Bidirectional direct-current converter feedback linearized back-stepping sliding-mode control mode

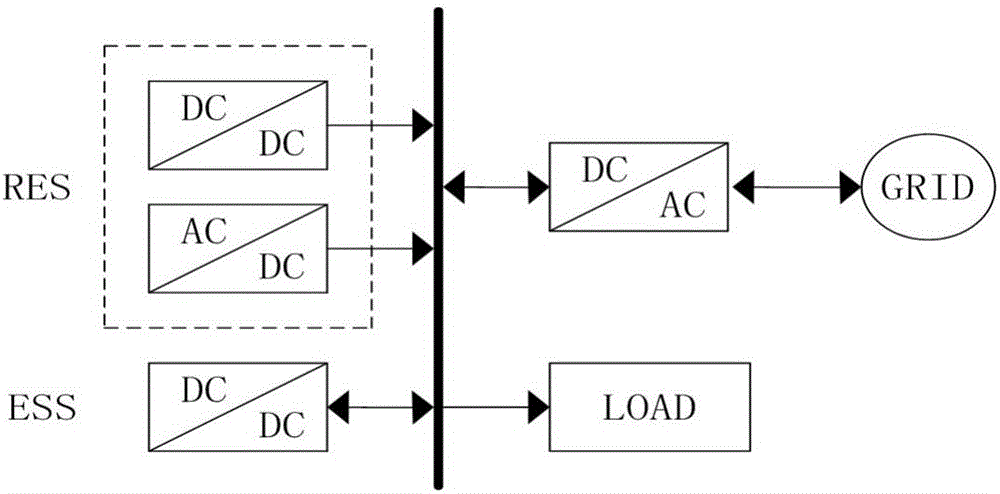

A technology of bidirectional DC conversion and feedback linearization, which is applied in the direction of converting DC power input to DC power output, control/regulation systems, and DC network circuit devices, etc. complicated formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

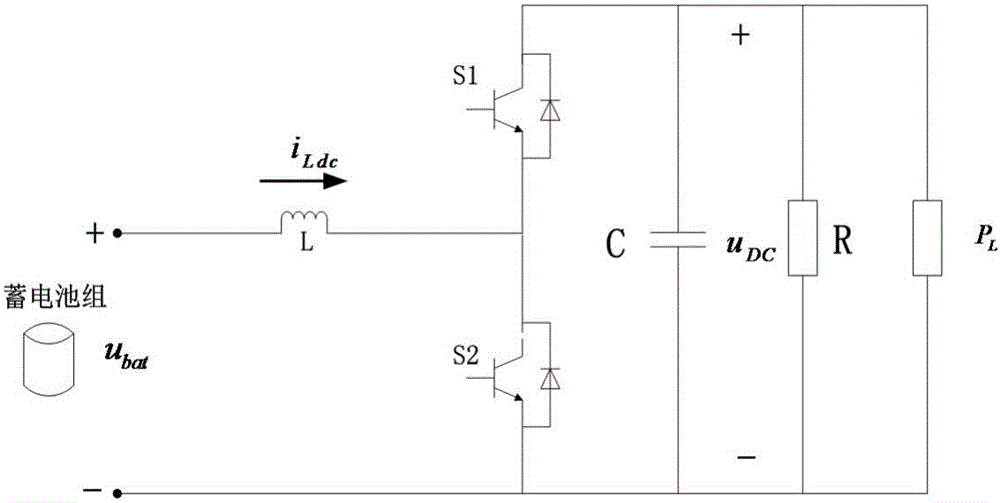

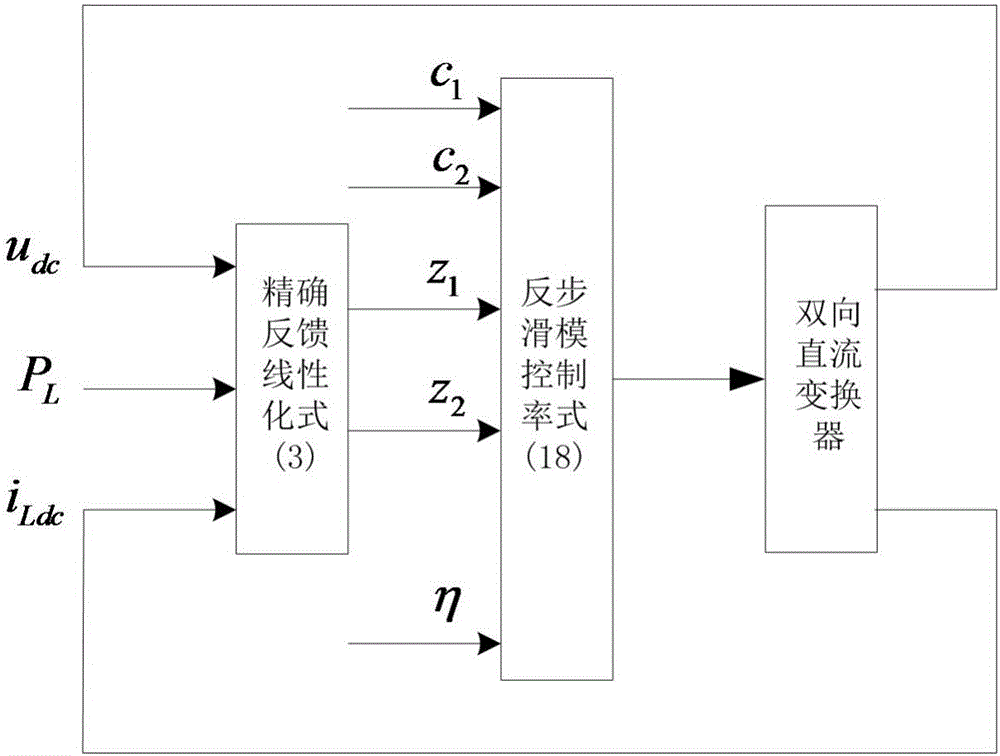

[0142] In order to verify the correctness of the proposed control method, the numerical simulation of the system is carried out by using PSCAD. The system parameters are battery terminal voltage 194V, rated load 21Ω, output DC voltage reference value 400V, filter inductance L=3mH, filter capacitor C=10 4 μF, switching frequency f s = 10kHz. Feedback linearized sliding mode variable structure control parameters: c 1 =10000, c 2 =6000, η=10000, δ 0 = 46 and k 1 =100.

[0143] Working condition: Photovoltaic is selected as the distributed power source in the system, and the light intensity changes from 1000W / m2 in 2.5s 2 Change to 1400W / m 2 , the light intensity change is 800W / m in 3s 2 , the light intensity change is 600W / m in 3.5s 2 , other distributed power sources and grid-connected inverters are in constant power control state, Figure 4 Given the input to the high voltage side of the battery (-P CPL ) of the power curve, the remaining capacity of the battery is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com