Micro-LED epitaxial structure and manufacturing method thereof

A technology of epitaxial structure and epitaxial growth, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as increasing carrier matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

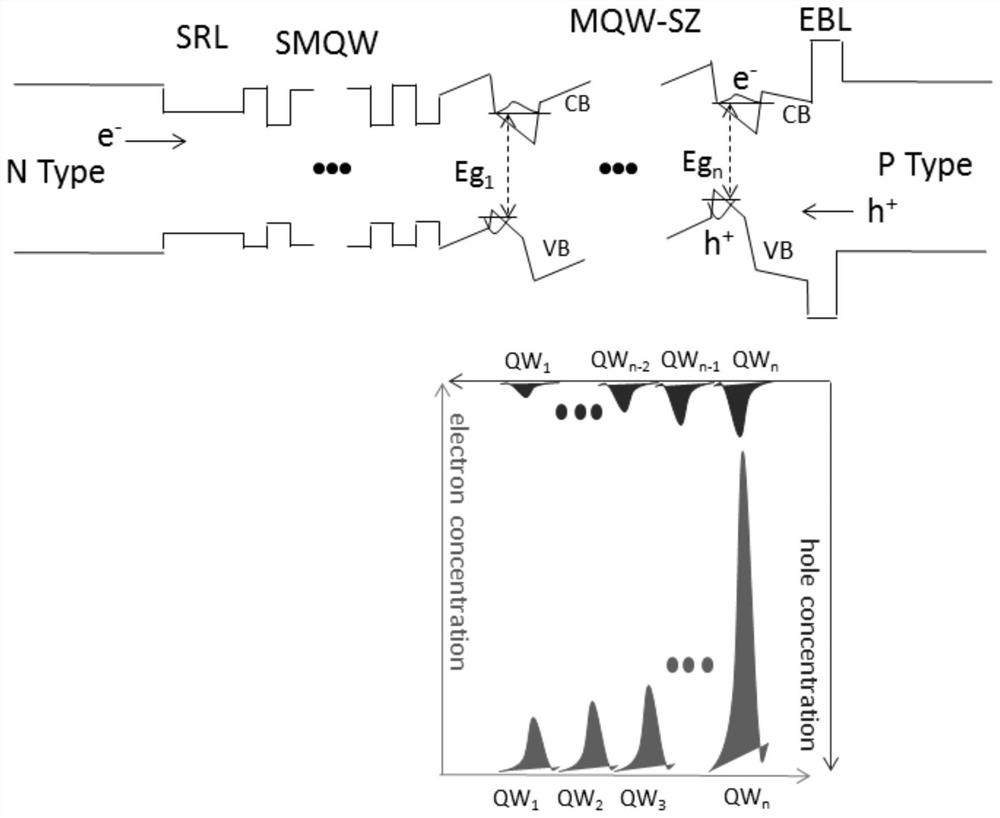

[0025] The specific implementation of the micro-LED epitaxial structure and its manufacturing method provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0026] attached figure 2 Shown is a schematic diagram of the structure of the micro-LED in this specific embodiment, including a substrate layer, and an n-type semiconductor layer on the surface of the substrate, a light-emitting layer, and a p-type semiconductor layer, and the light-emitting layer includes an electron deceleration layer ( EDL), superlattice active zone (SL-SZ), and hole gathering layer (HGL).

[0027] In this specific embodiment, the substrate is a sapphire substrate, and in other specific embodiments, the substrate may also be a GaN self-supporting substrate, either polar or non-polar. The n-type semiconductor layer, the light-emitting layer, and the p-type semiconductor layer are sequentially an n-type GaN layer, a light-emitting layer, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com