Coating for color inkjet printing paper and preparation method of coating

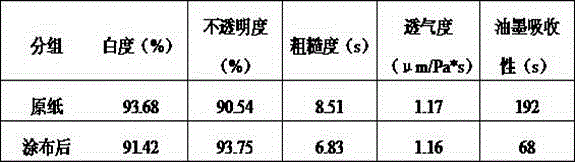

A technology of color inkjet and printing paper, applied in the direction of paper coating, copying/marking method, coating, etc., can solve the problem that it is difficult to achieve fast drying and high image resolution, processing capacity, production and theoretical research Improve the resolution and color gloss, enhance the three-dimensional effect, and good ink absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A coating for color inkjet printing paper, comprising a primer and a topcoat:

[0032] Primer coating is made from the raw material of following weight part:

[0033] 600 parts of water

[0034] Fixing agent H3538 parts

[0035] Defoamer F1110.4 parts

[0036] Silica 609100 parts

[0037] Polyvinyl alcohol 1799160 parts

[0038] Brightener 4 parts

[0039] Latex VEA70745 parts

[0040] 1.5 parts of whitening agent Z-10A;

[0041] A kind of preparation method for the coating of color inkjet printing paper, the preparation method of primer is: add 450 parts of water in the container, add fixing agent H35 and defoaming agent F111 and stir for 10 minutes, the solution is heated to 80 ℃, keep constant temperature, add silicon dioxide 609 in batches under the condition of stirring speed of 300 rpm, after complete dissolution, add whitening agent, polyvinyl alcohol 1799, latex VEA707 in sequence, and stir at 80 rpm Stir for 20 minutes under the same conditions, cool do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com