Diamond semiconductor element and process for producing the same

a semiconductor element and diamond technology, applied in the field of diamond semiconductor elements, can solve the problems of diamond single crystal having an extremely high density of crystal defects, diamond single crystal having physical derived limitations, and conventional art being incapable of simultaneously satisfying the two requirements, so as to reduce the occurrence of crystal defects and high transconductance of field-effect transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

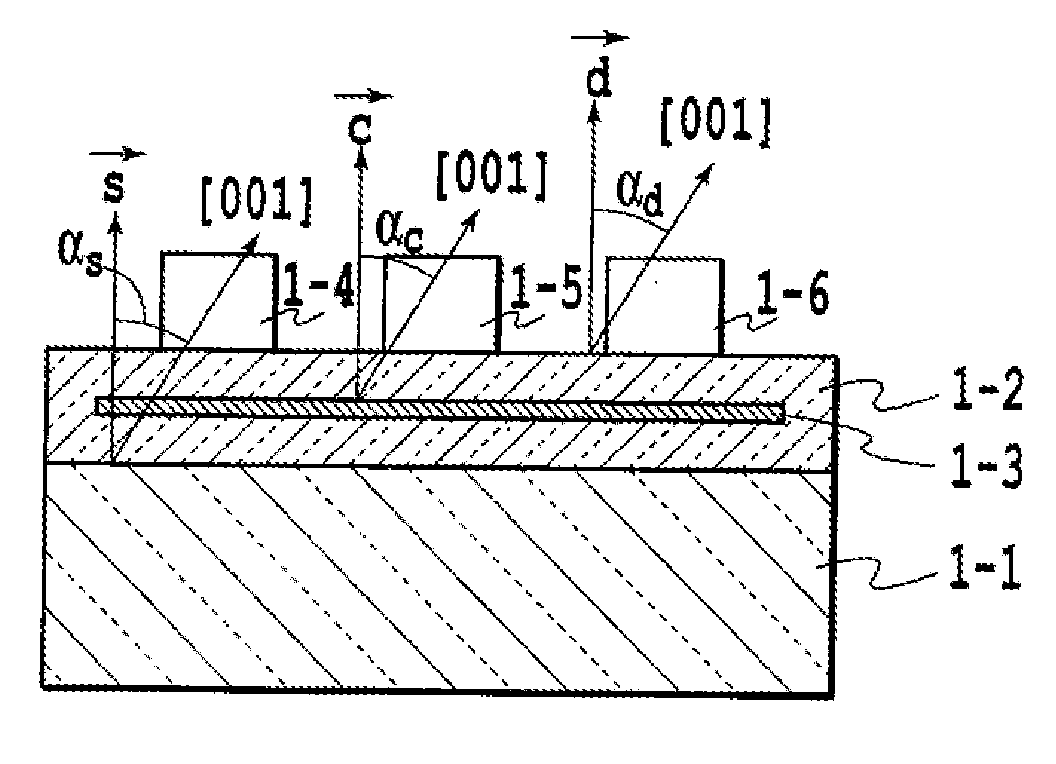

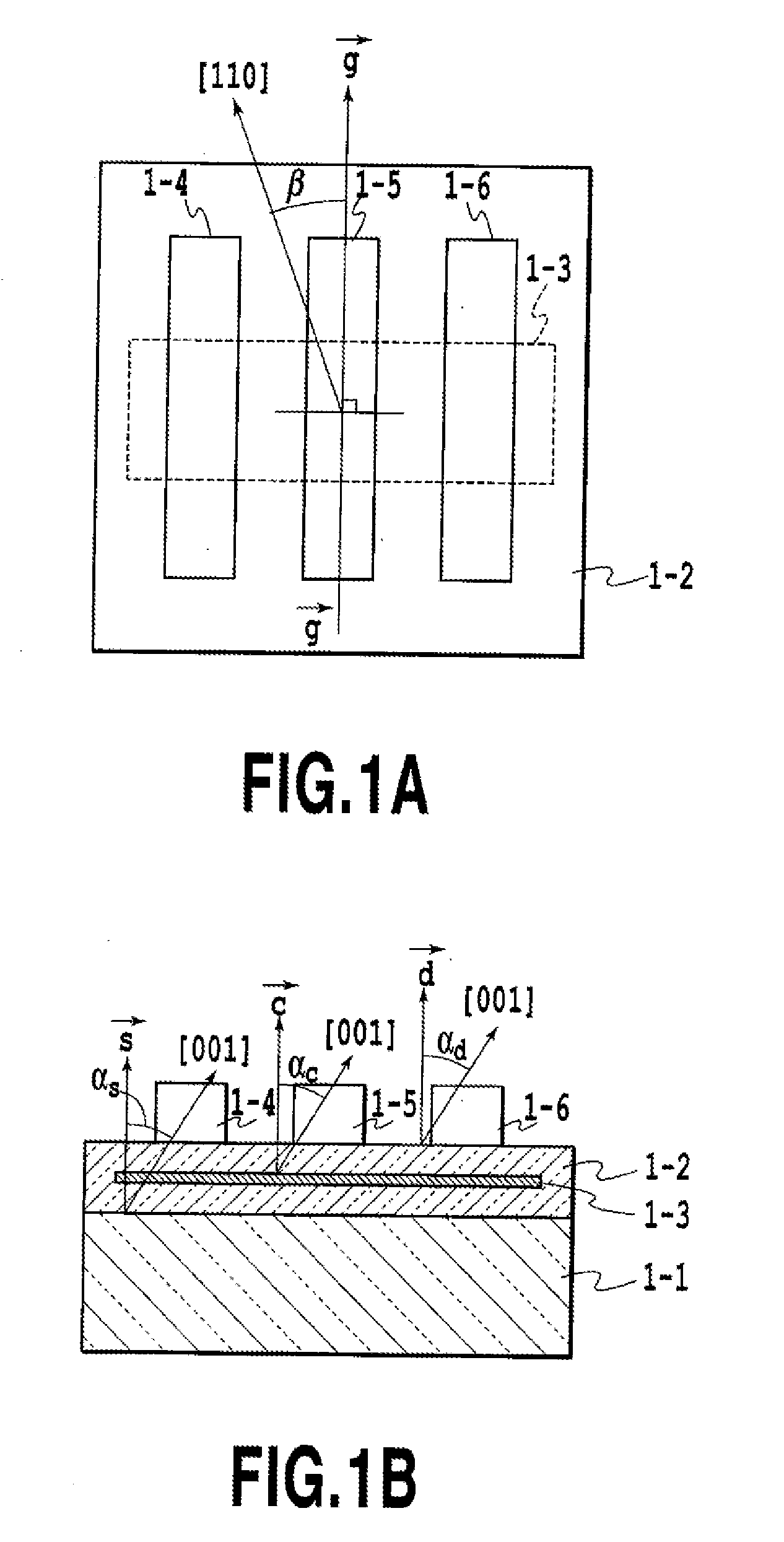

[0248]FIGS. 1A and 1B are schematic diagrams of a diamond semiconductor element according to embodiment 1 of the present invention. As illustrated in the sectional view in FIG. 1B, a single-crystal diamond thin-film 1-2 is formed on a single-crystal diamond substrate 1-1. A two-dimensional hole or electron channel 1-3 is formed in the single-crystal diamond thin-film 1-2. Then, an angle formed by the surface orientation of the single-crystal diamond substrate 1-1 and the crystal axis [001] direction of the single-crystal diamond substrate 1-1 is defined as αs, an angle formed by the surface orientation of the single-crystal diamond thin-film 1-2 and the crystal axis [001] direction of the single-crystal diamond thin-film 1-2 is defined as αd, and an angle formed by the surface orientation of the channel 1-3 and the crystal axis [001] direction of the single-crystal diamond thin-film 1-2 is defined as αc. As illustrated in the top view in FIG. 1A, a source electrode 1-4, a gate elect...

embodiment 2

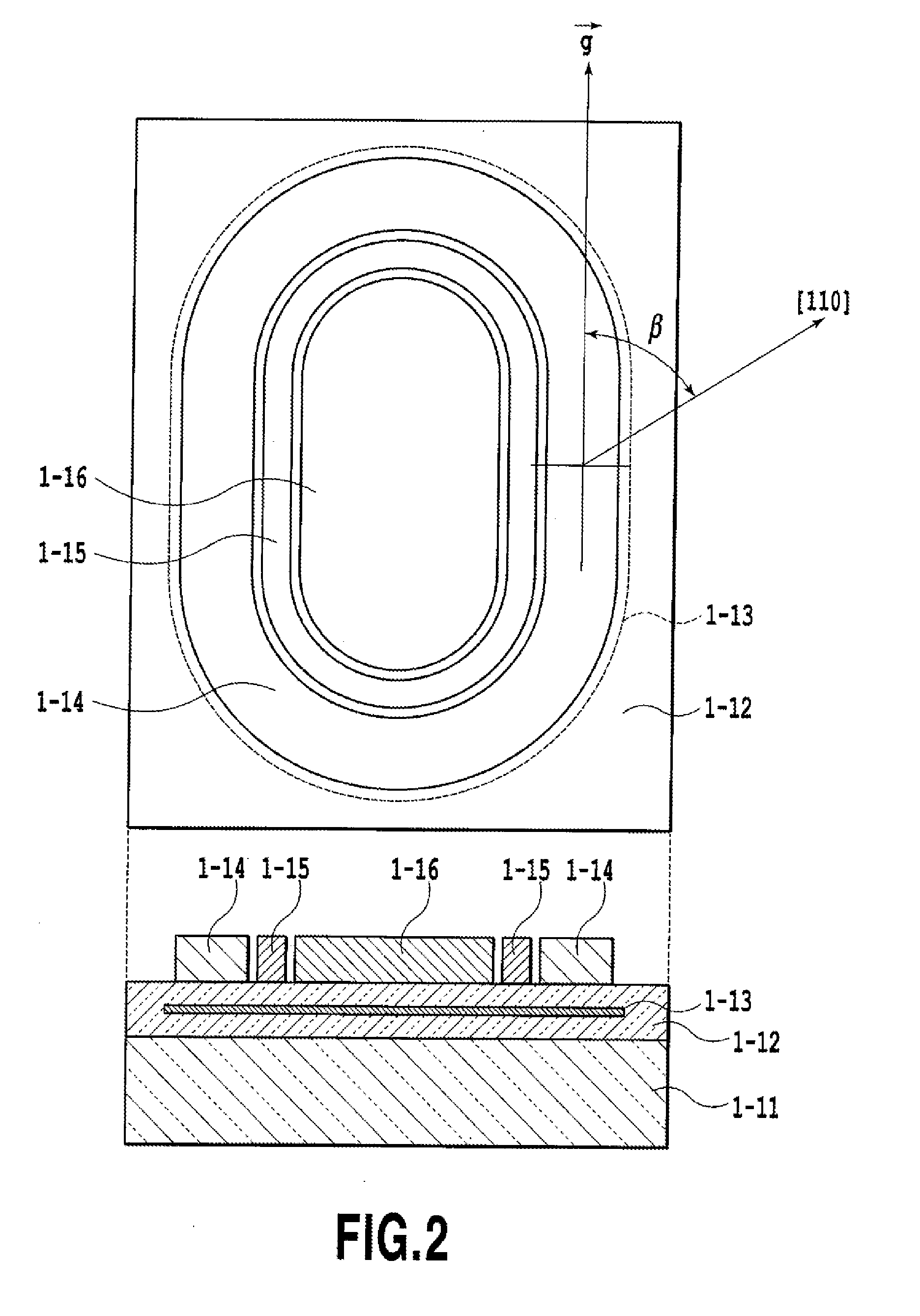

[0267]FIG. 2 is a diagram illustrating the structure of a diamond semiconductor element according to embodiment 2 of the present invention. The structure of embodiment 2 is suitable for high power operation. In embodiment 2, a gate electrode is arranged in the form of a sport ground track. A single-crystal diamond thin-film 1-12 is formed on a single-crystal diamond substrate 1-11 and a two-dimensional hole or electron channel 1-13 is formed inside the single-crystal diamond thin-film. As shown in FIG. 2, the channel has an oval shape. Then, a source electrode 1-14, a gate electrode 1-15 and a drain electrode 1-16 are formed on the surface of the single-crystal diamond thin-film 1-12 above the channel 1-13. The gate electrode 1-15 and the source electrode 1-14 are arranged outward in order so as to encircle the periphery of the oval-shaped drain electrode 1-16 placed innermost.

[0268]FIG. 2 does not clearly show, but in embodiment 2, the surface orientations of the single-crystal dia...

embodiment 3

[0271]FIGS. 7A to 7J illustrate process-steps in producing a diamond semiconductor element according to an embodiment of the present invention. A thin-film 2-1, which is a diamond single-crystal and has a two-dimensional hole channel extending parallel to the surface, (hereinafter referred to as “diamond single-crystal thin-film 2-1”) is prepared (FIG. 07A). Au is evaporated to a thickness of 0.1 μm onto the entire surface of the diamond single-crystal thin-film 2-1 to form an Au thin-film 2-2B (FIG. 7B). Then, the Au thin-film 2-2B is coated with a resist 2-3 with a width of 20 μm in the area in which a gate electrode will be provided (FIG. 7C), and from the above, an Au thin-film 2-2T is evaporated onto the entire surface of the sample (FIG. 7D). At this point, the thickness of the Au thin-film 2-2T is 0.4 μm.

[0272]Next, liftoff is performed on the resist 2-3 to remove the resist 2-3 and part of the Au thin-film 2-2T evaporated onto the resist 2-3 so as to form an aperture 2-7 in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com