Substrate surface pattern production method and product thereof

A technology of surface pattern and production method, applied in chemical instruments and methods, processes for producing decorative surface effects, layered products, etc., can solve problems such as complex processes and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

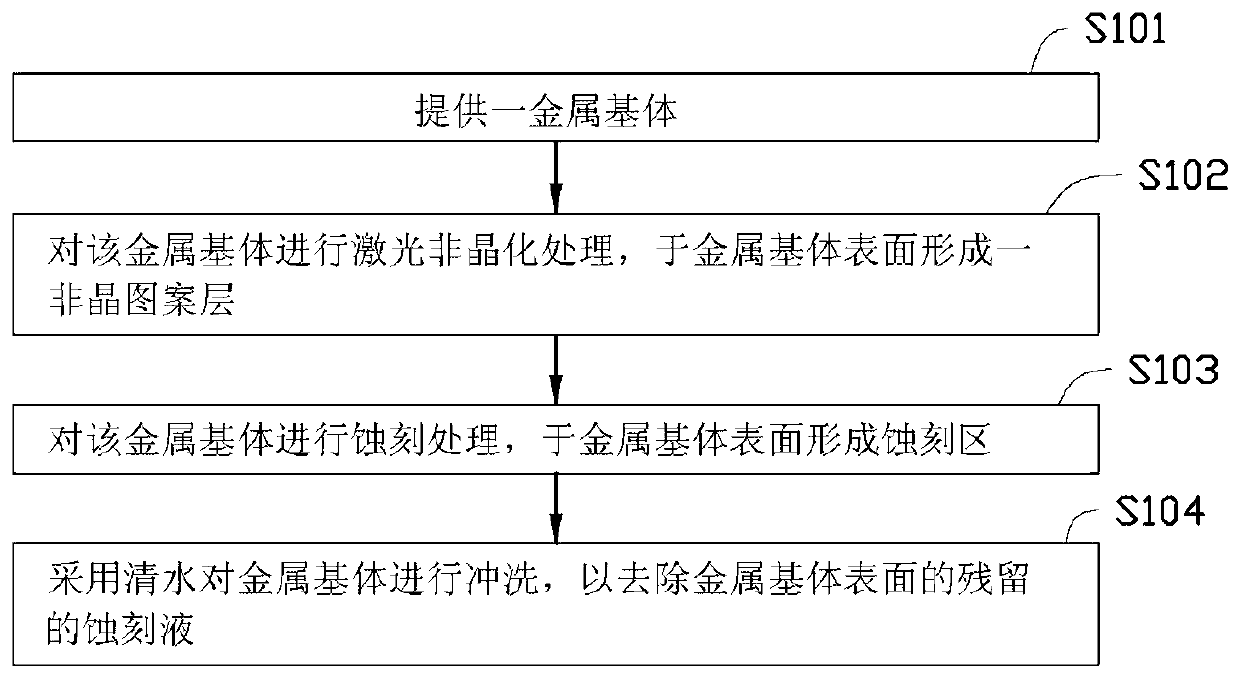

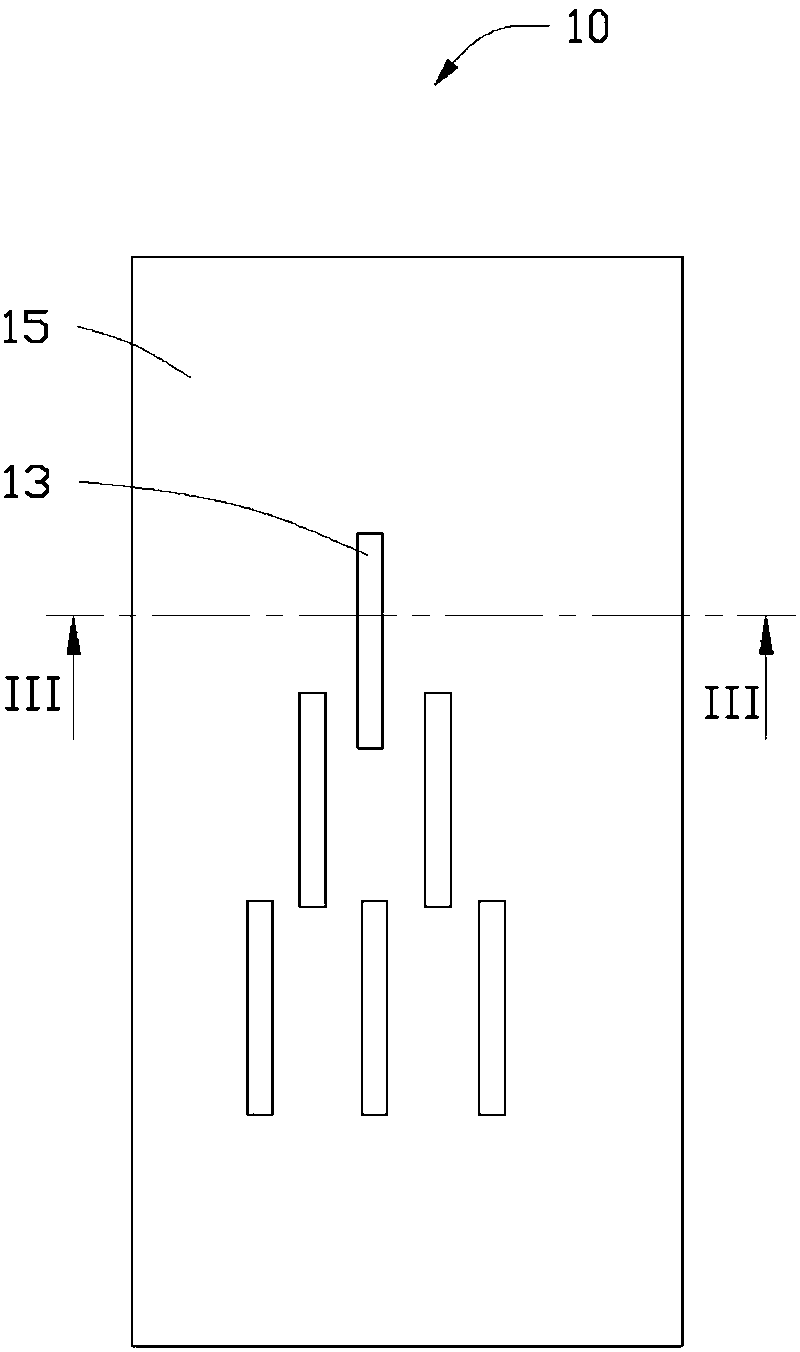

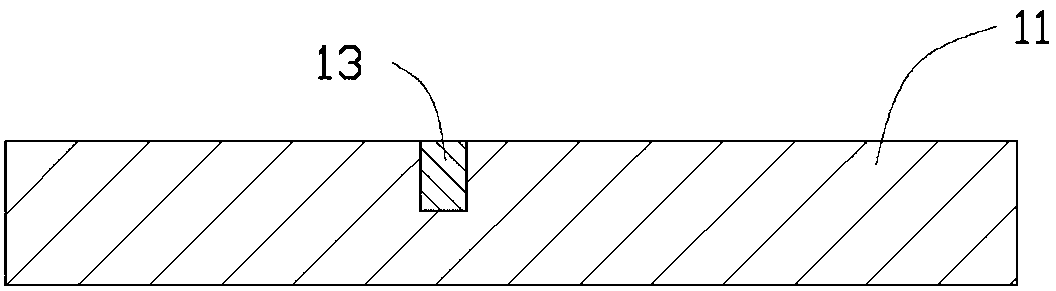

[0018] see figure 1 and figure 2 , the substrate surface pattern making method of a preferred embodiment of the present invention mainly comprises the following steps:

[0019] S101: Provide a metal base 11 .

[0020] The material of the metal base 11 is stainless steel, ordinary carbon steel, die steel or nickel-chromium alloy and the like. The surface of the metal substrate 11 is subjected to conventional treatments such as degreasing, degreasing and drying.

[0021] S102 : performing laser amorphization treatment on the metal base 11 to form an amorphous pattern layer 13 on the surface of the metal base 11 . The specific operation method is as follows:

[0022] A laser engraving machine (not shown) is provided, and a template pattern expected to be formed on the surface of the metal substrate 11 is imported into the engraving special operating software of the laser engraving machine. The surface of 11 is processed by laser scanning, and the track of the laser scanning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com