Piezoelectric sensor, beam type concrete sensor, and preparation methods and application thereof

A piezoelectric sensor and beam-type technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of being easily affected by the external environment, reflection Signal instability, easy damage and other problems, to achieve the effect of good dynamic characteristics, low cost, simple application method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

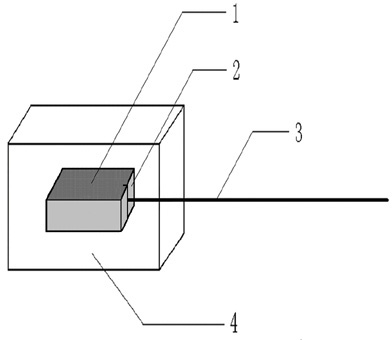

[0038] Such as figure 1 The piezoelectric sensor includes a sensing element, the sensing element includes a piezoelectric material 2 and a pair of electrodes 1 located on the upper and lower surfaces of the piezoelectric material, and a packaging shell 4 is covered outside the sensing element, and the piezoelectric material A pair of electrodes on the top is connected by a shielding wire 3 that runs through the package shell, and the package shell is made by mixing glycidyl ether epoxy resin, diethylenetriamine and cement at a mass ratio of 1:0.4:1. The piezoelectric material used is lead zirconate titanate ceramics, the electrode used is silver electrode, the cement used is barium sulfoaluminate cement clinker 70%, gypsum 10%, limestone 20%, water-cement ratio 0.25.

[0039] The preparation process is as follows: mix glycidyl ether epoxy resin, diethylenetriamine and cement evenly according to the mass ratio of 1:0.4:1, plate silver on the upper and lower surfaces (two stres...

Embodiment 2

[0041] The structure of the piezoelectric sensor is the same as that of Example 1, except that the package shell is made by mixing glycidyl ester epoxy resin, triethylenetetramine and cement at a mass ratio of 1: 0.4: 1, and the cement used is barium sulfur Aluminate cement clinker 76%, gypsum 5%, limestone 19%, water-cement ratio 0.3. The piezoelectric material used is a cement-based piezoelectric composite material, and the electrodes are silver electrodes.

[0042] The preparation process is: according to the mass ratio of 1:0.4:1, glycidyl ester epoxy resin, triethylenetetramine and cement are evenly mixed, and silver is plated on the upper and lower surfaces (two stress surfaces) of the cement-based piezoelectric composite material. Connect the two electrodes with a shielded wire, then put the sensing element into the mold, pour the above-mentioned mixture of glycidyl ester epoxy resin, triethylenetetramine and cement into the mold and harden for 3 days, and demould to ob...

Embodiment 3

[0044] The piezoelectric sensor structure is the same as in Example 1, except that the package shell is made by mixing linear aliphatic epoxy resin, triethylenetetramine and cement at a mass ratio of 1: 0.4: 1, and the cement used is barium Sulphoaluminate cement clinker 80%, gypsum 10%, limestone 10%, water-cement ratio 0.4. The piezoelectric material used is lead niobium magnesium zirconate titanate ceramics, and the electrodes are conductive silver glue electrodes.

[0045] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com