Monitoring method and optimal control method for supercritical circulating fluidized bed (CFB) boiler combustion signals

A boiler combustion and supercritical technology, which is applied in the direction of combustion method, fuel burned in molten state, combustion type, etc., can solve problems such as error, high experimental cost, and inaccurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Embodiments of the present invention: a large-scale CFB boiler heat signal monitoring method, comprising the following steps:

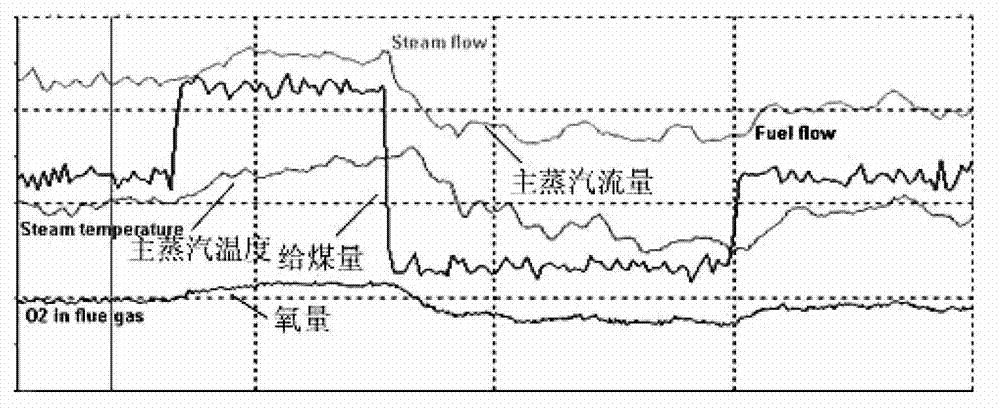

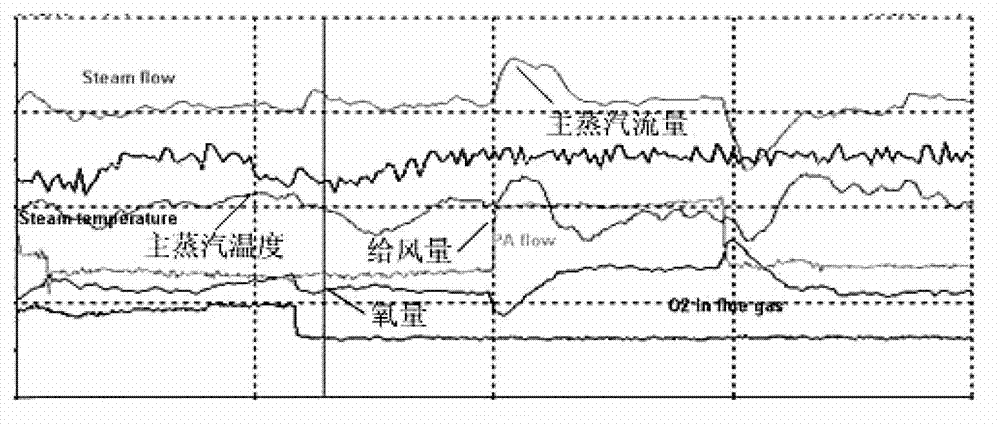

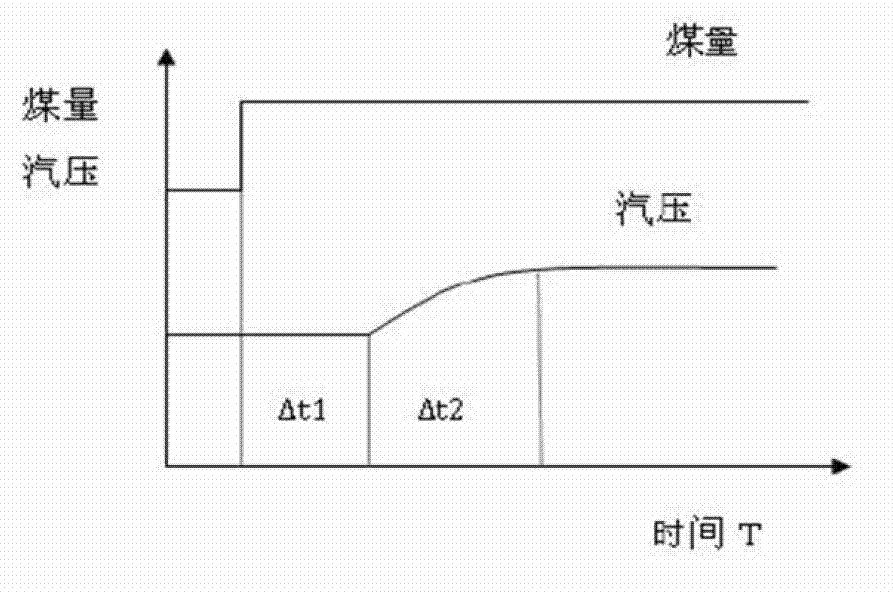

[0080] Step 1, collect on-site data, the on-site data includes coal feed rate, total air volume, slag discharge volume, main steam flow rate, feed water flow rate, main steam temperature, feed water temperature, coal calorific value and bed temperature, and carry out the above-mentioned on-site data Data preprocessing and determination of auxiliary variables for the instant carbon model;

[0081] Step 2, establishing a composite modeling instant carbon model based on mechanism modeling and data analysis, and using generalized Kalman filter information fusion technology to estimate the storage capacity of instant carbon in the furnace; the instant carbon model is:

[0082] dB ( t ) dt = F ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com