Shell and manufacturing method thereof

A manufacturing method and shell technology, applied in the direction of ion implantation plating, coating, transportation and packaging, etc., can solve problems such as shedding, inability to effectively prevent electrochemical corrosion of aluminum or aluminum alloy substrates, discoloration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

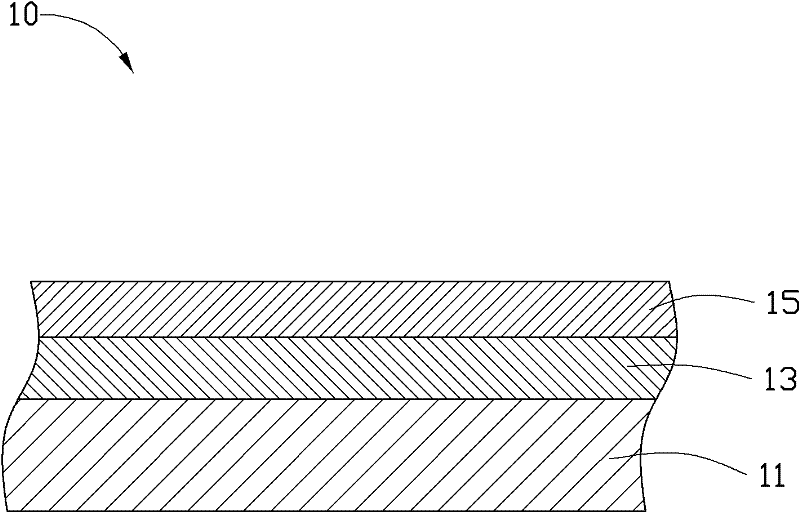

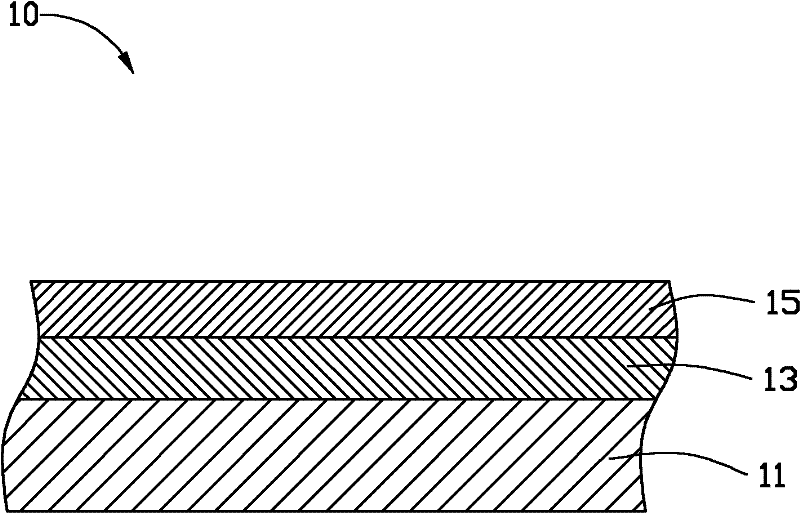

[0018] see figure 1 A housing 10 in a preferred embodiment of the present invention includes an aluminum or aluminum alloy substrate 11 , an electrical insulation layer 13 and a color layer 15 sequentially formed on the aluminum or aluminum alloy substrate 11 . The casing 10 can be a casing of a 3C electronic product, and can also be a frame of glasses, a construction piece, and a part of a vehicle such as an automobile.

[0019] The electrical insulating layer 13 is silicon dioxide (SiO 2 ) layer or aluminum oxide (Al 2 o 3 ) layer, the thickness of which is 2.0-3.0 μm. It can be understood that the electrical insulating layer 13 can also be a polytetrafluoroethylene layer or other insulating layers. The color of the electrical insulating layer 13 is preferably not to affect the color tone of the color layer 15 , such as silver, white, off-white and other light tones.

[0020] The color layer 15 is a TiN layer with a thickness of 0.5-3.0 μm. It can be understood that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com