Patents

Literature

55results about How to "Increase distribution rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

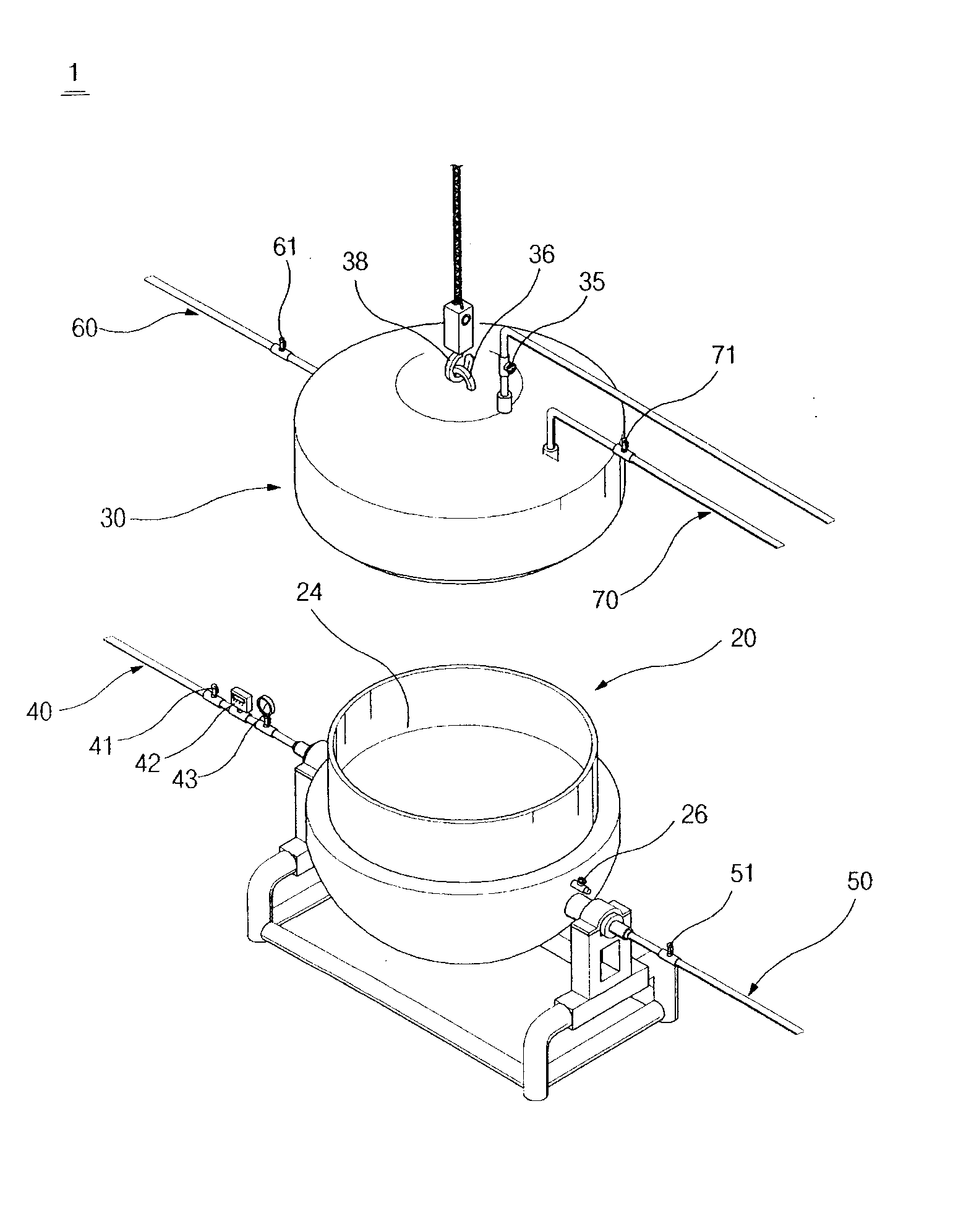

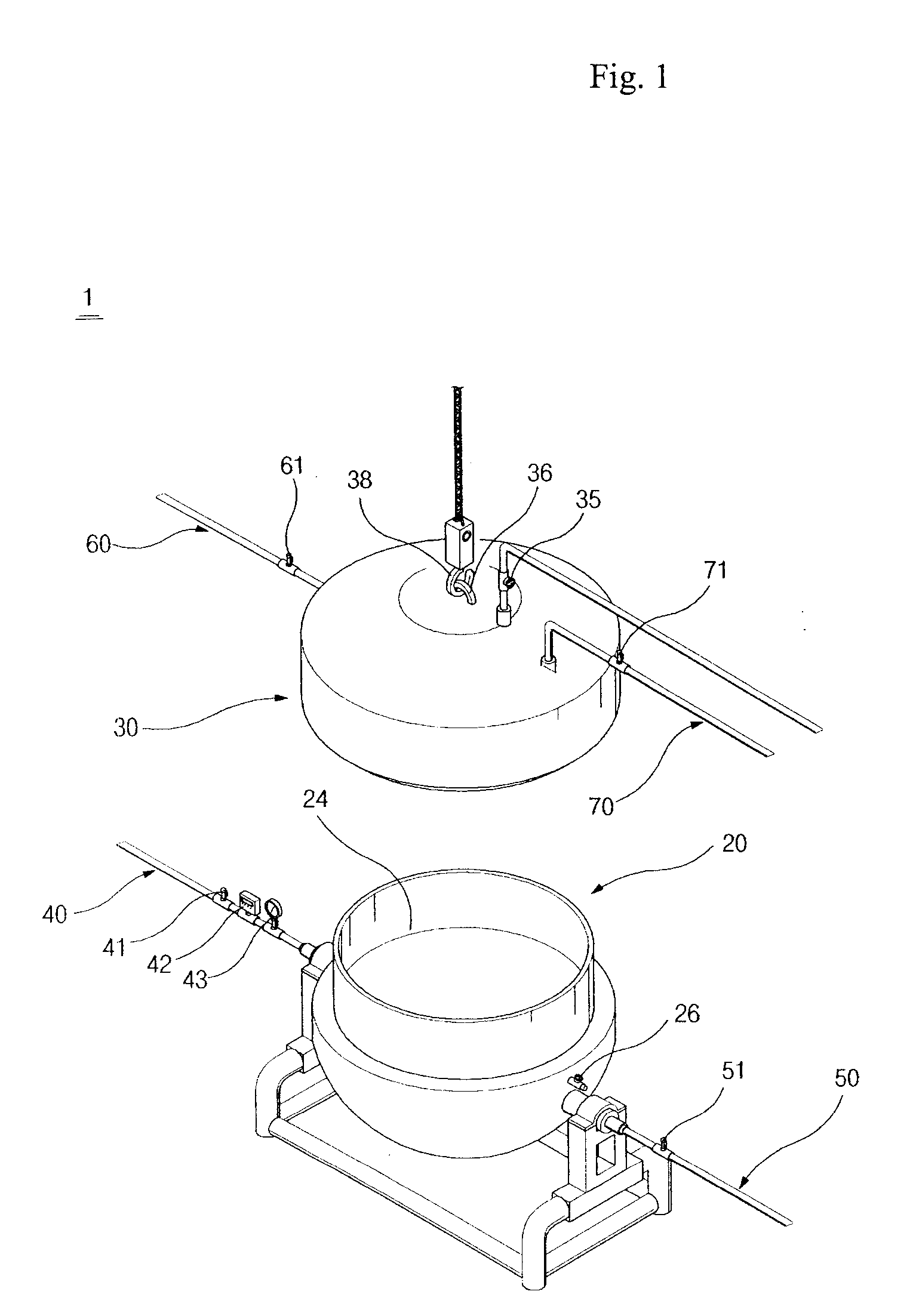

Vapor Heating Type Cooking Apparatus

InactiveUS20070209656A1Avoid stickingImprove the inconvenienceLighting and heating apparatusCooking-vessel lids/coversInterior spaceWater discharge

The present invention relates to a vapor heating type cooking apparatus cooking food materials using high pressure vapor as a heat source. A vapor heating type cooking apparatus includes: a vapor supply section generating the high pressure vapor; a vapor supply pipe and a vapor discharge pipe for introducing and discharging the high pressure vapor; a body section including a vapor introduction opening connected to the vapor supply pipe, an interior space having a dual structure so as to circulate the high pressure vapor in the caldron in which food materials are accommodated, a vapor discharge opening provided between the interior space and the vapor discharge pipe; a cooling water supply pipe and a hot water discharge pipe; a lid section including a cooling water introduction opening connected to the cooling water supply pipe, a storage space having a dual structure, in which the cooling water is temporarily stored, and a hot water discharge opening provided between the storage space and the hot water discharge pipe; and a control section for controlling introduction and discharge of the high pressure vapor, the cooling water, and the hot water.

Owner:LEE WON KI

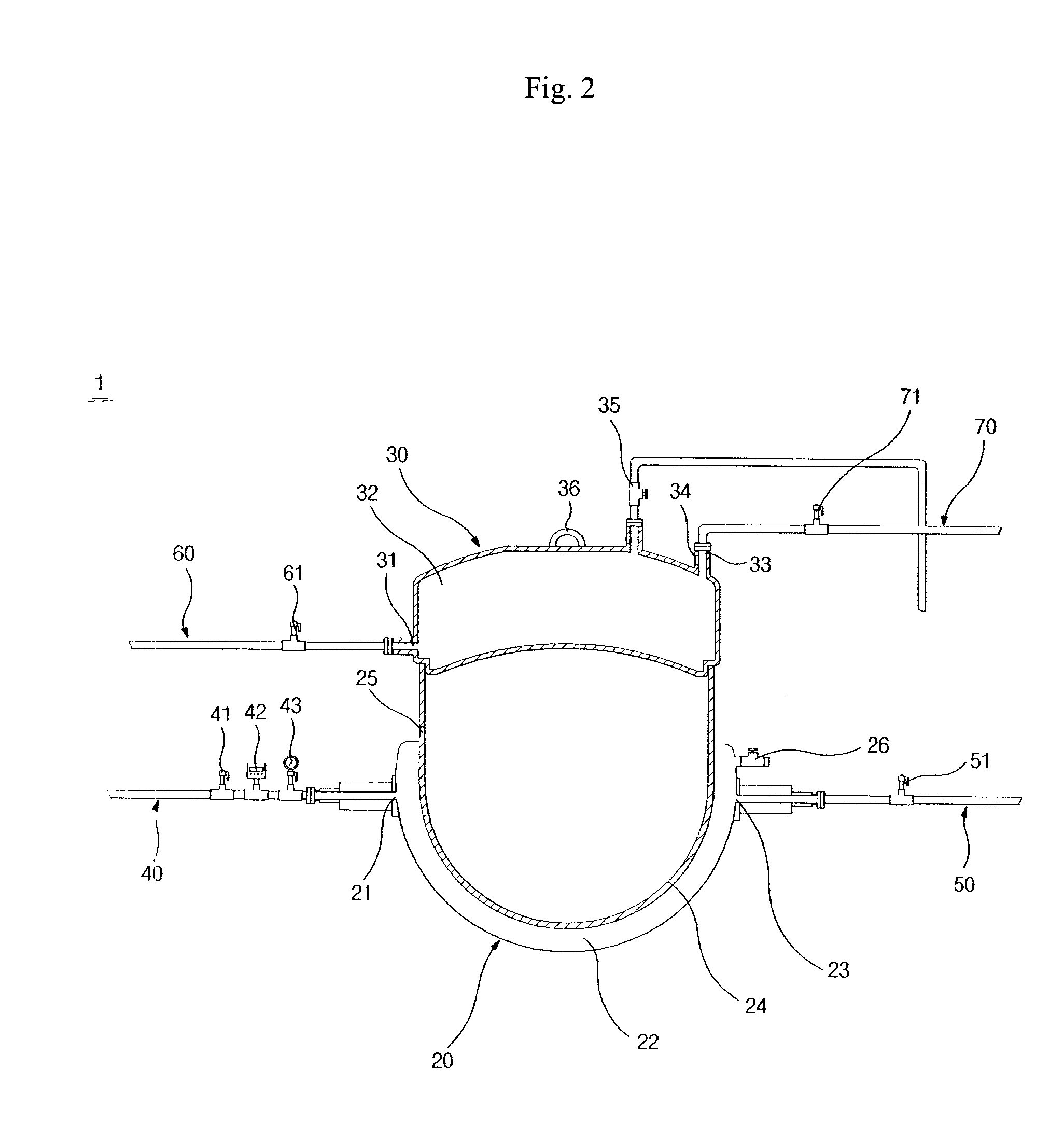

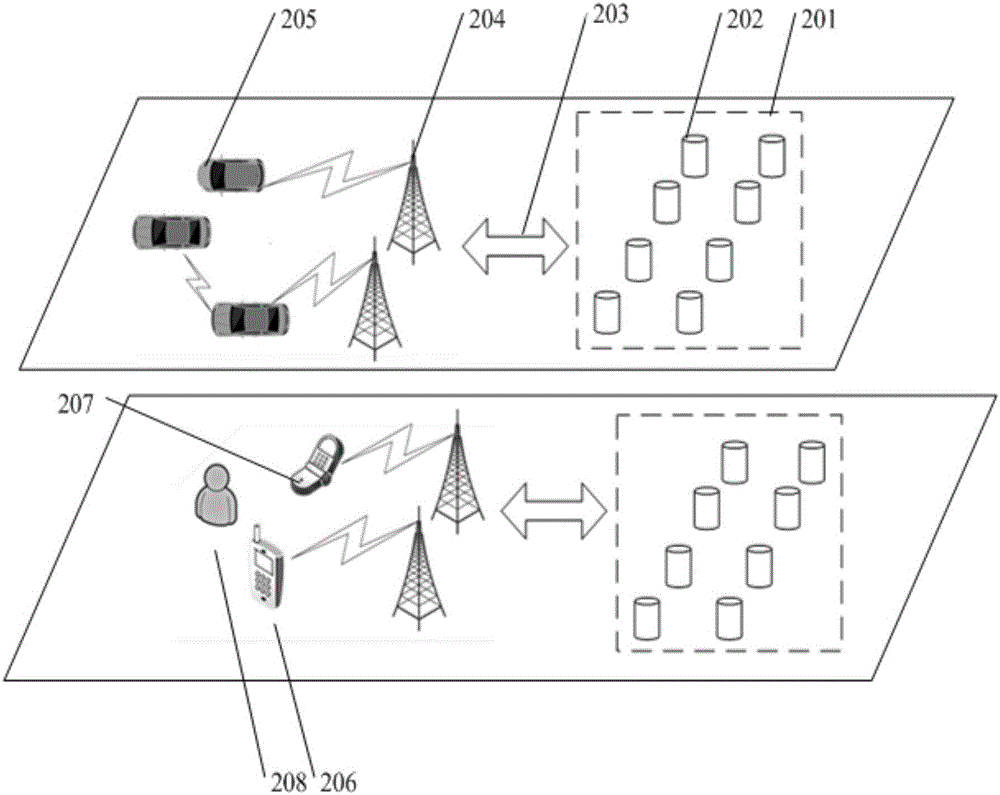

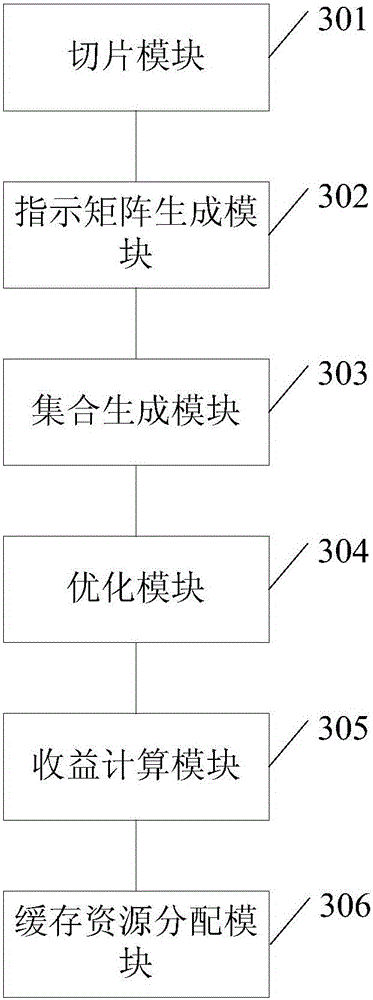

Cache resource allocation method and apparatus

ActiveCN106412040AIncrease distribution rateImprove resource utilizationTransmissionResource utilizationParallel computing

The embodiment of the invention provides a cache resource allocation method and apparatus, applied to the technical field of resource utilization. The method comprises the following steps: segmenting a plurality of cache nodes in a core network into a plurality of network slices, randomly carrying out cache resource allocation on the cache nodes at first to obtain a current cache resource allocation matrix set, selecting a current cache resource allocation matrix in the set for optimization, until the current gain of a network operator corresponding to the optimized current cache resource allocation matrix is greater than the initial gain of the network operator corresponding to the selected current cache resource allocation matrix, obtaining a finally optimized cache resource allocation matrix, and carrying out cache resource allocation according the obtained cache resource allocation matrix. In combination with the internal network caching technology and the network slicing technology, the cache resources of the cache nodes are allocated to a plurality of network slices, and iterative optimization is performed on the cache resource allocation of the cache nodes to improve the cache resource allocation rate and the resource utilization rate.

Owner:NEW H3C TECH CO LTD

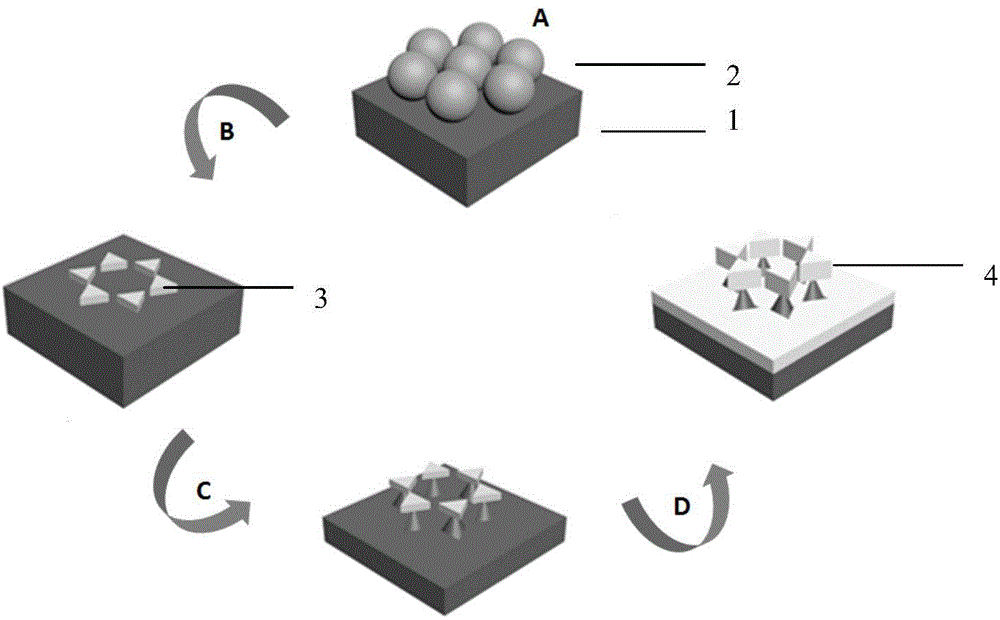

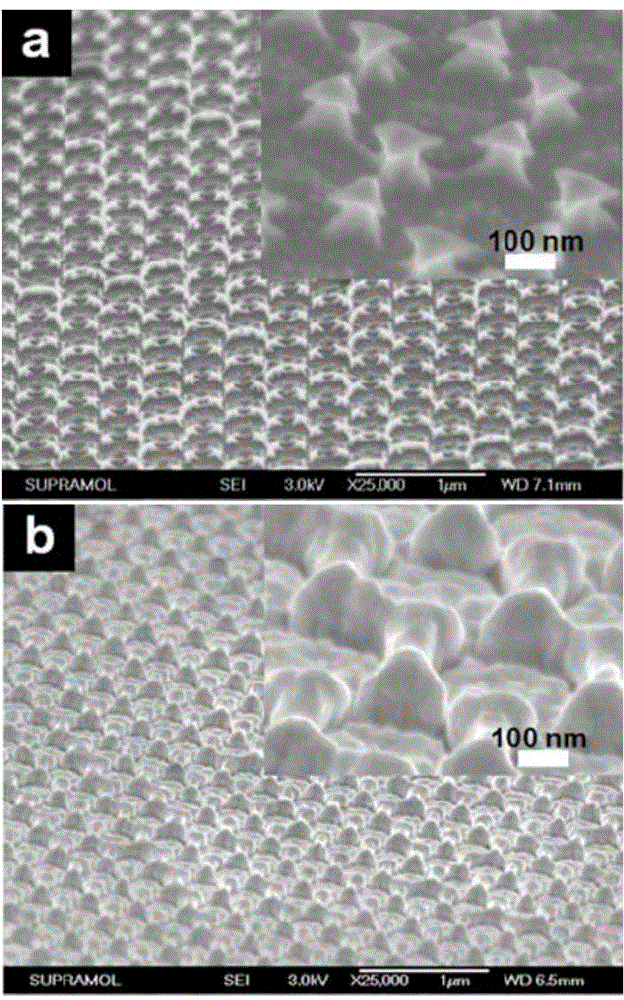

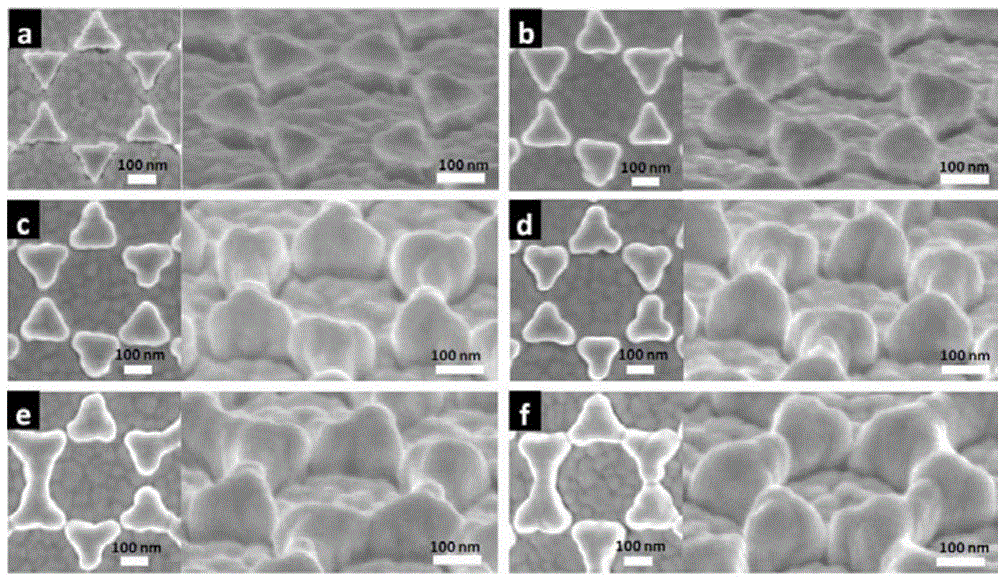

Method for preparing high-sensitivity surface enhanced raman scattering (SERS) substrate

InactiveCN104155283AHigh strengthIncrease distribution rateRaman scatteringEvaporationUltimate tensile strength

The invention discloses a method for preparing a high-sensitivity surface enhanced raman scattering (SERS) substrate and belongs to the technical fields of analysis and detection. The method particularly comprises the step of constructing a suspended nanometer antenna structure array on a silicon substrate, wherein the vibration mode of a metal nanostructure can be controlled through the thickness of evaporation silver; the shape and the vibration mode of a suspended nanometer antenna can mutate with the increase of the thickness of an evaporation silver film; through the mutation, the strength of a hotspot is increased and the hotspot can be moved from the bottom of the nanometer antenna to the top of the nanometer antenna. On the basis, by means of the molecule confinement effect caused by the hydrophobicity of the surface of silver, the possibility that the hotspot comes into contact with a to-be-detected molecule is increased and the detection sensitivity of the SERS substrate is increased; the optimized suspended nanometer antenna structure array has high SERS sensitivity, the maximum SERS enhancement factor is 9.8*10<9> and the minimum detectable concentration is 10<-12>mol / L.

Owner:JILIN UNIV

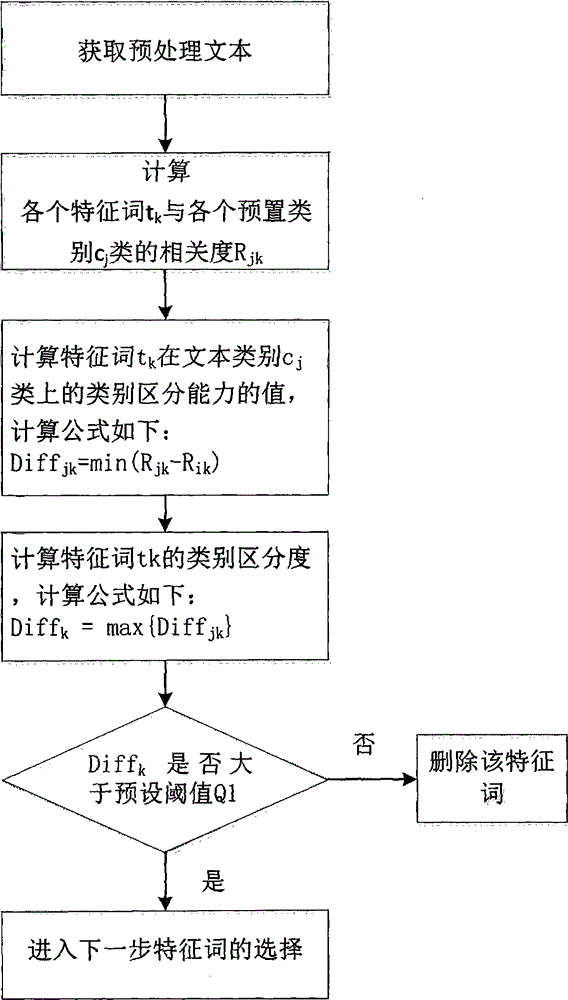

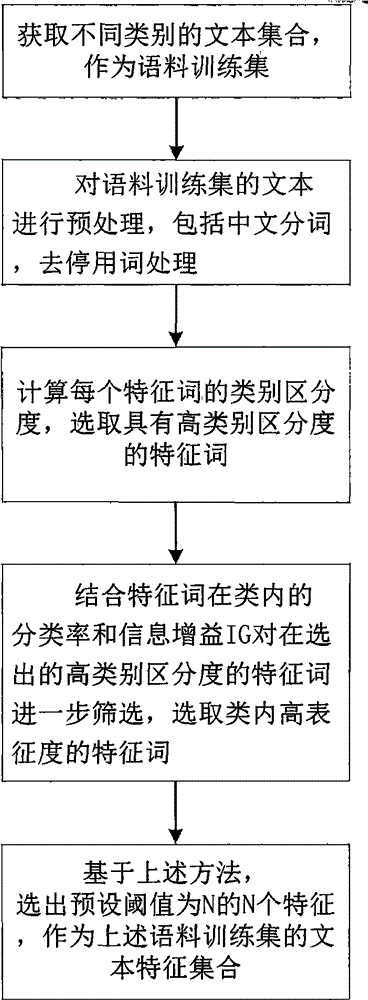

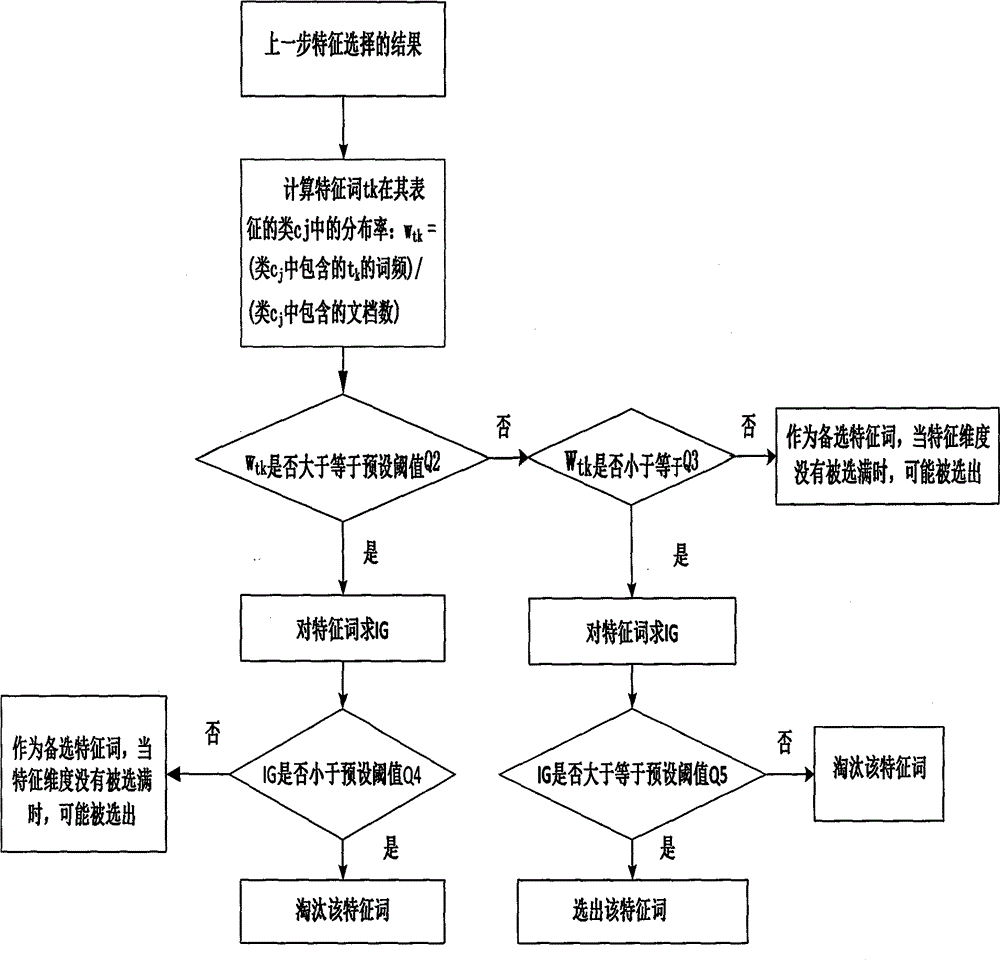

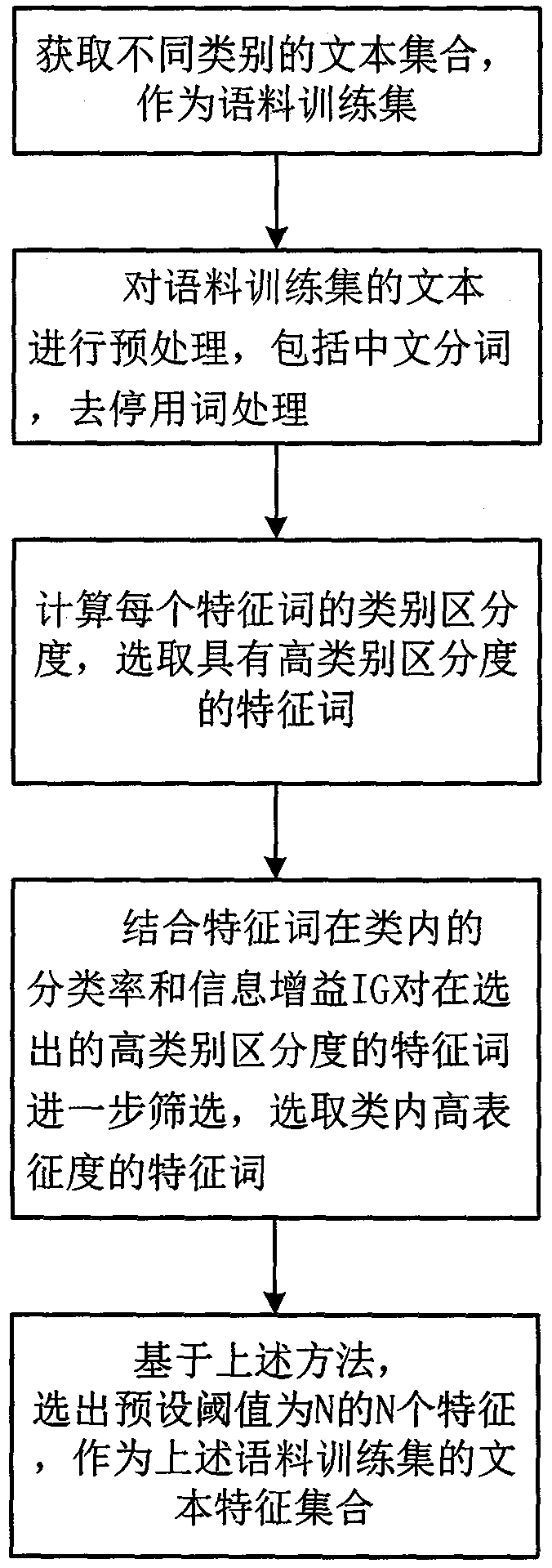

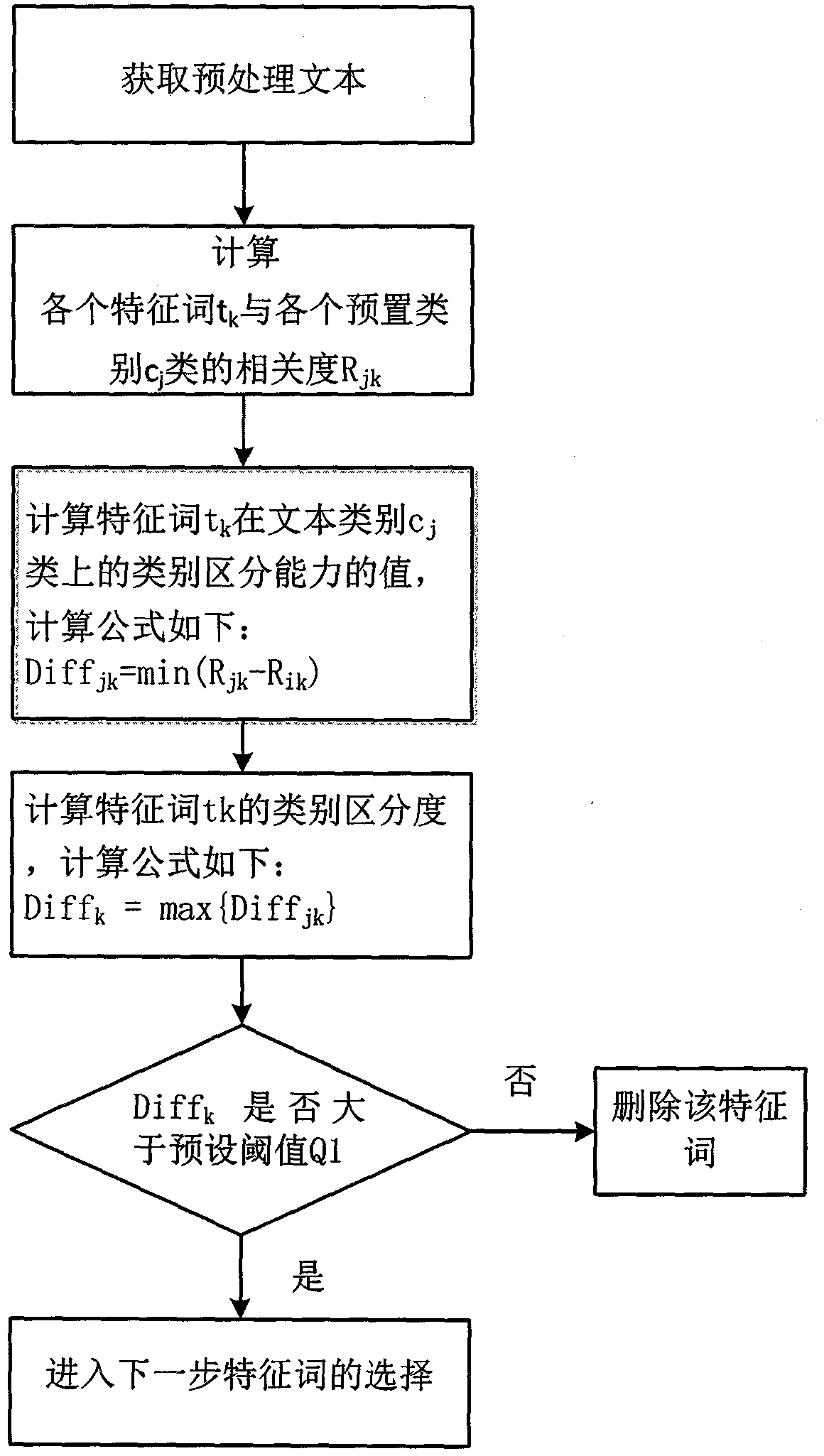

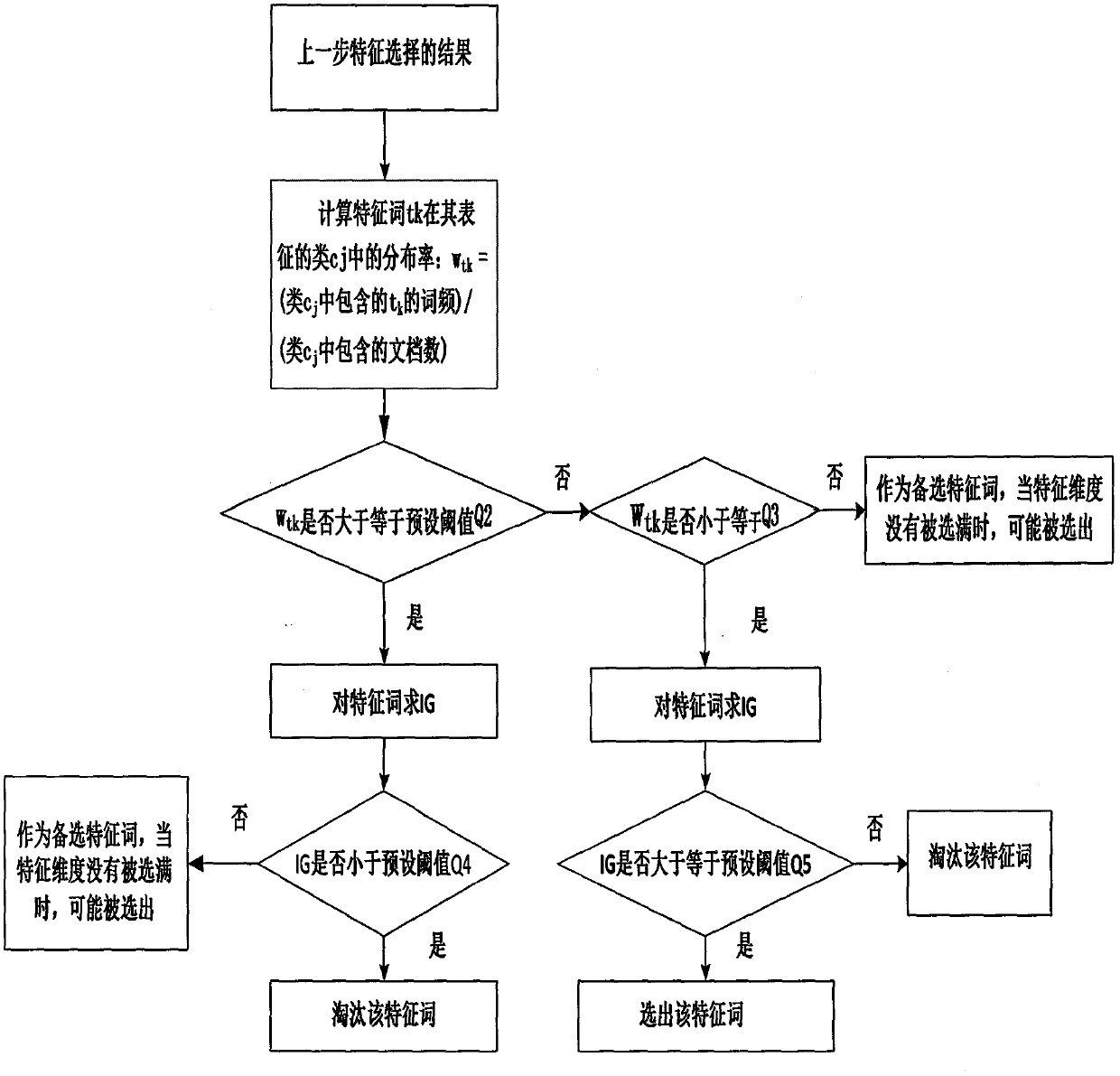

Text feature extracting method based on inter-class distinctness and intra-class high representation degree

ActiveCN105893388AIncrease distribution rateIncrease information entropySpecial data processing applicationsFeature extractionText categorization

The invention discloses a text feature extracting method based on inter-class distinctness and intra-class high representation degree. The method comprises the following steps: preprocessing a training set text; calculating the class distinctness of each feature word through an improved feature selecting method so as to select feature words with more class representation, wherein the selected feature words are of high distinctness among different classes; and further screening the selected feature words which are of high class distinctness based on the intra-class distribution rate and information gain (IG) of the feature words. With the adoption of the method, the feature selection is carried out twice to select the feature words which are of high intra-class information entropy and high intra-class distribution rate, and thus the classifying efficiency and accuracy can be improved; in addition, the calculation is simple, so that the text classifying speed and accuracy can be improved.

Owner:CHENGDU WANGAN TECH DEV

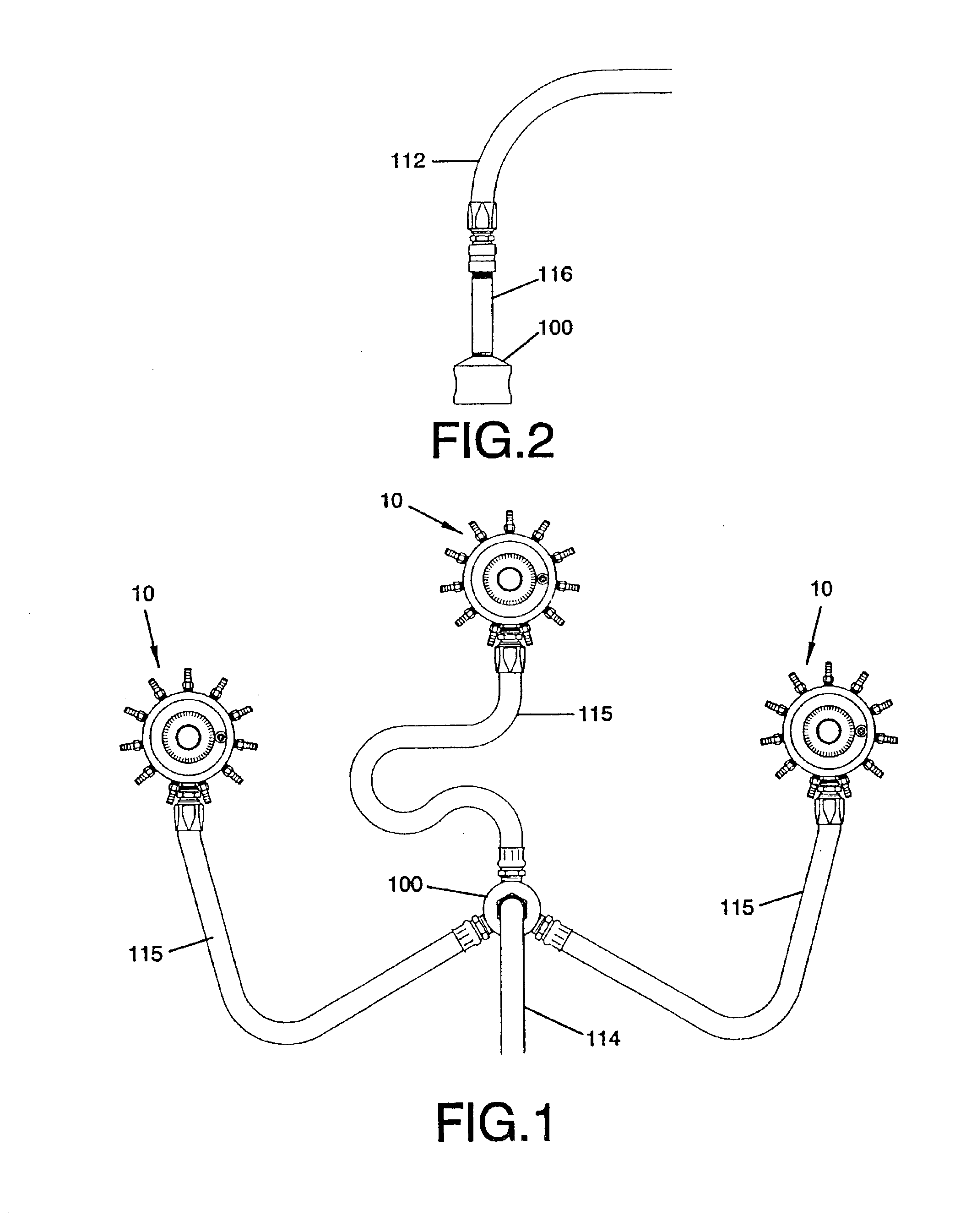

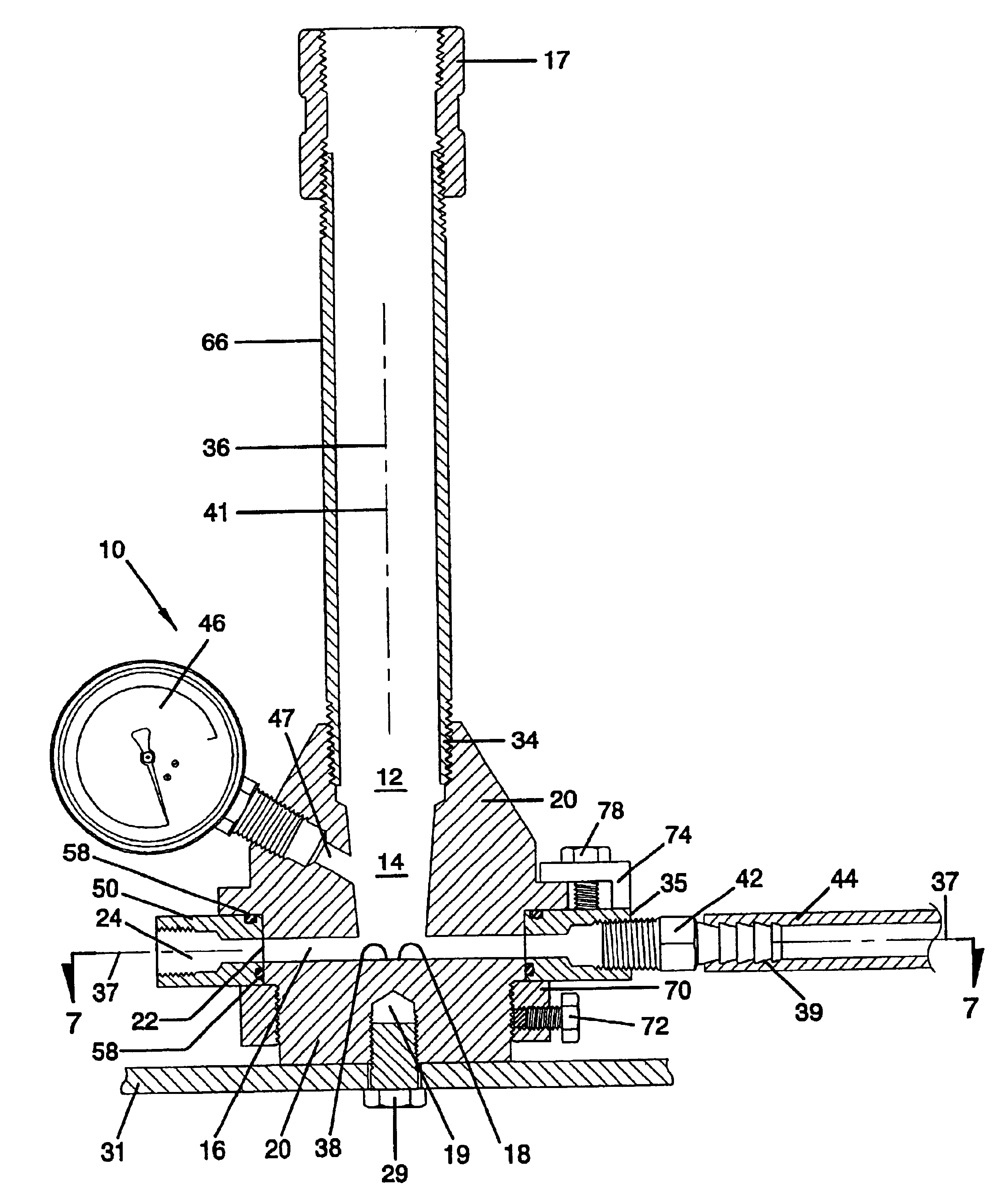

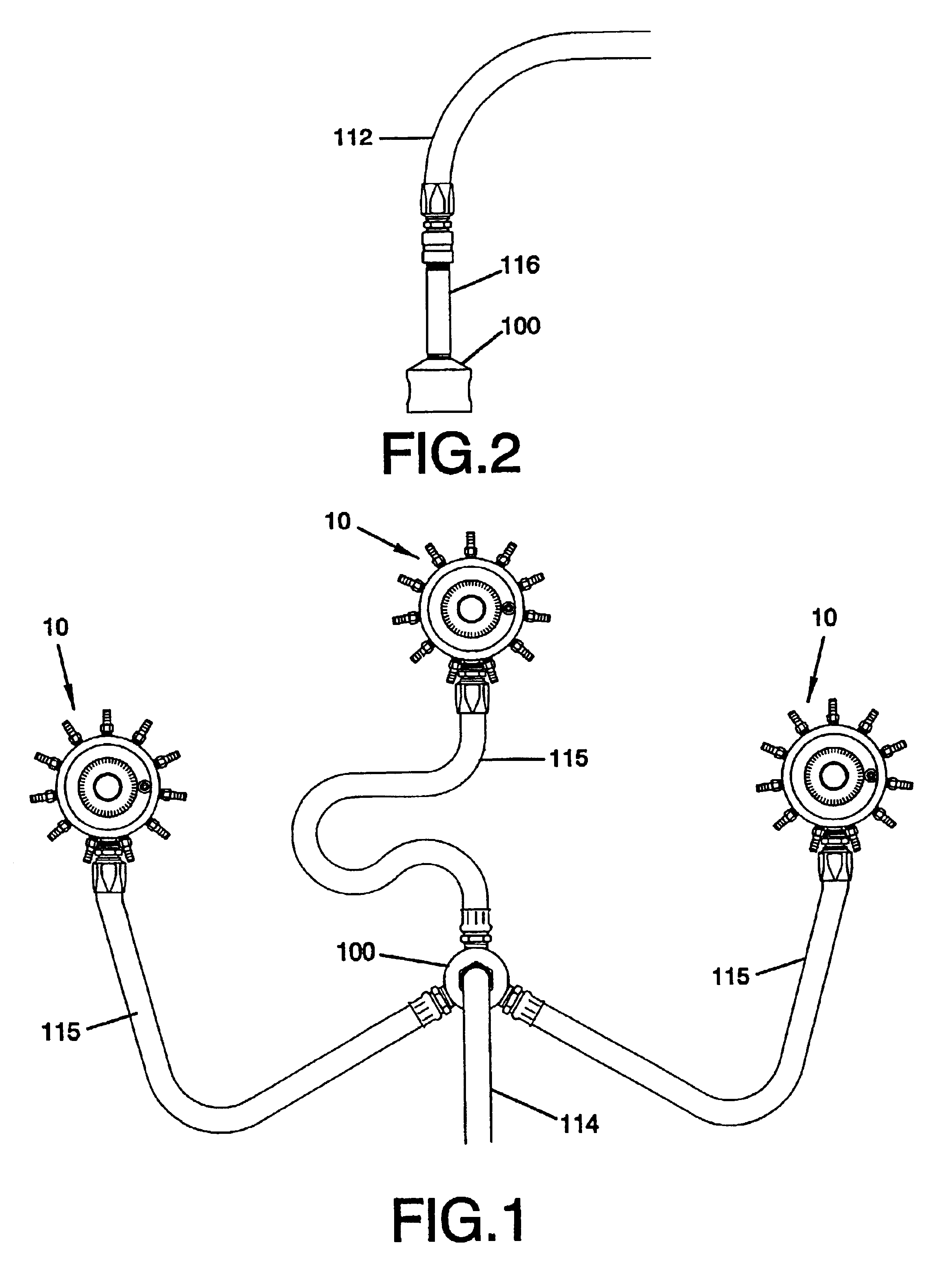

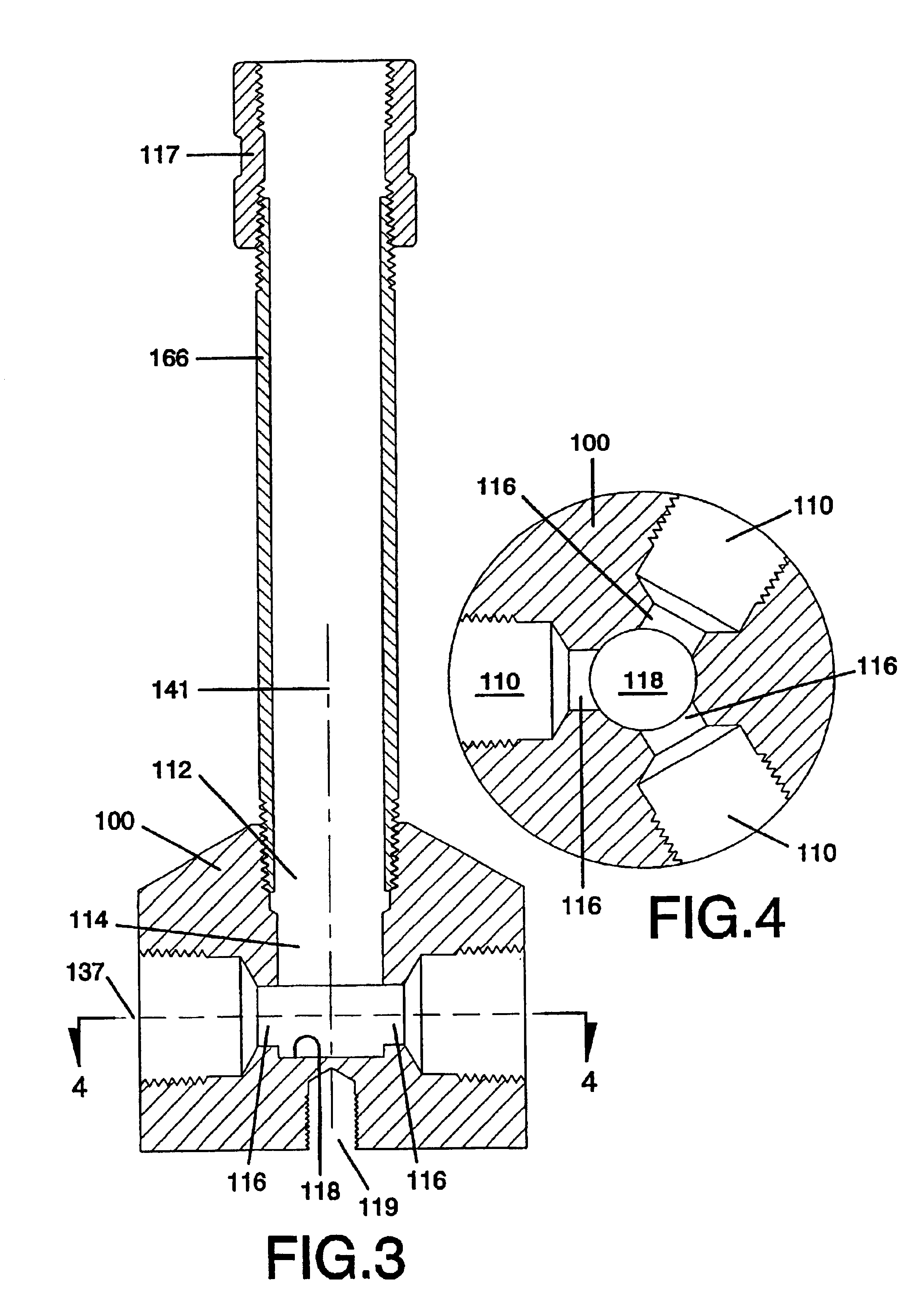

Liquid fertilizer distribution system and method

InactiveUS6851450B2Optimize allocationReduce variationLiquid fertiliser regulation systemsSpray nozzlesDistribution systemVaporization

Apparatus and methods are provided for a fluid fertilizer distributor 10, 200, 300, or 400 for distributing fluid fertilizer conducted from a supply vessel 11 to each of a plurality of applicator lines 44. The fluid distributor may regulate a fluid fertilizer flow rate by selectively moving a flow restrictor 50, 250, 350, or 450 relative to the distributor housing. The distributor housing may include a supply inlet port 12, 212, 312, or 412 and a plurality of distributor out ports 16, 216, 316, or 416 each for fluid communication with a respective one of the plurality of applicator lines 44. The fluid distributor may separate the fluid fertilizer into a plurality of fluid flow paths prior to reducing the pressure in the fluid to avoid gas flashing or vaporization prior to separation. Thereby, fluid distribution may be effected upon a substantially liquid fluid within the fluid distributor, which may result in substantially uniform fertilizer application, with reduced rate variation between applicator lines. The flow restrictor 50, 250, 350, or 450 may be substantially ring shaped and positioned on an external surface of the distributor housing, or substantially cylindrical shaped and positioned substantially internal to the distributor housing. The fluid distributor may provide for substantially infinitely regulating the application rate between a fully closed position and a fully open position. Rate regulation may be performed manually or by programmable controller.

Owner:PARKER INTANGIBLES LLC

A method for intelligently scheduling cloud resources based on DDoS attack

InactiveCN109088941AIncrease distribution rateEffective judgmentTransmissionPeak valueCloud resources

The invention relates to the technical field of network security protection, in particular to a method for intelligently scheduling cloud resources under DDoS attack, comprising the steps of integrating cloud resources, monitoring the health status of each node resource server, eliminating overloaded server resources, re-accessing after repair, and seamlessly migrating user services under cloud services. The invention has the advantages of not only monitoring the load state and the hardware utilization rate, but also increasing the cloud resource distribution rate and the state monitoring of the cleaning amount, and pre-evaluating the access node mode. The allocation rate indicates how many resources the cloud resources are allocated, i.e., the utilization rate. The cleaning amount indicates the magnitude of the node's resource cleaning data, and the attack peak value is obtained. The return of the cleaning throughput value is used as the parameter of the pre-evaluation protection. Ability to make resource judgments and adjustments efficiently and in a timely manner; make an effective judgment of cloud resource status in advance to provide users with online services to protect against attacks through the integration of cloud resources to ensure the normal operation of the business carried by users.

Owner:ANHUI ZHONGXIN SOFTWARE

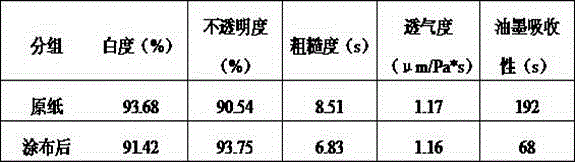

Coating for color inkjet printing paper and preparation method of coating

InactiveCN105696411AHigh-resolutionGood light fastnessDefoamers additionCoatings with pigmentsSurface layerWater insoluble

The invention discloses a coating for color inkjet printing paper. The coating comprises a bottom-layer coating and a surface-layer coating which are respectively prepared by selecting different raw materials and adopting different methods. Compared with the prior art, the coating disclosed by the invention has the following advantages that the bottom-layer coating and the surface-layer coating adopt different raw materials and processes, and the manufacturing process is simple; after base paper is treated, due to the synergistic effect, the ink absorbing capability is good, the structure function of the whole coating layer is optimized, and after the dye is contacted to charges at the bottom layer, the dye and the charges act rapidly to generate water-insoluble complex, so that the effect of fixing ink is achieved, the penetration and diffusion of ink are prevented; and due to the synergistic effect with the surface-layer coating, the distribution rate of images is increased, and the resolution and the color glossiness of the images are improved, so that the coating is applicable to manufacture of color-inkjet printing paper with high quality requirement.

Owner:安徽文峰新材料科技股份有限公司

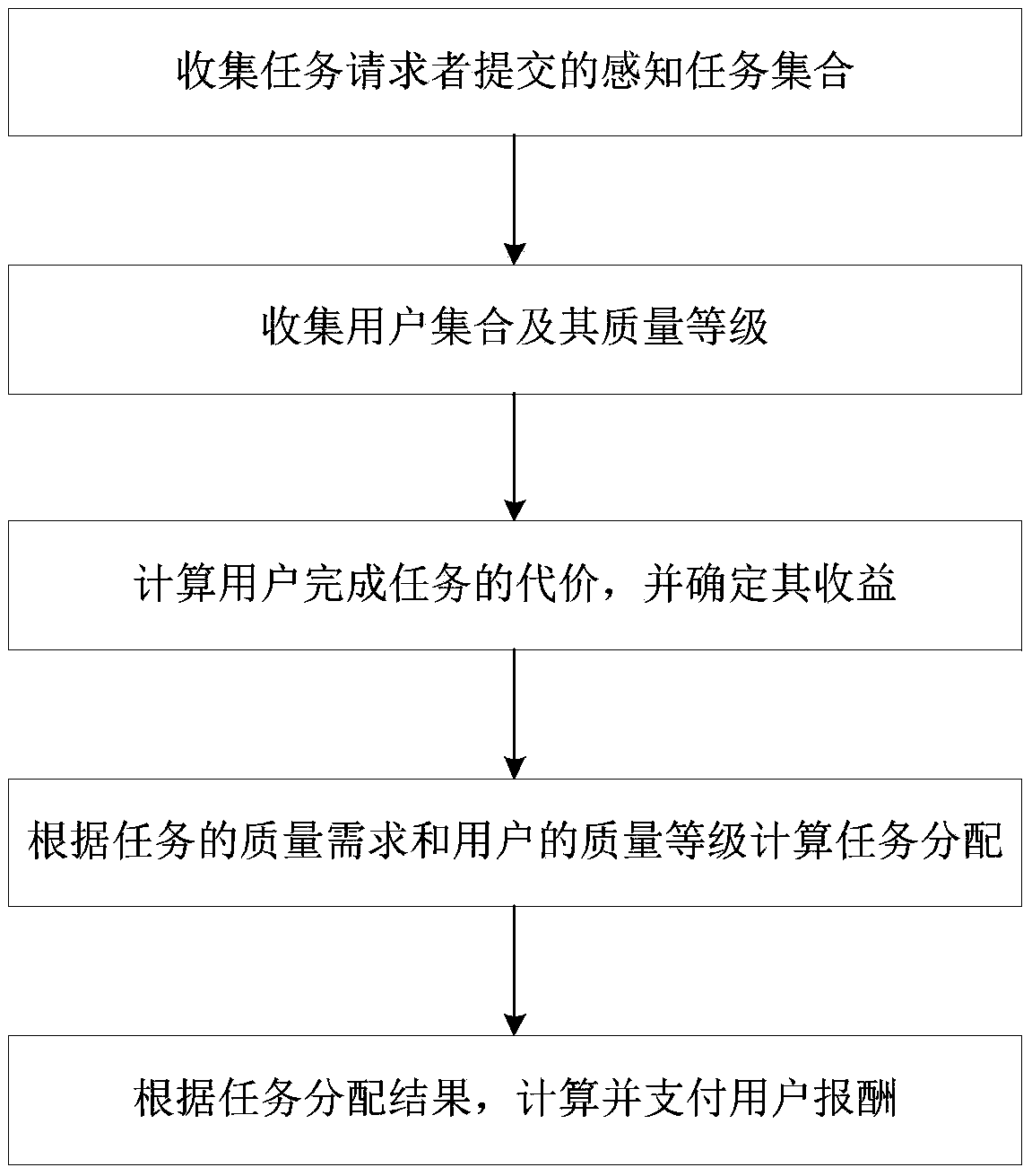

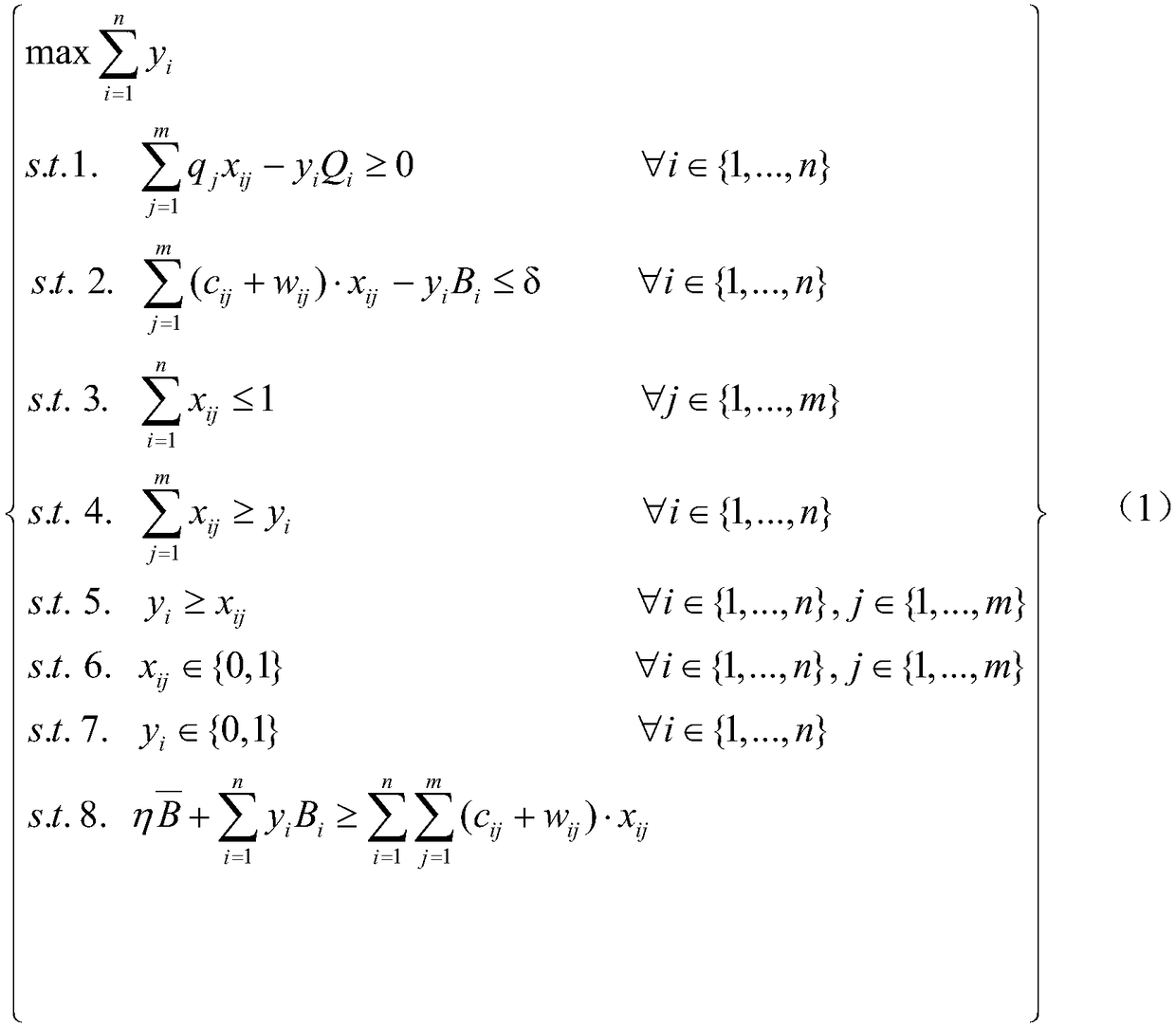

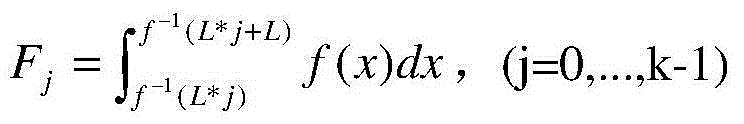

Group intelligence perception task allocation method based on budget allocation

ActiveCN109408228AQuality improvementMission Budget SavingsResource allocationMachine learningBudget allocation

The invention relates to a group intelligence perceptual task allocation method based on budget allocation. The method includes collecting the perceptual task set Gamma = {Tau 1,..., Tau i,..., Tau n}submitted by the task requester, n is a finite natural number, task Tau i= (Bi, Qi), Bi is the total budget of the completed task Tau i, which is a finite positive real number, Qi is the quality requirement value of the task Tau i, which is a finite positive integer; collect the user set U= {u1,..., uj,..., um} and the quality level qj, j Belongs to{1,..., m} of the user uj in the user set; calculating the cost cij of completing the task Tau i by the user uj, and determining the benefit wij of completing the task Tau i by the user uj; the tasks in the perceptual task set Gamma are assigned according to the quality requirement Qi of the task Tau i and the quality level qj of the user uj, and the user remuneration rj is calculated and paid according to the task assignment result.

Owner:广州阿拉丁智能科技有限公司

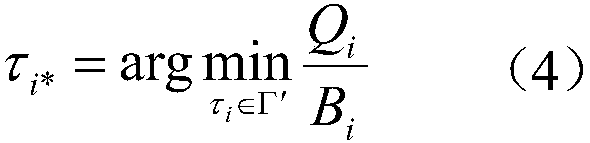

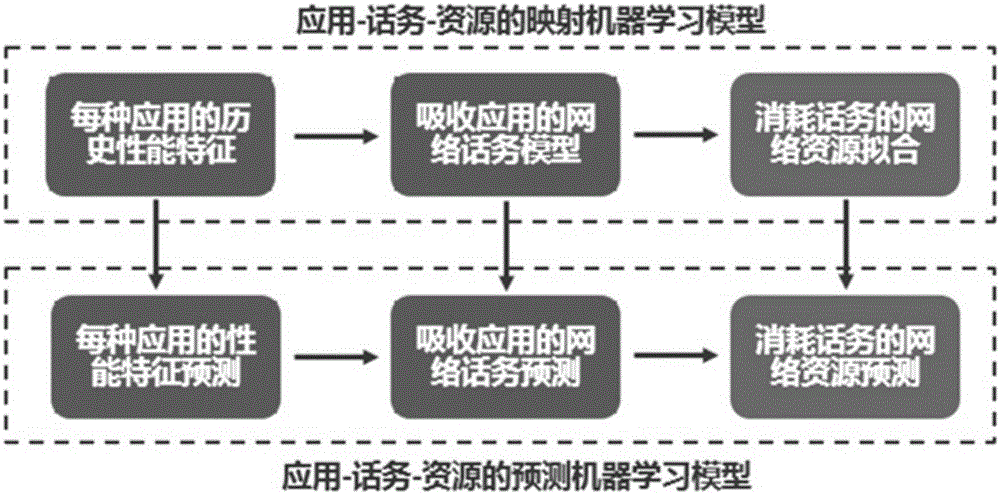

Method for analyzing utilization of mobile Apps on wireless network resources based on crowdsourcing mode

ActiveCN105227369AIncrease resourcesQuality improvementTelephonic communicationData switching networksMobile appsThree level

The invention provides a method for analyzing utilization of mobile Apps on wireless network resources based on a crowdsourcing mode. The method comprises the following steps: collecting behavior characteristic data of each mobile application App through a data collection tool based on the crowdsourcing technology and installed on a mobile client and an analysis algorithm located on a cloud server; establishing a three-level two-layer association mapping model among mobile application characteristic behaviors, wireless network traffic and the wireless network resources, and quantitatively analyzing how each mobile application service in a mobile communication network consumes the wireless network resources in a cell on a time dimension. The method provided by the invention is used for analyzing the condition of consumption of each mobile application service on the wireless network resources in the cell and obtaining a result through a machine learning algorithm to provide decision suggestions for mobile operators, for example, predicting, controlling and pricing the resources used by the mobile application App to improve the resource allocation rate and the quality of service level.

Owner:NANJING HOWSO TECH

Process for the preparation of cyclohexanol

InactiveUS20030018223A1Increase productionPromote recoveryOrganic compound preparationPreparation by hydrogenationSolubilityWater use

A method for producing cyclohexanol by subjecting cyclohexene to a hydration reaction in the presence of water using a solid acid as a catalyst in which as a reaction solvent, there is used an organic solvent having a solubility in water at 25° C. of not higher than 5% by weight, a boiling point which is at least 20° C. higher than that of the cyclohexanol produced, a conversion rate of not more than 3% under the hydration reaction conditions, and a solvent effect index of not less than 1.5 which indicates the effect of making the distribution of cyclohexene into the aqueous phase predominate.

Owner:ASAHI KASEI KK

Process for the preparation of cyclohexanol

InactiveUS6552235B2Increase productionPromote recoveryOrganic compound preparationPreparation by hydrogenationHydration reactionWater use

A method for producing cyclohexanol by subjecting cyclohexene to a hydration reaction in the presence of water using a solid acid as a catalyst in which as a reaction solvent, there is used an organic solvent having a solubility in water at 25° C. of not higher than 5% by weight, a boiling point which is at least 20° C. higher than that of the cyclohexanol produced, a conversion rate of not more than 3% under the hydration reaction conditions, and a solvent effect index of not less than 1.5 which indicates the effect of making the distribution of cyclohexene into the aqueous phase predominate.

Owner:ASAHI KASEI KK

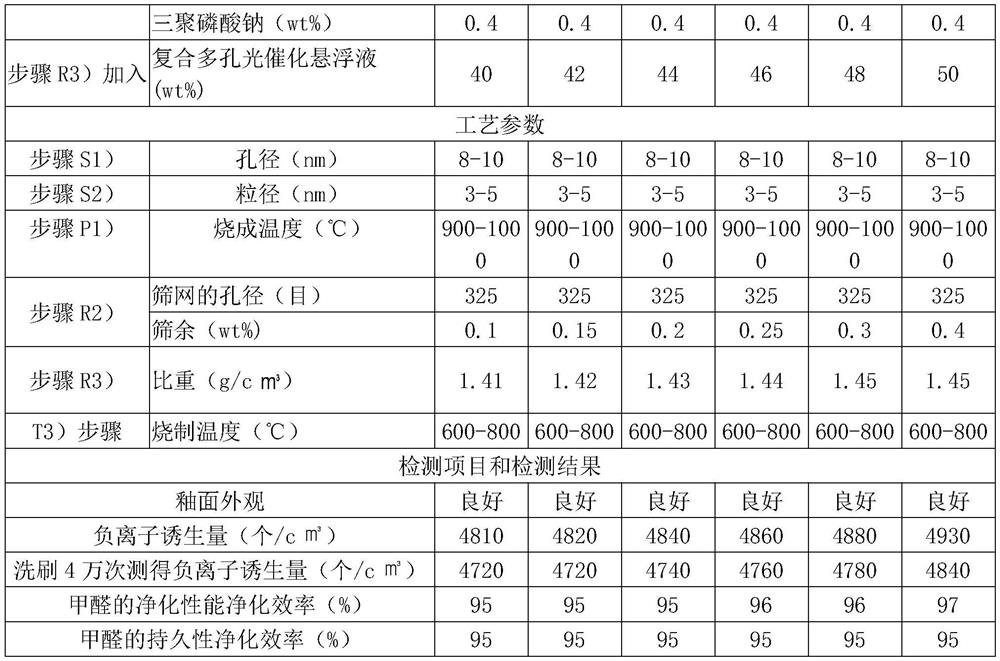

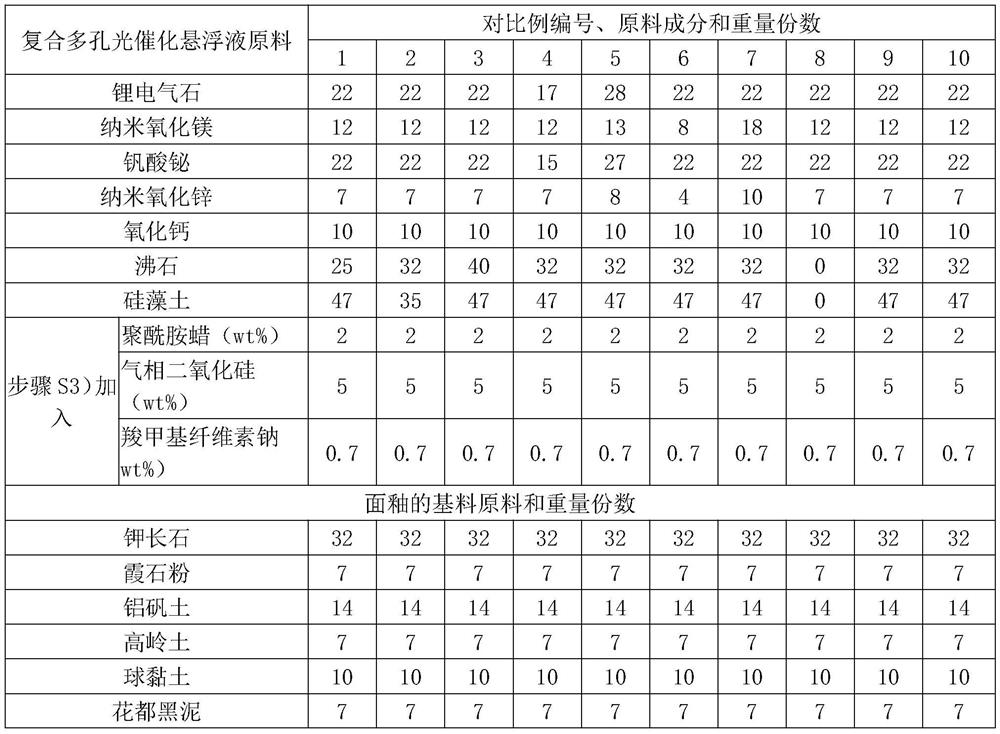

Photocatalytic negative ion ceramic tile containing modified porous material and preparation process of ceramic tile

PendingCN112321270AEfficient harmful gas purification efficiencyWith photocatalytic functionCeramic materials productionClaywaresNano zinc oxidePhoto catalysis

The invention relates to the technical field of ceramics and functional decorative materials, in particular to a photocatalytic negative ion ceramic tile containing a modified porous material and a preparation process of the ceramic tile. The ceramic tile comprises a ceramic tile blank and cover glaze, raw materials of the cover glaze comprise a composite porous photocatalytic suspension and a base material, wherein the composite porous photocatalytic suspension accounts for 40-50 wt% of the weight of the base material, the composite porous photocatalytic suspension is prepared from the following raw materials: a porous material, elbaite, nano magnesium oxide, bismuth vanadate, nano zinc oxide and calcium oxide, the porous material is prepared from zeolite and diatomite, and the particle sizes of the elbaite, the nano magnesium oxide, the bismuth vanadate, the nano zinc oxide and the calcium oxide are all smaller than the pore diameters of micropores of the porous material. The prepared photocatalytic negative ion ceramic tile cover glaze contains a porous material, micropores of the porous material can absorb harmful gas in air, and harmful gas is purified through negative ions, photocatalysis, far infrared rays and other materials.

Owner:FOSHAN DONGPENG CERAMIC +2

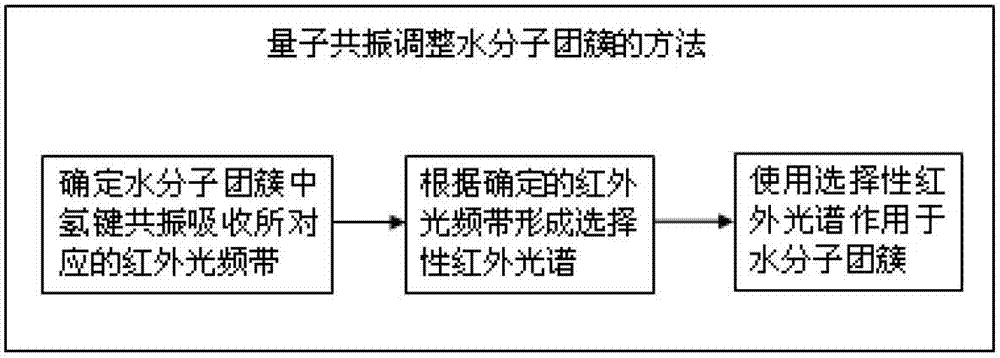

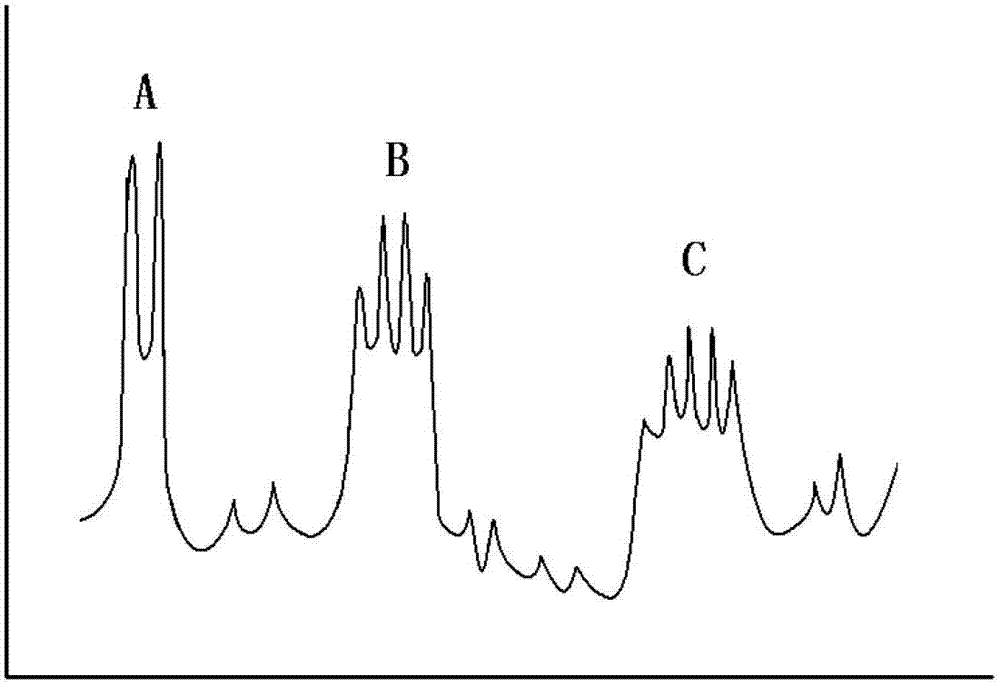

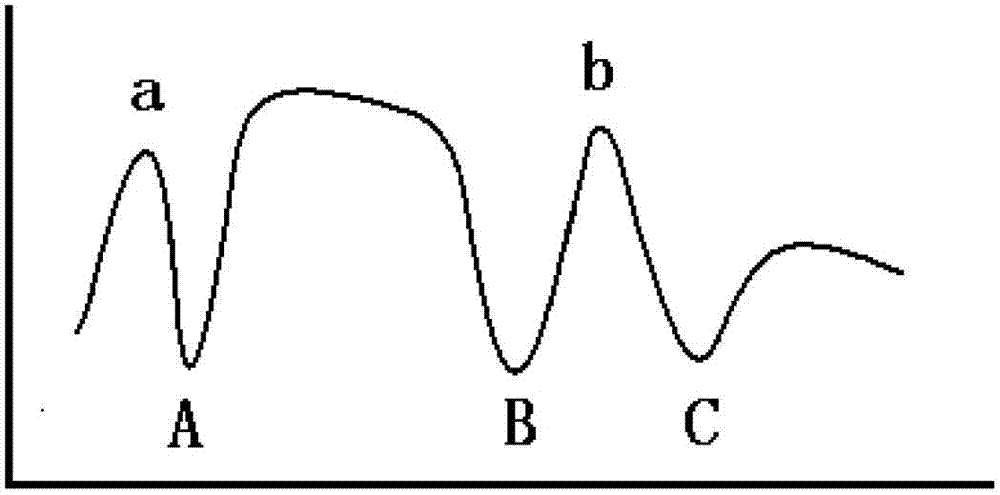

Method for adjusting water molecule cluster through quantum resonance

InactiveCN103708576AIncrease distribution rateHigh activityWater/sewage treatment by irradiationQuantum levelQuantum resonance

The invention relates to a method for adjusting water molecule cluster through quantum resonance, which is characterized in that according to hydrogen bond quantum levels of different water molecule cluster structures, by combining with an infrared spectroscopy experiment technology, an infrared light frequency band corresponding to the resonance absorption is determined, the selective infrared spectroscopy is formed by reducing or increasing the infrared light intensity of different frequency bands, the infrared light formed by the selective infrared spectroscopy is used for acting on the water molecule cluster, the break probability of the hydrogen bond of different water molecule cluster structures can be reduced or increased, thereby the water molecule cluster structures can be adjusted, ordering water molecule cluster having synergism with biomolecule can be increased, so that better biological activity effect can be provided.

Owner:苏永安

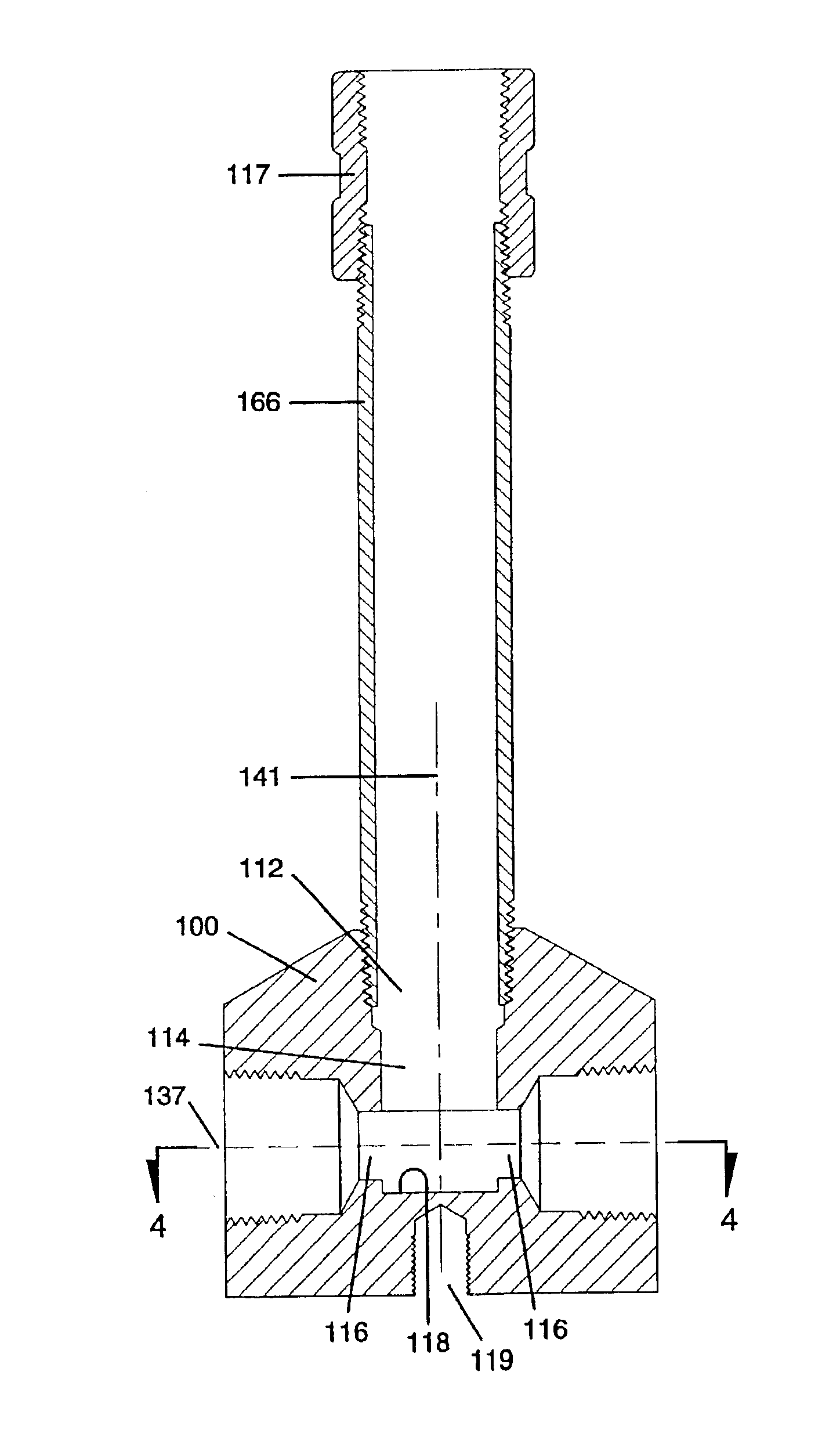

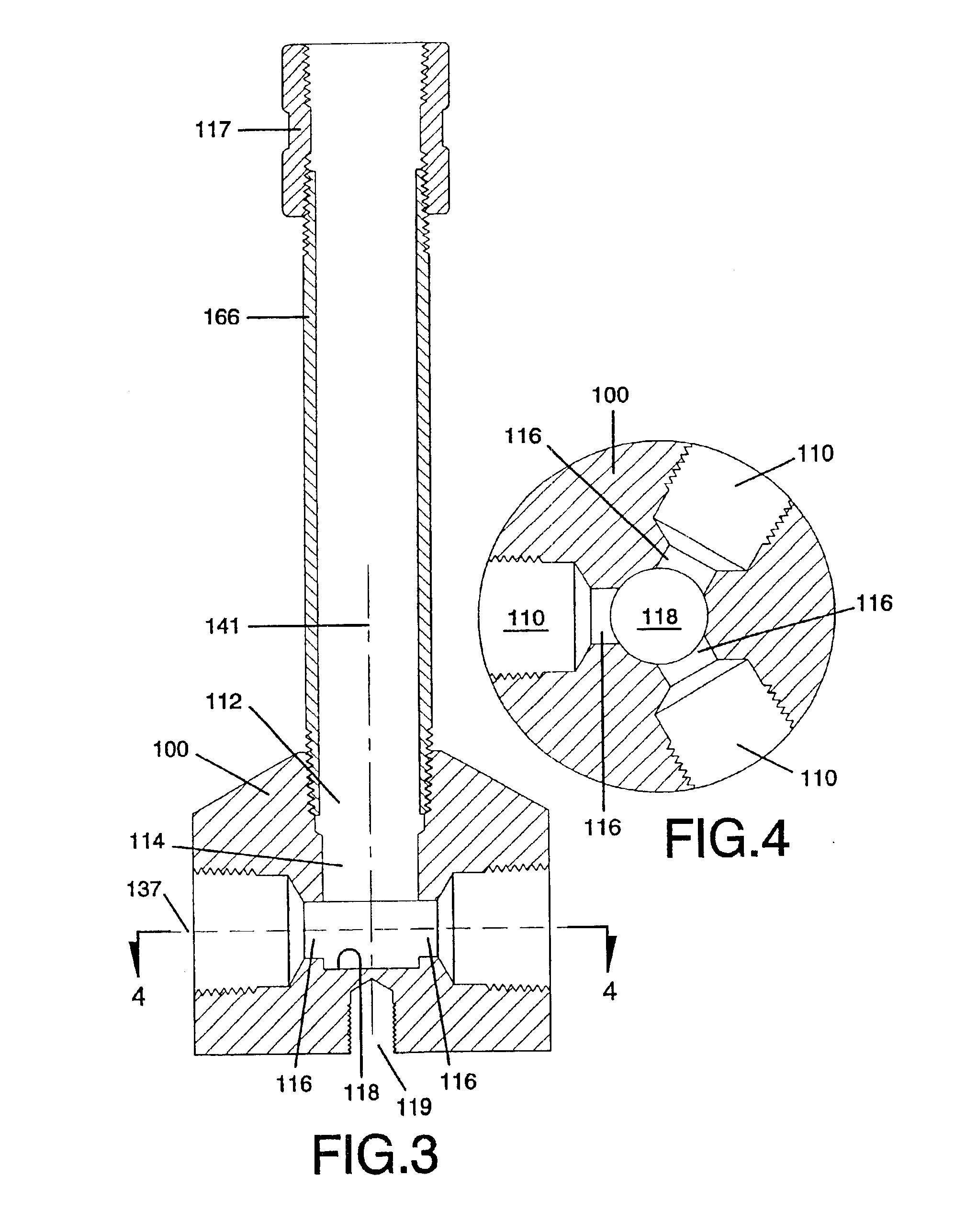

Liquid fertilizer distribution system and method

InactiveUS6901948B2Optimize allocationReduce variationLiquid fertiliser regulation systemsPipe elementsDistribution systemDistributor

A removable flow restrictor 750 and a corresponding method for regulating flow through a fluid fertilizer distributor 700 are provided. A supply inlet port 712 is in fluid communication with a plurality of fluid outlet ports 716. The flow restrictor 750 is removable positionable within the fluid distributor 700 between the inlet port 712 and the outlet ports 716, for restricting flow between the inlet port 712 and the outlet ports 716. A restrictor engagement member 752, which may be a thread, on the flow restrictor 750, engages with a tool engagement member 762 on a retrieval tool 760. With the restrictor engagement member 752 engaged with the tool engagement member 762, the retrieval tool can be used to both position the flow restrictor 750 within the fluid distributor 700, and to remove the flow restrictor 750 from the fluid distributor 700. After positioning within or removing from the fluid distributor 700, the flow restrictor 750 may be disengaged from the retrieval tool 760.

Owner:PARKER HANNIFIN CORP

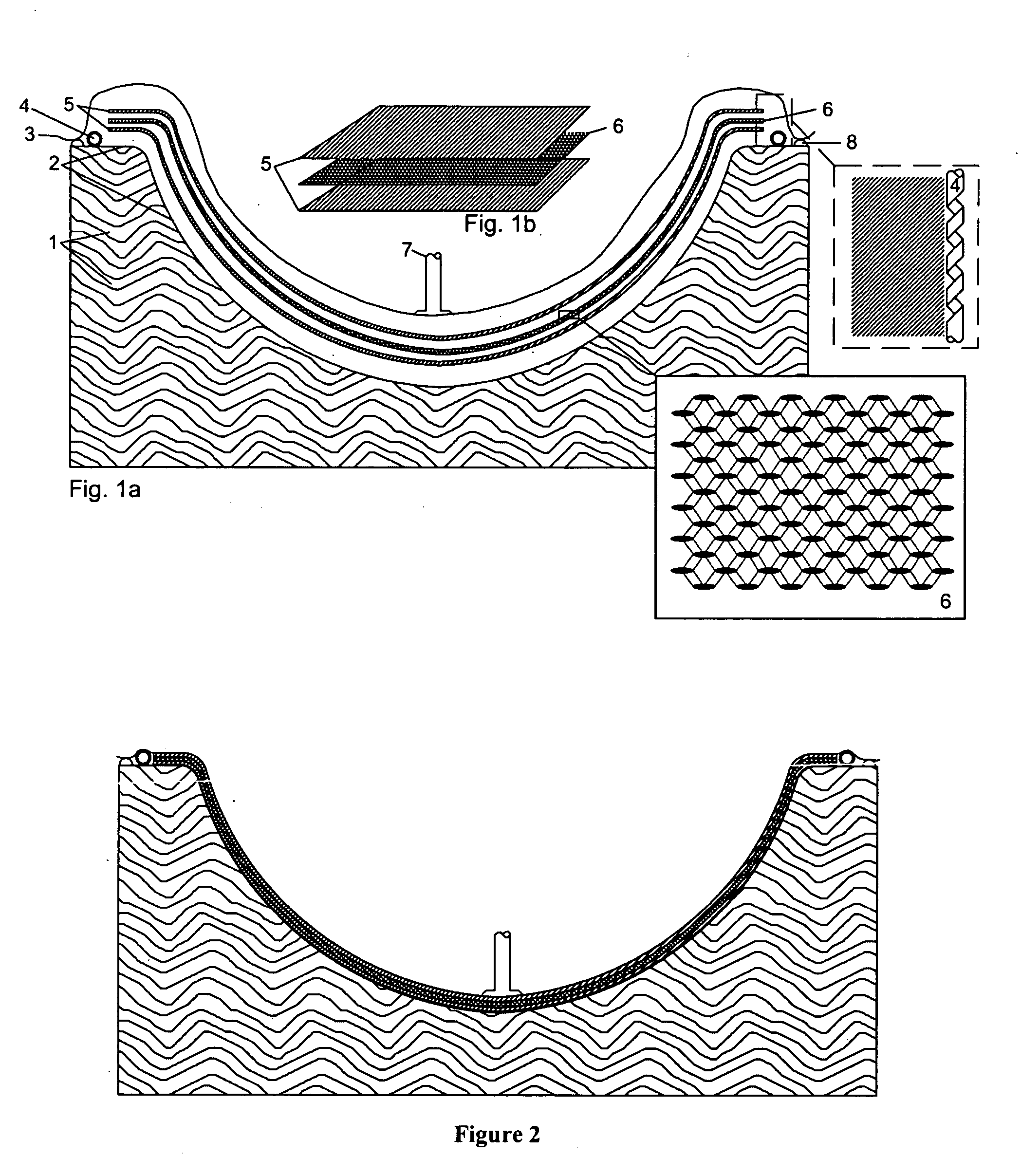

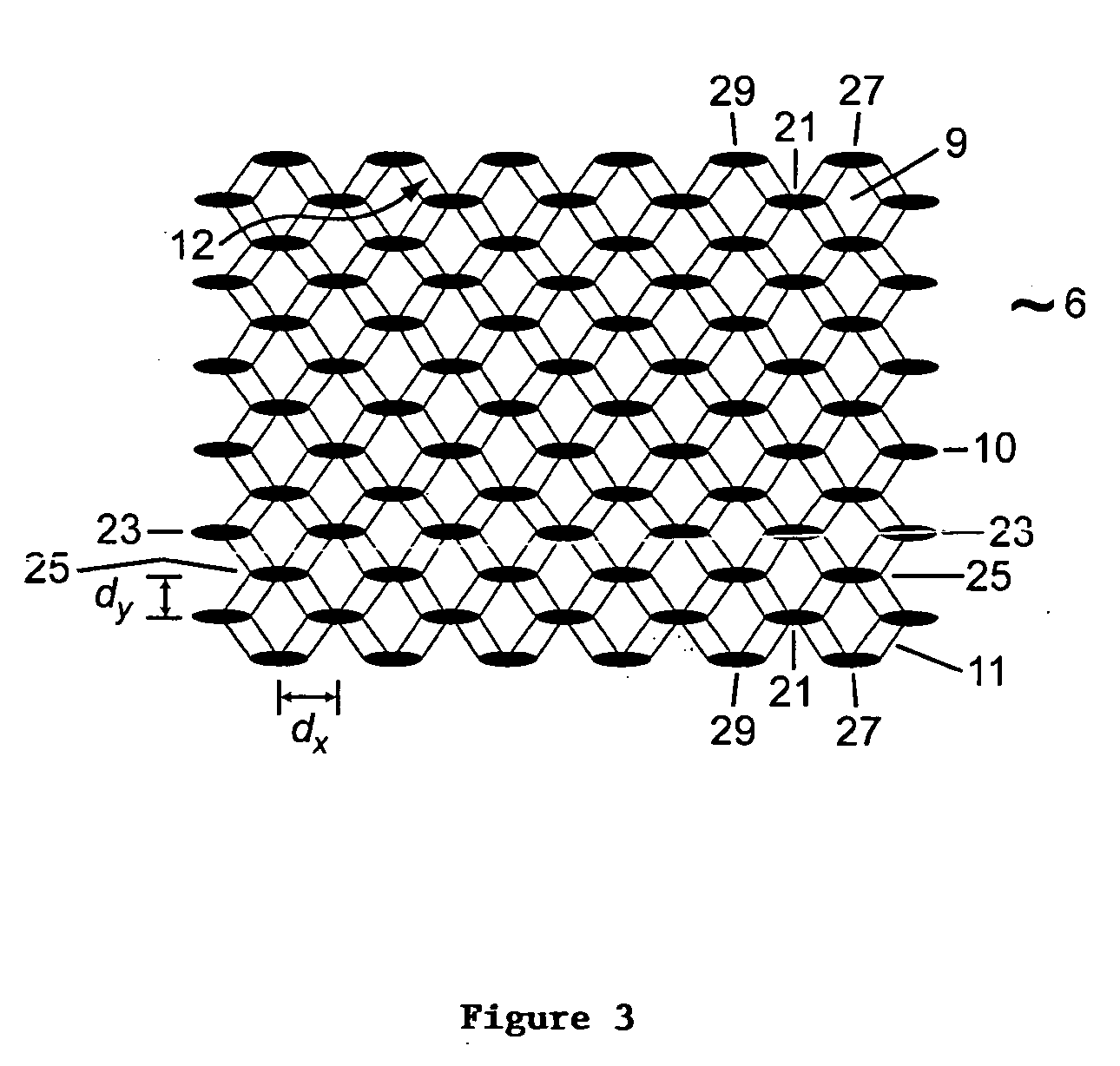

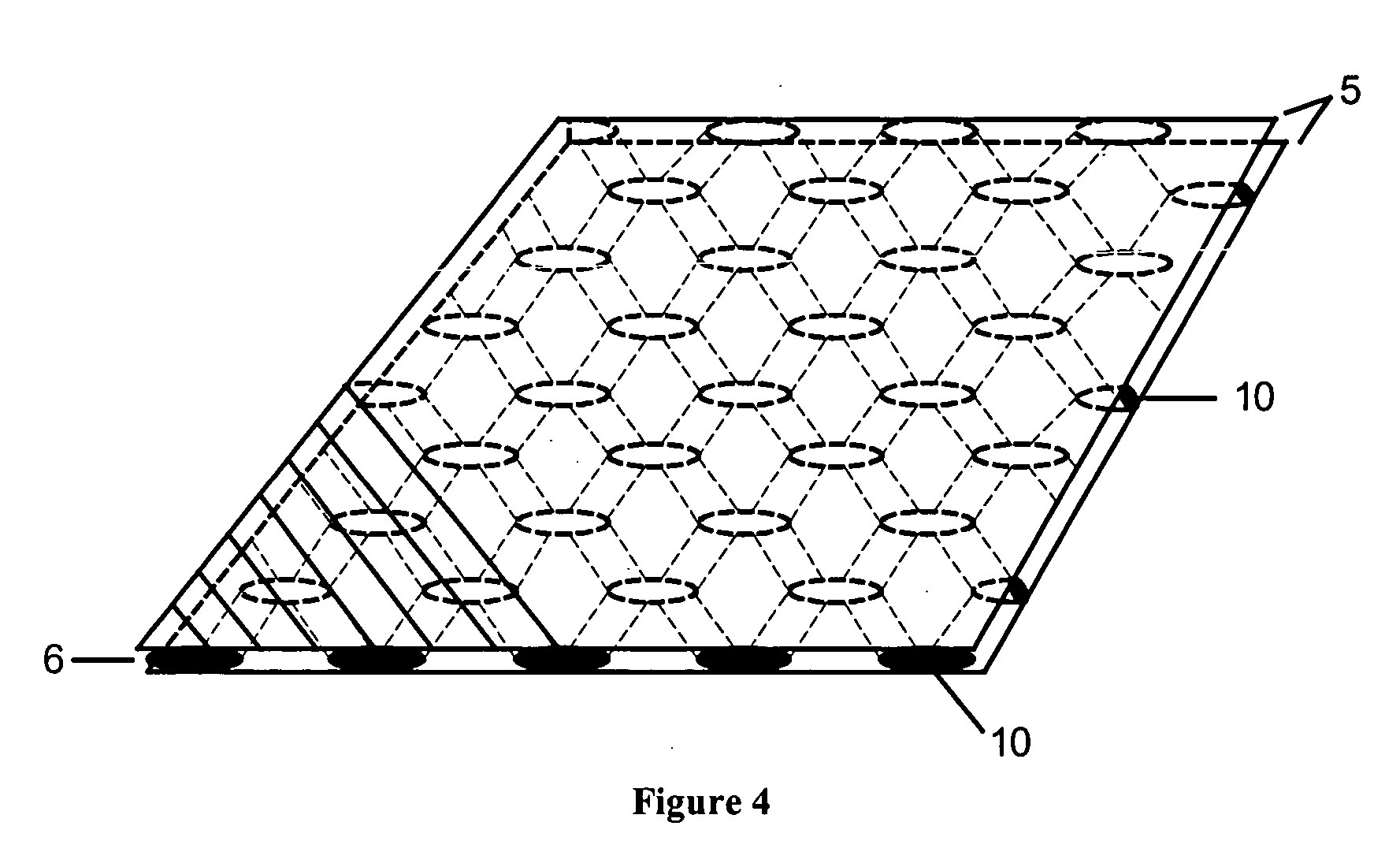

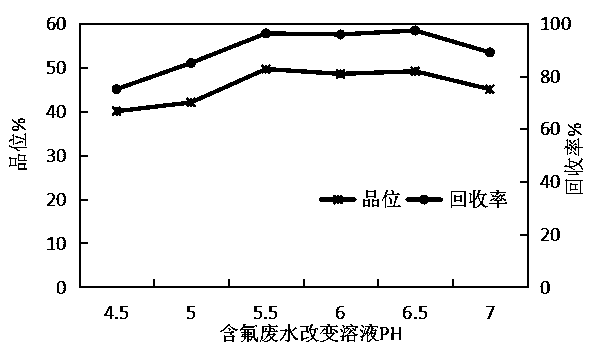

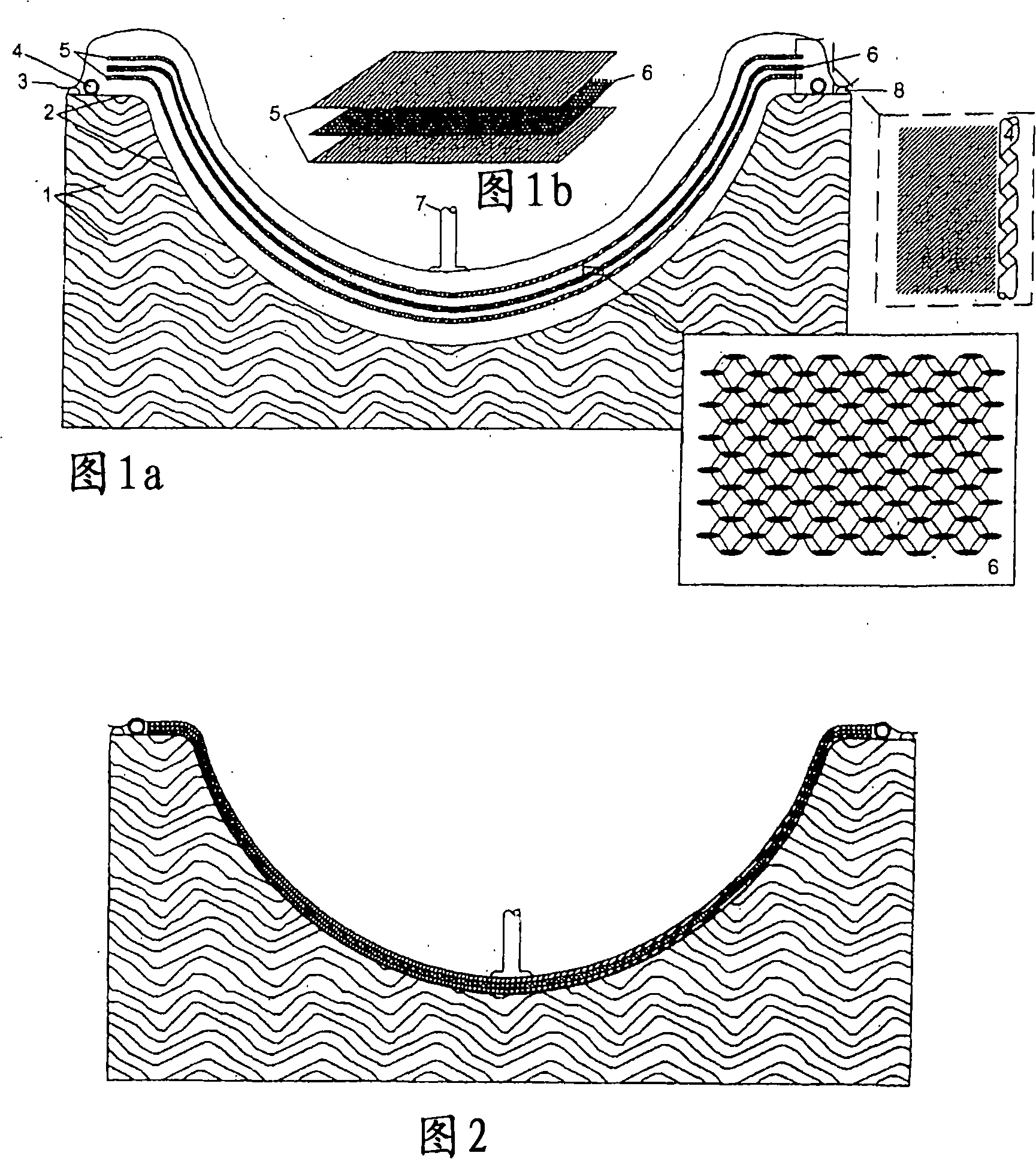

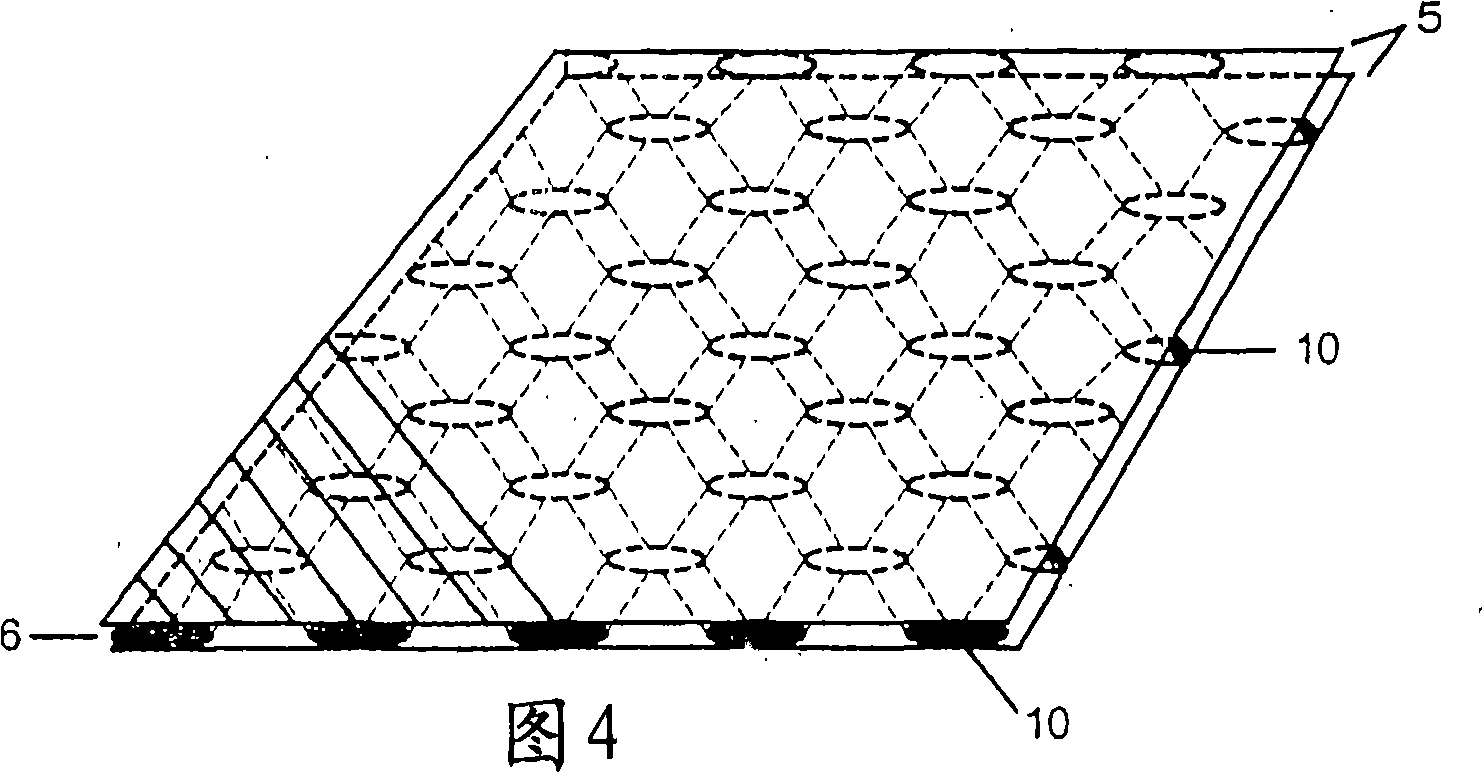

Open-work knitted textile resin infusion medium and reinforcing composite lamina

InactiveUS20060035546A1Increase distribution rateImprove uniformityOrnamental textile articlesLayered productsEngineeringTextile resin

Resin infusion medium and reinforcing composite lamina textile constituted by a warp knit open work structure produced in the form of polygons of which at least some of the edges are defined by knops such as to give prominence to the design to provide for fluidic channels, the knops being knitted to be sufficiently non-compressible in order to resist collapse of the fluid channels during compression of the composite preform under vacuum induced process pressure.

Owner:VRAC

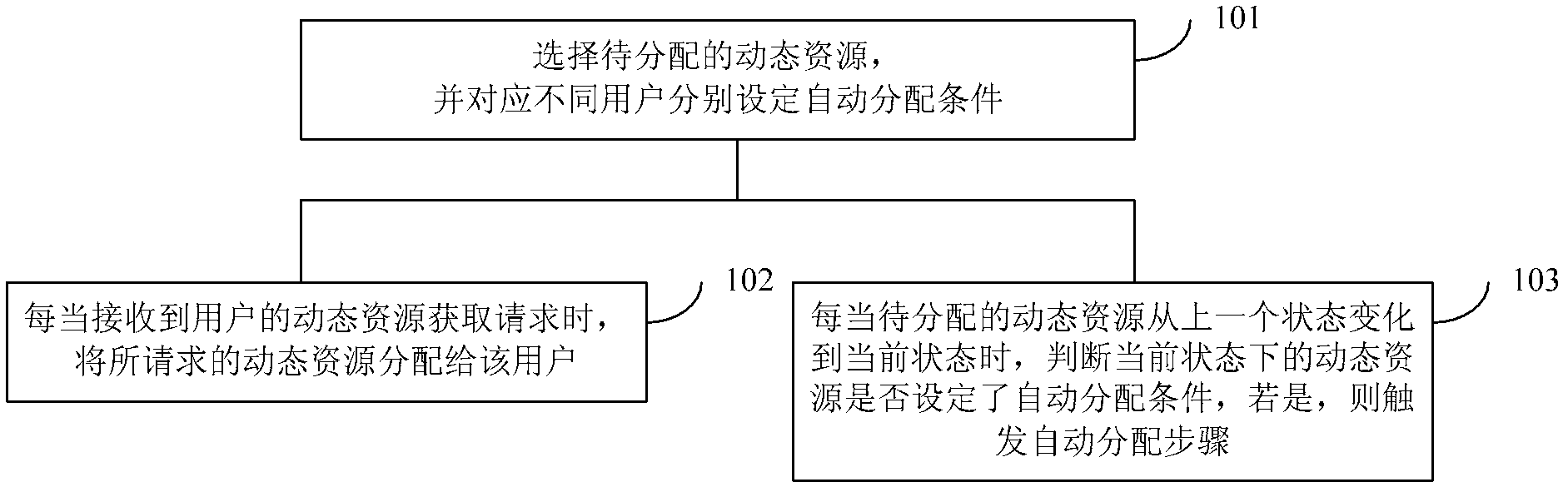

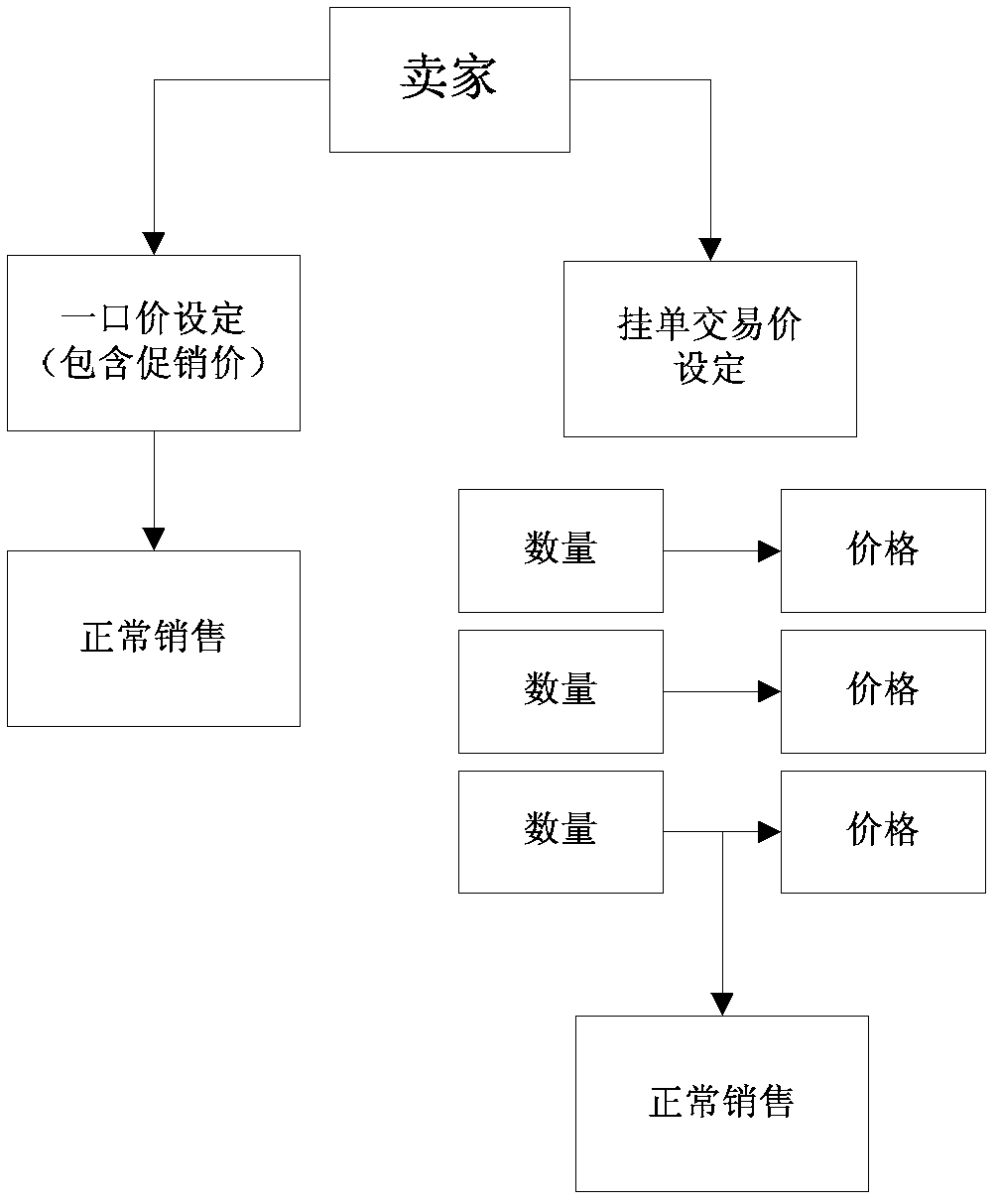

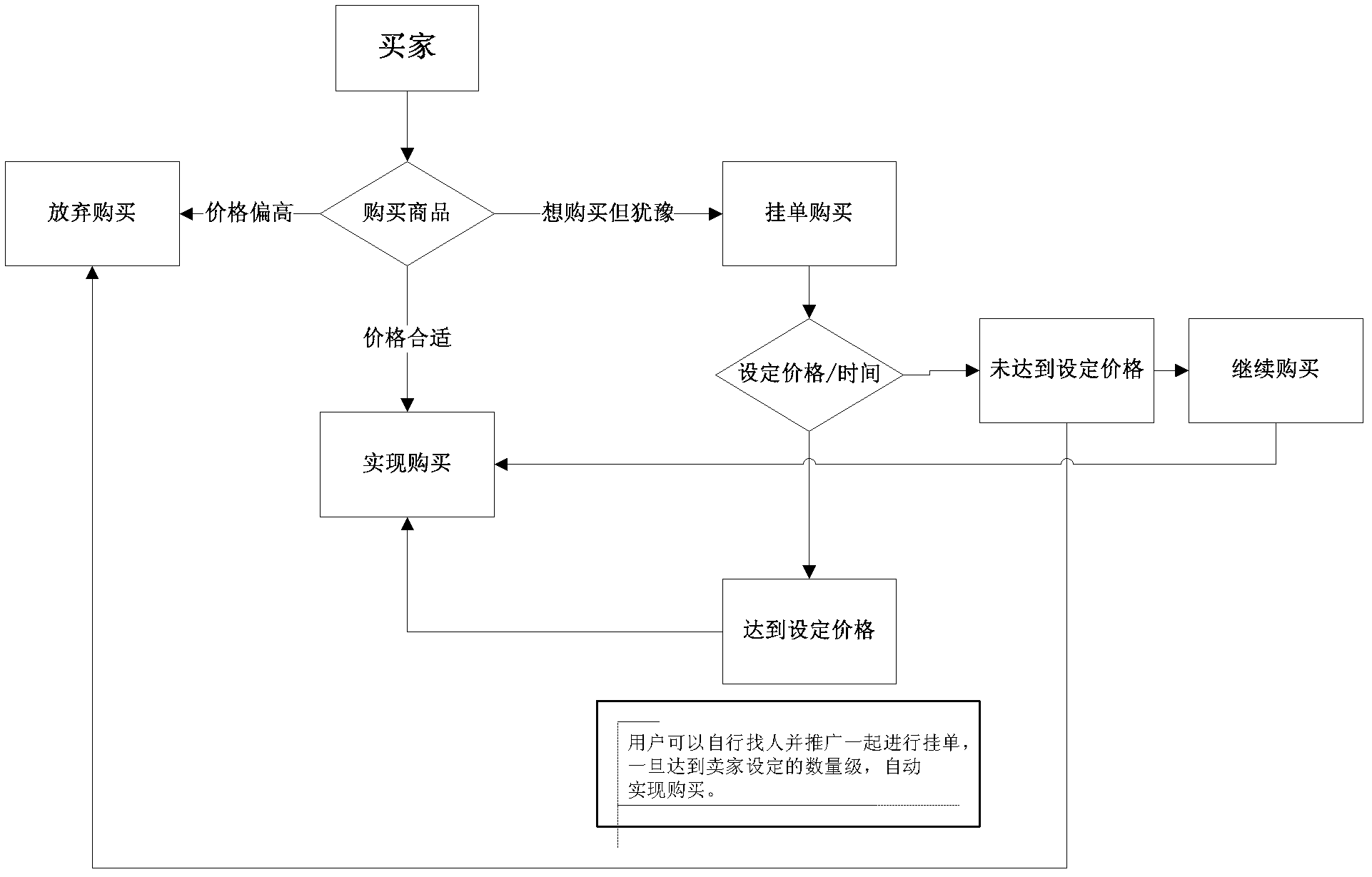

Dynamic resource allocation method and system for online transaction

ActiveCN103077468AAvoid the problem of not being able to assign to the right userIncrease distribution rateSpecial data processing applicationsMarketingDynamic resourceOperating system

The invention provides a dynamic resource allocation method and a dynamic resource allocation system for online transaction, which aim to solve the existing problems of low dynamic resource allocation rate and occupation of storage space. According to the method and the system, automatic allocation conditions can be set for a dynamic resource, and when the dynamic resource is changed from the previous state to the current state, if the dynamic resource in the current state conforms to the automatic allocation conditions of a user, the dynamic resource is automatically allocated to the user who conforms to the allocation conditions. According to the method and the system, the allocation rate of the dynamic resource is increased, thereby increasing the transaction processing efficiency and reducing the occupation of the storage space by the dynamic resource, the access burden of a transaction processing server is effectively relieved, and the occupation of network bandwidth resources is reduced.

Owner:ALIBABA GRP HLDG LTD

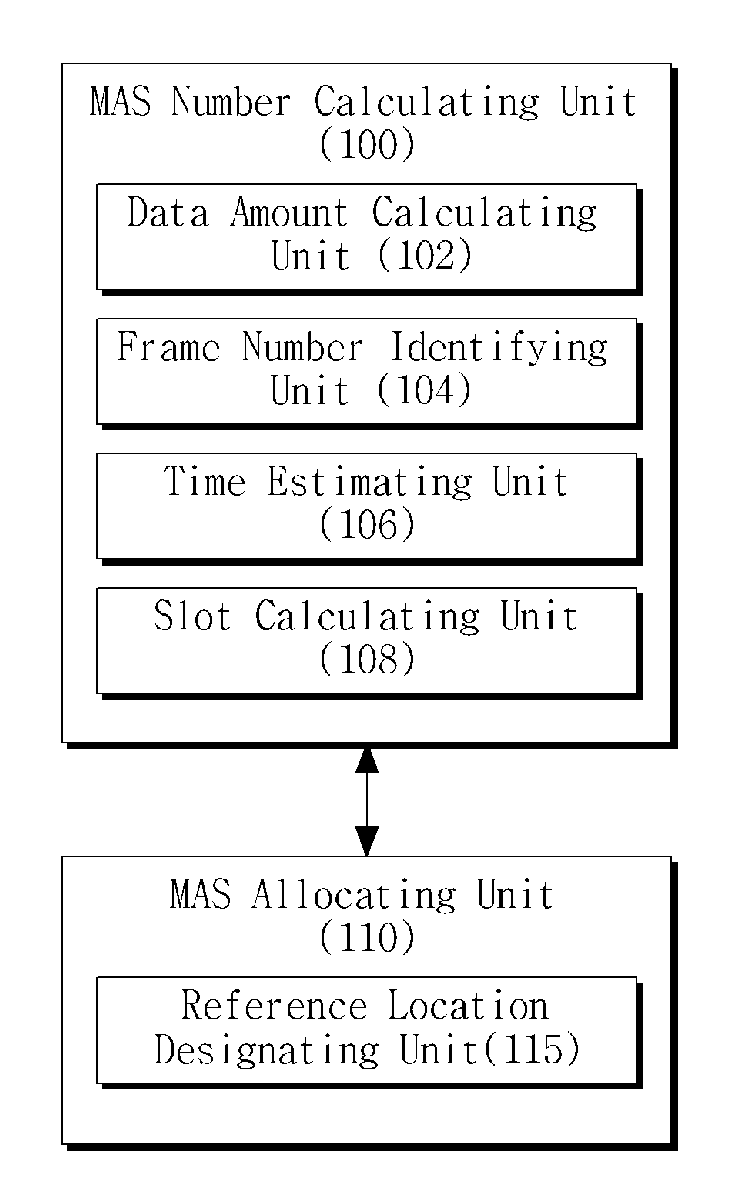

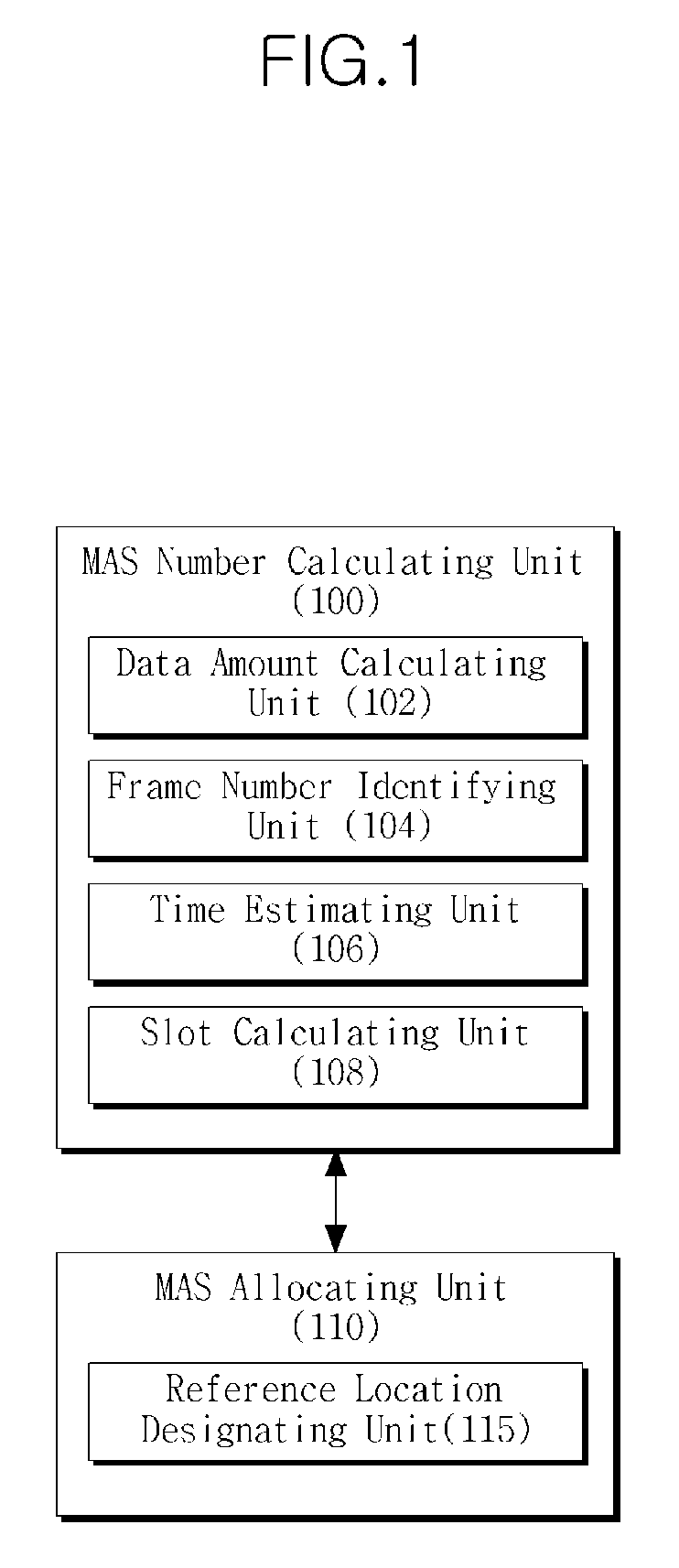

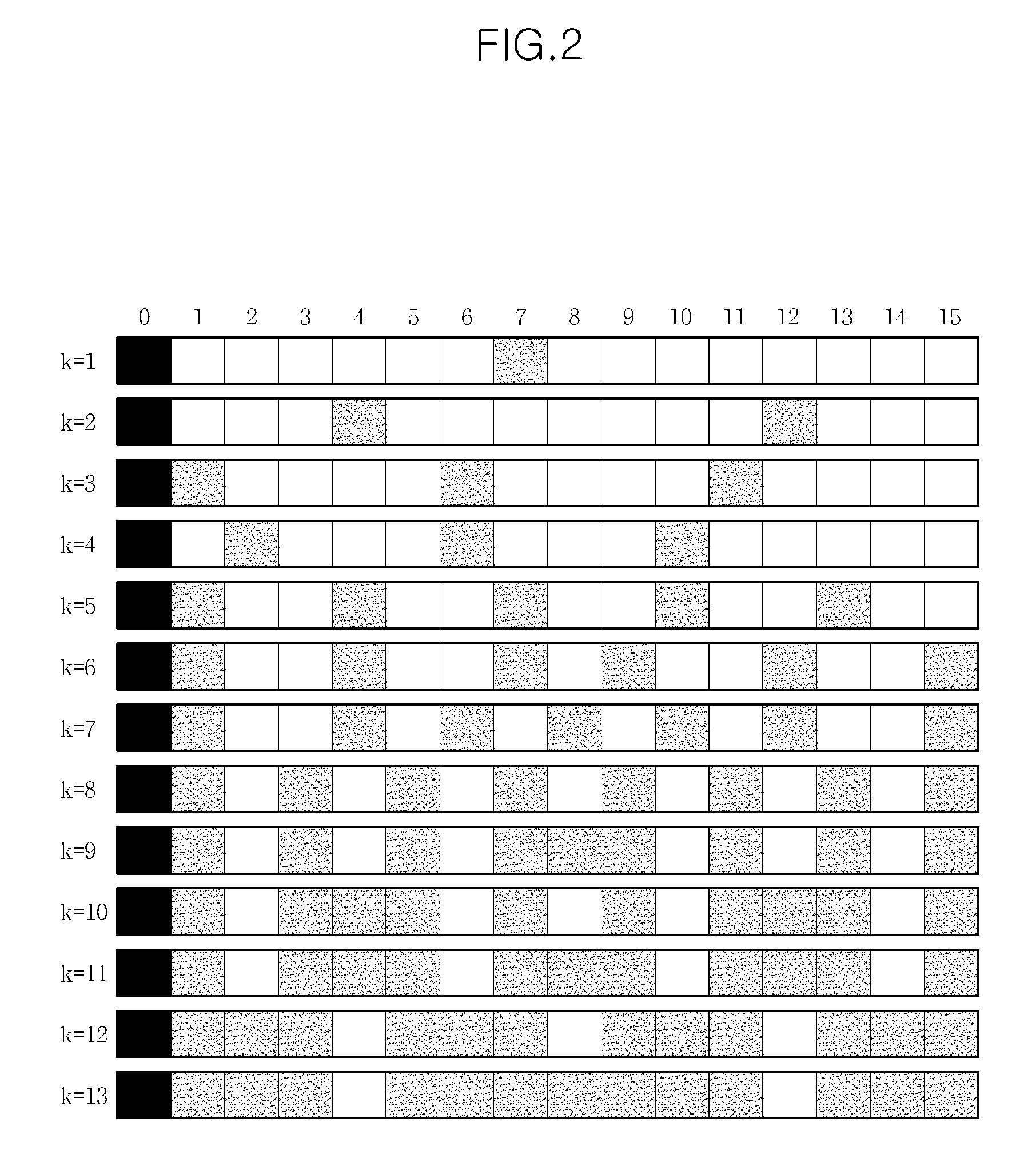

Method and apparatus for allocating wireless resource and wireless network system

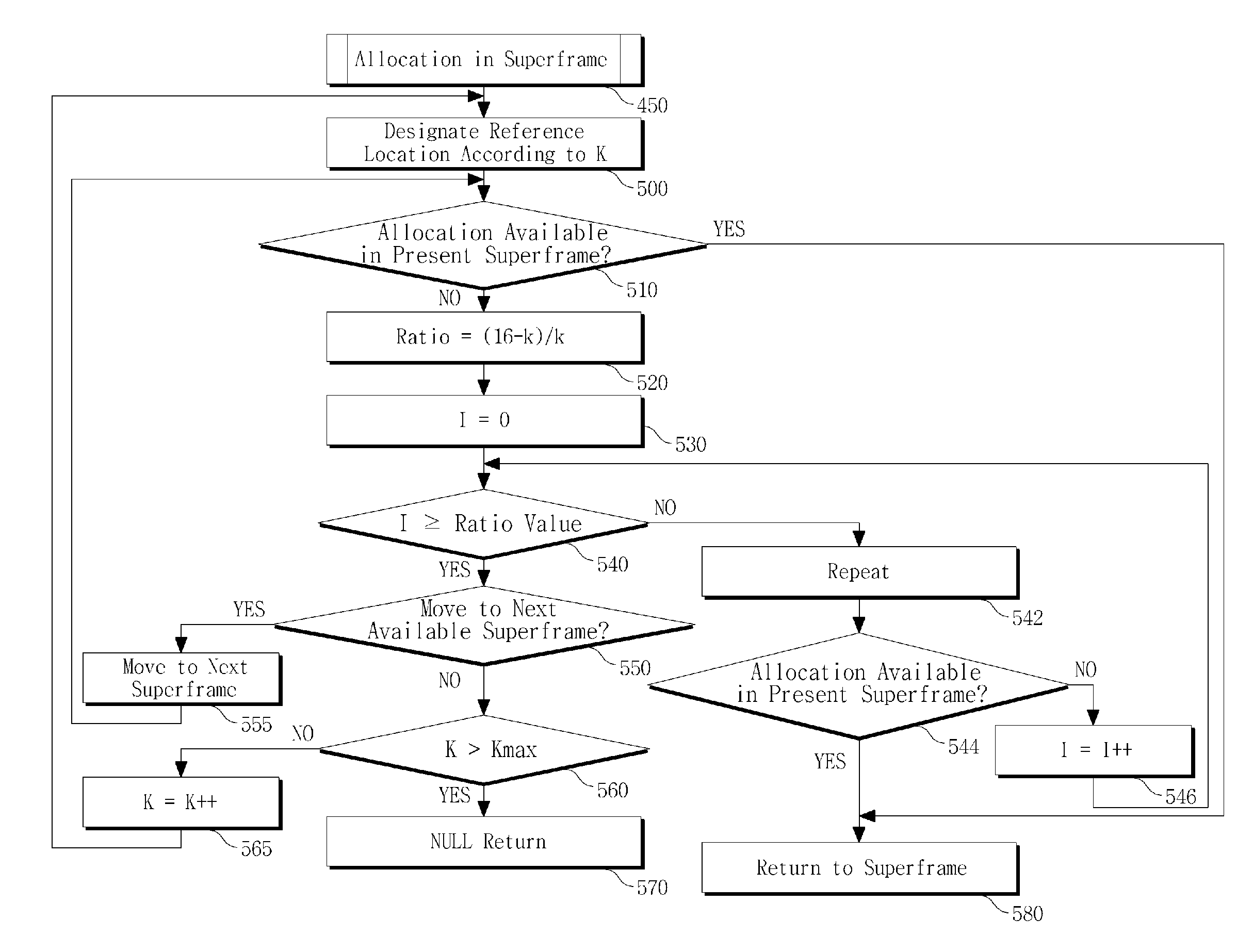

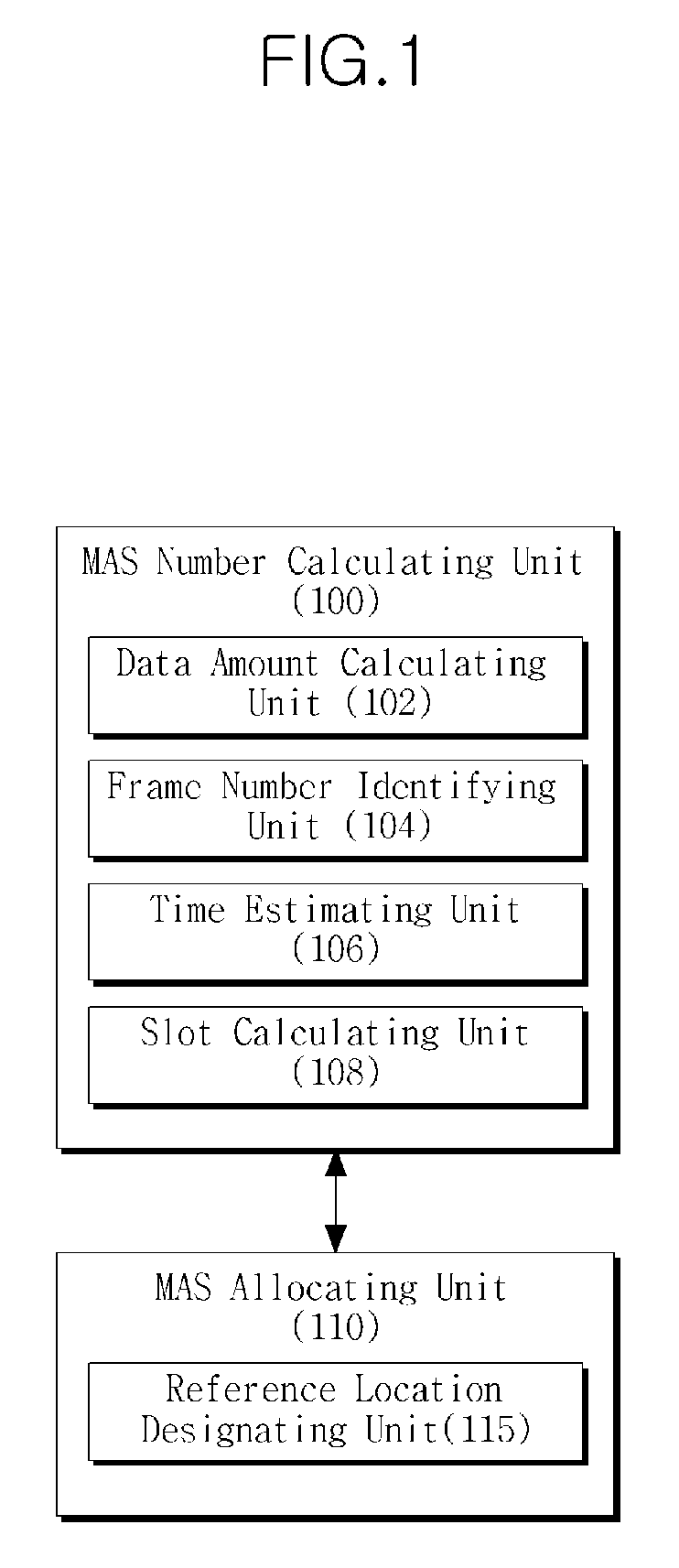

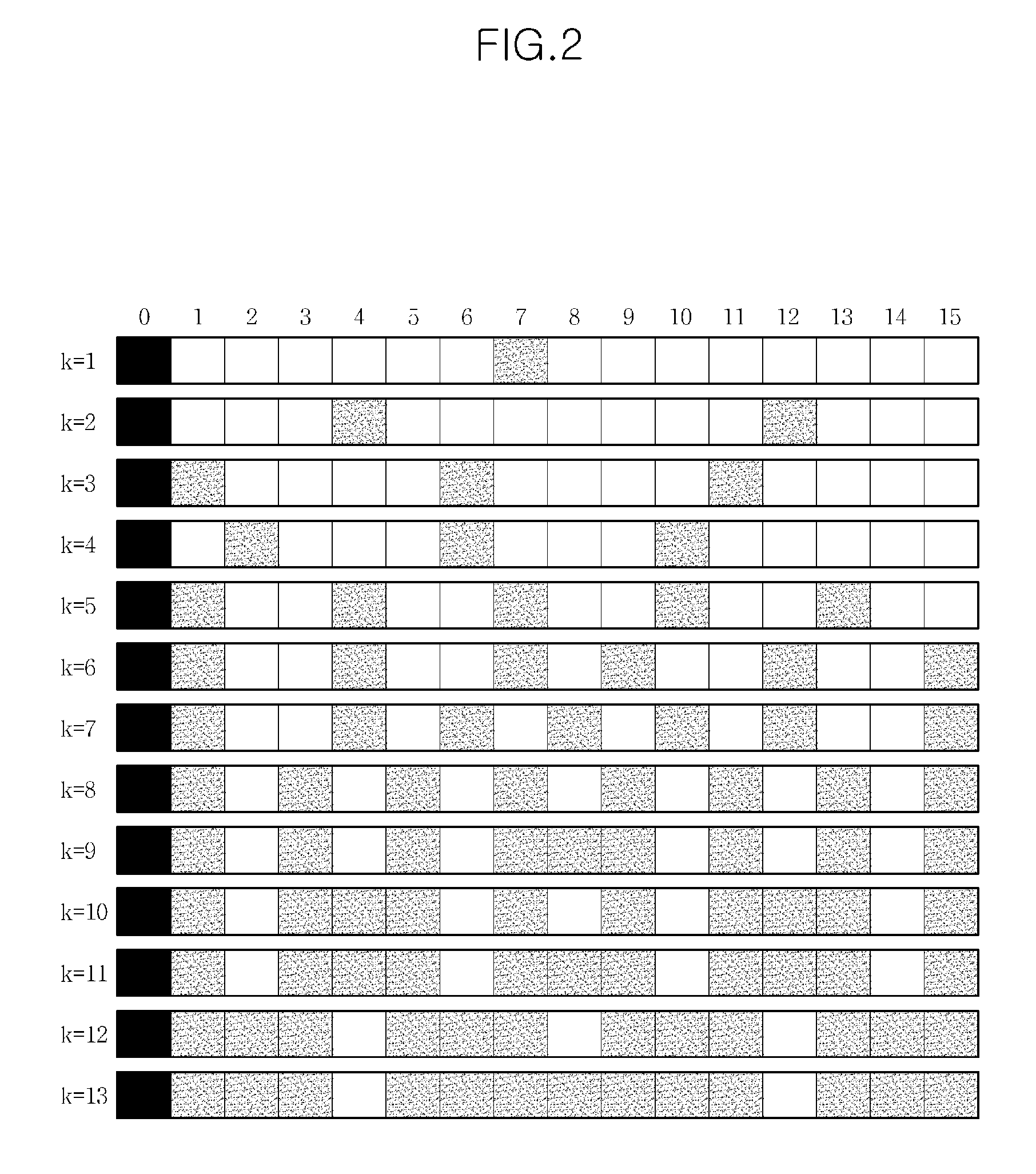

InactiveUS20100098106A1Improve quality of serviceImprove service qualityLoop networksWireless communicationMedia accessMedia access control

A wireless resource allocation apparatus and method which maintain quality of service (QoS) in a wireless communication network are provided. The wireless resource allocation method includes calculating the number of medium access slots (MAS) to be allocated to at least one of a plurality of divided zones of at least one superframe, designating a reference location for MAS allocation to divided zones out of the plurality of divided zones of the superframe based on the calculated number of medium access slots, and allocating the medium access slots to the divided zones based on the designated reference location. Accordingly, more uniform service intervals can be supported, and thus efficient MAS resource allocation can be performed to satisfy media access control (MAC) based QoS requirements.

Owner:ELECTRONICS & TELECOMM RES INST

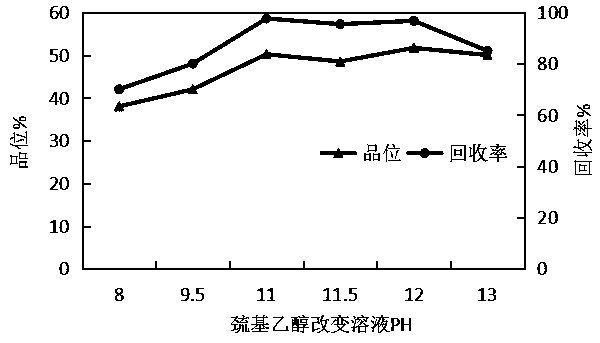

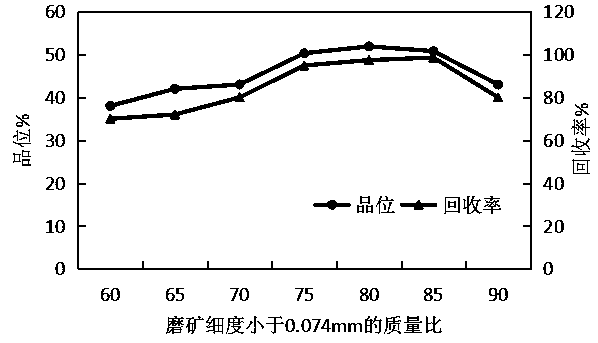

Ore dressing method of pyrite

ActiveCN109985732AReduce dosageHigh recovery rateFlotationGrain treatmentsResource developmentSulfur

The invention belongs to the technical field of metal mineral resources development, in particular to an ore dressing method of pyrite. The method comprises the following steps: taking pyrite, addingdepressant, adjusting PH, grinding; adding water to obtain raw ore slurry; roughing the slurry, adding butyl xanthate and No.2 oil, and performing ultrasonic treatment to obtain roughed sulfur ore andtailings; adding activator into tailings, carrying out secondary roughing, adding butyl xanthate and No.2 oil, and carrying out ultrasonic treatment to obtain roughed sulfur ore and tailings; treating the roughed sulphur ore by ultrasonic wave, and repeatedly cleaning the obtained tailings twice, and scavenging the tailings, adding butyl xanthate and No.2 oil to the tailings for ultrasonic wave treatment, and continuously roughing and scavenging the obtained tailings once. By this method, the production cost can be reduced and the recovery rate can be increased, a good application prospect can be obtained.

Owner:迁安市永德元工贸有限公司

Open-work knitted textile resin infusion medium and reinforcing composite lamina

InactiveCN101495688AImprove dynamic characteristicsImprove physical propertiesOrnamental textile articlesLayered productsEngineeringTextile resin

Resin infusion medium and reinforcing composite lamina textile constituted by a warp knit open work structure (6) produced in the form of polygons (9) of which at least some of the edges (1 1) are defined by knops (10) such as to give prominence to the design to provide for fluidic channels, the knops (10) being knitted to be sufficiently non-compressible in order to resist collapse of the fluid channels during compression of the composite preform (5, 6) under vacuum induced process pressure.

Owner:VRAC

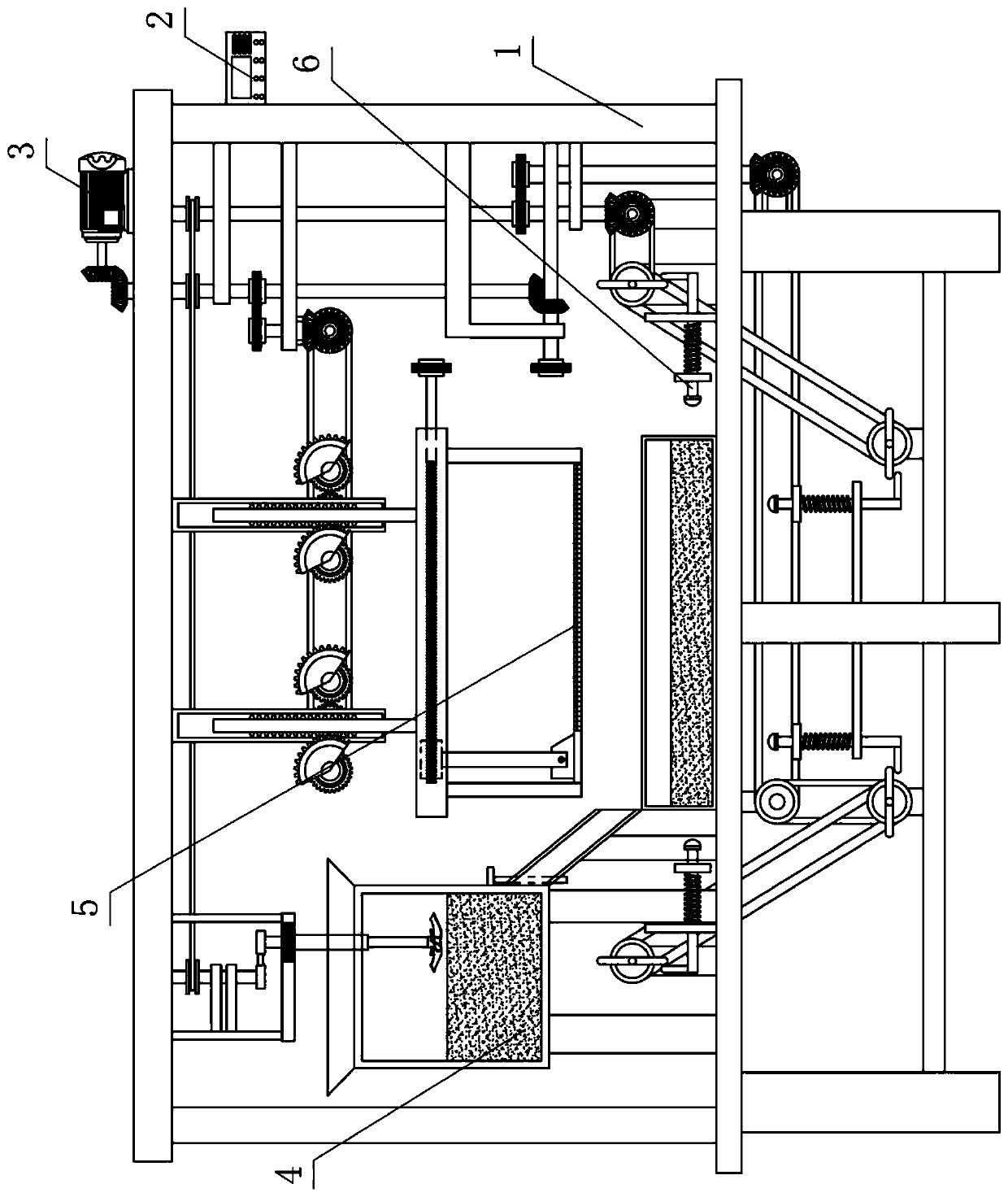

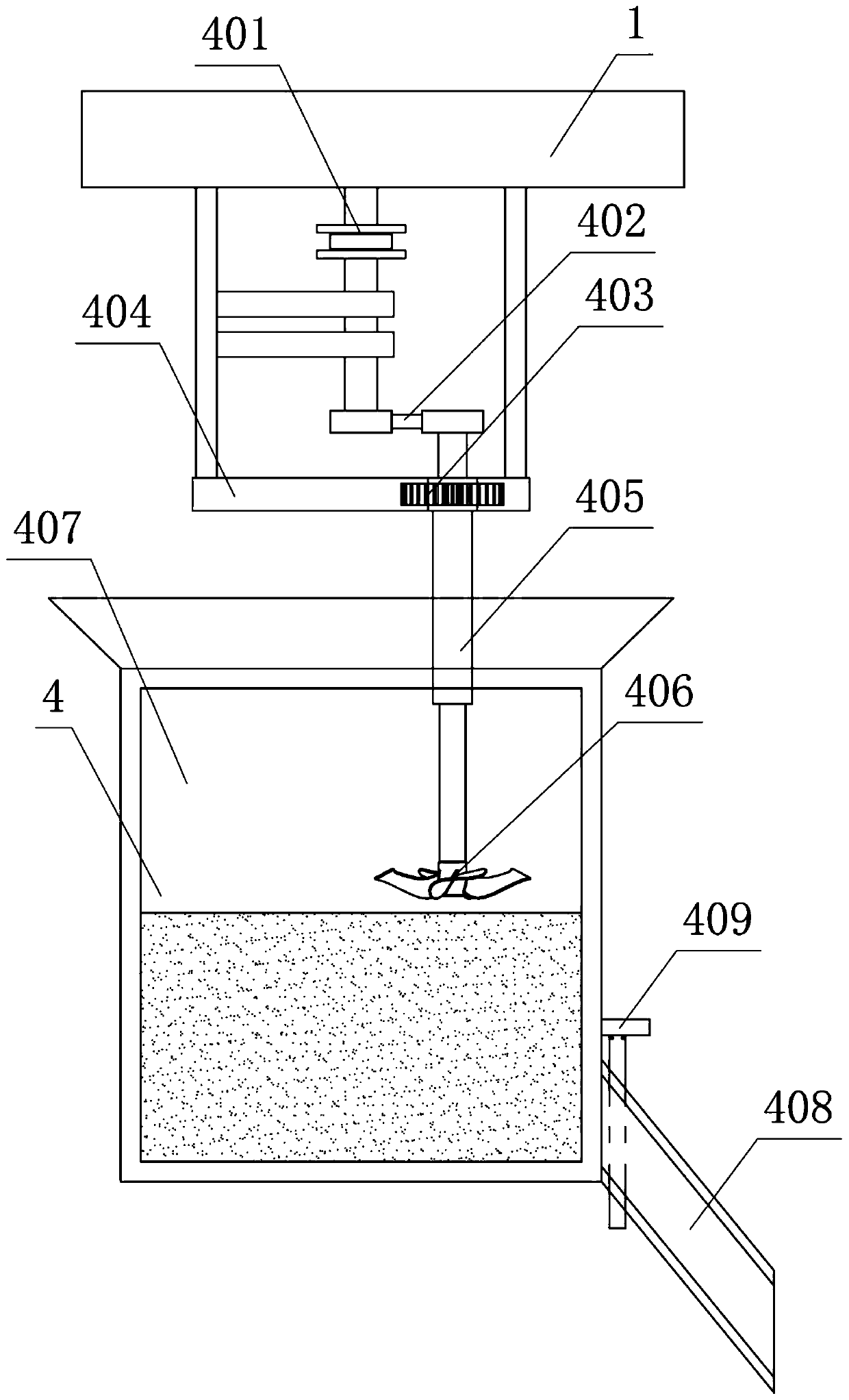

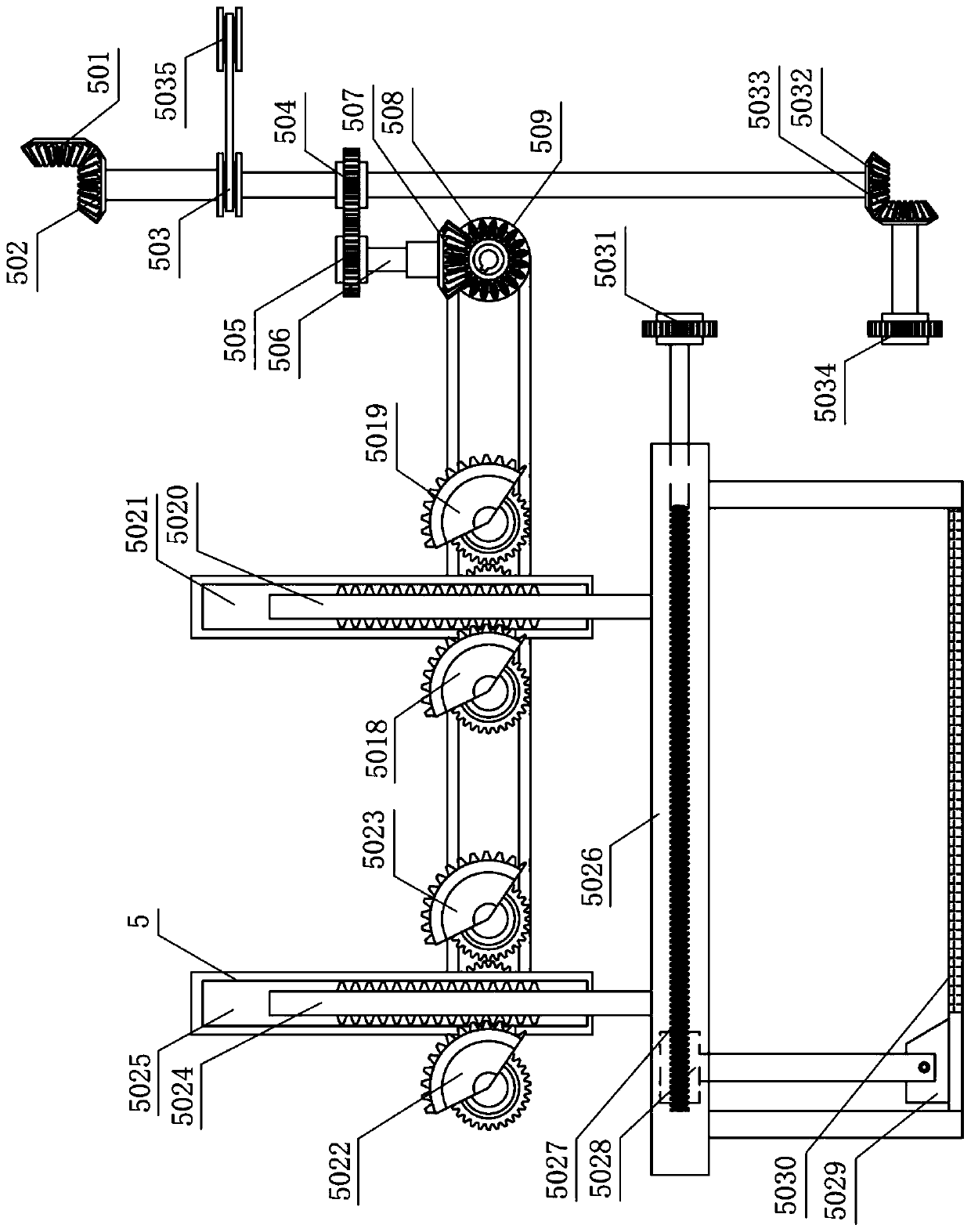

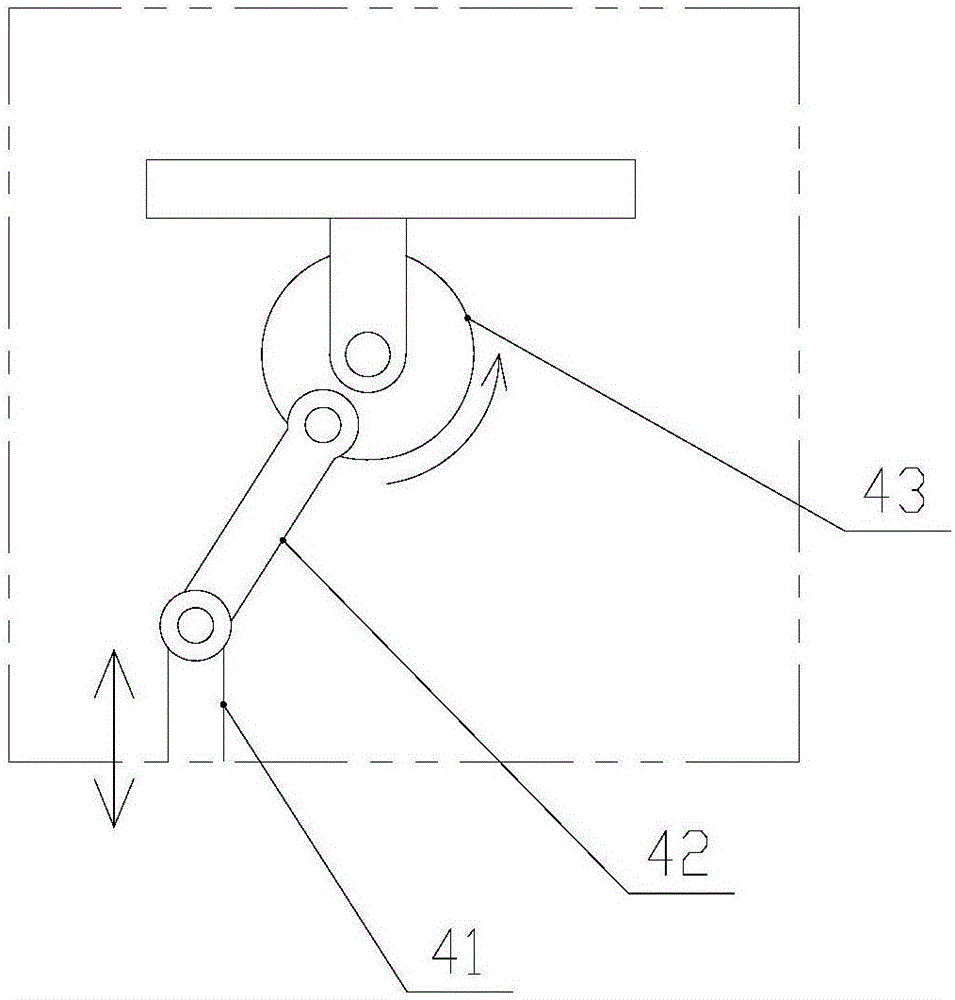

Household particle board processing device

InactiveCN111251405ASmall nail holding powerFit tightlyFlat articlesDomestic articlesAdhesive glueElectric machinery

The invention relates to a household board, in particular to a household particle board processing device. The technical effect to be achieved by the invention is to provide the household particle board processing device. The household particle board processing device comprises a supporting frame, a control screen, a motor, a gluing mechanism, a glue pressing mechanism and a demolding mechanism, the control screen is arranged at the top of the right end of the supporting frame, the motor is arranged on the right portion of the top end of the supporting frame, and the gluing mechanism is arranged at the left top in the supporting frame. The household particle board processing device has the effects that by stirring wood particles and glue, the wood particles and the glue are tightly combined, the situation that relatively large gaps are generated among the particles, so that expansion deformation is caused due to water absorption and damp is avoided, meanwhile, the wood particles in a mold are extruded, then the wood particles are tightly attached, the distribution rate of the wood particle is increased, the situation that the nail holding force of the board is small, then a fixingpiece is prone to looseness, so that a finished product is not firm is prevented, and through vibration demolding after forming, the situation that the board is damaged when the board is taken out dueto adhesion between the board and the mold is prevented.

Owner:上海储络信息科技有限公司

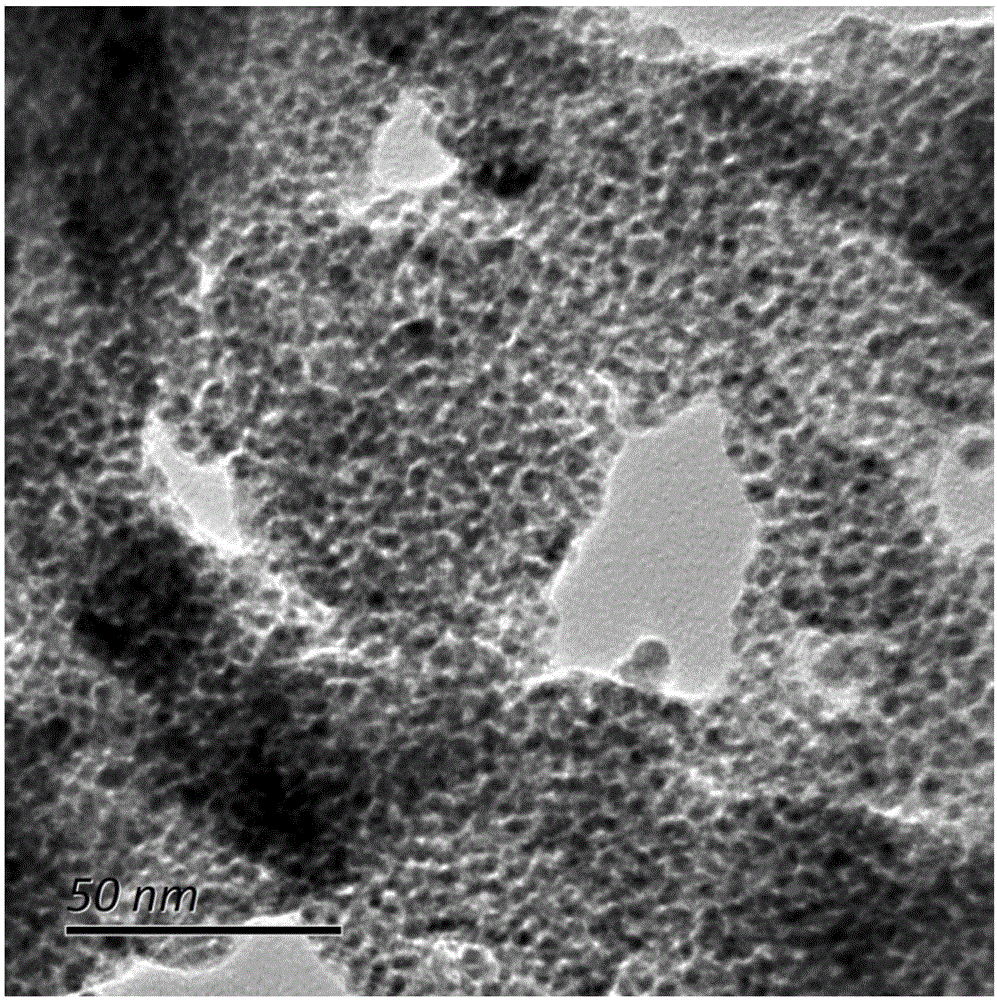

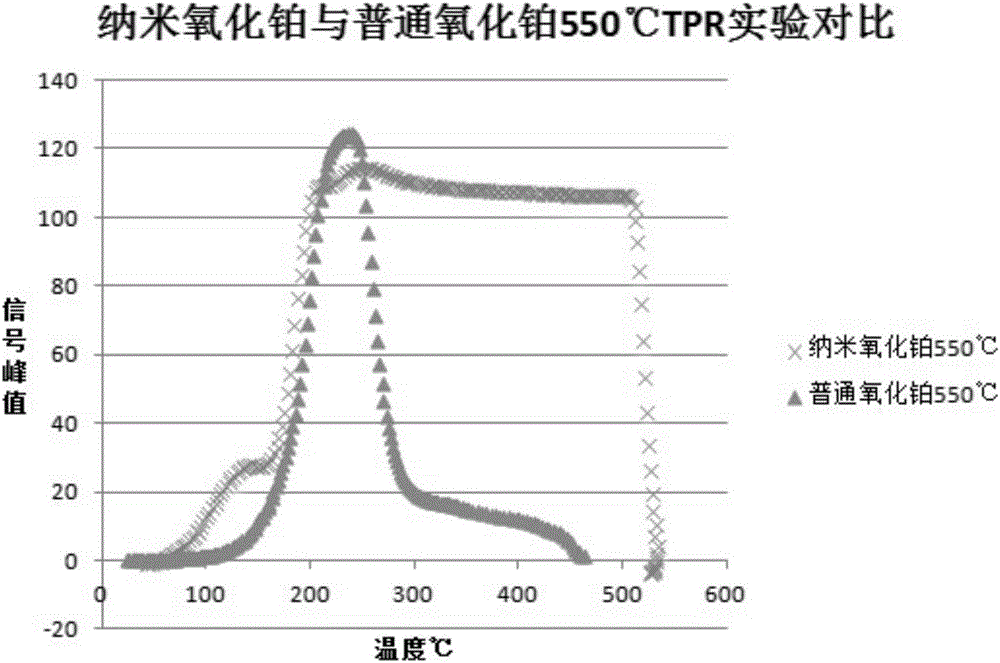

Preparation method and application of nanometer platinum oxide catalyst

ActiveCN105833862ALarge specific surface areaStrong catalytic performanceGas treatmentInternal combustion piston enginesOleic Acid TriglycerideHydrogen peroxide

The invention discloses a preparation method and application of a nanometer platinum oxide catalyst. The preparation method comprises the following concrete steps: heating a platinum salt solution to about 65 DEG C; then rapidly adding an oleate solution (a mixed solution of oleic acid and excess sodium hydroxide) and carrying out rapid stirring for 10 to 15 min so as to obtain a mixed platinic hydroxide solution; adding cetyl trimethyl ammonium bromide and hydrogen peroxide with a concentration of 30% into the solution and stopping a reaction in 30 to 40 min so as to obtain a nanometer platinum oxide colloidal solution, wherein nanometer platinum oxide are uniformly dispersed in the solution due to existence of oleate and cetyl trimethyl ammonium bromide; and adding materials like AC100, RC25 and RC35 into the nanometer platinum oxide colloidal solution, then carrying out mixing and drying; and then carrying out sintering to 550 DEG C so as to prepare nanometer platinum oxide catalyst powder. According to the invention, the specific surface area of platinum oxide in the catalyst material is increased through preparation of nanometer platinum oxide, so the distribution rate and usage efficiency of platinum in the catalyst are improved; and thus, the purposes of thorough utilization and improvement of catalytic activity of platinum oxide are achieved.

Owner:HUNAN JIANTE TECH CO LTD

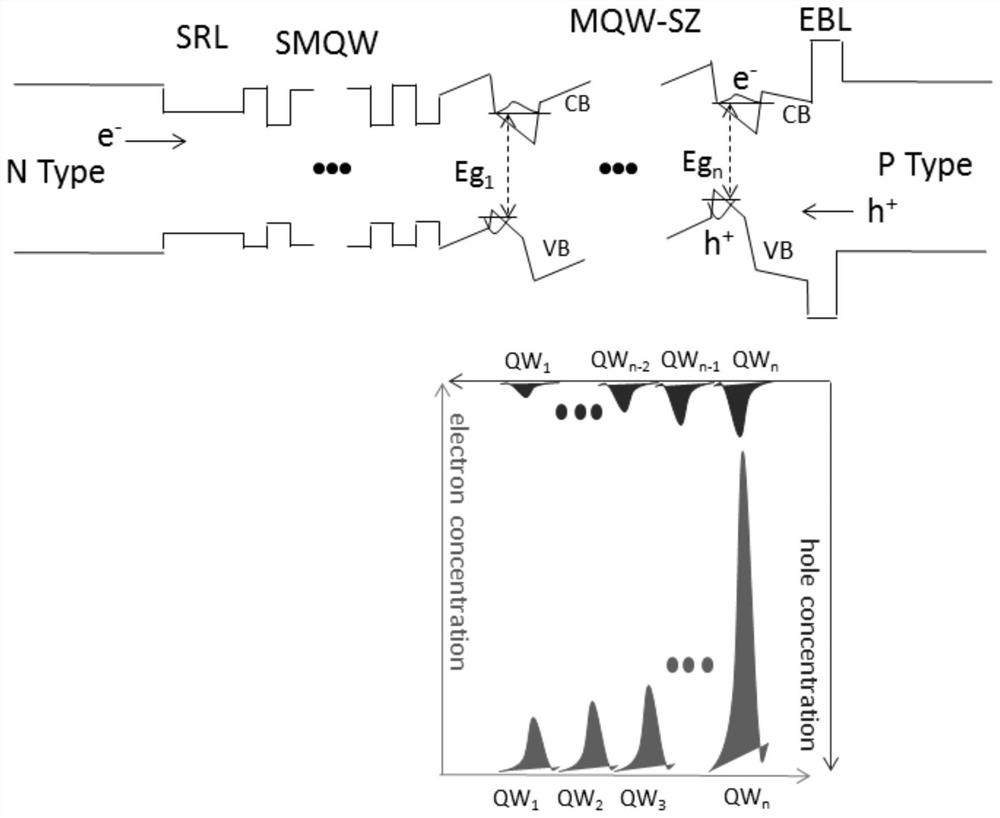

Micro-LED epitaxial structure and manufacturing method thereof

PendingCN111864017ARealize distributionReduce overflowSemiconductor devicesSemiconductorMaterials science

The invention provides a micro-LED epitaxial structure and a manufacturing method thereof, the micro-LED epitaxial structure comprises a substrate and also comprises an n-type semiconductor layer, a light-emitting layer and a p-type semiconductor layer which are arranged on the surface of the substrate, and the light-emitting layer comprises an electron deceleration layer, a superlattice active region and a hole aggregation layer. According to the structure, the epitaxial growth structure can be simplified, the light emitting efficiency of a micro-LED is improved, and the application of the micro-LED in the display field is promoted.

Owner:JIANGSU INST OF ADVANCED SEMICON CO LTD

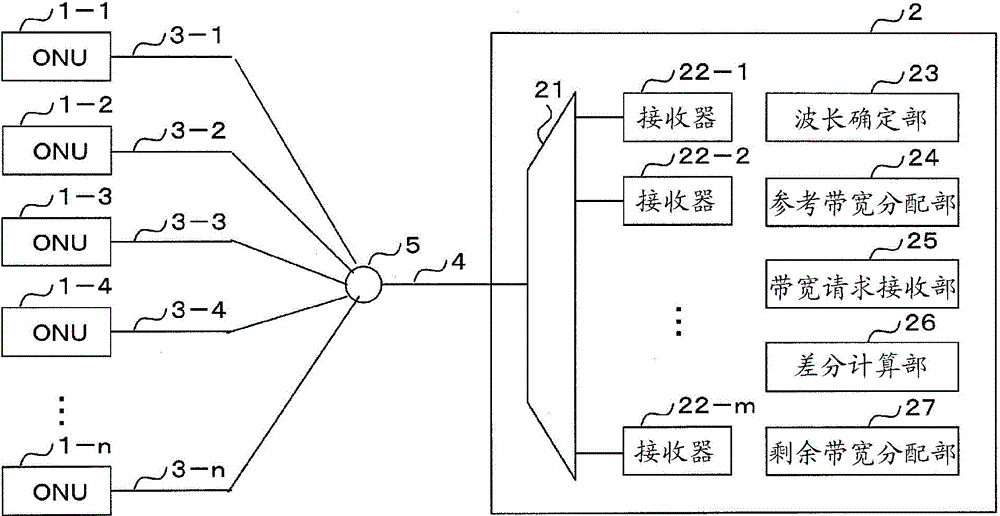

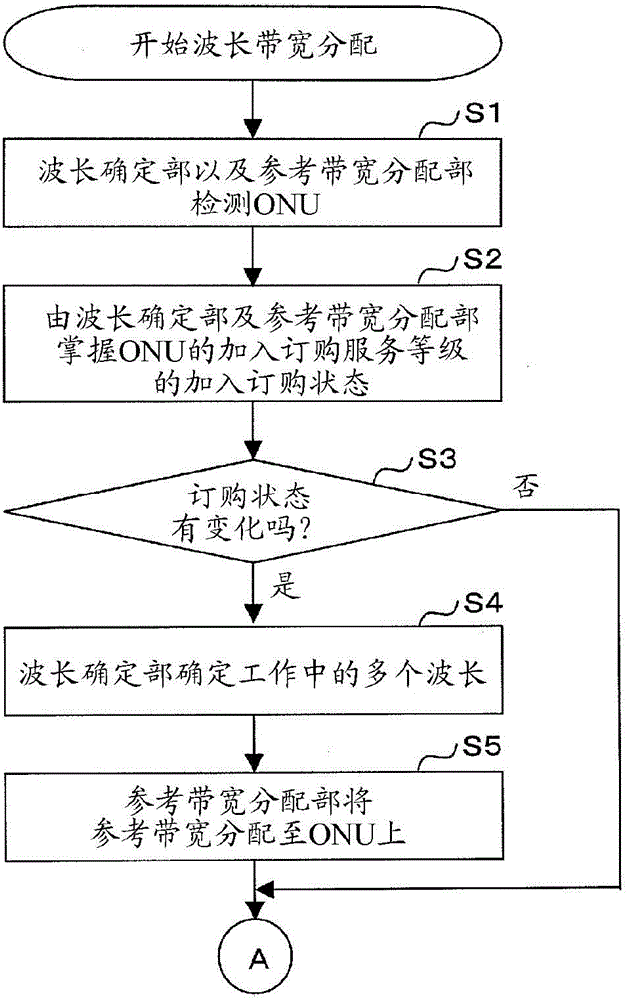

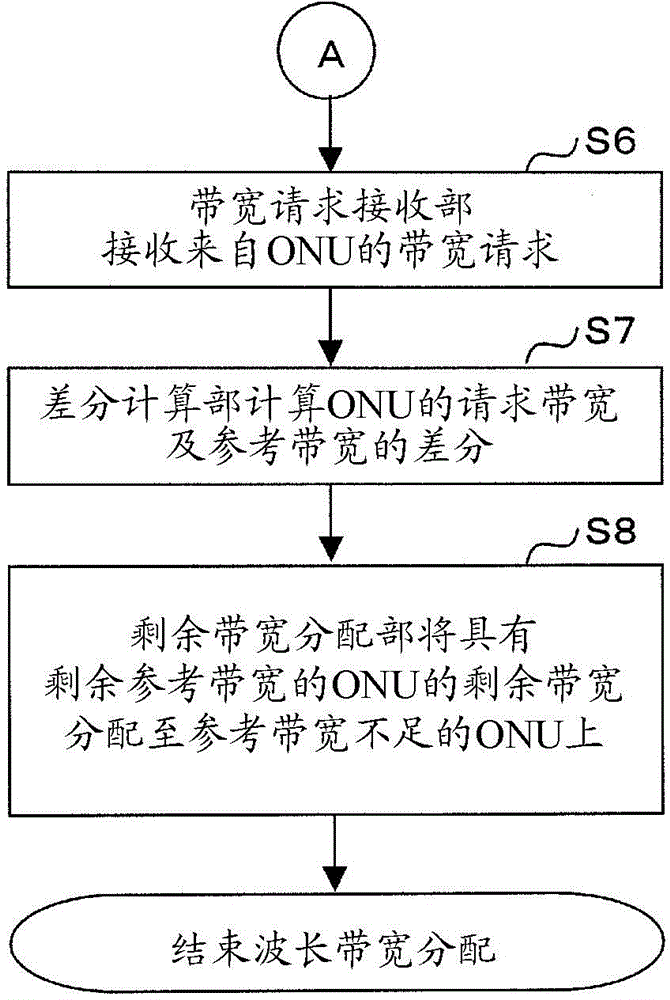

Wavelength bandwidth allocation method

ActiveCN104040961AIncrease distribution rateAppropriate distributionMultiplex system selection arrangementsStar/tree networksGrade of serviceLength wave

The present invention is a wavelength bandwidth allocation method characterized by including in the given order: a wavelength determination step (S4) for determining a plurality of wavelengths for uplink signals from each ONU to an OLT so as to guarantee a guaranteed bandwidth corresponding to the client service class of each ONU; and a reference bandwidth distribution step (S5) in which the entire bandwidth having the plurality of wavelengths determined in the wavelength determination step (S4) is distributed as reference bandwidth to each ONU in accordance with the client service class of each ONU, and the reference bandwidth of each ONU having the same client service class is made to be the same.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

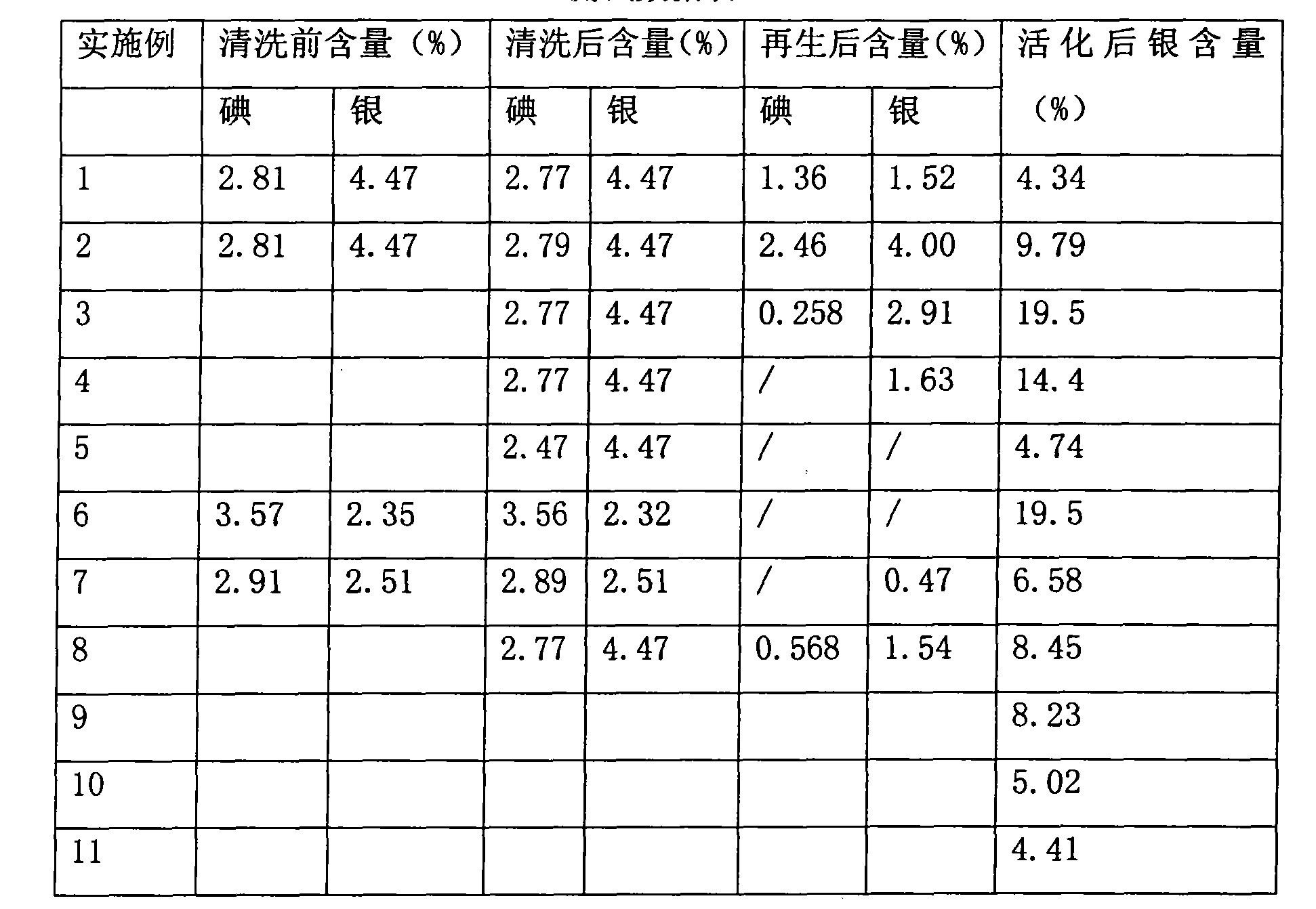

Regeneration and activation technique of iodine pollution solid adsorbent

ActiveCN101380567AEffective desorptionInhibitory activityDispersed particle separationCombustible gas purificationAcetic acidDesorption

The invention relates to a regeneration and activation technique of solid adsorbent polluted by iodine, which comprises the following steps in sequence: the solid adsorbent polluted by iodine is placed in 0.01 to 1 percent of acetic acid for cleaning; (2) the cleaned adsorbent is soaked in sodium thiosulfate solution with the concentration of 0.01 to 2 percent in static state or placed in a column and the sodium thiosulfate solution with the concentration of 0.01 to 2 percent is injected for regeneration so as to lead the pollutants in effective pore channels of the adsorbent polluted by iodine to be precipitated completely; (3) then the obtained adsorbent is placed in the column and ion exchange is carried out by injecting active metal Ag<+> solution till the concentration of the active metal Ag<+> on the solid adsorbent reaches the concentration before the solid adsorbent is polluted. The invention has low energy consumption and convenient operation, in particular to the regenerative technique condition that any heating facility is not used, the concentration of the used regenerative liquid is low and can effectively desorb iodine pollutants; the appearance of the activated adsorbent is same as new carriers, is off white, is characterized by high silver-loaded quantity and high adsorption and effectively prolongs the service life of the adsorbent, thus reducing the cost of iodine desorption.

Owner:SHANGHAI HUAYI ENERGY CHEM

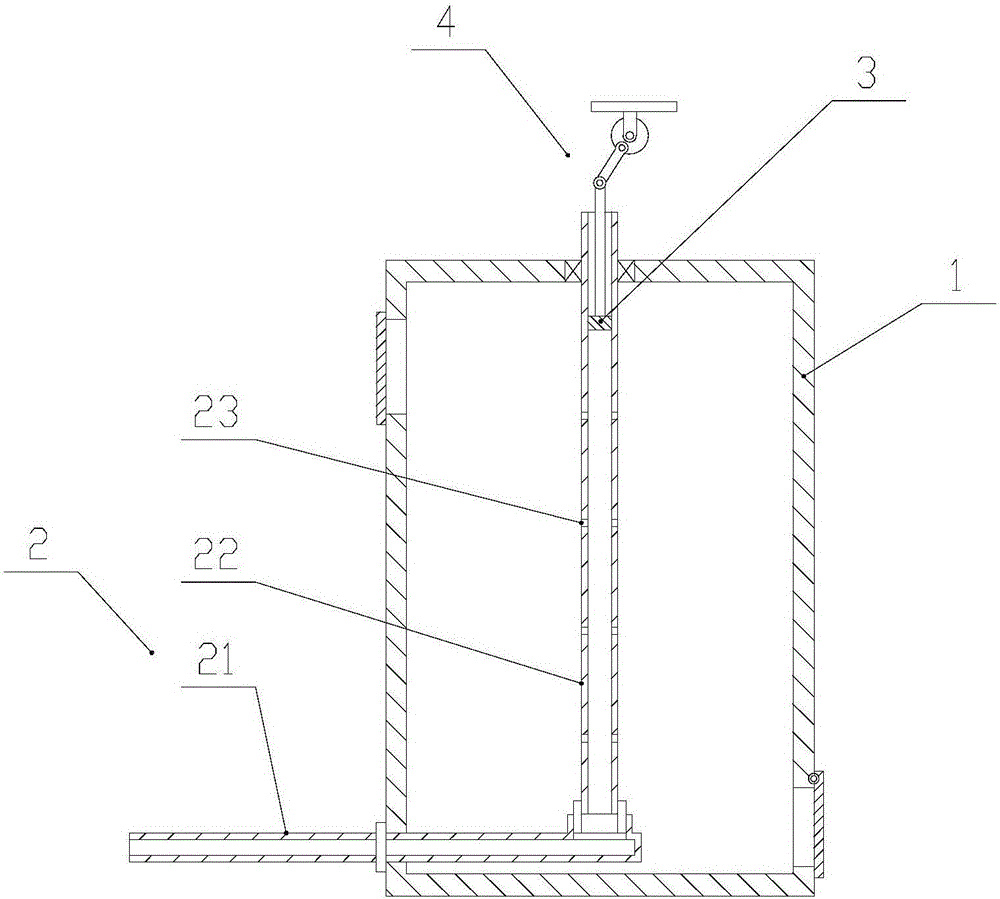

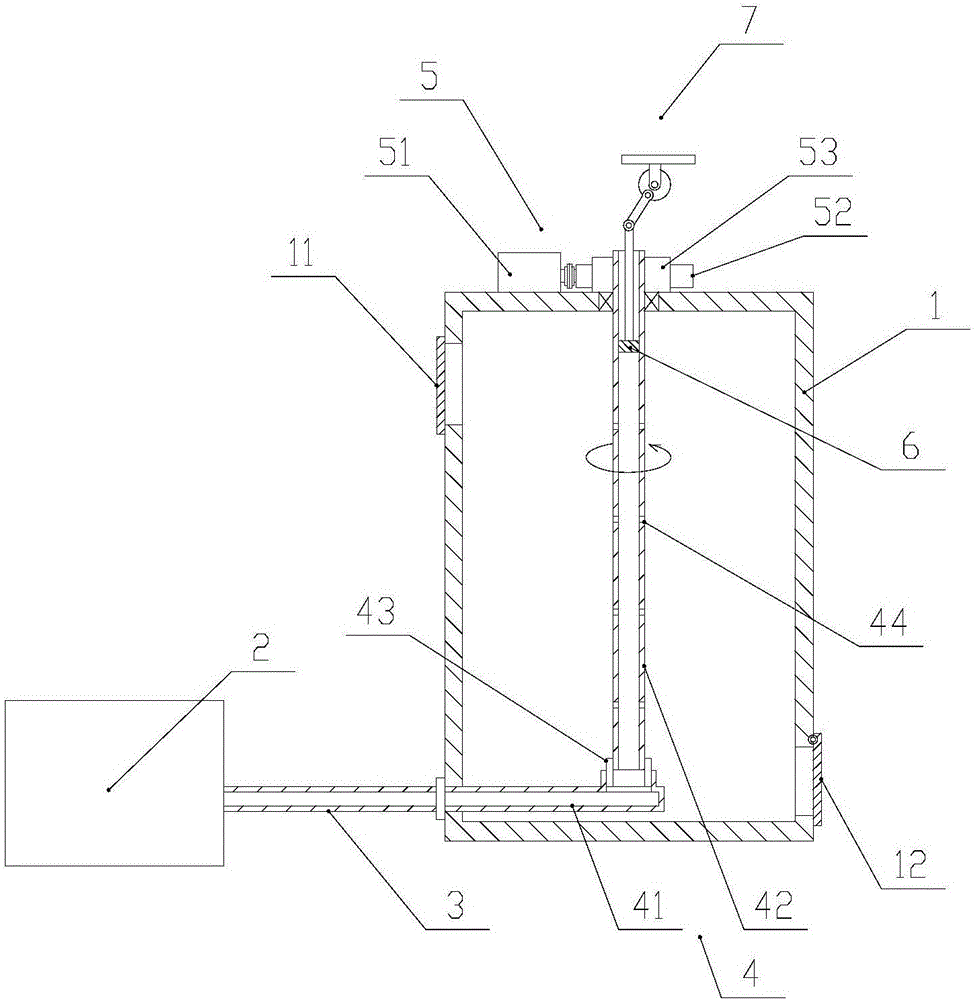

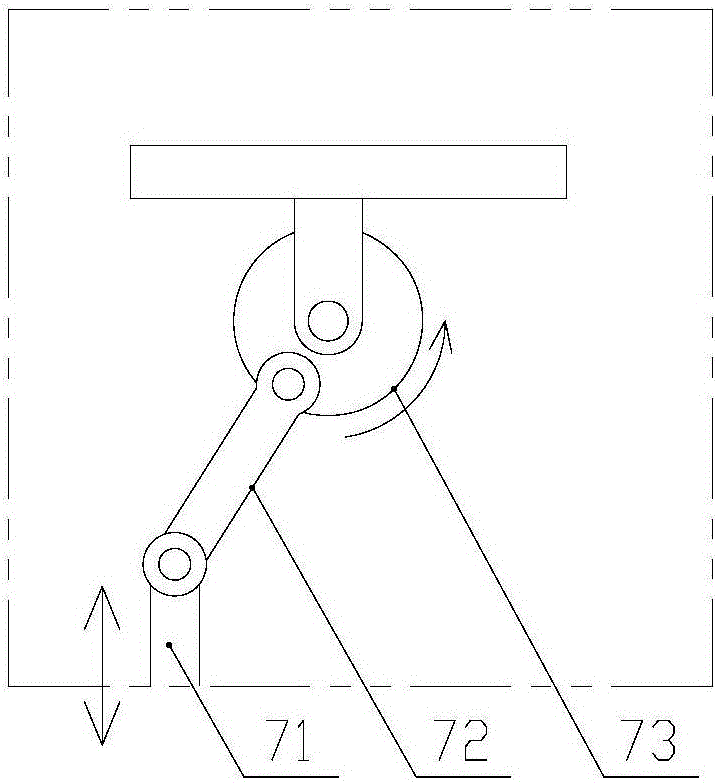

Foaming tank

The invention discloses a foaming tank. The foaming tank comprises a tank body and an air inlet tube, wherein the air inlet tube comprises a transverse tube and a vertical tube, wherein the transverse tube horizontally penetrates into the tank body from the outside of the tank body; the vertical tube vertically penetrates into the tank body from the outside of the tank body and communicates with the transverse tube in the tank body; a piston block capable of sliding vertically is arranged in the vertical tube; space between the piston block and the vertical tube is airtight; the piston block is driven by a screw down mechanism to move vertically; and a plurality of air outlets which correspond to the inside of the tank body are formed in the vertical tube and are positioned below the piston block. The piston block moves downwards in the vertical tube to increase pressure of steam sprayed out from the air outlets, and therefore, the distribution rate of the steam in the foaming tank is increased.

Owner:重庆市盛塑包装制品有限公司

A text feature extraction method based on inter-class discrimination and intra-class high representation

ActiveCN105893388BIncrease distribution rateIncrease information entropyText database queryingText database clustering/classificationFeature extractionAlgorithm

The invention discloses a text feature extracting method based on inter-class distinctness and intra-class high representation degree. The method comprises the following steps: preprocessing a training set text; calculating the class distinctness of each feature word through an improved feature selecting method so as to select feature words with more class representation, wherein the selected feature words are of high distinctness among different classes; and further screening the selected feature words which are of high class distinctness based on the intra-class distribution rate and information gain (IG) of the feature words. With the adoption of the method, the feature selection is carried out twice to select the feature words which are of high intra-class information entropy and high intra-class distribution rate, and thus the classifying efficiency and accuracy can be improved; in addition, the calculation is simple, so that the text classifying speed and accuracy can be improved.

Owner:CHENGDU WANGAN TECH DEV CO LTD

Mulching film master batch based on silver anti-aging performance and preparation method thereof

InactiveCN105440419AIncrease distribution rateImprove bindingPlant protective coveringsSilver pastePowder talcum

The invention discloses a mulching film master batch based on silver anti-aging performance and a preparation method thereof. The mulching film master batch, 100% in total, is prepared from, by weight, 25-35% of silver paste, 10-20% of talcum powder, 8-10% of dispersing agent, 1-2% of coupling agent, 30-40% of carrier resin and 3-5% of anti-aging agent. By designing silver paste, talcum powder, dispersing agent, coupling agent, carrier resin and anti-aging agent, a mulching film is silver due to the distribution of silver paste, the distribution rate of silver paste is increased due to talcum powder and dispersing agent, the binding force of silver paste is improved due to coupling agent, carrier resin and anti-aging agent, and therefore the silver mulching film is formed, and performance of the mulching film is expanded.

Owner:SHANDONG WAVE SHAIMULIAO GRP

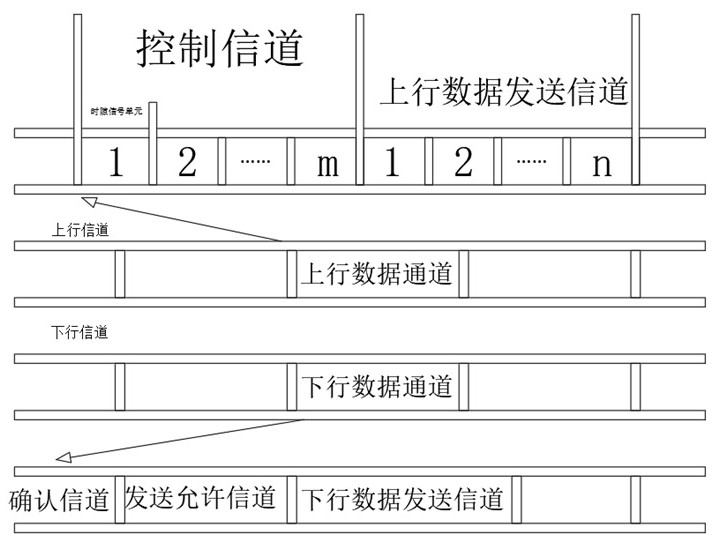

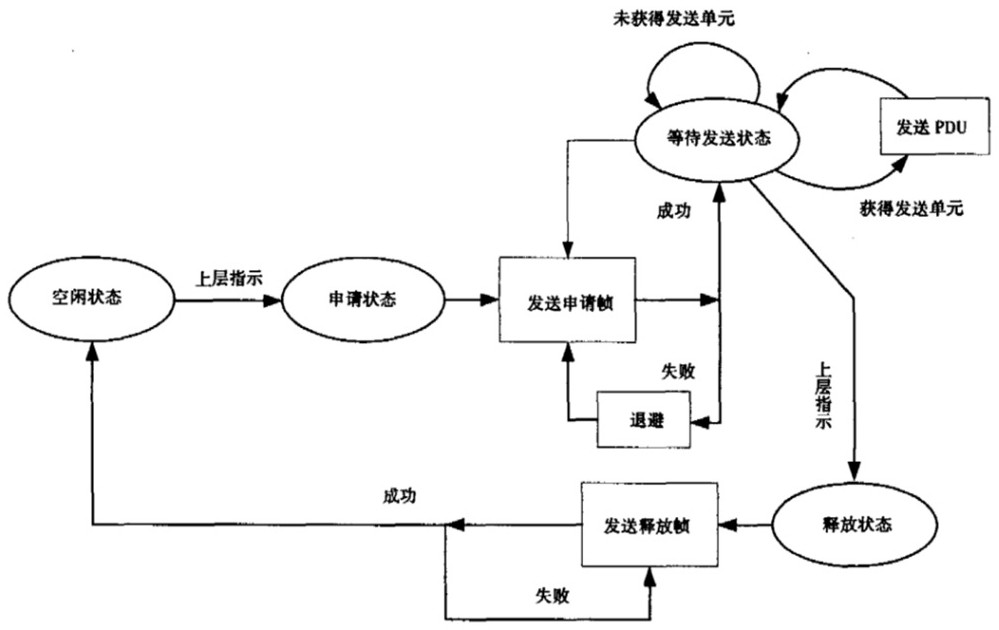

Resource allocation method of broadband uplink

ActiveCN111615152AIncrease distribution rateIncrease the operation planNetwork traffic/resource managementHigh level techniquesResource assignmentMobile end

The invention belongs to the technical field of network communication. Specifically disclosed is a resource allocation method for a broadband uplink. The method comprises a broadband uplink resource allocation system. The broadband uplink resource allocation system comprises a base station end and a mobile end. The mobile terminal sends a broadband request signal through the uplink control unit. The base station terminal performs uplink broadband resource allocation according to a predetermined broadband uplink resource allocation system, and when each mobile terminal transmits a request signal for one time, the base station terminal allocates a resource proportion result by sending an allowing signal, and the mobile terminal sends data after acquiring allocated broadband resources. According to the broadband uplink resource allocation system provided by the invention, mobile terminal services are allocated into the constant rate unit, the real-time speed change unit and the non-real-time speed change unit, and the three service management ports operate correspondingly, so that the allocation rate of system resources is greatly increased.

Owner:中国人民解放军军事科学院军事科学信息研究中心

EPP pre-foaming machine

The invention belongs to the field of plastic machining, and provides an EPP pre-foaming machine. The EPP pre-foaming machine of the present invention comprises a foaming tank, a steam generator and a gas inlet pipe; the steam generator and the foaming tank are connected by the gas inlet pipe; the pre-foaming machine also comprises a gas guide pipe and a rotary mechanism; the gas guide pipe comprises a horizontal pipe and a vertical pipe; the horizontal pipe is located in the foaming tank; one end of the horizontal pipe is communicated with the gas inlet pipe while the other end is closed; one end of the vertical pipe is communicated with the horizontal pipe while the other end upwards extends out of the foaming tank; the vertical pipe and the horizontal pipe are in rotary match; the upper part of the vertical pipe is provided with a closing plug for preventing steam from leaking outside; the vertical pipe is provided with a plurality of gas outlets corresponding to the interior of the foaming tank; and the rotary mechanism is located above the foaming tank and drives the vertical pipe to rotate. According to the EPP pre-foaming machine, the steam can be quickly and uniformly distributed in the foaming tank by the rotation of the vertical pipe, thereby improving the foaming efficiency of beads.

Owner:重庆市盛塑包装制品有限公司

Method and apparatus for allocating wireless resource and wireless network system

InactiveUS8045577B2Improve service qualityIncrease distribution rateError preventionFrequency-division multiplex detailsQuality of serviceWireless mesh network

A wireless resource allocation apparatus and method which maintain quality of service (QoS) in a wireless communication network are provided. The wireless resource allocation method includes calculating the number of medium access slots (MAS) to be allocated to at least one of a plurality of divided zones of at least one superframe, designating a reference location for MAS allocation to divided zones out of the plurality of divided zones of the superframe based on the calculated number of medium access slots, and allocating the medium access slots to the divided zones based on the designated reference location. Accordingly, more uniform service intervals can be supported, and thus efficient MAS resource allocation can be performed to satisfy media access control (MAC) based QoS requirements.

Owner:ELECTRONICS & TELECOMM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com