P-type electric-conducting Sb mixed SnO2 film and stannic oxide homogeneous pn junction containing film and preparation methods thereof

A pn junction and tin oxide technology, which is applied in cable/conductor manufacturing, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of difficult thickness control, poor film compactness and uniformity, and achieve easy control of process conditions and mature technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Weigh SnO with purity ≧99.9% 2 and Sb 2 o 3 Powder, wherein the atomic ratio of Sb / (Sb+Sn) is 33:100, pour the above powder into a ball mill jar equipped with agate balls and add absolute ethanol for wet milling, the ball milling time is 5 hours, so that the powder can be mixed better Uniform and to some extent refined. Then the ground raw materials were dried in a drying oven at a temperature of 100° C. for 10 hours. Grind the dried raw materials in an agate grinder, and then use a mold to press the raw materials into shape. The molded body is subjected to cold isostatic pressing at 200 MPa, and finally placed in a sintering furnace, heated to 1250 °C at a rate of 3 °C per minute, kept for 5 hours, and naturally cooled to obtain p-type Sb-doped SnO 2 ceramic target;

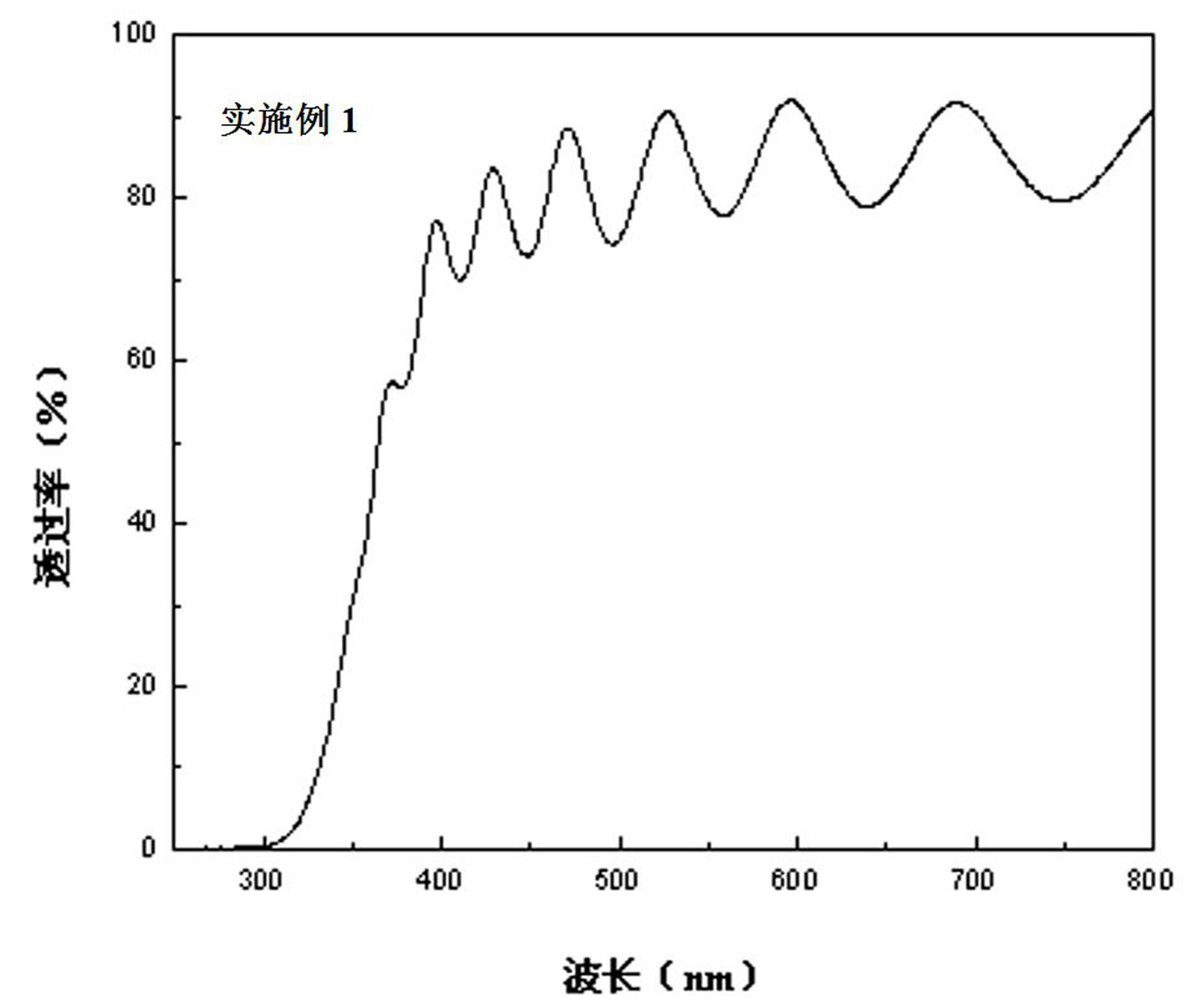

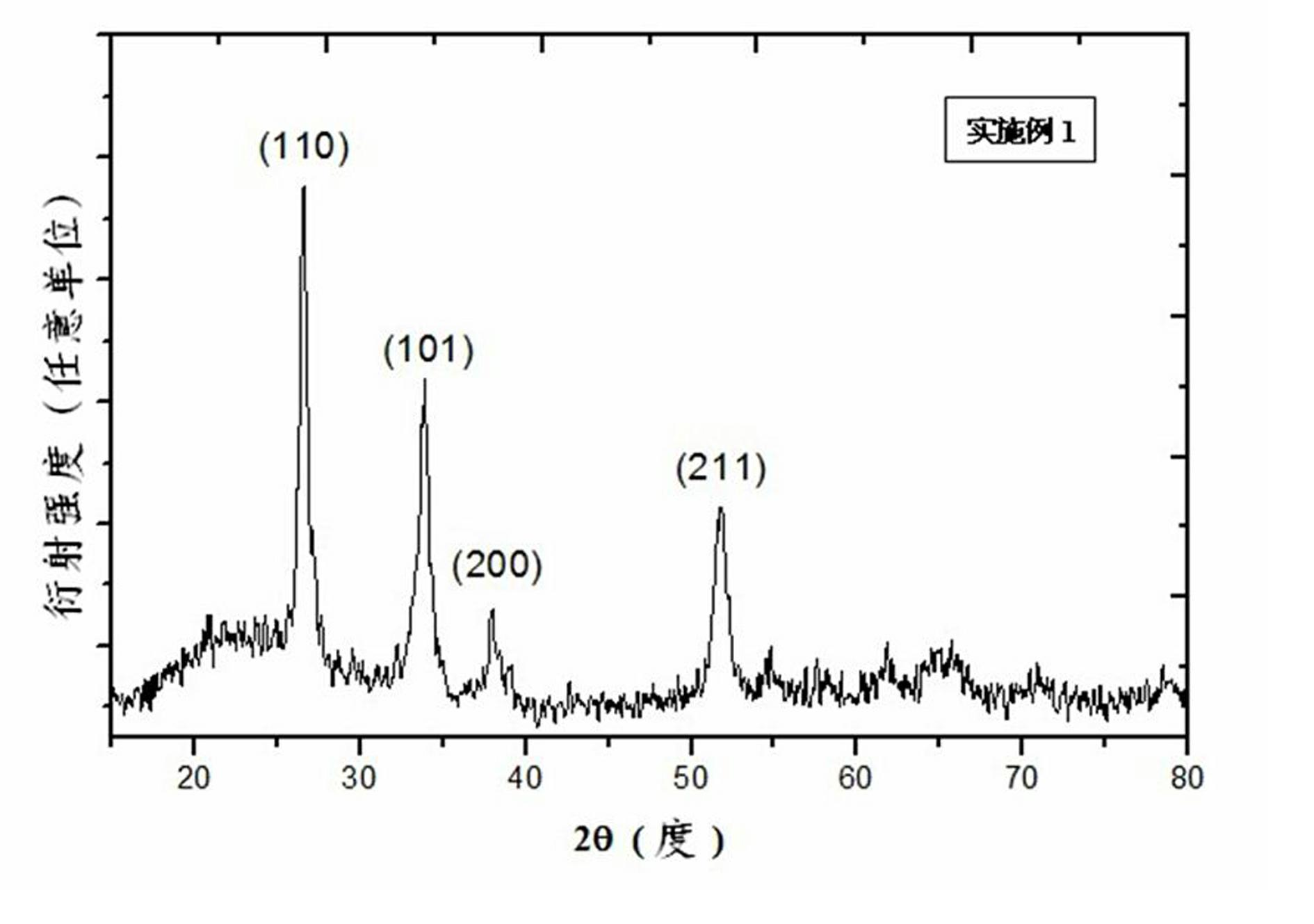

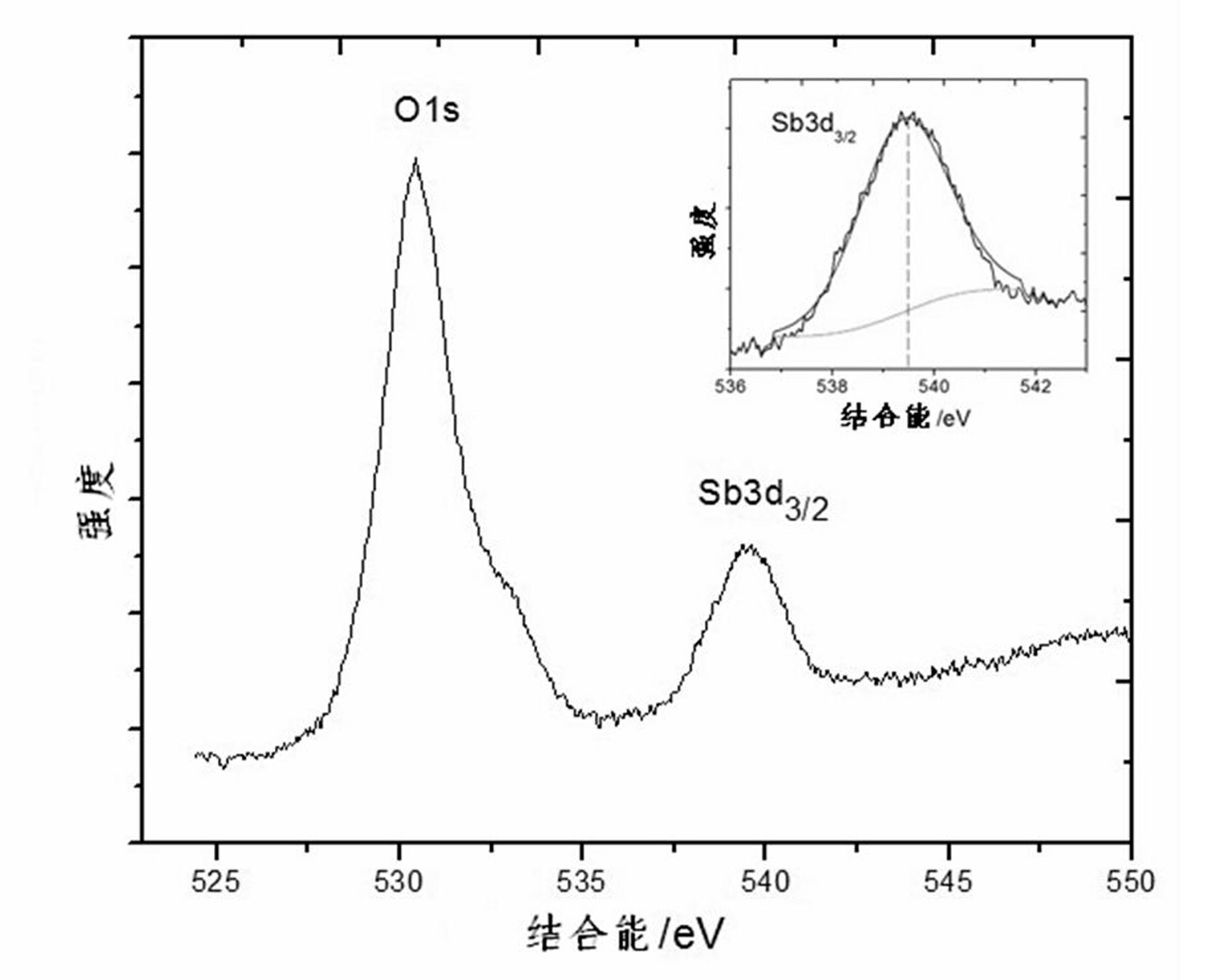

[0035] 2) Using the p-type Sb-doped SnO made in step 1) 2 Ceramic target, using magnetron sputtering method, with quartz glass as substrate, substrate temperature 200°C, high-purity argon as work...

Embodiment 2

[0038] 1) Weigh SnO with purity ≧99.9% 2 and Sb 2 o 3 Powder, wherein the atomic ratio of Sb / (Sb+Sn) is 18:100, pour the above powder into a ball mill jar equipped with agate balls and add absolute ethanol for wet milling, the ball milling time is 5 hours, so that the powder can be mixed better Uniform and to some extent refined. Then the ground raw materials were dried in a drying oven at a temperature of 100° C. for 10 hours. Grind the dried raw materials in an agate grinder, and then use a mold to press the raw materials into shape. The molded body is subjected to cold isostatic pressing at 200 MPa, and finally placed in a sintering furnace, heated to 1250 °C at a rate of 3 °C per minute, kept for 5 hours, and naturally cooled to obtain p-type Sb-doped SnO 2 ceramic targets.

[0039] 2) Using the Sb-doped SnO made in step 1) 2 Ceramic target, using magnetron sputtering method, using single crystal Si (100) sheet as substrate, substrate temperature 250°C, high-purity a...

Embodiment 3

[0042] Adopt the p-type Sb doped SnO prepared on the quartz substrate obtained in embodiment 1 2 The thin film is used as the substrate, and the first layer of p-type Sb is doped with SnO by radio frequency magnetron sputtering method. 2 A second layer of n-type Sb-doped SnO is plated on the film 2 film. The specific method is as follows:

[0043] 1) n-type Sb doped SnO2 Preparation of ceramic target: Weighing SnO with purity ≧99.9% 2 and Sb 2 o 5 Powder, wherein the atomic ratio of Sb / (Sb+Sn) is 11:100, the above powder is mixed uniformly by ball milling, pressed into shape, and then sintered at 1250°C for 5h to obtain n-type Sb-doped SnO 2 ceramic target;

[0044] 2) Using the n-type Sb-doped SnO made in step 1) 2 Ceramic target material, utilizes magnetron sputtering method, is coated with p-type Sb doping SnO with the obtained in embodiment 1 2 thin-film quartz glass as the substrate, p-type Sb doped with SnO 2 A layer of n-type Sb-doped SnO was deposited on the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Hall mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com