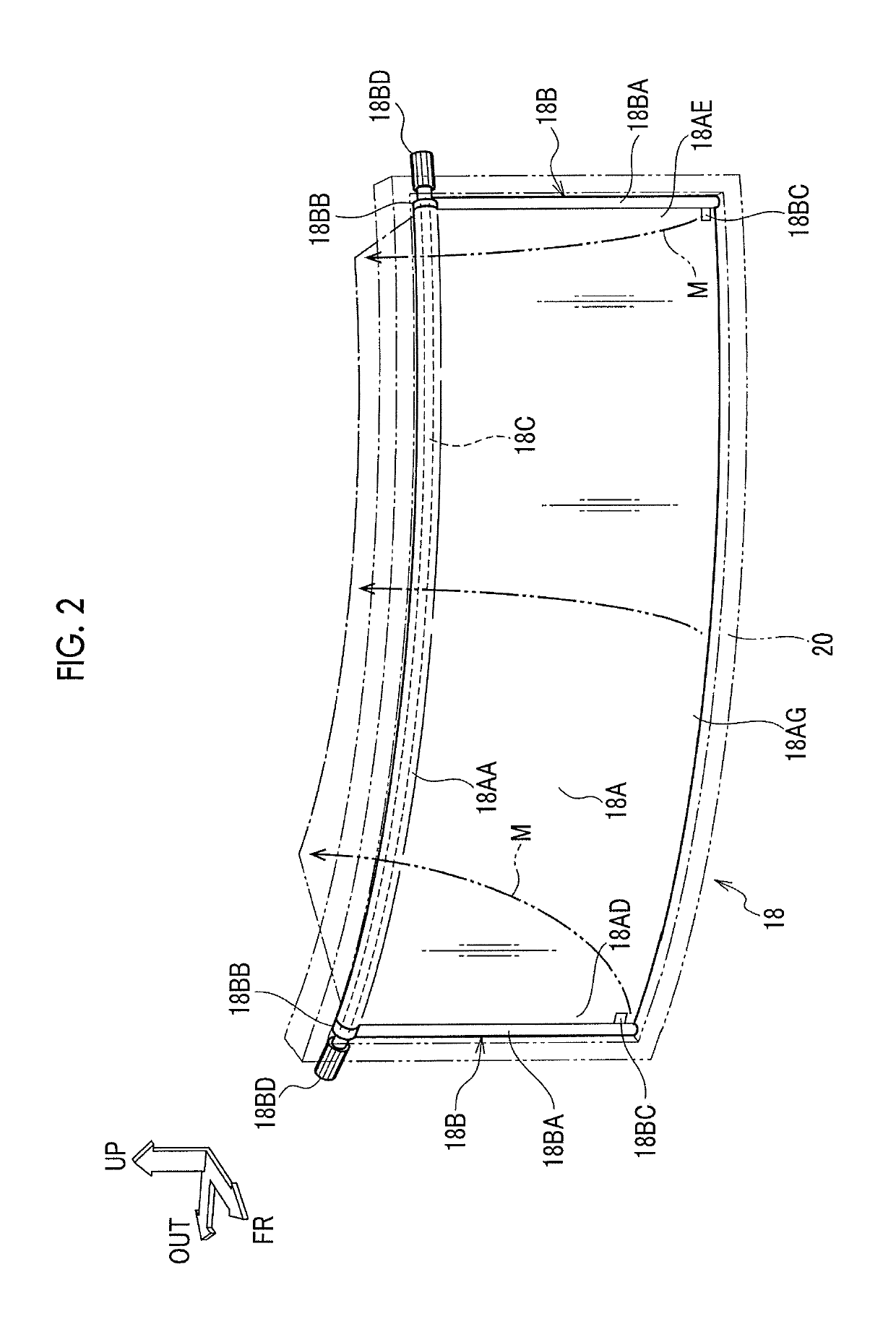

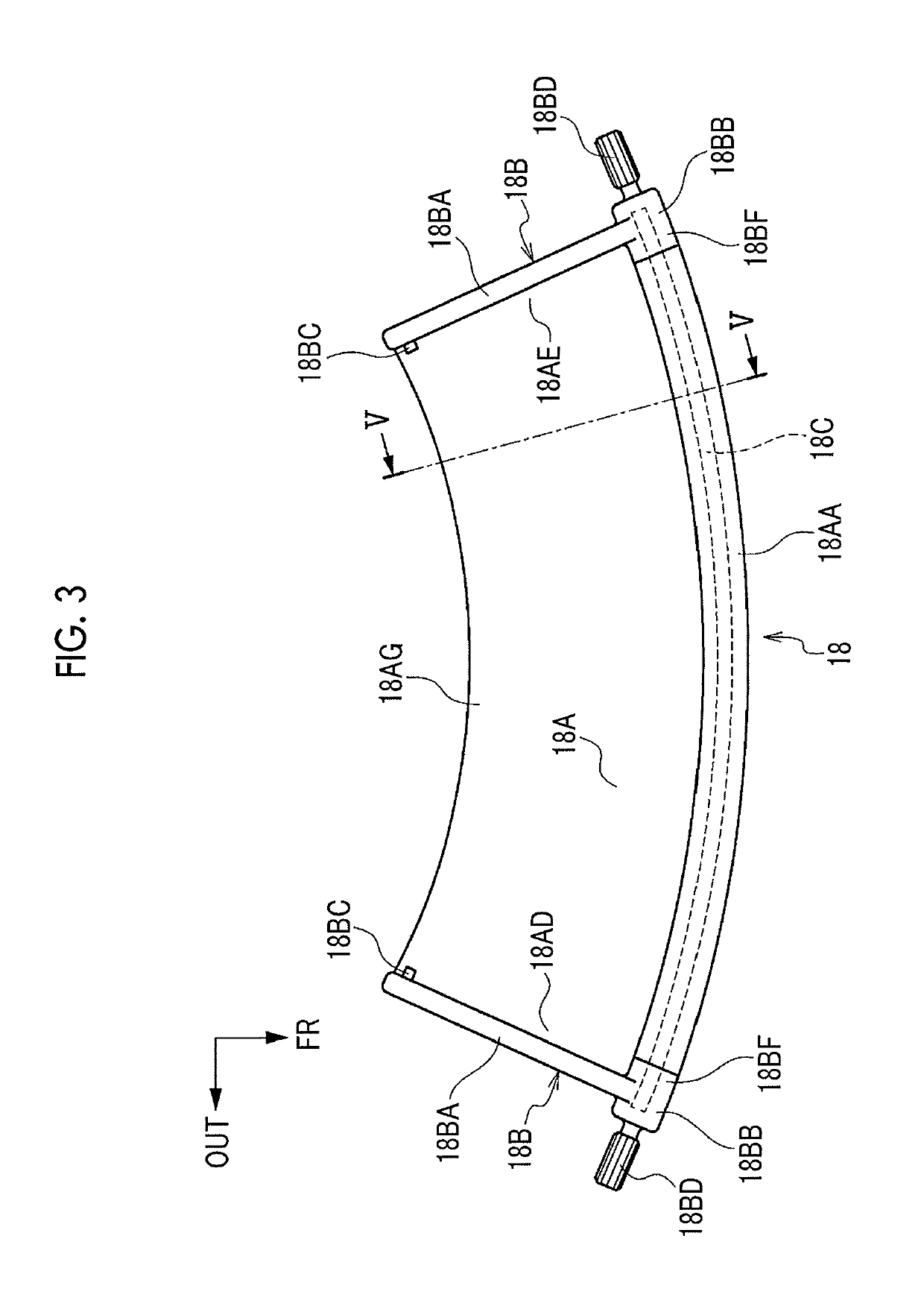

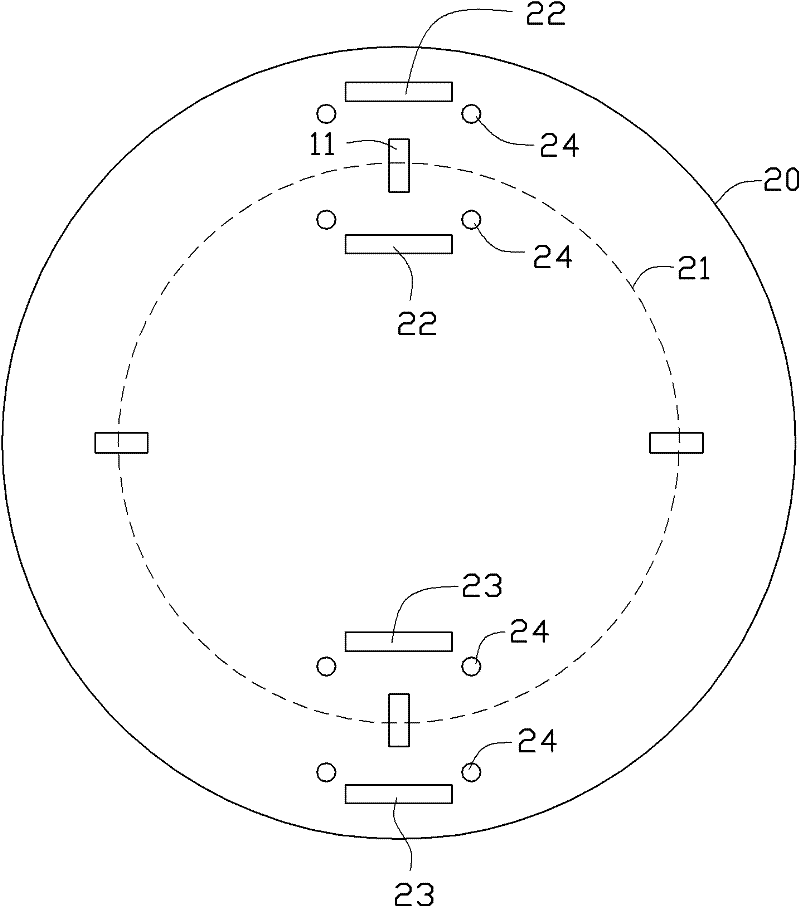

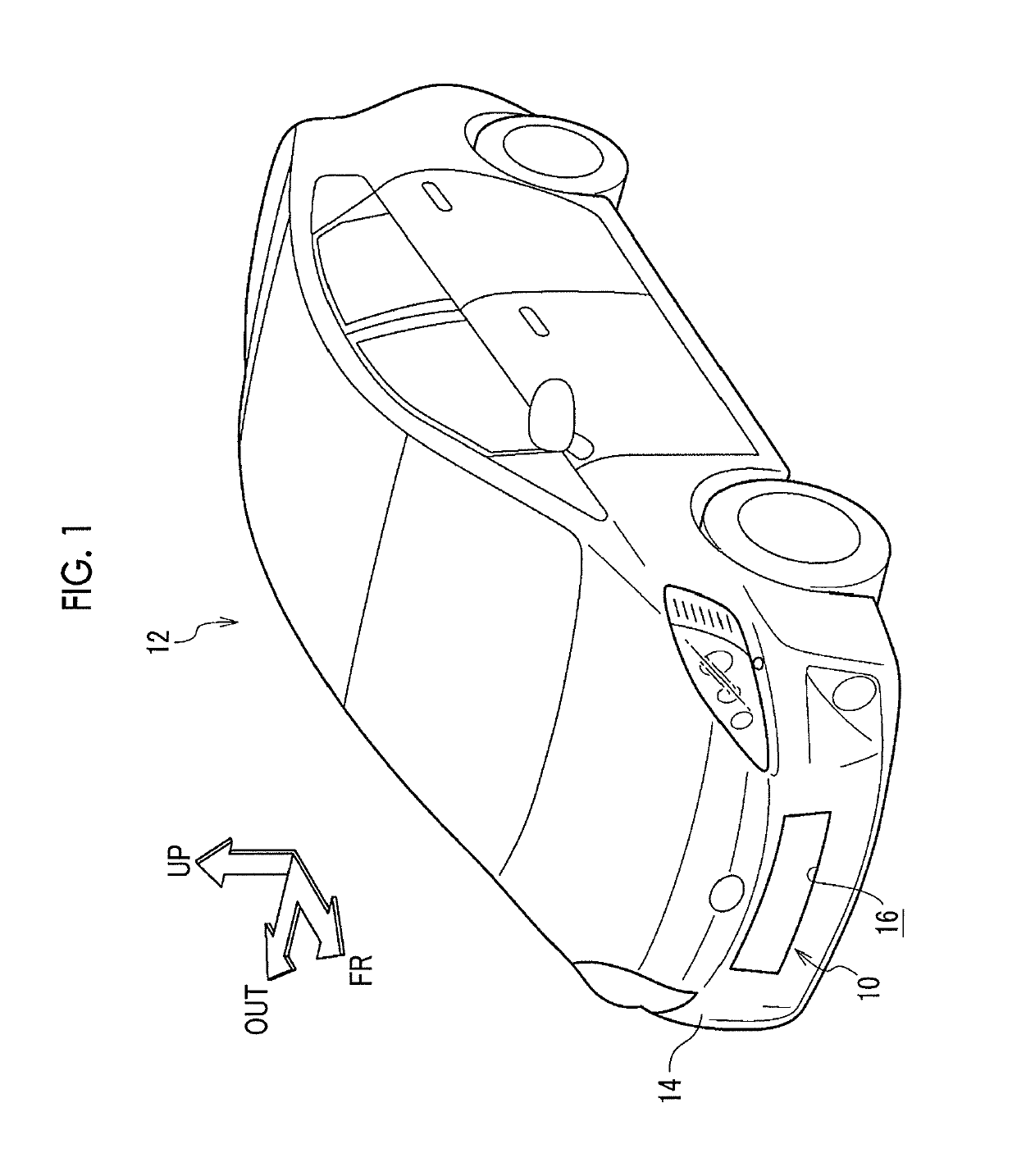

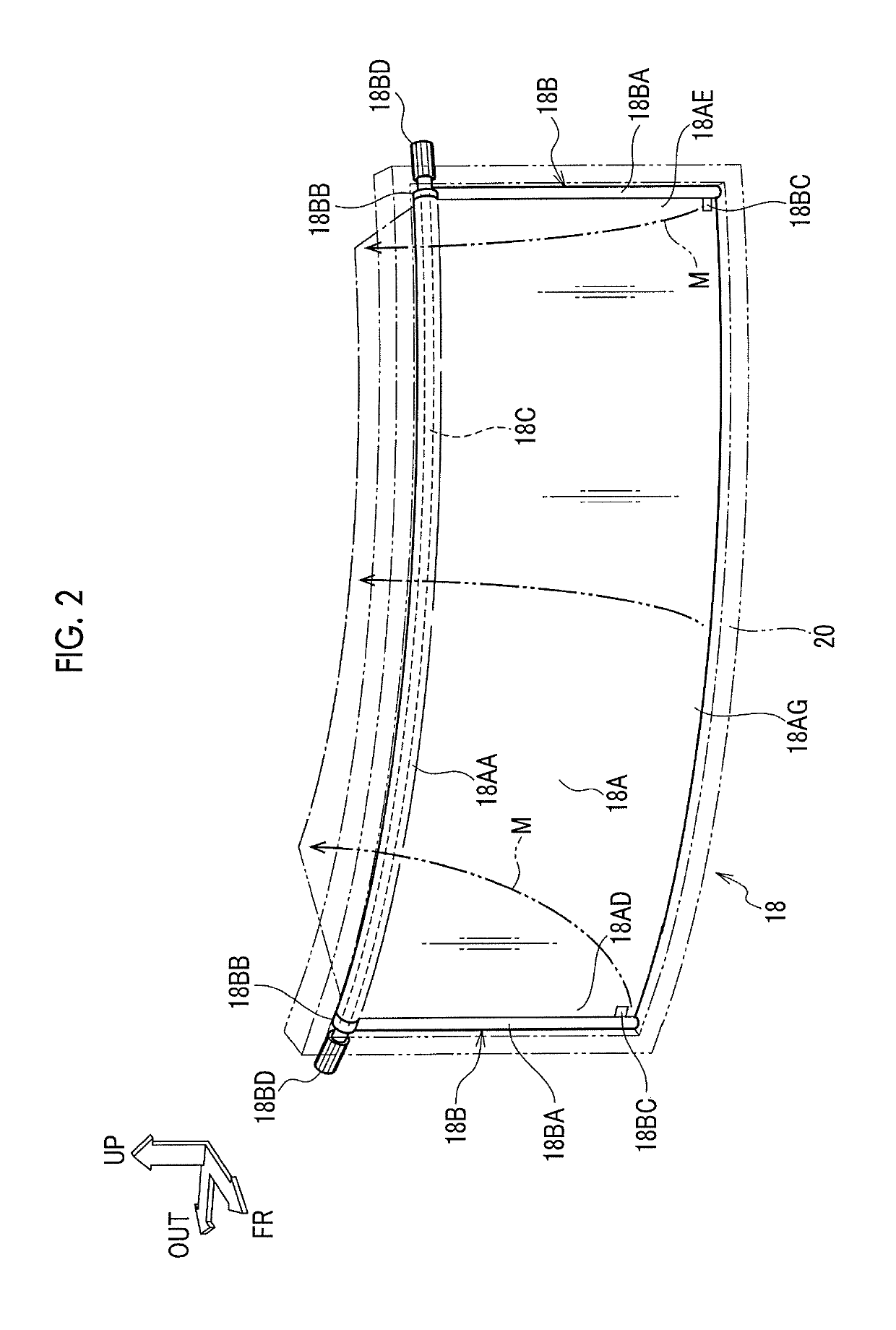

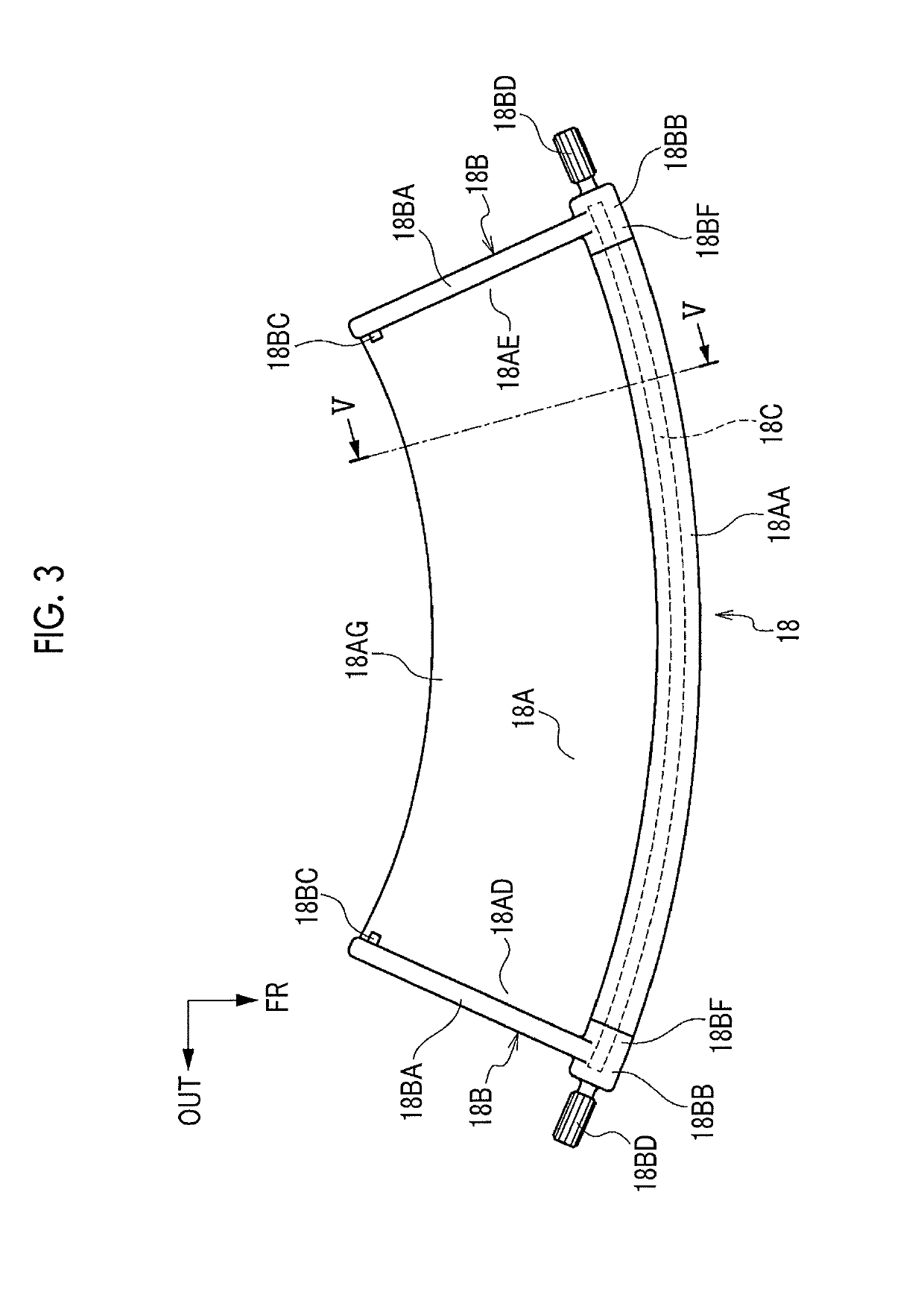

Grille shutter device

ActiveUS10479193B2Improve decorative appearanceCoolant flow controlMachines/enginesWindow shutterEngineering

A grille shutter device includes a decorative surface curved in a convex shape toward a front side of a vehicle in a vehicle width direction of a vehicle front portion and provided with an opening in a part; and a fin provided in the opening and configured to rotate about a shaft so as to open and close the opening. In the open state in which the opening is opened, a tip end on a front portion of the fin in a front-rear direction of the vehicle is in a linear shape as viewed from the front side of the vehicle, and in the closed state in which the opening is closed, an opposing tip end on the opposite side of the fin from the tip end is enlarged in the vehicle width direction to form a curve in a convex shape toward the front side of the vehicle.

Owner:TOYOTA JIDOSHA KK

Shell and manufacture method thereof

InactiveCN102477526AImprove corrosion resistanceImprove decorative appearanceVacuum evaporation coatingSputtering coatingSputteringMagnesium silicide

The invention provides a shell, which comprises a magnesium or magnesium alloy substrate, and a magnesium silicide layer and a color layer formed orderly on the magnesium or magnesium alloy substrate. The color layer is a corrosion-resistant electric insulating layer. The shell has good corrosion resistant performance and decorative appearance. The invention further provides a manufacture method of the shell, comprising the steps of: providing the magnesium or magnesium alloy substrate; forming the magnesium silicide layer on the magnesium or magnesium alloy substrate by magnetic sputtering; and forming the color layer on the magnesium silicide layer by magnetic sputtering.

Owner:UR IND MATERIALS LANGFANG CO LTD

Double-bottoming electroplating method for nickel-plating magnesium alloy hub

The invention discloses a double-bottoming electroplating method for a nickel-plating magnesium alloy hub. The method includes the following operation steps that firstly, preplating treatment is conducted; secondly, preplating cyanide-free copper bottoming treatment is conducted, wherein a plating solution of preplating cyanide-free copper includes 120-130 g / L of copper sulfate, 160-180 g / L of sodium ethylenediamine tetramethylene phosphonate, 80-100 g / L of potassium tartrate and 0.3-0.5 g / L of 2-mercaptobenzothiazole, according to the technology of the plating solution of the preplating cyanide-free copper, the pH of the plating solution is 8.5-9.5, the temperature of the plating solution is 45-55 DEG C, the electroplating time is 15-25 min, the cathodic current density is 1.2-1.4 A / dm<2>, the anodic current density is 0.6-0.8 A / dm<2>, and gas stirring is adopted; thirdly, pyrophosphate copper plating bottoming treatment is conducted, wherein a plating solution of pyrophosphate copper plating treatment comprises 100-120 g / L of copper pyrophosphate, 140-160 g / L of potassium pyrophosphate, 6-8 mL / L of ammonia water with the concentration of 25-30%, 8-12 g / L of potassium citrate, 15-25 g / L of potassium sodium tartrate, 0.2-0.3 mL / L of a brightening agent and the balance water, according to the technology of the plating solution, the pH of the plating solution is 8.5-9.5, the temperature of the plating solution is 45-55 DEG C, the electroplating time is 25-35 min, the cathodic current density is 1.2-1.4 A / dm<2>, the anodic current density is 0.7-0.9 A / dm<2>, and gas stirring is adopted; and fourthly; nickel electroplating is adopted.

Owner:张颖

Casing and manufacturing method thereof

InactiveCN102548308AImprove corrosion resistanceLess prone to stress corrosionVacuum evaporation coatingSputtering coatingControl mannerCopper

A casing comprises an aluminum / magnesium metal substrate, an anti-corrosion layer and a colored layer, wherein the anti-corrosion layer is formed on the surface of the aluminum / magnesium metal substrate and comprises an aluminum copper film and an aluminum nitride gradient film which are sequentially formed on the surface of the aluminum / magnesium metal substrate, and the percentage composition of the N atoms in the aluminum nitride is increased in a gradient manner from near to far from the aluminum / magnesium metal substrate. The casing has excellent corrosion resistance and decorative appearance. The invention further provides a manufacturing method of the casing, which includes the following steps of providing the aluminum / magnesium metal substrate, sputtering an anti-corrosion layer on the aluminum / magnesium metal substrate and a decorative color layer on the anti-corrosion layer in a magnetic control manner, wherein the anti-corrosion layer comprises the aluminum copper film and the aluminum nitride gradient film which are sequentially formed on the surface of the aluminum / magnesium metal substrate.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Grille shutter device

ActiveUS20190241062A1Improve decorative appearanceGood effectCoolant flow controlMachines/enginesWindow shutterEngineering

A grille shutter device includes a decorative surface curved in a convex shape toward a front side of a vehicle in a vehicle width direction of a vehicle front portion and provided with an opening in a part; and a fin provided in the opening and configured to rotate about a shaft so as to open and close the opening. In the open state in which the opening is opened, a tip end on a front portion of the fin in a front-rear direction of the vehicle is in a linear shape as viewed from the front side of the vehicle, and in the closed state in which the opening is closed, an opposing tip end on the opposite side of the fin from the tip end is enlarged in the vehicle width direction to form a curve in a convex shape toward the front side of the vehicle.

Owner:TOYOTA JIDOSHA KK

Electrochromism combined plating solution for aluminum alloy hub

The invention discloses an electrochromism combined plating solution for an aluminum alloy hub. The electrochromism combined plating solution is characterized by being composed of an electronickelling plating solution, a pyrophosphate copper plating solution and an electrochromism plating solution; the electronickelling plating solution is prepared from 80-90 g / L of nickel sulfate, 0.8-0.9 mol / L of fluorine ions, 15-20 g / L of ammonium citrate and 1-3 g / L of sodium sulfate; the pyrophosphate copper plating solution is prepared from 65-75 g / L of copper pyrophosphate, 230-240 g / L of potassium pyrophosphate and 28-32 g / L of ammonium citrate; the electrochromism plating solution is prepared from 260-280 g / L of chromic anhydride, 1.5-2.5 g / L of sulfuric acid, 2.0-2.2 g / L of trivalent chromium, 0.01-0.03 mol / L of lauryl sodium sulfate and 15-25 g / L of sodium sulfate.

Owner:姜少群

Shell body and manufacturing method thereof

InactiveCN102595834AImprove decorative appearanceAvoid failures such as falling offVacuum evaporation coatingSpecial ornamental structuresWear resistanceMaterials science

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Information handling system reflective outer housing

ActiveUS20200393877A1Reduce disadvantagesReduce problemsDigital processing power distributionLight reflectionHandling system

Owner:DELL PROD LP

Shell and method for producing the same

InactiveCN102485940AImprove decorative appearanceImprove adhesionVacuum evaporation coatingSputtering coatingSputteringSilicon nitride

The invention provides a shell, comprising an aluminium or aluminium alloy matrix, a combined layer, and an anti-corrosion layer, wherein the combined layer and the anti-corrosion layer are formed successively on the aluminium or aluminium alloy matrix, the combined layer is a silicon layer, and the anti-corrosion layer is a silicon nitride layer. The invention further provides a method for producing the shell, comprising the following steps: providing the aluminium or aluminium alloy matrix and successively forming the combined layer and the anti-corrosion layer on the aluminium or aluminium alloy matrix by magnetron sputtering. The shell has good corrosion resistance and decorative appearance.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Stainless steel product and manufacturing method thereof

InactiveCN103042758ALoose surfaceReduce erosionVacuum evaporation coatingSputtering coatingVacuum coatingChromium

The invention provides a stainless steel product comprising a stainless steel substrate, wherein a pattern part and a non-pattern part are formed on the stainless steel substrate; the pattern part is composed of a vacuum coating layer which is a chromium element contained coating layer; and the non-pattern layer has a polished appearance effect. The invention also provides a manufacturing method of the stainless steel product.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

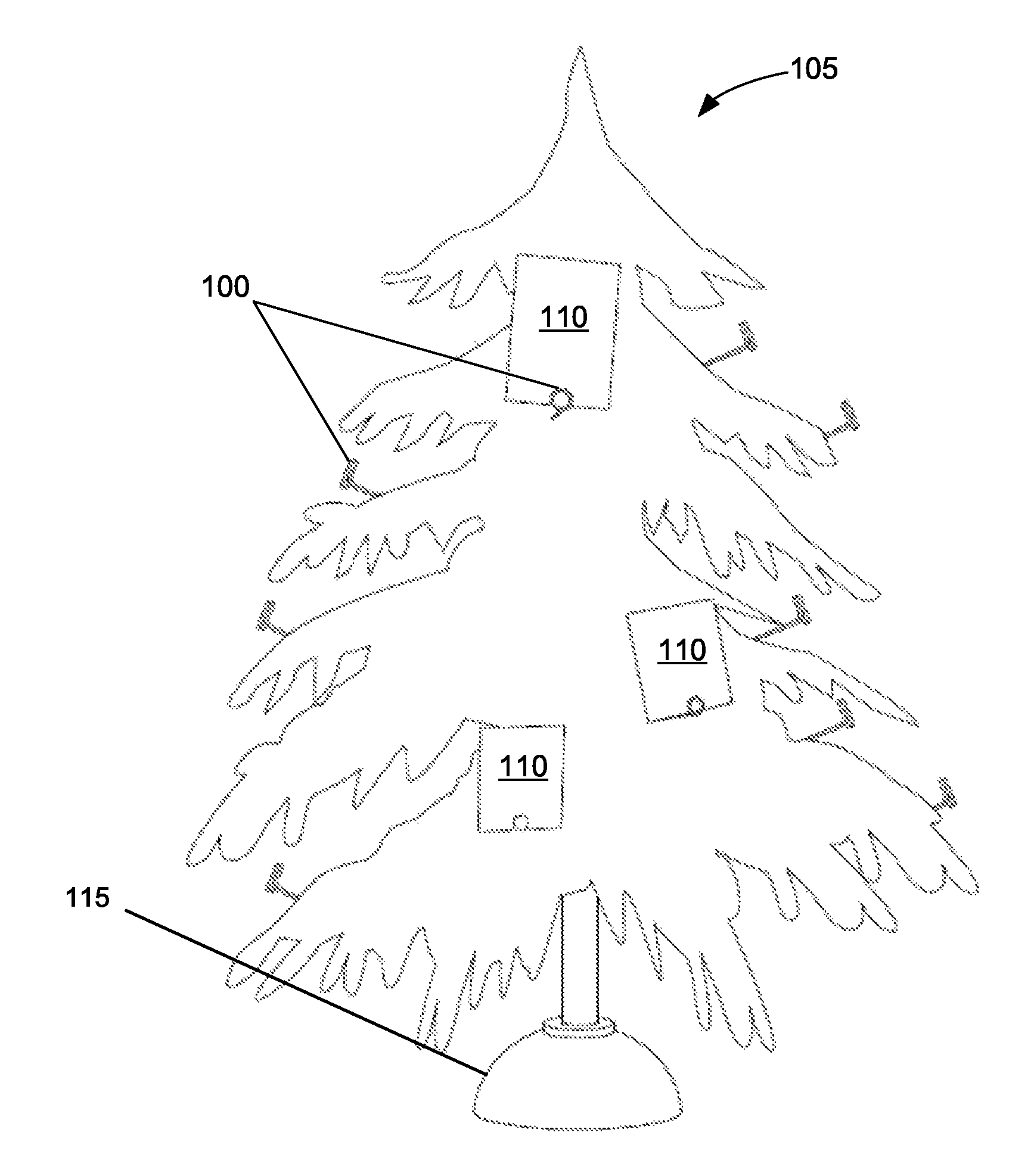

Decoration holder

InactiveUS8968843B1Improve decorative appearanceAvoid obstructed viewDead plant preservationArtificial flowers and garlandsEngineering

Owner:POLYGROUP MACAU BVI

Shell and manufacture method thereof

InactiveCN102485936AImprove corrosion resistanceImprove decorative appearanceVacuum evaporation coatingSputtering coatingSputteringMagnesium nitride

The invention provides a shell which comprises a magnesium or magnesium alloy matrix, an anticorrosion layer formed on the surface of the magnesium or magnesium alloy matrix and a color layer formed on the surface of the anticorrosion layer, wherein, the anticorrosion layer comprises a magnesium layer and a magnesium nitride layer, which are sequentially formed on the surface of the magnesium or magnesium alloy matrix, and the shell has good corrosion resistance and a decorative appearance. The invention also provides a manufacture method for the shell. The method comprises the following steps: providing the magnesium or magnesium alloy matrix; forming the anticorrosion layer on the magnesium or magnesium alloy matrix through magnetron sputtering, wherein the anticorrosion layer comprises the magnesium layer and the magnesium nitride layer, which are sequentially formed on the surface of the magnesium or magnesium alloy matrix; and forming the decorative color layer on the anticorrosion layer through magnetron sputtering.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com