LED epitaxial structure based on h-BN tunnel junction as hole injection layer

A technology of hole injection layer and light-emitting diode, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low internal quantum efficiency and restricted efficiency, achieve a large band gap, increase the probability of tunneling, and slow down the current crowding effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

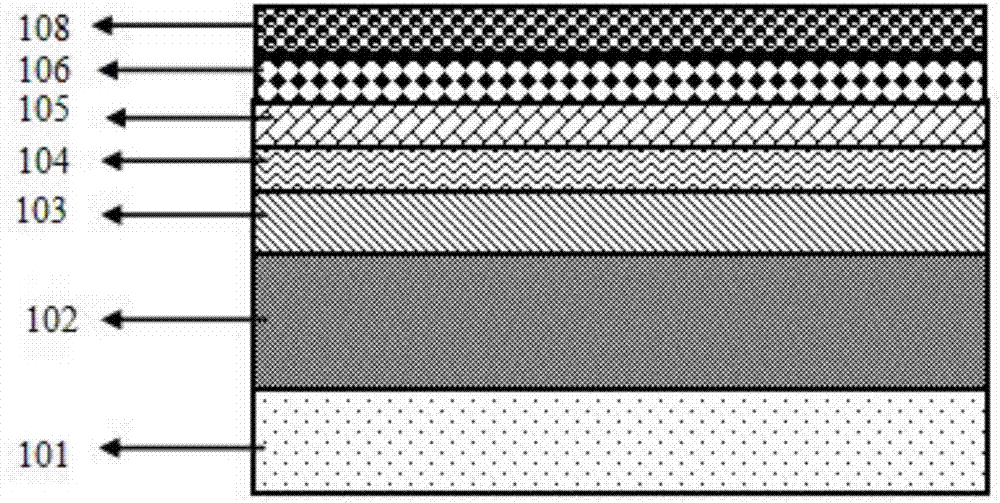

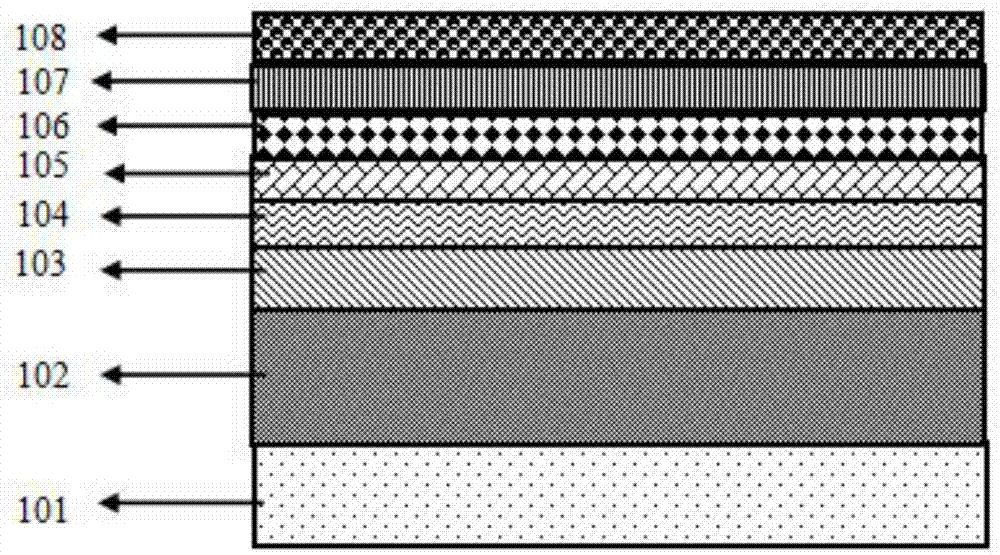

[0046] This embodiment is based on the light-emitting diode epitaxial structure (referred to as the epitaxial structure, see figure 2 ) includes substrate 101, n-type semiconductor material layer 102, multiple quantum well layer 103, p-type electron blocking layer 104, p-type semiconductor material layer 105, p-type heavily doped semiconductor material layer 106, h-BN layer 107 and an n-type heavily doped semiconductor material layer 108, wherein the relative permittivity of the h-BN layer is 4, which is smaller than the relative permittivity and n of the p-type heavily doped semiconductor material layer 106 -type heavily doped semiconductor material layer 108; the p-type heavily doped semiconductor material layer 106, h-BN layer 107 and n-type heavily doped semiconductor material layer 108 together form a tunnel junction.

[0047] Wherein, the doping element concentration of the n-type heavily doped semiconductor material layer 108 needs to be not less than that of the n-typ...

Embodiment 2

[0062] The composition and preparation method of each part of the epitaxial structure in this embodiment are the same as in Embodiment 1, except that the substrate 101 described in this embodiment is AlN, which is [0001] polar; the material of the n semiconductor material layer 102 is Al 0.60 Ga 0.40 N, with a thickness of 400nm; the structure of the multi-quantum well layer 103 is Al 0.45 Ga 0.55 N / Al 0.60 G a0.40 N, where the quantum barrier Al 0.60 G a0.40 The thickness of N is 10nm, the quantum well Al 0.45 Ga 0.55 The thickness of N is 3nm, the number of quantum wells is 7; the p-type electron blocking layer 104 is made of Al0.65 Ga 0.35 N thickness is 20nm; p-type semiconductor material layer 105 is made of Al 0.40 Ga 0.60 N, with a thickness of 200nm; the material of the p-type heavily doped semiconductor material layer is GaN, with a thickness of 20nm; the thickness of the h-BN layer 107 is 3nm, and the relative dielectric constant of the h-BN layer is 5.1, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com