Shell body and manufacturing method thereof

A manufacturing method and shell technology, which are applied in chemical instruments and methods, metal casings, decorative arts, etc., can solve the problems of insufficient color, complexity, and difficulty in maintaining decorative appearance of the vacuum coating layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

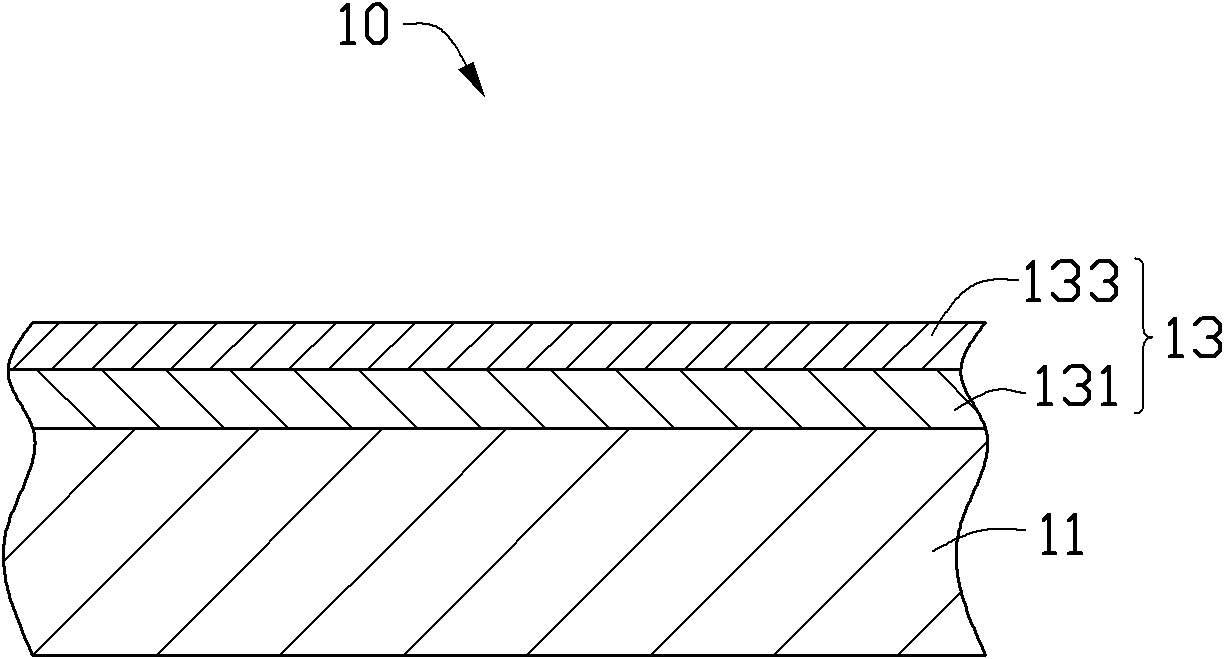

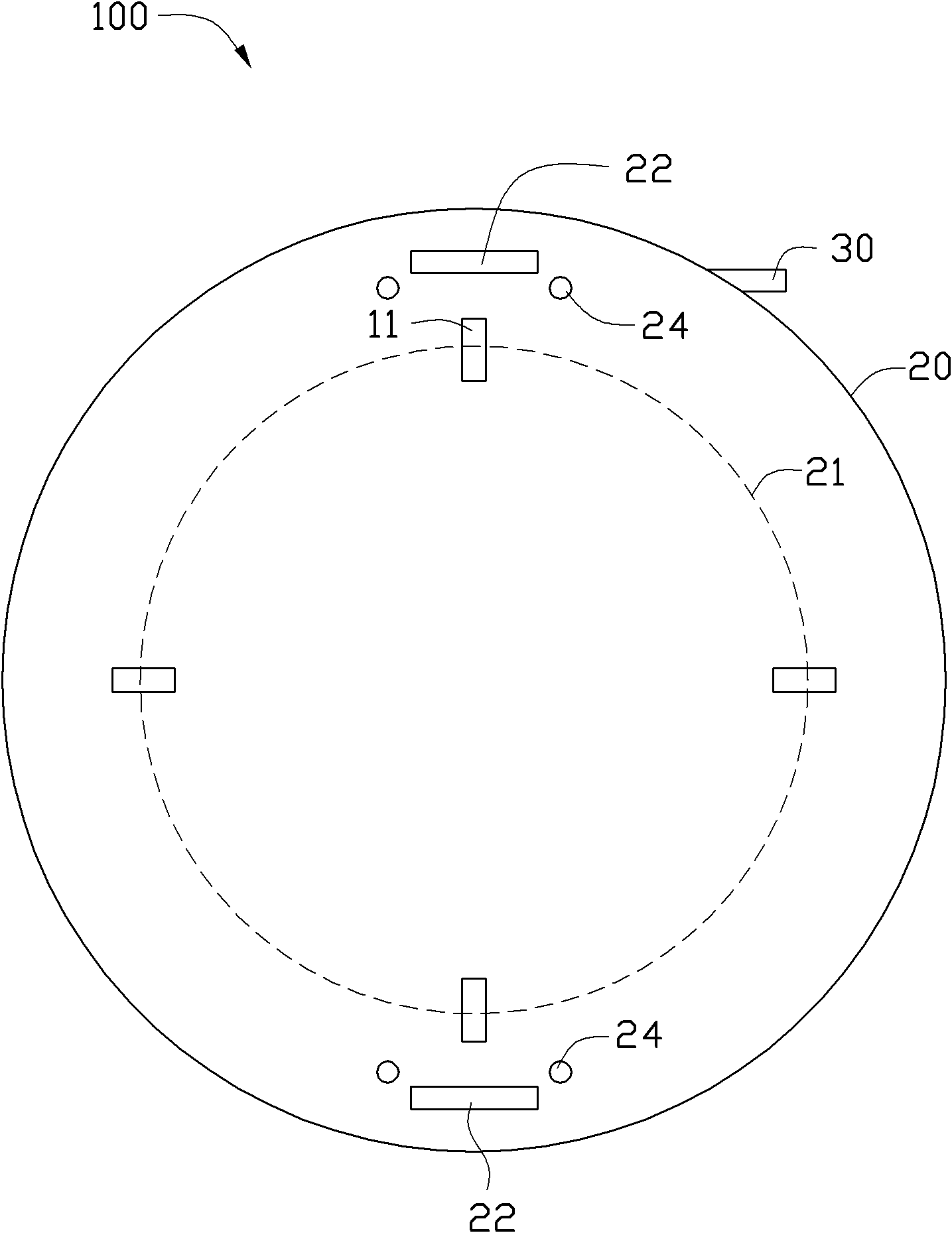

[0039] Plasma cleaning: the argon gas flow rate is 300 sccm, the bias voltage of the aluminum or aluminum alloy substrate 11 is -300V, and the plasma cleaning time is 10 minutes;

[0040] Sputtering the aluminum layer 131: argon gas 150 sccm is introduced, the power of the aluminum target 22 is set to 10 kw, the bias voltage of the aluminum or aluminum alloy substrate 11 is set to 200 V, and the deposition is 90 min;

[0041] Sputtering aluminum oxide layer 133: the process parameters are: use argon as the working gas with a flow rate of 150 sccm, use oxygen as the reaction gas, set the flow rate of oxygen to 50 sccm, and apply a bias voltage of -200V on the aluminum or aluminum alloy substrate , the deposition time is 60min.

Embodiment 2

[0043] Plasma cleaning: the argon gas flow rate is 300 sccm, the bias voltage of the aluminum or aluminum alloy substrate 11 is -300V, and the plasma cleaning time is 10 minutes;

[0044] Sputtering the aluminum layer 131: argon gas 150 sccm is introduced, the power of the aluminum target 22 is set to 10 kw, the bias voltage of the aluminum or aluminum alloy substrate 11 is set to -200 V, and the deposition is 90 min;

[0045] Sputtering aluminum oxide layer 133: using argon as the working gas with a flow rate of 150 sccm, using oxygen as the reaction gas, setting the flow rate of oxygen to 100 sccm, applying a bias voltage of -200V on the aluminum or aluminum alloy substrate, and the deposition time is 60 minutes .

Embodiment 3

[0047] Plasma cleaning: the argon gas flow rate is 300 sccm, the bias voltage of the aluminum or aluminum alloy substrate 11 is -300V, and the plasma cleaning time is 10 minutes;

[0048]Sputtering the aluminum layer 131: argon gas of 150 sccm is introduced, the power of the aluminum target 22 is set to 10 kw, the bias voltage of the aluminum or aluminum alloy substrate 11 is set to -200 V, and the deposition time is 90 min;

[0049] Sputtering aluminum oxide layer 133: using argon as the working gas with a flow rate of 150 sccm, using oxygen as the reaction gas, setting the flow rate of oxygen to 75 sccm respectively, applying a bias voltage of 200V on the aluminum or aluminum alloy substrate, and the deposition time is 60 minutes .

[0050] The manufacturing method of the casing 10 is to sequentially form a decorative color layer 13 on the aluminum or aluminum alloy substrate by magnetron sputtering. The color layer 13 includes an aluminum layer 131 and an aluminum oxide la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com