Shell and method for producing the same

A manufacturing method and shell technology, applied in ion implantation plating, coating, transportation and packaging, etc., can solve the problems of PVD coating discoloration, peeling off, difficulty in maintaining decorative appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

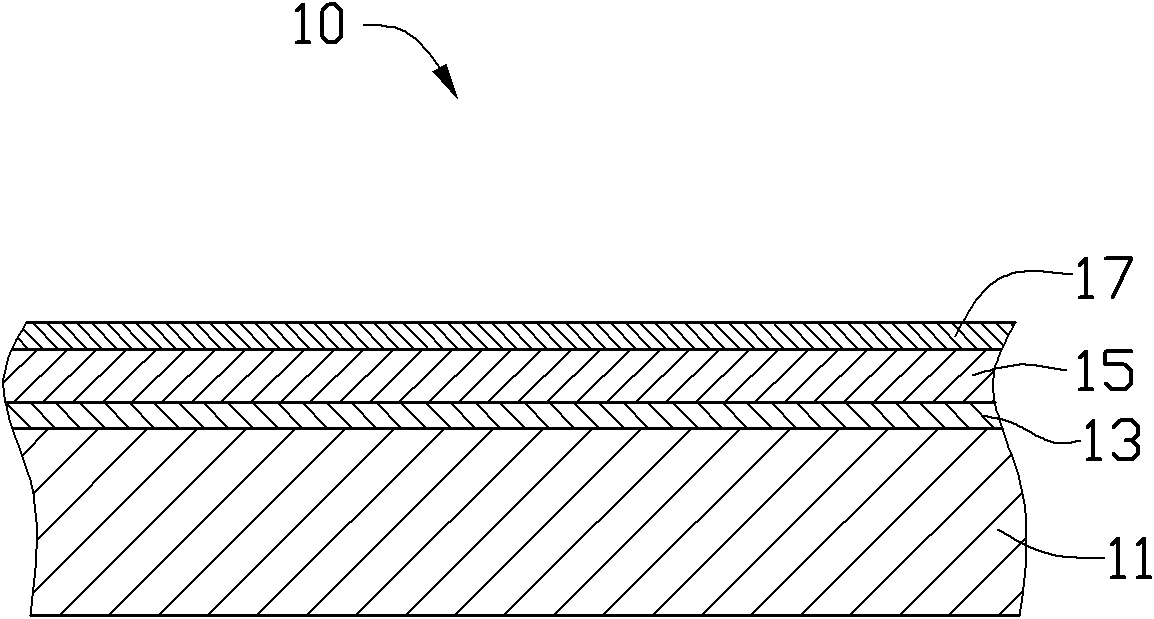

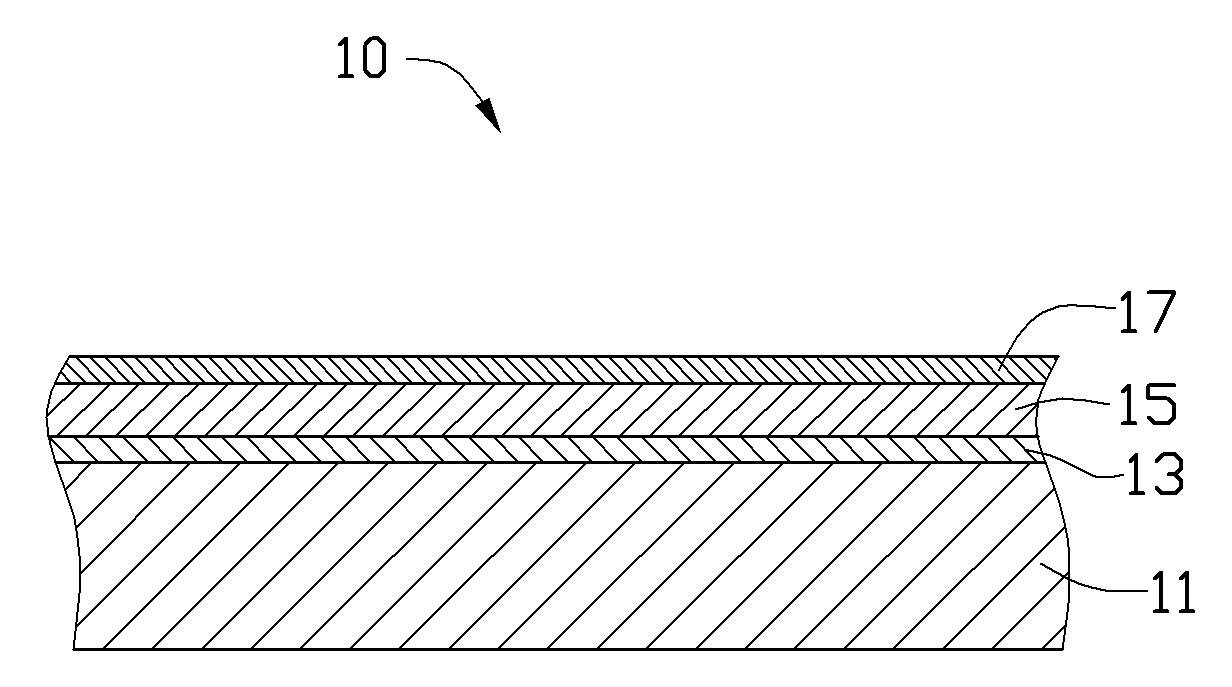

[0019] see figure 1 , The casing 10 of a preferred embodiment of the present invention includes an aluminum or aluminum alloy substrate 11 , a bonding layer 13 and an anti-corrosion layer 15 sequentially formed on the aluminum or aluminum alloy substrate 11 . The casing 10 can be a casing of a 3C electronic product, and can also be an industrial, building component, and a vehicle component such as an automobile.

[0020] The bonding layer 13 is a silicon layer with a thickness of 0.1-0.2 μm.

[0021] The anti-corrosion layer 15 is a silicon nitride layer with a thickness of 0.5-1.0 μm.

[0022] A colored layer may also be magnetron sputtered on the anti-corrosion layer 15, and the colored layer 17 is a titanium nitride layer (Ti-N) with a thickness of 1.0-3.0 μm.

[0023] It can be understood that the color layer 17 can also be a chromium nitride layer (Cr—N) or other decorative color layers.

[0024] The bonding layer 13, the anti-corrosion layer 15 and the color layer 17 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com