Patents

Literature

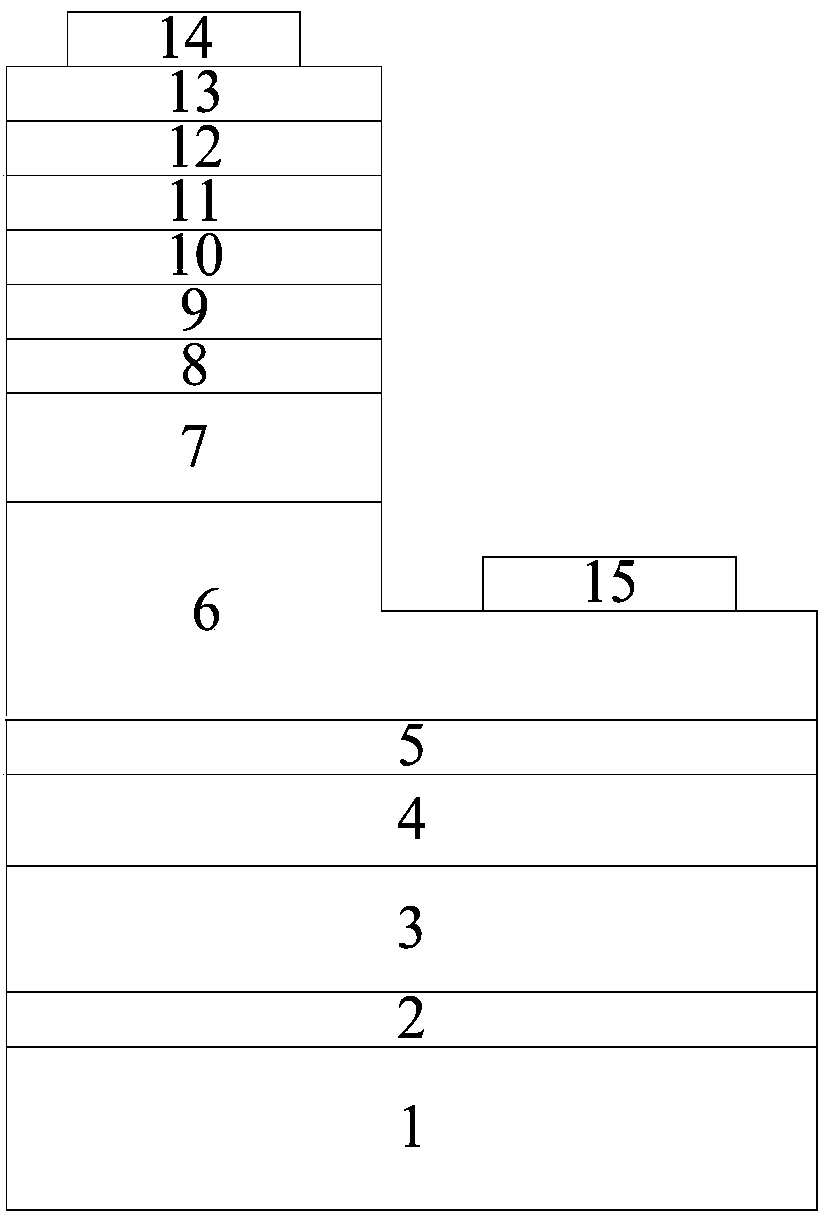

313results about How to "Increase hole concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and structure for manufacture of light emitting diode devices using bulk GaN

ActiveUS8252662B1Minimize re-absorptionThickness minimizationSemiconductor/solid-state device manufacturingSemiconductor devicesCrystalline materialsGallium nitride

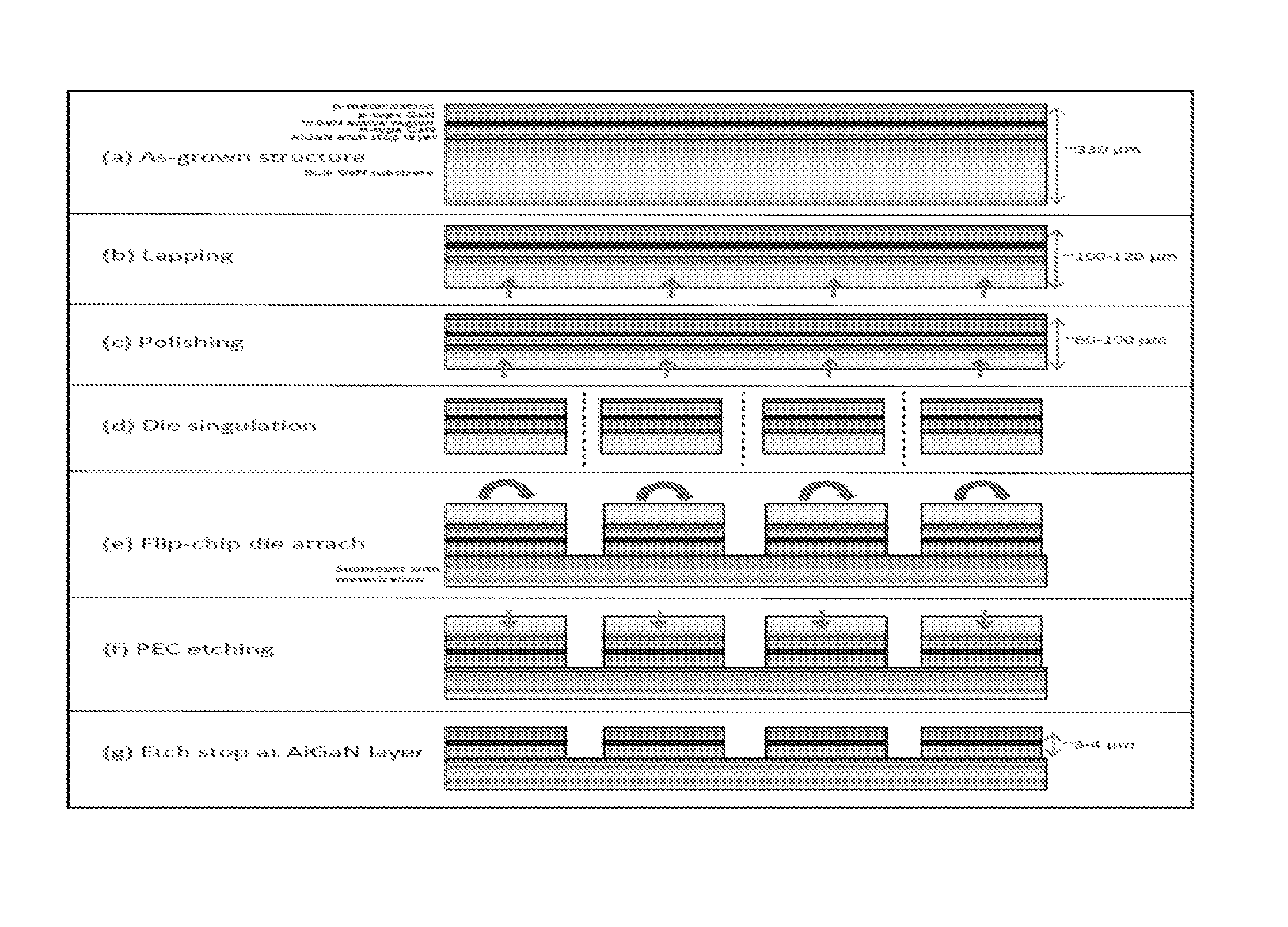

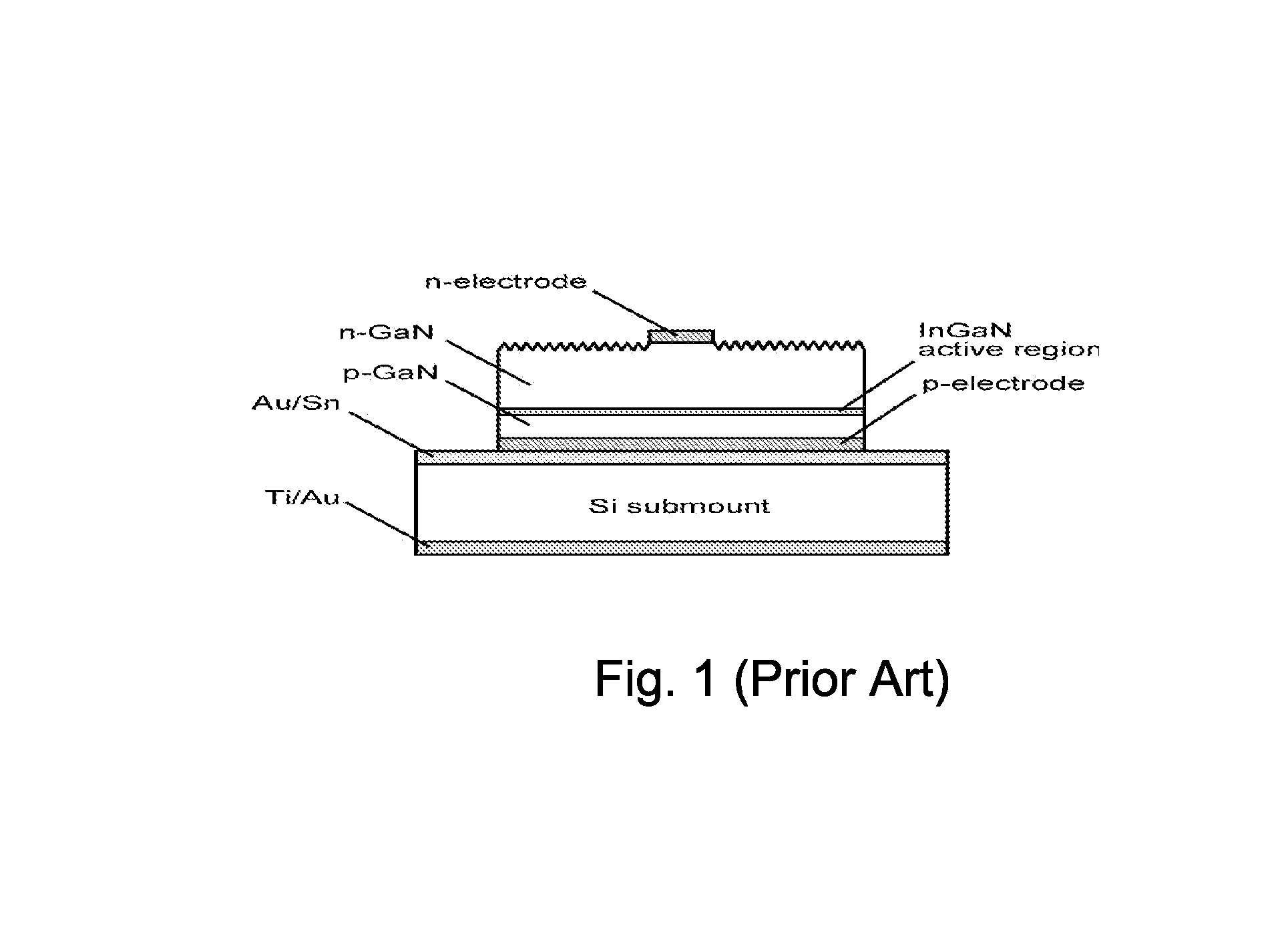

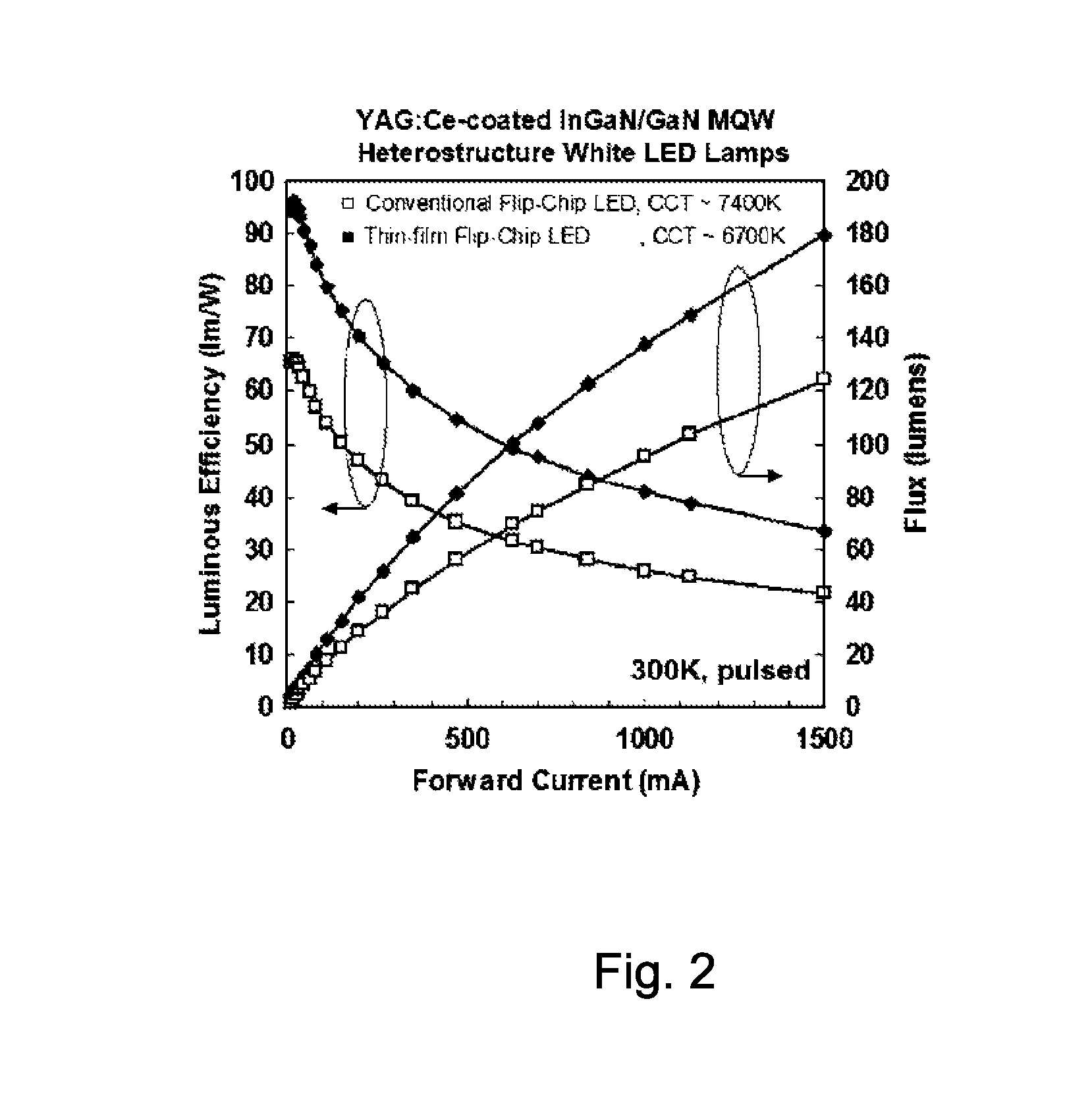

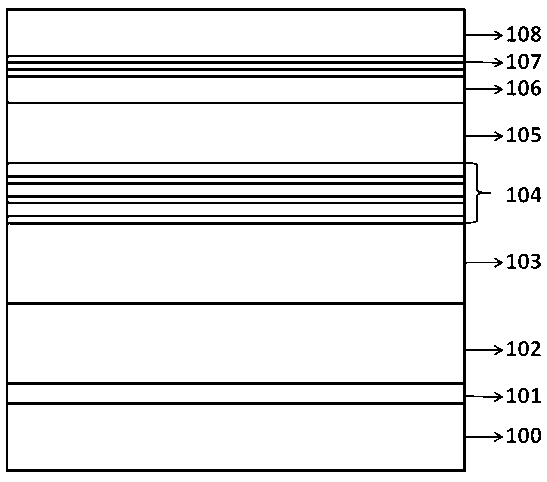

A method for manufacturing a plurality light emitting diodes includes providing a gallium nitride containing bulk crystalline substrate material configured in a non-polar or semi-polar crystallographic orientation, forming an etch stop layer, forming an n-type layer overlying the etch stop layer, forming an active region, a p-type layer, and forming a metallization. The method includes removing a thickness of material from the backside of the bulk gallium nitride containing substrate material. A plurality of individual LED devices are formed from at least a sandwich structure comprising portions of the metallization layer, the p-type layer, active layer, and the n-type layer. The LED devices are joined to a carrier structure. The method also includes subjecting the gallium nitride containing bulk crystalline substrate material to at least one etching process to selectively remove crystalline material underlying the etch stop layer, wherein the etch stop layer is exposed, and the etch stop layer remains substantially intact.

Owner:SLT TECH

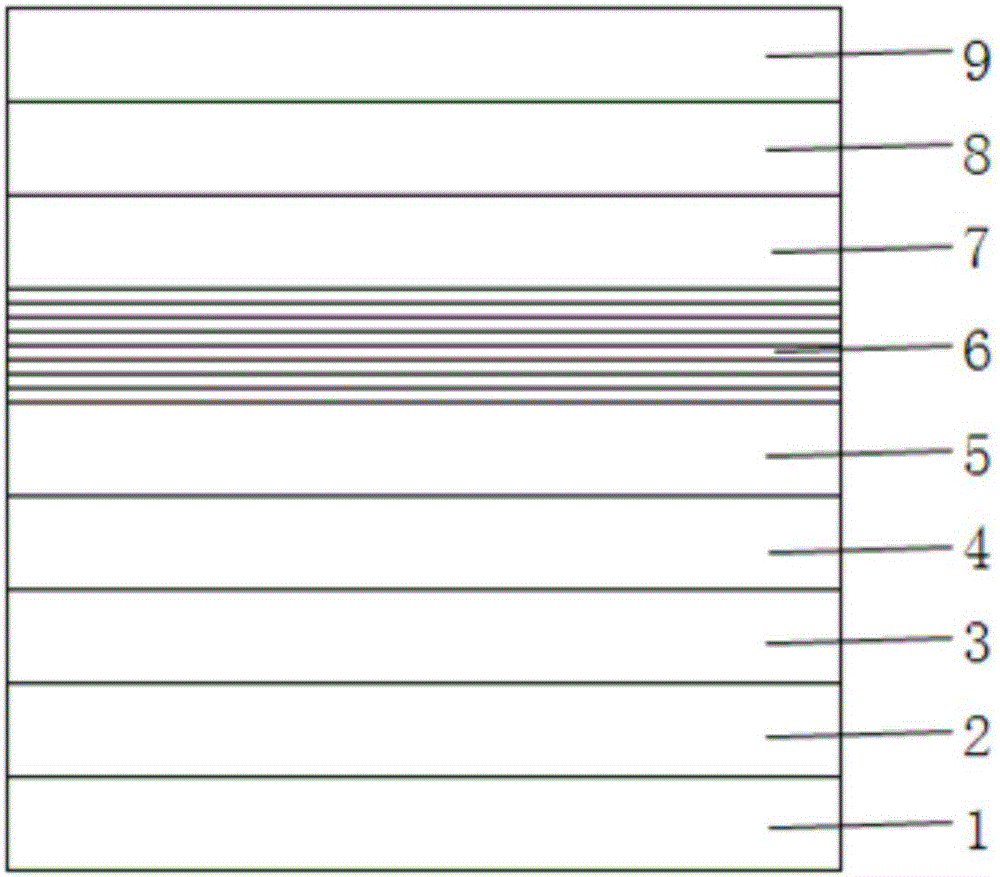

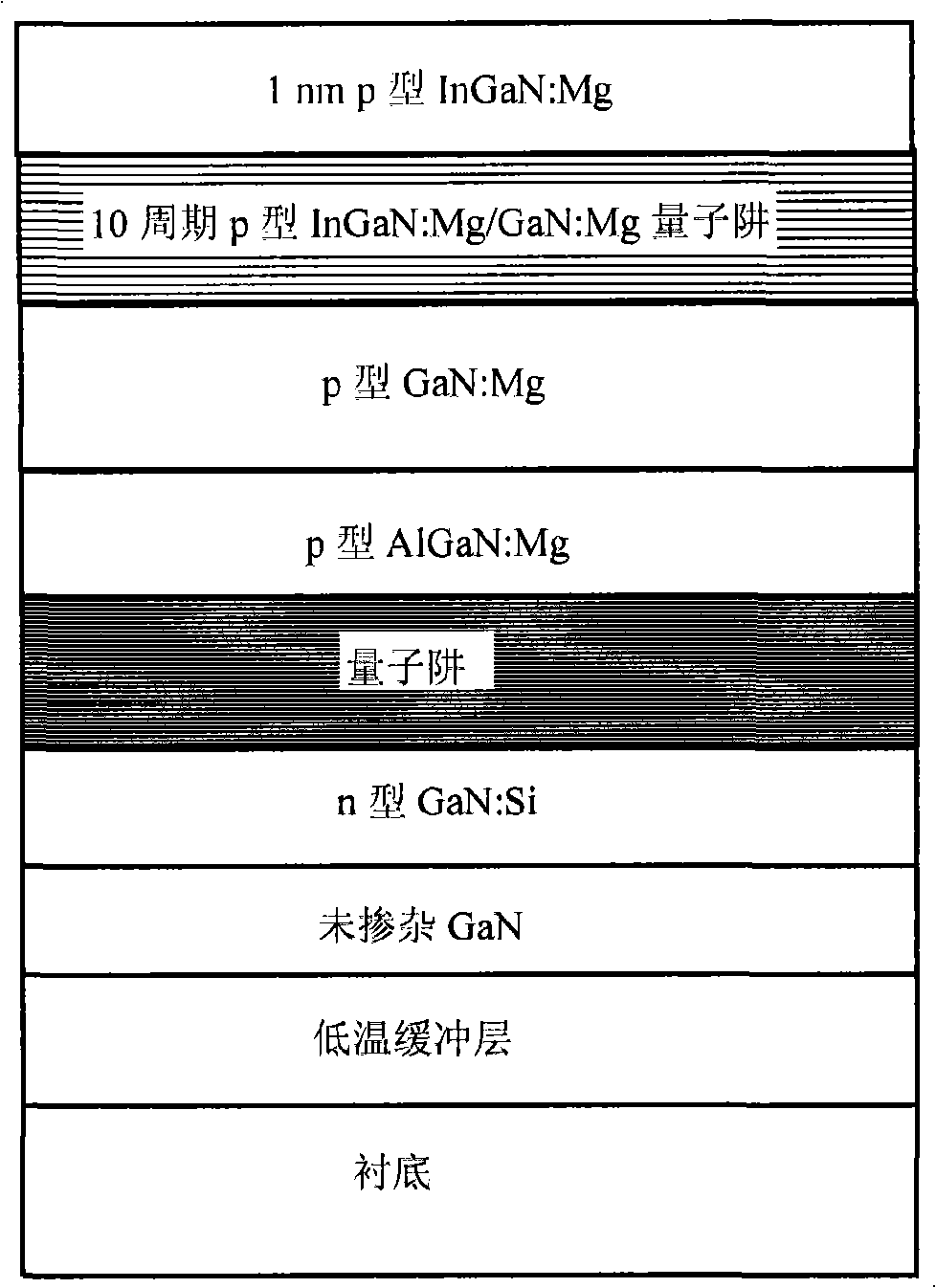

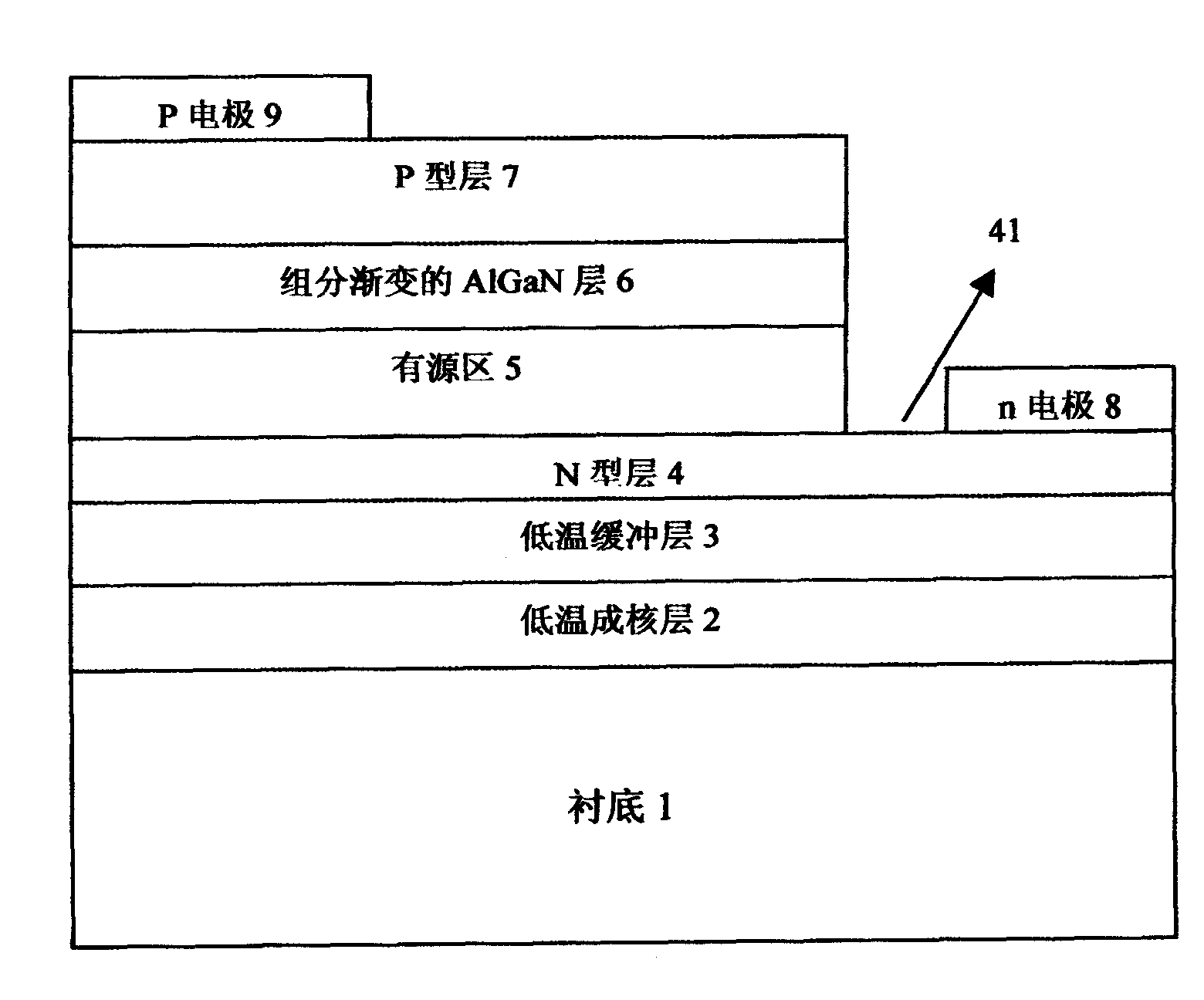

Nitride light-emitting diode (LED) epitaxial wafer and growing method thereof

InactiveCN102969416AStress reliefReduced polarizing electric fieldSemiconductor devicesPower flowHole injection layer

The invention provides a nitride light-emitting diode (LED) epitaxial wafer and a growing method thereof and relates to the technical field of semiconductor optoelectronics. The nitride LED epitaxial wafer structurally and sequentially comprises a substrate, a low-temperature buffer layer, an unintentionally doped GaN, an N-shaped electron-injection layer, an InGaN / GaN inserting layer, an active area, an electron blocking layer, a u-GaN / p-GaN superlattice and a p-GaN hole-injection layer from bottom to top. The InGaN / GaN inserting layer is grown between the N-shaped electron-injection layer and the active area so as to effective relieve stress of the active area, lower polarization electric fields, reduce limitation of stark effect through a quantum well, and improve luminance and anti-static properties. The u-GaN / p-GaN superlattice is inserted between the electron blocking layer and the P-shaped hole-injection layer so as to improve current expansion capacity and lower chip operating voltage.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

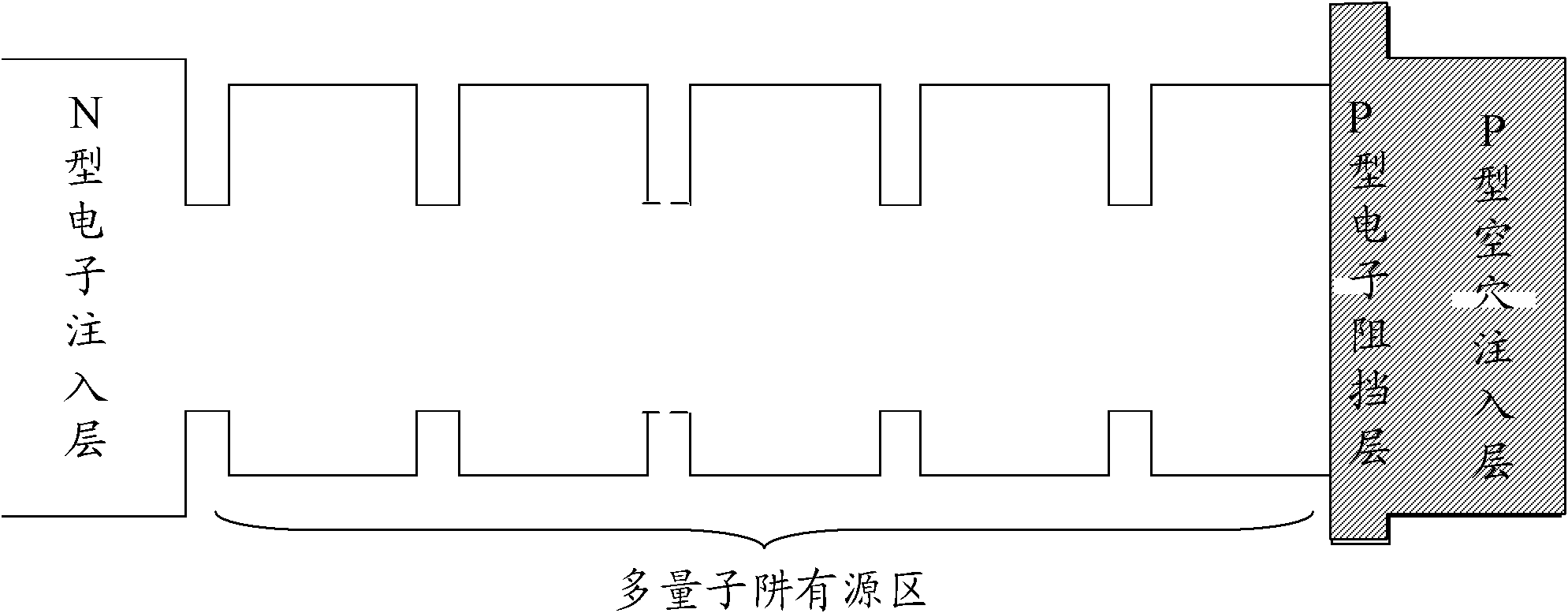

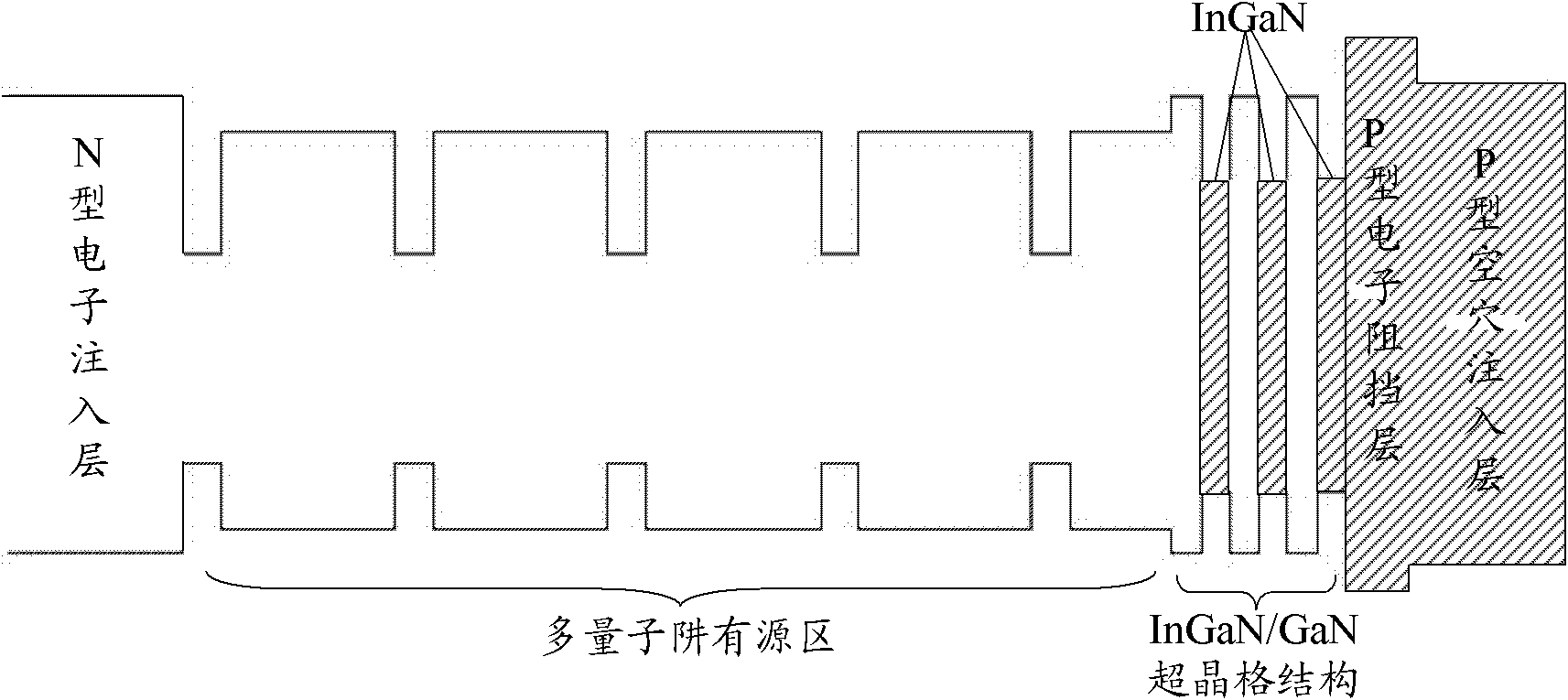

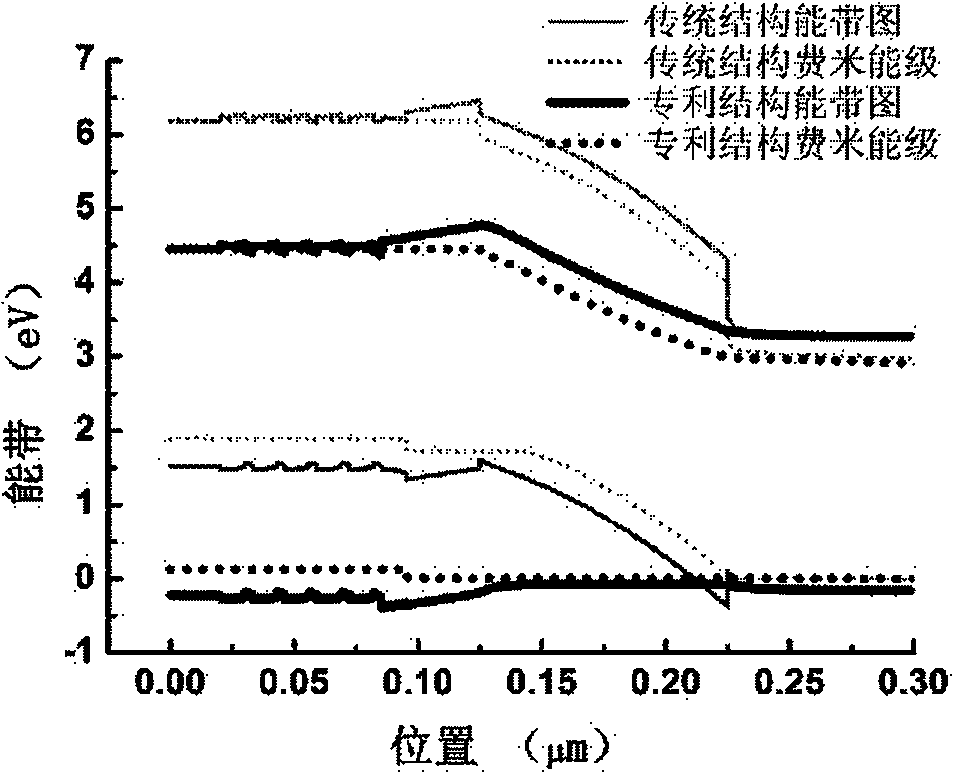

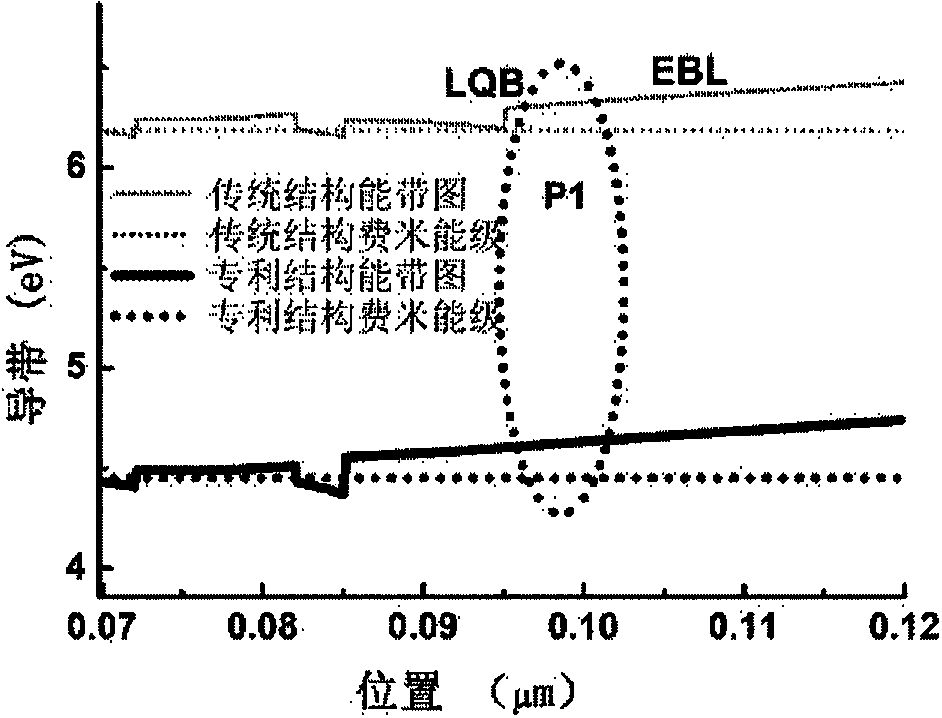

Nitride LED (light-emitting diode) structure and nitride LED structure preparing method

InactiveCN102185057AIncrease hole concentrationImprove internal quantum efficiencySemiconductor devicesPotential wellQuantum efficiency

The invention discloses a nitride LED (light-emitting diode) structure. A P-type doped InGaN / GaN superlattice structure is inserted between a multiple quantum well active layer and an electronic barrier layer so as to improve the hole concentration and reduce the dosage concentration of the P-type hole injection layer; the superlattice structure has polarization effect, thus being capable of improving the doping efficiency and reducing the P-type impurity concentration; and impurity atoms are prevented from being diffused to the potential well, and the inner quantum efficiency and the luminous efficiency of the device can be improved. The invention also discloses a preparation method of the nitride LED structure, through inserting the P-type doped InGaN / GaN superlattice structure between the multiple quantum well active layer and the electronic barrier layer, the hole concentration can be improved, and the dosage concentration of the P-type hole injection layer can be reduced; since the superlattice structure has polarization effect, the doping efficiency can be improved and the P-type impurity concentration can be reduced; and the impurity atoms are prevented from being diffused to the potential well, and the inner quantum efficiency and the luminous efficiency of the device can be improved.

Owner:ENRAYTEK OPTOELECTRONICS

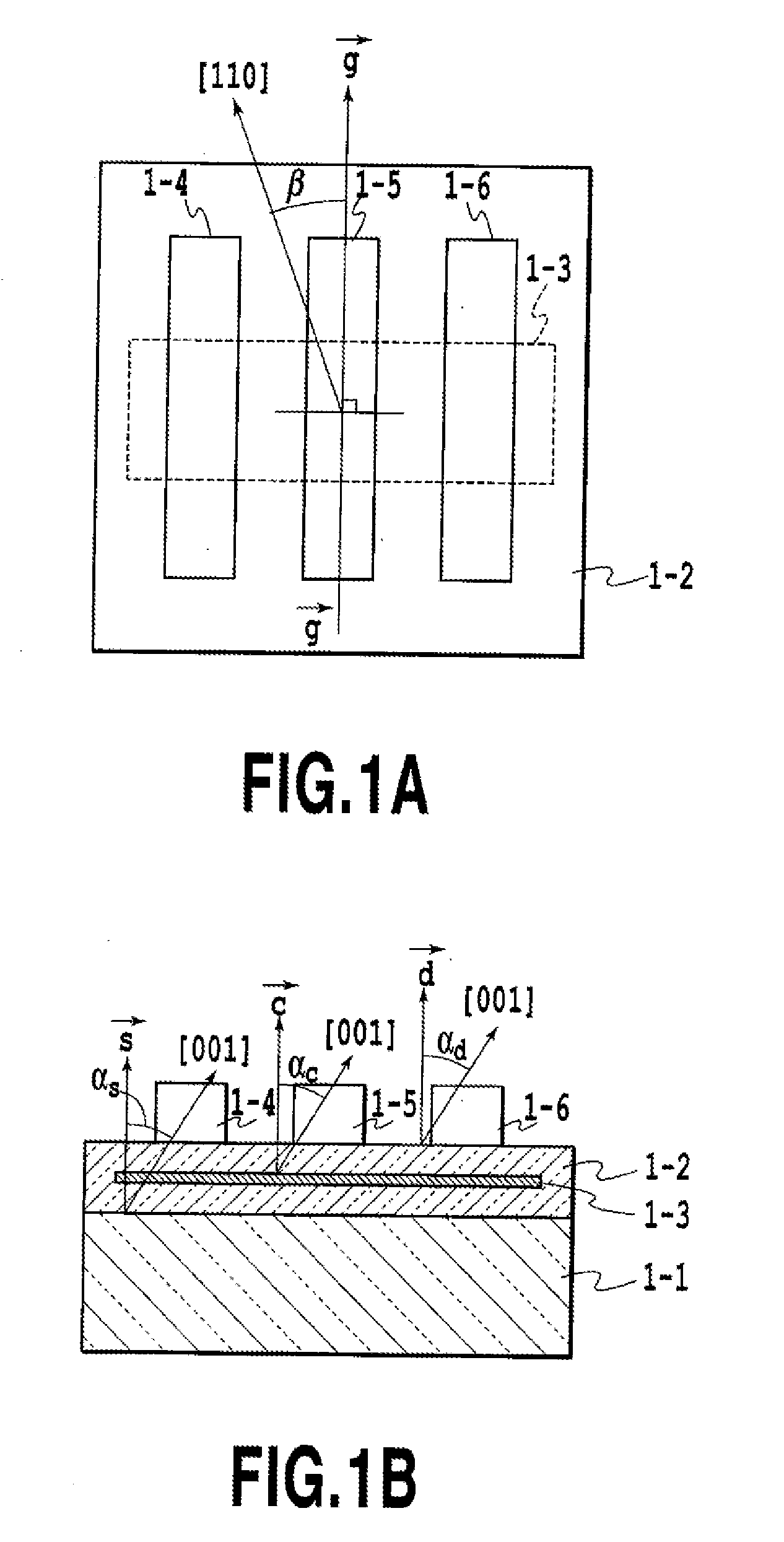

Diamond semiconductor element and process for producing the same

InactiveUS20080134959A1Reduce generationImprove transconductanceTransistorPolycrystalline material growthRefractive indexWaveguide

An integrated optical waveguide has a first optical waveguide, a second optical waveguide, and a groove. The second optical waveguide is coupled to the first optical waveguide and has a refractive index that is different from the first optical waveguide. The groove is disposed so as to traverse an optical path of the first optical waveguide and is separated from an interface between the first optical waveguide and the second optical waveguide by a predetermined spacing. The spacing from the interface and the width of the groove are determined such that reflection at a boundary between the first optical waveguide and the second optical waveguide is weakened. A semiconductor board may be disposed at a boundary between the first optical waveguide and the second optical waveguide. In this case, the width of the groove and the thickness of the semiconductor board are determined such that light reflected off an interface between the first optical waveguide and the groove is weakened by light reflected from an interface between the groove and the semiconductor board, and by light reflected from an interface between the semiconductor board and the second optical waveguide.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

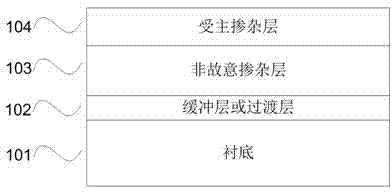

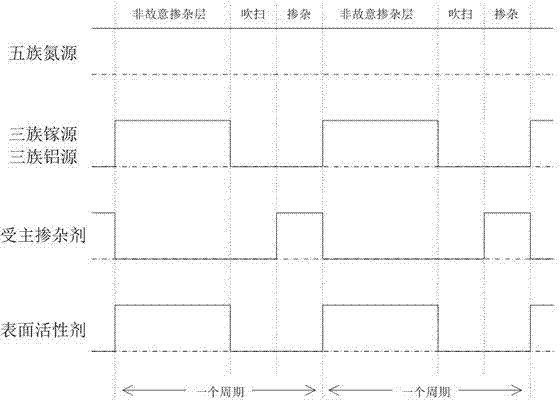

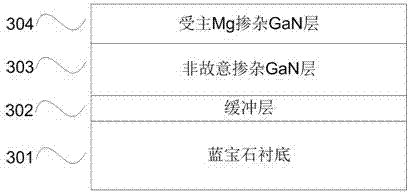

Preparation method of p type GaN and AlGaN semiconductor material

ActiveCN102903615AEasy to desorbImprove bindingSemiconductor/solid-state device manufacturingDimethylhydrazineSemiconductor materials

The invention discloses a preparation method of a p type GaN and AlGaN semiconductor material. A substrate, and a buffer layer or a transition layer, an unintended doped layer and an acceptor doped layer grown on the substrate from bottom to top are contained; in a growth process of the structure, ammonia or nitrogen dimethylhydrazine is used as a five-group nitrogen source; trimethyl gallium or TEGa used as a three-group gallium source, trimethylaluminium or triethyl aluminum used as a three-group aluminium source, and trimethylindium or TEIn used as a three-group indium source are collectively called three-group metal sources; and the trimethylindium or the TEIn is also used as a surface active agent and used in the acceptor doped layer. According to the method, the trimethylindium or the TEIn is used as the surface active agent to assist growth, and simultaneously, the acceptor doped layer is prepared by adopting a delta doping method. According to the method, the doping efficiency of acceptor doped magnesium atoms is increased, and simultaneously, the self-compensation effect is suppressed, so that the p type GaN and AlGaN semiconductor material with favorable crystalline quality and high hole concentration is obtained.

Owner:SUN YAT SEN UNIV

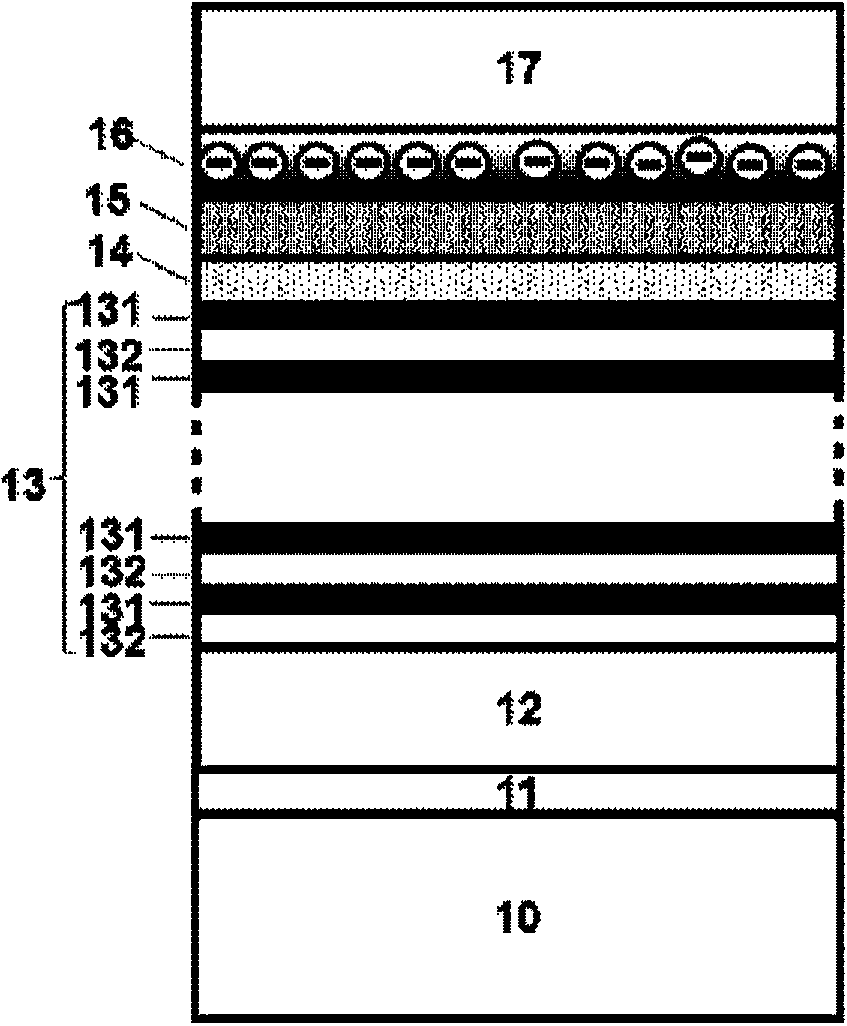

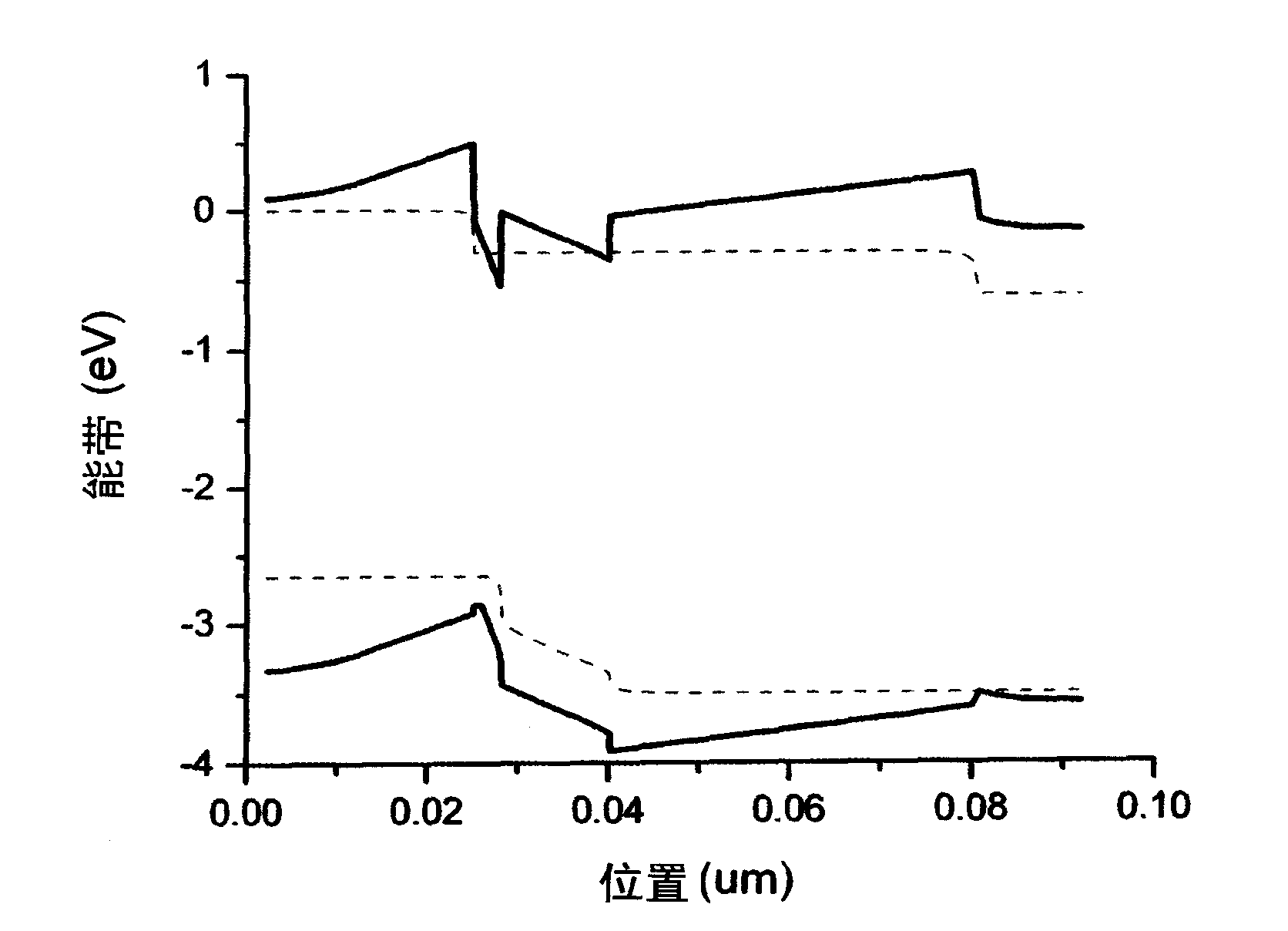

Polarity face GaN-based light-emitting device capable of improving light-emitting efficiency

ActiveCN103887385AEliminate accumulationImprove the blocking effectSemiconductor devicesContact layerLight emitting device

A polarity face GaN-based light-emitting device capable of improving the light-emitting efficiency sequentially comprises a substrate, a buffering layer, an n-type AluGal-uN contact layer, a light-emitting active region, a last AlxGal-xN quantum barrier layer, an AlyGal-yN electron barrier layer, an Al component gradual-change AlGaN layer and a p-type AlzGal-zN contact layer, wherein 0<=u, x, y, z <= 1. The polarity face GaN-based light-emitting device is characterized in that an Al component x in the last AlxGal-xN quantum barrier layer is identical to an Al component y in the AlyGal-yN electron barrier layer. According to the polarity face GaN-based light-emitting device, the electron blocking effect is improved and hole injection is improved so that electron leakage can be effectively reduced, and therefore the light-emitting efficiency of the device is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Epitaxial wafer, growing method and LED structure of Mg-doped electronic barrier layer

ActiveCN104134730AImprove injection efficiencyIncrease the amount of holesSemiconductor devicesHigh concentrationOptoelectronics

The invention discloses an epitaxial wafer, growing method and LED structure of an Mg-doped electronic barrier layer. The epitaxial wafer comprises a substrate, a low-temperature GaN buffer layer, a high-temperature GaN buffer layer, an n type GaN layer, an n type AlGaN layer, an n type contact layer, a multiple quantum well layer and a GaN base layer from bottom to top in sequence. An AlGaN / GaN electronic barrier layer is arranged on the GaN base layer, a low-temperature P type GaN layer is arranged on the AlGaN / GaN electronic barrier layer, a high-concentration AlGaN / InGaN electronic barrier layer doped with Mg is arranged on the low-temperature P type GaN layer, a high-temperature P type GaN layer is arranged on the AlGaN / InGaN electronic barrier layer, and a P type contact layer is arranged on the high-temperature P type GaN layer. The epitaxial wafer, growing method and LED structure of the Mg-doped electronic barrier layer have the advantages that the hole concentration of the part injected into multiple quantum wells of a P layer is improved, and the barrier function of electrons is improved so that the luminous efficiency can be improved, and the brightness can be obviously improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

High carrier concentration p-type transparent conducting oxide films

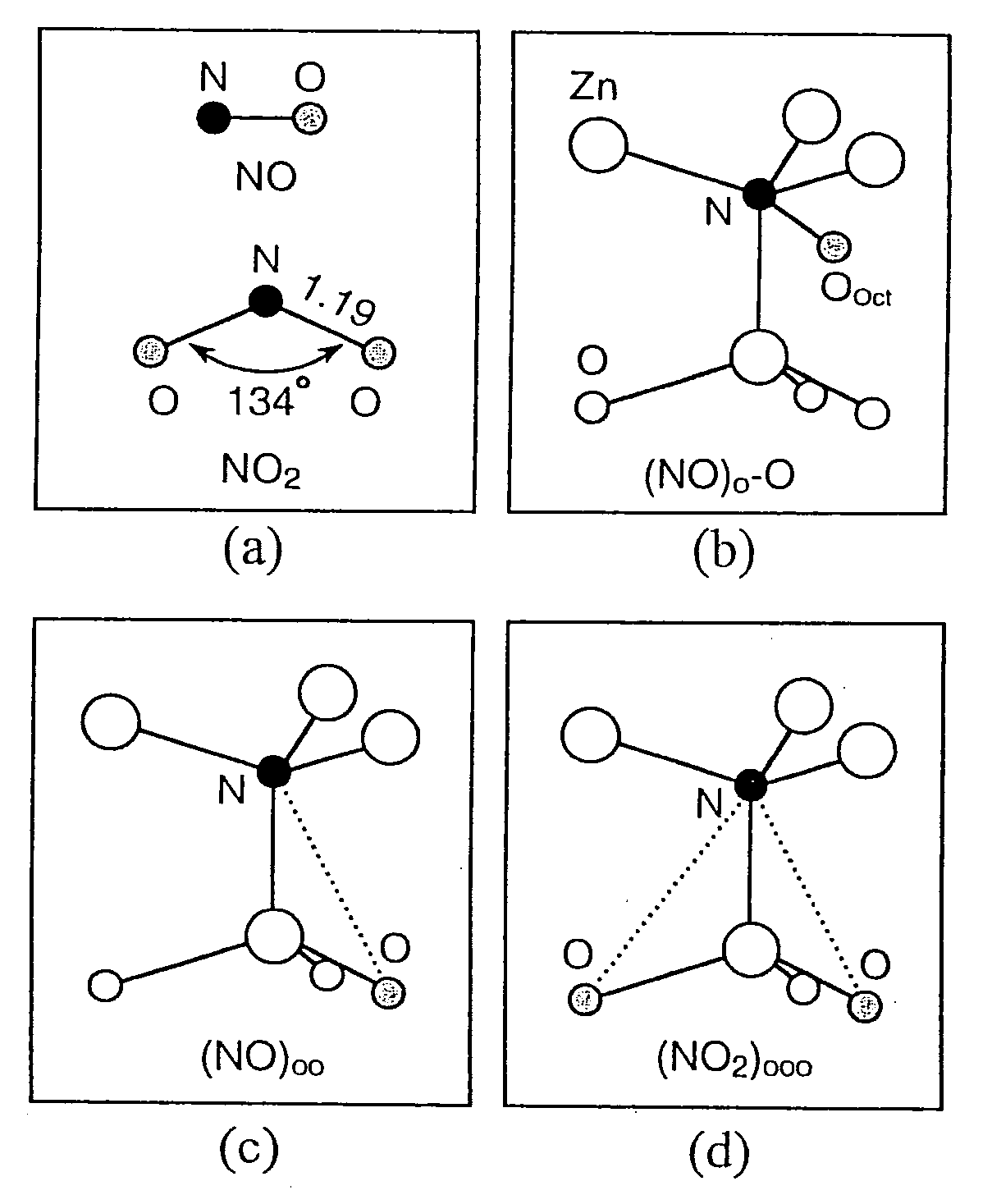

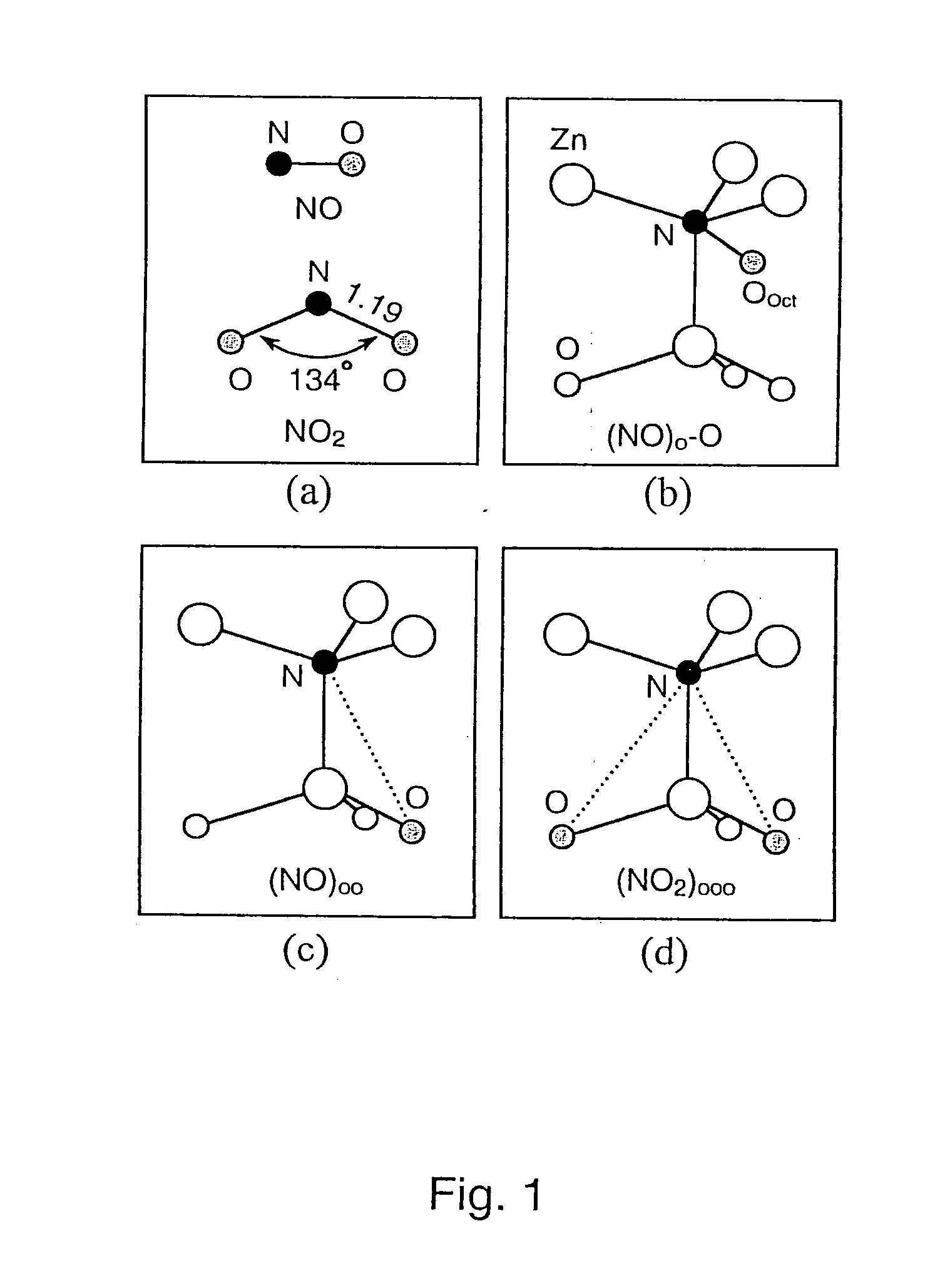

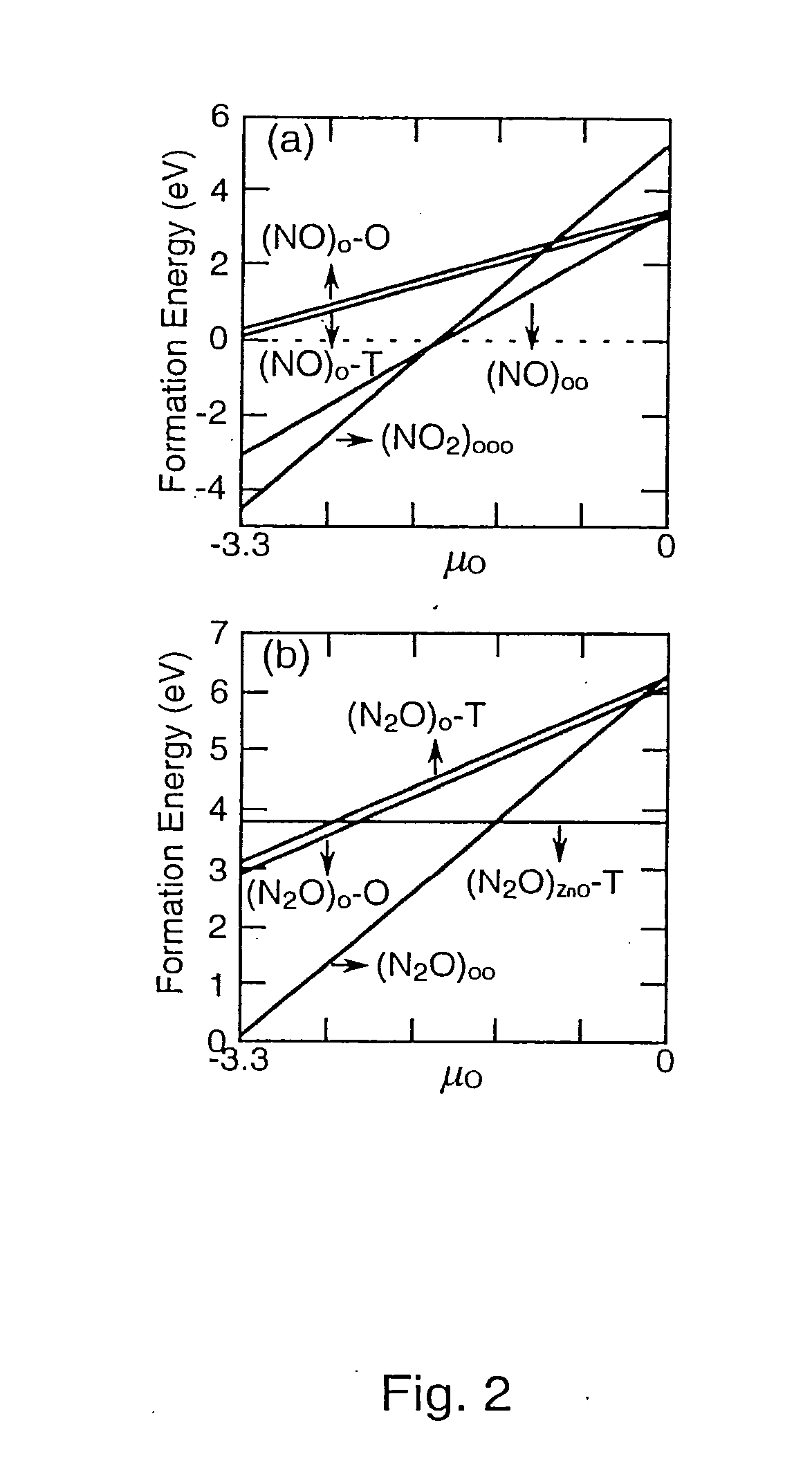

InactiveUS20040061114A1Increase hole concentrationHigh hole mobilityZinc oxides/hydroxidesSolid-state devicesPhysical chemistryElectrically conductive

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

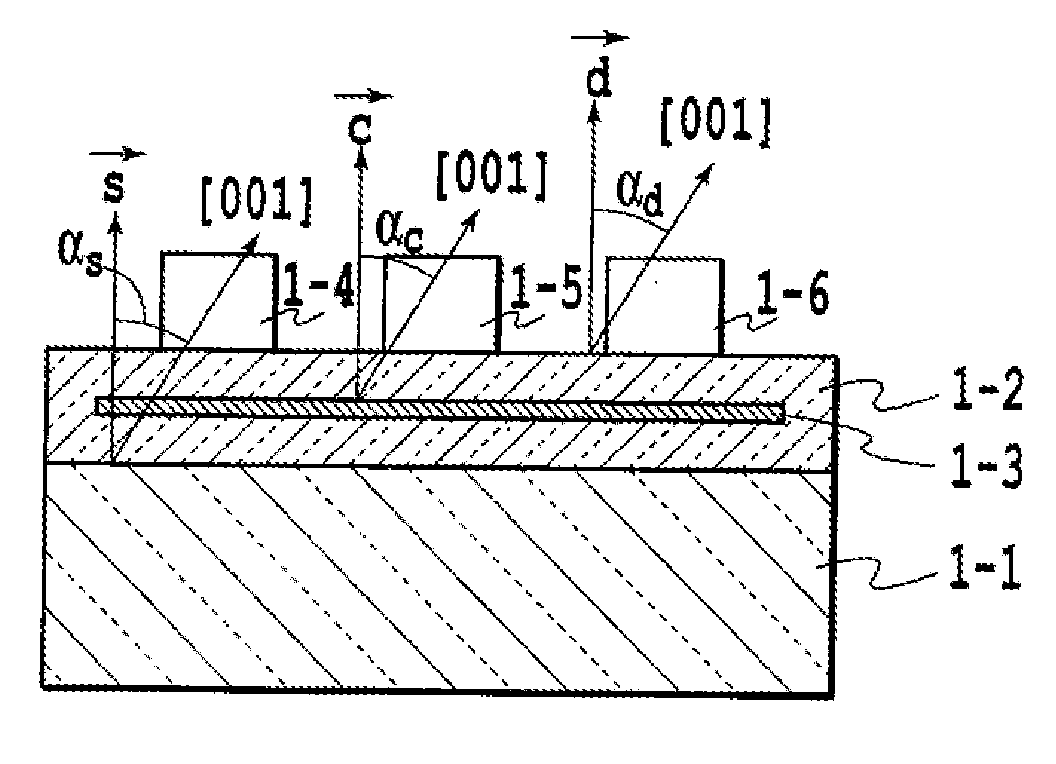

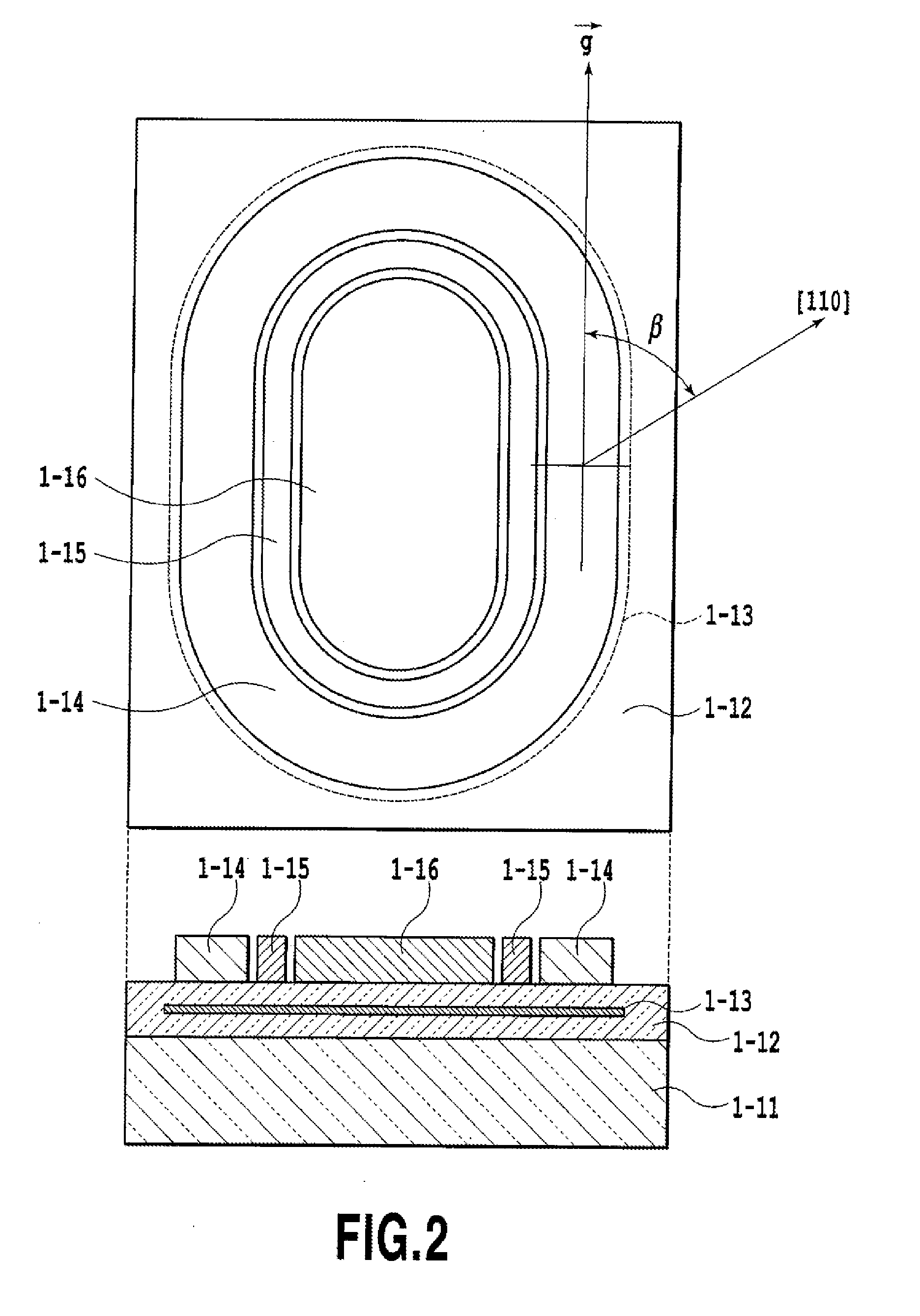

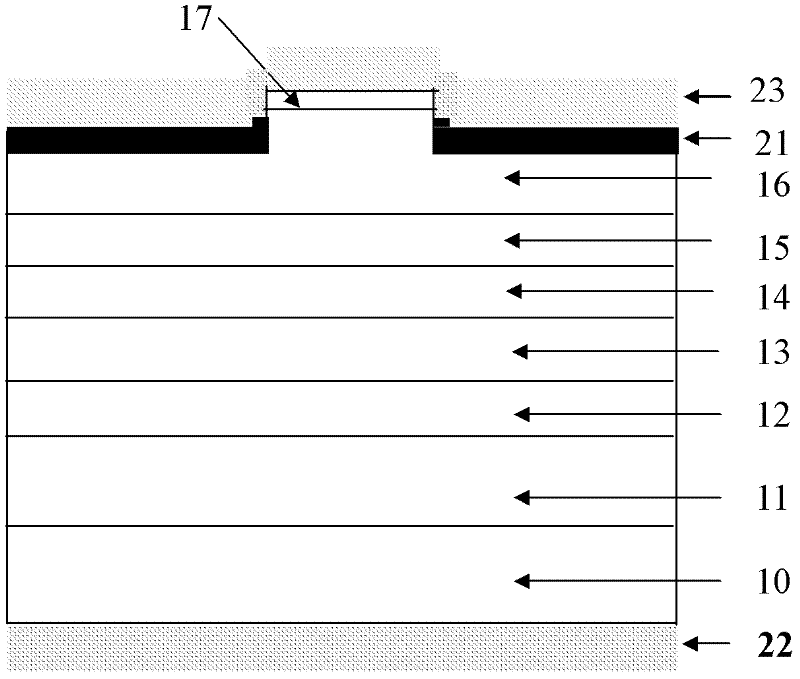

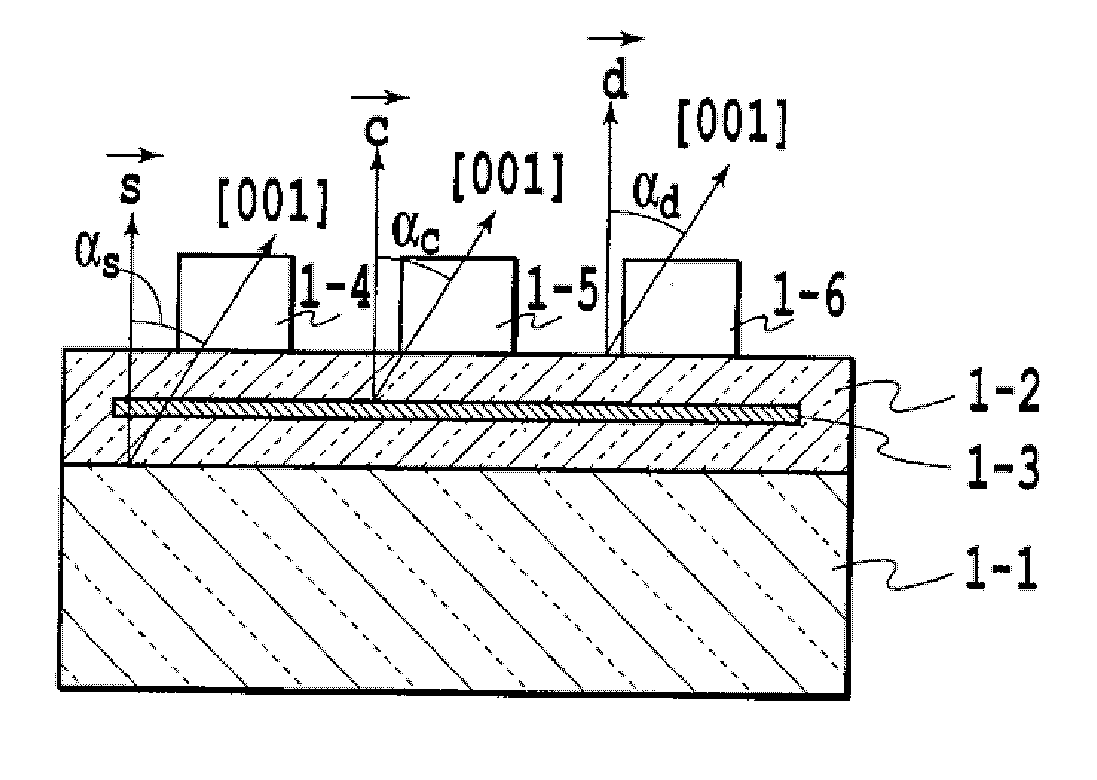

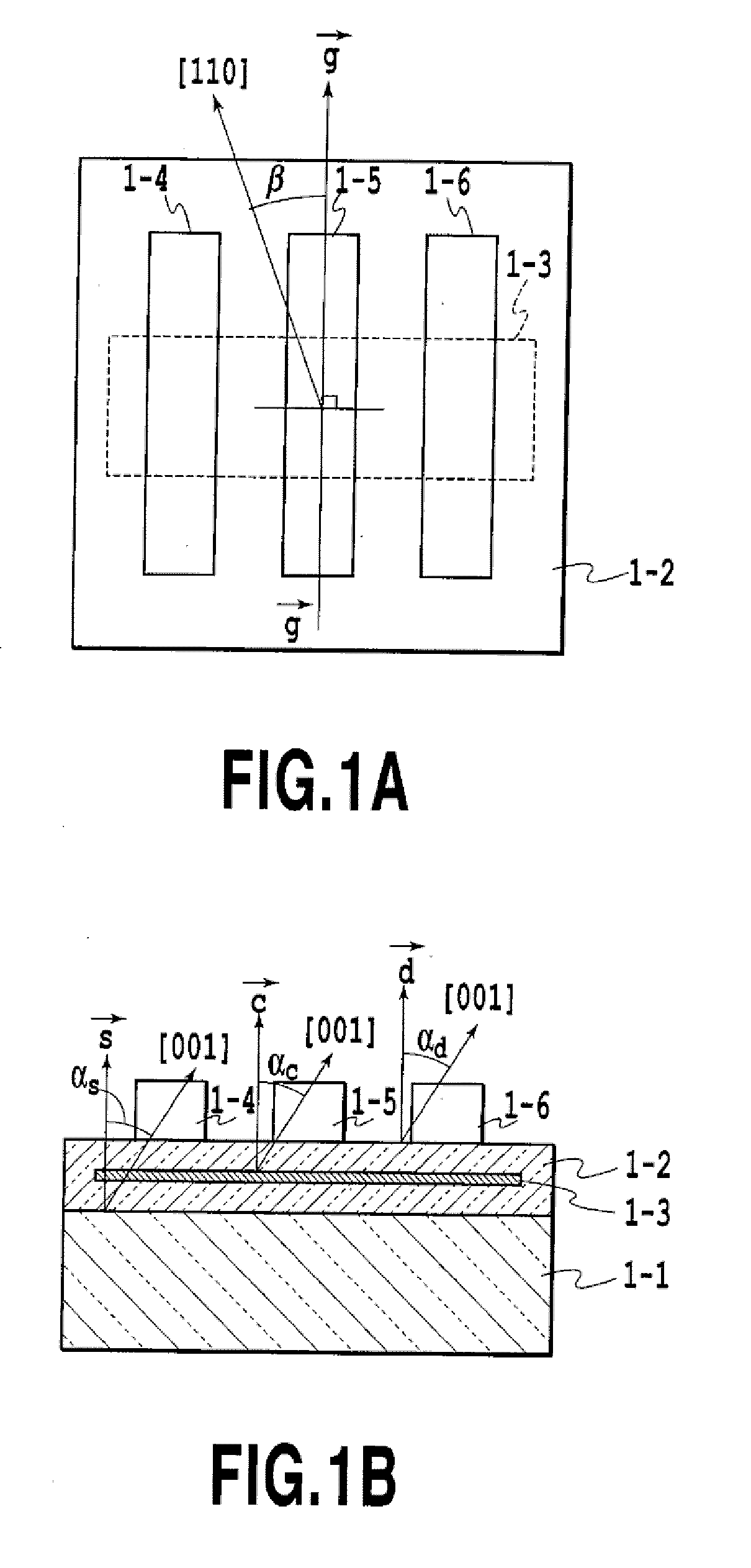

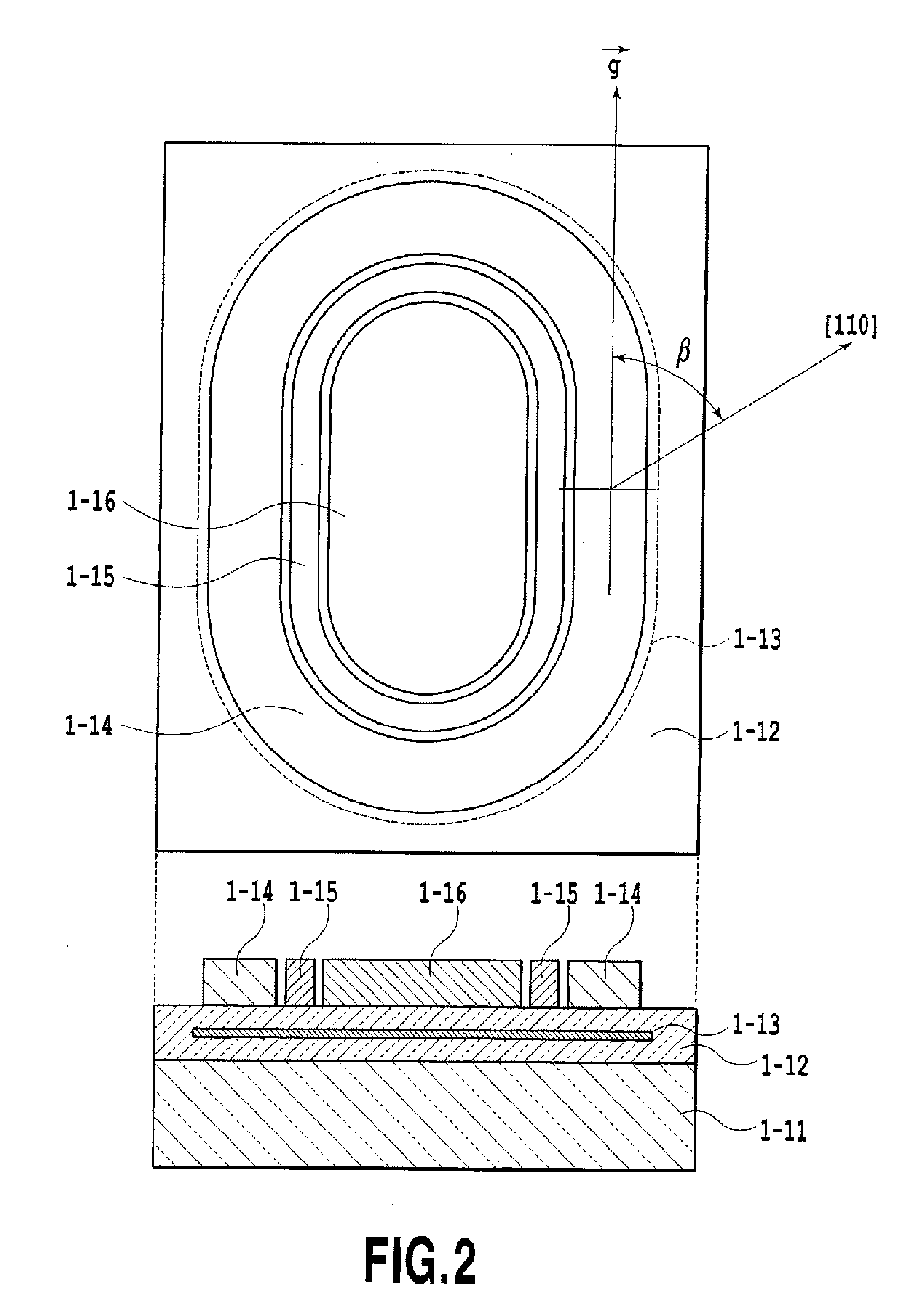

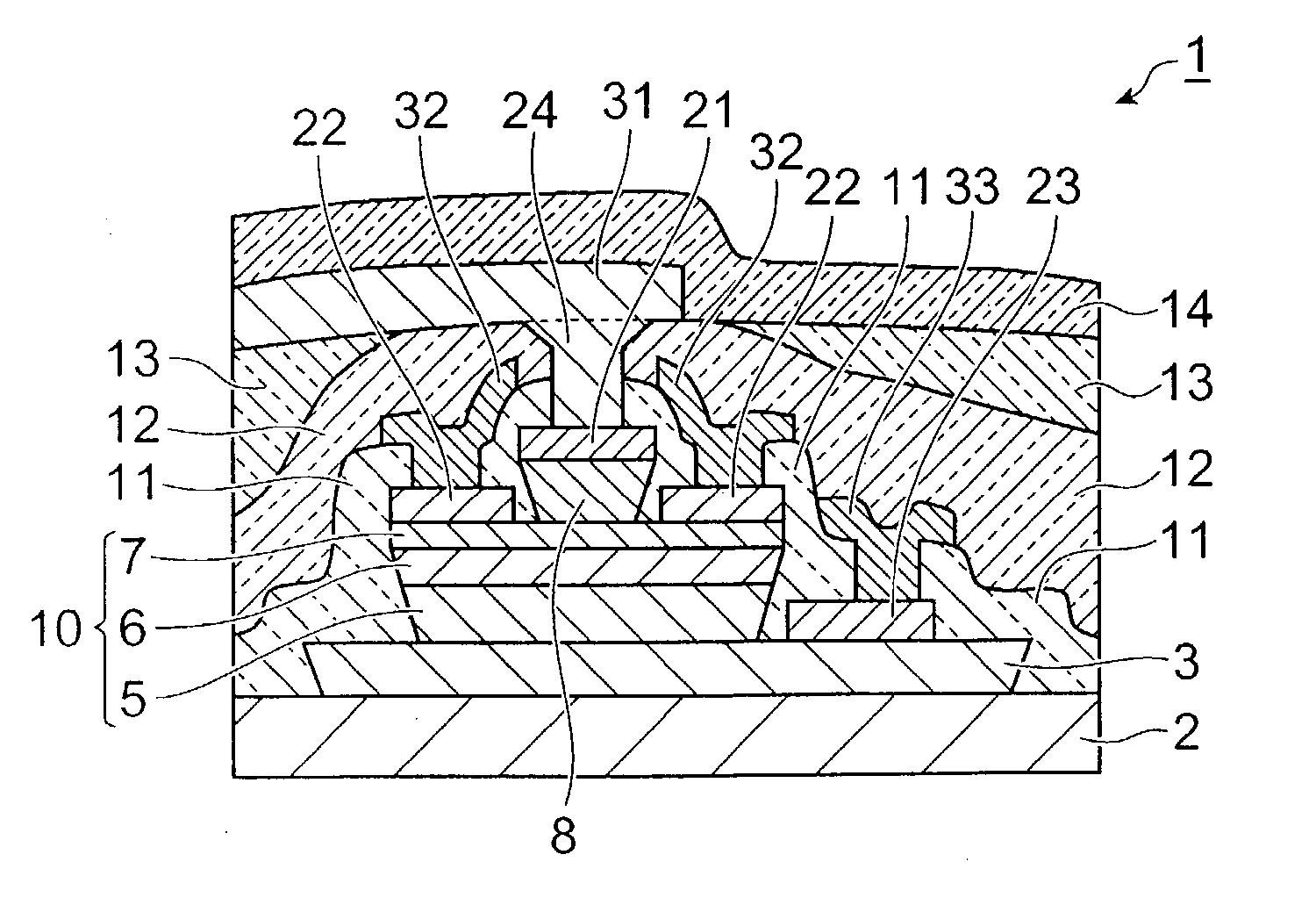

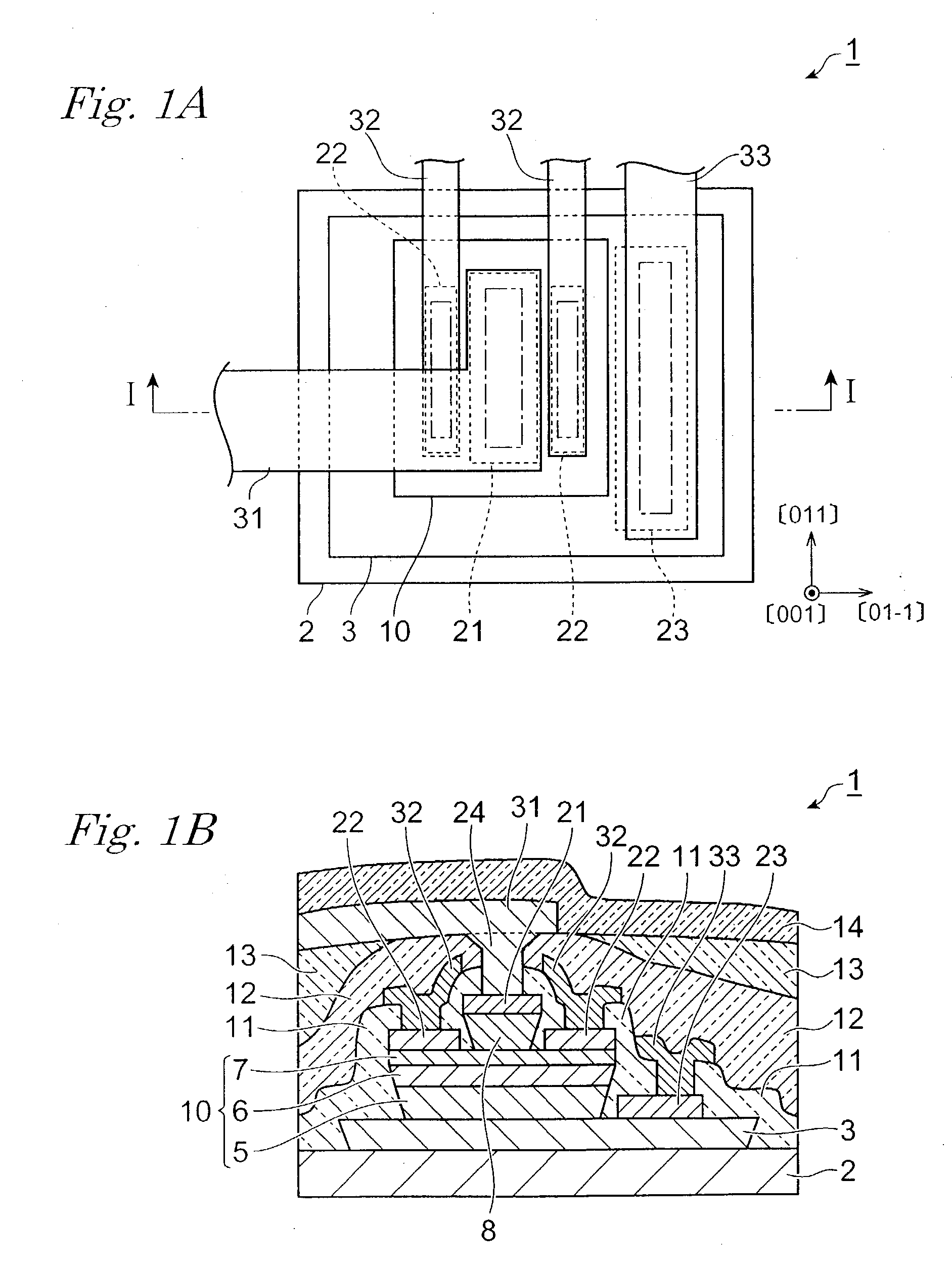

Nitride semiconductor device and manufacturing method of the device

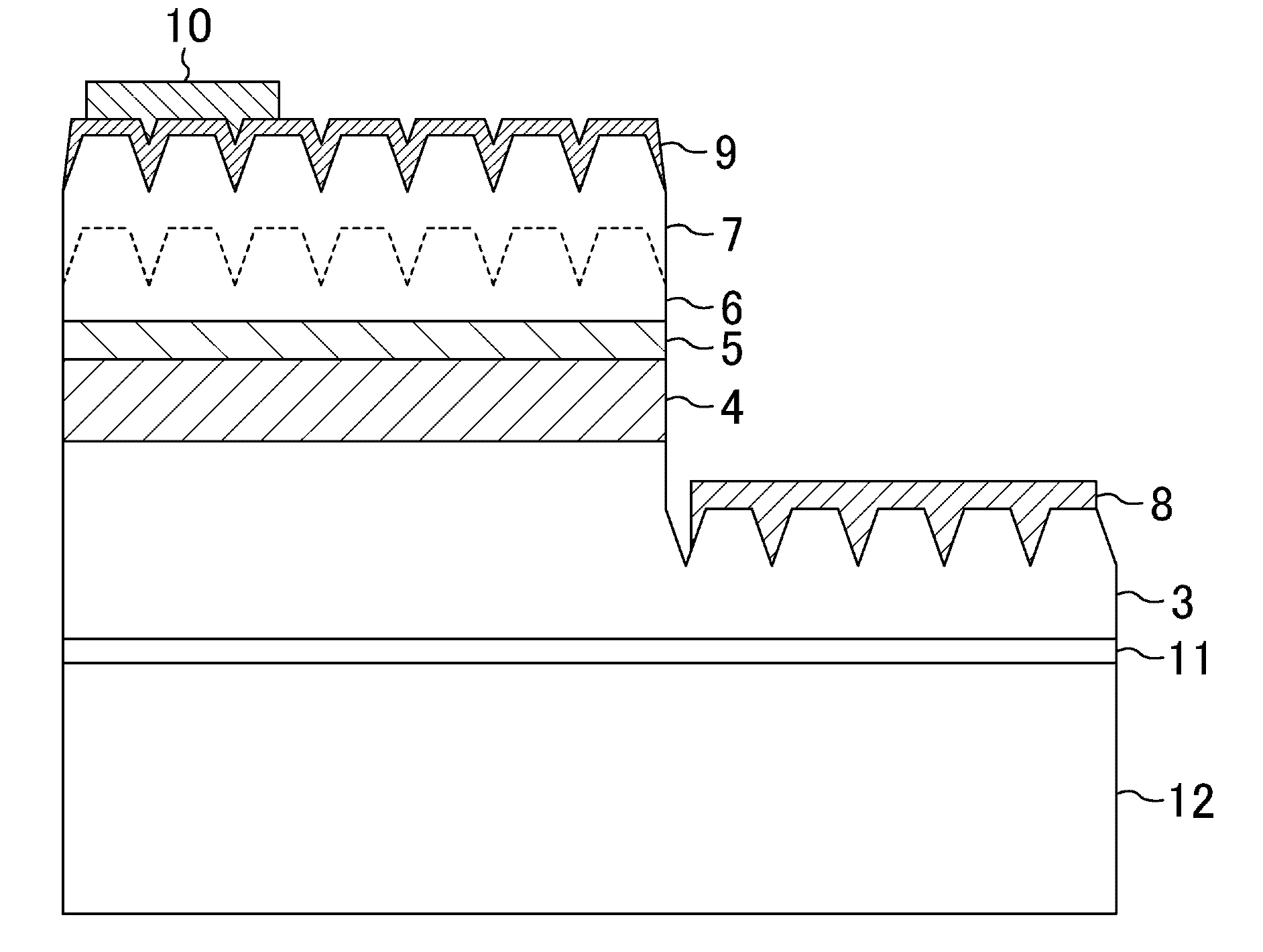

ActiveUS20110309400A1Improve luminous efficiencyDeterioration in light absorptionSemiconductor/solid-state device manufacturingSemiconductor devicesNitride semiconductorsEngineering

A nitride semiconductor device includes a first nitride semiconductor layer having a C-plane as a growth surface, and unevenness in an upper surface; and a second nitride semiconductor layer formed on the first nitride semiconductor layer to be in contact with the unevenness, and having p-type conductivity. The second nitride semiconductor layer located directly on a sidewall of the unevenness has a p-type carrier concentration of 1×1018 / cm3 or more.

Owner:PANASONIC CORP

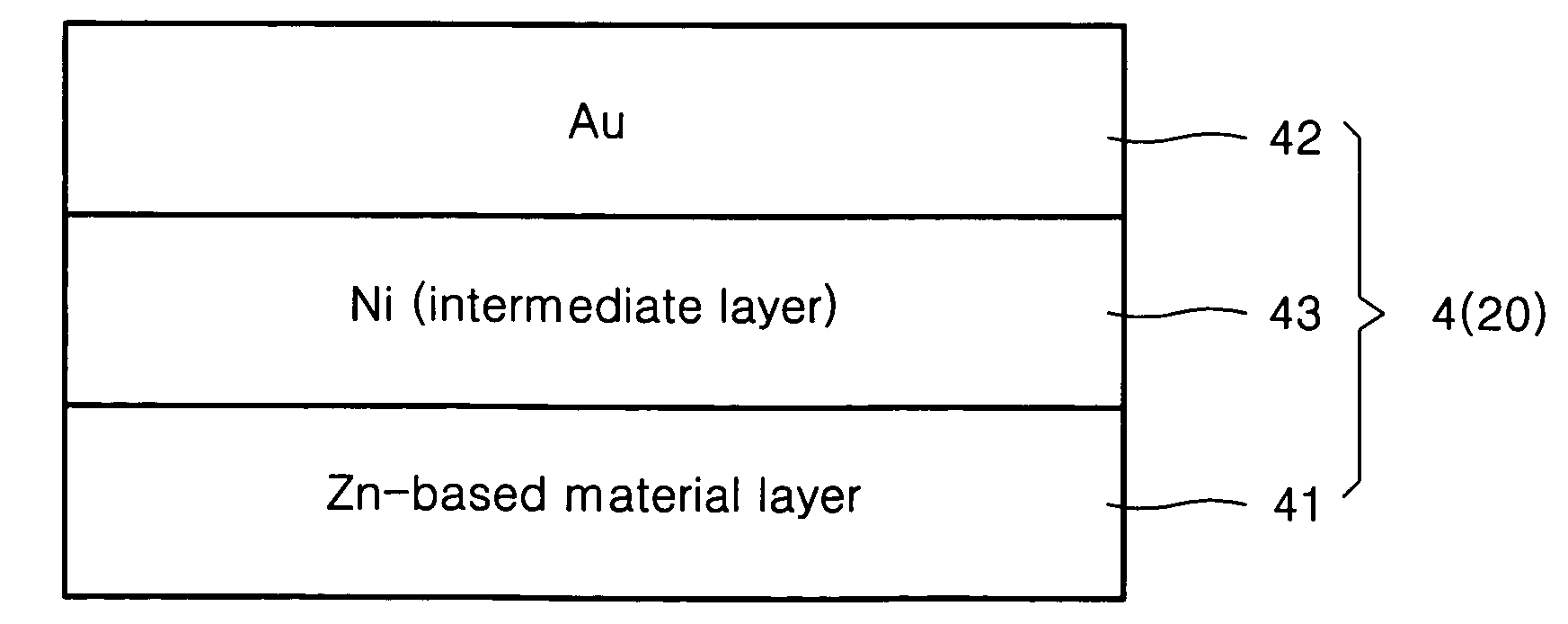

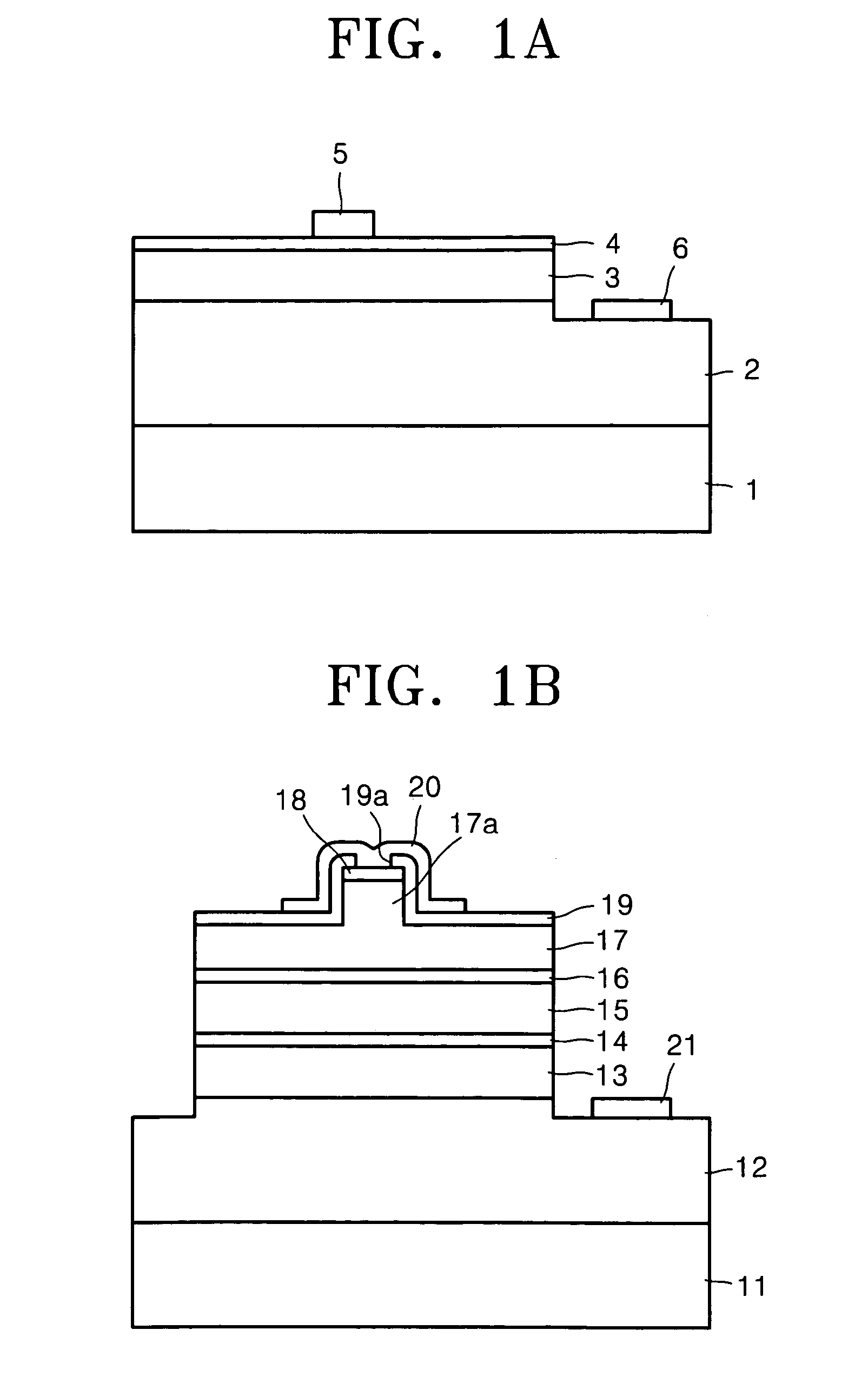

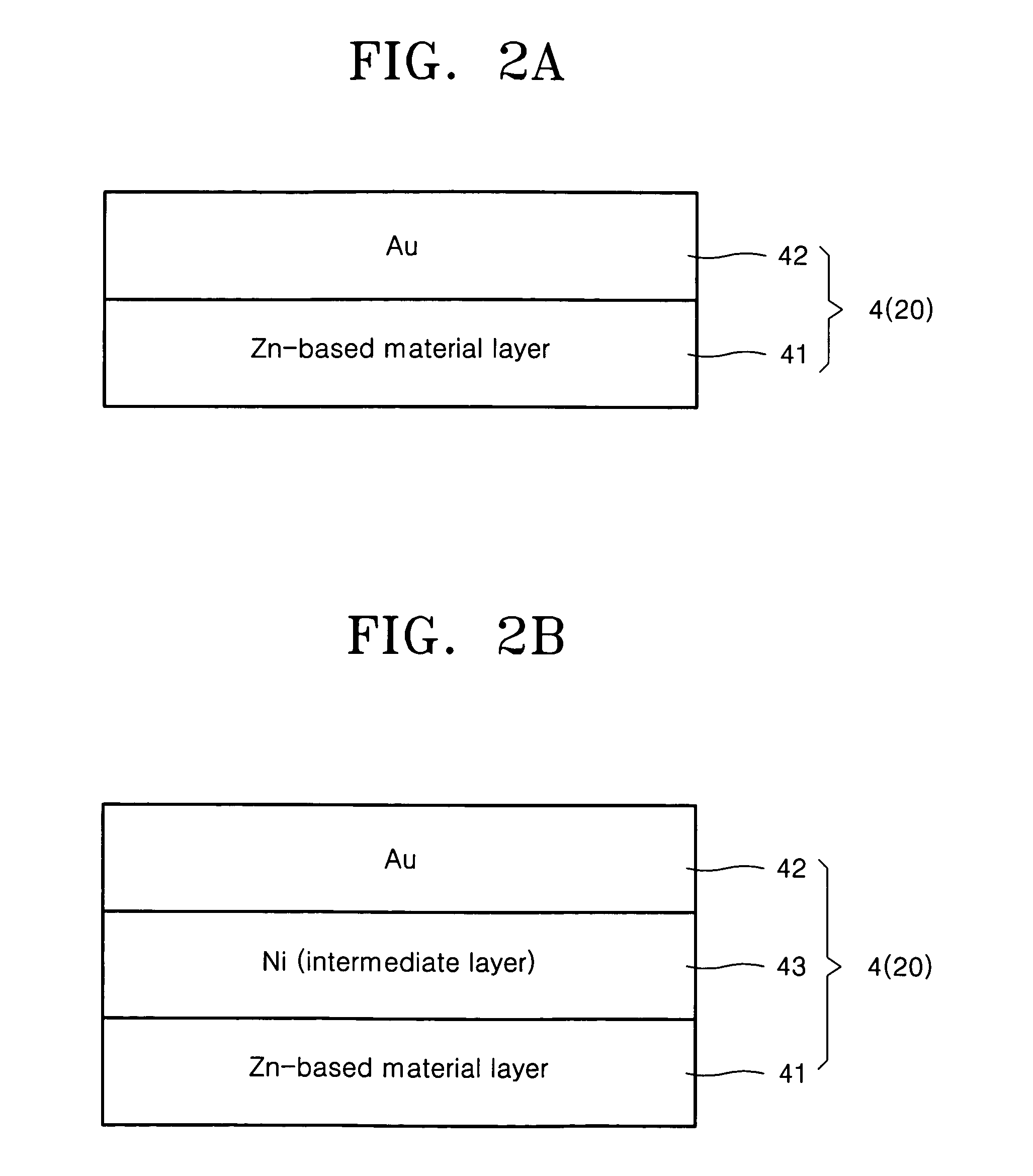

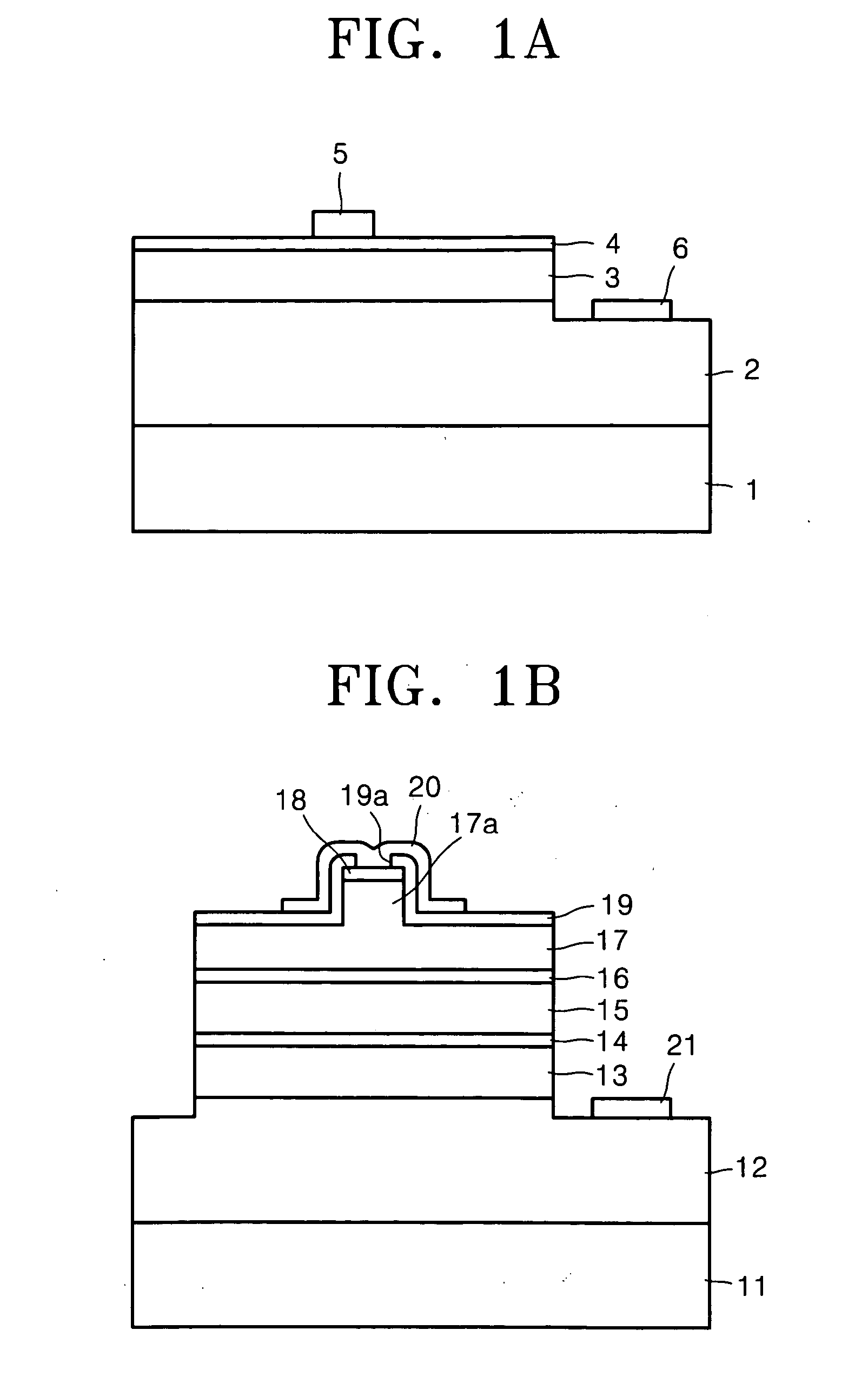

GaN-based III-V group compound semiconductor device and p-type electrode for the same

ActiveUS7285857B2Excellent electrical and optical and thermal characteristicGood electrical and optical and thermal characteristicLaser detailsSemiconductor/solid-state device detailsNitride semiconductorsSemiconductor device

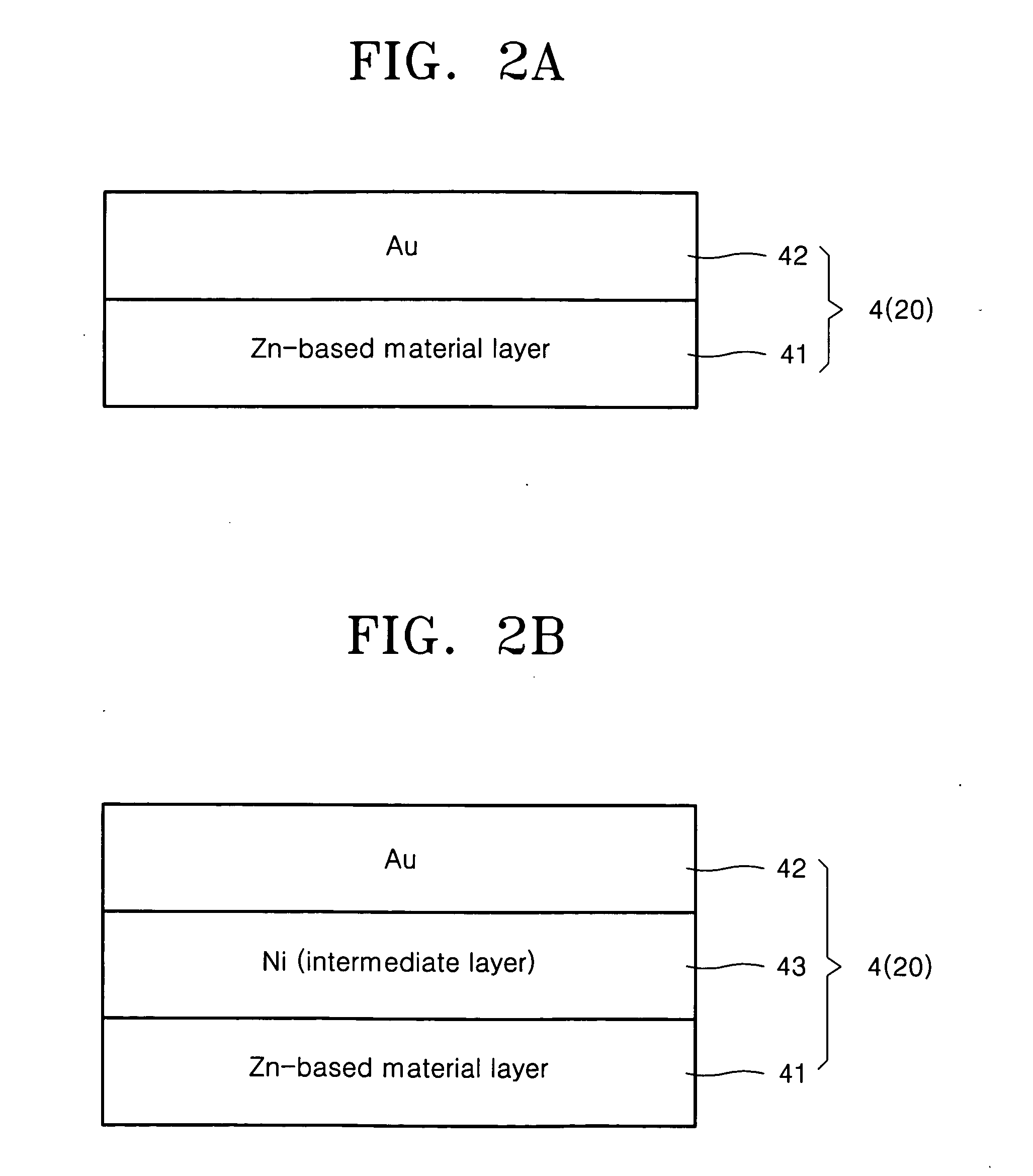

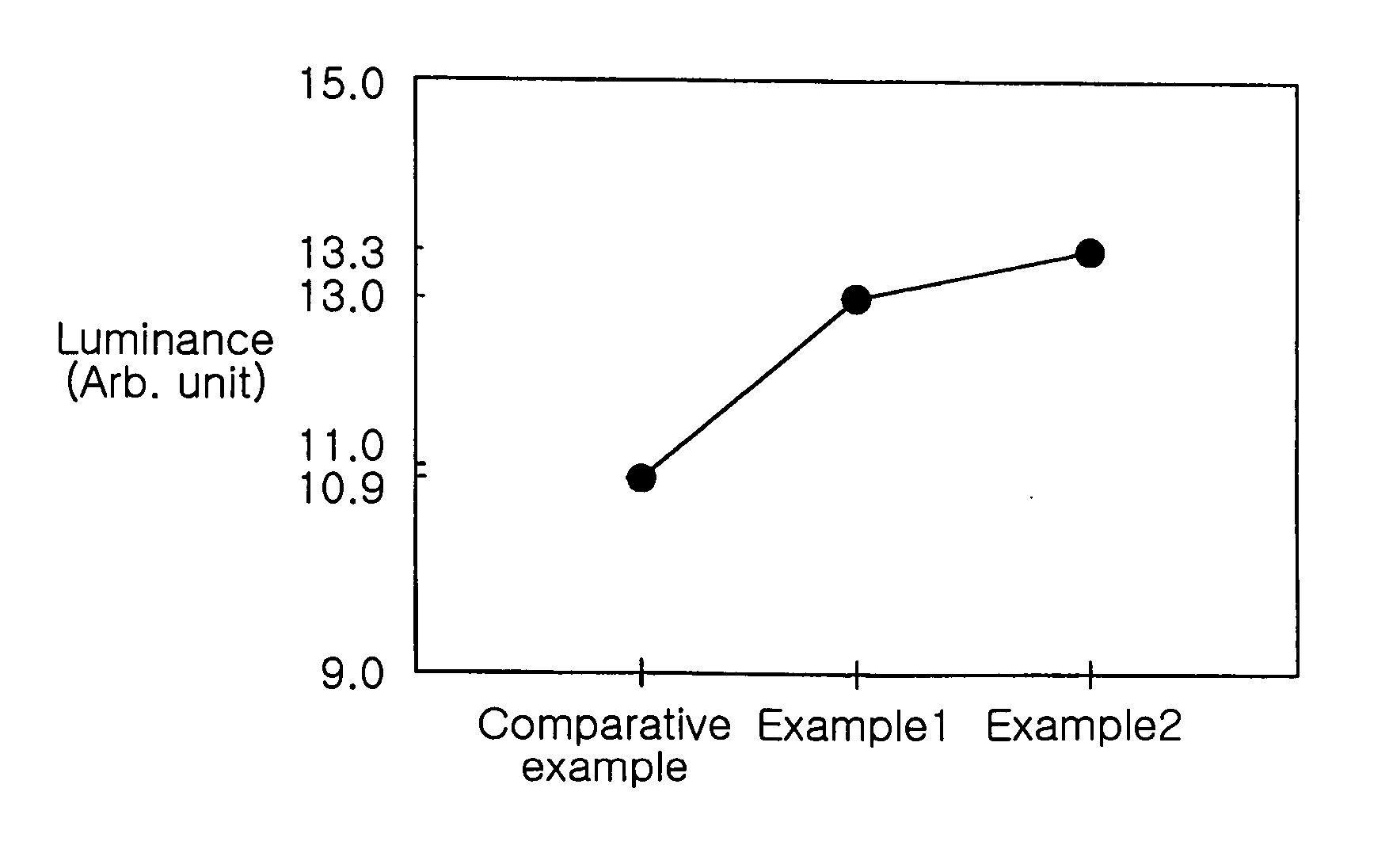

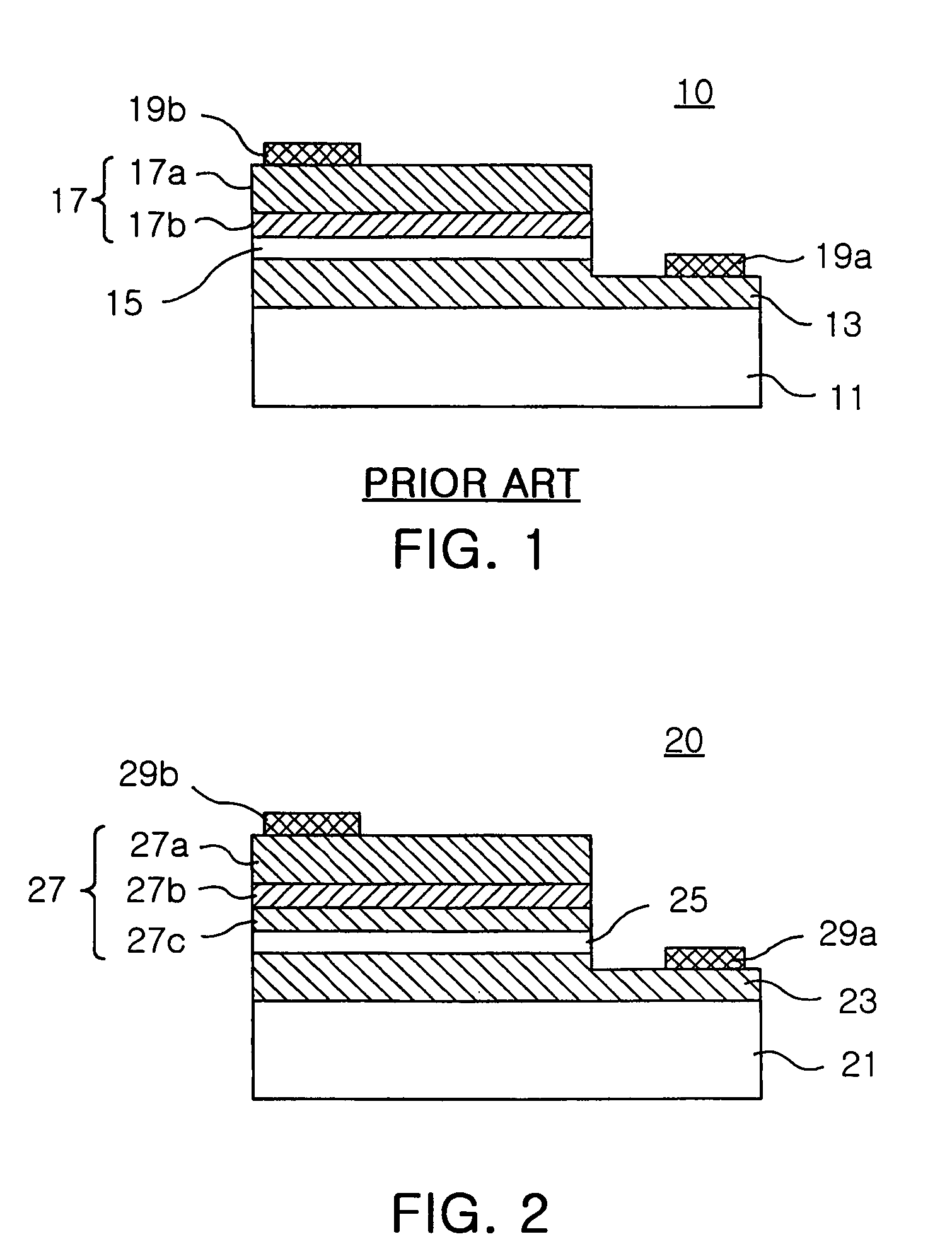

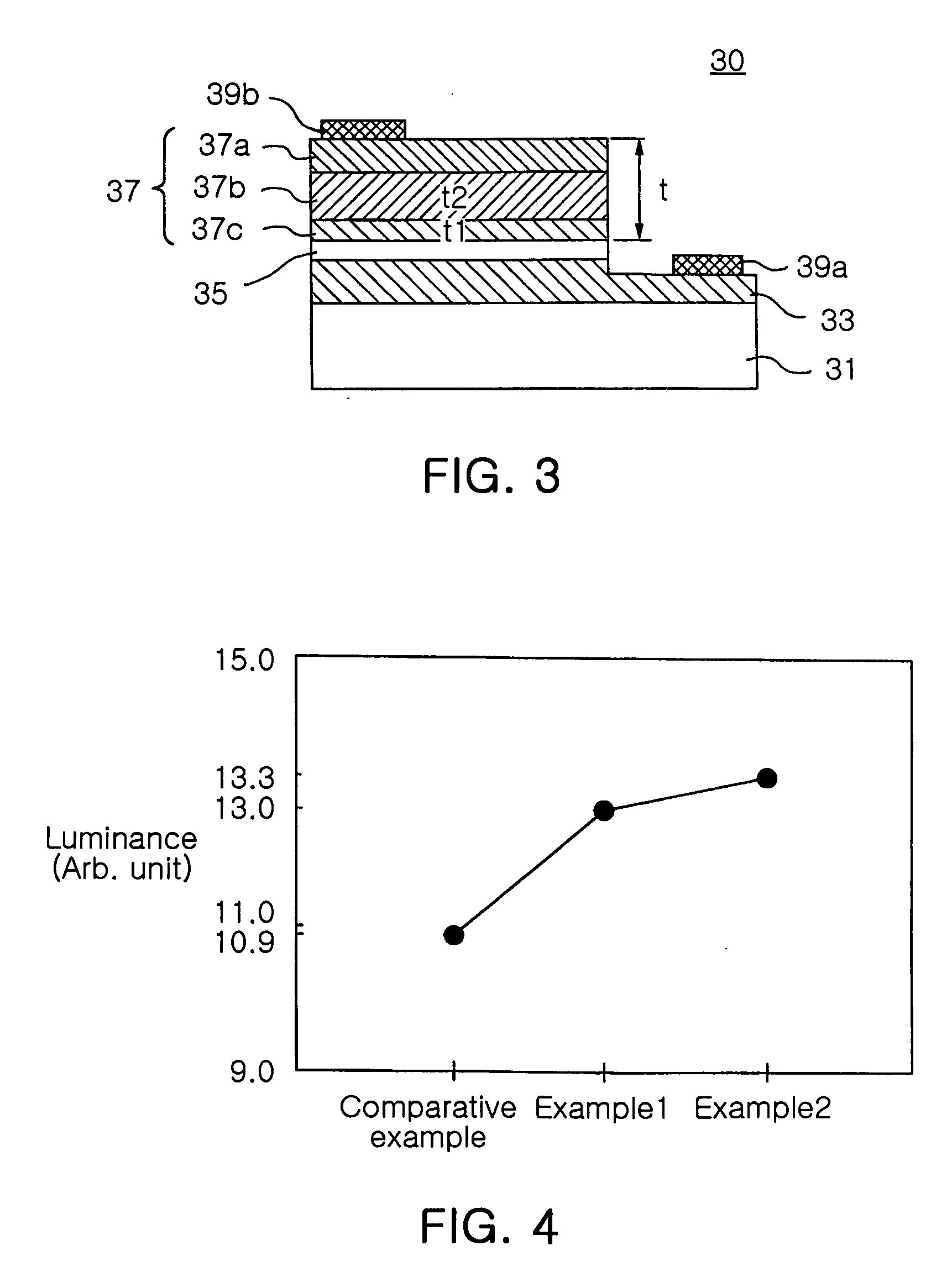

Provided are a p-type electrode and a III-V group GaN-based compound semiconductor device using the same. The electrode includes a first layer disposed on a III-V group nitride compound semiconductor layer and formed of a Zn-based material containing a solute; and a second layer stacked on the first layer and formed of at least one selected from the group consisting of Au, Co, Pd, Pt, Ru, Rh, Ir, Ta, Cr, Mn, Mo, Tc, W, Re, Fe, Sc, Ti, Sn, Ge, Sb, Al, ITO, and ZnO. The Zn-based p-type electrode has excellent electrical, optical, and thermal properties.

Owner:SAMSUNG ELECTRONICS CO LTD +1

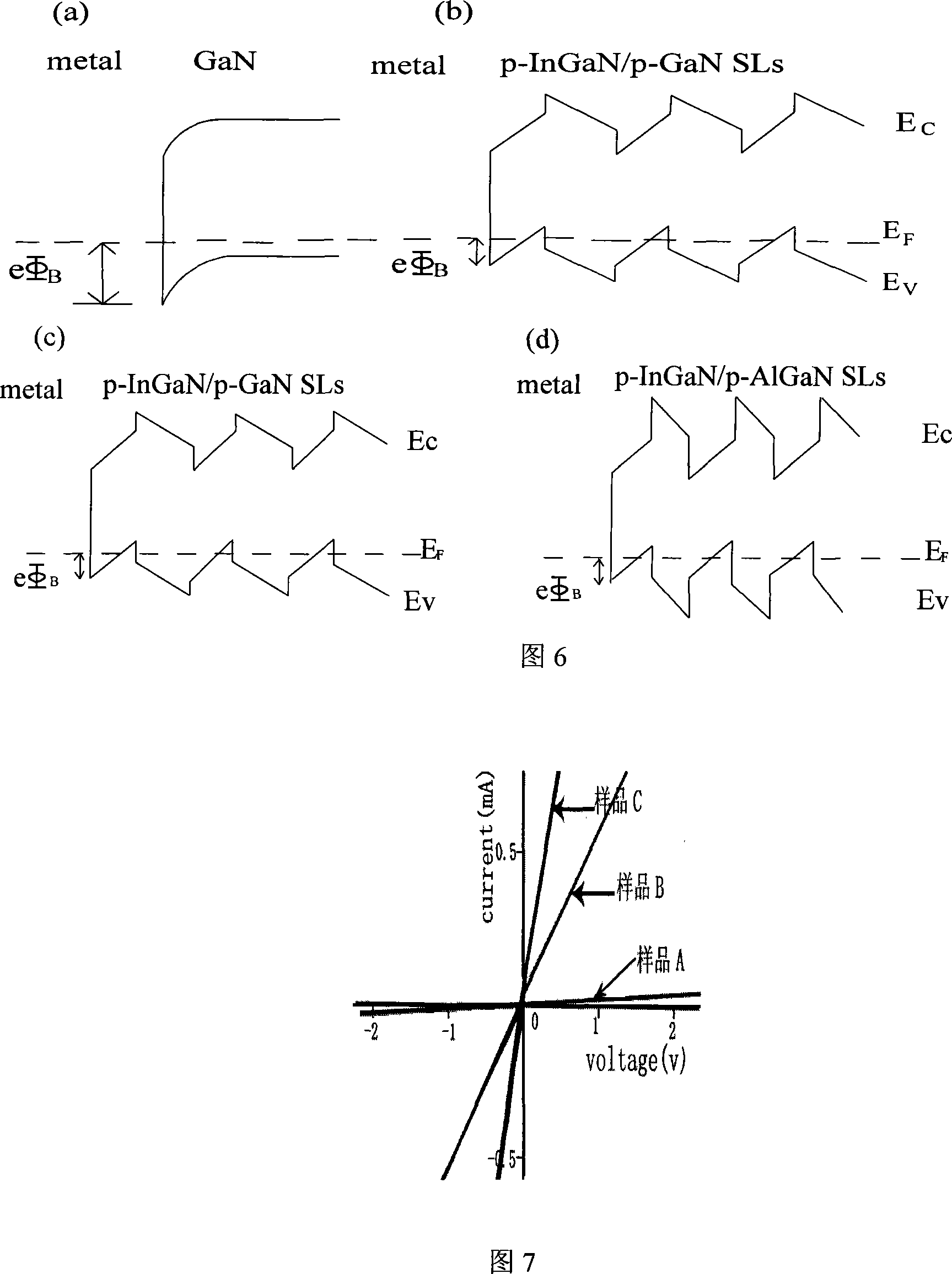

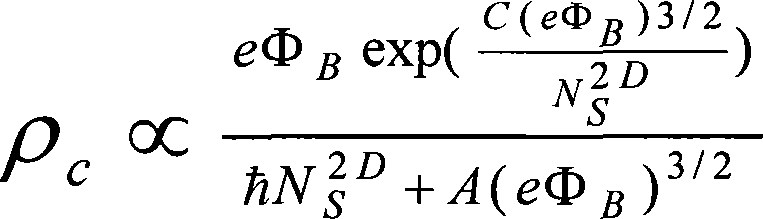

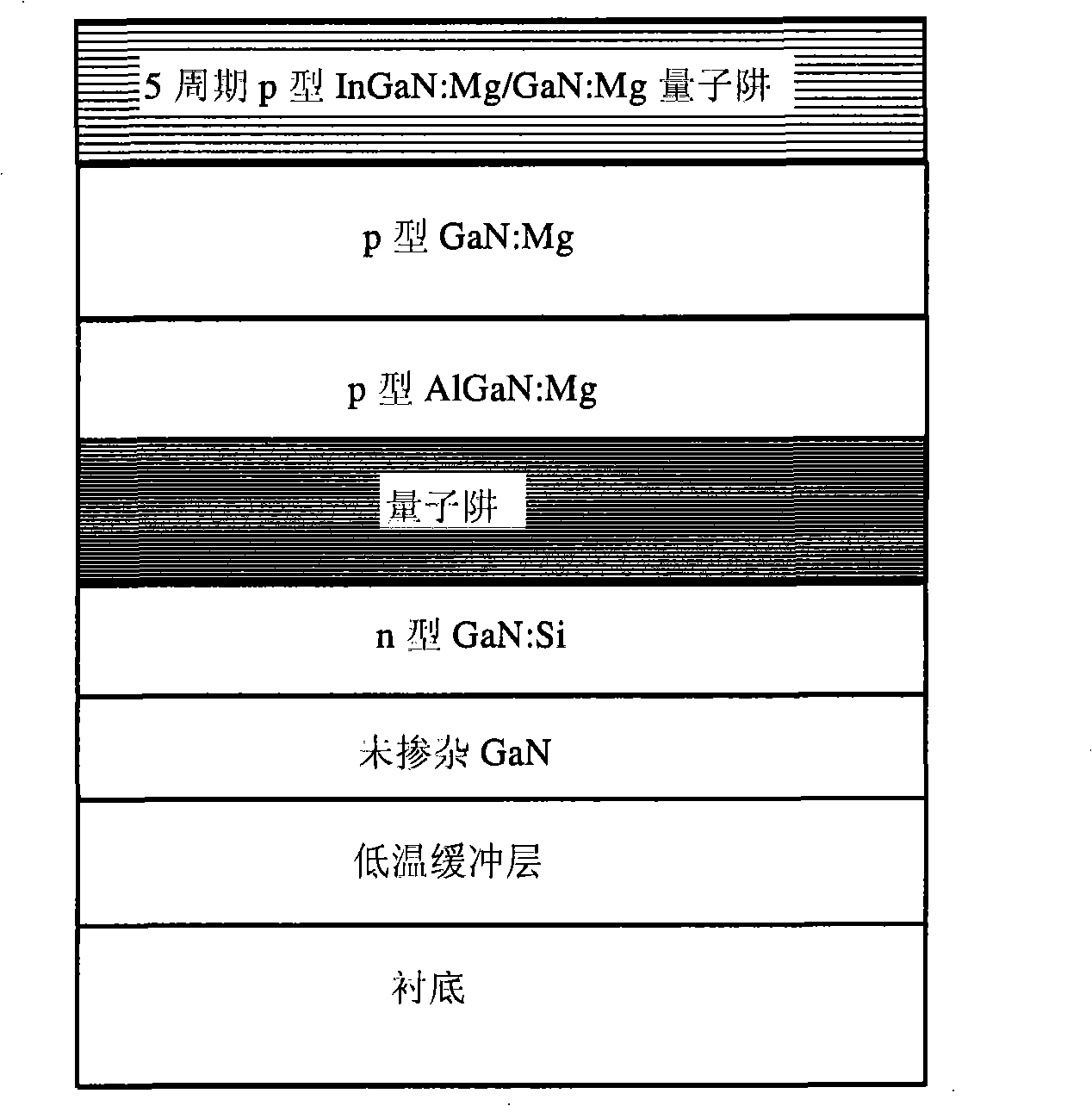

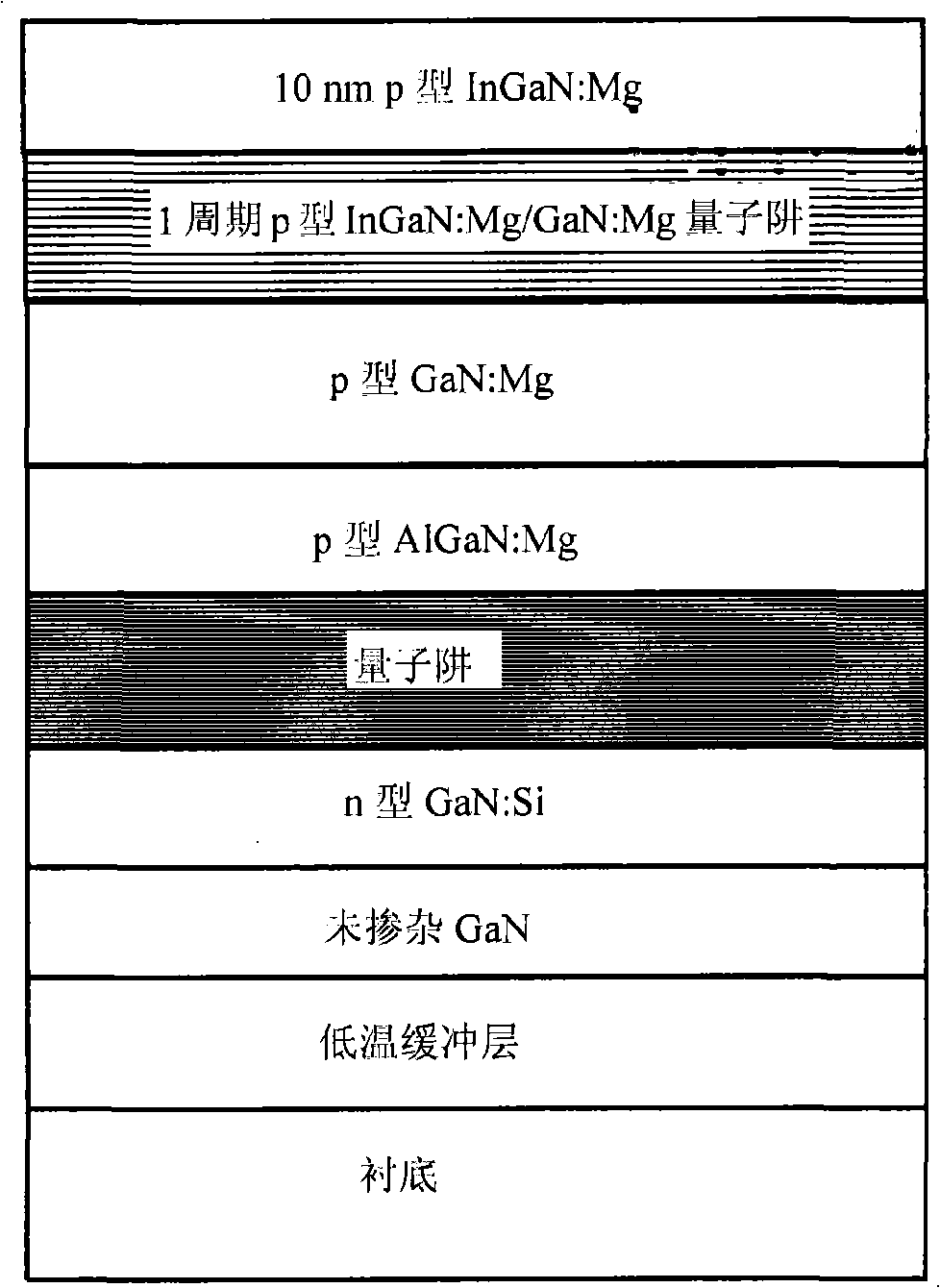

Method of producing p-GaN low-resistance Ohm contact

InactiveCN101183642AImprove surface qualityIncrease hole concentrationFinal product manufactureSemiconductor/solid-state device manufacturingOhmic contactGallium nitride

The invention discloses a preparation method of the p-GaN ohmic contact with a low resistance, relating to a p-GaN, and provides a preparation method of a low resistance p-GaN ohmic contact. The invention comprises the following steps: a (0001) oriented sapphire substrate is arranged in a reaction chamber and heated in an atmosphere of H2, and then is cooled, and a nitriding treatment is performed on the substrate; cooling the material and a GaN buffer layer grows on the material, then the material is heated to recrystallize the GaN buffer layer; a layer of GaN grows on the epitaxy of the material; the material is cooled to grows a GaN layer doping Mg; the material is cooled to grow five cycles of p-InGaN / p-AlGaN superlattice layer; a p-InGaN top layer grows on the five cycles of p-InGaN / p-AlGaN superlattice layer. The result shows that adopting the p-InGaN / p-AlGaN superlattice layer as a top layer can provide a lower specific contact resistance.

Owner:EPITOP PHOTOELECTRIC TECH

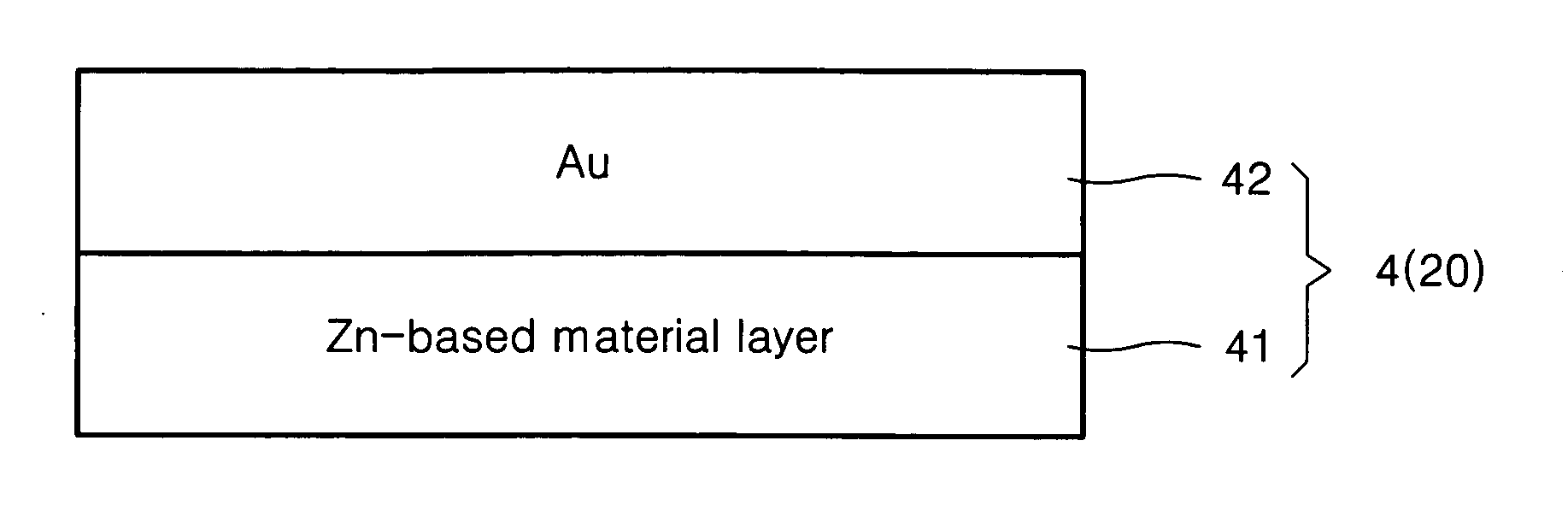

GaN-based III - V group compound semiconductor device and p-type electrode for the same

ActiveUS20050087758A1Excellent ElectricalExcellent opticalLaser detailsSemiconductor/solid-state device detailsNitride semiconductorsSemiconductor device

Provided are a p-type electrode and a III-V group GaN-based compound semiconductor device using the same. The electrode includes a first layer disposed on a III-V group nitride compound semiconductor layer and formed of a Zn-based material containing a solute; and a second layer stacked on the first layer and formed of at least one selected from the group consisting of Au, Co, Pd, Pt, Ru, Rh, Ir, Ta, Cr, Mn, Mo, Tc, W, Re, Fe, Sc, Ti, Sn, Ge, Sb, Al, ITO, and ZnO. The Zn-based p-type electrode has excellent electrical, optical, and thermal properties.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Nitride based semiconductor light-emitting device

InactiveUS20050179027A1Improve hole injection efficiencyImprove injection efficiencyNanoopticsPackagingGalliumActive layer

Disclosed herein is a nitride-based semiconductor light-emitting device. The nitride-based semiconductor light-emitting device comprises an n-type clad layer made of n-type Alx1Iny1Ga(1−x1−y1)N (where 0≦x1≦1, 0≦y1≦1, and 0≦x1+y1≦1), a multiple quantum well-structured active layer made of undoped InAGa1−AN (where 0<A<1) formed on the n-type clad layer, and a p-type clad layer formed on the active layer wherein the p-type clad layer includes at least a first layer made of p-type Iny2Ga1−y2N (where 0≦y2<1) formed on the active layer and a second layer made of p-type Alx3Iny3Ga(1−x3−y3)N (where 0<x3≦1, 0≦y3≦1, and 0<x3+y3≦1) formed on the first layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

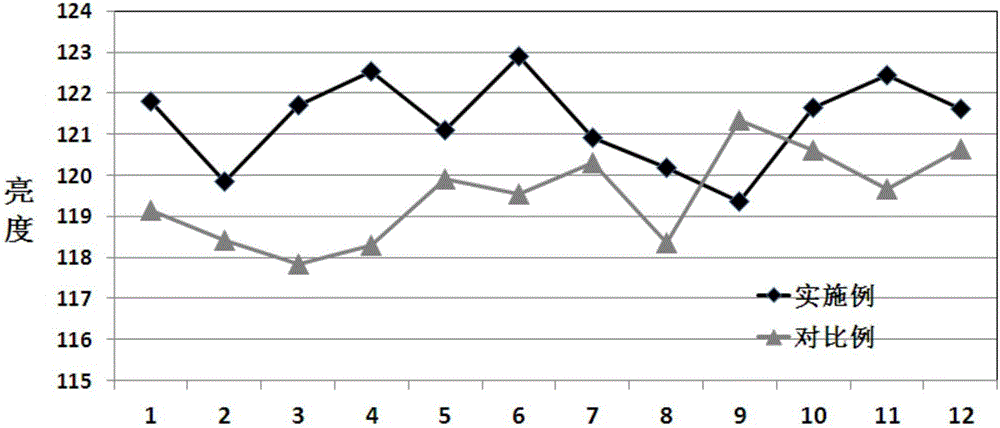

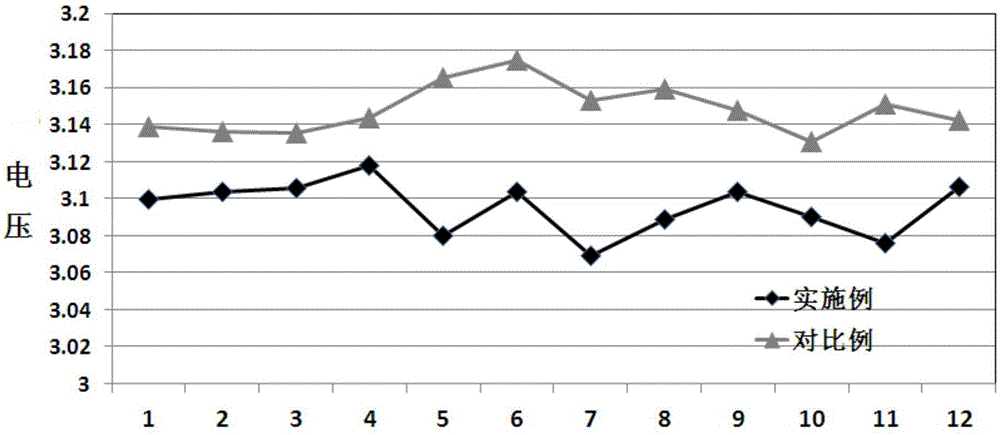

LED epitaxial layer growing method and LED epitaxial layer

InactiveCN103996759AImprove crystal qualityIncrease contactSemiconductor devicesDelta dopingTotal thickness

The invention provides an LED epitaxial layer growing method and an LED epitaxial layer. The method for growing a P-type GaN layer comprises the steps that A, NH3 and Cp2Mg are introduced in a reaction chamber at the temperature of 900 DEG C to 950 DEG C, wherein pressure of a reaction cavity ranges from 200 mbar to 600 mbar, TMGa is closed, and pretreatment of doping Mg is carried out for 10 minutes-20 minutes; B, TMGa is introduced, Cp2Mg is closed, a GaN layer grows for 20 minutes-40 minutes, and the thickness of GaN is 5 nm-10 nm; the step A and the step B are repeated ten to twenty times until the total thickness of the P-type GaN layer is 80 nm-200 nm. According to the method, delta doping is used for growing the P-type GaN layer, the crystal quality of the P-type GaN layer is improved, the dislocation density is reduced, and hole concentration and the migration rate of P-type GaN are improved; more hole-electron pairs can be provided for light-emitting active areas of an LED device, the composite probability is improved, the brightness is promoted, and therefore photoelectric property of the LED device is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

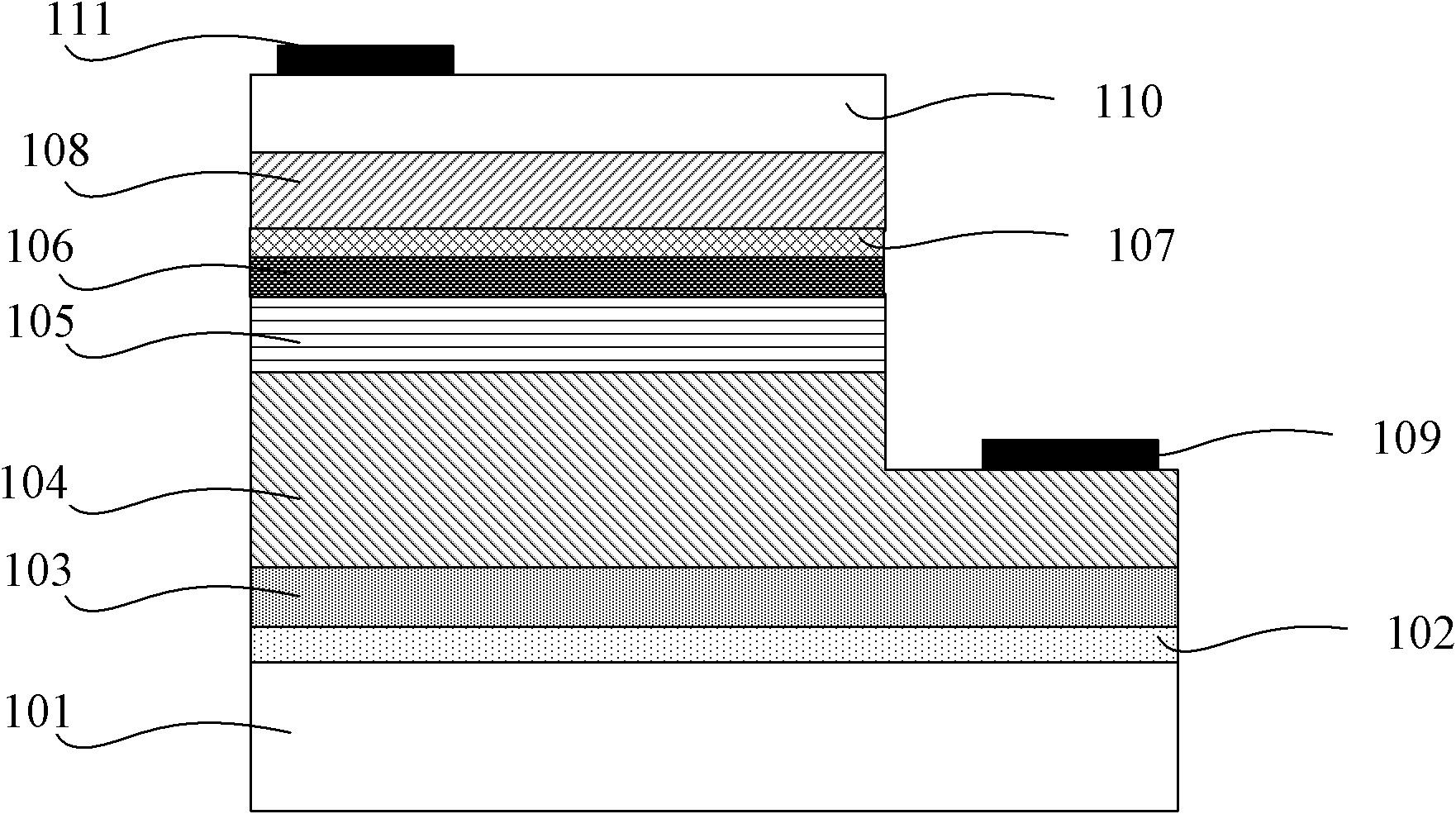

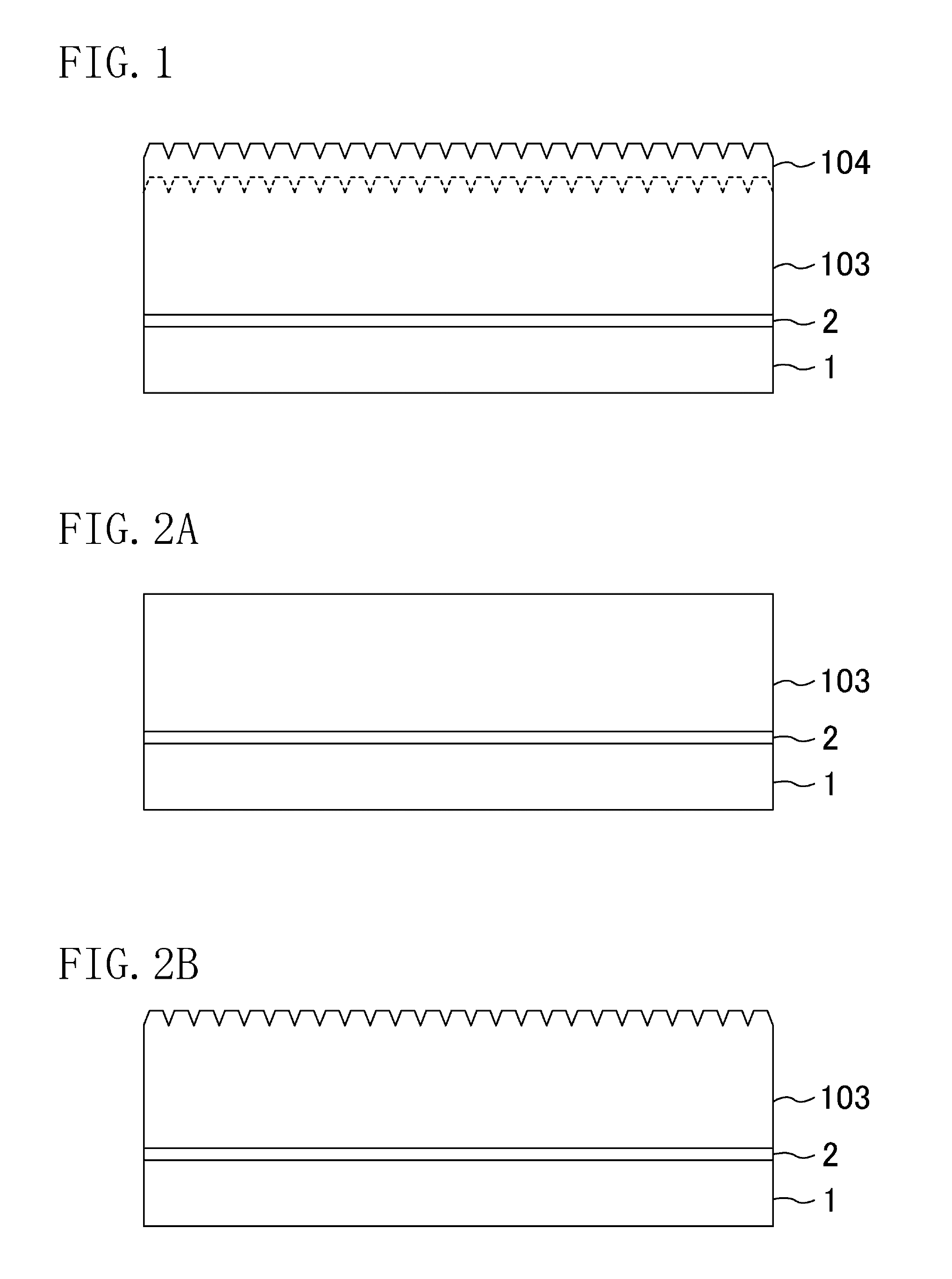

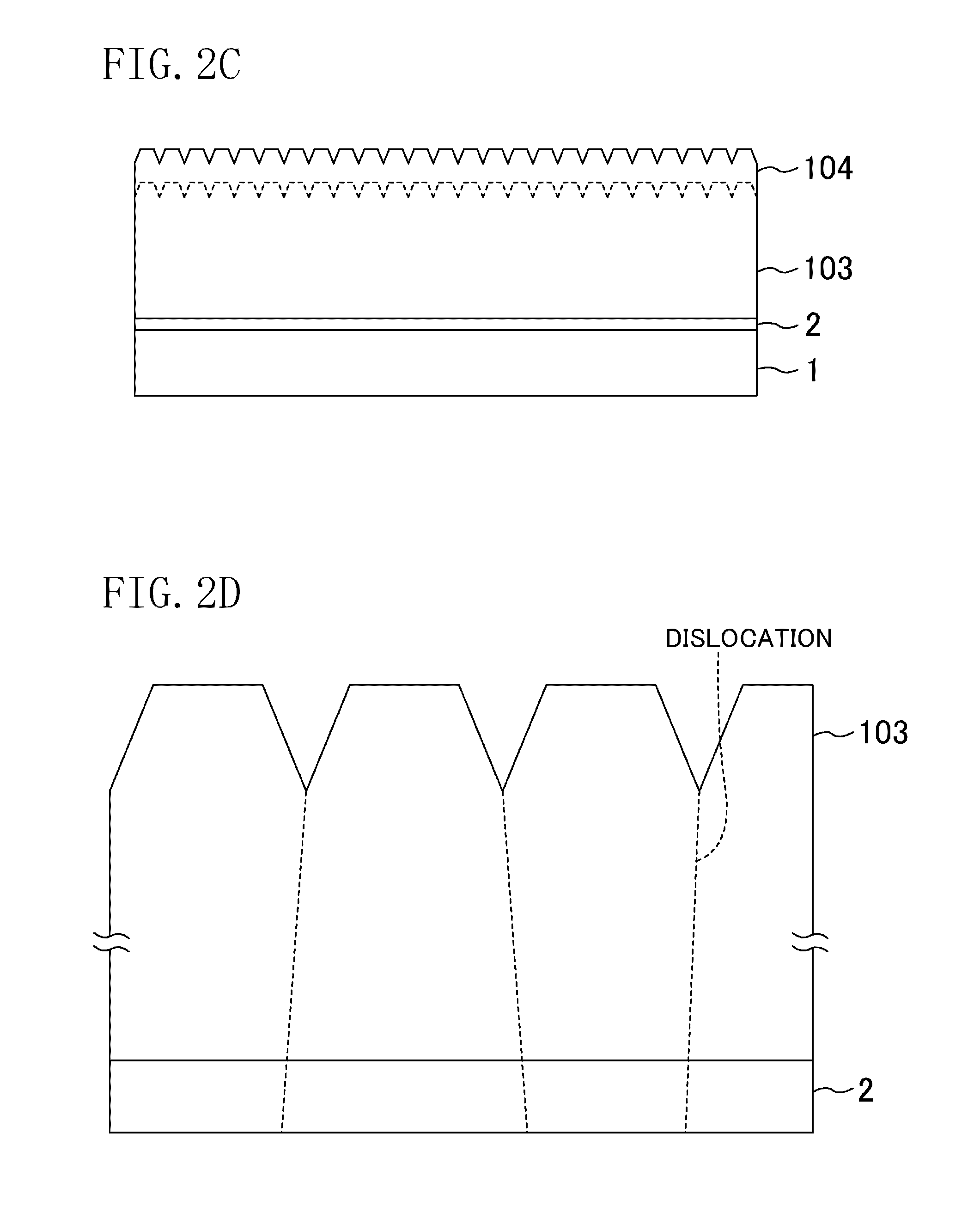

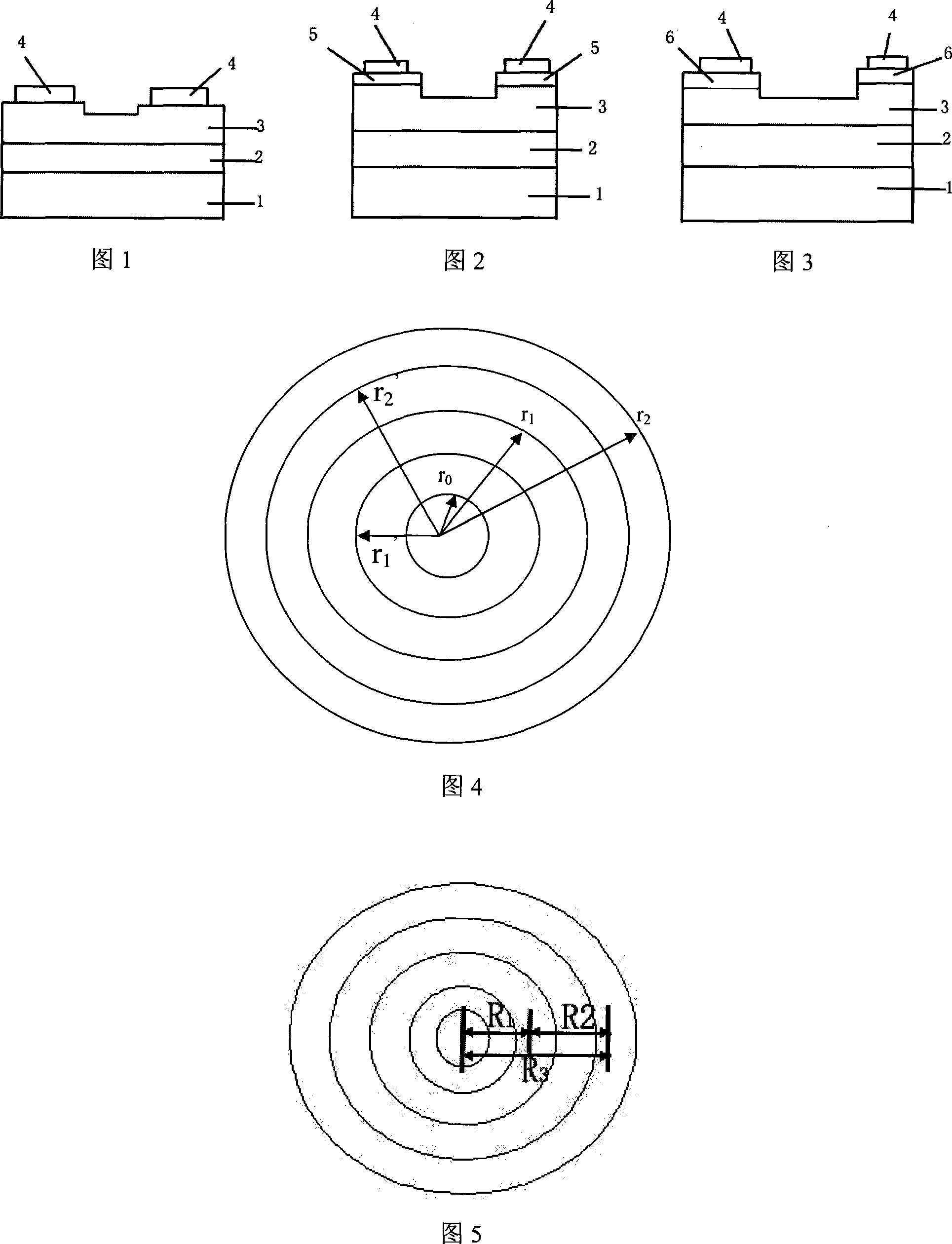

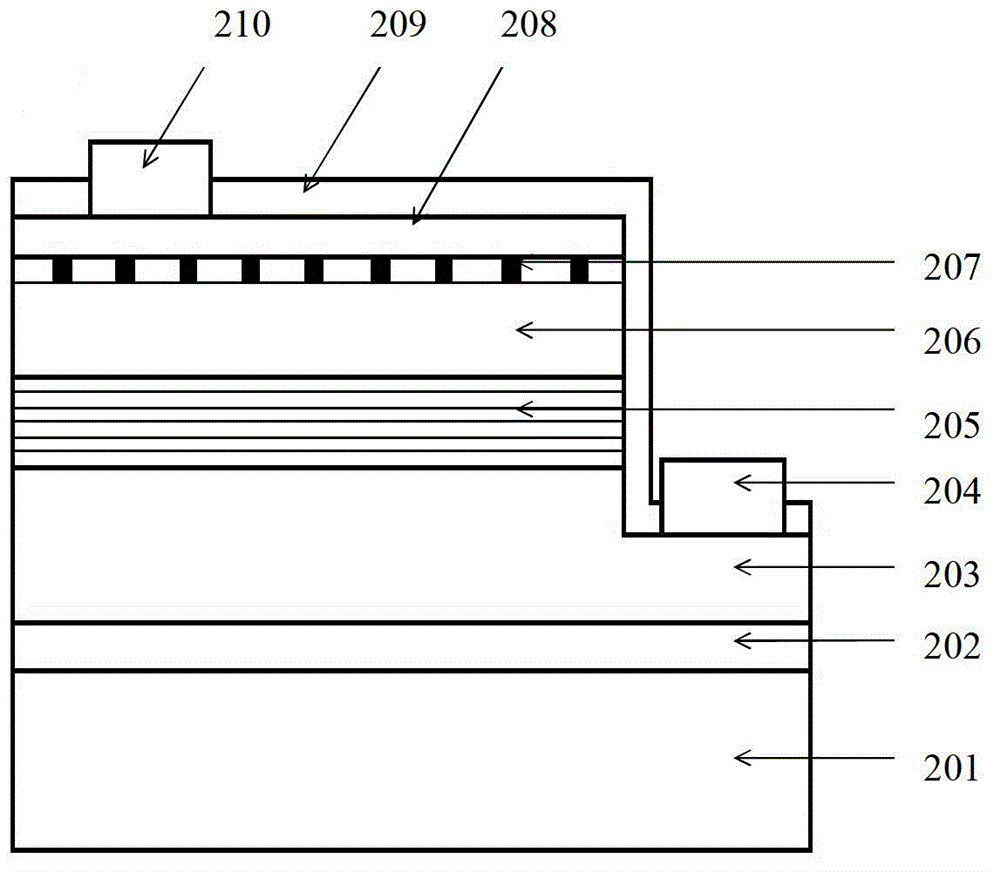

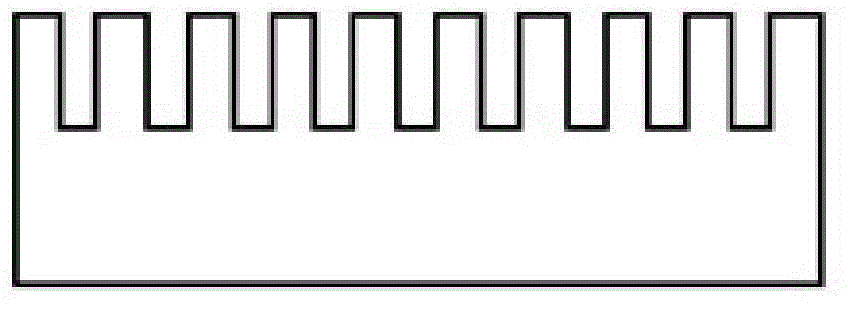

Light-emitting diode of photonic crystal structure and application thereof

ActiveCN102945902AImprove light extraction efficiencyReduced ohmic contact resistanceSemiconductor devicesCrystal structurePhotonic crystal structure

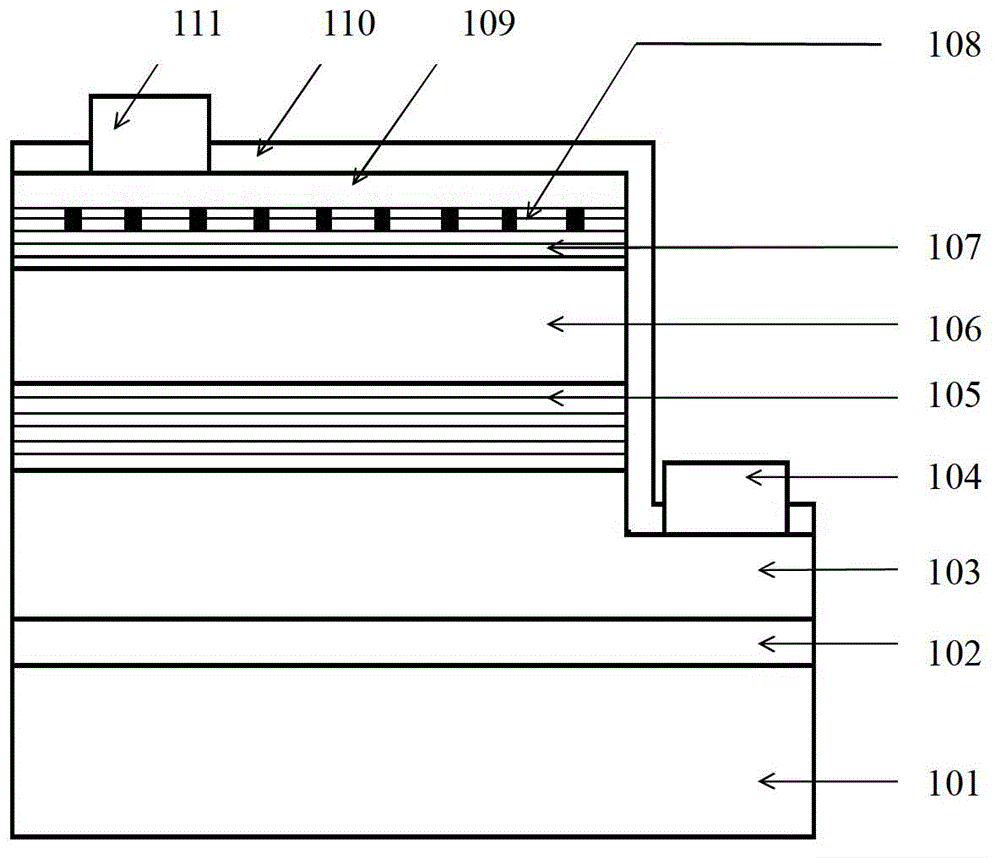

The invention provides a light-emitting diode of a photonic crystal structure. The light-emitting diode is provided with a substrate (101), a buffer layer (102), an n-type GaN epitaxial layer (103), an active luminescent layer (105) with InGaN / GaN multiple quantum wells, a p-type GaN epitaxial layer (106), a p-type super-lattice structure (107), a transparent conducting layer (109) and a passivation layer (110) in sequence from bottom to top, wherein an n-type electrode (104) is further arranged on the n-type GaN epitaxial layer (103); a p-type electrode (111) is further arranged on the transparent conducting layer (109); and a photonic crystal structure (108) is prepared in the p-type super-lattice structure (107). The light-emitting diode is applicable to a GaN-based LED (Light-emitting Diode), and is also applicable to other photo-electronic apparatuses which need to improve reflectivity of a certain wave band.

Owner:SOUTHEAST UNIV

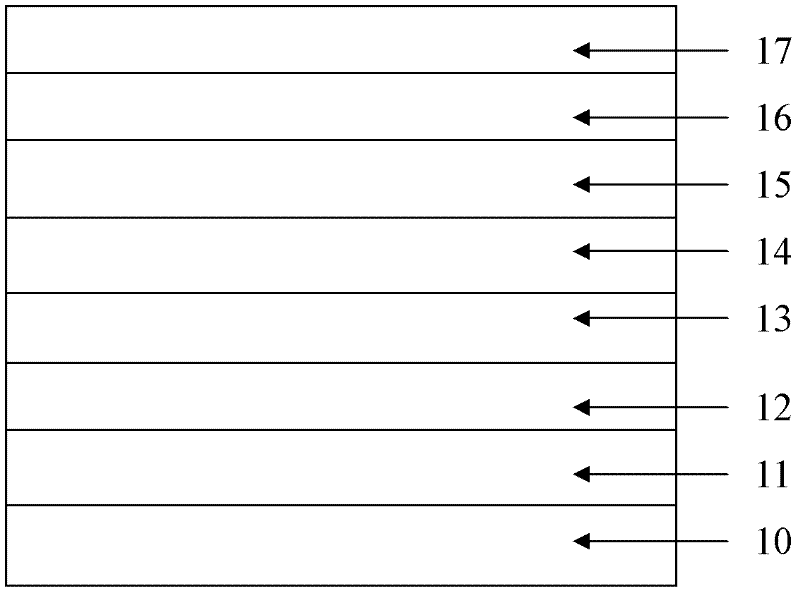

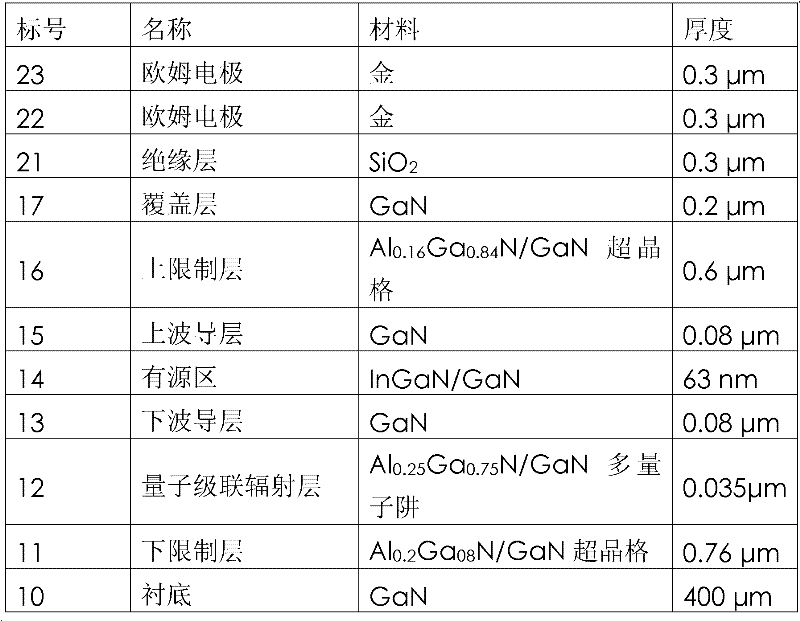

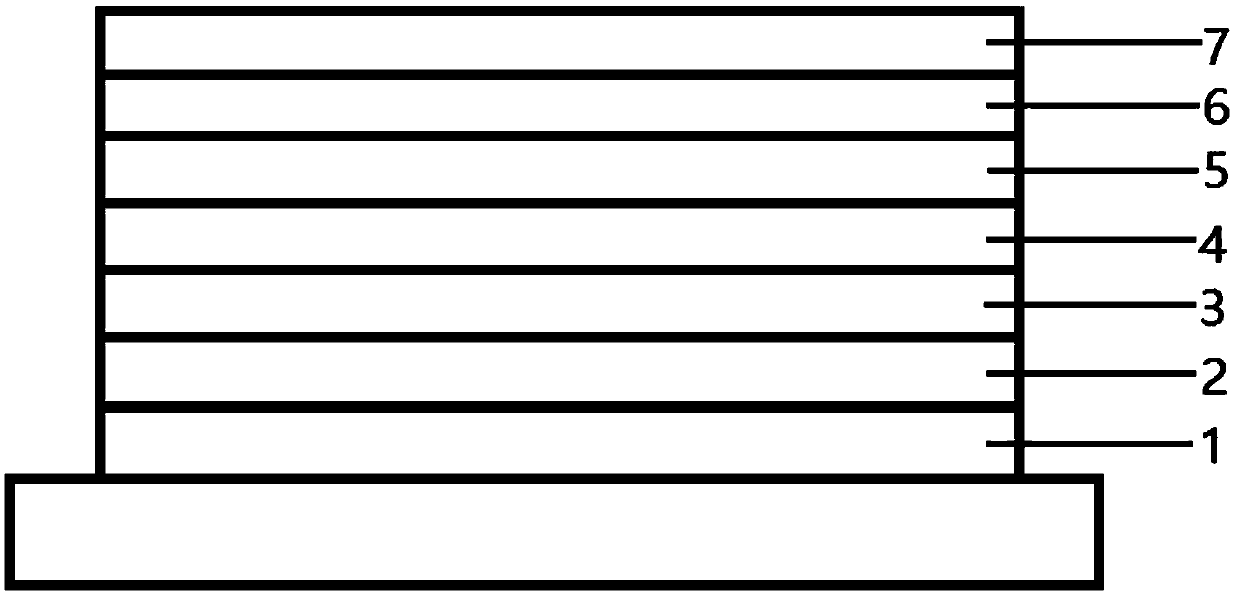

GaN (gallium nitride)-based semiconductor laser and manufacturing method thereof

InactiveCN102227046AReduce leakageIncrease the injection currentLaser detailsSemiconductor lasersIonizationMagnesium

The invention provides a GaN (gallium nitride)-based semiconductor laser and a manufacturing method thereof, belonging to the field of semiconductor lasers. The GaN-based semiconductor laser does not have an electronic barrier layer, thus reducing the working voltage of the laser and prolonging the service life of the laser. For the laser, a quantum cascade radiation layer is arranged between an n-type optical limited layer and an n-type waveguide layer of the laser and utilized to generate infrared radiation when the laser operates, thus realizing ionization of magnesium acceptor impurities in a p-type GaN waveguide layer and a AlGaN optical limited layer, improving carrier concentration in each p-type layer, increasing hole injection current, reducing leakage of electronics from an active area, avoiding introduction of a AlGaN electronic barrier layer and eliminating optical absorption loss caused by the magnesium-doped AlGaN electronic barrier layer, thereby reducing the threshold current of the laser, reducing the working voltage of the laser and prolonging the service life of the laser.

Owner:BEIJING UNIV OF CHEM TECH

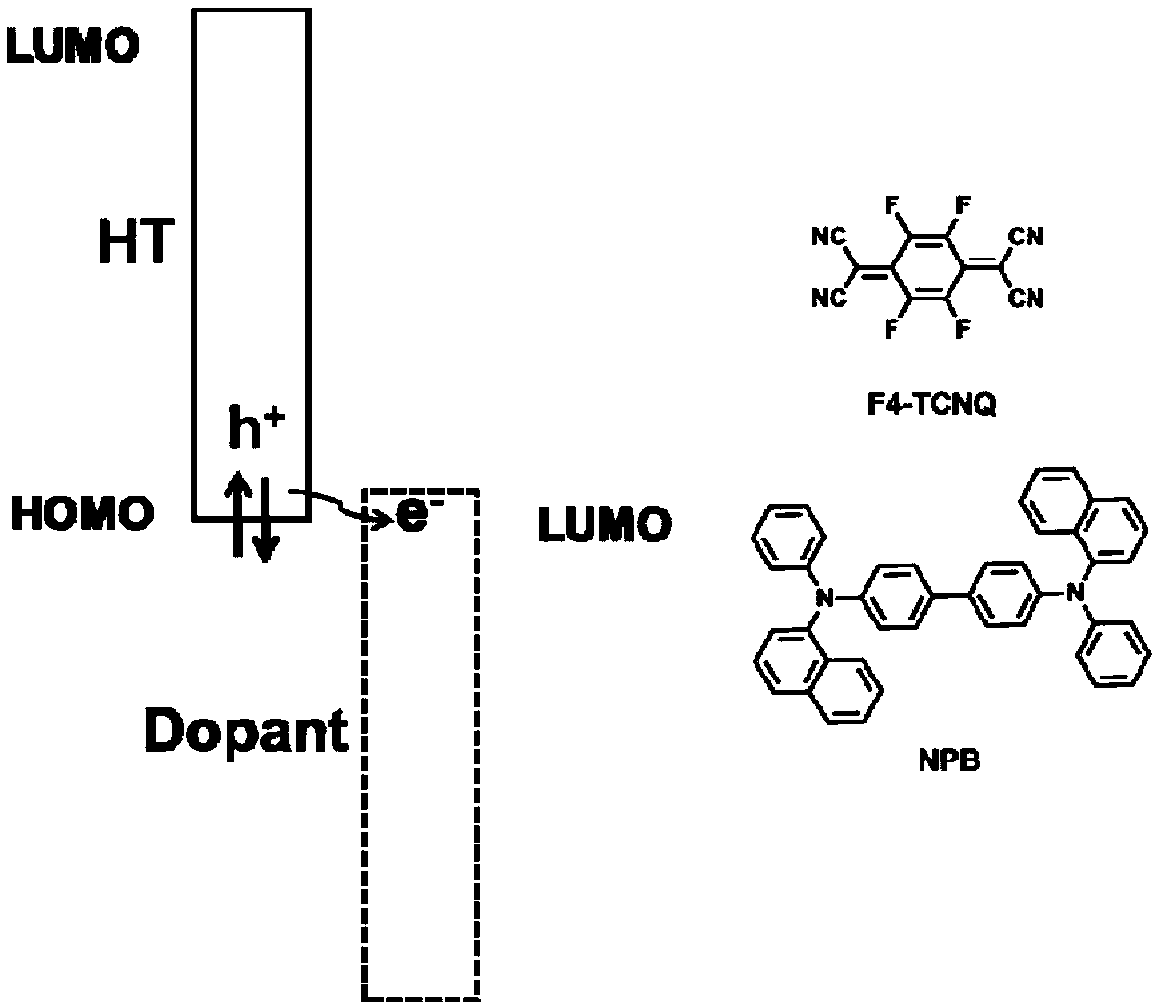

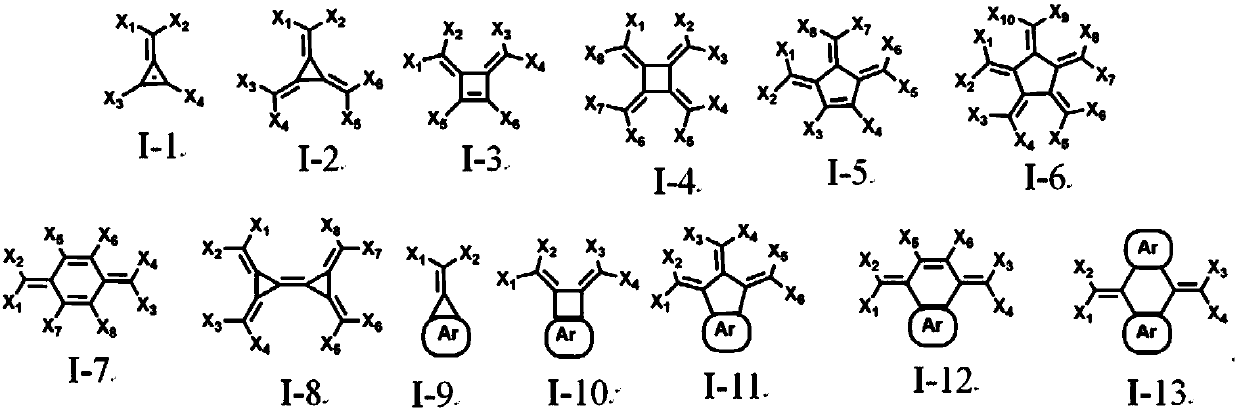

Multi-element ring-containing compound, application and organic electroluminescent device

ActiveCN109928894AImprove thermal stabilityReduce volatilityOrganic chemistrySolid-state devicesDecompositionThermal stability

The invention discloses a multi-element ring-containing compound, application and an organic electroluminescent device. The molecular design is carried out on the multi-element ring-containing compound, so that low molecular LUMO energy level (-4.0 to -6.0 ev) is effectively realized, and the LUMO energy level of the molecule can be well matched with the HOMO of a hole transport material, when themulti-element ring-containing compound is used as a hole doping material in the organic electroluminescent device, the hole concentration and the hole mobility can be effectively improved, and the hole transmission and injection efficiency can be improved. Meanwhile, through accurate regulation and control of the molecular structure, the molecule has good thermal stability, low volatility and high decomposition temperature, and can be uniformly and stably distributed in a specific functional layer.

Owner:NINGBO LUMILAN NEW MATERIAL CO LTD

Diamond semiconductor element and process for producing the same

ActiveUS20080134960A1Reduce generationImprove transconductanceSolid-state devicesVacuum evaporation coatingRefractive indexWaveguide

An integrated optical waveguide has a first optical waveguide, a second optical waveguide, and a groove. The second optical waveguide is coupled to the first optical waveguide and has a refractive index that is different from the first optical waveguide. The groove is disposed so as to traverse an optical path of the first optical waveguide and is separated from an interface between the first optical waveguide and the second optical waveguide by a predetermined spacing. The spacing from the interface and the width of the groove are determined such that reflection at a boundary between the first optical waveguide and the second optical waveguide is weakened. A semiconductor board may be disposed at a boundary between the first optical waveguide and the second optical waveguide. In this case, the width of the groove and the thickness of the semiconductor board are determined such that light reflected off an interface between the first optical waveguide and the groove is weakened by light reflected from an interface between the groove and the semiconductor board, and by light reflected from an interface between the semiconductor board and the second optical waveguide.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

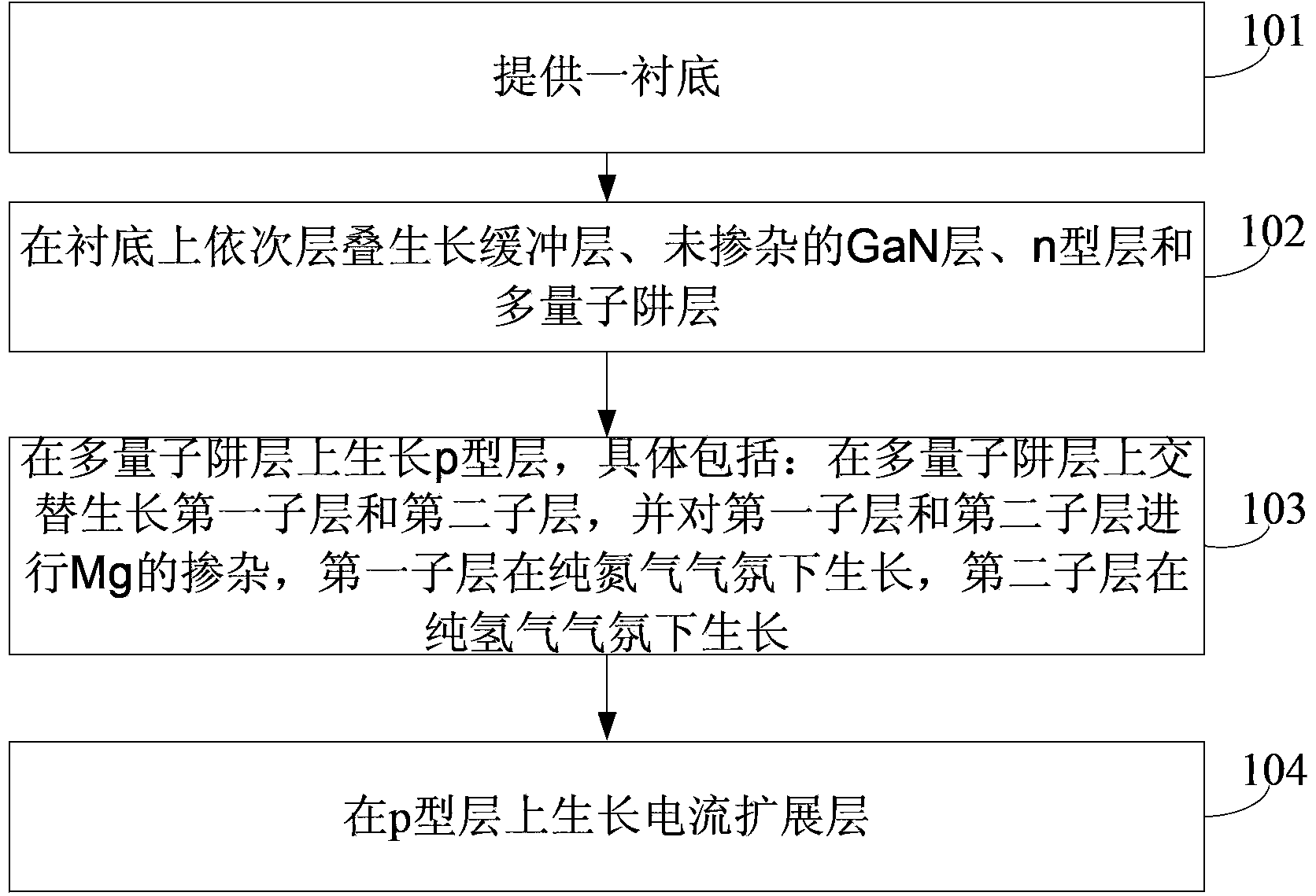

GaN-base light-emitting diode chip growing method

ActiveCN103515495AIncrease hole concentrationImprove efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesMultiple quantumNitrogen atmosphere

The invention discloses a GaN-base light-emitting diode chip growing method and belongs to the technical field of semiconductors. The method comprises the steps that a substrate is provided; a buffering layer, an undoped GaN layer, an n-type layer and a multiple-quantum-well layer grow on the substrate in sequence in an overlapping mode; a p-type layer and a current expanding layer grow on the multiple-quantum-well layer; the p-type layer grows on the multiple-quantum-well layer. Specifically, the GaN-base light-emitting diode chip growing method comprises the steps that a first sub-layer and a second sub-layer grow on the multiple-quantum-well layer in an alternating mode, Mg doping is carried out on the first sub-layer and the second sub-layer, the first sub-layer grows in a pure-nitrogen atmosphere, and the second sub-layer grows in a pure-hydrogen atmosphere. According to the method, the first sub-layer grows in the pure-nitrogen atmosphere, doped Mg activation can be well improved, Mg activation can improve hole concentration; the second sub-layer grows in the pure-hydrogen atmosphere, due to the strong reducing property of hydrogen, impurities in crystals can be reduced, the injection efficiency of holes is increased, and crystal quality and chip light-emitting efficiency are improved.

Owner:HC SEMITEK CORP

LED epitaxial structure of composite P-type GaN layer and fabrication method of LED epitaxial structure

InactiveCN106784184AImprove solubilityImprove luminous efficiencySemiconductor devicesDopantSolubility

The invention provides an LED epitaxial structure of a composite P-type GaN layer and a fabrication method of the LED epitaxial structure. The P-type GaN layer of the LED epitaxial structure sequentially comprises a first P-type GaN layer, a second P-type GaN layer and a third P-type GaN layer, wherein the thickness of the first P-type GaN layer is 40-80 nanometers, the thickness of the second P-type GaN layer is 30-70 nanometers, and the thickness of the third P-type GaN layer is 4-10 nanometers. In the P-type GaN layer structure, two effects are achieved by simultaneously doping an n-type dopant and a P-type dopant: the solubility of the dopants (the formation energy of the dopants is reduced) is increased to prevent a self-compensation effect, and the activation ratio is improved by reducing an acceptor level, so that the self-compensation effect of the P-type GaN layer is prevented better, the hole concentration is improved, and the purpose of improving the luminous efficiency and the electricity of a GaN device is achieved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

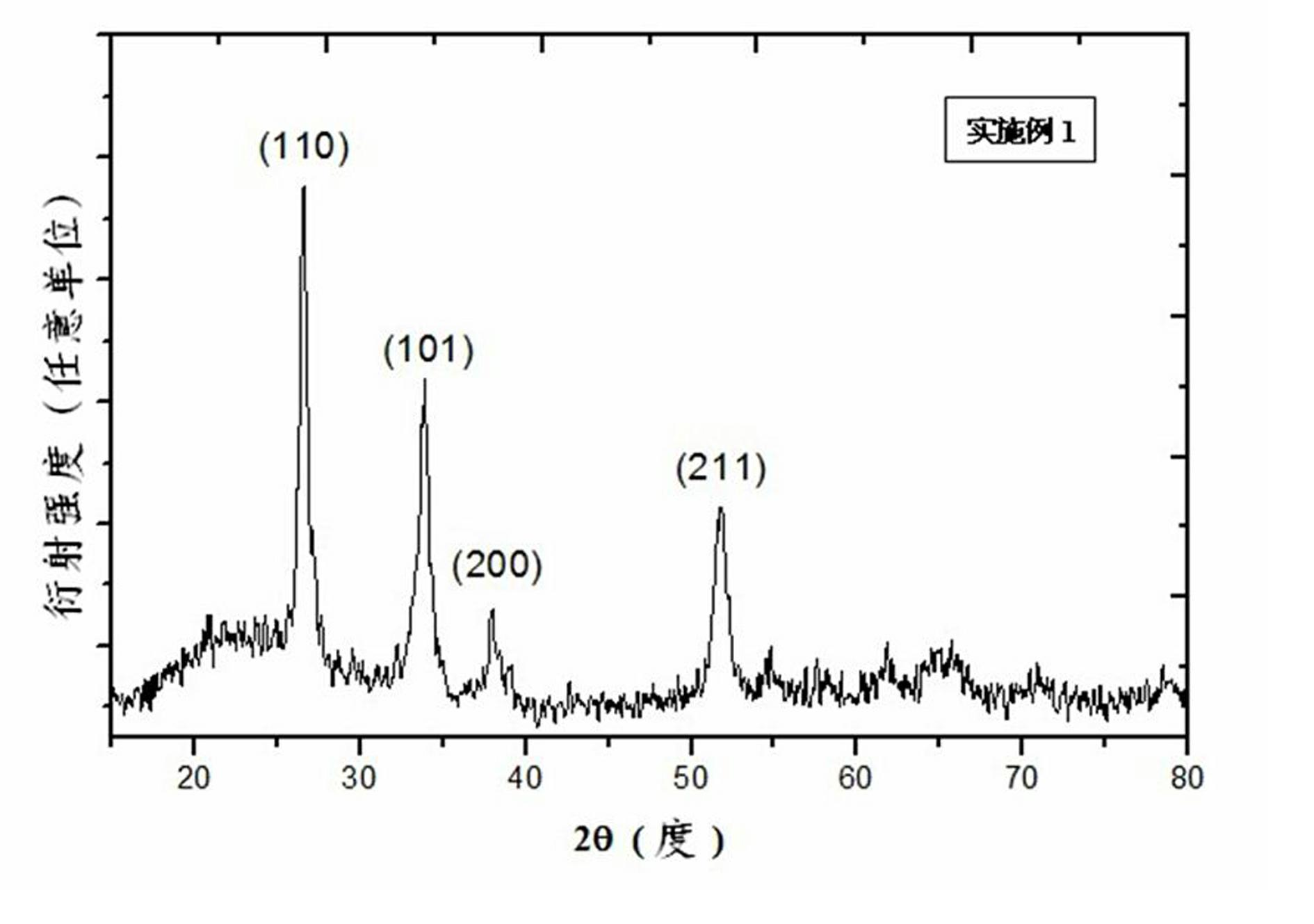

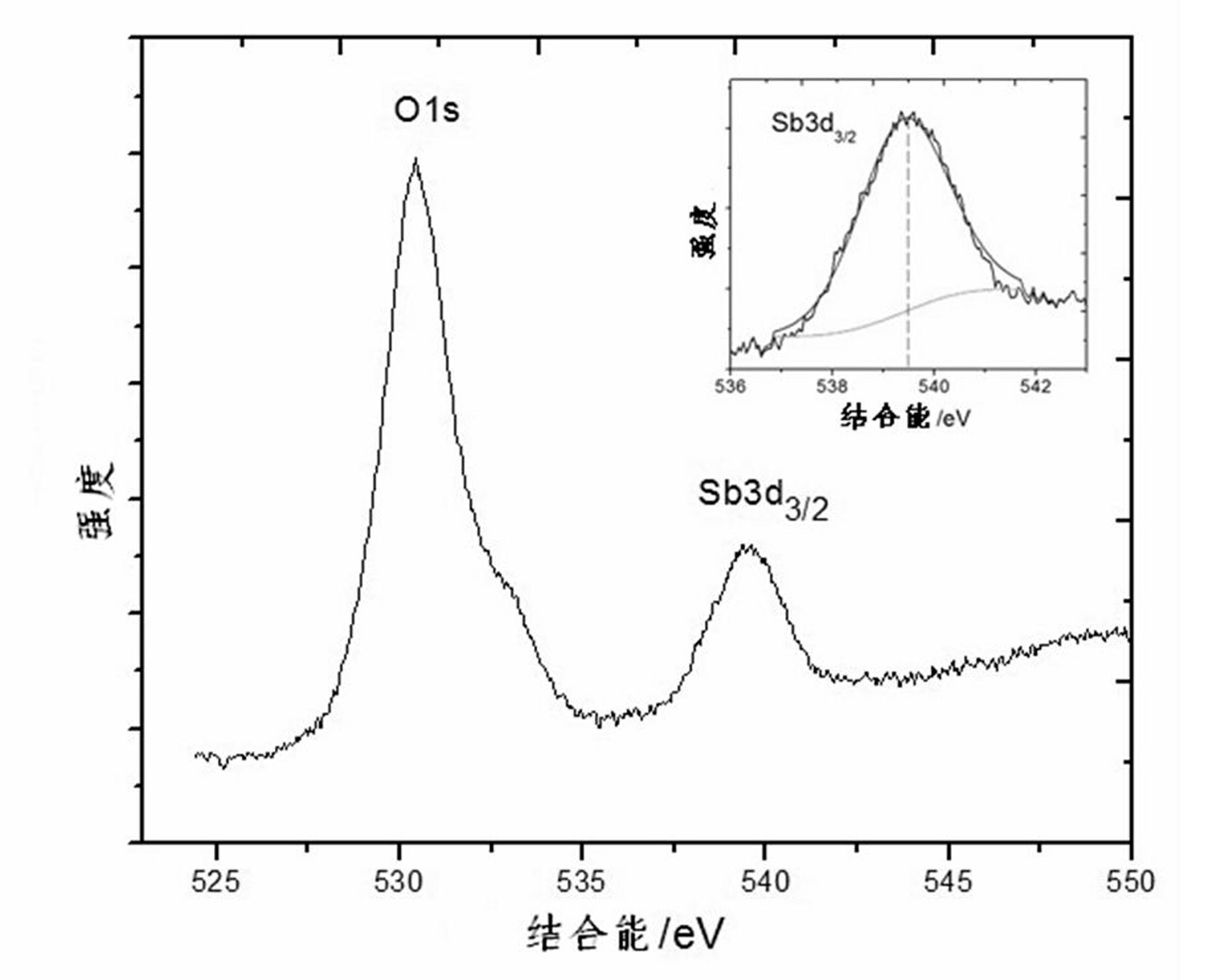

P-type electric-conducting Sb mixed SnO2 film and stannic oxide homogeneous pn junction containing film and preparation methods thereof

InactiveCN102586748AMature technologyProcess conditions are easy to controlVacuum evaporation coatingSputtering coatingVolt-ampereOrder of magnitude

The invention relates to a p-type electric-conducting Sb mixed SnO2 film and a stannic oxide homogeneous pn junction containing film and preparation methods thereof. The p-type electric-conducting Sb mixed SnO2 film is prepared by adopting Sb mixed SnO2 ceramic target on single crystal and quartz glass in a magnetron sputtering method. The stannic oxide homogeneous pn junction is prepared by sputtering and depositing an n-type Sb mixed SnO2 film on the p-type electric-conducting Sb mixed SnO2 film. The p-type electric-conducting Sb mixed SnO2 film is stable in electric conductivity, has high hole concentration, hole mobility and specific conductance and has high transparency in visible light, wherein hole concentration is as high as 1020cm-3 order of magnitudes, specific conductance is 60S.cm-1, and hole mobility is as high as 2-30cm<2>V-1s-1. The preparation methods are simple in process and good in repeatability, can be industrialized easily, and the prepared homogeneous stannic oxide based transparent pn junction has volt-ampere curve characteristics of wide bandgap semiconductor pn junction.

Owner:WUHAN UNIV OF TECH

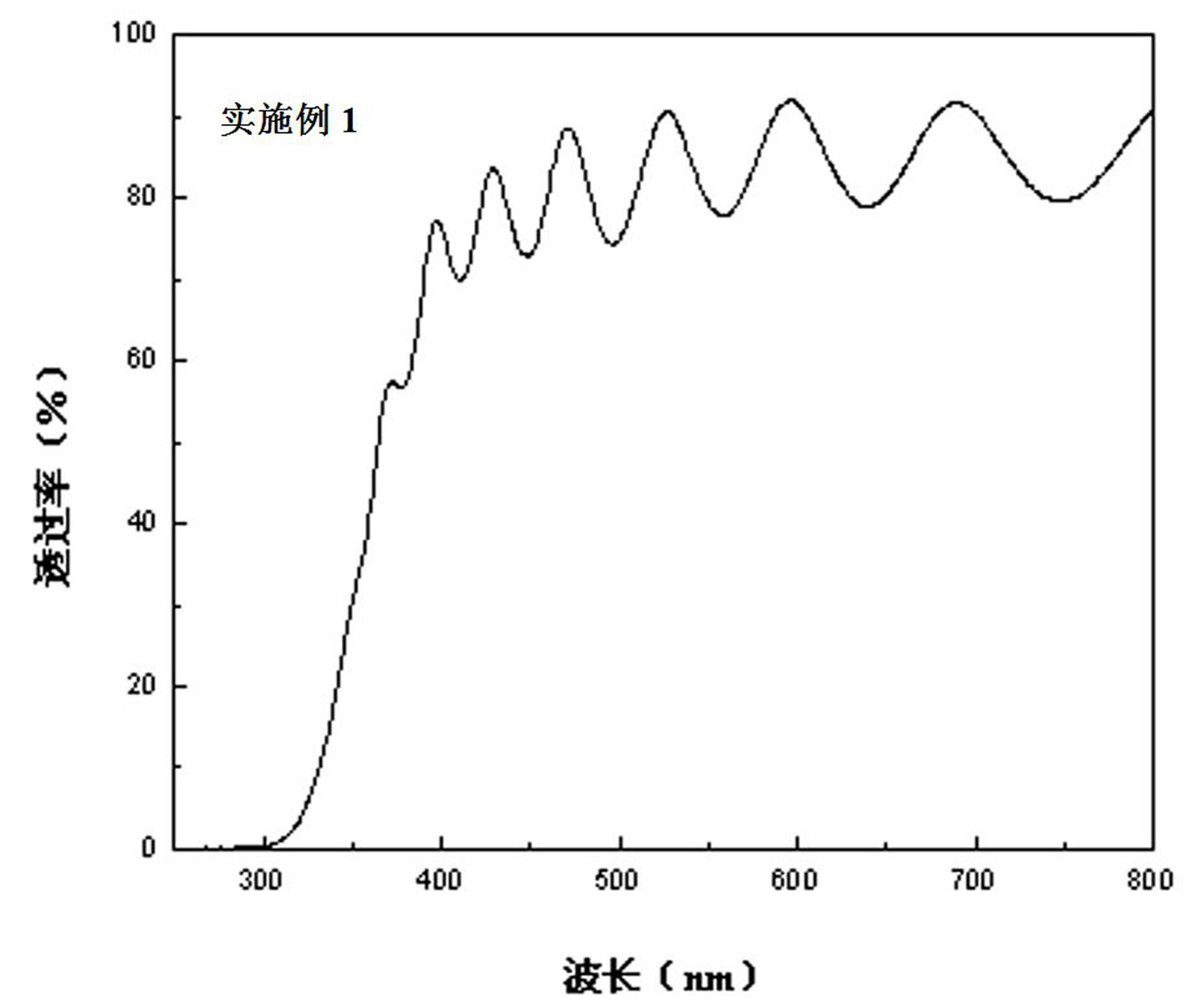

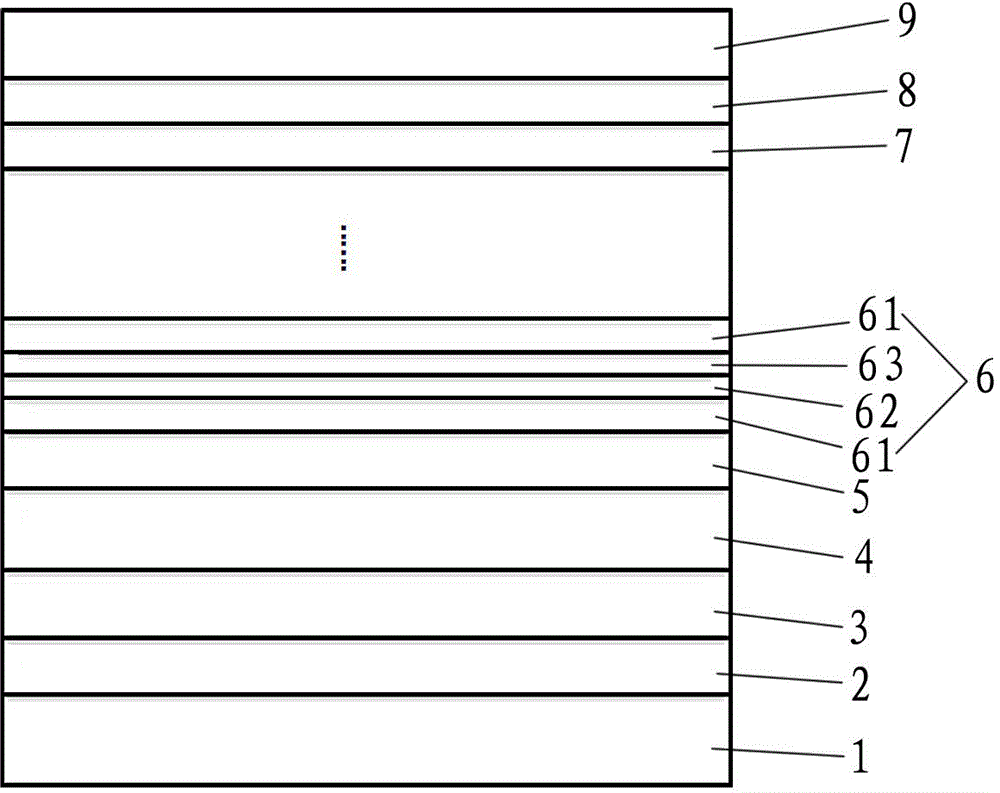

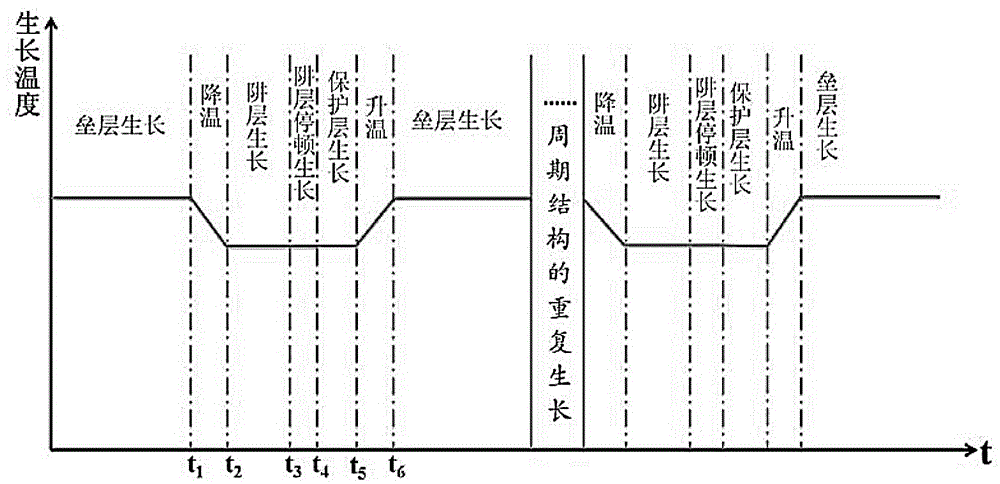

Method for growing LED epitaxial structure with high-quality InGaN/GaN active layer

ActiveCN104319330AQuality improvementImprove luminous efficiencySemiconductor devicesOptoelectronicsActive layer

The invention discloses a method for growing an LED epitaxial structure with a high-quality InGaN / GaN active layer. The InGaN / GaN active layer is grown by use of the steps of introducing a Ga source and NH3 to grow a GaN barrier layer of 8-5nm in the atmosphere of H2 serving as a main carrier gas, switching the main carrier gas to N2 and introducing the Ga source, an In source and the NH3 to grow an InxGa1-xN trap layer of 2-5nm, shutting down the Ga source and the In source while keeping normal introduction of the NH3 to stop the growth of the InxGa1-xN, turning on the Ga source to grow a GaN protective layer of 1-5nm, switching the main carrier gas to the H2 and introducing the Ga source and the NH3 to grow the GaN barrier layer of 8-5nm, and finally, repeating the second to fifth growth steps for 1-20 cycles. The method for growing the LED epitaxial structure with the high-quality InGaN / GaN active layer is capable of obtaining the high-quality InGaN / GaN active layer and improving the LED luminous efficiency.

Owner:XIAMEN CHANGELIGHT CO LTD

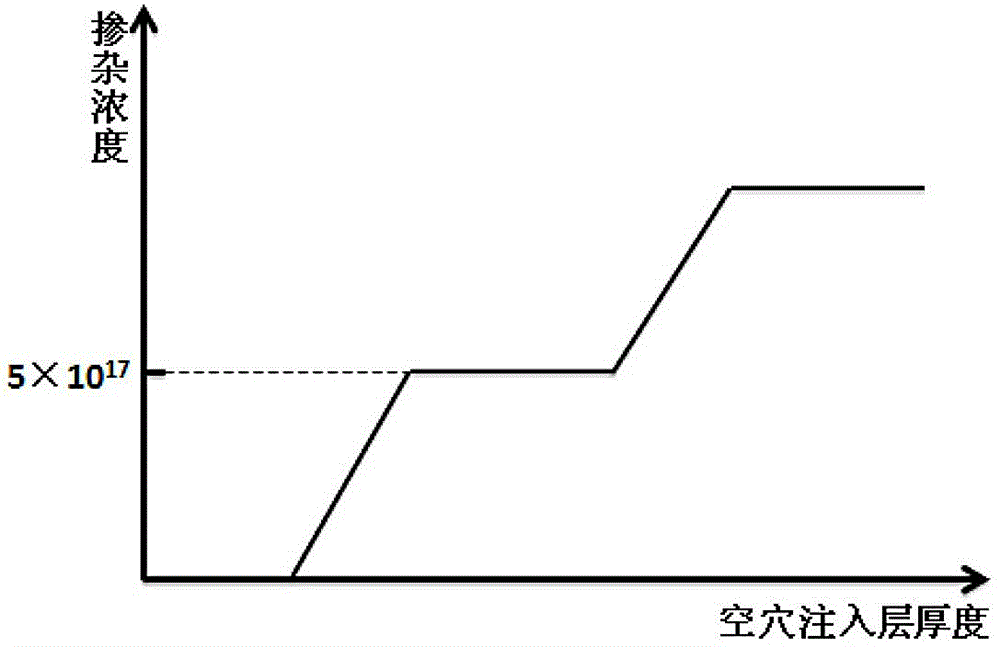

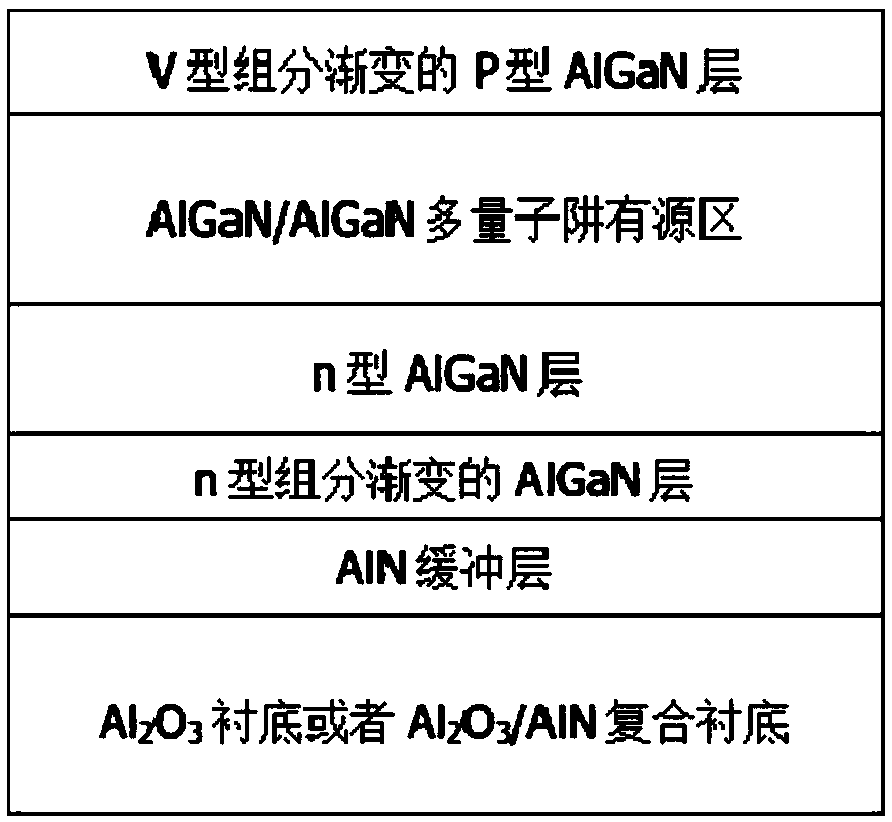

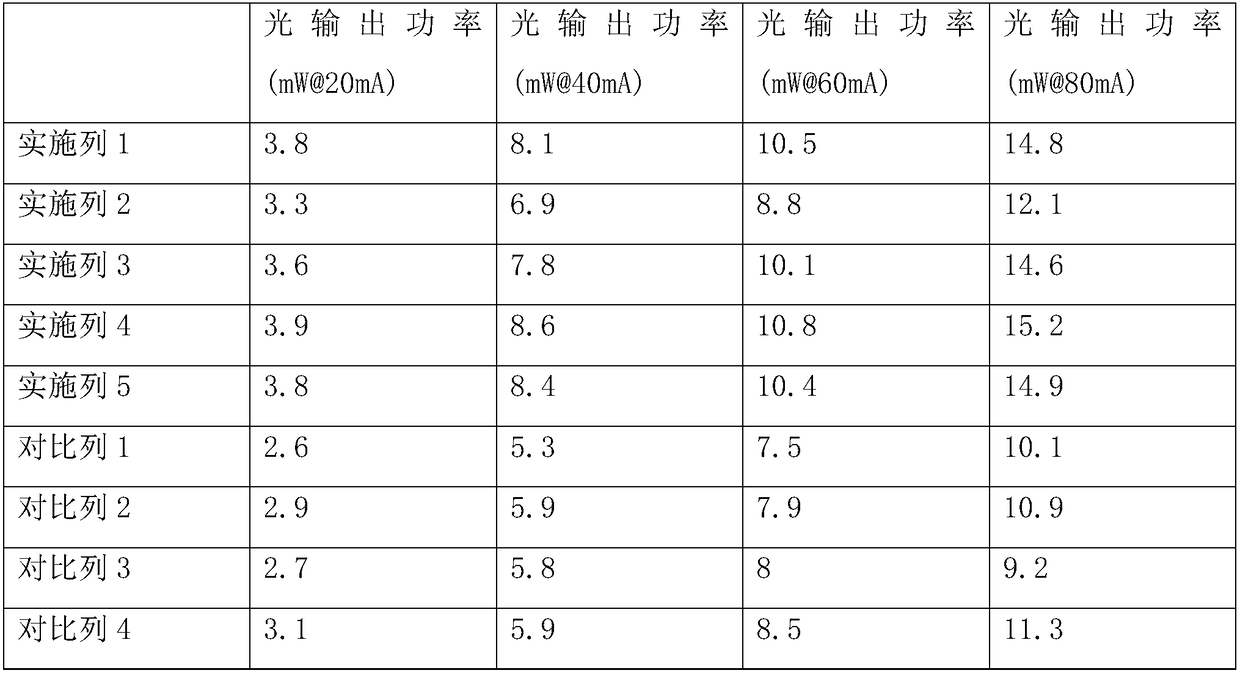

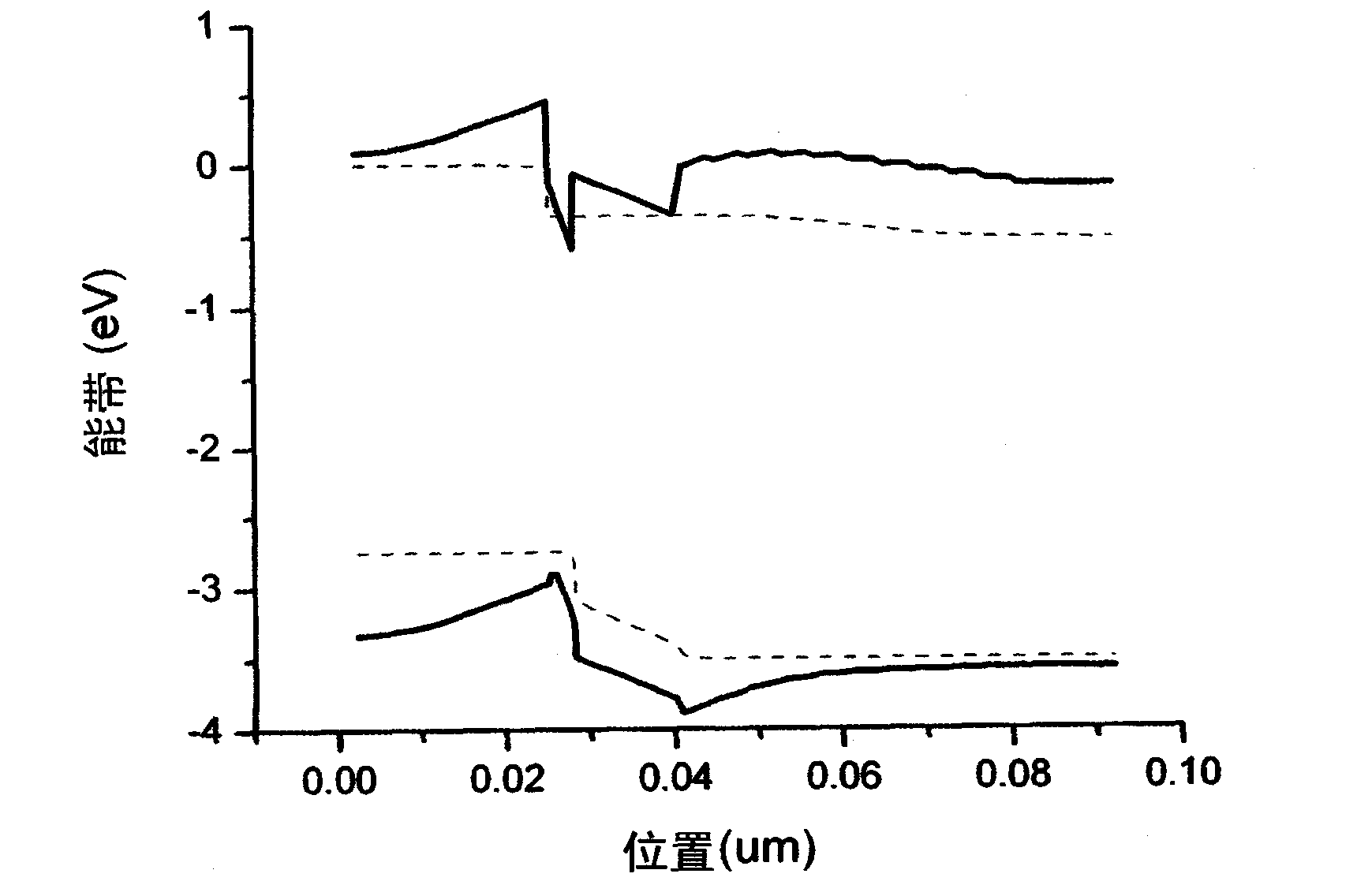

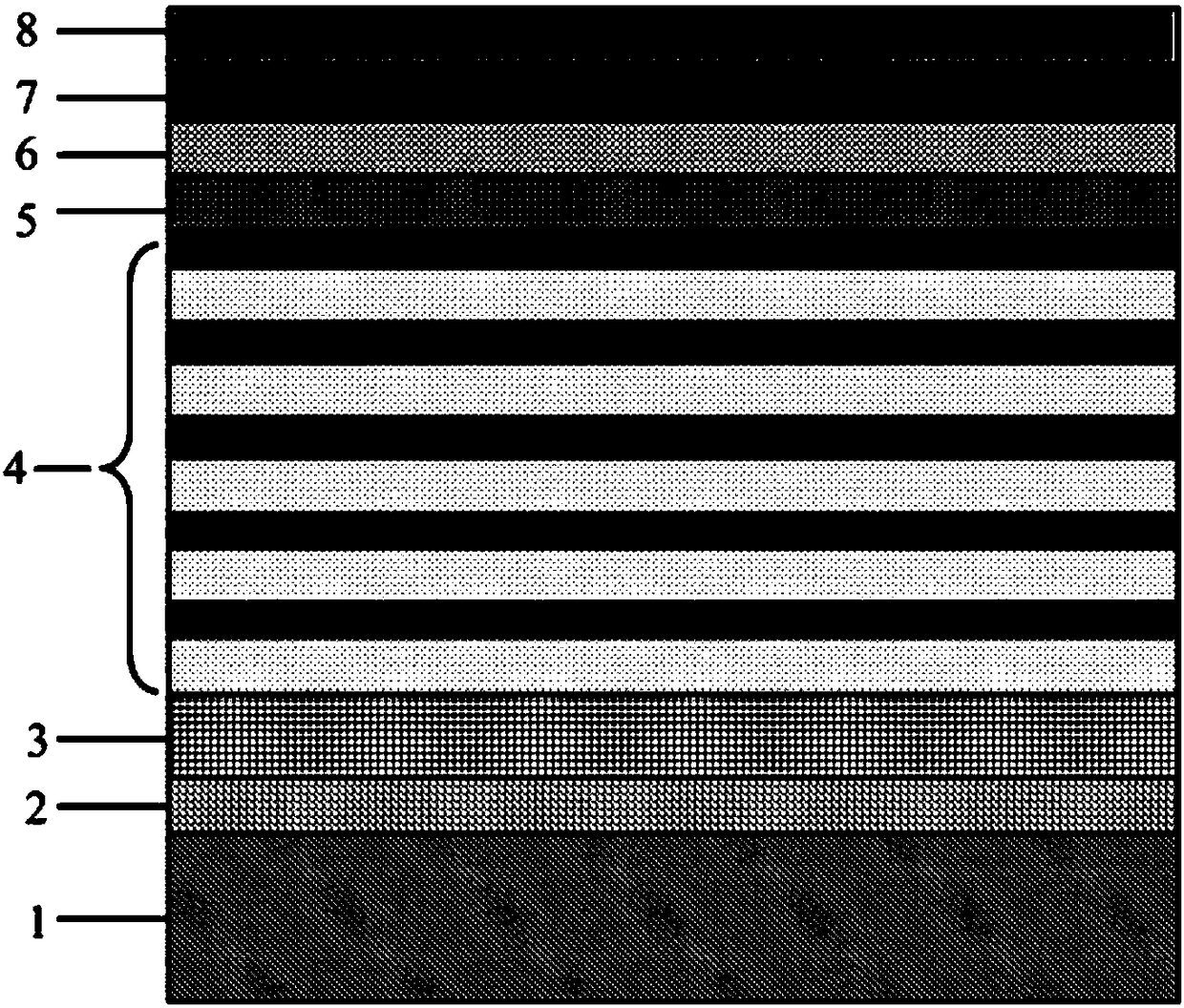

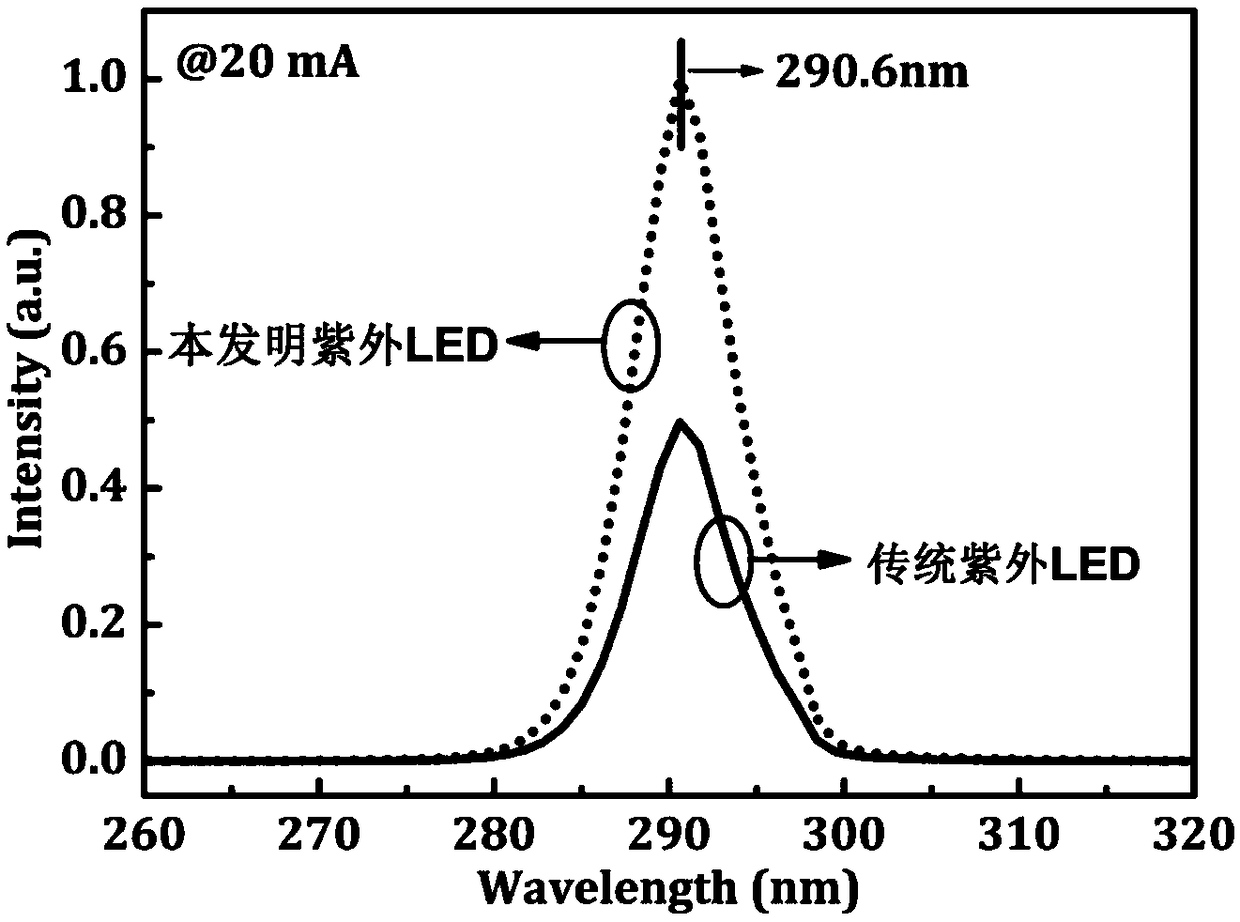

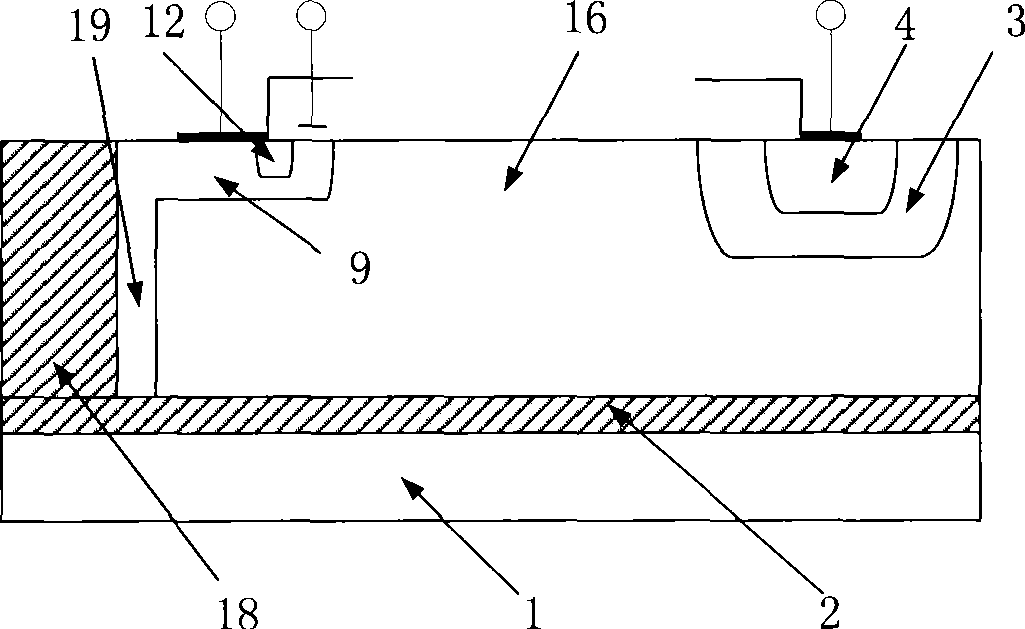

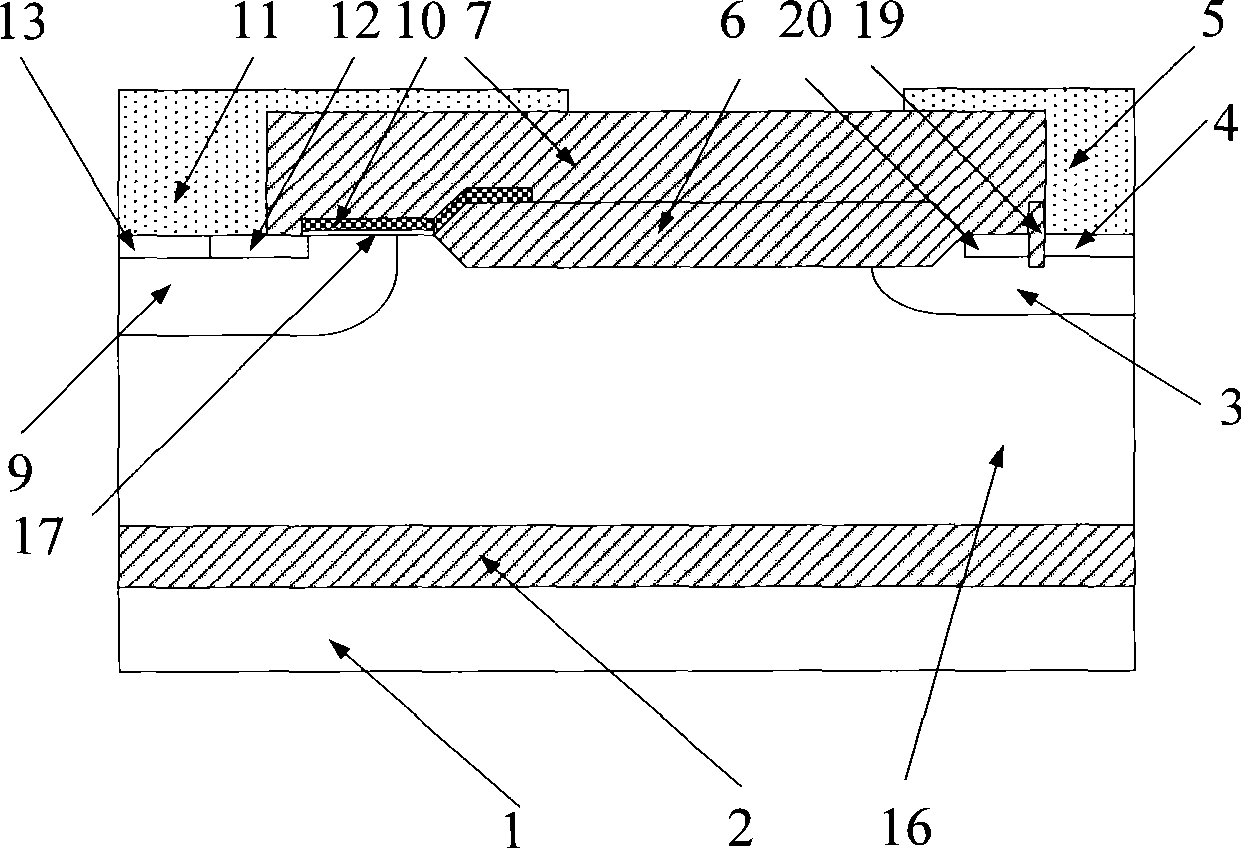

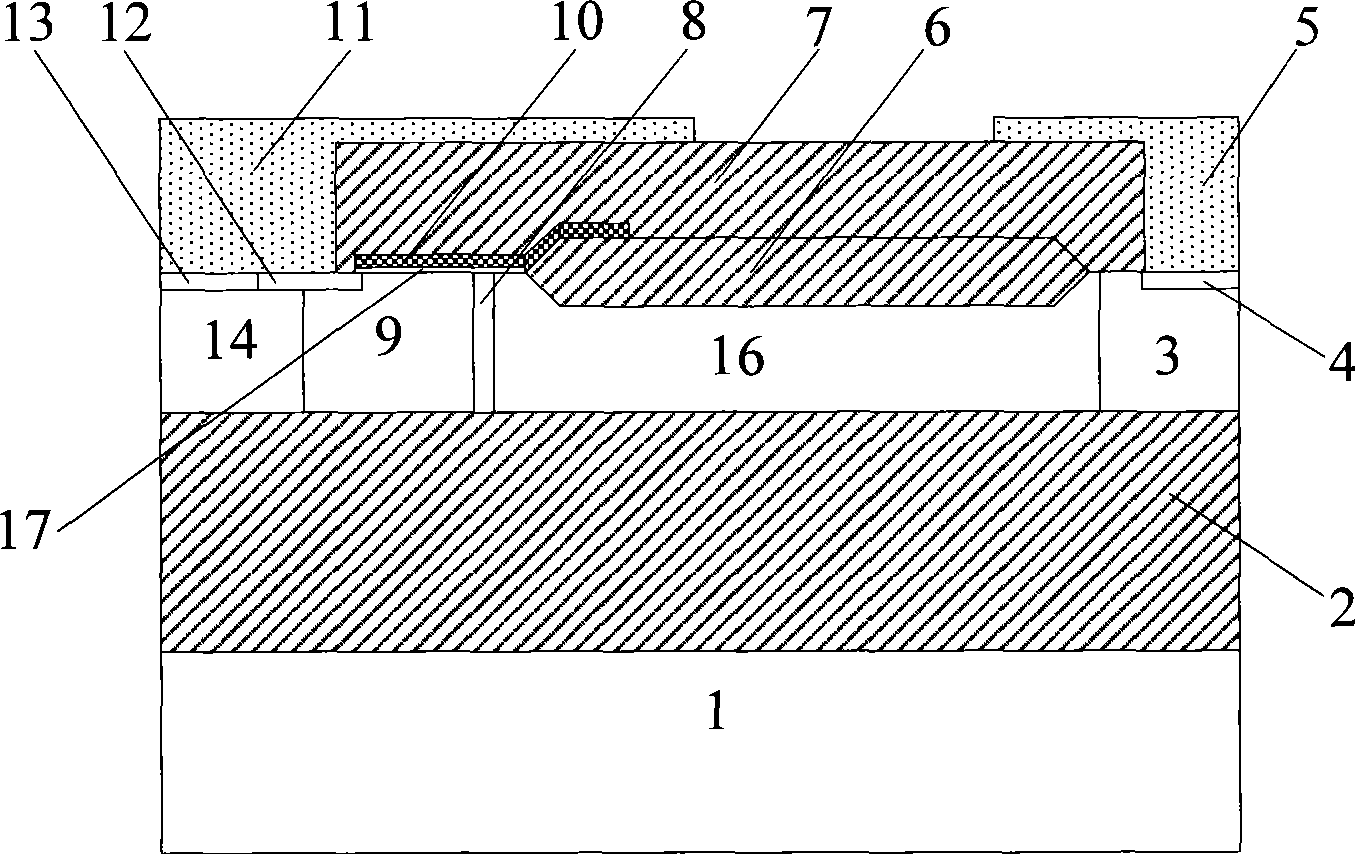

Preparation method of high-luminance V-shaped polarized doped deep ultraviolet LED

ActiveCN108365069AIncrease hole concentrationAvoid light absorptionSemiconductor devicesQuantum wellUltraviolet

The invention provides a preparation method of a high-luminance V-shaped polarized doped deep ultraviolet LED. The prepared deep ultraviolet LED structure comprises a substrate, an AlN buffer layer, astress relief layer, an N type AlGaN layer, an AlGaN / AlGaN multi-quantum-well active region and a P type AlGaN layer with V-shaped gradually changed Al components. By virtue of the P type AlGaN layerwith the V-shaped gradually changed Al components, the light emitting efficiency is improved; meanwhile, by adopting the V-shaped gradually changed structure to replace a P type AlGaN electron barrier layer, a P type AlGaN contact layer and a P type P-GaN layer, the light extracting efficiency is improved; and by virtue of the structure, the hole concentration of the P type layer is greatly improved, light absorption of the P type contact layer is avoided fundamentally, the manufacturing process is simple, and industrial production can be realized.

Owner:迪优未来科技(清远)有限公司

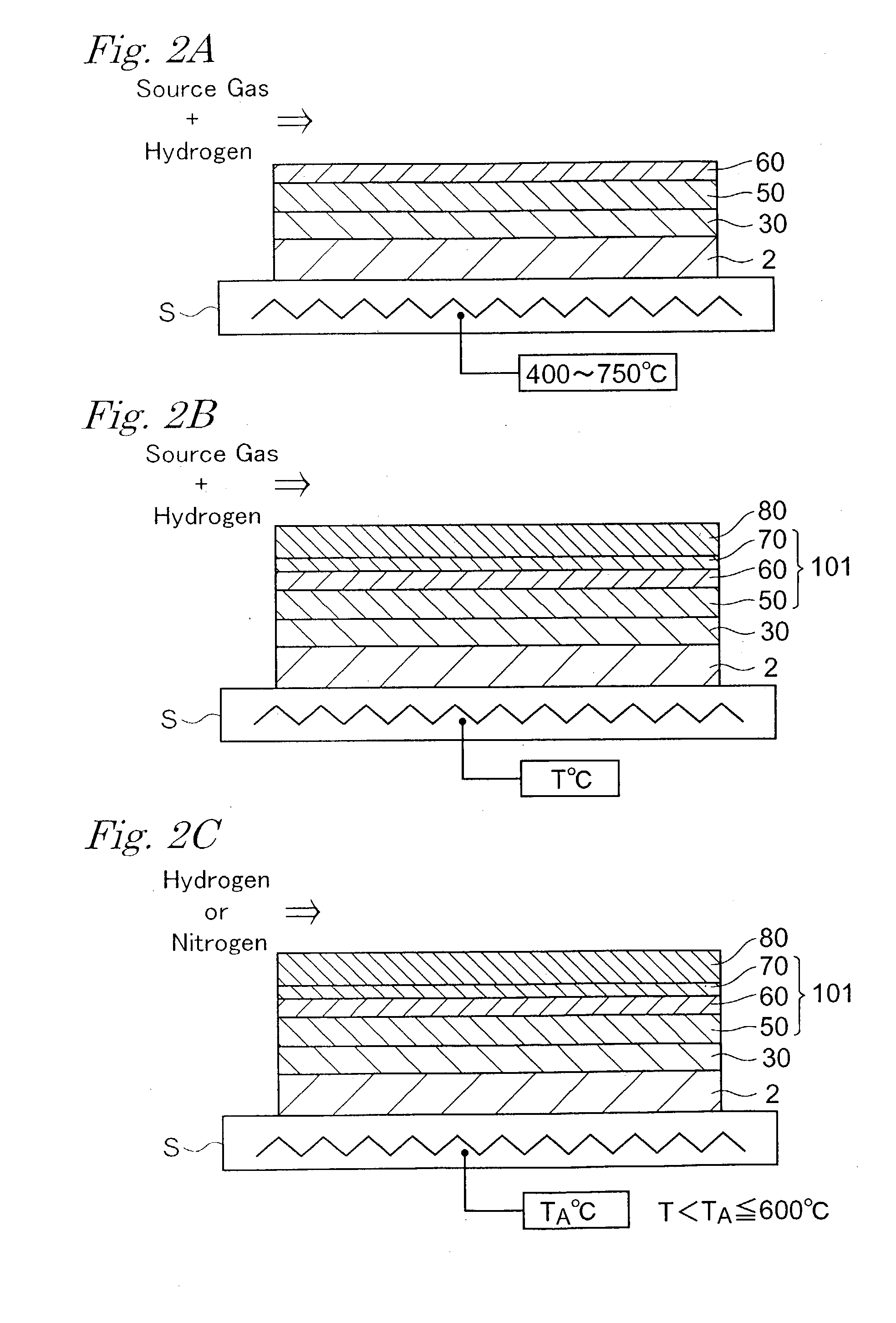

Method of manufacturing a hetero-junction bipolar transistor

InactiveUS20030232478A1Increase hole concentrationDeterioration of the surface morphology of grown semiconductor layer can be preventedTransistorSemiconductor/solid-state device manufacturingPhysical chemistrySemiconductor

This invention provides a method for manufacturing a hetero-junction bipolar transistor, in which a hole concentration of a base layer doped with carbon can be increased. The method comprises the following steps. 1) A sub-collector 30, a collector 50, a base 60 doped with carbon are sequentially grown after setting a semiconductor substrate on the stage in the growth chamber; 2) an emitter 70 and an emitter contact 80 are grown at a temperature T; and 3) grown layers are annealed at a temperature TA, where the relation of T<Ta<=600° is satisfied. This process enhances the activation of carbon atoms by dissociating hydrogen atoms captured in the base 60 to the ambience.

Owner:SUMITOMO ELECTRIC IND LTD

GaN-based LED epitaxial wafer and preparation method thereof

InactiveCN101299449AImprove performanceSimple manufacturing methodSemiconductor devicesValence bandQuantum well

The invention discloses a GaN base LED epitaxial wafer with the p-type contact layer and the preparation method, wherein the structure of the epitaxial wafer is a substrate, a low temperature buffer layer, an n-type layer, a quantum well, a p-type layer, a p-type contact layer in turn from the lower to the upper and the p-type contact layer is the quantum well layer structure. The invention is added with a p-type contact layer structure on the structure basis of the epitaxial wafer, wherein the p-type contact layer adopts the quantum well structure, due to the different energy of the well layer and the barrier layer valence band to effectively advance the hole density of the layer. Meanwhile, the motion of the hole on the direction vertical to the quantum well plane is restricted, which is favorable for the two-dimensional motion for the hole on the quantum well plane, under the applied voltage is favorable for the expansion in the p-type layer to cause the current distribution more uniform, to increase the performance of the LED. The preparation method of the epitaxial wafer provided in the invention is simple, low in cost, precise in the preparation condition, which realizes the industrialization production.

Owner:SOUTH CHINA NORMAL UNIVERSITY

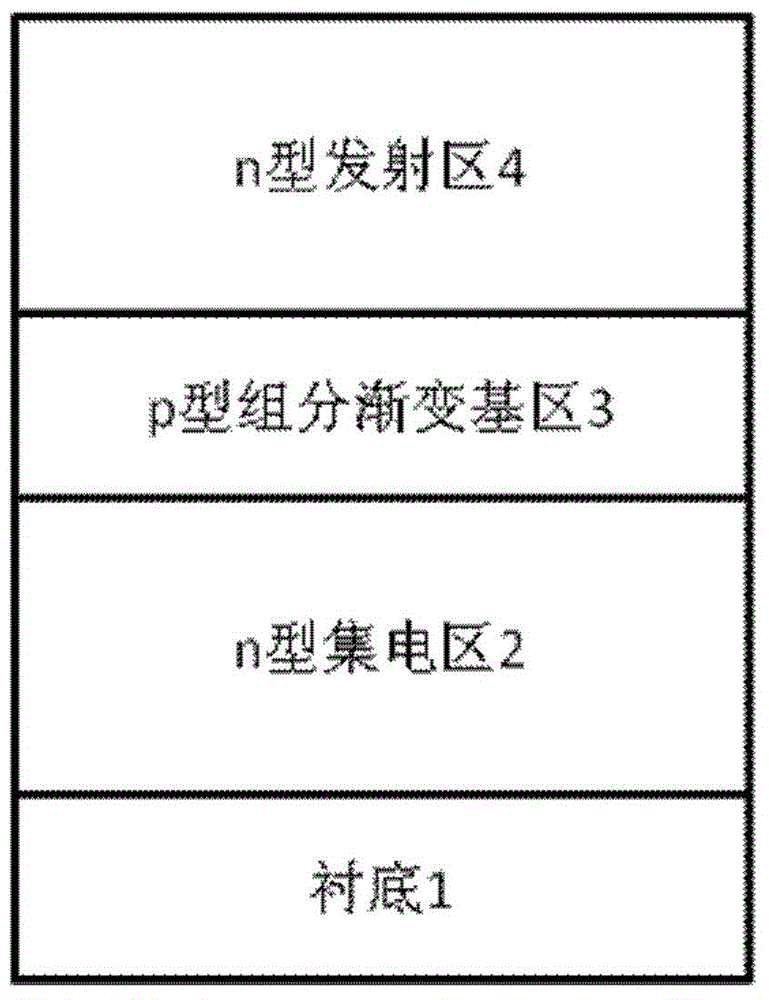

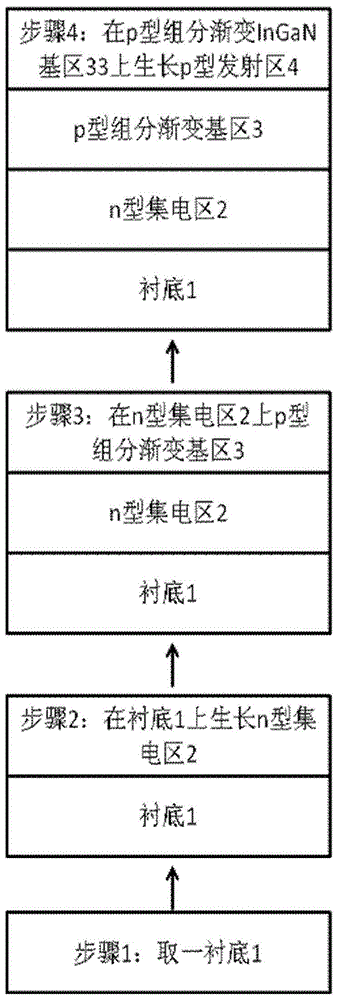

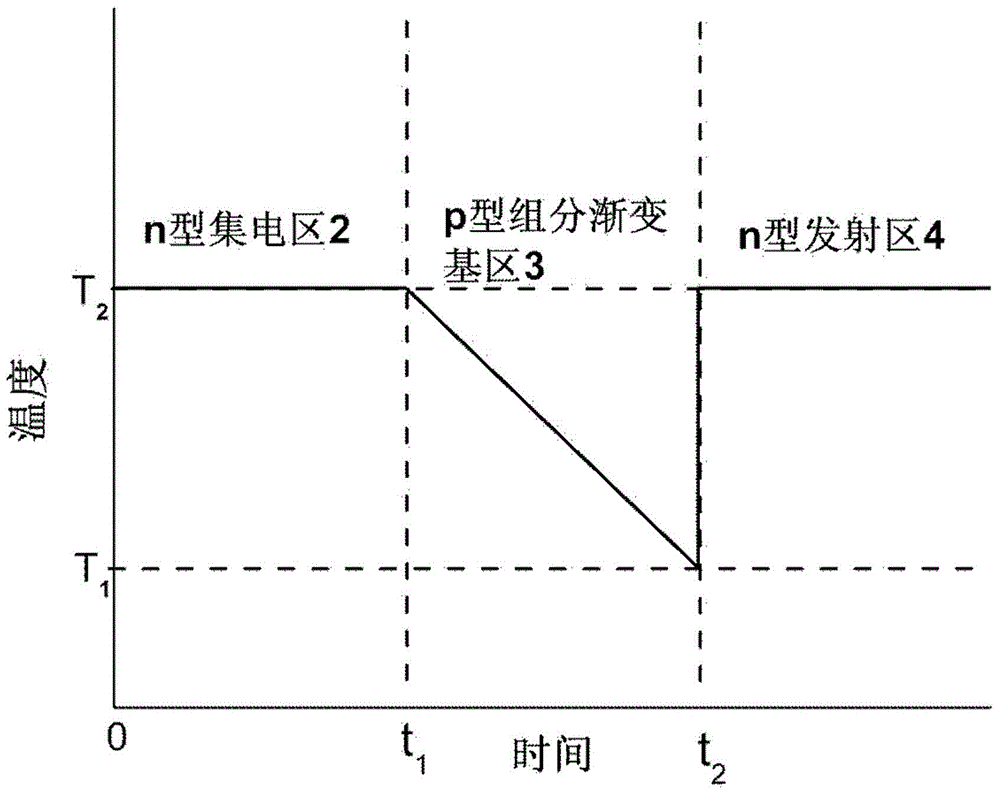

GaN-based HBT epitaxial structure for reducing electrical resistivity at base region and growing method

Owner:丽水中科半导体材料研究中心有限公司

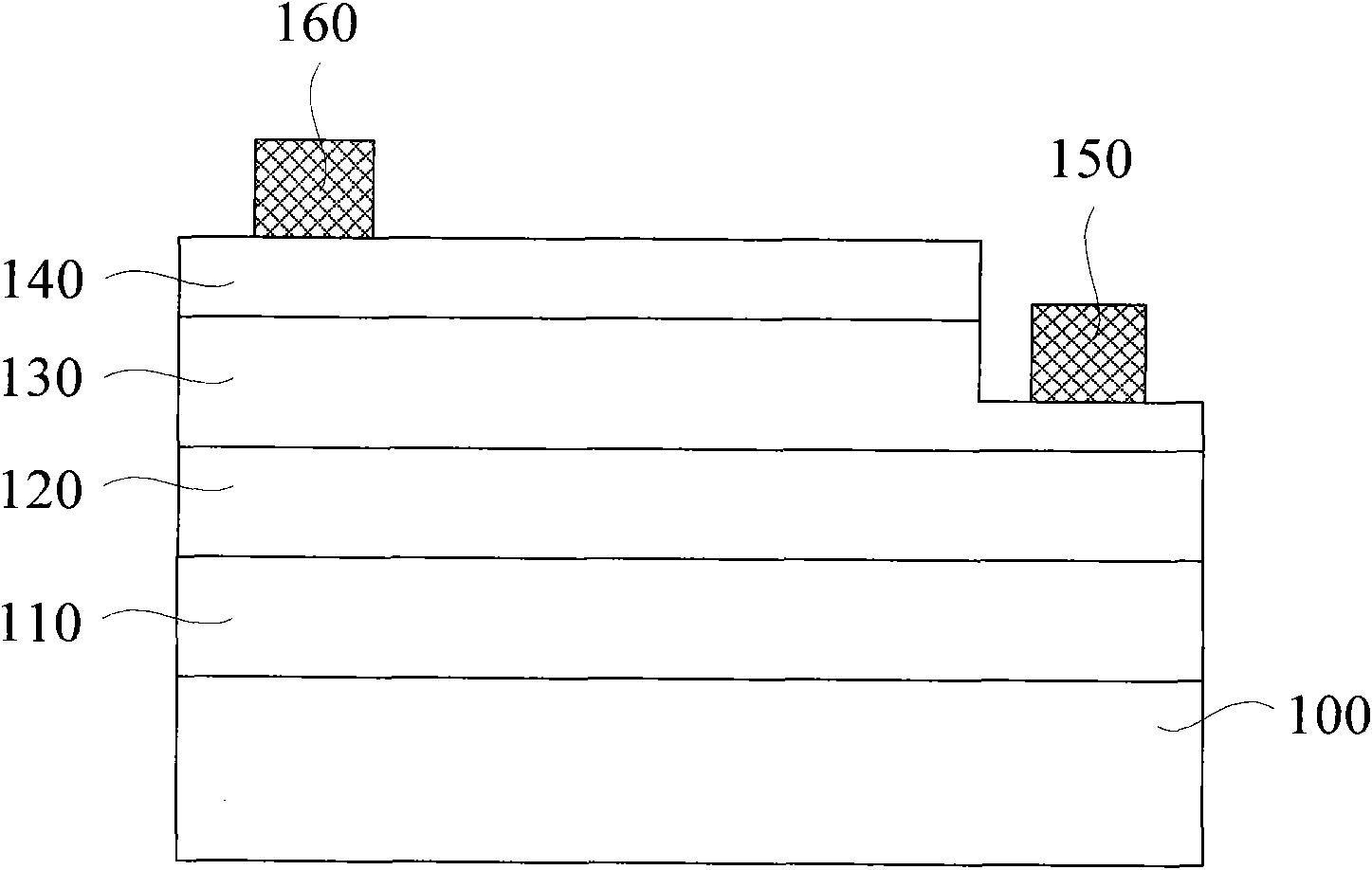

LED (Light Emitting Diode) and manufacturing method thereof

InactiveCN102064252AImprove luminous efficiencyIncrease hole concentrationSemiconductor devicesEngineeringLight-emitting diode

The invention discloses an LED (Light Emitting Diode) and a manufacturing method thereof. The LED comprises a substrate, an n-type semiconductor layer, an active layer, a p-type semiconductor layer, a p-type buried electrode layer, an opening, a first electrode and a second electrode. The n-type semiconductor layer, the active layer and the p-type semiconductor layer are sequentially arranged on the substrate. The p-type buried electrode layer is formed in the p-type semiconductor layer. The opening extends into the n-type semiconductor layer in depth. The first electrode is formed in the opening, and the n-type semiconductor layer is electrically connected with the negative electrode of a power source by the first electrode. The second electrode is formed on the p-type semiconductor layer, and the p-type semiconductor layer is electrically connected with the positive electrode of the power source by the p-type buried electrode layer. The p-type buried electrode layer can increase the hole concentration contributing to light emission so as to improve the light emitting efficiency of the LED.

Owner:ENRAYTEK OPTOELECTRONICS

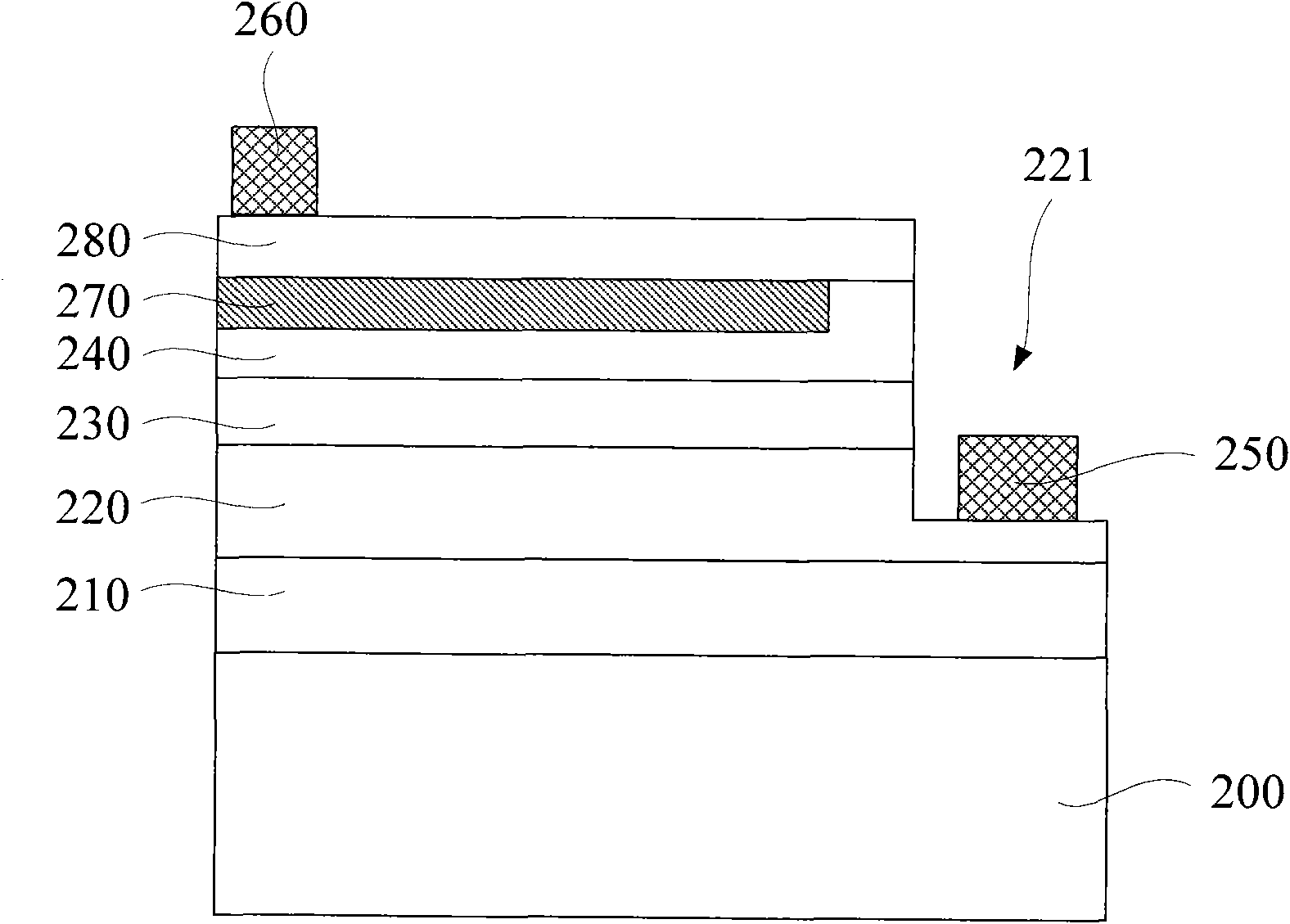

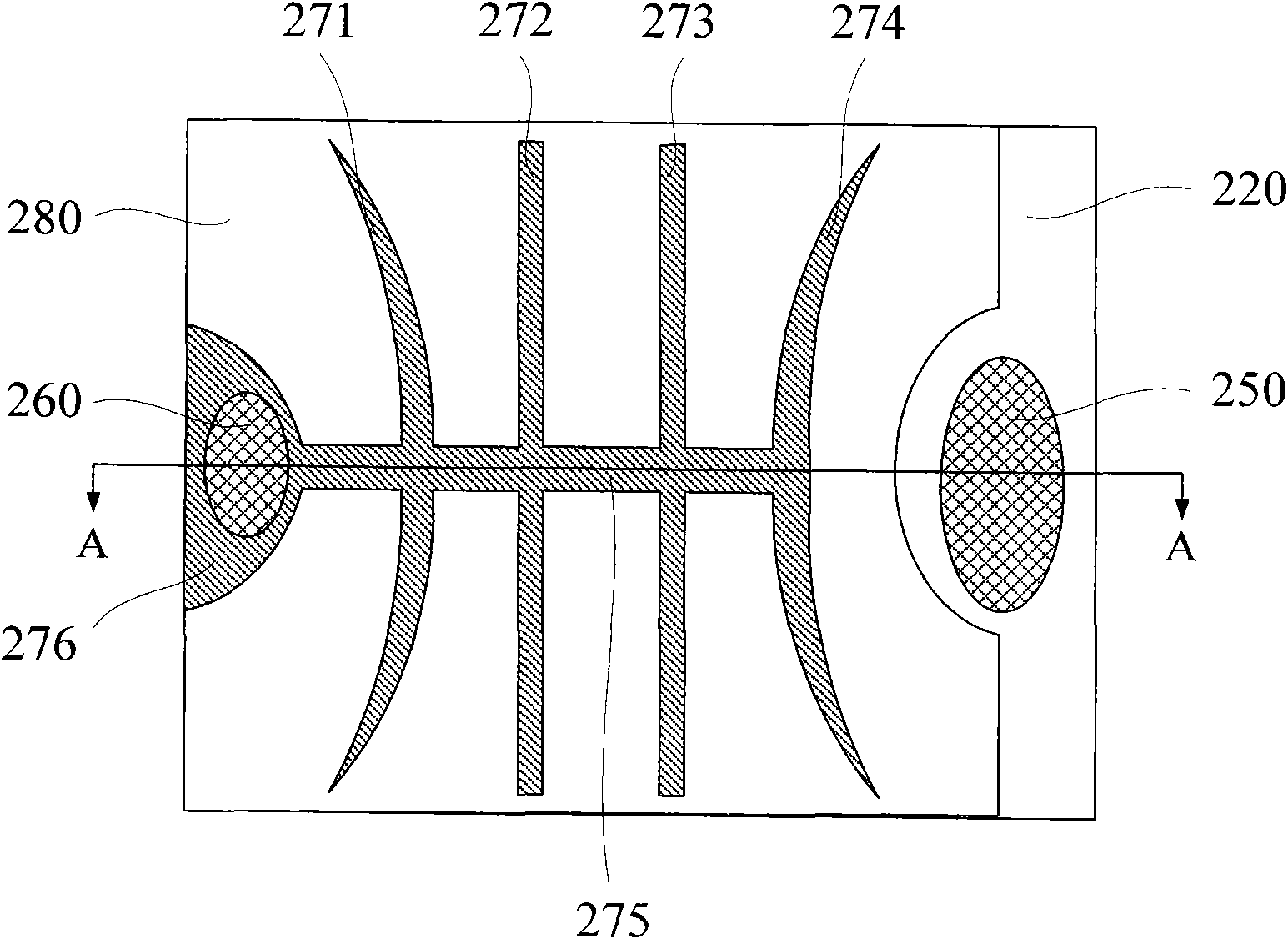

Method for improving LED luminous efficiency by using three-dimensional polarized induction positive hole gas

InactiveCN101807640AImprove luminous efficiencyIncrease hole concentrationSemiconductor devicesLuminous efficacyEpiwafer

The invention discloses a method for improving the LED luminous efficiency by using a three-dimensional polarized induction positive hole gas, which comprises the following steps of: firstly, selecting a substrate; secondly, growing a low-temperature nucleating layer, a low-temperature buffer layer, an n-type layer, an active area, a wide forbidden band barrier layer and a p-type layer on the substrate in turn to form an epitaxial wafer; thirdly, performing etching on one side on the epitaxial wafer to form a playing surface, wherein the etching depth reaches the surface of the n-type layer; fourthly, preparing an n electrode on the playing surface; and fifthly, preparing a p electrode on the p-type layer.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

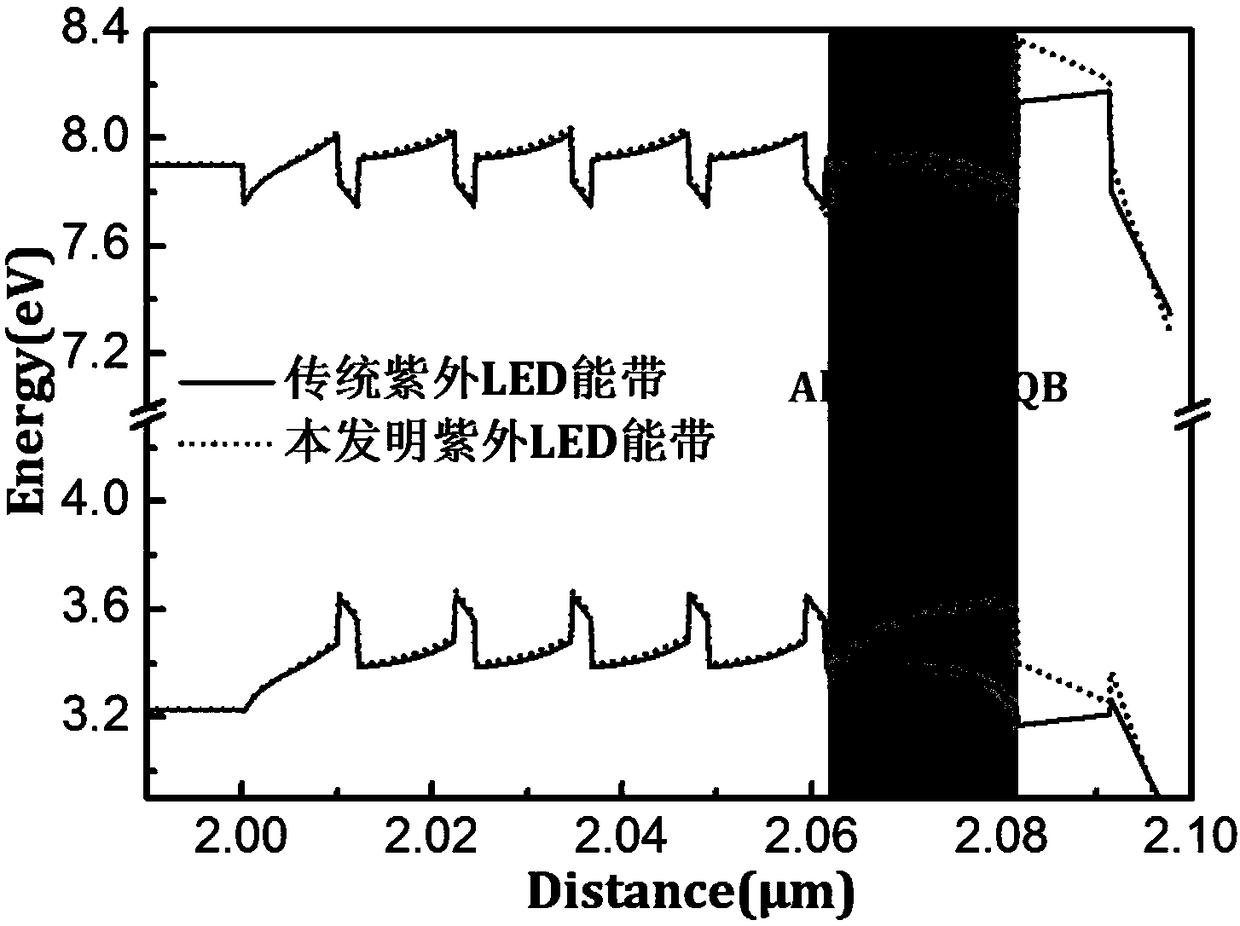

AlGa-based semiconductor ultraviolet device for improving luminous efficiency and preparation method thereof

PendingCN108231960AHigh light efficiencyReduce contentSemiconductor devicesQuantum efficiencyQuantum well

The present invention provides an AlGa-based semiconductor ultraviolet device for improving luminous efficiency and a preparation method thereof, and relates to the technical field of semiconductors.The epitaxial structure of the device comprises a substrate, an AlN buffer layer, an n-type AlGaN layer, an AlxGa1-xN / AlyGa1-yN luminescence active region, the last one AlGaN quantum barrier layer, ap-type AlGaN electron blocking layer, a p-type AlGaN layer and a contact layer, wherein 0.01<=x and y<=1. The luminescence active region comprises a plurality of quantum well layers and a plurality ofquantum barrier layers, the quantum well layers and the quantum barrier layers are alternately arranged, and the last one AlGaN quantum barrier layer is an aluminium ingredient gradient layer. The last one AlGaN quantum barrier layer of aluminium ingredient gradient is introduced in the ultraviolet device to optimize the energy band structure of the device, effectively improve the electron restriction effect and enhance the cavity injection efficiency so as to improve the quantum efficiency and the luminescence efficiency of the semiconductor ultraviolet device.

Owner:GUANGDONG INST OF SEMICON IND TECH

Thin layer SOILIGBT device

InactiveCN101431097AReduce power consumptionStrong radiation resistanceSemiconductor devicesThin layerConduction loss

The invention relates to a folium SOILIGBT device which belongs to the technical field of semiconductor power device. The thickness of SOI layer of the device is 1 mu m to 2 mu m; a cavity barrier layer is arranged between a body zone and a drift zone; the cavity is blocked in the drift zone to the utmost extent; and then the cavity consistence near the side of a cathode in the drift zone is increased; and conduction losses of the device are reduced. A P type depletion zone can also be added near the cavity barrier layer to assist to deplete the N type cavity barrier layer, and so drift zone depletion is strengthened when the device bears a high pressure, and breakdown characteristics of the device are improved. The folium SOILIGBT device has the advantages of small parasitics, fast speed, low power consumption, strong anti-radiation performance, and is compatible with the standard process. An LIGBT device having good performance, high pressure, high speed and low conduction losses can be made when the folium SOILIGBT device is adopted.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com