Nitride based semiconductor light-emitting device

a technology of semiconductor light-emitting devices and nitride, which is applied in semiconductor devices, electrical devices, packaging, etc., can solve problems such as the problem of obtaining a high luminous efficiency, and achieve the effects of preventing current loss, enhancing hole injection efficiency, and increasing hole mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

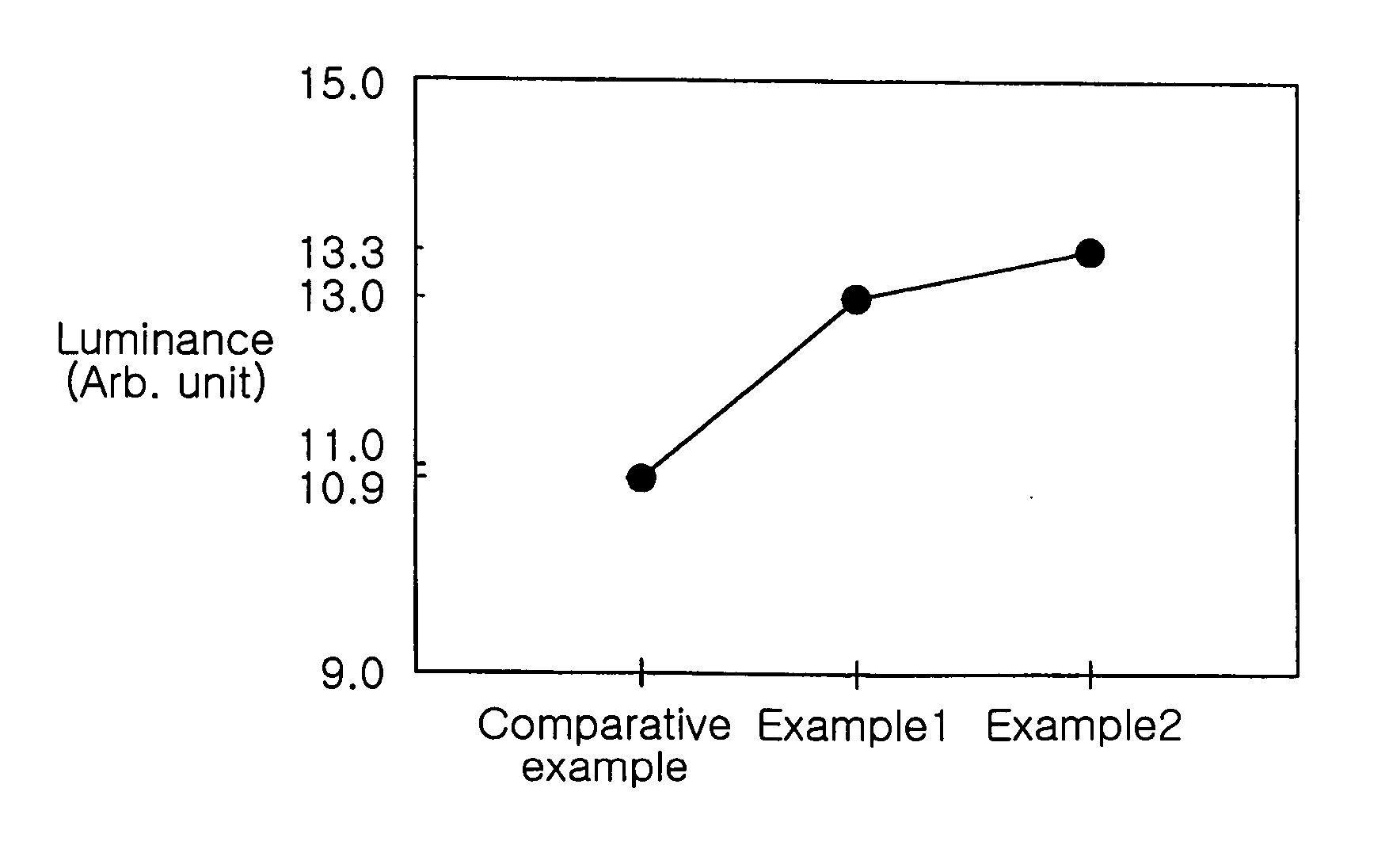

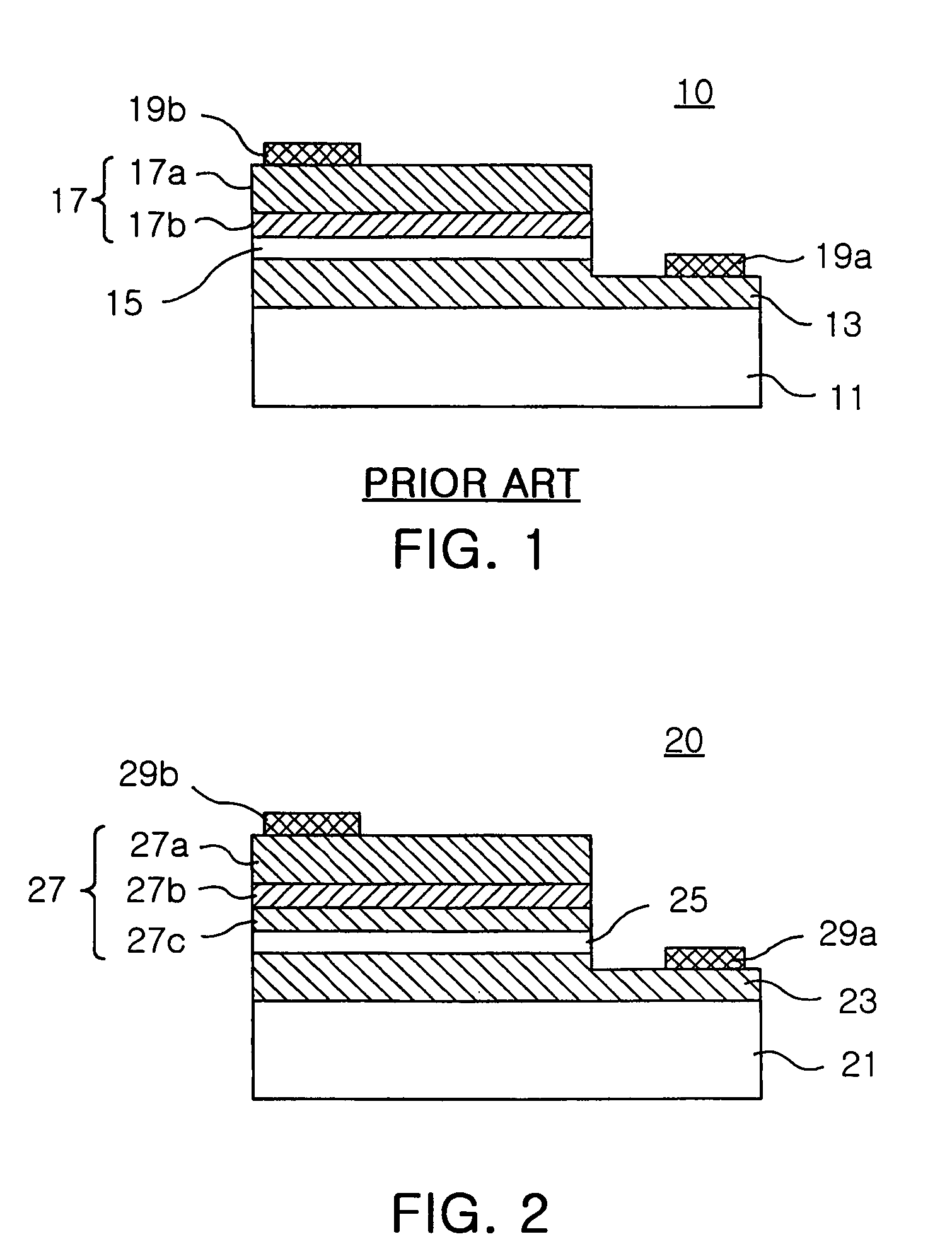

[0045] In order to identify the improvement in the characteristics of the nitride-based semiconductor light-emitting device according to the present invention, the nitride-based semiconductor light-emitting device shown in FIG. 2 was fabricated.

[0046] First, after a GaN low temperature-nuclei growing layer as a buffer layer was formed on a sapphire substrate, an n-type GaN clad layer was formed thereon so as to have an impurity concentration of 4×1018 / cm3. Thereafter, a multiple quantum well-structured active layer composed of five In0.15Ga0.85N quantum well layers and five GaN quantum barrier layers was formed on the n-type clad layer.

[0047] Further, a hole injection efficiency-enhancing layer made of p-type GaN, an electron blocking layer (EBL) made of p-type Al0.15Ga0.85N, and a contact layer made of p-type GaN were deposited sequentially on the active layer to prepare a p-type clad layer. The hole injection efficiency-enhancing layer was formed so as to have an impurity concen...

example 2

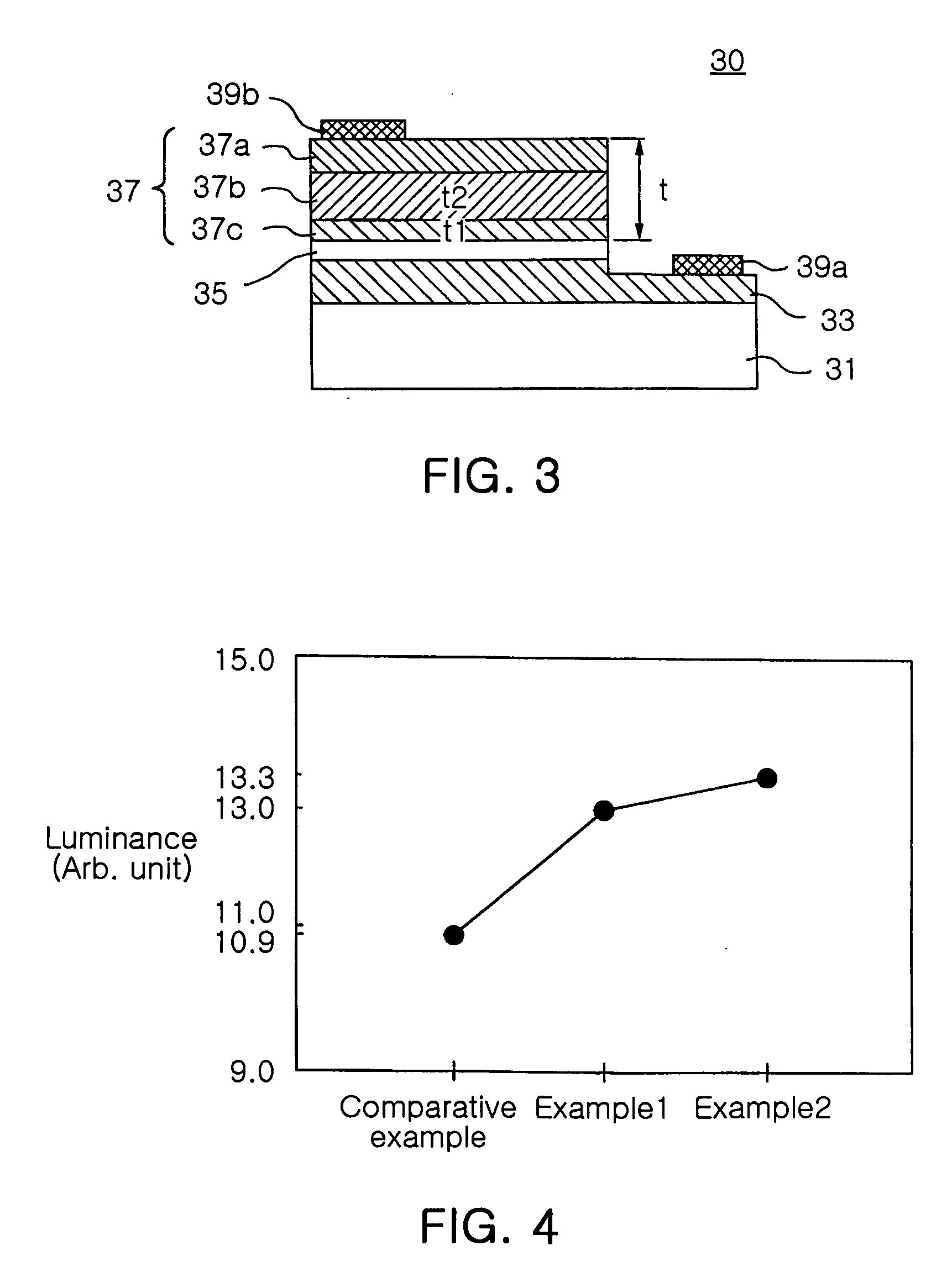

[0049] To observe changes in the characteristics of the nitride-based semiconductor light-emitting device of the present invention according to increasing thickness of the p-type EBL, the thickness of the EBL was increased, compared to in the light-emitting device fabricated in Example 1.

[0050] In this example, a nitride-based semiconductor light-emitting device was fabricated in the same manner as in Example 1, except that the structure of the p-type clad layer was varied. Specifically, a hole injection efficiency-enhancing layer was made of p-type GaN so as to have an impurity concentration of about 5×1017 / cm3 and a thickness of about 20 nm, an electron blocking layer was made of p-type Al0.15Ga0.85N so as to have an impurity concentration of 1×1017 / cm3 and a thickness of about 69 nm, and a p-type contact layer was made of p-type GaN so as to have an impurity concentration of 5×1017 / cm3 and a thickness of about 76 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com