Thin layer SOILIGBT device

A device and thin-layer technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as increasing process costs, and achieve the effects of reducing process difficulty and cost, small parasitic effects, and low leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] By adopting the thin-layer SOI LIGBT of the present invention, high-voltage, high-speed, and low-conduction-loss power devices with excellent performance can be obtained, which can meet the requirements of high-voltage, high-current, and low-conduction power devices for driving stages such as 150-250V PDP row driver ICs and 600V switching power supply ICs. pass loss requirements.

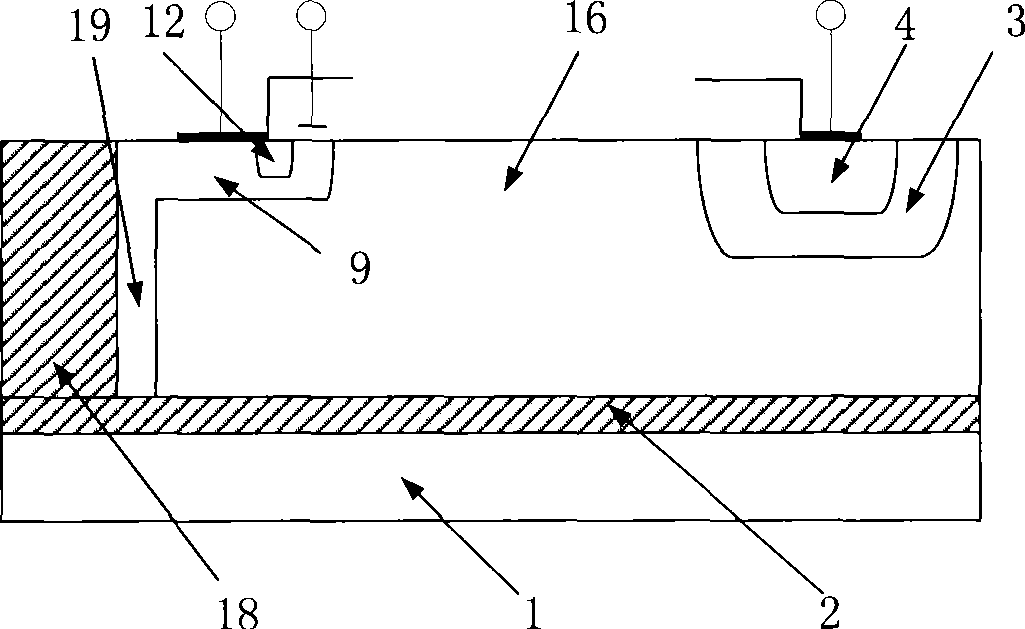

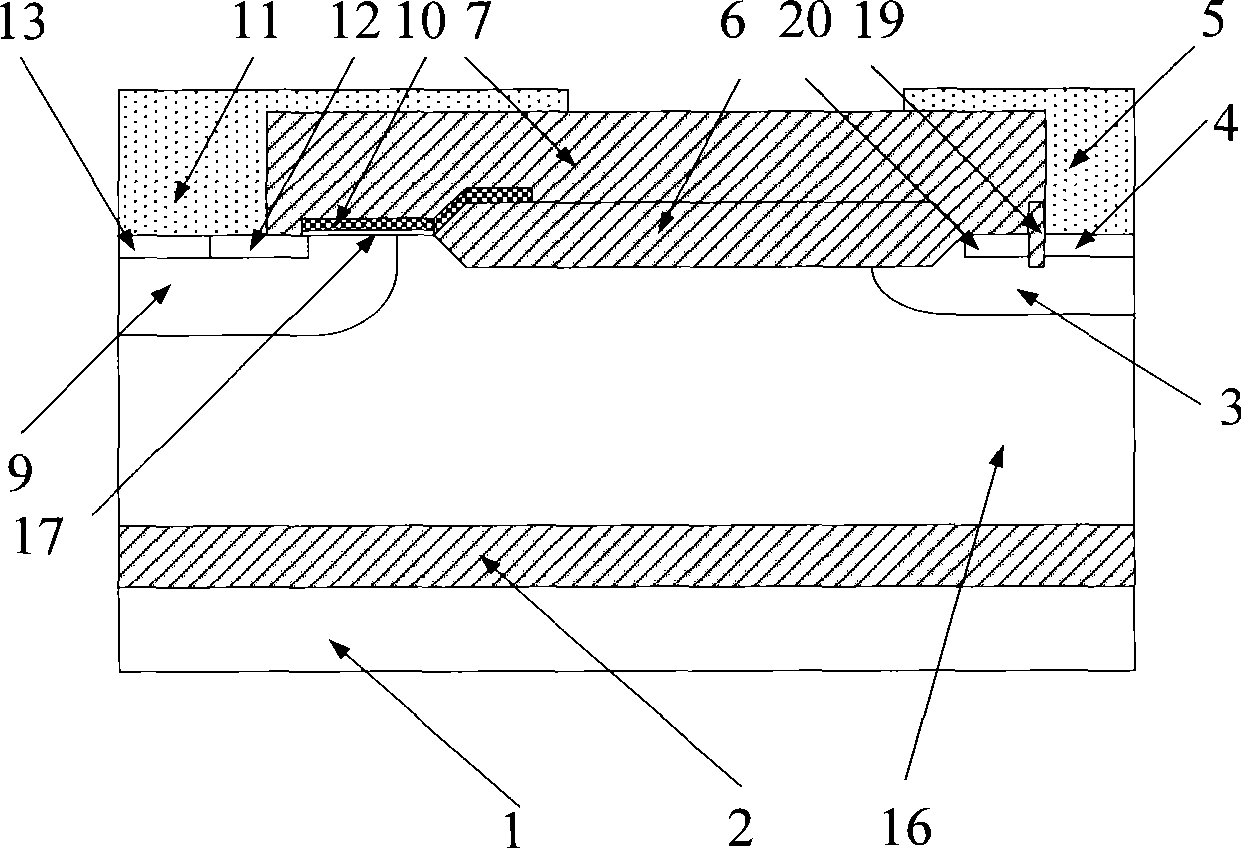

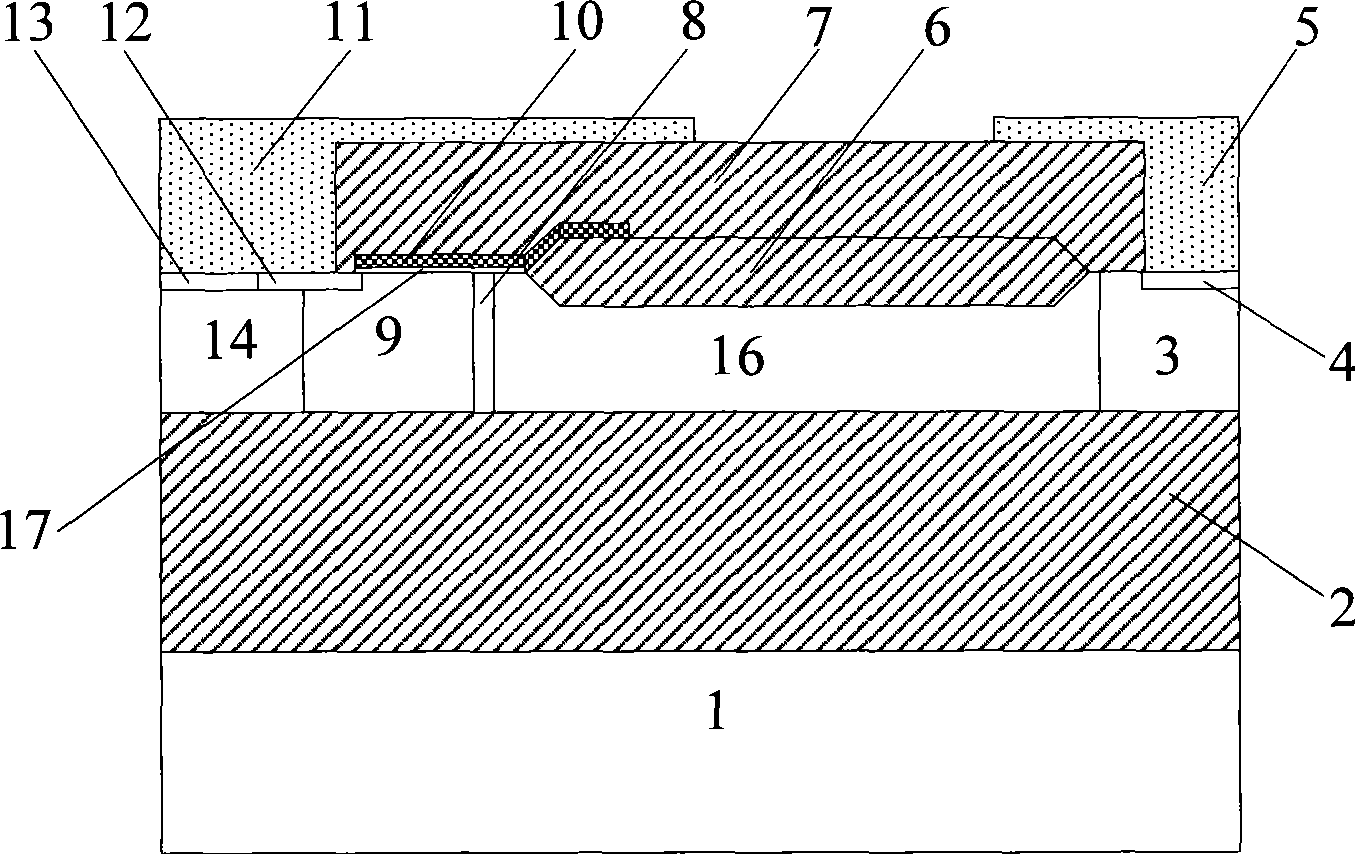

[0026] A kind of thin layer SOI LIGBT device provided by the present invention, such as image 3 As shown, including: substrate 1, buried oxide layer 2, N-type buffer layer 3, P + Anode region 4, anode metal 5, field oxygen region 6, pre-metal dielectric 7, N-type hole barrier layer 8, P-type body region 9, polysilicon gate 10, cathode metal 11, cathode N + Zone 12, Cathode P + Region 13, P-type region 14, N - Drift region 16 and gate oxide layer 17. The upper surface of the substrate 1 is a buried oxide layer 2, and the upper surface of the buried oxide layer 2 is an SOI layer with a thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com