LED epitaxial structure of composite P-type GaN layer and fabrication method of LED epitaxial structure

An epitaxial structure, n-type technology, used in electrical components, circuits, semiconductor devices, etc., can solve the problem of low hole concentration, and achieve the effect of increasing hole concentration, increasing activation rate, improving luminous efficiency and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

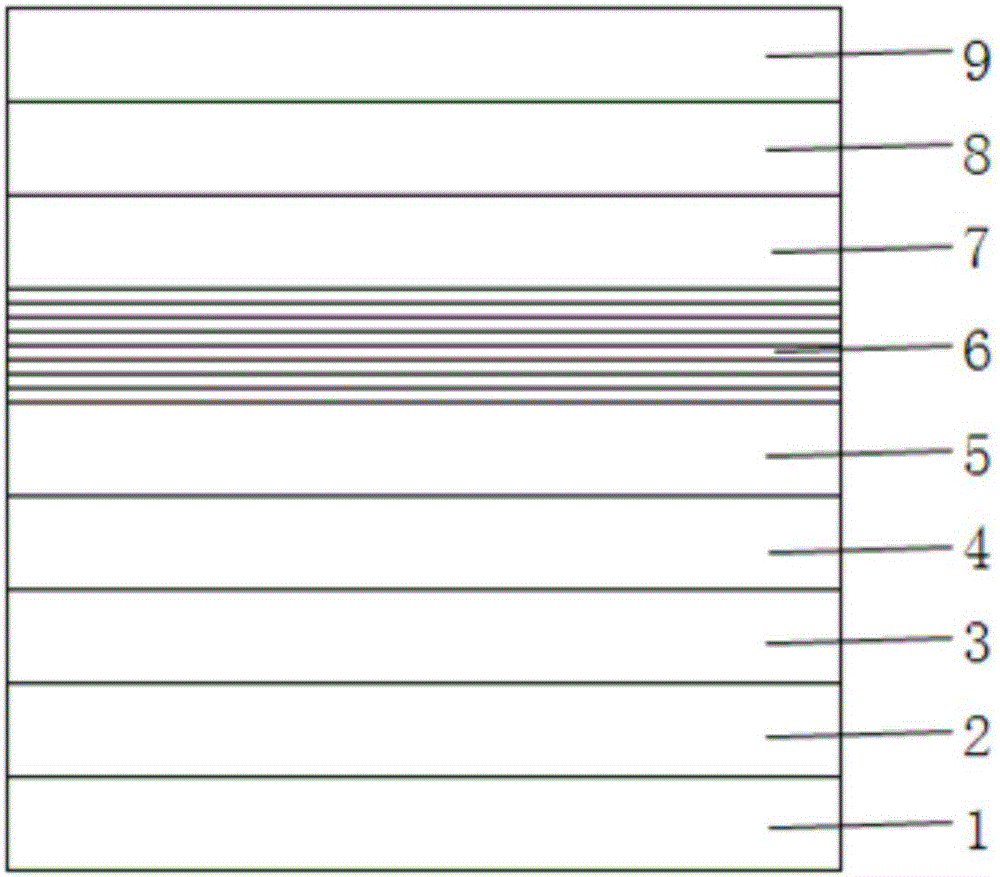

[0053] The concrete steps of this embodiment are as follows:

[0054] 1. Substrate treatment: raise the temperature to 1230-1250°C, and treat the substrate for 4-8 minutes;

[0055] 2. Growth buffer layer: lower the temperature to 520-550°C, 2 growing a buffer layer with a thickness of 20-25 nm on the above substrate under the atmosphere;

[0056] 3. Growing u-type GaN layer: Raise the reaction chamber temperature to 1160-1180°C, 2 Under the atmosphere, grow a 3-3.5 μm thick u-type GaN layer on the above buffer layer;

[0057] 4. Growth of n-type GaN layer: raise the temperature of the reaction chamber to 1240-1260°C, the pressure of the reaction chamber is 550-600mbar, in H 2 Under the atmosphere, grow a 3-3.5 μm thick n-type GaN layer on the above-mentioned u-type GaN layer, and the doping concentration of Si is 8×10 18 ~1.1×10 19 atoms / cm 3 ;

[0058] 5. To grow the MQW active layer: reduce the temperature of the reaction chamber to 900-970°C, 2 Under the atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com