Ore dressing method of pyrite

A mineral processing method and pyrite technology, applied in flotation, solid separation, grain processing, etc., can solve the problem of large consumption of butyl xanthate collector, unsatisfactory gravity separation effect, unfavorable separation of sulfide ore and other problems, to achieve the effect of improving buoyancy, reducing the dosage of chemicals, and saving the dosage of acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

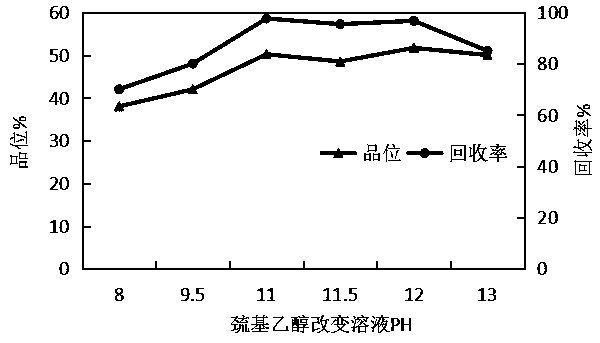

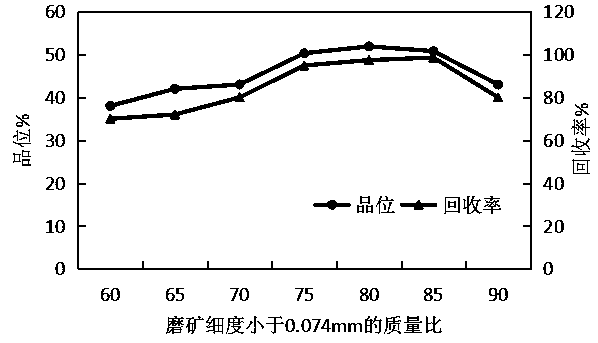

[0035] (1) Get 100g pyrite and add mercaptoethanol, adjust pH=11, adopt ceramic ball medium to carry out grinding process, the quality of grinding fineness less than 0.074mm is 80% of the pyrite quality that gets;

[0036] (2) Add water to the raw ore grinding obtained in step (1) to obtain raw ore slurry, wherein the ratio of ore amount to water is 1:2.2;

[0037] (3) Carry out rough separation to the ore slurry that step (2) obtains, add butyl xanthate, No. 2 oil, carry out ultrasonic treatment, obtain rough separation sulfur ore and tailings, wherein butyl xanthate is 180g / t, No. 2 The oil is 30g / t, the ultrasonic power is 70W, and the action time is 5min;

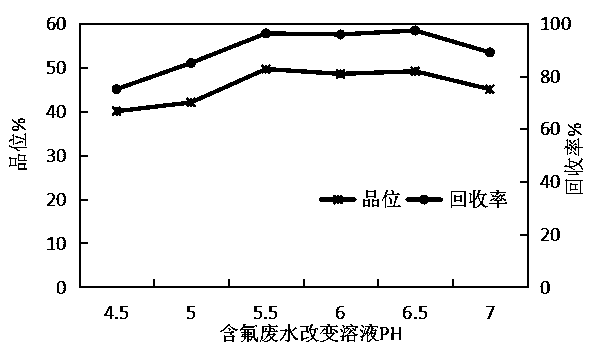

[0038] (4) Add fluorine-containing acidic waste water to the tailings obtained in step (3), and adjust the pH to be 6;

[0039] (5) Carry out secondary roughing in step (4), add butyl xanthate, No. 2 oil, carry out ultrasonic treatment, obtain roughing sulfur ore and tailings, wherein butyl xanthate is 90g / t, No. 2 Th...

Embodiment 4-6

[0049] (1) Get 100g pyrite and add mercaptoethanol, adjust pH=12, adopt porcelain ball medium to carry out grinding process, the quality of grinding fineness less than 0.074mm is 75% of the pyrite quality that gets;

[0050] (2) Add water to the raw ore grinding obtained in step (1) to obtain raw ore slurry, wherein the ratio of ore amount and water is 1:2;

[0051] (3) Carry out rough separation to the ore slurry that step (2) obtains, add butyl xanthate, No. 2 oil, carry out ultrasonic treatment, obtain rough separation sulfur ore and tailings, wherein butyl xanthate is 190g / t, No. 2 The oil is 38g / t, the ultrasonic power is 75W, and the action time is 5min;

[0052] (4) Add fluorine-containing acidic waste water to the tailings obtained in step (3), and adjust the pH to 5.5;

[0053](5) Carry out secondary roughing in step (4), add butyl xanthate, No. 2 oil, carry out ultrasonic treatment, obtain roughing sulfur ore and tailings, wherein butyl xanthate is 95g / t, No. 2 The...

Embodiment 7-9

[0062] (1) Get 100g pyrite and add mercaptoethanol, adjust pH11.5, adopt porcelain ball medium to carry out grinding process, the quality of grinding fineness less than 0.074mm is 85% of the pyrite quality that gets;

[0063] (2) Add water to the raw ore grinding obtained in step (1) to obtain raw ore slurry, wherein the ratio of ore amount and water is 1:2.5;

[0064] (3) Carry out rough separation to the ore slurry that step (2) obtains, add butyl xanthate, No. 2 oil, carry out ultrasonic treatment, obtain rough separation sulfur ore and tailings, wherein butyl xanthate is 200g / t, No. 2 The oil is 40g / t, the ultrasonic power is 80W, and the action time is 5min;

[0065] (4) Add fluorine-containing acidic waste water to the tailings obtained in step (3), and adjust the pH to 5.5;

[0066] (5) Carry out secondary roughing in step (4), add butyl xanthate, No. 2 oil, carry out ultrasonic treatment, obtain roughing sulfur ore and tailings, wherein butyl xanthate is 95g / t, No. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com