Patents

Literature

172 results about "Magnesium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium nitride, which possesses the chemical formula Mg₃N₂, is an inorganic compound of magnesium and nitrogen. At room temperature and pressure it is a greenish yellow powder.

Environmental-protection anti-corrosive heat-dissipation powder paint, and preparation method and application thereof

ActiveCN102061121AFacilitate cross-linkingImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsHexagonal boron nitrideCooling effect

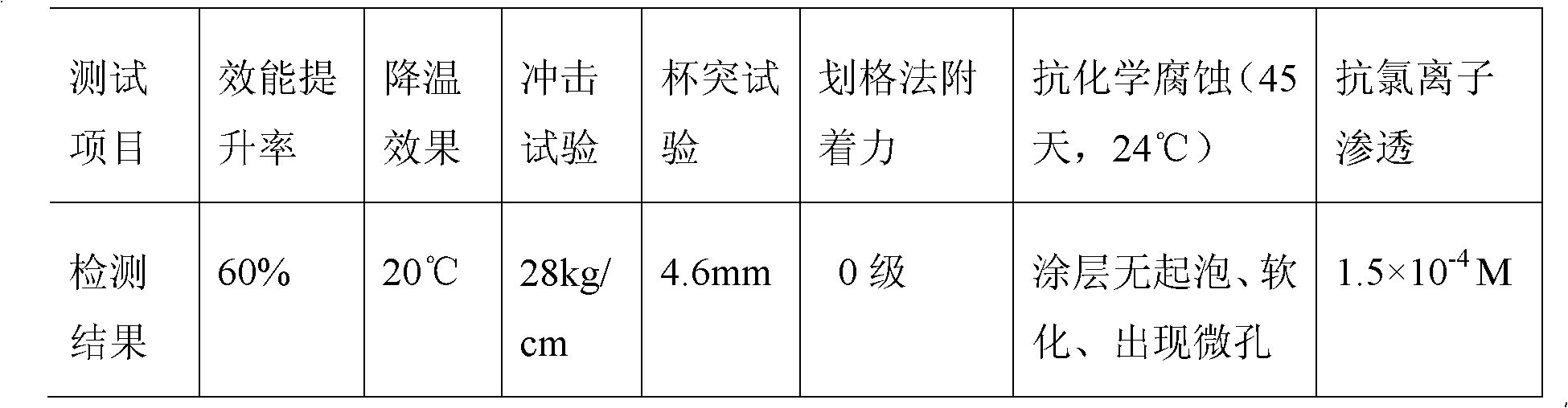

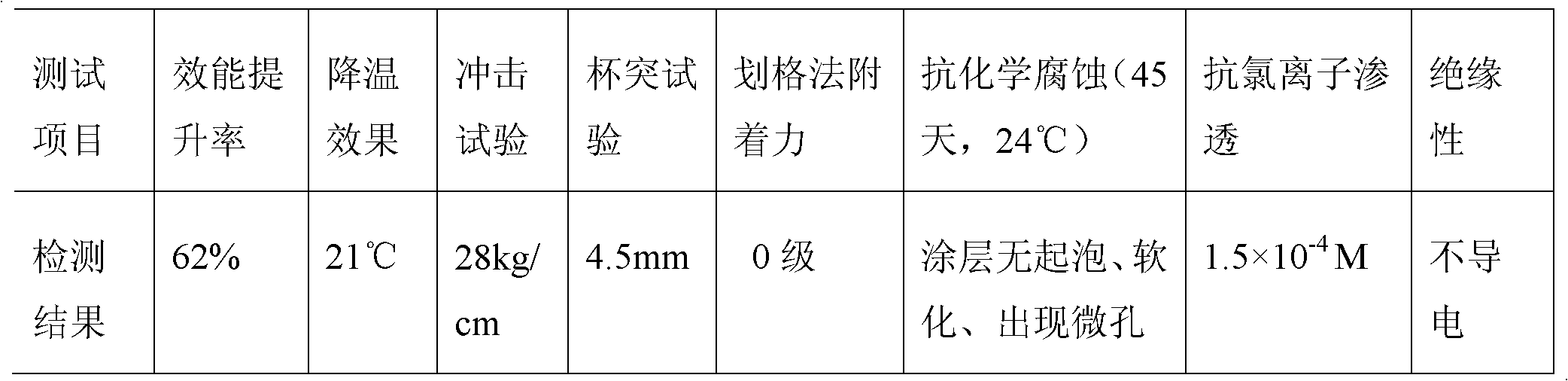

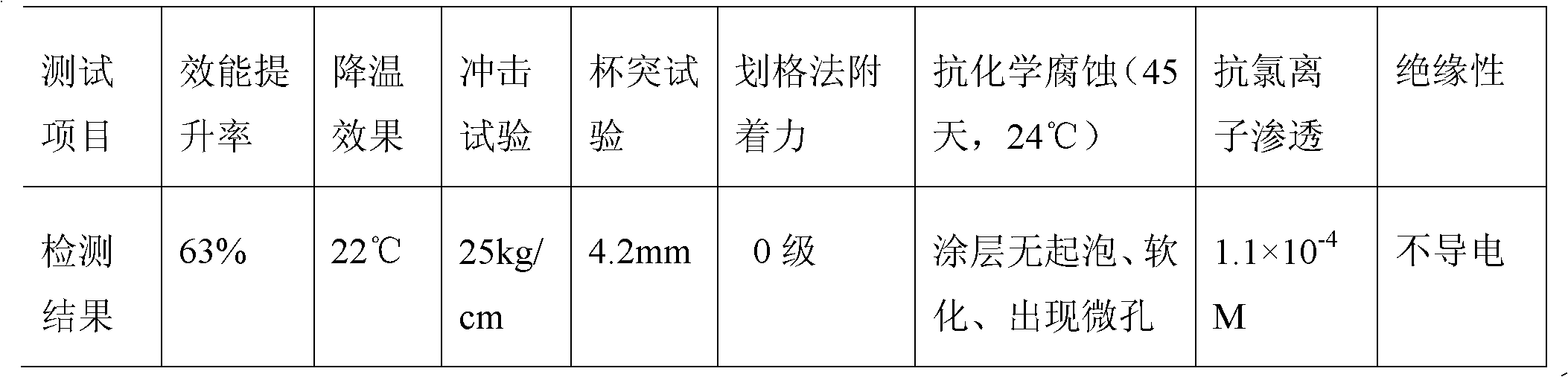

The invention discloses an environmental-protection anti-corrosive heat-dissipation powder paint, and a preparation method and application thereof. The environmental-protection anti-corrosive heat-dissipation powder paint comprises the following raw materials in parts by weight: 40-90 parts of matrix resin, 2-40 parts of curing agent, 0.5-10 parts of carbon nanotube, 0.5-2 parts of additive, 0-4.5 parts of hexagonal boron nitride, 0-15 parts of aluminum nitride, 0-10 parts of magnesium nitride, 0-10 parts of silicon carbide and 5-30 parts of pigment and filler. The composition and proportioning of the raw materials of the powder paint disclosed by the invention are scientific and reasonable. The experimental result indicates that the powder paint has the advantages of favorable heat-dissipation effect, high efficacy enhancement rate (higher than 60%) and favorable cooling effect (more than 20 DEG C), and can effectively solve the problem of poor heat-dissipation effect in the high-power electronic product, thereby prolonging the service life of the electronic product. The powder paint disclosed by the invention is free of organic solvent, and is environment-friendly and safe; the powder paint disclosed by the invention also has favorable comprehensive properties, such as flexibility, hardness, adhesive force and the like, and stable chemical properties; and the coating formed by the powder paint has the advantages of high corrosion resistance and shock resistance, favorable insulation property and wide application range.

Owner:TIGER DRYLAC TAICANG

Cotton fibers with antibacterial and insect-resisting effects and production method of cotton fibers

InactiveCN104278359AEasy to cleanNot easy to fluffConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsCnidium monnieriFatty alcohol

The invention discloses cotton fibers with antibacterial and insect-resisting effects. The cotton fibers are characterized by being prepared from the following raw materials in parts by weight: 21-24 parts of cotton fibers, 10-12 parts of apocynum venetum fibers, 6-8 parts of silk fibers, 7-9 parts of cashmere fibers, 9-11 parts of pineapple fibers, 4-7 parts of polypropylene fibers, 6-8 parts of taxus chinensis superfine micro-powder, 3-5 parts of ailanthus altissima leaf extracted powder, 1-3 parts of zeolite powder, 1.1-2.3 parts of chitosan, 0.5-0.7 part of magnesium nitride, 0.8-1.4 parts of N,N-dicyanoethylaniline, 5-7 parts of sulfonated castor oil, 15-18 parts of fatty alcohol alkoxy ether, 1-2 parts of mashed garlic, 1.3-2.5 parts of cnidium monnieri cuss, 2.1-3.6 parts of coptis chinensis, 90-95 parts of 1-ethyl-3-methylimidazolium diethylphosphate, 95-100 parts of 1-butyl-3-methylimidazolium acetate, 3-6 parts of an addition agent and a proper amount of water. According to the cotton fibers, the taxus chinensis superfine micro-powder is added into raw materials by adopting an ultrasonic technology and a prepared cotton textile has a very good health effect and a useful pain-relieving effect on tumor patients and female symptoms; furthermore, the other active ingredients are added so that the good clothes properties of sweat absorption, breathability, softness, allergy prevention, easiness of washing, low probability of fuzzing and balling up and the like of natural cotton fibers are maintained, and the cotton fibers have good antibacterial and insect-resisting functions, a good electromagnetic radiation shielding function and the like.

Owner:ANHUI SWAN TECH IND GRP

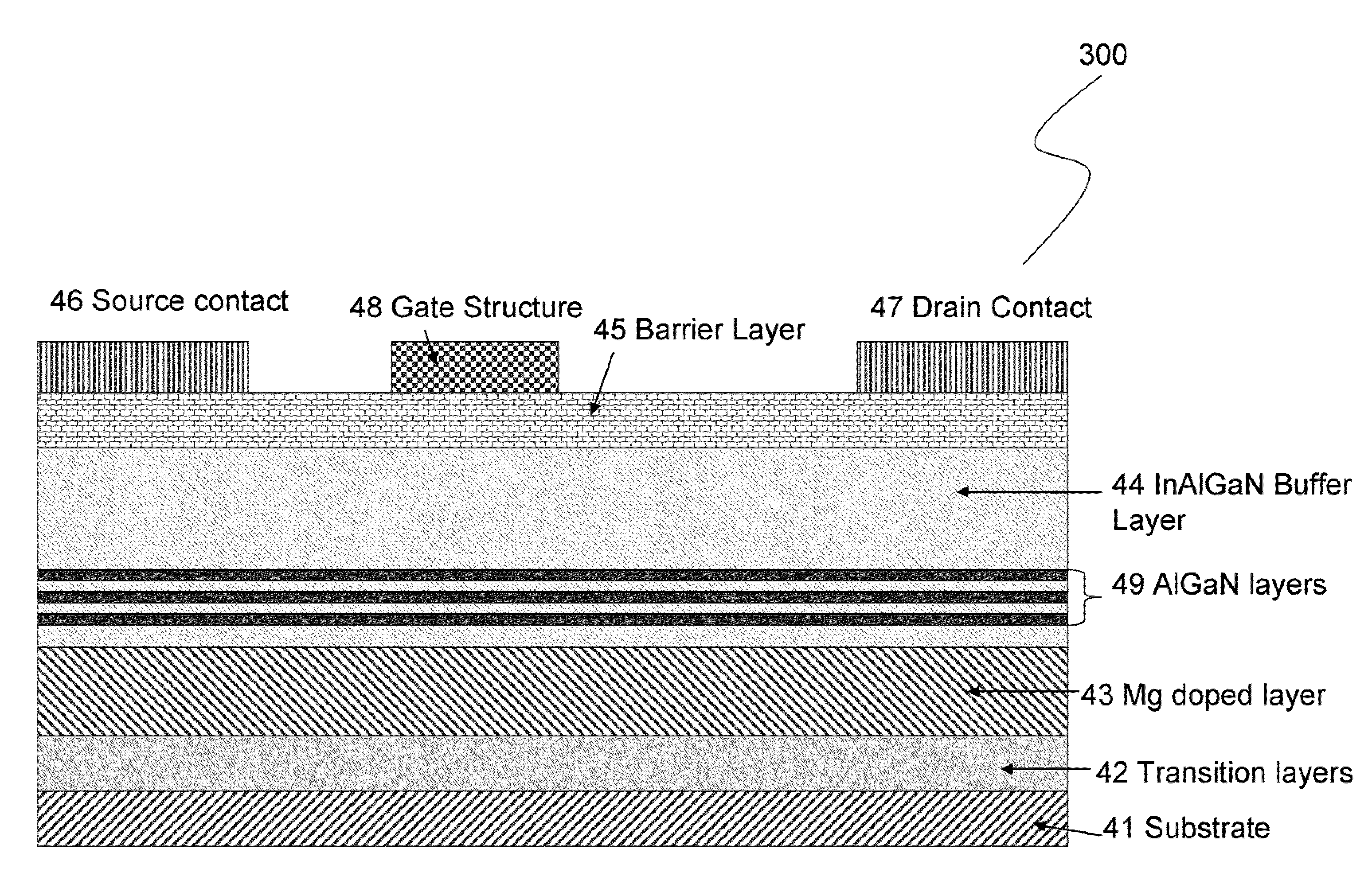

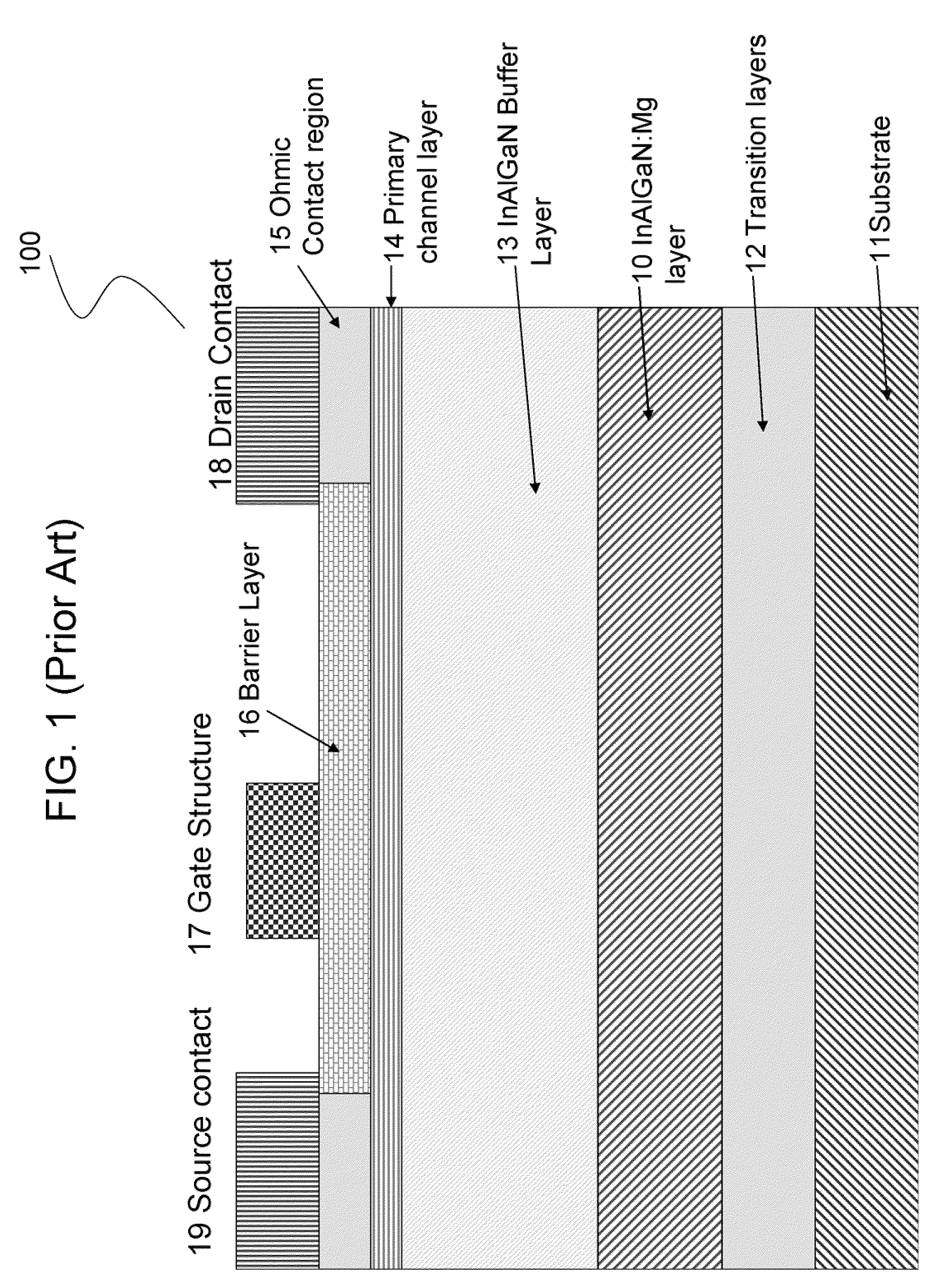

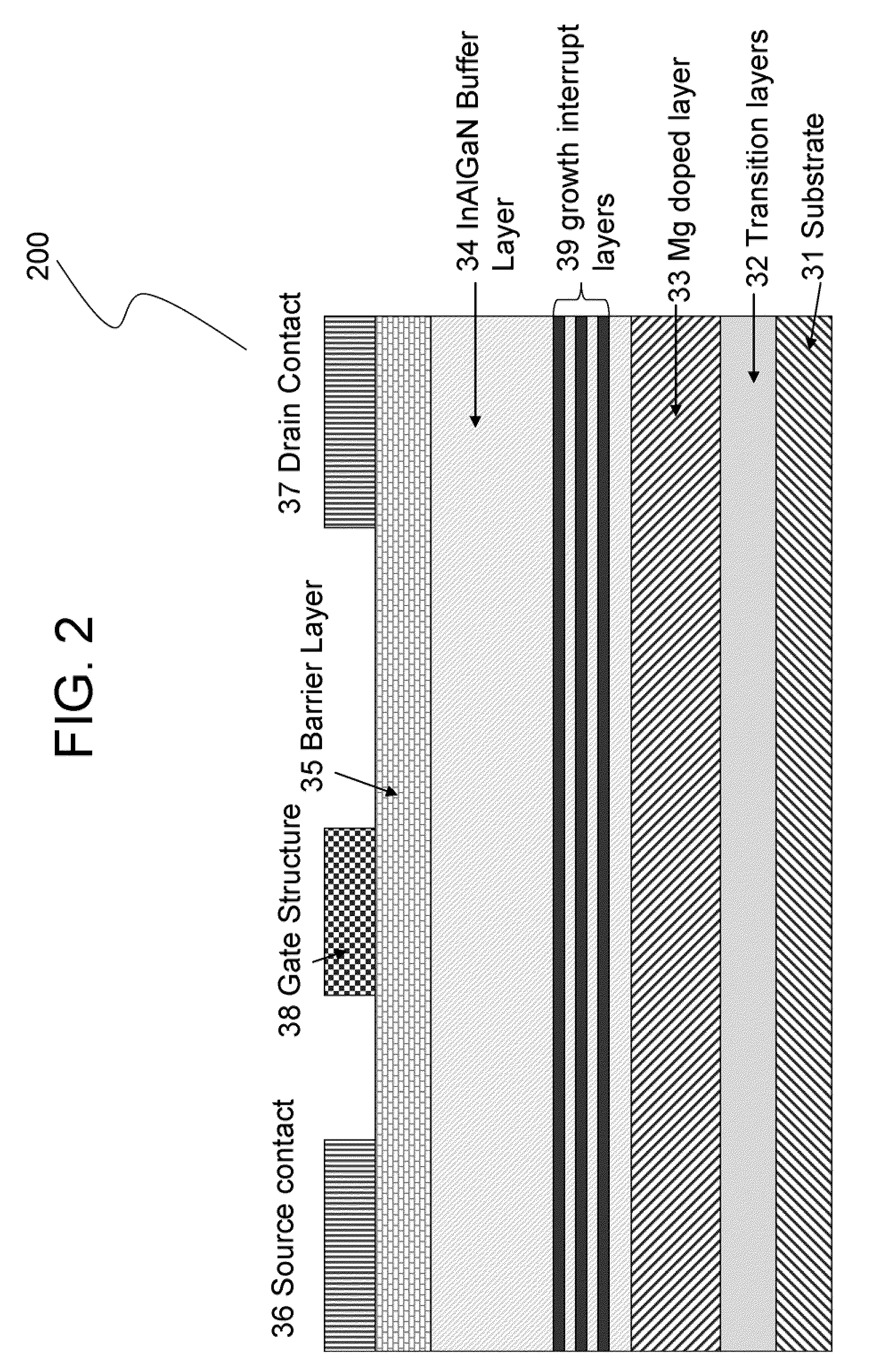

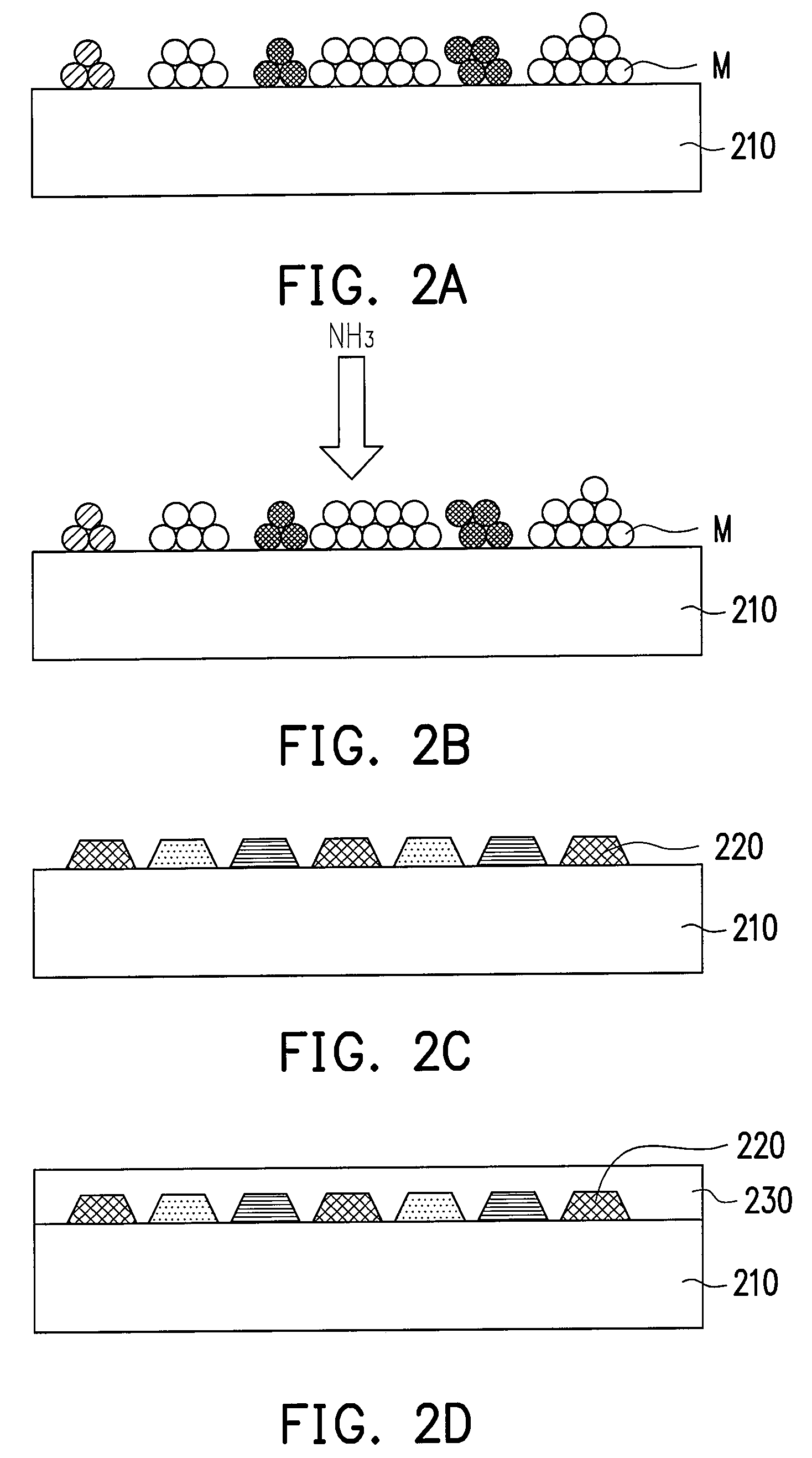

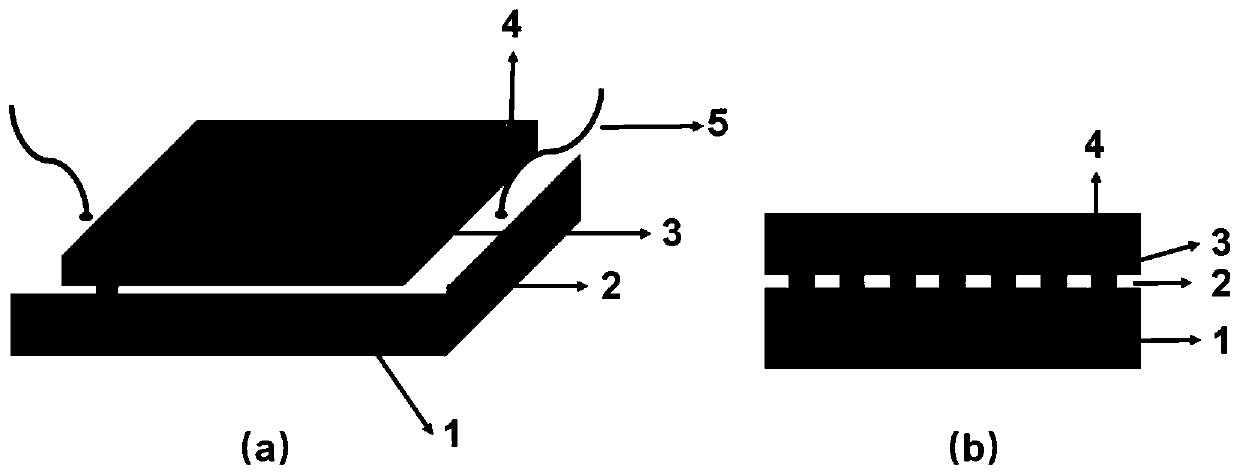

Dopant diffusion modulation in GaN buffer layers

ActiveUS8431960B2Improve faultEliminate variationSemiconductor/solid-state device manufacturingSemiconductor devicesDopantNitrogen

An enhancement mode gallium nitride (GaN) transistor with a Mg doped layer and a Mg growth interruption (diffusion barrier) layer to trap excess or residual Mg dopant. The Mg growth interruption (diffusion barrier) layer is formed by growing GaN, stopping the supply of gallium while maintaining a supply of ammonia or other nitrogen containing source to form a layer of magnesium nitride (MgN), and then resuming the flow of gallium to form a GaN layer to seal in the layer of MgN.

Owner:EFFICIENT POWER CONVERSION CORP

Eggplant straw modified activated carbon water purifying agent and preparation method thereof

InactiveCN103566890AWell-developed pore structureWell-developed structureOther chemical processesWater/sewage treatment by sorptionAluminium sulfateActivated carbon

The invention discloses an eggplant straw modified activated carbon water purifying agent which is prepared from the following raw materials in parts by weight: 40-50 parts of eggplant straw, 110-120 parts of activated carbon, 3-6 parts of magnesium nitride powder, 10-15 parts of bentonite, 15-20 parts of industrial aluminum sulfate, 4-7 parts of jade powder, 4-7 parts of medical stone powder, 8-10 parts of sepiolite powder, 10-15 parts of corn starch, 4-5 parts of modified diatomite and a suitable amount of water. By using eggplant straw as a raw material for production, the eggplant straw modified activated carbon water purifying agent disclosed by the invention has the advantages of developed activated carbon pore structure, large specific surface area, high adsorption speed, good adsorption capability to various solutes, free gases and the like; the use of stone powder of bentonite and the like has the effects of bacterium inhibition, decoloration, ionic exchange and release of microelements beneficial to a human body; the use of aluminum sulfate can be used for flocculating pollutants in water. The eggplant straw modified activated carbon water purifying agent disclosed by the invention is safe, nontoxic, and suitable for water purification and indoor air purification.

Owner:BENGBU HUAFANG FILTER

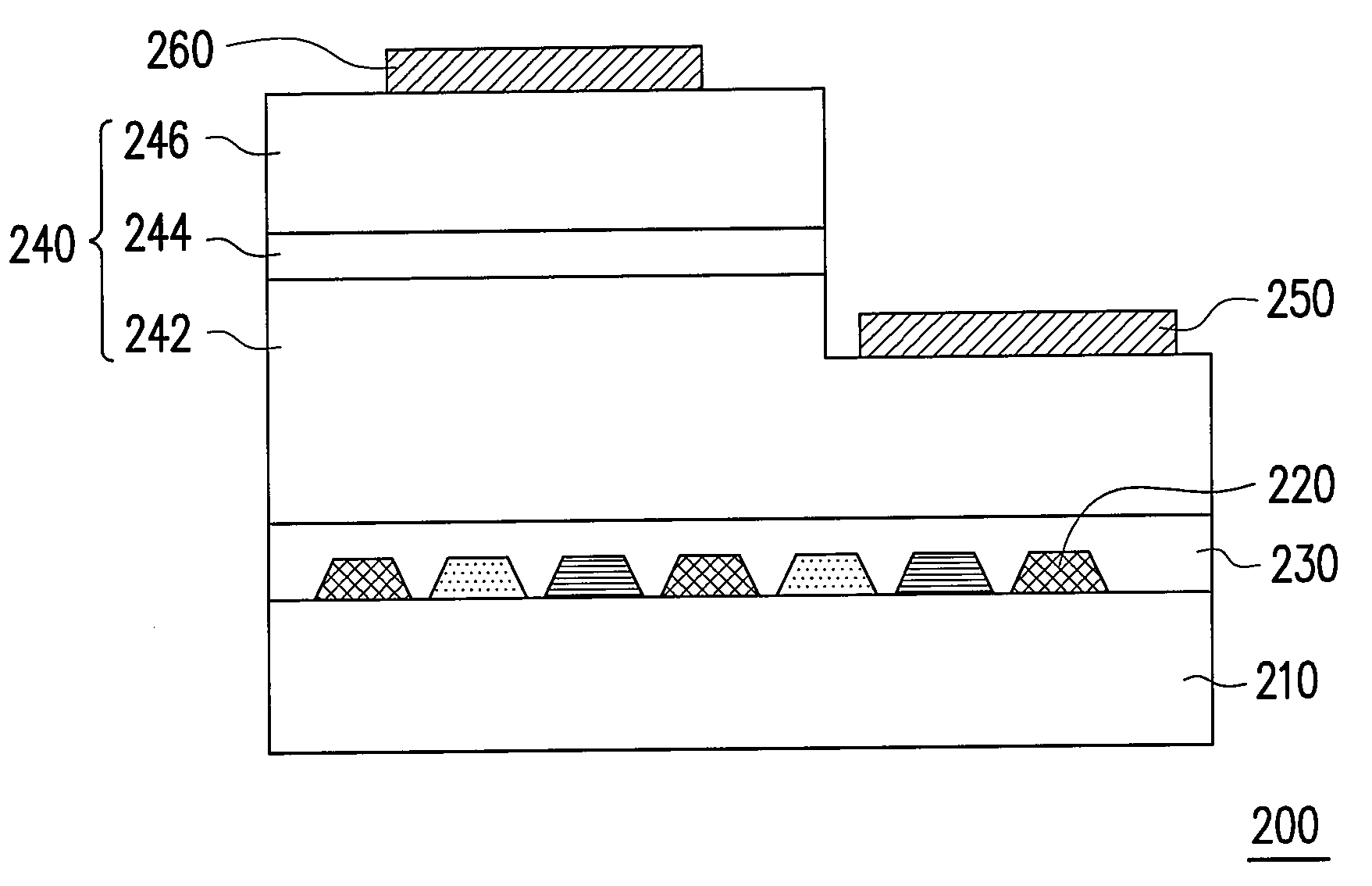

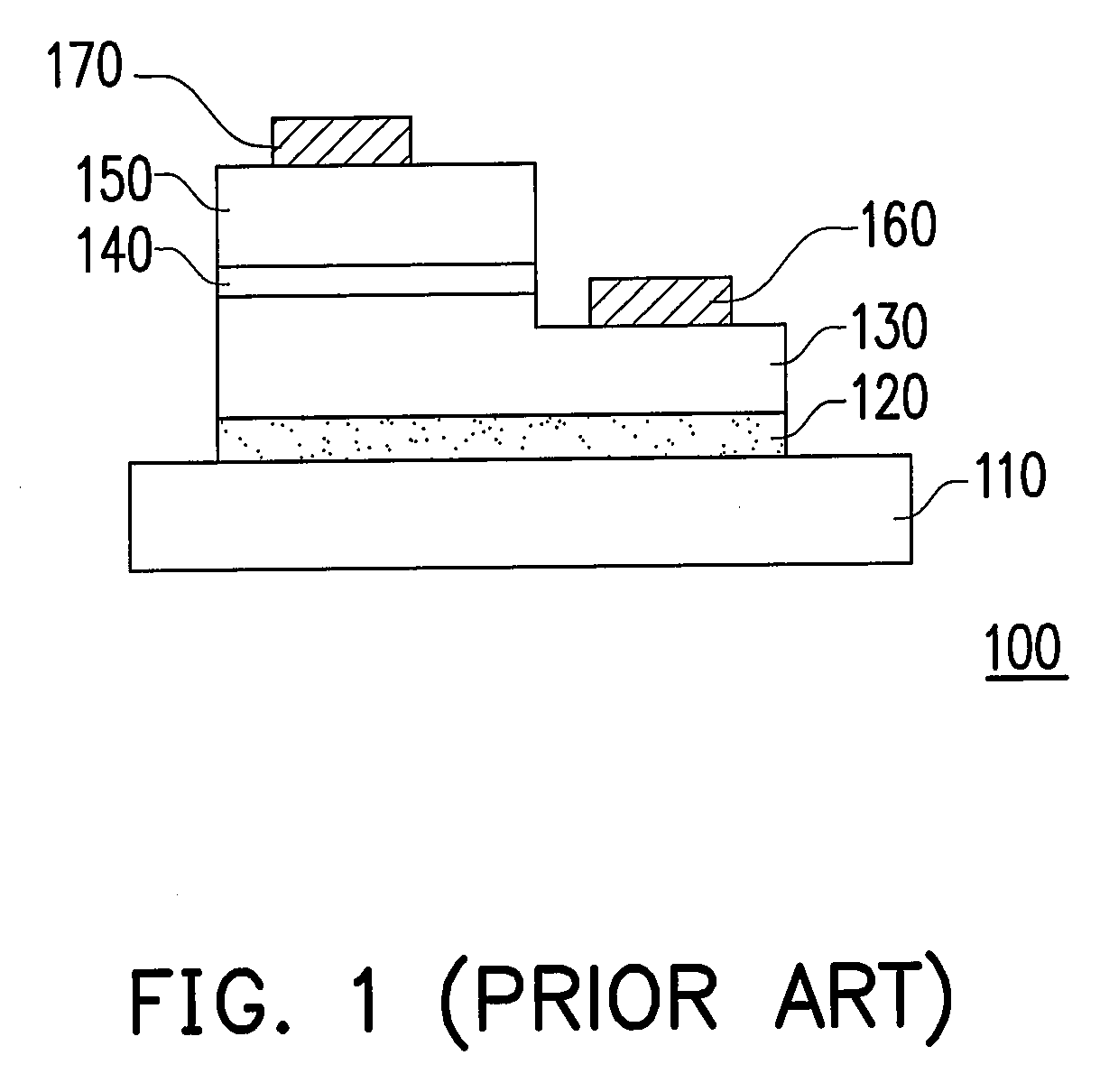

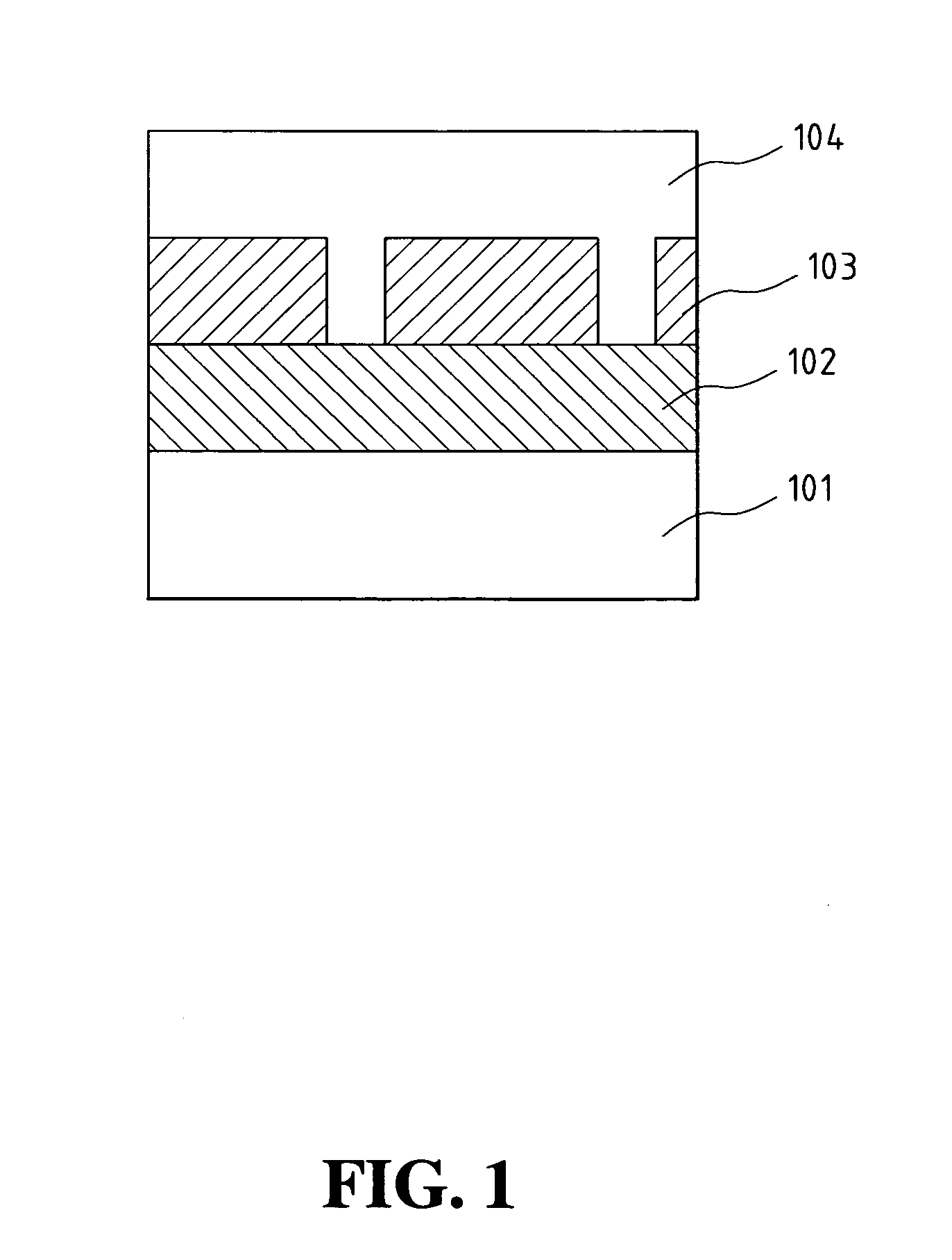

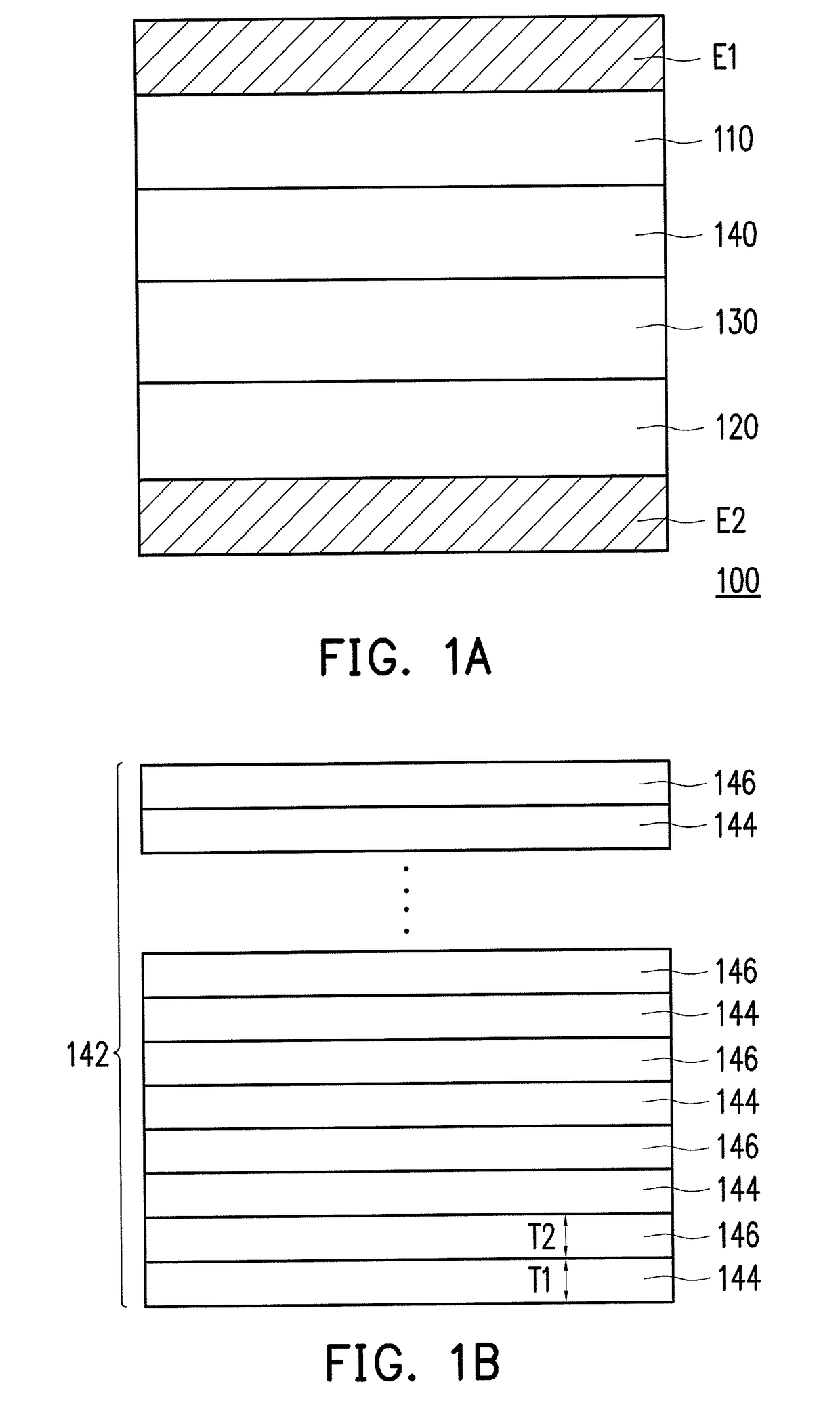

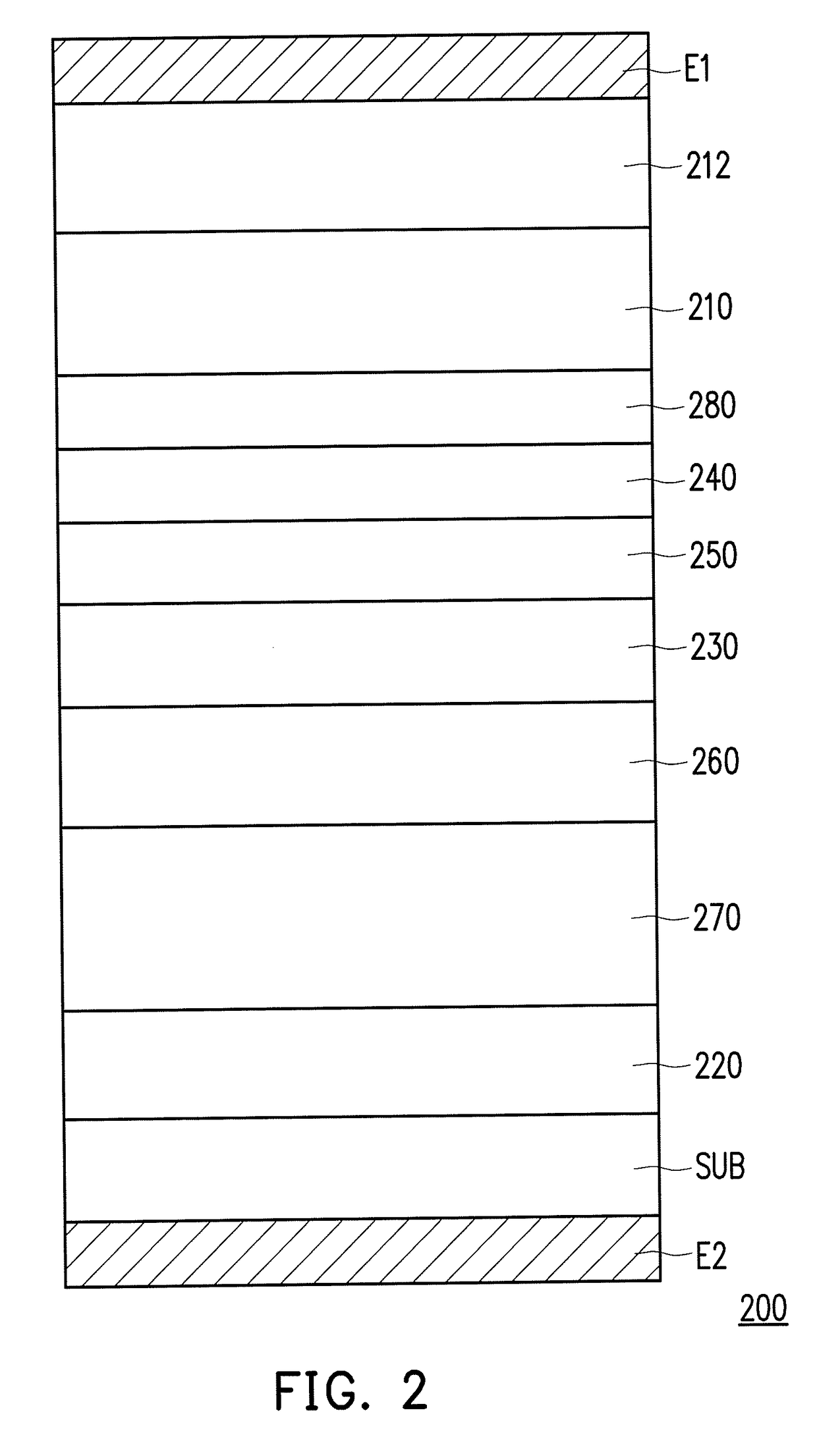

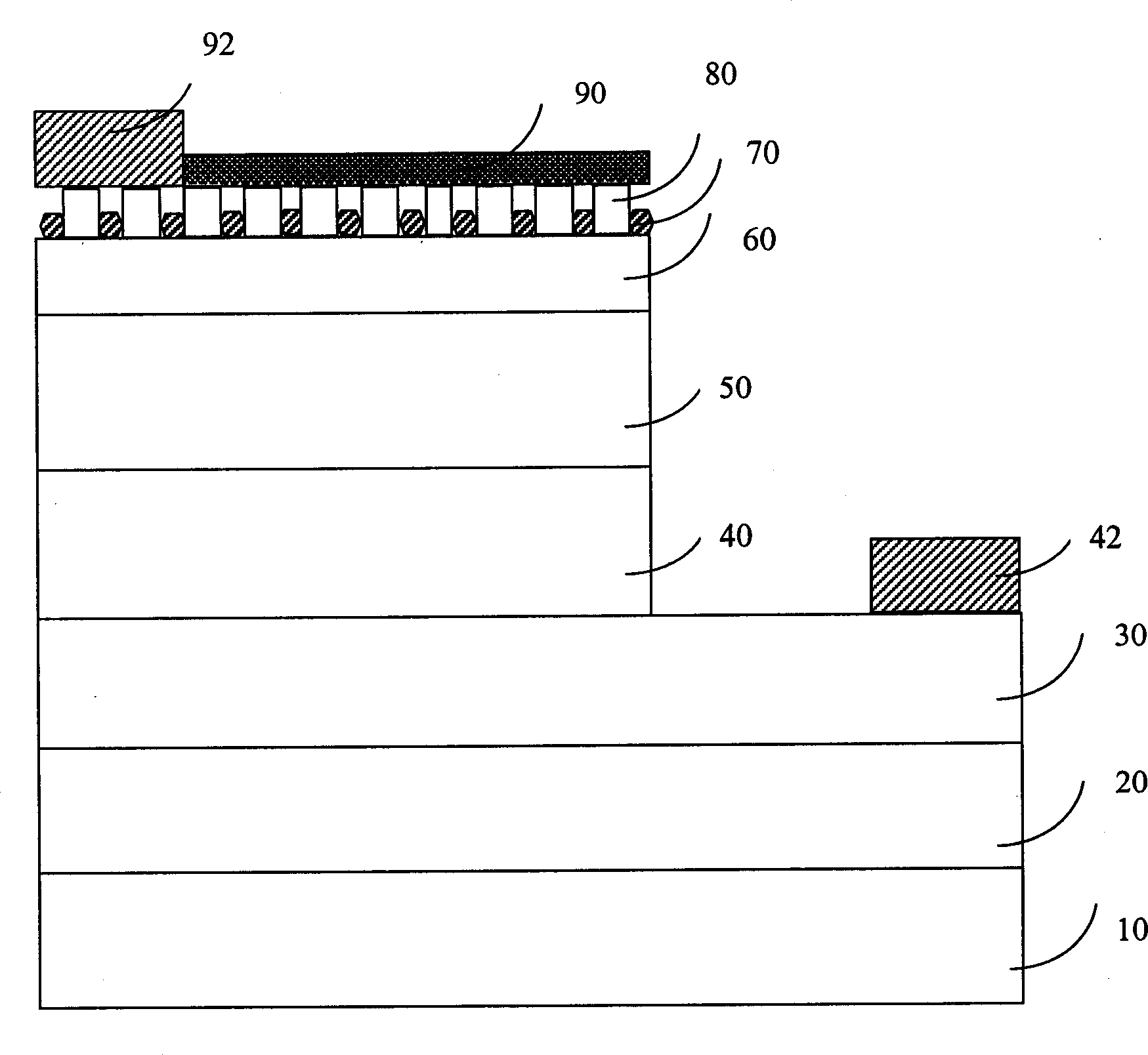

Light emitting diode, optoelectronic device and method of fabricating the same

InactiveUS20080315226A1Structural strainReduce dislocation densitySemiconductor/solid-state device manufacturingSemiconductor devicesOpto electronicLight-emitting diode

A light emitting diode structure including a substrate, a strain-reducing seed layer, an epitaxial layer, a first electrode and a second electrode is provided. The strain-reducing seed layer having a plurality of clusters is disposed on the substrate, and the material of the clusters is selected from a group consisting of aluminum nitride, magnesium nitride and indium nitride. The epitaxial layer includes a first type doped semiconductor layer, a light emitting layer and a second type doped semiconductor layer. The first electrode is disposed on the exposed first type doped semiconductor layer and electrically connected thereto. The second electrode is disposed on the second type doped semiconductor layer and electrically connected thereto.

Owner:NAT CENT UNIV

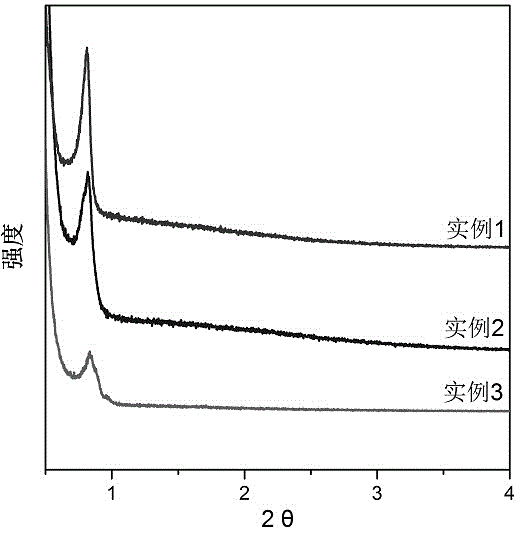

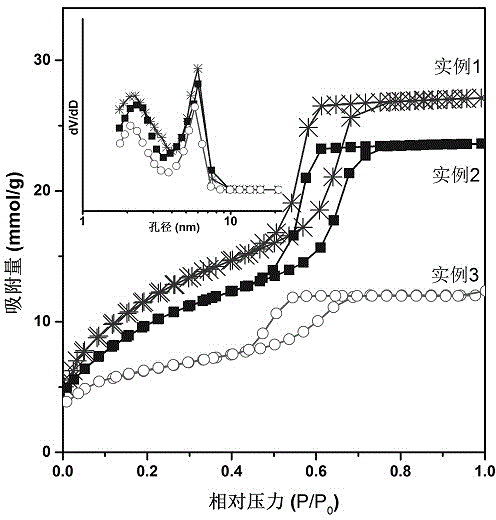

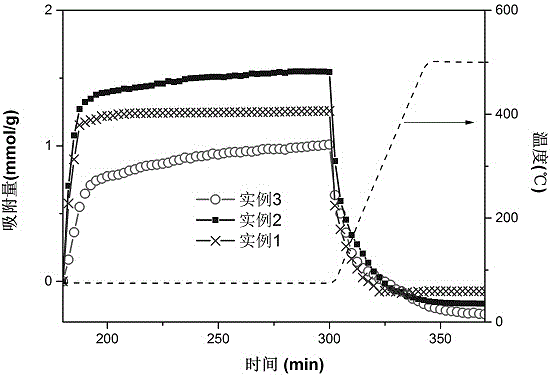

Preparation method of magnesium oxide-mesoporous carbon composite material

InactiveCN104014302ALarge specific surface areaIncrease loadOther chemical processesCarbon compositesSalt solution

The invention discloses a preparation method of a magnesium oxide-mesoporous carbon composite material. The method is characterized by comprising the following steps: oxidizing the surface of a carbon material by adopting mesoporous carbon as a carrier, so that the carbon material is more likely to adsorb a metal salt solution; eliminating water impurities in pores in a vacuum drying box, so that the pores are adequately opened; adding a magnesium nitride solution onto the carbon material to be completely absorbed; and roasting the carbon material under the inert gas after the solution is completely volatized, so that the magnesium nitride is decomposed into magnesium oxide to be remained in the pores of the mesoporous carbon. The magnesium oxide-mesoporous carbon composite material prepared by the method is high in specific surface area and high in magnesium oxide loading capacity; when being applied to the carbon dioxide adsorption at a high temperature, the magnesium oxide-mesoporous carbon composite material has the following good properties: the adsorption capacity of CO2 at the temperature of 50 to 80 DEG C and the pressure of 0.1MPa to 0.2MPa is 2.0 to 2.5 mmol / g, the adsorption agent can be reduced and regenerated at the temperature of 350 to 500 DEG C, and the magnesium oxide-mesoporous carbon composite material is a CO2 adsorption material with a promising application prospect.

Owner:SHANGHAI UNIV

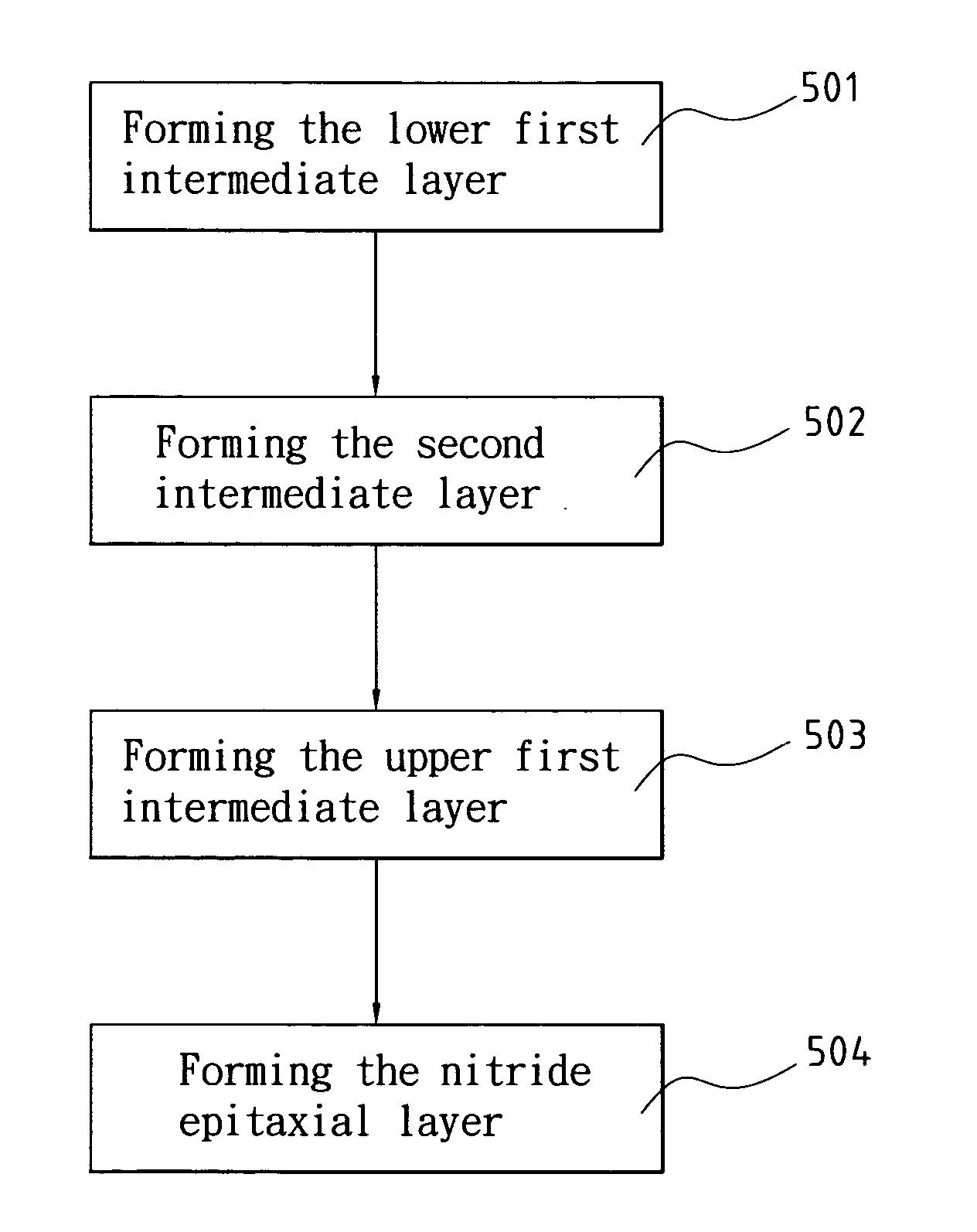

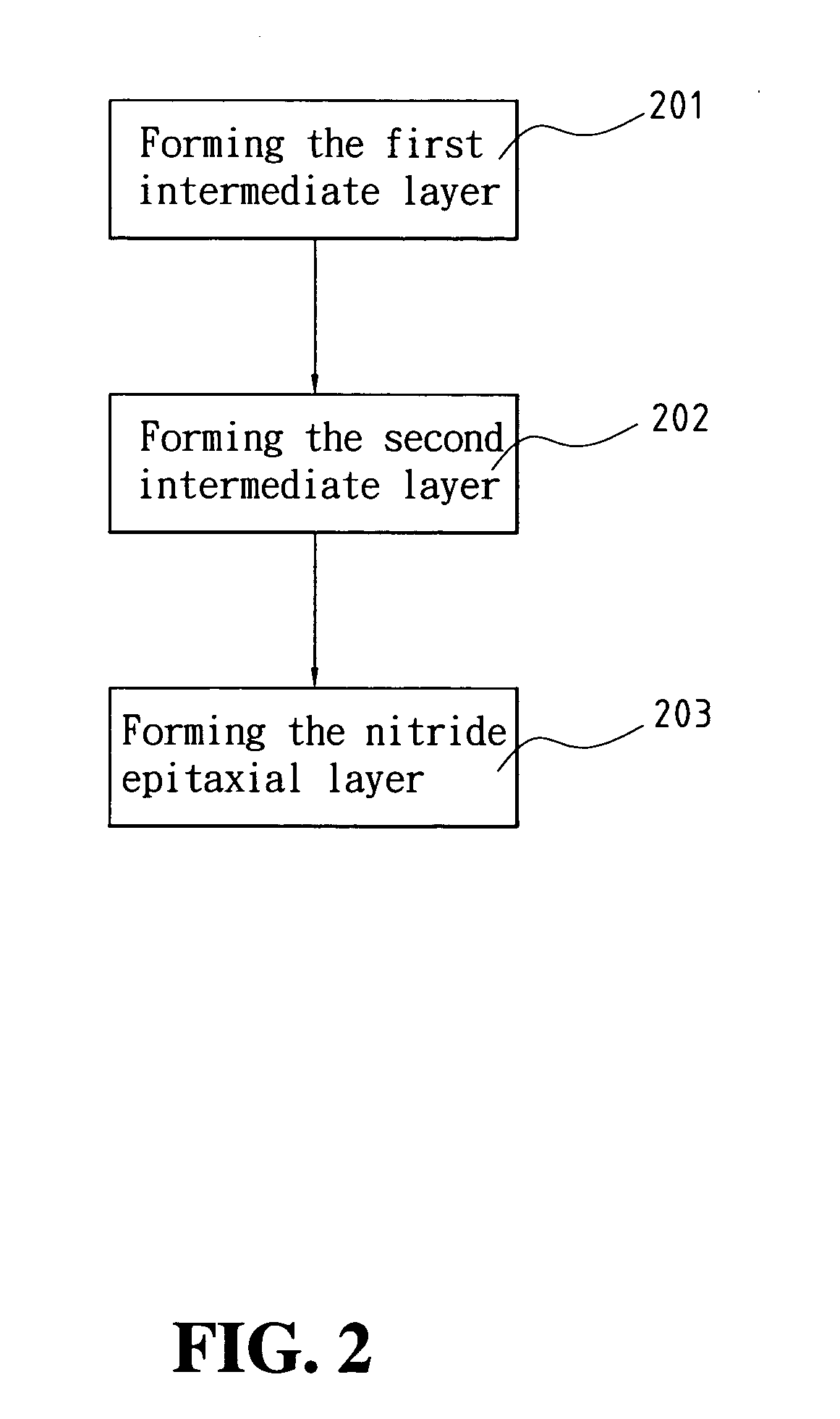

Epitaxial structure and fabrication method of nitride semiconductor device

InactiveUS20060049418A1Semiconductor/solid-state device manufacturingSemiconductor devicesInter layerLattice constant

Owner:FORMOSA EPITAXY INCORPORATION

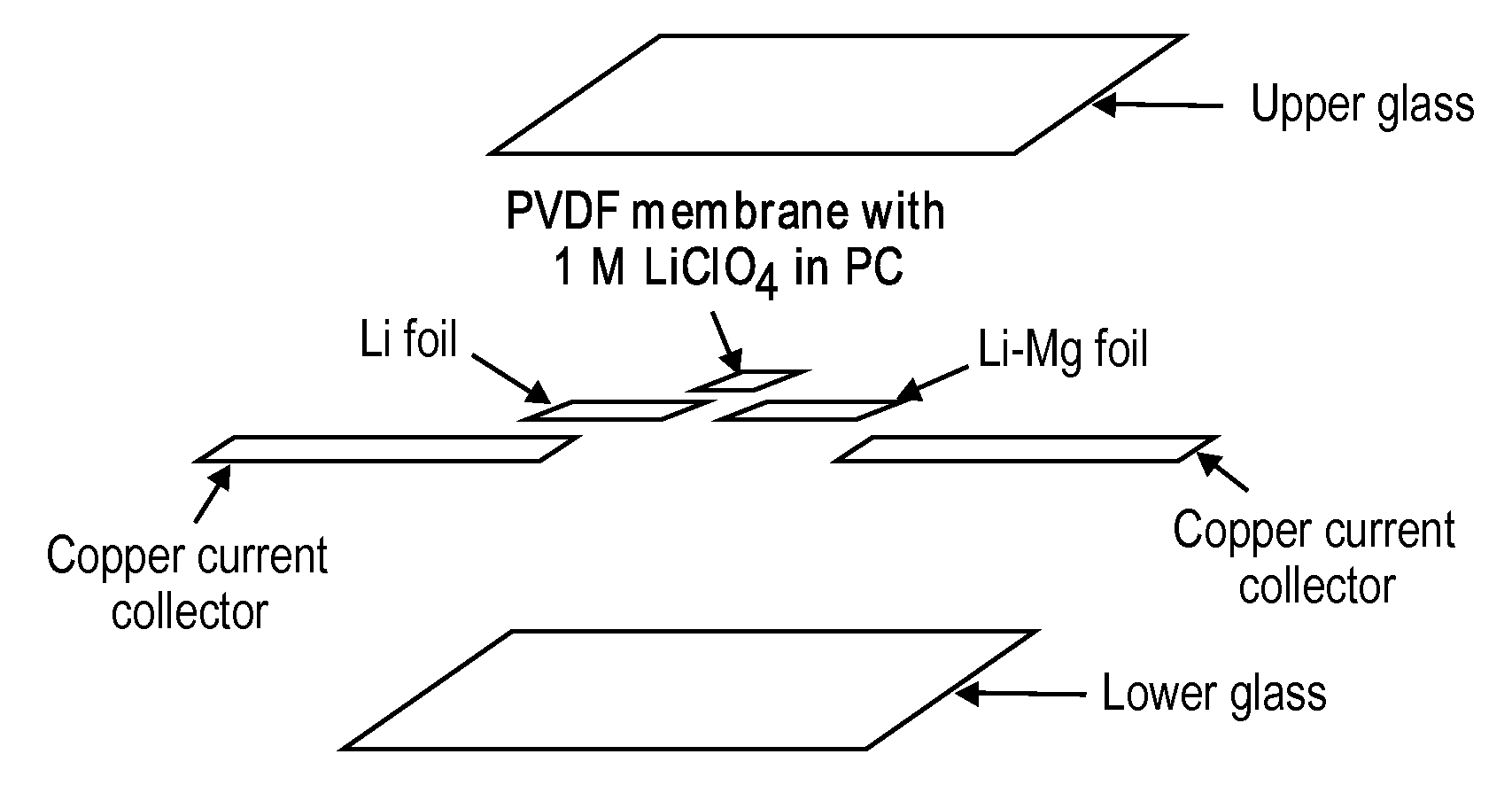

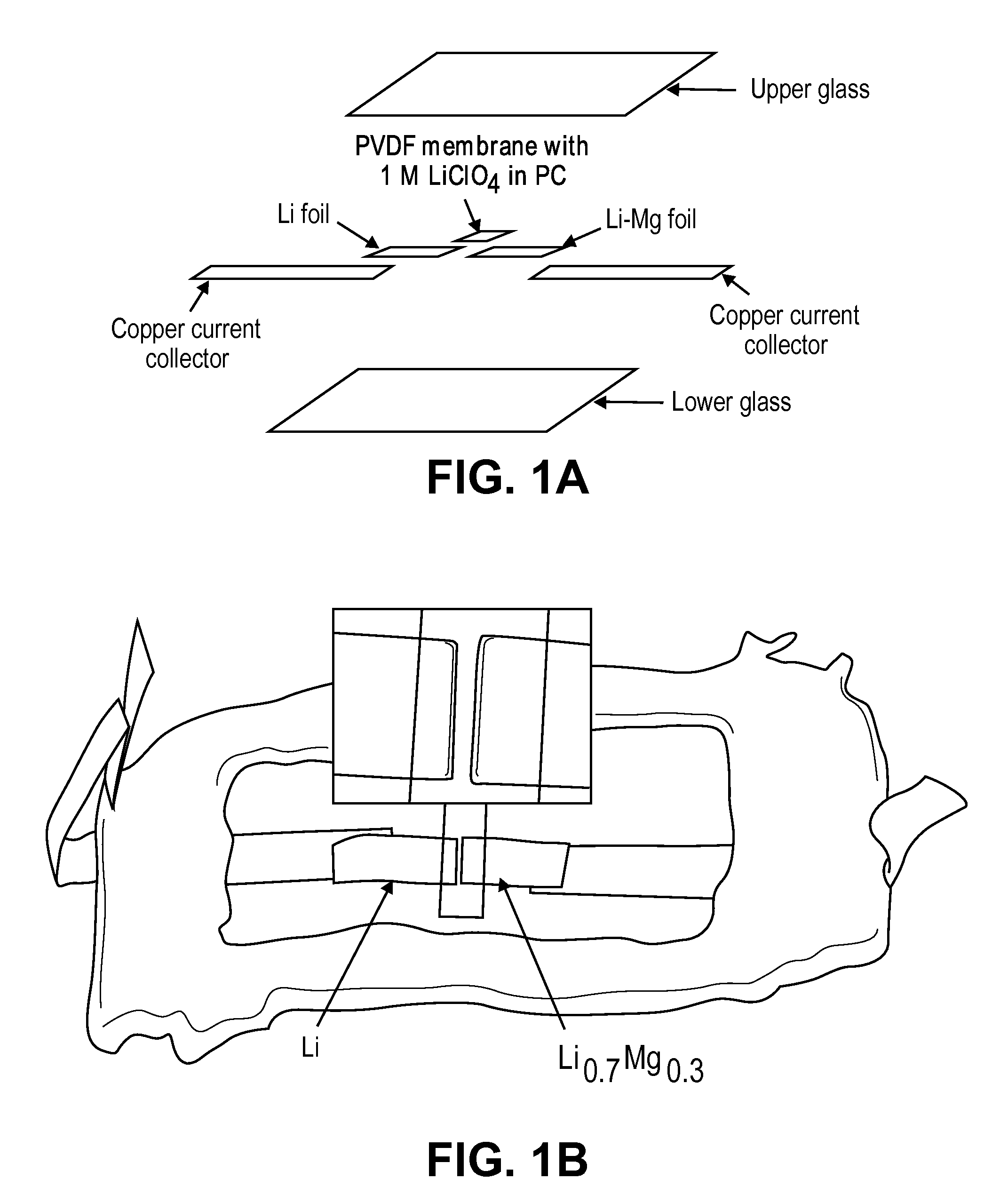

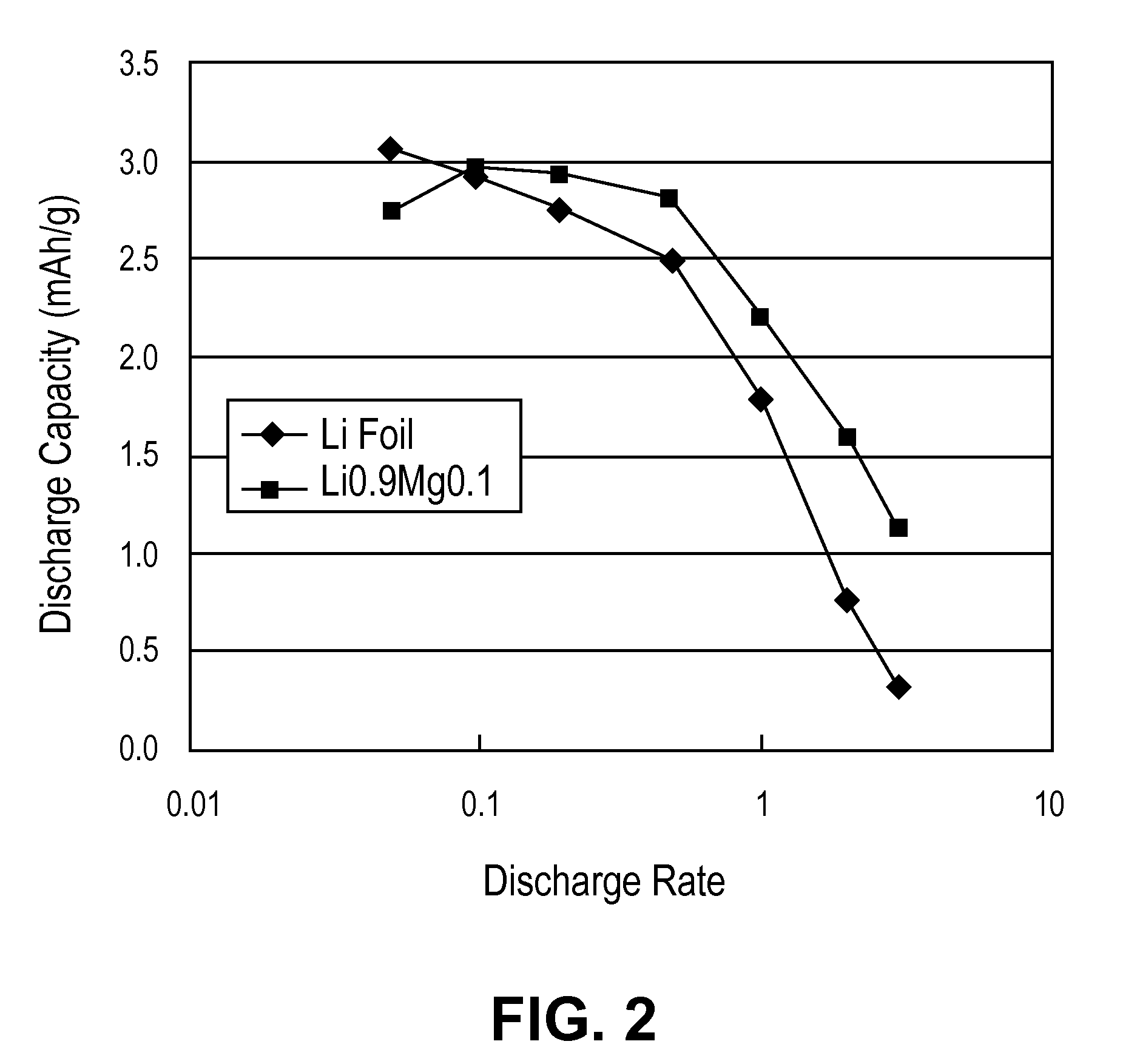

Solid solution lithium alloy cermet anodes

ActiveUS20100181528A1Easy to produceMinimal post reaction manipulationNitrogen-metal/silicon/boron binary compoundsCell temperature controlChemical reactionCeramic composite

A metal-ceramic composite (“cermet”) has been produced by a chemical reaction between a lithium compound and another metal. The cermet has advantageous physical properties, high surface area relative to lithium metal or its alloys, and is easily formed into a desired shape. An example is the formation of a lithium-magnesium nitride ceiniet by reaction of lithium nitride with magnesium. The reaction results in magnesium nitride grains coated with a layer of lithium. The nitride is inert when used in a battery. It supports the metal in a high surface area form, while stabilizing the electrode with respect to dendrite formation. By using an excess of magnesium metal in the reaction process, a cermet of magnesium nitride is produced, coated with a lithium-magnesium alloy of any desired composition. This alloy inhibits dendrite formation by causing lithium deposited on its surface to diffuse under a chemical potential into the bulk of the alloy.

Owner:RGT UNIV OF CALIFORNIA

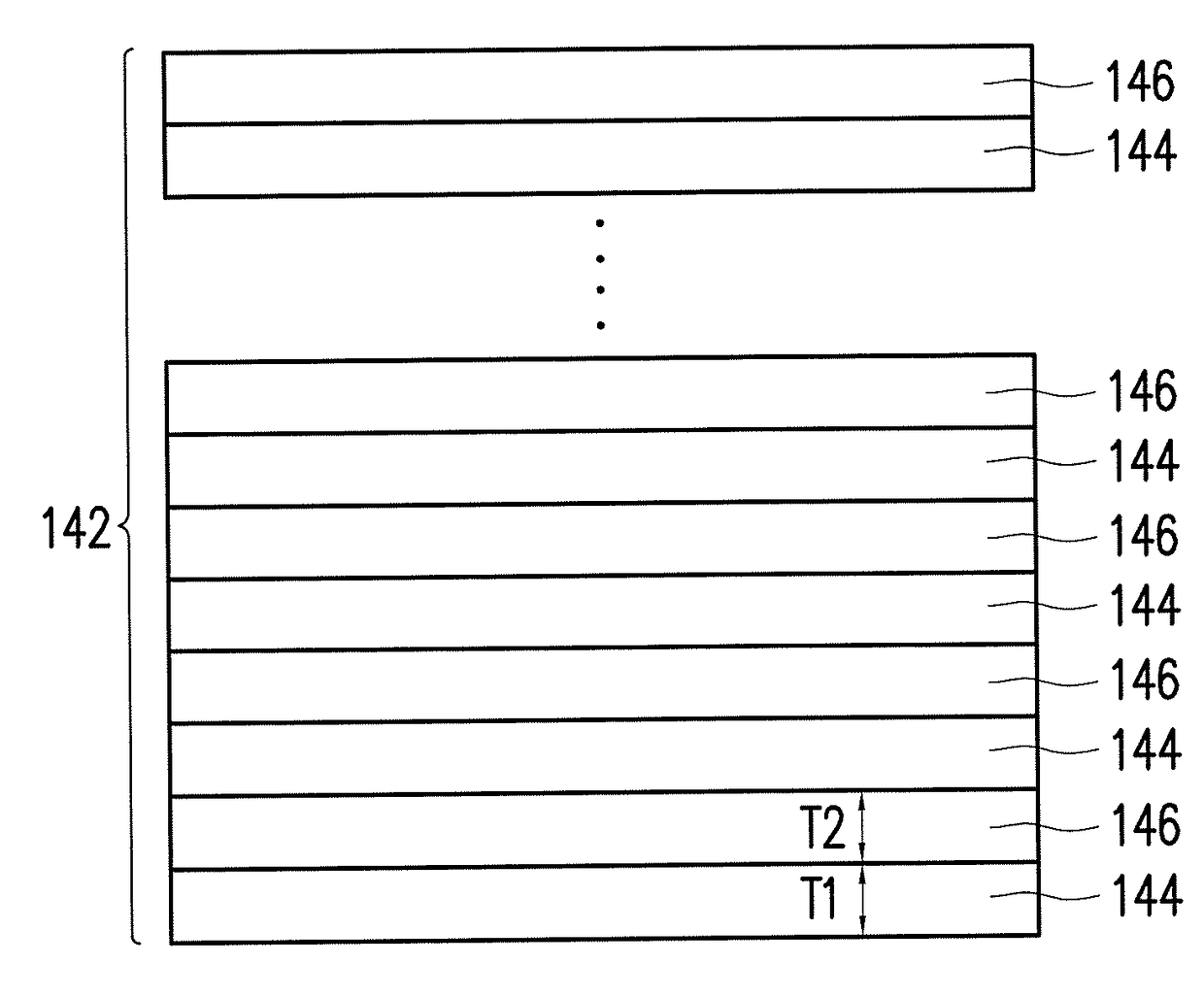

Semiconductor light-emitting device

A semiconductor light-emitting device including a P-type semiconductor cladding layer, an N-type semiconductor layer, a light-emitting layer, and a hole injection layer is provided. The P-type semiconductor cladding layer is doped with magnesium. The light-emitting layer is disposed between the P-type semiconductor cladding layer and the N-type semiconductor layer. The hole injection layer is disposed between the P-type semiconductor cladding layer and the light-emitting layer. The hole injection layer includes a first super lattice structure formed by alternately stacking a plurality of magnesium nitride layers and a plurality of semiconductor material layers. The chemical formula of each of the semiconductor material layers is AlxInyGa1-x-yN, and 0≦x≦1, 0≦y≦1, and 0≦x+y≦1.

Owner:PLAYNITRIDE

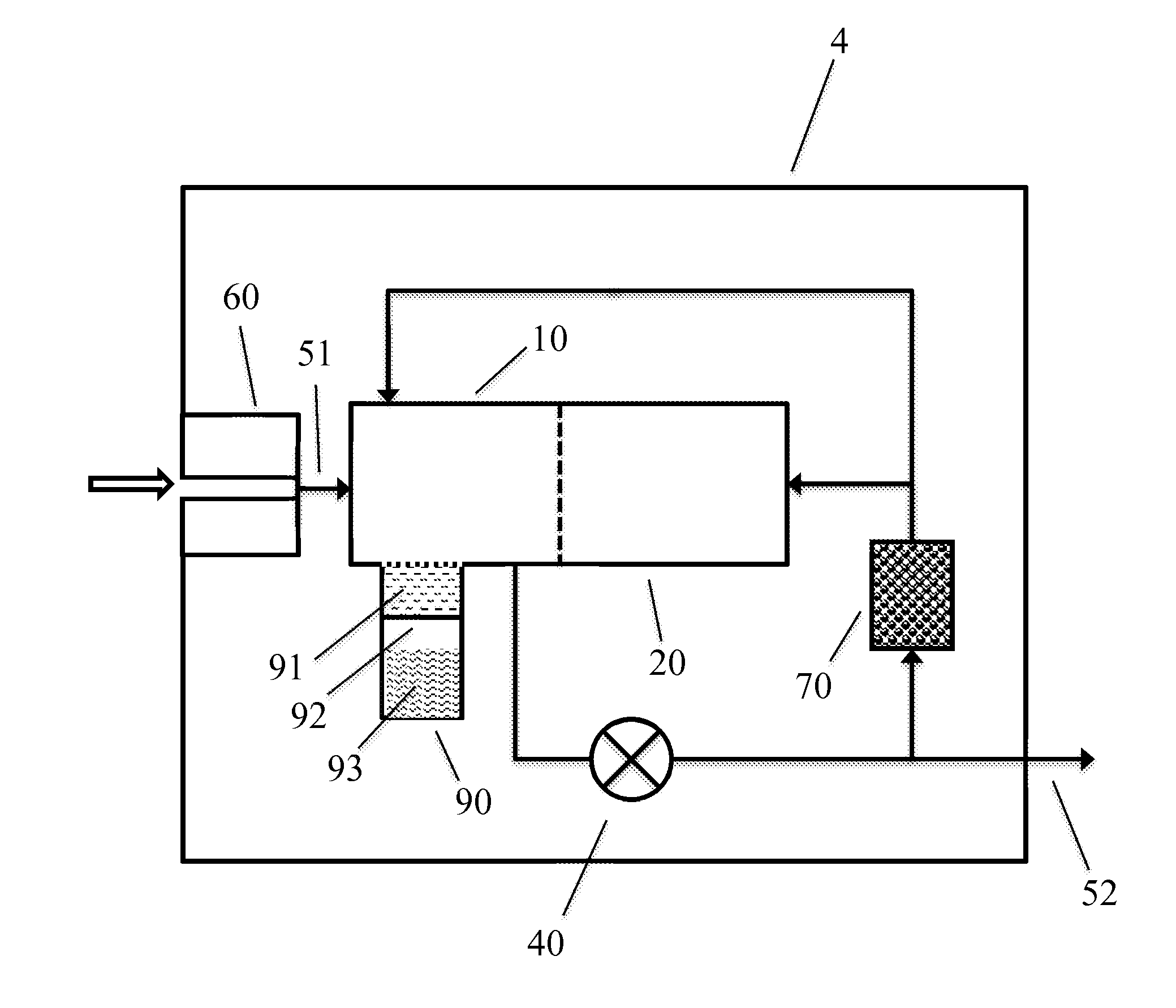

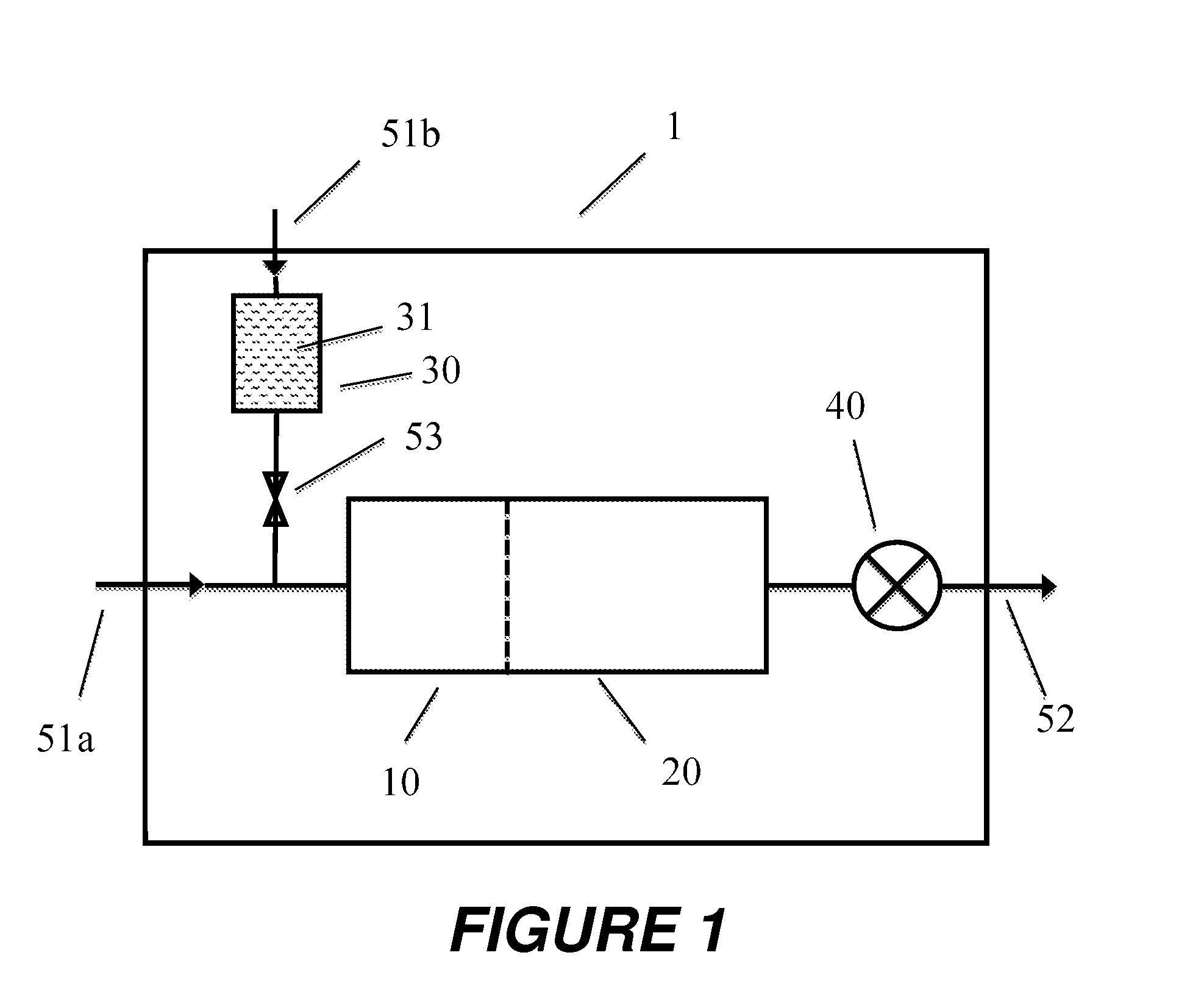

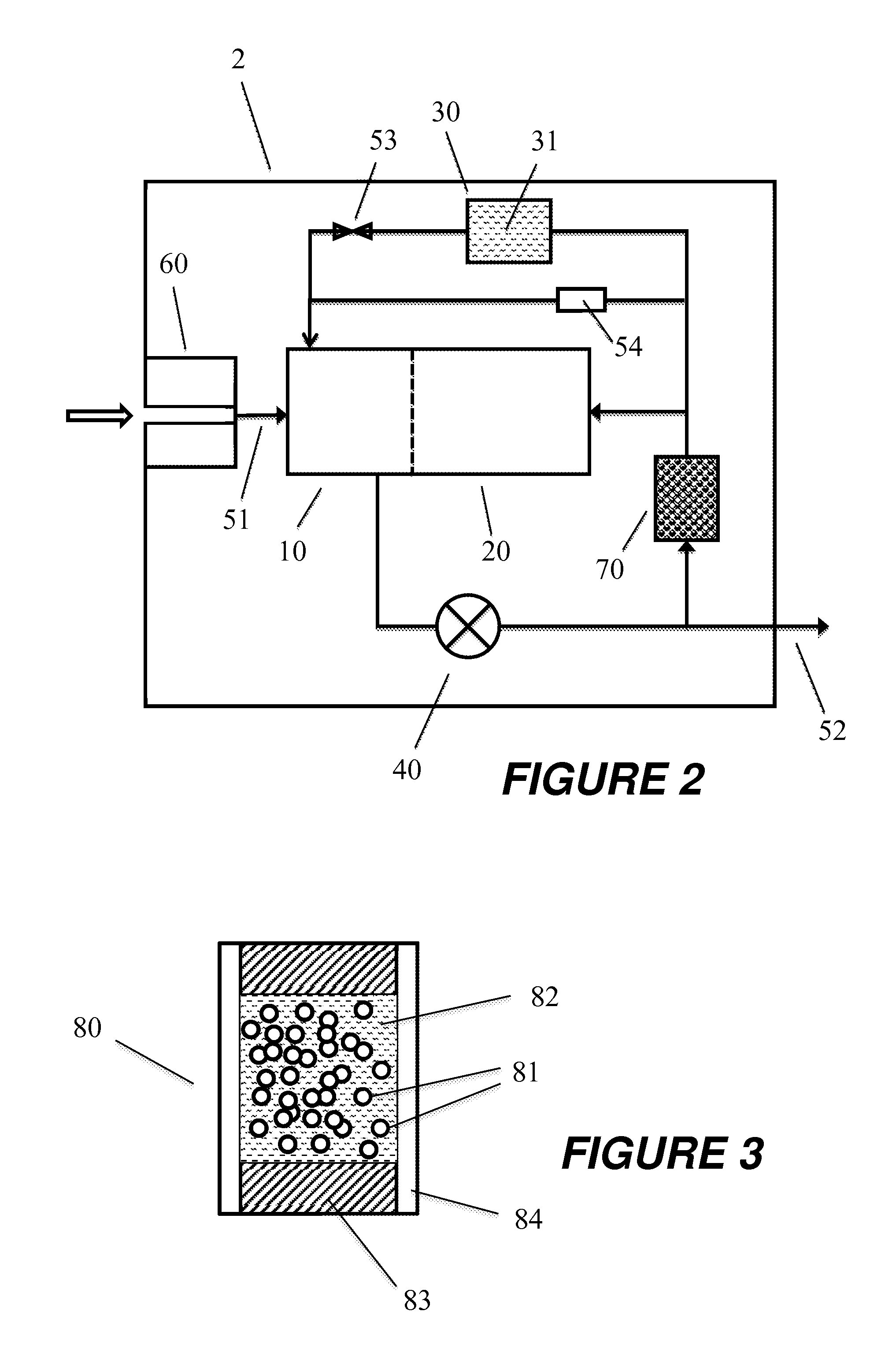

Ion mobility spectrometer with device for generating ammonia gas

ActiveUS20140319332A1Particle separator tubesMaterial analysis by electric/magnetic meansDopantAlkaline earth metal

The present invention relates to ion mobility spectrometry, in particular to methods and devices for generating and delivering of ammonia gas as dopant into the ionization region of an ion mobility spectrometer. It provides an ion mobility spectrometer (IMS) with an ion source and device for generating ammonia gas, wherein the device comprises a dopant reservoir filled with alkali metal nitride or alkaline earth metal nitride, preferably lithium nitride and / or magnesium nitride, said reservoir being fluidly coupled to the ion source and to a water reservoir.

Owner:BRUKER OPTICS GMBH & CO KG

High brightness gallium nitrate kind LED structure

InactiveCN1787241AAvoid Total Internal ReflectionImprove external quantum efficiencySemiconductor devicesQuantum efficiencyRefractive index

The invention advances a structure of high brightness GaN LED, which uses silicon nitride, magnesium nitride or silicon- and magnesium- highly doped aluminum gallium indium nitride to form a mask buffer layer comprising plural random distributed crowded masks, then growing a p-type rough contact layer composed of p-type aluminum gallium indium nitride which is not directly grown on the mask buffer layer but grown from the top surface of the part of the p-type contact layer unmasked by the mask buffer layer, and not stop growing the p-type rough contact layer until it extends to exceed the masks of the buffer layer by a certain height. The structure can roughen the surface of the GaN LED, avoiding the inner all reflection and then raise the outer quantum efficiency and light emitting efficiency.

Owner:FORMOSA EPITAXY INCORPORATION +1

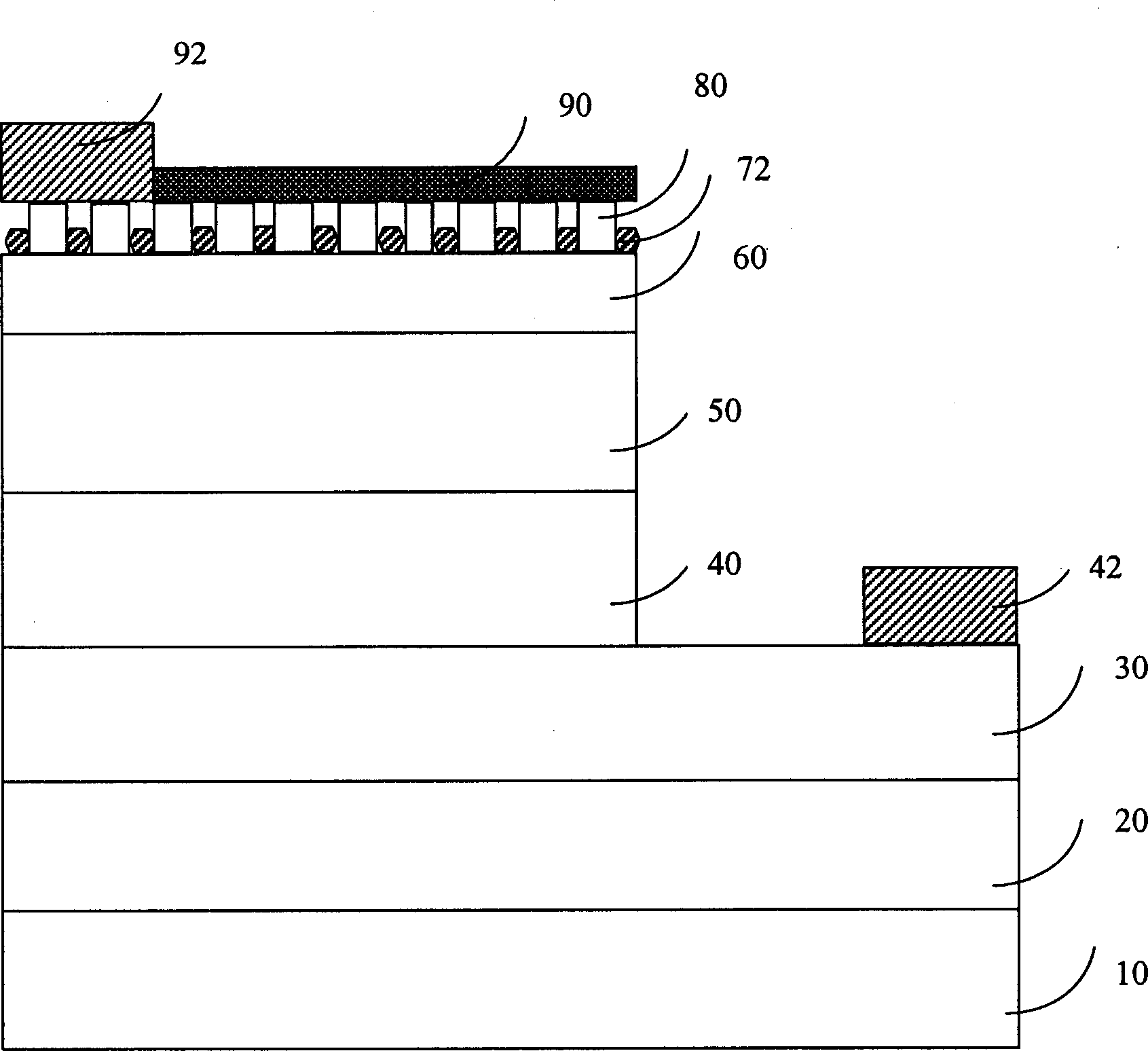

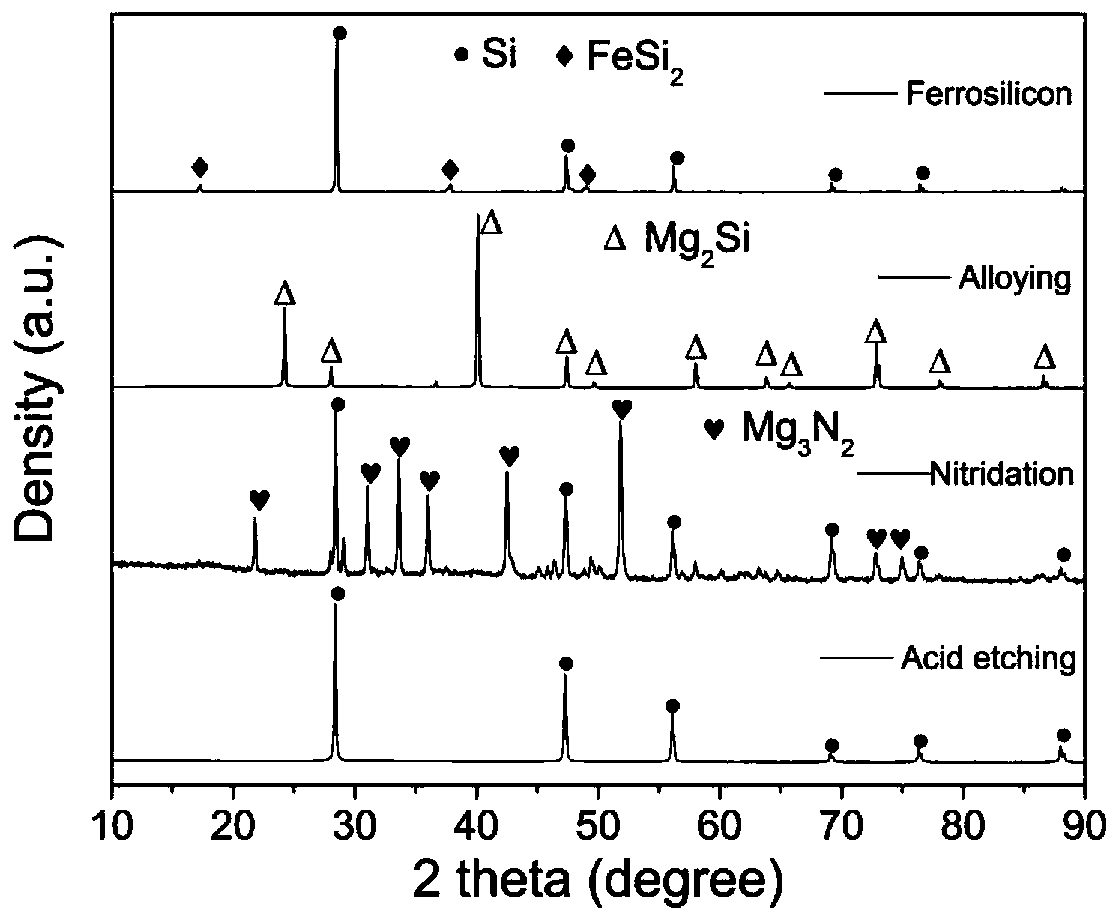

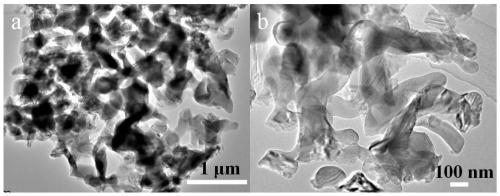

Method for purifying silicon through phase separation and dealloying

ActiveCN109941998AAchieve the first separationAchieve separationSilicon compoundsReaction temperatureMetal impurities

The invention belongs to the technical field of purification of silicon, and particularly relates to a method for purifying silicon through a phase separation and dealloying reaction method. Firstly,a silicon raw material containing metal or non-metal impurities is mixed with magnesium powder, and then a sufficient reaction is carried out under the inert atmosphere, so that silicon atoms in the silicon raw material react with magnesium to be converted into magnesium silicide, and the impurities in the silicon raw material are separated from silicon to obtain a first product; then the first product is subjected to a nitridation reaction under the nitrogenous atmosphere, the magnesium silicide in the first product is converted into liquid-phase magnesium nitride at the reaction temperature,silicon separates crystals from the liquid-phase magnesium nitride, three-dimensional porous silicon and magnesium nitride distributed in pore passages of the three-dimensional porous silicon are formed, and a second product is obtained; in the process of separating out the crystals by the silicon, the impurities are further separated and dissolved in the liquid-phase magnesium nitride; finally,the second product is treated through acid pickling, wherein the magnesium nitride and the impurities are dissolved and converted into a solution, and a solid product is high-purity porous silicon.

Owner:WUHAN UNIV OF SCI & TECH

Ultraviolet LED and manufacturing method therefor

ActiveCN107799636ALower activation energyIncrease hole concentrationSemiconductor devicesHole injection layerActivation energy

The invention discloses an ultraviolet LED and a manufacturing method therefor. According to the technical scheme, a p type hole injection layer comprises a plurality of superlattice layer period units stacked in a first direction, wherein each superlattice layer period unit comprises an aluminum nitride layer, at least one magnesium nitride layer and at least one gallium nitride layer; the magnesium nitride layer and the gallium nitride layer are both positioned on one side, deviating from a substrate, of the aluminum nitride layer; at least one of the two opposite surfaces of the magnesium nitride layer in the first direction is adjacent to the gallium nitride layer. At least one of the two side surfaces of the magnesium nitride layer is adjacent to the gallium nitride layer, so that more Ga atoms can be distributed around Mg atoms by virtue of the abovementioned setting, and the activation energy of the Mg acceptor can be greatly lowered, thereby improving the hole concentration ofa p type doped Al<X>Ga<1-X>N material.

Owner:XIAMEN CHANGELIGHT CO LTD

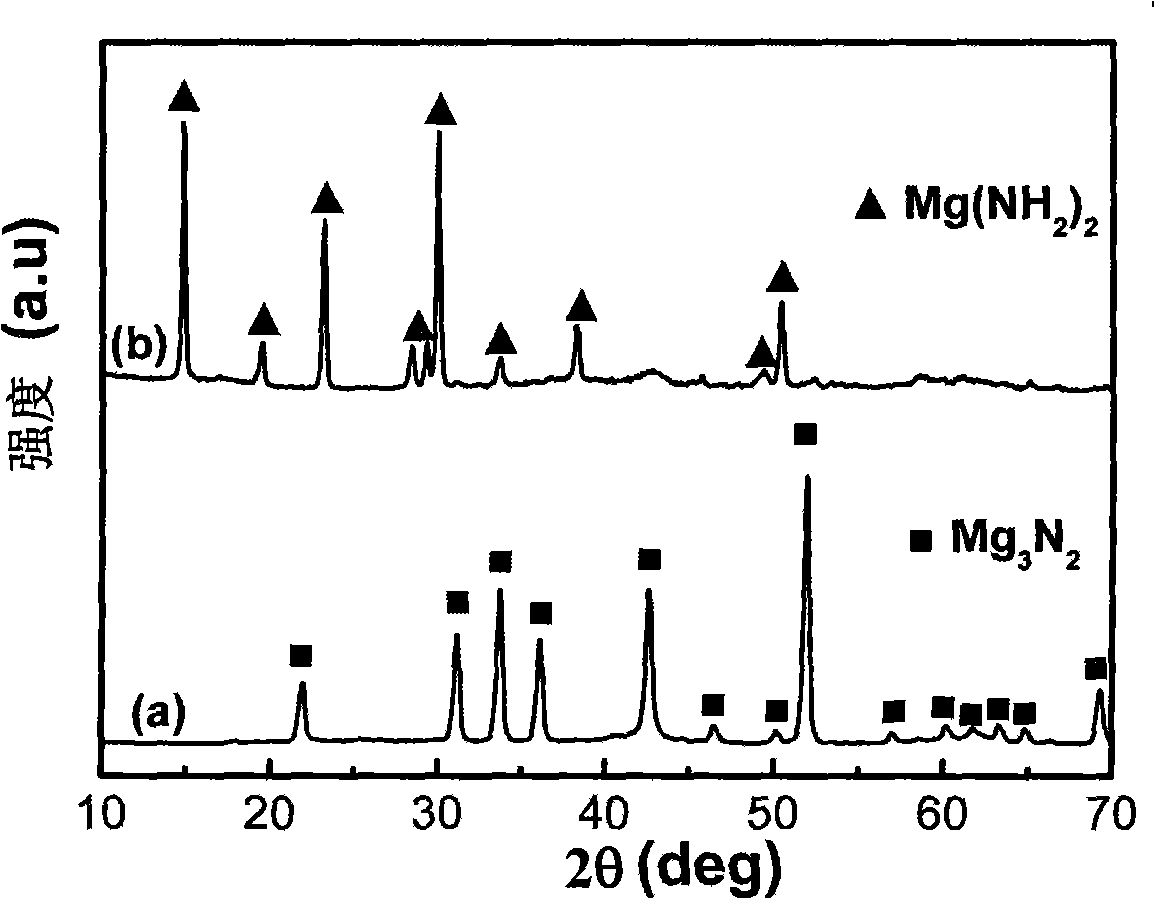

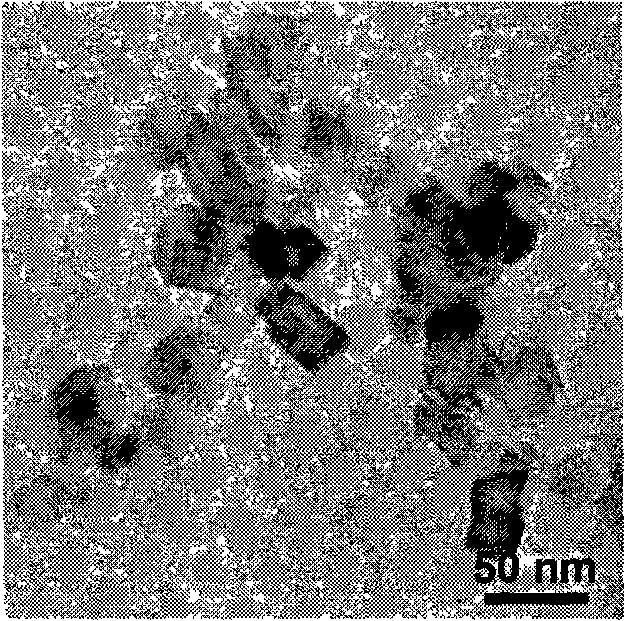

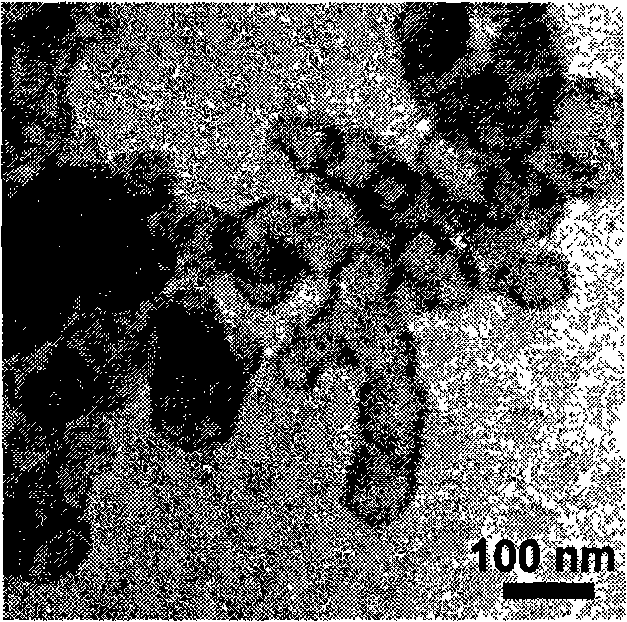

Magnesium amide nano-particle hydrogen storage material and preparation thereof

InactiveCN101279724AShorten the diffusion distanceHigh purityNitrogen compoundsNanoparticleHydrogen absorption

The invention discloses an amino magnesium nano-particle product which can be used as hydrogen storage materials and a preparation method thereof. Nano magnesium nitride is prepared by the method of arc heating and is aminated to obtain Mg (NH2)2 particle product with particle size which is 50-200nm. The nano Mg(NH2)2 particle of the method has high purity and has excellent hydrogen absorption and desorption kinetic properties when used as the hydrogen storage materials, and therefore has very significant application value and wide application prospect in the technical field of hydrogen storage.

Owner:PEKING UNIV

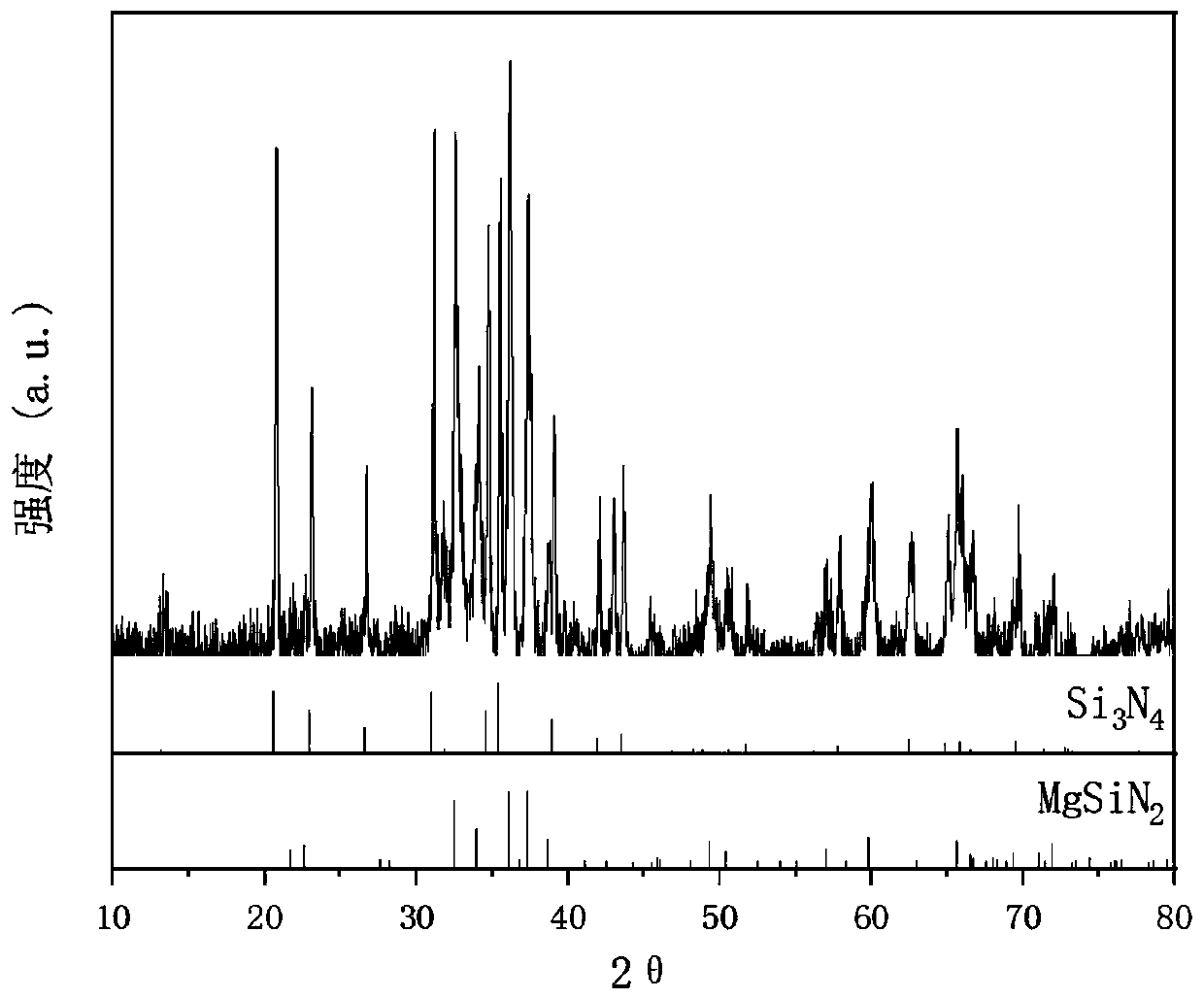

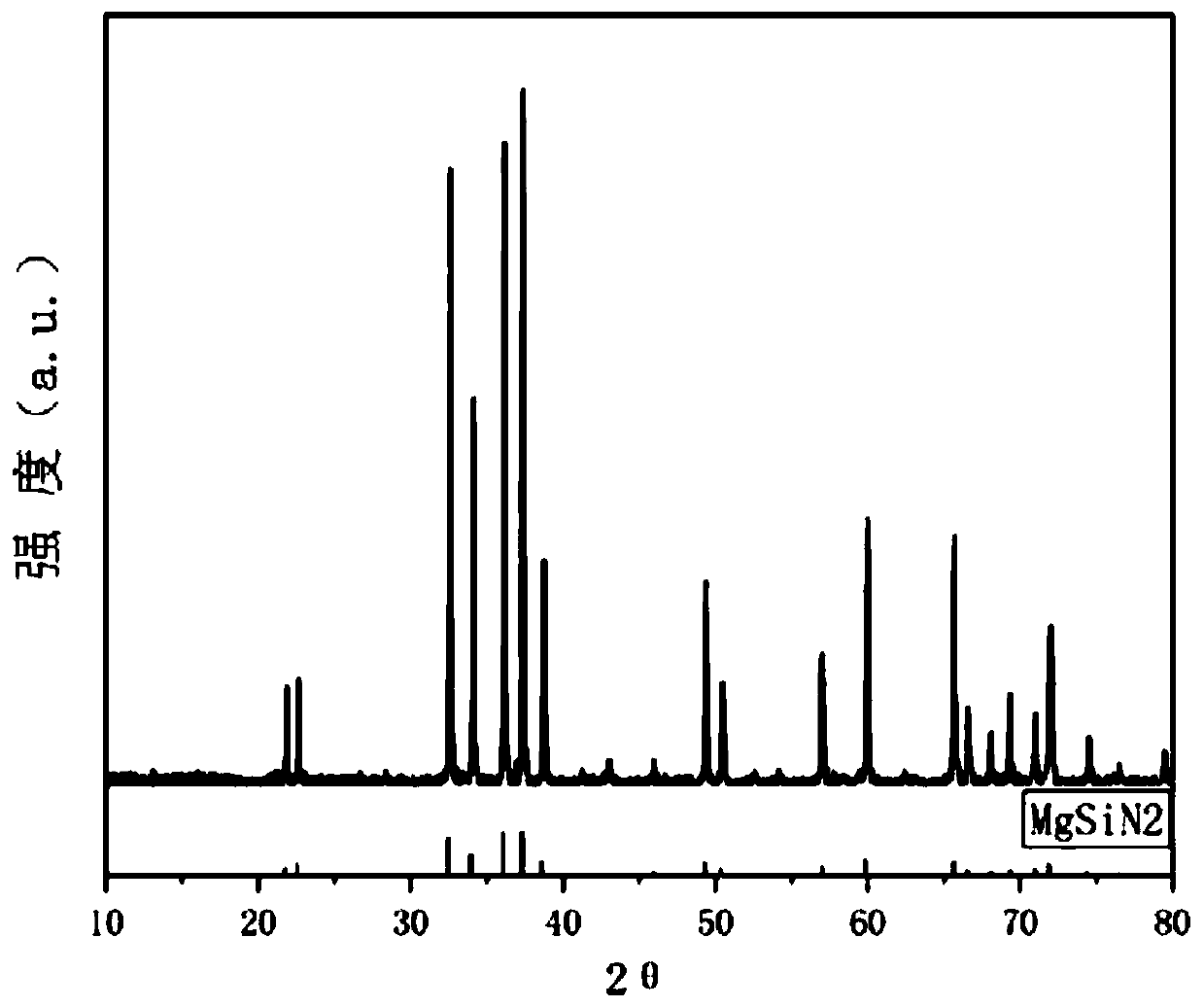

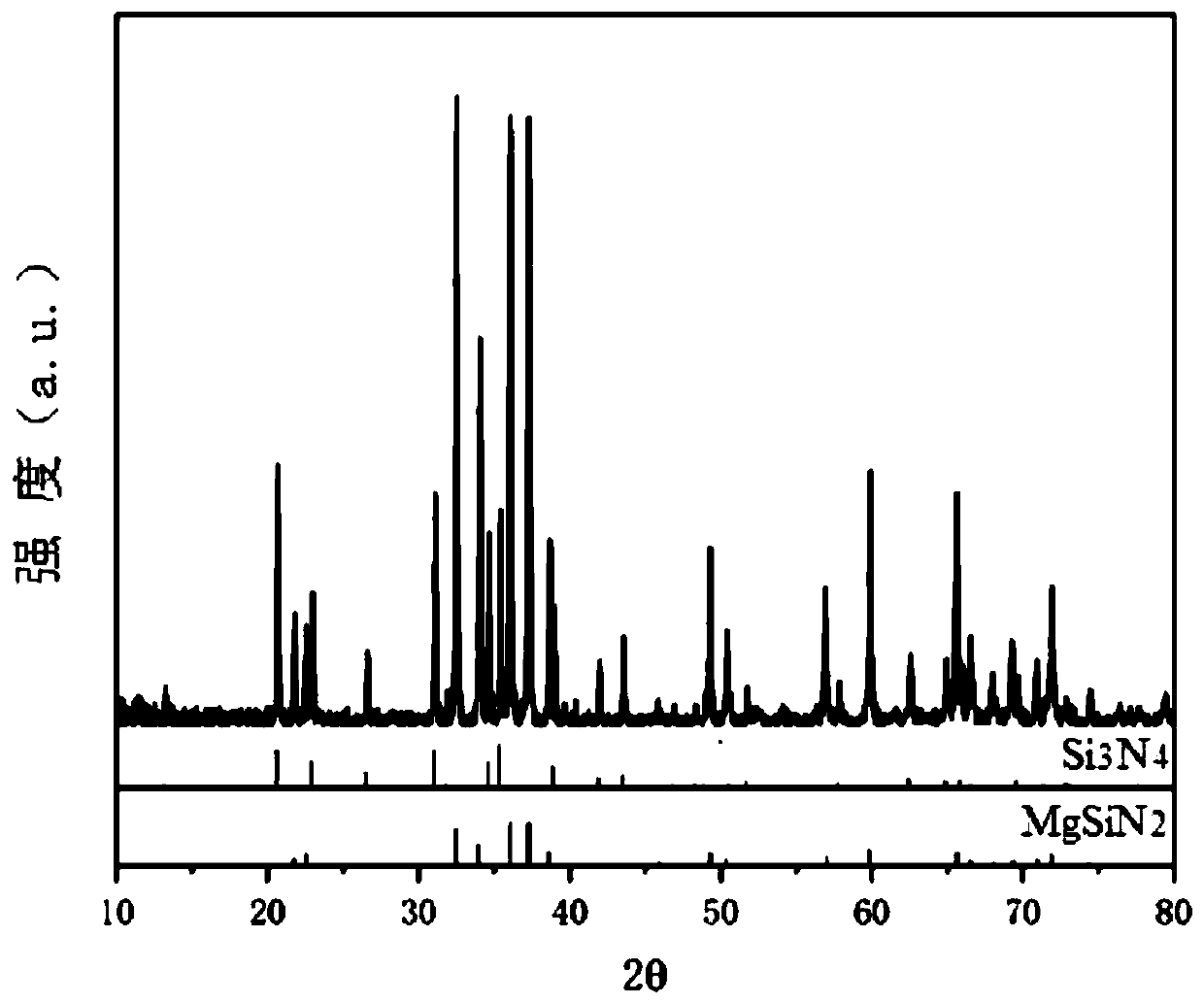

Preparation method of silicon nitride magnesium powder

InactiveCN109775674AIncrease productivitySynthetic reaction is rapidNitrogen and non-metal compoundsHigh energyAcid washing

The invention discloses a preparation method of silicon nitride magnesium powder, and belongs to the technical field of inorganic non-metal powder material preparation. A silicon source and a magnesium source are used as raw materials, urea and / or ethanol are used as additives, combustion synthesis reaction is carried out in a nitrogen atmosphere, and silicon nitride magnesium powder is prepared;the silicon source is one or two of silicon powder and alpha-silicon nitride powder; the magnesium source is one or two of magnesium powder and magnesium nitride powder. The preparation method of theinvention overcomes the problems of long production period, high energy consumption, easy occurrence of residual silicon in products and the like in the prior process for preparing the silicon nitridemagnesium by a direct nitridation method; the preparation method has the advantages of simple equipment, high production efficiency, rapid synthesis reaction and low energy consumption; the preparedsilicon nitride magnesium powder has good crystallinity, uniform morphology, controllable phase content, no other impurity phase, and high purity, and total impurity content is less than 1wt% and oxygen content is less than 1wt%; the subsequent steps of acid washing and purification and the like are not needed, and the product only needs to be crushed to the required particle size.

Owner:QINGDAO CUP NEW MATERIALS CO LTD

Lignin modified activated carbon adsorbent, and preparation method thereof

InactiveCN103566889AWell-developed poresImprove adsorption capacityOther chemical processesDesorptionPotassium

The invention discloses a lignin modified activated carbon adsorbent which is prepared from the following raw materials in parts by weight: 20-25 parts of rice husk, 20-25 parts of bamboo charcoal, 6-9 parts of potassium chloride, 2-3 parts of cerium oxide, 0.5-1 part of ammonium persulfate, 6-9 parts of powdered pumice, 8-10 parts of diatomite powder, 100-120 parts of activated carbon powder, 10-13 parts of attapulgite, 3-5 parts of magnesium nitride, 10-14 parts of lignin, 4-5 parts of modified diatomite and a suitable amount of water. By virtue of high-temperature carbonization of the rice husk, a thin pore structure can be easily formed, and activated carbon with more-developed pores and better adsorptive property can be prepared; by use of powdered pumice, the pores of the activated carbon can be increased; by use of the diatomite powder and attapulgite, antibacterial property, deodorization, moisture absorption, mould prevention as well as catalytic decomposition of organics can be realized; by use of the lignin, the cohesive force is improved, so the lignin modified activated carbon adsorbent is less in possibility of being disintegrated, and is safe and environment-friendly. The lignin modified activated carbon adsorbent disclosed by the invention is suitable for dust desorption.

Owner:BENGBU HUAFANG FILTER

Special heat dissipation electrostatic spraying coating for LED lamp

InactiveCN106675329AImprove brittle defectsImprove bending strengthPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyModified carbon

The invention discloses a special heat dissipation electrostatic spraying coating for an LED lamp. The heat dissipation electrostatic spraying coating is prepared from the following raw materials: epoxy resin, polyurethane, unsaturated polyester resin, maleic anhydride, methyl tetrahydrophthalic anhydride, m-phthalic anhydride, 2,4,6-tri(dimethylamine methyl) phenol, trimethylolpropane, 2-butyl-2-ethyl-1,3-propylene glycol, magnesium nitride, modified carbon nano tube, graphene, nano calcium carbonate, cerium oxide, silica powder, hexamethyl-disilazane, phenyltrimethoxysilane, phenyl methyl dimethoxysilane, dibutyltin dilaurate, a leveling agent and benzoin, wherein the epoxy resin is a mixture of biscyclopentadiene dioxide epoxy resin and o-cresol formaldehyde epoxy resin. The heat dissipation electrostatic spraying coating is high in heat dissipation property and high in high temperature resistance, and the service life of the LED lamp can be prolonged.

Owner:TIANCHANG JINLING ELECTRONICS

Reinforced active aluminum-based composite heat dissipation material for LED (light emitting diode)

ActiveCN104087794AExcellent decontaminationReduced moisture resistanceHeat-exchange elementsRare-earth elementSlag

The invention relates to a heat dissipation material for lamps, and in particular relates to a reinforced active aluminum-based composite heat dissipation material for an LED (light emitting diode) and a production method of the material. The heat dissipation material is prepared from the following raw materials in parts by weight: 83-85 parts of aluminum, 15-18 parts of aluminum nitride, 4-5 parts of magnesium nitride, 8-10 parts of zirconia, 4-6 parts of magnesium oxide, 1-3 parts of straw powder, 1-2 parts of tourmaline powder, 0.1-0.2 part of monazite slag, 0.5-1 part of natrolite and 4-5 parts of aids. The heat dissipation material disclosed by the invention integrates the advantages of aluminum, aluminum nitride, zirconia and the like, has good heat conduction and heat dissipation capabilities; the tourmaline powder is an active matter and can endow the material with good detergency, electromagnetic radiation reducing capability and moisture resistance, the monazite slag contains multiple rare earth elements and can effectively improve the heat dissipation performance of the material and can improve the sintering effect and the compactness of the material together with the aids. The material has good mechanical properties, is simple in use and maintenance and durable and can be used for effectively protecting an LED lamp and greatly prolonging the service life of the lamp.

Owner:YANYANG LAMP SET TIANCHANG CITY

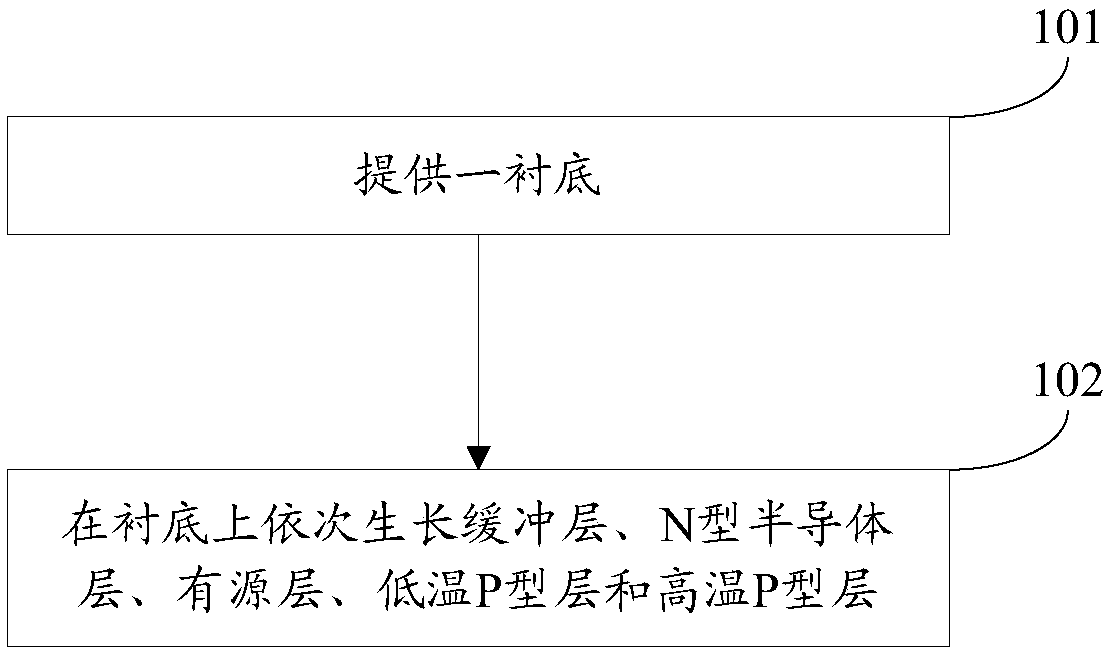

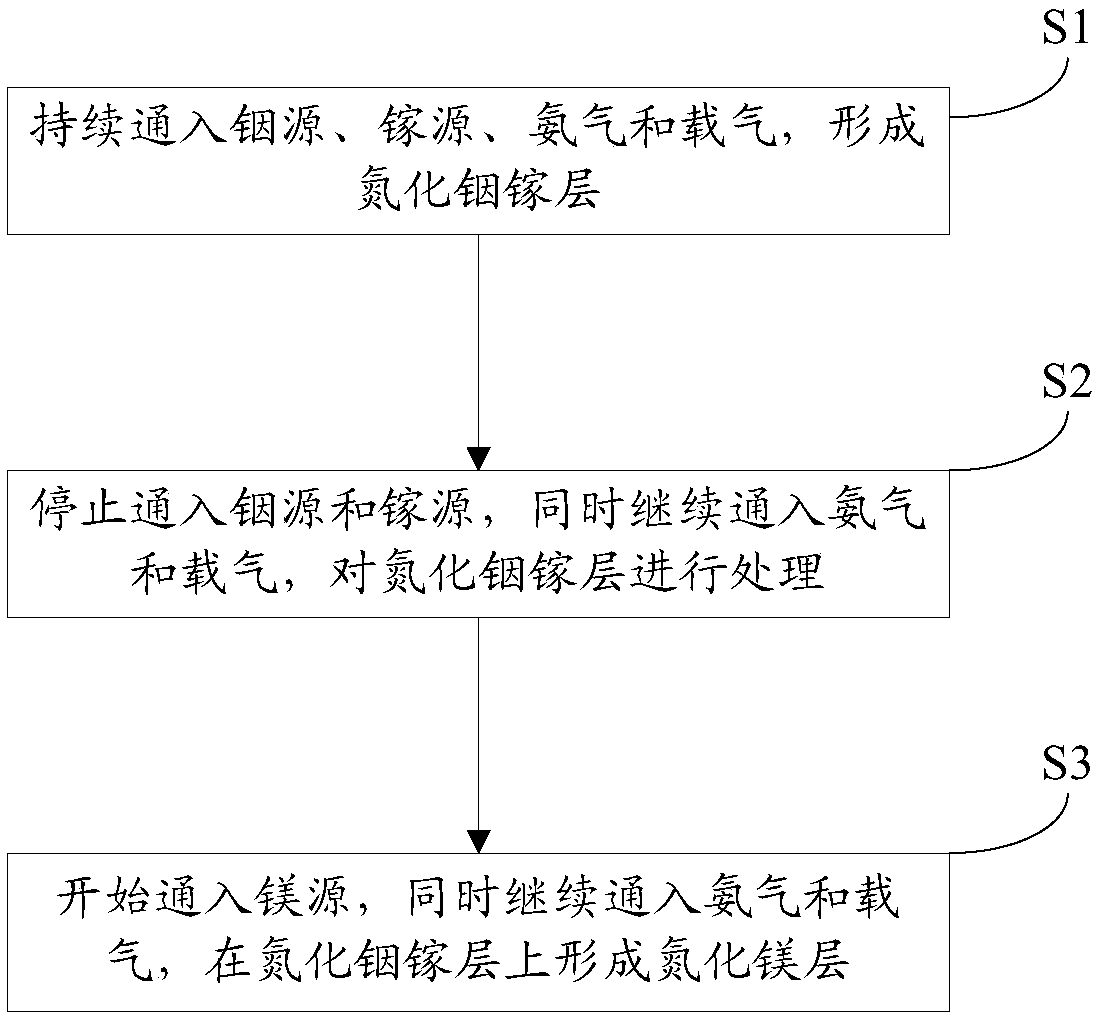

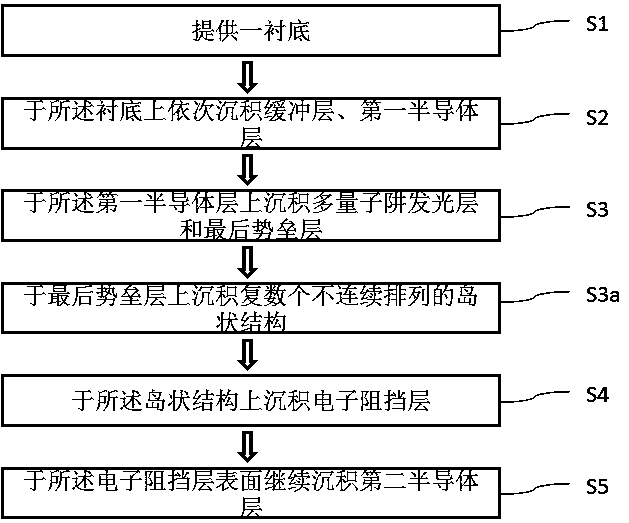

A preparation method of a light emitting diode epitaxial wafer and a light emitting diode epitaxial wafer

ActiveCN109103303AReduce merge efficiencyReduce incorporationNanotechnologySemiconductor devicesIndiumActive layer

The invention discloses a preparation method of a light emitting diode epitaxial wafer and a light emitting diode epitaxial wafer, belonging to the field of semiconductor technology. The preparation method comprises the following steps of: providing a substrate; sequentially growing a buffer layer, an N-type semiconductor layer, an active layer, a low-temperature P-type layer and a high-temperature P-type layer on the substrate, wherein the growth temperature of the low-temperature P-type layer is lower than the growth temperature of the high-temperature P-type layer, at least one of the low-temperature P-type layer and the high-temperature P-type layer is a superlattice structure, ,the superlattice structure comprises a plurality of sub-layers stacked in sequence, and each of the sub-layers is formed by continuously passing an indium source, a gallium source, an ammonia gas and a carrier gas to form an indium gallium nitride layer; stopping the injection of the indium source and the gallium source, and simultaneously continuing to inject the ammonia gas and the carrier gas, and processing the indium gallium nitride layer; injecting a magnesium source while ammonia and a carrier gas are continuously injected to form a magnesium nitride layer on the indium gallium nitride layer. The invention can improve the concentration of holes in the superlattice structure.

Owner:HC SEMITEK ZHEJIANG CO LTD

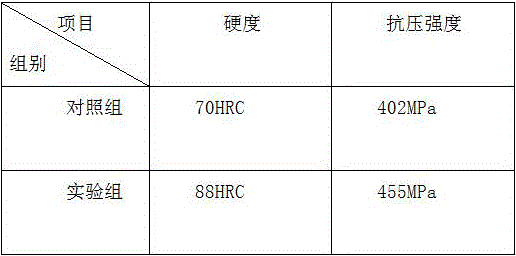

Niobium and tungsten alloy and preparation method thereof

The invention discloses a niobium and tungsten alloy. The niobium and tungsten alloy comprises the raw materials including, by weight, 100-102 parts of niobium, 14-16 parts of tungsten carbide powder, 5-7 parts of zirconium, 1-3 parts of tin, 1-3 parts of iridium, 5-7 parts of hafnium carbide, 1-3 parts of titanium carbide, 2-4 parts of tantalum carbide, 2-4 parts of ytterbium oxide, 1-3 parts of sintered aluminum, 1-3 parts of aluminum nitride, 1-3 parts of magnesium nitride, 1-3 parts of silicon dioxide, 1-3 parts of yttrium oxide and 2-4 parts of boron carbide. The niobium and tungsten alloy is high and good in strength.

Owner:林海英

Efficient heat-radiating powder coating

InactiveCN104293000AImprove cooling effectExtended service lifePowdery paintsCarbide siliconPower efficient

The invention discloses an efficient heat-radiating powder coating comprising the following components in parts by weight: 40-90 parts of polypropylene, 2-40 parts of carbon nano-tubes, 0.5-2 parts of additives, 0-4.5 parts of hexagonal boron nitride, 0-15 parts of aluminum nitride, 0-10 parts of magnesium nitride, 0-10 parts of silicon carbide and 5-30 parts of pigment and filler. The efficient heat-radiating powder coating is good in heat radiating effect, high in efficiency increasing rate (more than 60%), high in cooling effect (more than 20 DEG C) and capable of effectively solving the problem of poor heat radiating effect of a high-power electronic product and prolonging the service life of the electronic product.

Owner:QINGDAO JINGYIXIN ELECTRONICS TECH

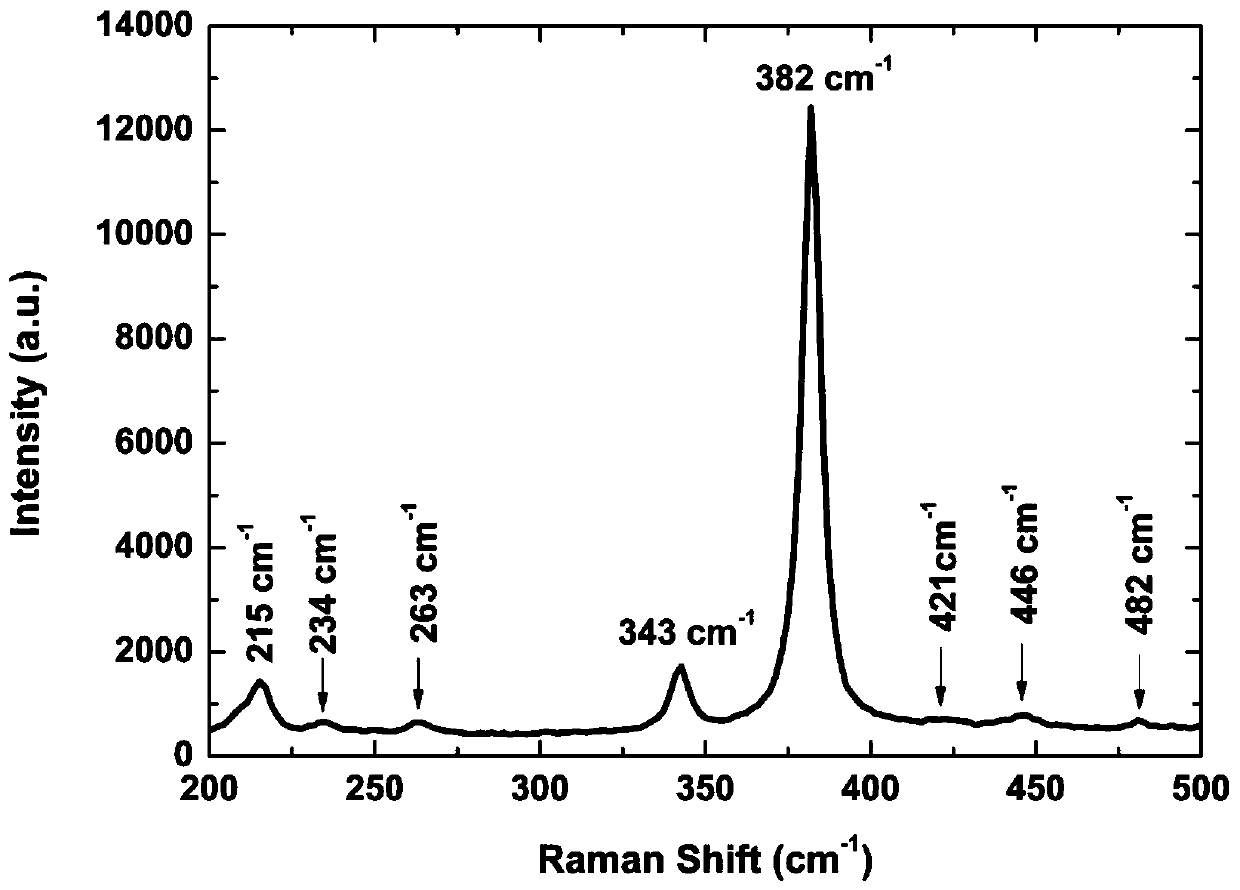

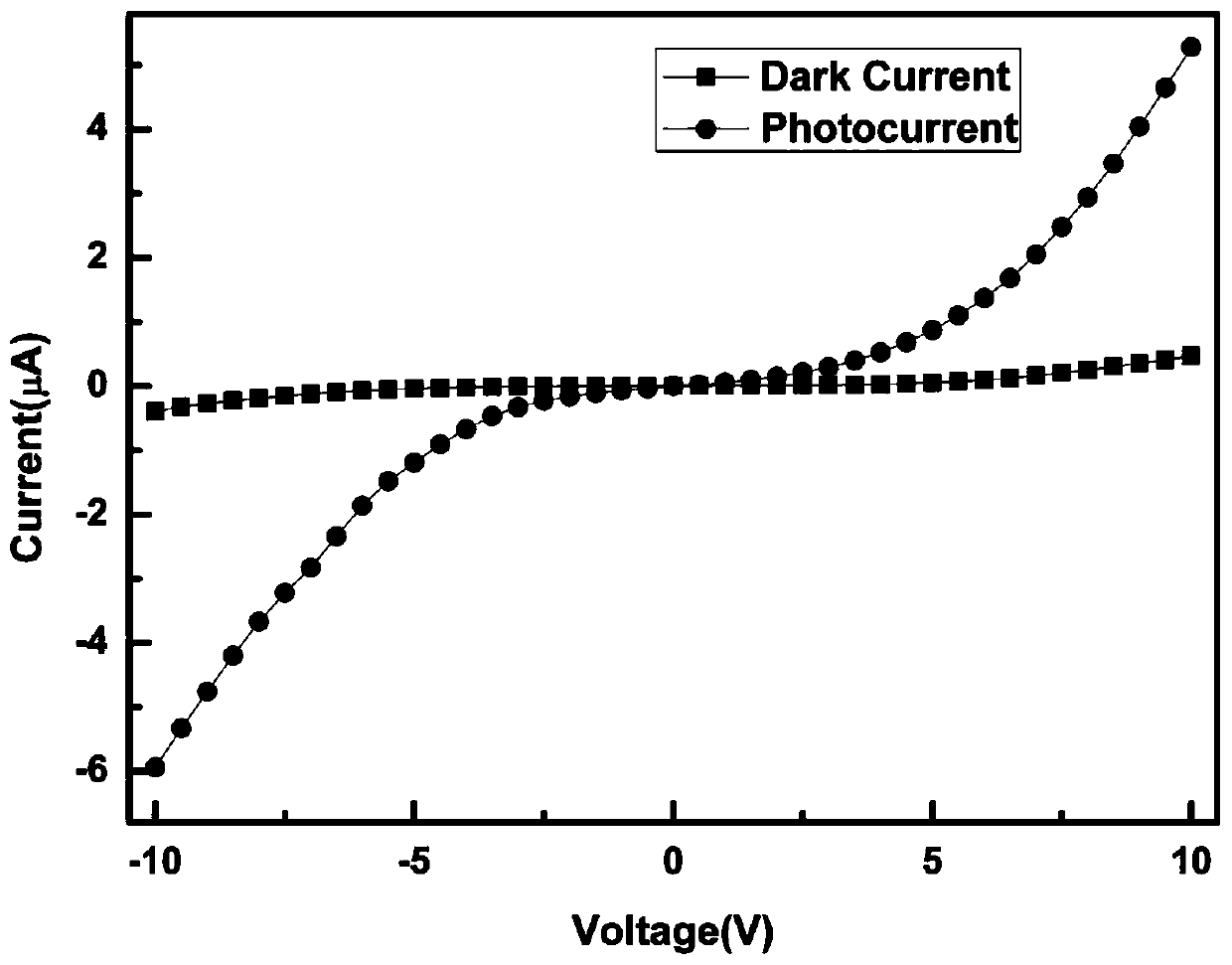

Photoelectric detector based on magnesium nitride film and preparation method thereof

ActiveCN111106202AAvoid hydrolysisIncrease exposure areaFinal product manufactureVacuum evaporation coatingSputteringMetallic electrode

The invention discloses a photoelectric detector based on a magnesium nitride film and a preparation method thereof, which belongs to the field of semiconductor photoelectric detectors. The preparation method comprises the steps of firstly, growing a layer of transition metal electrode on a substrate by adopting a magnetron sputtering or evaporation technology; using a wet etching technology or adry etching technology to prepare an interdigital electrode structure ; then growing an Mg3N2 thin film on the substrate with the prepared interdigital electrode structure by adopting a reaction radiofrequency magnetron sputtering method; and finally growing a BN or AlN thin film as an Mg3N2 protective layer on the Mg3N2 thin film in an in-situ sputtering manner, so as to obtain the photoelectricdetection device based on the Mg3N2 thin film. According to the invention, the application of Mg3N2 in the field of photoelectric functional materials and devices is expanded; the BN or AlN thin filmnot only effectively inhibits hydrolysis of the Mg3N2 thin film and improves the stability of the Mg3N2 thin film, but also is transparent in infrared, visible light and most ultraviolet bands, and is an ideal optical window of the Mg3N2 photoelectric device.

Owner:JILIN UNIV

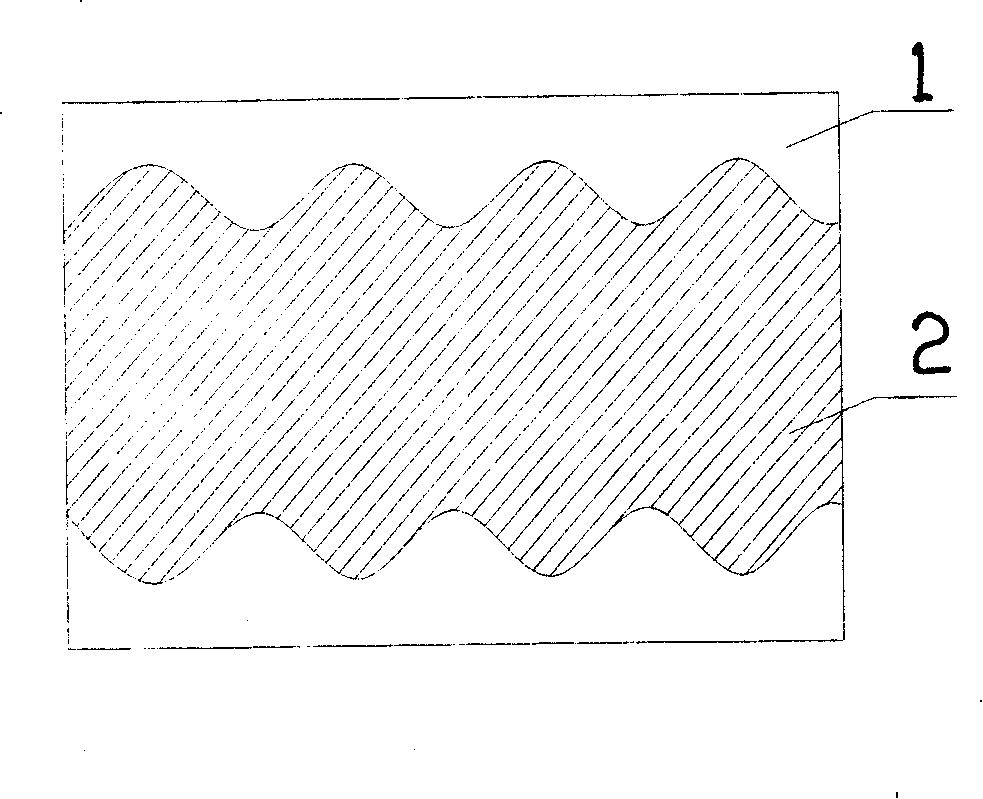

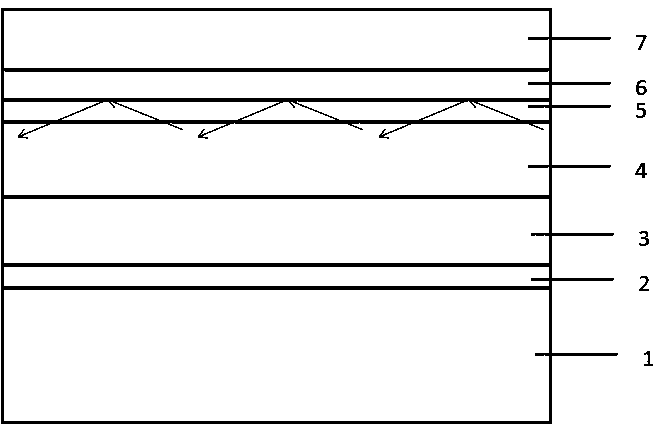

Ultra-hard composite sheet with hard alloy interlayer

InactiveCN101168313AImprove flexural strengthImprove impact toughnessMetal layered productsCemented carbideTungsten

The invention discloses a super-hard composite sheet with rigid alloy sandwich, which comprises a dual-face super-hard layer and a rigid alloy sandwich, wherein the super-hard layer is composed of artificial diamond or cubic boron nitride, and conjugation agent. The conjugation agent is at least one of aluminium nitride, titanium nitride, molybdenum nitride, nitride magnesium, nitride zirconium, nitride chromium, nitride tungsten, aluminum oxide, cobalt, molybdenum, titanium, iron, aluminum, nickel, copper, tungsten, and chromium. The surface of the rigid alloy sandwich is concave-convex one, which is combined with the super-hard layer via the concave-convex contact faces. The invention uses the concave-convex engaged sandwich structure to improve the bending strength and impact flexibility of the super-hard composite sheet, reduce the consumption of consumption of super-hard material powder, and reduce production cost, thereby expanding the application range of the super-hard composite sheet.

Owner:FUNIK ULTRAHARD MATERIAL

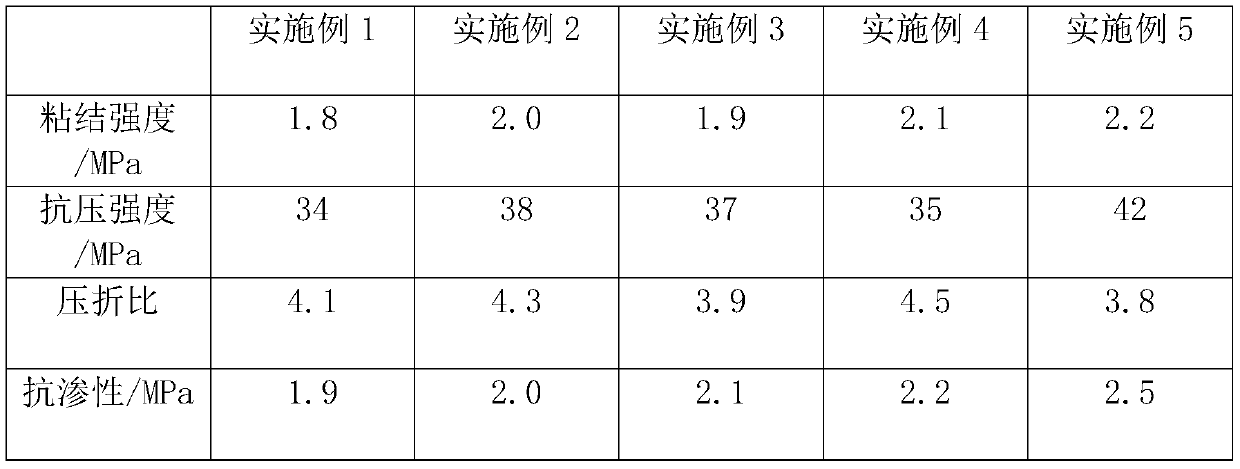

Cementitious capillary crystalline waterproofing coating, preparation method and using method thereof

The invention discloses a cementitious capillary crystalline waterproof coating, a preparation method and a using method thereof. The coating comprises the following components in parts by weight: 45-50 parts of 42.5 ordinary Portland cement, 45-50 parts of 70-120 mesh quartz sand, 1.5-2 parts of a dispersible latex powder, 2-2.5 parts of capillary crystalline masterbatch, 0.1-0.2 part of hydroxypropyl methylcellulose, and 0.2-0.3 part of an organosilicone antifoaming agent, wherein the capillary crystalline masterbatch comprises the following raw materials in percent by weight: 30-55% of barium oxide, 10-15% of magnesium nitride, 5-10% of chromium sulfate dodecahydrate, 5-10% of copper sulfate, 15-20% of magnesium sulfate, and 10-15% of maleic acid-acrylic acid copolymer sodium salt. Thewaterproof coating is applied to the surface of a concrete structure, and capillary crystallization is carried out with water, so that impermeability of the concrete is improved; dormancy is carried out without water, and thereby the coating has secondary impermeability; cracks of 0.4 mm or less on the concrete surface can be repaired; the coating is high temperature resistant and freeze-thaw resistant; a coating layer is solid, and subsequent engineering construction without an additional protective layer can be directly performed on the coating layer; and the coating is non-toxic and environment-friendly, and has air-permeability.

Owner:ANHUI LENCAQI BUILDING MATERIAL

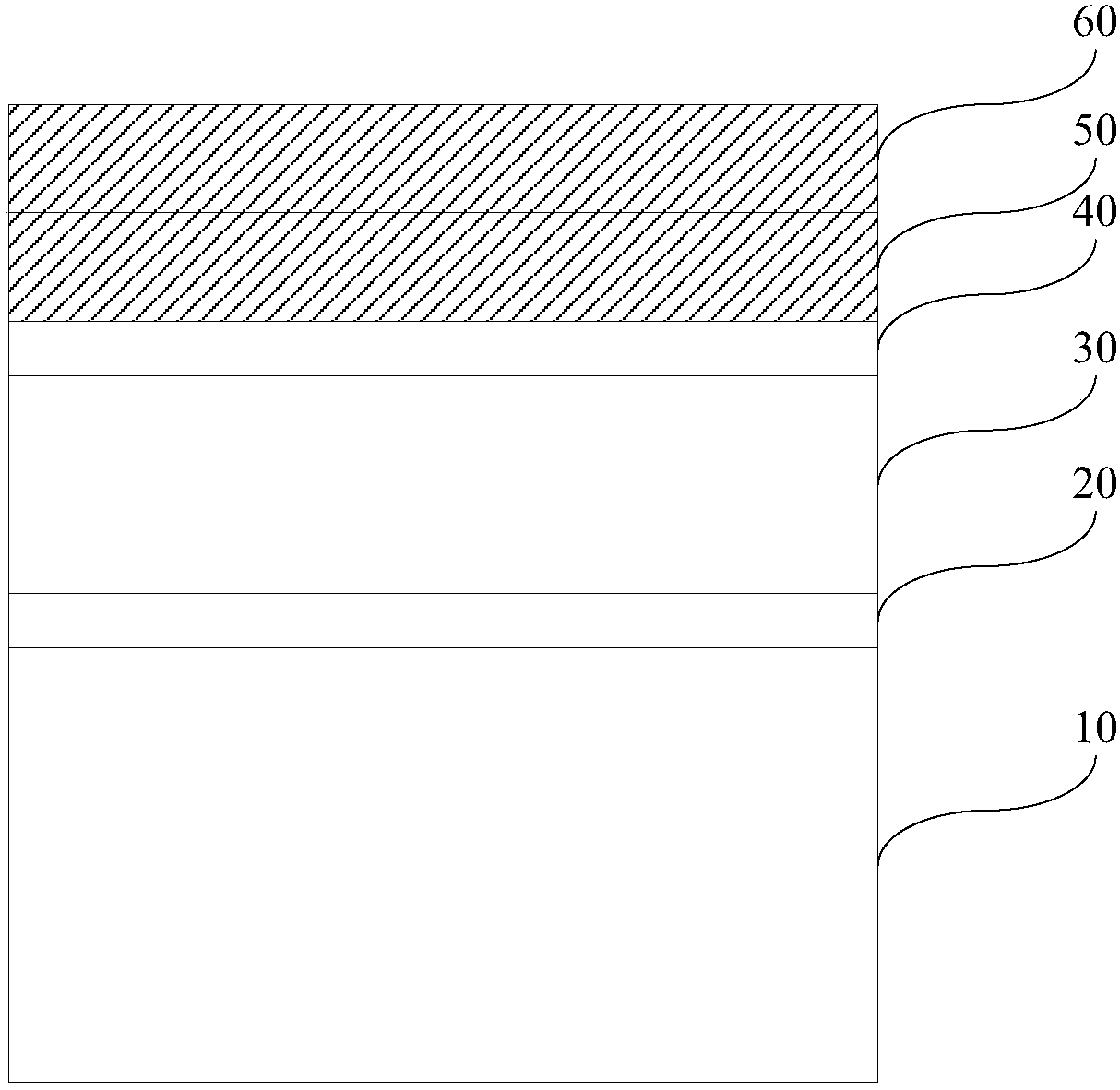

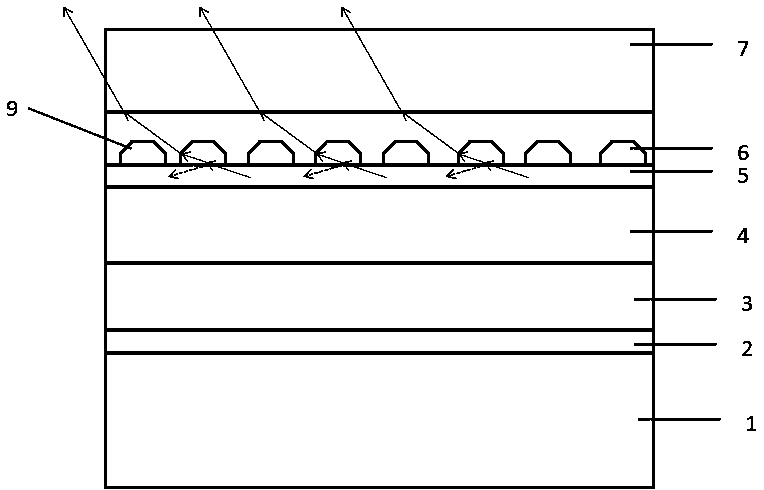

LED epitaxial structure and preparation method thereof

ActiveCN107768494AReduce reflectionImprove light extraction efficiencySemiconductor devicesQuantum wellNucleation

The invention belongs to the technical field of semiconductors, and particularly relates to an LED epitaxial structure and a preparation method thereof. In the invention, a plurality of magnesium nitride compound nucleation structures are inserted between an electron blocking layer and the last barrier layer; by taking the nucleation structures as the core, a plurality of island structures are grown to reduce the total reflection of light at the interface between the electron blocking layer and the last barrier layer, so that the light emitted from a multi-quantum well light emitting layer enters the electron blocking layer more and the light emitting efficiency of the LED epitaxial structure is further improved; and the island structures are filled through the electron blocking layer, andthen the LED epitaxial structure with a flat surface is obtained.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

Method for realizing gallium nitride p-type doping based on Mg ion implantation and high-temperature annealing process

PendingCN111613527AP-type doping uniformEvenly dopedSemiconductor/solid-state device manufacturingGalliumGallium nitride

The invention discloses a method for realizing gallium nitride p-type doping based on Mg ion implantation and a high-temperature annealing process. The method comprises the steps of performing Mg ionimplantation and high-temperature annealing on a GaN material; adopting the Mg ion implantation and high-temperature annealing processes compatible with a silicon process, and combining the application of a gallium nitride surface protective layer, protecting the surface of gallium nitride from being decomposed while Mg acceptor impurities are activated at high temperature and gallium nitride crystal lattices are repaired, so that the p-type doping of gallium nitride is realized. The first protective layer introduced in the ion implantation process is a multi-layer composite media composed ofone or more of aluminum nitride, aluminum gallium nitrogen, magnesium nitride, magnesium oxide and silicon nitride, and the deposition mode is at least one of metal organic compound chemical vapor deposition, low-pressure chemical vapor deposition, plasma enhanced chemical vapor deposition or atomic layer deposition.

Owner:NANJING UNIV

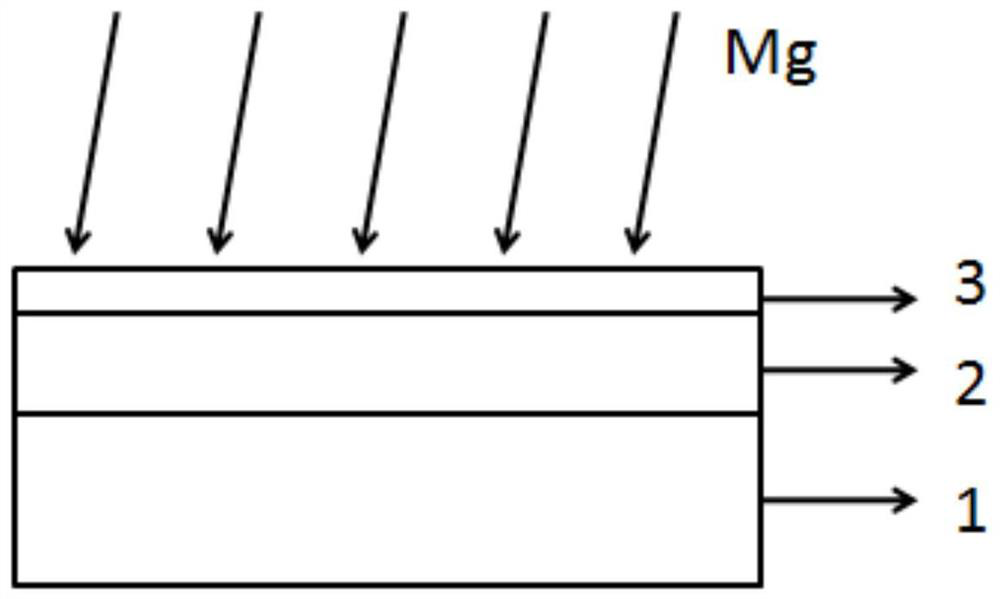

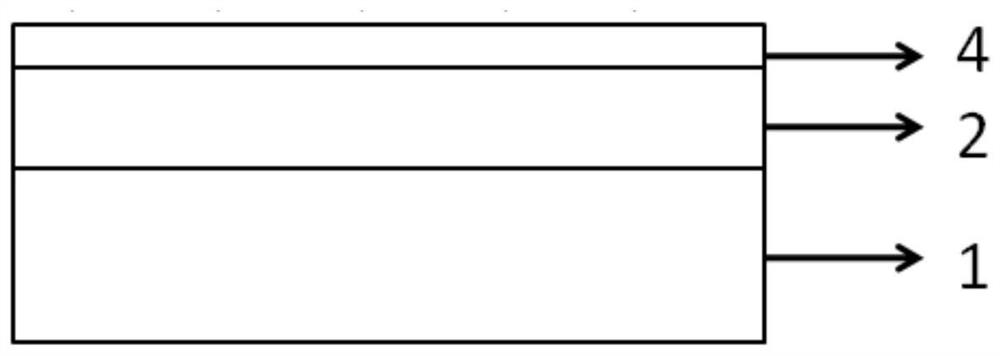

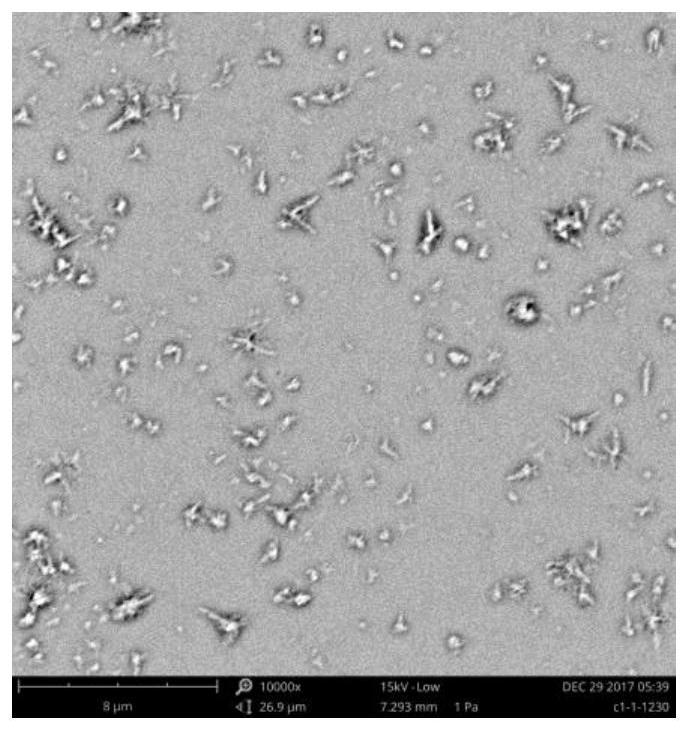

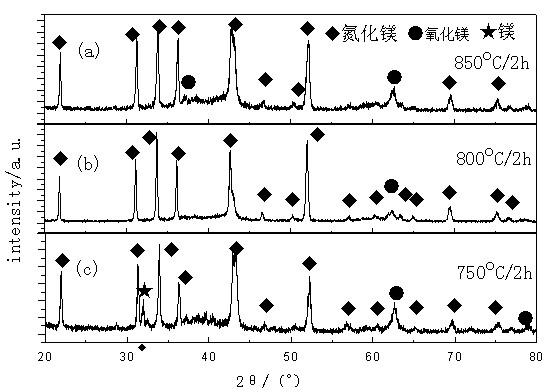

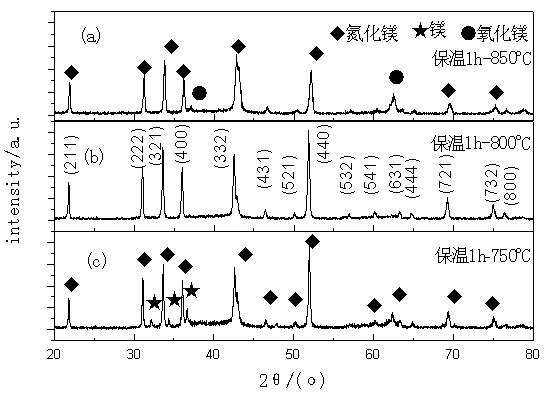

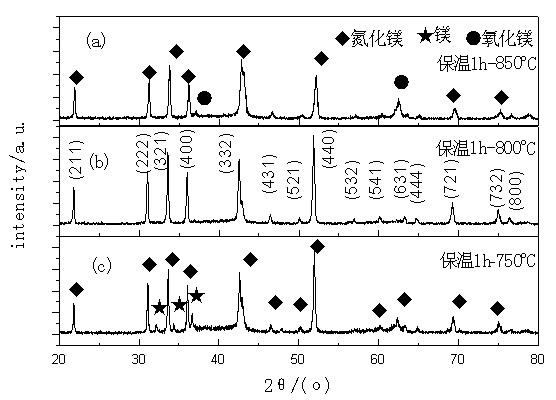

Process for preparing magnesium nitride through airflow method

InactiveCN102241393ASimple and fast operationGuaranteed purityNitrogen-metal/silicon/boron binary compoundsTube furnaceNitrogen

The invention relates to a process for preparing magnesium nitride through an airflow method. The process comprises the following steps: placing Mg powder into a ceramic boat; sending the ceramic boat to a tube furnace; sealing the tube furnace; introducing ammonia gas for 10 to 15 min for displacing air in the tube furnace to avoid an influence of air on test results; keeping a temperature for 40 to 80 min in ammonia gas atmosphere when the temperature of a tube thermostatic furnace achieves 600 to 610 DEG C; ammonifying for 50 to 70 min through opening an ammonia gas valve with an ammonia gas flow of 400 to 600 ml / min when the temperature of the tube thermostatic furnace gradually achieves three specific values of 750 DEG C, 800 DEG C, and 850 DEG C; and carrying out natural cooling on the ceramic boat in the tube furnace after nitridation. The process of the present invention allows any additive not to be needed, operation to be simple, product purity to be guaranteed, synthesis efficiency to be high, a case that the process is more economical and has a higher production efficiency than processes adopting nitrogen to be realized, technology to be easily control, and low nitridation temperature, less energy consumption, short production period, and uniformity of product particles to be realized.

Owner:NANCHANG UNIV

High-nitrogen composite ceramic sprue cap for casting aluminum alloy

ActiveCN103331420AA large proportionHigh strengthFoundry mouldsFoundry coresComposite ceramicSilicon oxide

The invention relates to a high-nitrogen composite ceramic sprue cap for casting aluminum alloy. The sprue cap is made from silicon nitride, aluminium nitride, titanium dioxide, silicon dioxide and magnesium nitride through pre-forming and sintering. The silicon nitride, the aluminium nitride, the titanium dioxide, the silicon dioxide and the magnesium nitride are taken as raw materials, so that the nitride proportion in the manufactured ceramic sprue cap is large, and the sprue cap has excellent strength, toughness, high temperature resistance, corrosion resistance and non-sticky aluminum performance. The high-nitrogen composite ceramic sprue cap is suitable for casting of aluminum alloy.

Owner:LIAONING YIFEI TECH

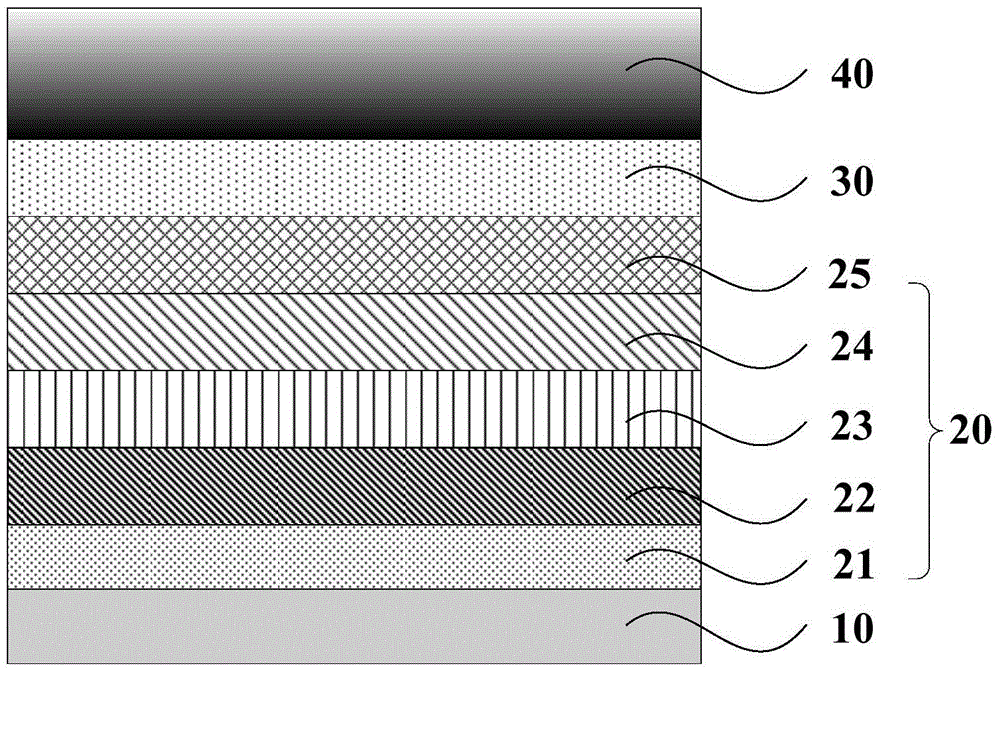

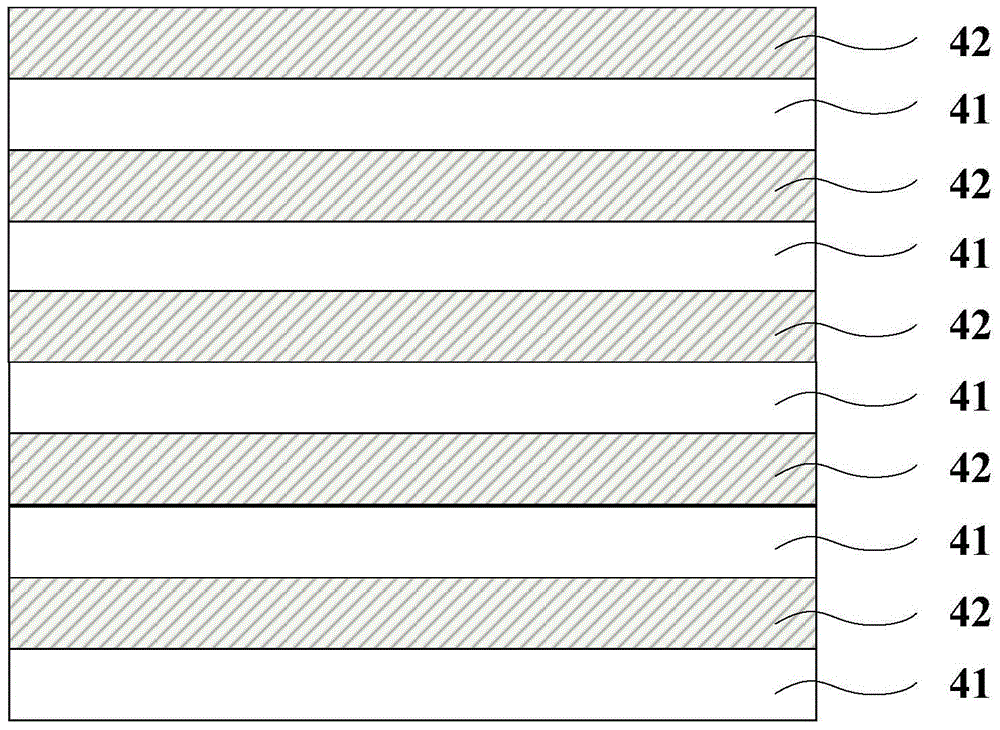

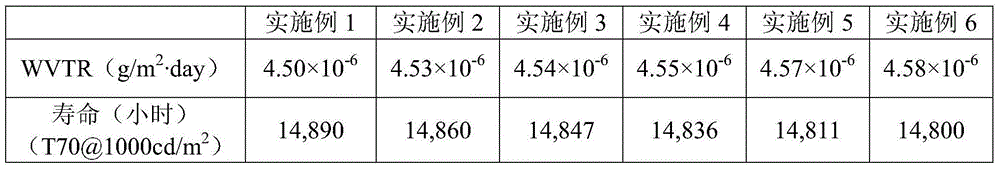

Organic electroluminescent device and preparation method thereof

InactiveCN104882560AReduce erosionExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingAlkaline earth metalWater vapor

The invention provides an organic electroluminescent device which comprises an anode conductive substrate, an organic light emitting functional layer, a cathode layer and a packaging layer; wherein the anode conductive substrate, the organic light emitting functional layer, the cathode layer and the packaging layer are successively laminated. The packaging layer comprises an organic barrier layer and inorganic barrier layer which are successively laminated. The organic barrier layer is made of a Hydrogenated carbon nitrogen compound. The inorganic barrier layer is made of an alkaline earth metal nitride. The alkaline earth metal nitride is beryllium nitride, magnesium nitride, calcium nitride, strontium nitride or barium nitride. The packaging layer of the organic electroluminescent device has high obstruction for oxygen and water vapor and furthermore has a high stress releasing function. After packaging, the lowest water vapor transmission rate of the organic electroluminescent device after packaging is only 4.50*10<-6>g / m<2>*day, and the service life is more than 14800 hours (T70@1000cd / m<2>. The invention further provides a preparation method for the organic electroluminescent device. The preparation method is particularly suitable for packaging a flexible organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

High-heat conductivity temperature-resistant aluminum-based composite radiating material for LED (Light-Emitting Diode)

The invention relates to a lamp radiating material, and particularly relates to a high-heat conductivity temperature-resistant aluminum-based composite radiating material for an LED (Light-Emitting Diode) and a production method thereof. The radiating material is prepared from the following raw materials in parts by weight: 63-65 parts of aluminum, 15-18 parts of iron, 4-5 parts of magnesium nitride, 5-8 parts of vanadium diboride, 1-2 parts of zirconium diboride, 4-5 parts of ferrochrome slag, 8-10 parts of parts of gold ore tailings, 1-3 parts of propanetriol, 1-2 parts of triethanolamine, 0.5-0.8 part of boric acid, 12-14 parts of organic chelated titanium and 4-5 parts of auxiliary agents. The radiating material disclosed by the invention integrates the advantages of components, namely the aluminum, the iron, the vanadium diboride, the gold ore tailings and the like, has good heat-conducting property and insulating property and can be used for enhancing the resource utilization ratio by removing impurities contained in the gold ore tailings and the ferrochrome slag by carrying out soaking treatment on the gold ore tailings and the ferrochrome slag by utilizing a dilute boric acid solution; the radiating material prepared through the production method disclosed by the invention has the advantages of ideal sintering effect, smoothness and compactness of a material surface, stability in temperature change, durability and excellent heat-conduction coefficient and can be used for effectively protecting the LED lamp and greatly prolonging the service life of the lamp.

Owner:YANYANG LAMP SET TIANCHANG CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com