Open-work knitted textile resin infusion medium and reinforcing composite lamina

A resin-impregnated, braided fabric technology for fabrics, warp knits, leno fabrics, etc. that addresses issues of increased complexity, high waste, and non-profit flow costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

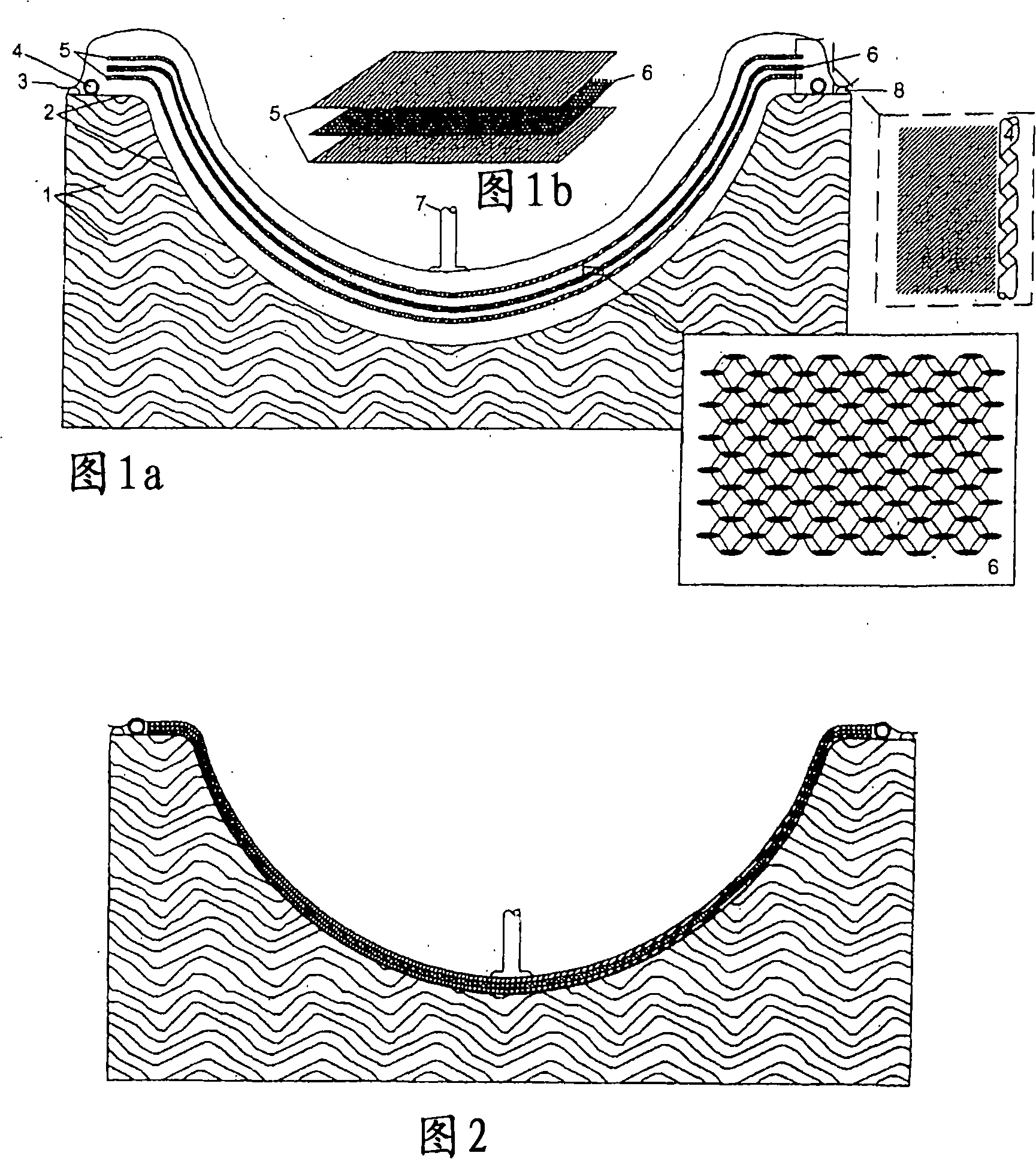

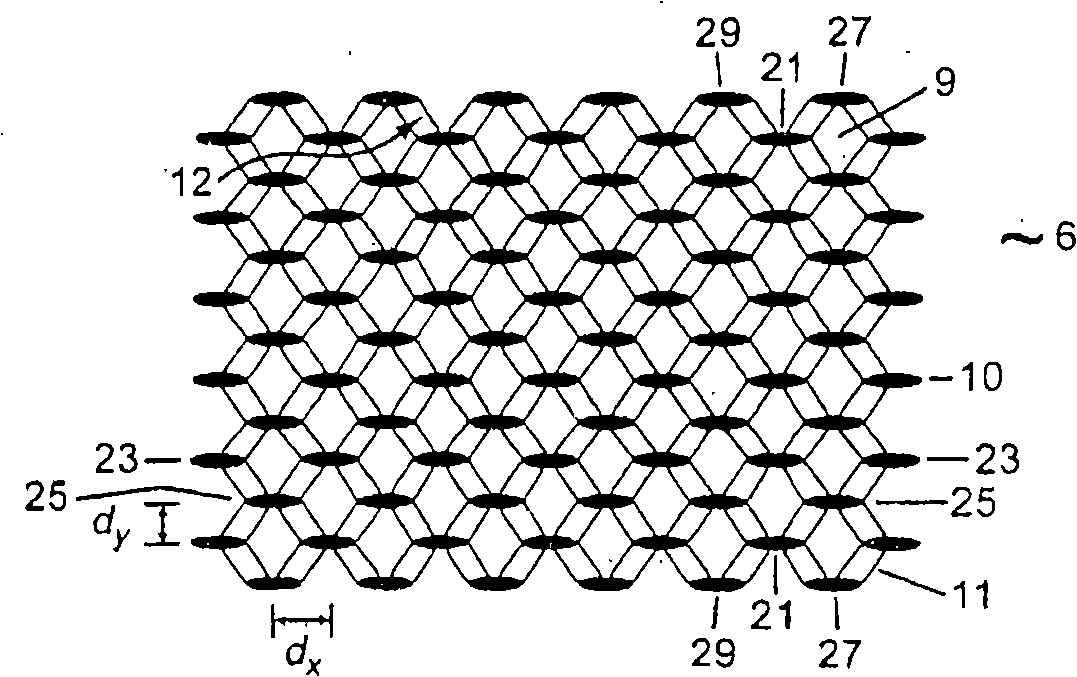

[0041] The following is an embodiment of the actual invention of the art of open-work pile knitting using warp knitting, one of which is shown graphically in image 3 (6) In.

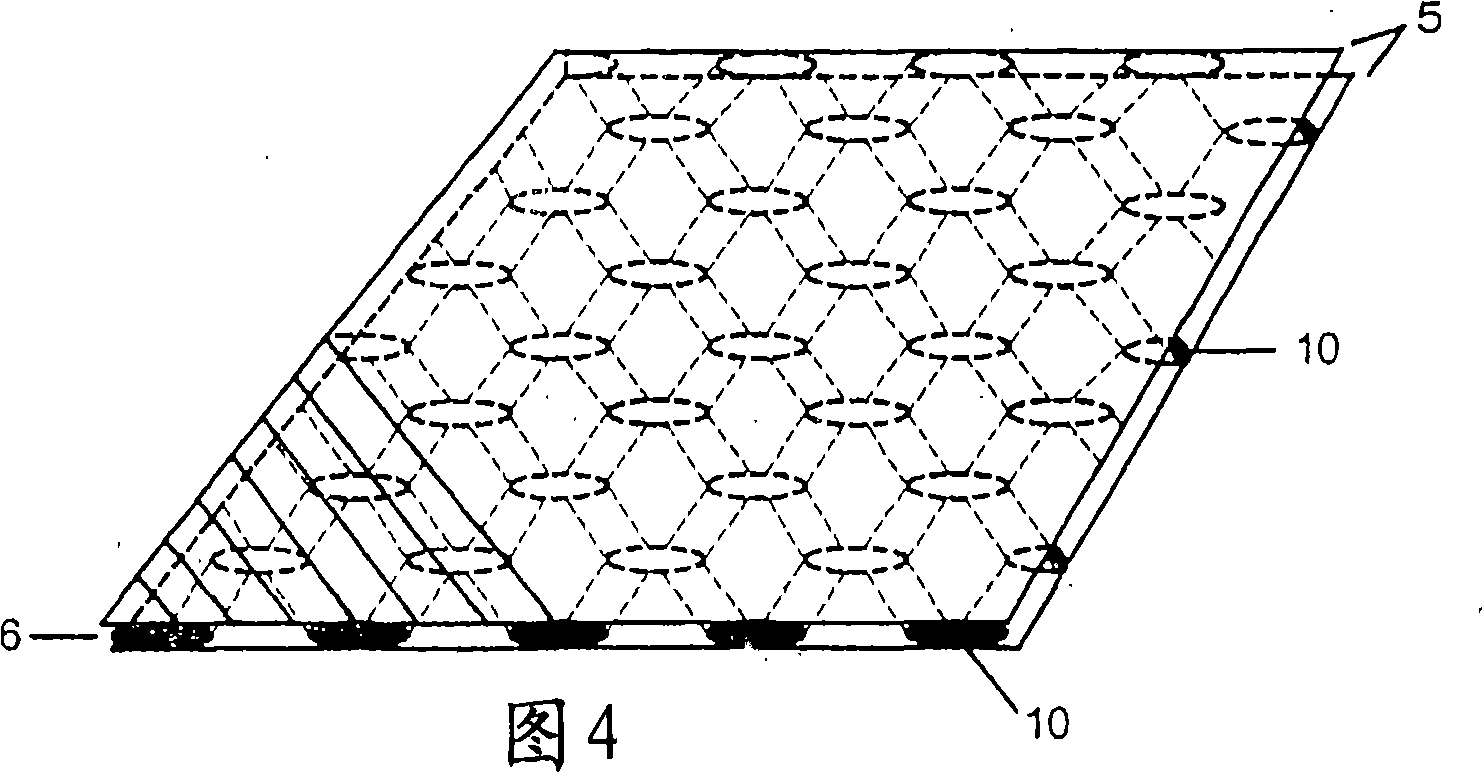

[0042] As shown above, one form of the open work knitted fabric 6 is a warp woven fiber fabric, in which the open mesh has a main porous structure defined as a polygon, wherein at least some edges of the polygon are defined by piles to provide periodically raised Three-dimensional protrusions or ribs.

[0043] Multiple piles are separated by distances dx and dy (see image 3 ), where the distance dx varies with the specifications of the machine knitting the knitted fabric, the size of the yarn forming the knitted fabric, and the weaving structure, and dy varies with the number of routes selected. Therefore these intervals are a design choice.

[0044] In use, the surface 6 of the pile open work knitted fabric is arranged in a manner of being in face-to-face contact with the adjacent layer of the preform 5. Du...

Embodiment 2

[0052] Figures 6a-f show a warp braided guide rod-winding diagram of another non-limiting embodiment of the open working braid 6 of the present invention.

[0053] Figures 6a and 6b show the winding movement of the bottom net. In Figure 6a, in order to form an open chain stitch defined by the yarn 13, the guide rod 1 performs a repeated movement of 0-4 / 4-0, like a weft 14 hooking, in order to form a 4-needle intarsia as shown in the guide bar 2 in Fig. 6b, the weft yarn performs a repeated movement of 0-0 / 16-16. Figures 6c and 6d show the winding motion of a suitable multi-row tuck embossed structure. Rod 3 in Figure 6c works according to the following code: 4-4 / 4-0 / 4-0 / 4-4 / 8-12 / 8-12 and the screw is at both ends of each guide, two in and six out repeat. Rod 4 in Figure 6d works according to the following code: 4-4 / 8-12 / 8-12 / 4-4 / 4-0 / 4-0 and the screw is at both ends of each guide, four out, then two Repeat in and out.

[0054] The timing of the winding movement of the rod 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com