Patents

Literature

42 results about "Activation technique" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and use of carbon molecular sieve

InactiveCN101935032ASolve the problem of difficult and efficient separation of methane-nitrogenNitrogen purification/separationOther chemical processesHigh concentrationLoss rate

The invention relates to a preparation method and use of a carbon molecular sieve. The preparation method comprises the following steps: preparing a conventional carbon molecular sieve; and expanding the pores in the conventional carbon molecular sieve by using a secondary activation technique and modifying the conventional carbon molecular sieve by adjusting the pores. The new carbon molecular sieve is prepared by using coal, coconut shell or phenolic resin, and the like as raw materials, by the conventional production steps of crushing, forming, carbonizing, steam activating, hydrocarbon settling and shrinking and the like and by secondary activation with KOH or CO2 as an activator. The activation temperature is between 550 and 850 DEG C; and the ignition loss rate of the product is kept be between 0.1 and 30 percent. In aspect of use, the carbon molecular sieve can be used for absorbing nitrogen molecules and can also be used for absorbing and separating methane and nitrogen in seam gas under a variable pressure while achieving an adsorption dynamic separation effect and allowing high-concentration methane gas to be collected at the exit of an adsorption tower directly; and thus, the methane in the seam gas can be used efficiently.

Owner:TONGJI UNIV

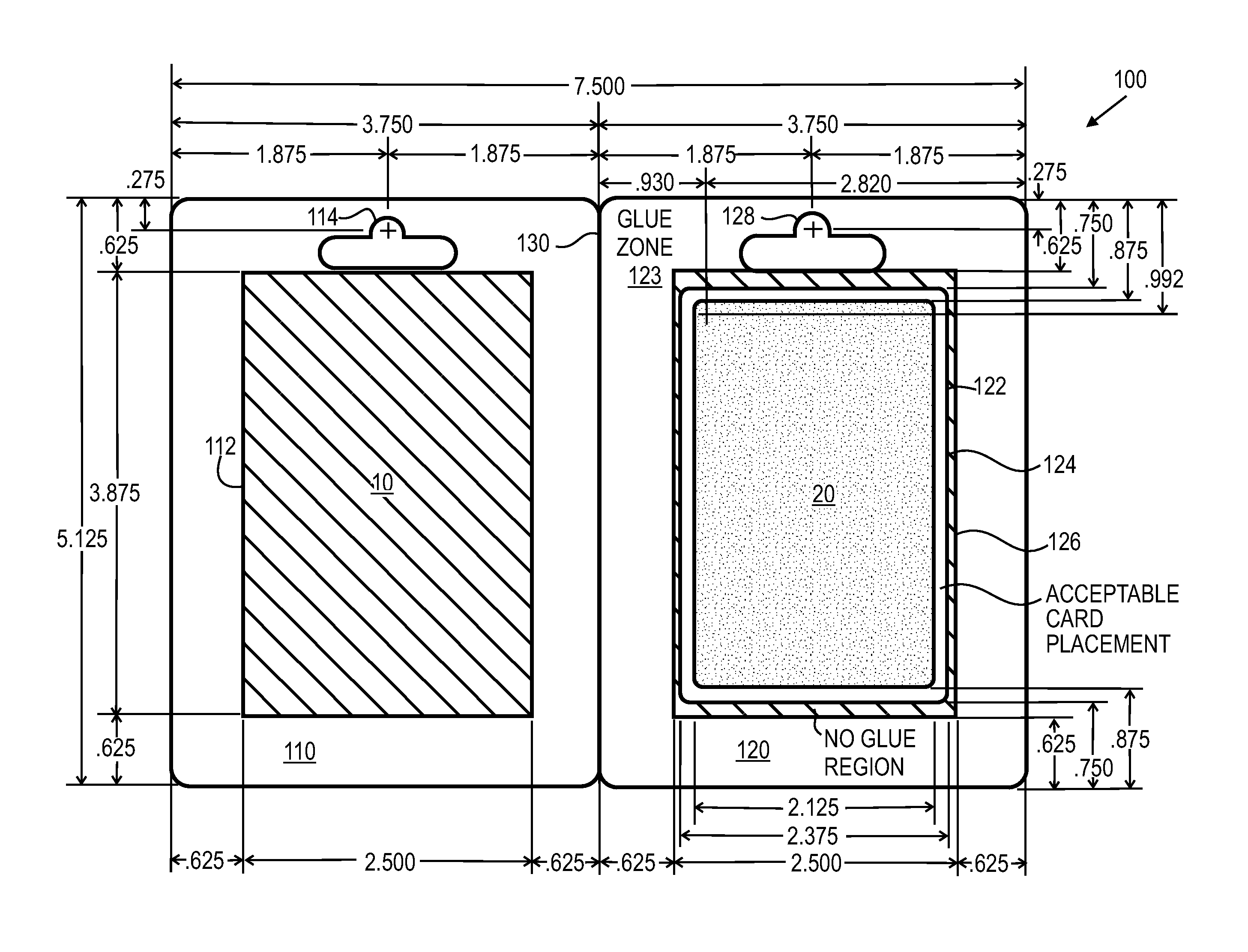

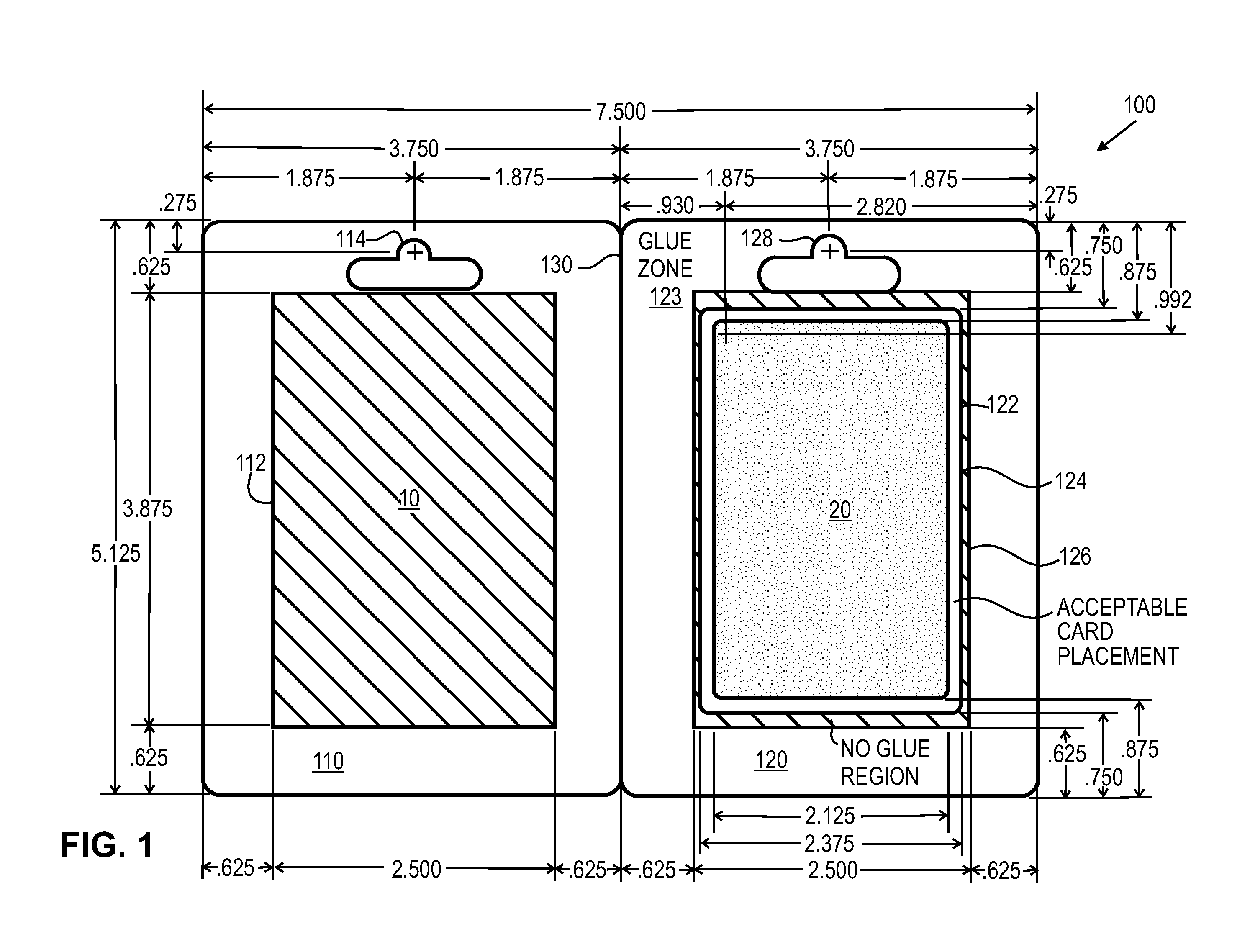

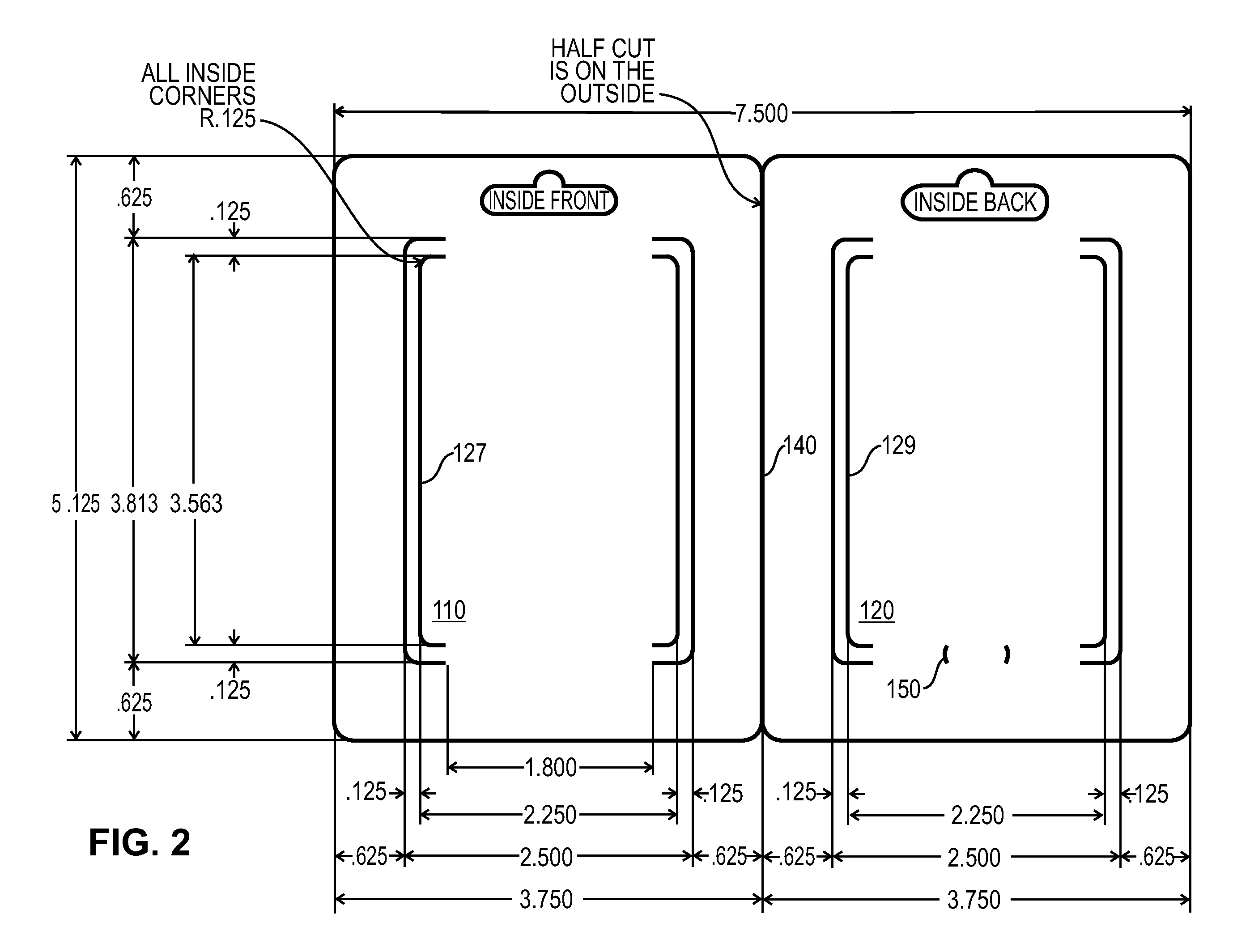

Methods and Apparatus for Prepaid Card Packaging and Activation

InactiveUS20100213092A1Opening closed containersBottle/container closureActivation techniqueEngineering

Owner:OBERTHUR TECH OF AMERICA CORP

Polyether modified silicon oil with ultra-low surface tension and synthesis process thereof

ActiveCN101434615AReduce surface tensionAvoid complex separationGroup 4/14 element organic compoundsHydrogenActivation technique

The invention relates to polyether modified silicone oil and a synthetic process thereof, in particular to the polyether modified silicone oil with extremely low surface tension, and a synthetic process thereof. In the preparation of the polyether modified silicone oil with extremely low surface tension, an activation technique is adopted to treat an activator H2PtCl6 and the surface tension of the polyether modified silicone oil prepared by reaction between allyl polyether and methyl hydric silicone oil is 20mN / m to 22mN / m. Due to the preeminent wetting property, the polyether modified silicone oil with the surface tension lower than 22mN / m and prepared by the synthetic technique provided by the invention can be applied as an additive in the fields such as pesticide, cosmetics and the like. The polyether modified silicone oil and the synthetic process thereof do not adopt solvents including toluene and has milder reaction condition and simple reaction process. Due to no adoption of a toluene solvent, the complex segregation between a finished product and the solvent is avoided, which is conducive to reducing the surface tension.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

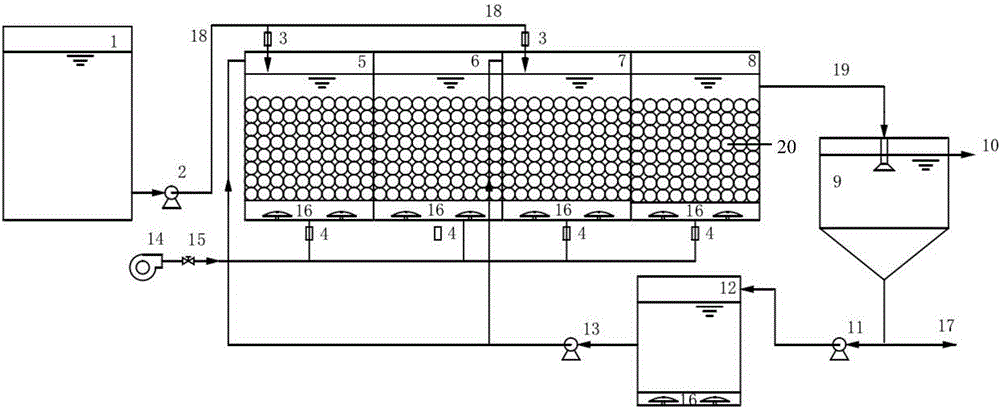

Multistage A/O (anoxic/oxic) biomembrane-sludge activation coupled denitrification and dephosphorization device and application thereof

InactiveCN105948251AIncrease profitAvoid direct accessWater contaminantsTreatment with aerobic and anaerobic processesTreatment effectSludge

The invention discloses a multistage A / O (anoxic / oxic) biomembrane-sludge activation coupled denitrification and dephosphorization device and a sewage treatment method by using the device. The device comprises a raw water tank, a biomembrane region, a sedimentation tank and a sludge activation reactor. By combining a continuous-flow sectionalized water inlet biomembrane technique with a sludge activation technique, the synchronous nitrification-denitrification process is reinforced to obtain the low-carbon / nitrogen-ratio domestic sewage, thereby implementing the coupled technique with the optimized treatment effects. The speed-separation ball filler is arranged in the biomembrane region to increase the system stability, lower the sludge load, reduce the surplus sludge and enhance the treatment efficiency of the system.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Method for preparing ultrasonic alkylated lignosulfonate bio-based surfactant

InactiveCN103755972AIncrease contentImprove structural regularityOther chemical processesTransportation and packagingActivation techniquePetroleum

The invention discloses a method for preparing an ultrasonic alkylated lignosulfonate bio-based surfactant, which belongs to the field of lignosulfonate alkylated synthesized surfactant. According to the method, the number of active groups of lignosulfonate is increased and the tidiness of the molecular structure is improved by using an environment-friendly and efficient ultrasonic wave activation technique, the defects that the industrial lignosulfonate is low in reaction activity and poor in tidiness of the molecular structure are overcome; the bio-based surfactant is synthesized from the lignosulfonate through alkylation in a mixture solution system of alkali organic solvents and water in the presence of pyridine and derivatives of pyridine serving as catalysts. The surface tension force of an aqueous solution of the bio-based surfactant with the mass concentration of 1% is as low as 28.2mN / m, and the critical micelle concentration is 5*10<-5>g / L. The surfactant has the advantages of low cost and characteristics of chemical environment-friendless, is possibly used for completely or partially replacing a petroleum base surfactant to be applied to daily chemical fields and is wide in application prospect.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Method for remediating contaminated underground water in situ on basis of persulfate thermal activation technique

InactiveCN102241454AStrong oxidationImprove mineralization abilityMultistage water/sewage treatmentWater/sewage treatment by oxidationPersulfateSulfate

The invention discloses a method for remediating contaminated underground water in situ on basis of a persulfate thermal activation technique, which relates to a method for remediating contaminated underground water. The method is used to solve the problems of large investment and low efficiency of the conventional underground water remediation technique. The method comprises: adding persulfate or persulfate compound oxidizer into water, and pumping the solution by an anticorrosion pump into underground water to be remediated; and 2, after the persulfate or persulfate compound oxidizer is mixed with the underground water for 10 to 24 hours, pumping high-pressure vapor into the underground water to be remediated, and remediating the contaminated underground water after 1 to 2 days. When the method disclosed by the invention is used, the work amount is small, the technical investment is small, new toxic matters are not introduced into water, the implementation is easy, and the removal rate of the contaminants reaches 85 to 95 percent. The method is used in the field of underground contaminated water treatment.

Owner:HARBIN INST OF TECH

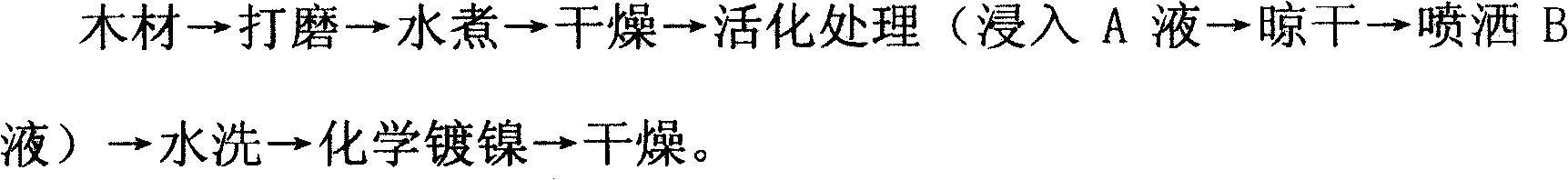

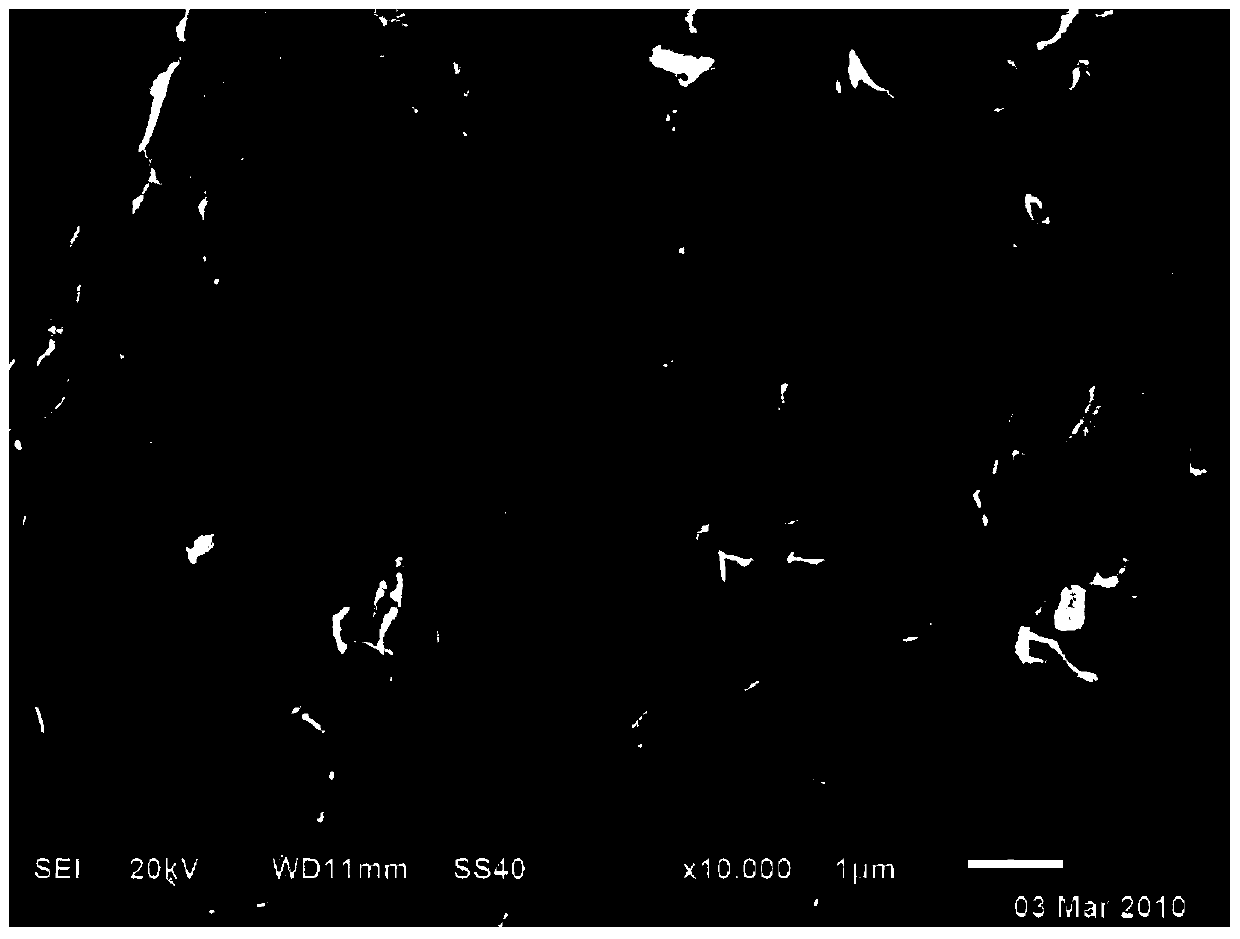

Activation technique for lumber chemical nickel plating

InactiveCN101270474AAvoid failureLow priceLiquid/solution decomposition chemical coatingMetallic materialsActivation technique

The invention discloses an activation technology for the chemical nickel plating of wood. Activation liquid consists of A liquid and B liquid. Nickel vitriol is dissolved in the distilled water added with hydrochloric acid to prepare nickel vitriol liquid, namely the A liquid; sodium borohydride is dissolved in the distilled water added with sodium hydroxide to prepare the alkaline liquid of the sodium borohydride, namely the liquid B. The wood is immerge in the A liquid and is taken out to be dried, the liquid B is sprayed uniformly on the surface of the wood to activate the wood. The activated wood after being rinsed by distilled water can be treated by the chemical nickel plating technology on the surface; after being plated, the wood after being washed for a plurality of times is arranged in a drying box for drying. The material of the activation liquid of the activation technology has lower price, is simple to be prepared, can not lose effect after a long assembly time; besides, the activation technology can replace the activation technology of a noble metal Pd. The activation technology omits the working procedure of using an organic solvent to treat the surface of the wood, thus being able to further reduce the cost of chemical nickel plating of wood. The invention is extremely suitable for the chemical nickel plating of large wood product, is easy to realize the production line manufacture of a factory and can also be used for the activation of chemical nickel plating of other non-metal materials.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

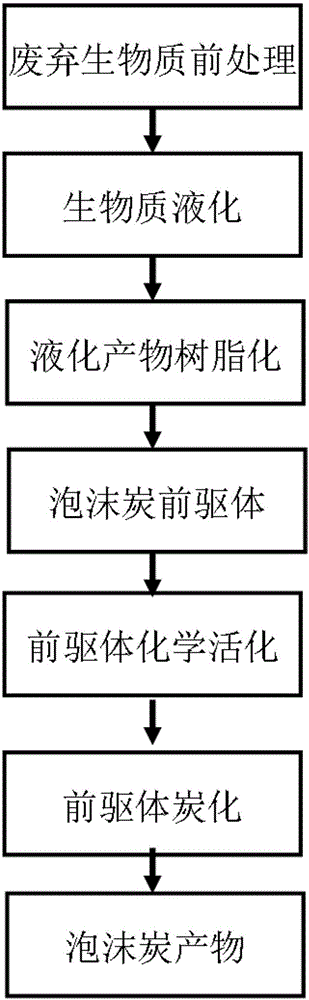

Foam carbon preparation method based on waste biomass

InactiveCN106587001AAvoid pollutionSolve the shortageCarbon preparation/purificationActivation techniquePetroleum

The invention discloses a foam carbon preparation method based on waste biomass. The method comprises the following steps that waste biomass is pretreated; 2, the waste biomass is liquefied; 3, a liquefaction product is resinified, and a resin product is obtained; 4, the resin product is foamed, and a foam carbon precursor is obtained; 5, the foam carbon precursor is chemically activated and carbonized, and foam carbon is obtained. According to the foam carbon preparation method based on the waste biomass, the forestry waste biomass, the agriculture waste biomass and the aquatic plant waste biomass are taken as raw materials and can partially replace traditional petroleum and coal chemical industry intermediates to serve as raw materials for synthesizing the foam carbon, therefore, the economic cost is effectively reduced, and the raw material shortage problem is solved. By combining a liquefaction technique, a resinification technique, a foam carbon precursor preparation technique and an activation technique, the porous foam carbon with the uniform size and the ordered structure can be synthesized, and the application value and the economic benefit of the foam carbon are increased.

Owner:HAINAN UNIVERSITY +1

Production technique of cationic starch

ActiveCN102775508AIncrease the activation processIncrease compoundingNon-fibrous pulp additionPaper/cardboardActivation techniqueBiological activation

The invention relates to a production technique of cationic starch. A starch activation technique and a starch compounding and impregnation technique are added, and the rest of techniques are correspondingly innovated. The production technique of cationic starch comprises the following main steps: starch activation, etherifying agent activation, starch compounding and impregnation, etherification reaction, blast cooling, neutralization, blast cooling, pulverization and the like. The production technique provided by the invention has the advantages of safe material, no gelatinization of start particles, shorter reaction time, lower energy consumption, higher reaction efficiency and higher product yield, and is simple and practical to operate; and the prepared cationic starch product has the advantages of high quality and stable properties.

Owner:山东米能生物科技有限公司

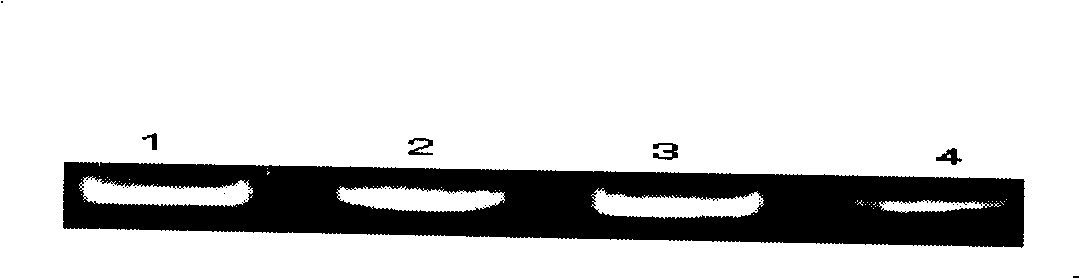

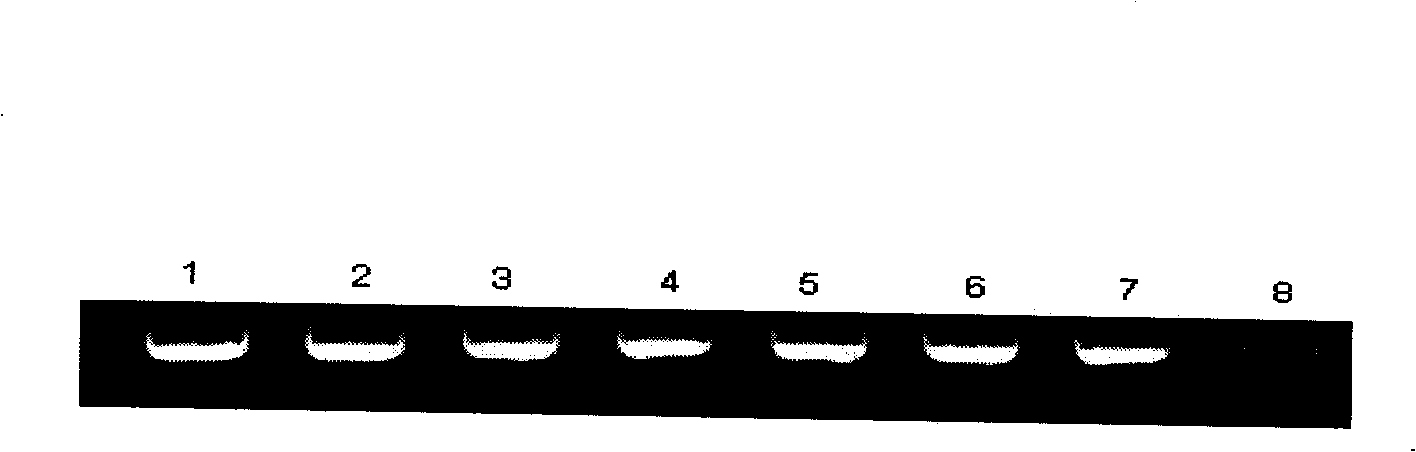

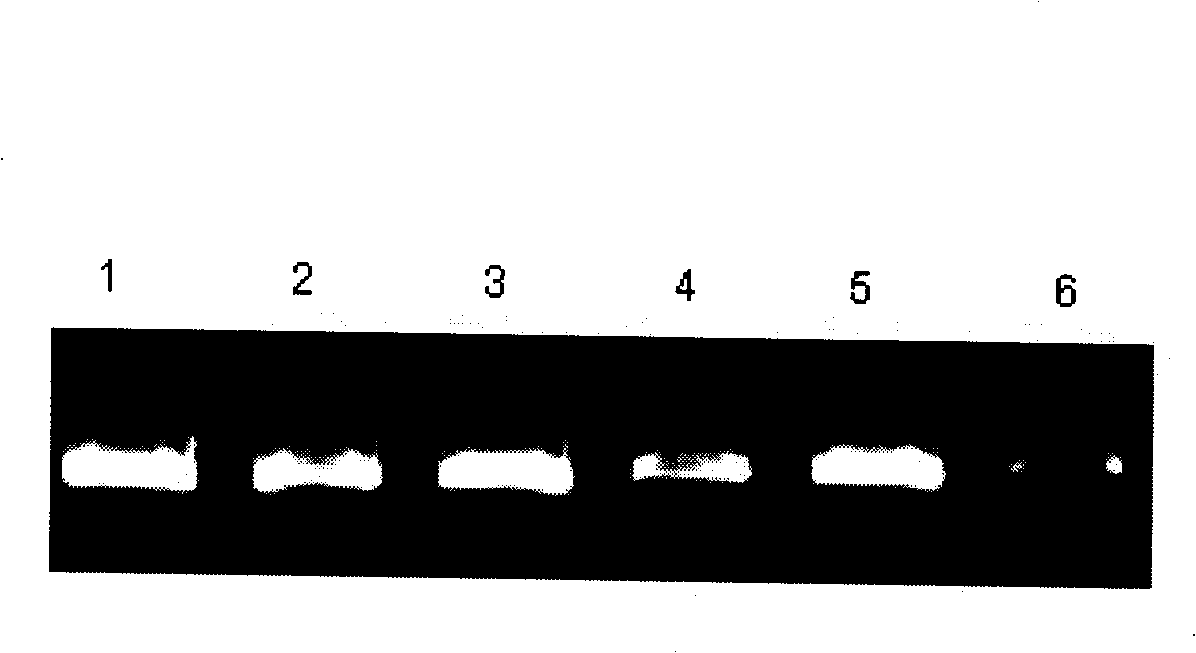

Pellosil activate fluid and applications thereof for extracting nucleic acid

InactiveCN101338312AImprove bindingImprove uniformitySugar derivativesSugar derivatives preparationSilicon membraneActivation technique

The invention belongs to the technical field of nucleic acid extraction, in particular to a silicon membrane activation liquor and an application thereof. The invention aims at providing a method for carrying out processing on the silicon membrane; an activation technique can be adopted to increase the combining force of the silicon membrane and the nucleic acid; besides, the combining force thereof has excellent uniformity and stability. The invention improves the biological utilizing degree of the nucleic acid and better exerts the function for extracting the nucleic acid of the invention; besides, the silicon membrane is coated inside an activator by the method, thus isolating the contact with the outside environment; therefore, the character is more stable and the application range thereof is enlarged so as to meet different production demands.

Owner:TIANGEN BIOTECH BEIJING

Polyether modified silicon oil with ultra-low surface tension and synthesis process thereof

ActiveCN101434615BAvoid complex separationMild reaction conditionsGroup 4/14 element organic compoundsHydrogenActivation technique

The invention relates to polyether modified silicone oil and a synthetic process thereof, in particular to the polyether modified silicone oil with extremely low surface tension, and a synthetic process thereof. In the preparation of the polyether modified silicone oil with extremely low surface tension, an activation technique is adopted to treat an activator H2PtCl6 and the surface tension of the polyether modified silicone oil prepared by reaction between allyl polyether and methyl hydric silicone oil is 20mN / m to 22mN / m. Due to the preeminent wetting property, the polyether modified silicone oil with the surface tension lower than 22mN / m and prepared by the synthetic technique provided by the invention can be applied as an additive in the fields such as pesticide, cosmetics and the like. The polyether modified silicone oil and the synthetic process thereof do not adopt solvents including toluene and has milder reaction condition and simple reaction process. Due to no adoption of a toluene solvent, the complex segregation between a finished product and the solvent is avoided, which is conducive to reducing the surface tension.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

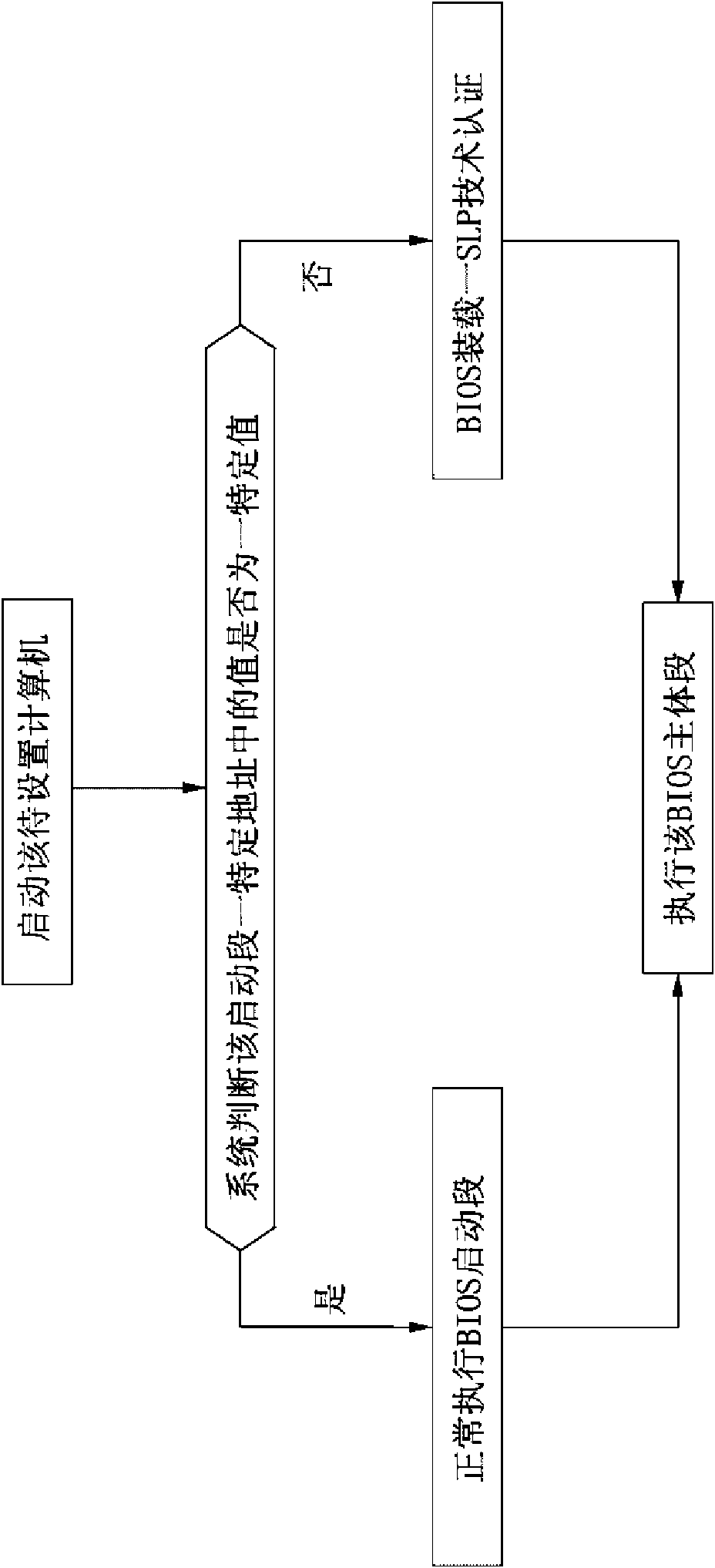

Method for implementing system assistant activation technique

InactiveCN101650658APlatform integrity maintainanceProgram loading/initiatingComputer architectureSystem requirements

The invention discloses a method for implementing a system assistant activation technique, comprising the following steps: when starting a computer to be set up, judging the value in a specified address in an initiation section of BIOS in the computer to be set up; if yes, normally executing BIOS initiation section; if no, loading the system assistant activation technique certification to the BIOS. The invention realizes SLP technique method with a netter implementation manner, and stores a specified value in the initiation section to realize starting the SLP technique or not according to system requirements.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

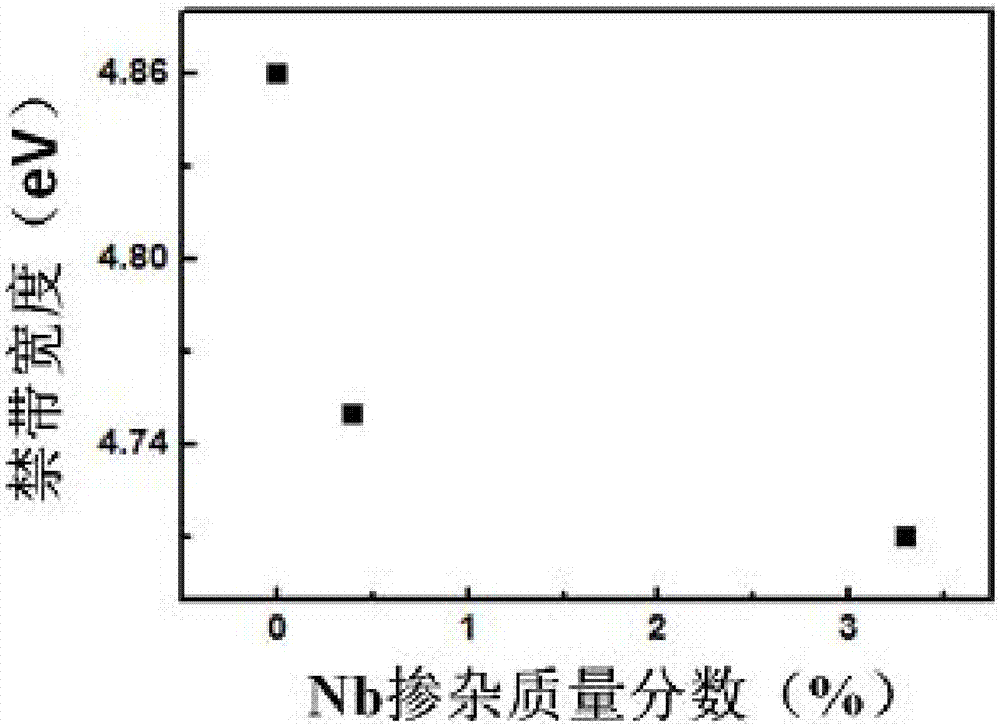

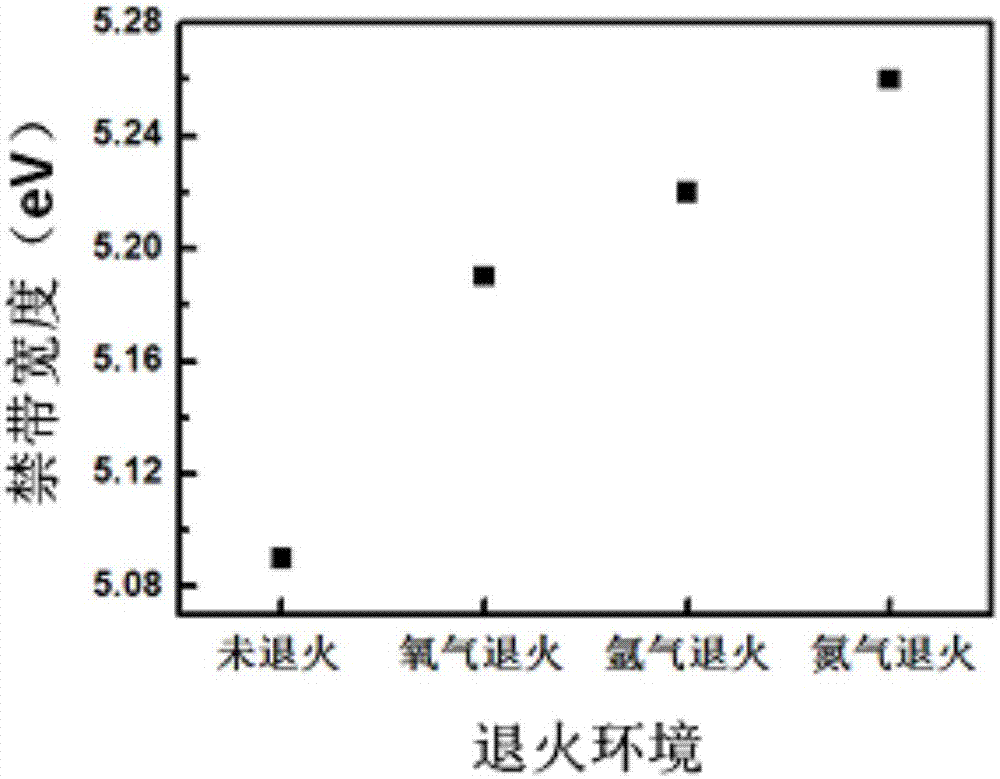

Method for tuning forbidden band width of Ga2O3 through Nb doping

InactiveCN107513695ALarge tuning rangeVacuum evaporation coatingSputtering coatingSemiconductor materialsRadio frequency magnetron sputtering

The invention discloses a method for tuning the forbidden band width of Ga2O3 through Nb doping and belongs to the field of semiconductor materials. Radio frequency magnetron sputtering equipment is used for depositing a layer of Nb:Ga2O3 thin film material on a monocrystal polished silicon wafer (Si); an impurity activation technique adopting slow annealing in a tubular furnace is used for enabling Nb distribution in the Nb:Ga2O3 thin film material to be uniformized; Nb ions are transferred to vacancy defect positions in crystal lattices, and the gap positions occupy the replacement positions; and the structural defects are reduced, the crystallization degree is improved, the crystal grain size is increased, and the quality of the thin film is further improved. Compared with the prior art, the method for tuning the forbidden band width of Ga2O3 through Nb doping is characterized in that Nb is selected as a dopant, so that the forbidden band width of Ga2O3 has wider forbidden band width tuning range.

Owner:BEIJING UNIV OF TECH

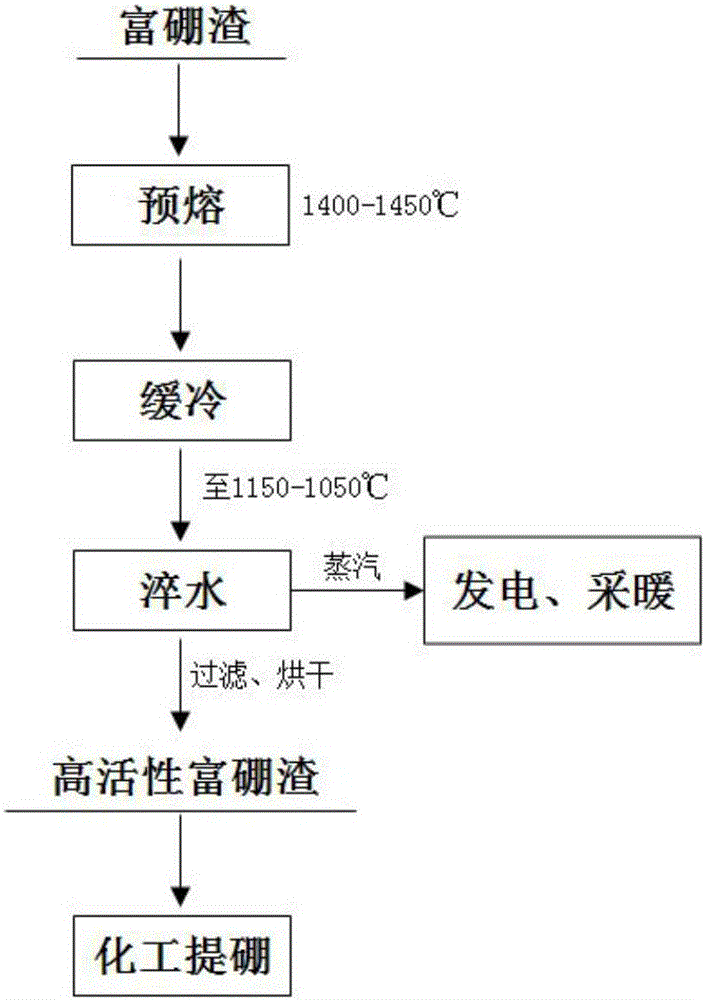

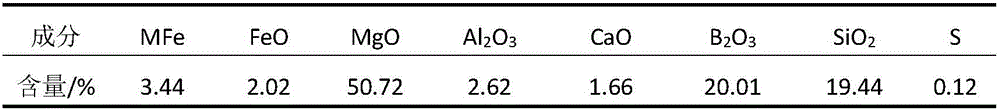

Low cost activation technique of boron-rich slag

The invention discloses a low cost activation technique of boron-rich slag, and belongs to the field of chemical metallurgy and comprehensive utilization of resources. The invention relates to a method of efficiently activation extracting boric oxide through high magnesium boron-rich slag, and is used for development and utilization of resources of paigeite. The method is characterized in that the boron-rich slag obtained after revivification and melt separation through a paigeite pyrogenic process is used as a raw material, the purpose that boric oxide is not revivified during the revivification and melt separation processes is guaranteed, an existential state of a boracic phase in the boron-rich slag is regulated and controlled after temperature control and slow cooling and rapid quenching, so that activity of the boron-rich slag reaches 87%; the activity of the boron-rich slag is improved, leaching efficiency of the boron can be improved, consumption of acid liquor is reduced, leaching time is shortened, leaching of impurity elements is reduced, finally production cost can be lowered, and environment pollution is reduced. The method is simple in technology, short in technological process, high in efficiency, low in energy consumption, free of addition of any chemical auxiliaries, capable of being perfectly connected with an existing pyrogenic process ferroboron separation technology, further capable of recycling partially sensible heat of fusion boron-rich slag, thus having good social and economic benefits.

Owner:UNIV OF SCI & TECH BEIJING

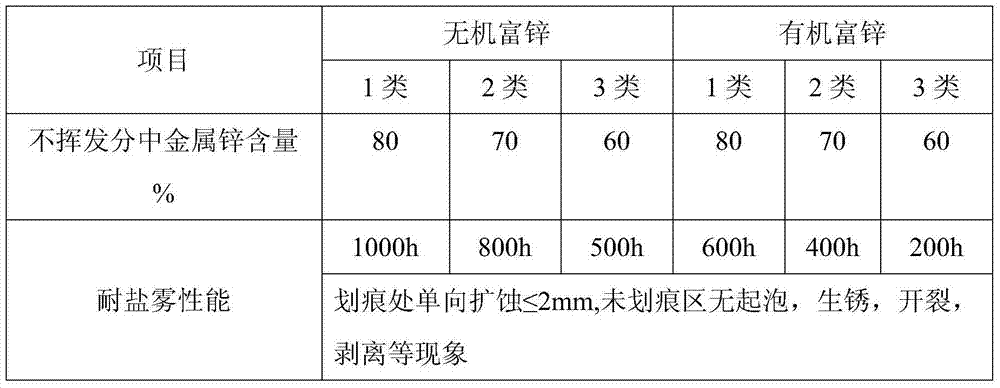

Zinc-rich primer using activation technique

InactiveCN104745044AIncrease contentIncrease profitAnti-corrosive paintsEpoxy resin coatingsMicrometerActivation technique

The invention discloses a zinc-rich primer using an activation technique. The zinc-rich primer is composed of a component A and a component B. The component A is prepared from the following raw materials in percentage by weight: 1-5% of matrix resin, 0.1-1% of anti-settling agent, 1-2% of thickener, 0.1-0.5% of drier, 80-85% of zinc powder, 1-5% of activator, 0.5-2% of toughener and 5-10% of solvent. The component B is composed of a curing agent. The weight ratio of the component A to the component B is (5-10):1. The salt-mist-resistance of the zinc-rich primer can reach 1200 hours above, and the inorganic zinc-rich cracking resistance can reach 260 micrometers without cracking.

Owner:XINHE NEW MATERIALS CO LTD

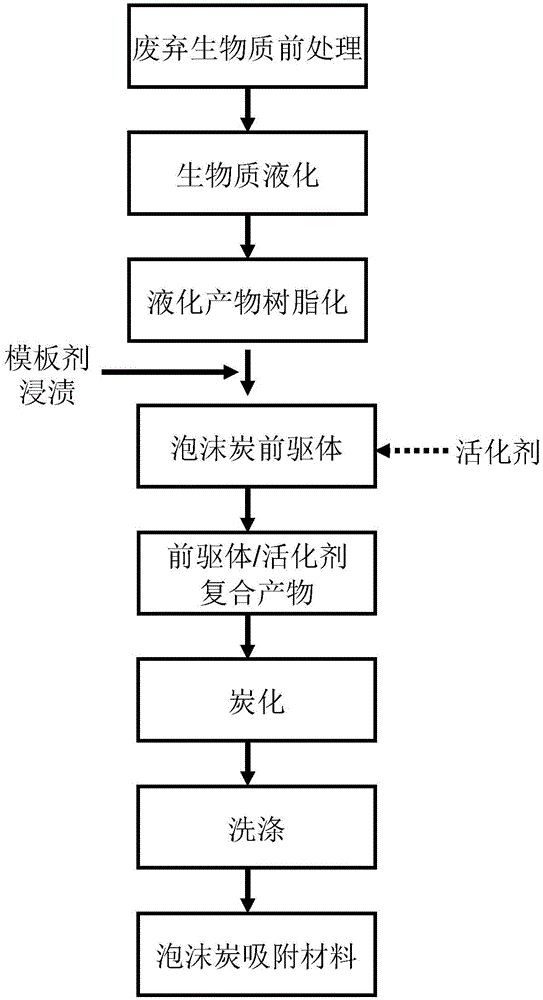

Method for preparing foam carbon adsorbing material with template process

The invention discloses a method for preparing a foam carbon adsorbing material with a template process. The method comprises following steps: (1), pretreatment of waste biomass; (2), liquefaction of the waste biomass; (3), resinification of a liquefied product; (4), preparation of a precursor of foam carbon: a template agent used as a foam carbon framework is repeatedly impregnated in resinified colloid, and after an organic solvent is removed through volatilization, a precursor product of foam carbon is obtained; (5), activation and carbonization of the foam carbon precursor: the foam carbon precursor is put in an activator solution for impregnation and then is calcinated, and the foam carbon adsorbing material is obtained. With the adoption of the method, a liquefaction technology, a resinification technology, a technology for preparing the foam carbon precursor with the template process and an activation technique are combined, so that porous foam carbon with uniform size and orderly structure can be synthesized and prepared.

Owner:GUANGXI UNIV +1

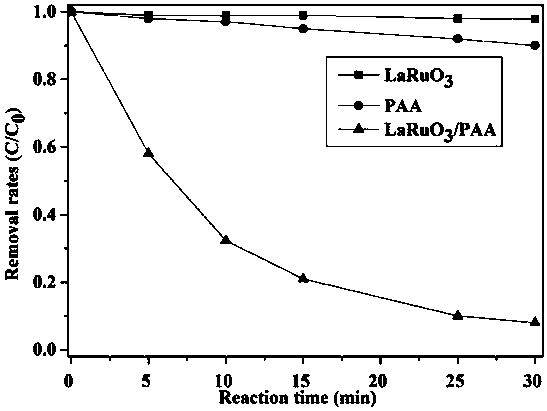

Method of using lanthanum ruthenate-bearing perovskite to activate peracetic acid to degrade fluoroquinolone antibiotics

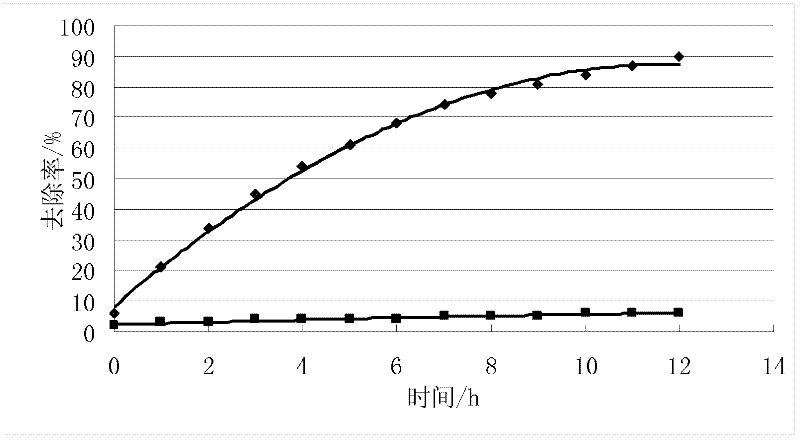

ActiveCN109574317ANo secondary pollutionHigh catalytic efficiencyWater contaminantsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsHigh activationActivation technique

The invention discloses a method of using a lanthanum ruthenate-bearing perovskite (LaRuO3) catalyst to heterogeneously activate peracetic acid to treat fluoroquinolone antibiotics wastewater, and relates to the field of water treatment. The invention is intended to solve the problem that existing peracetic acid catalytic activation techniques have low efficiency and may cause secondary pollution,and develops a more efficient, economical and environment-friendly method. In the method, lanthanum ruthenate-bearing perovskite is used for the first time to activate peracetic acid to generate hydroxy free radicals via activation, thereby further oxidizing fluoroquinolone antibiotics in wastewater. The method has evident effect in removing the typical fluoroquinolone antibiotic ciprofloxacin, with removal rate reaching about 92% in 30 min. The method has the advantages of high activation efficiency, high efficiency and speed of pollutant removal, wide pH applicable range, lower cost owing to LaRuO3 reusability, good operational convenience and the like.

Owner:TONGJI UNIV

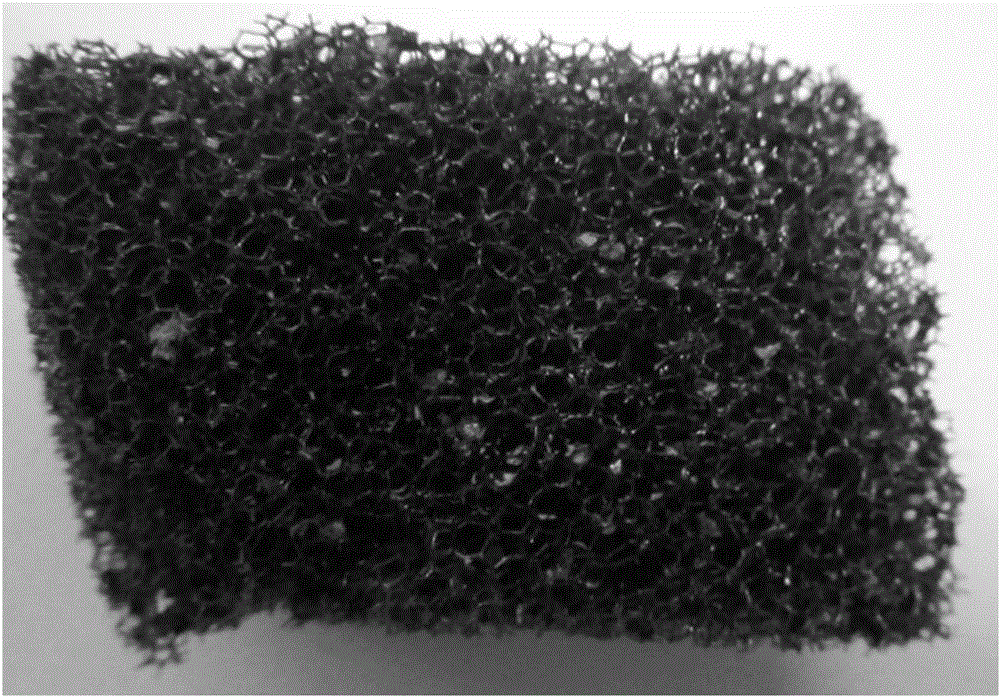

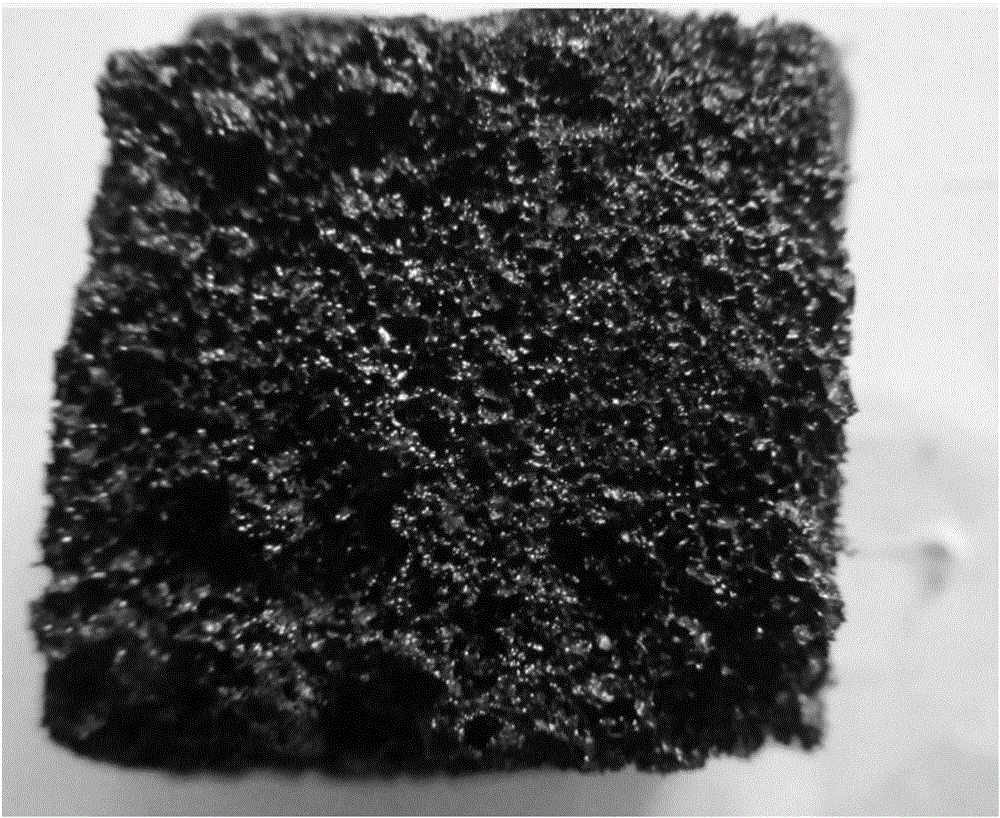

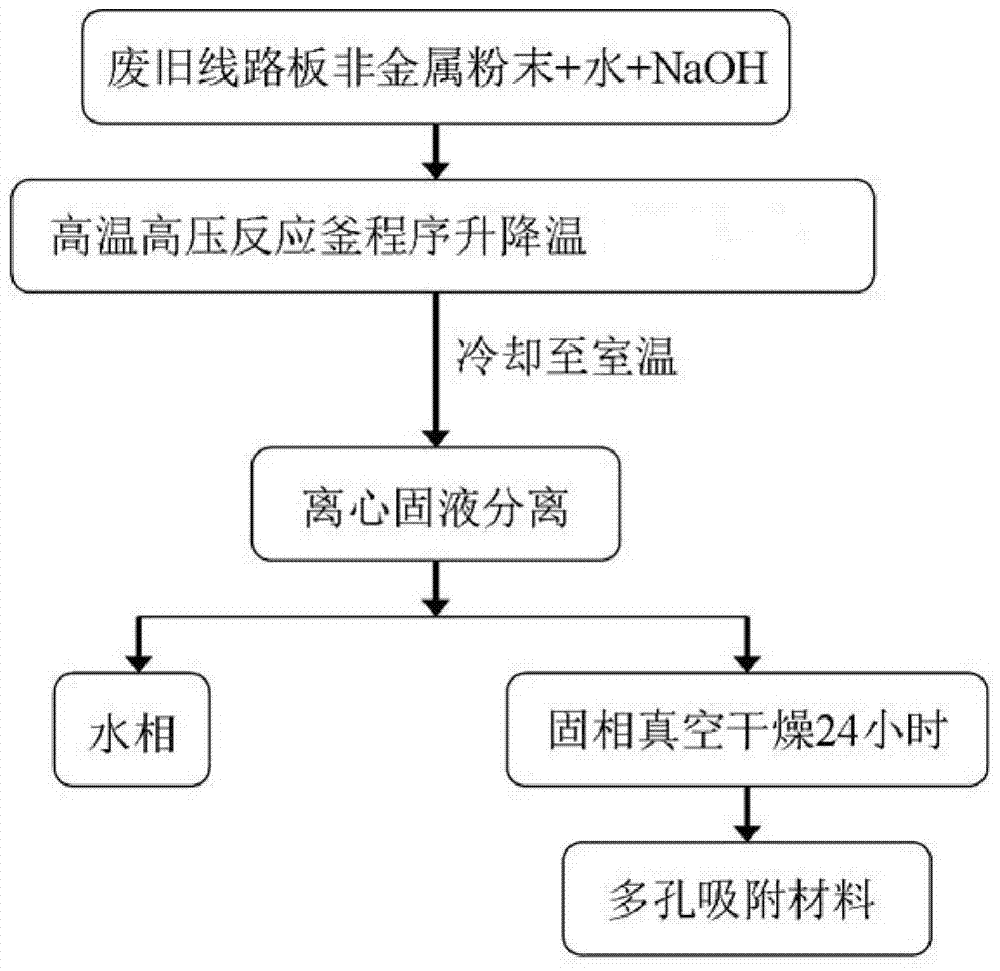

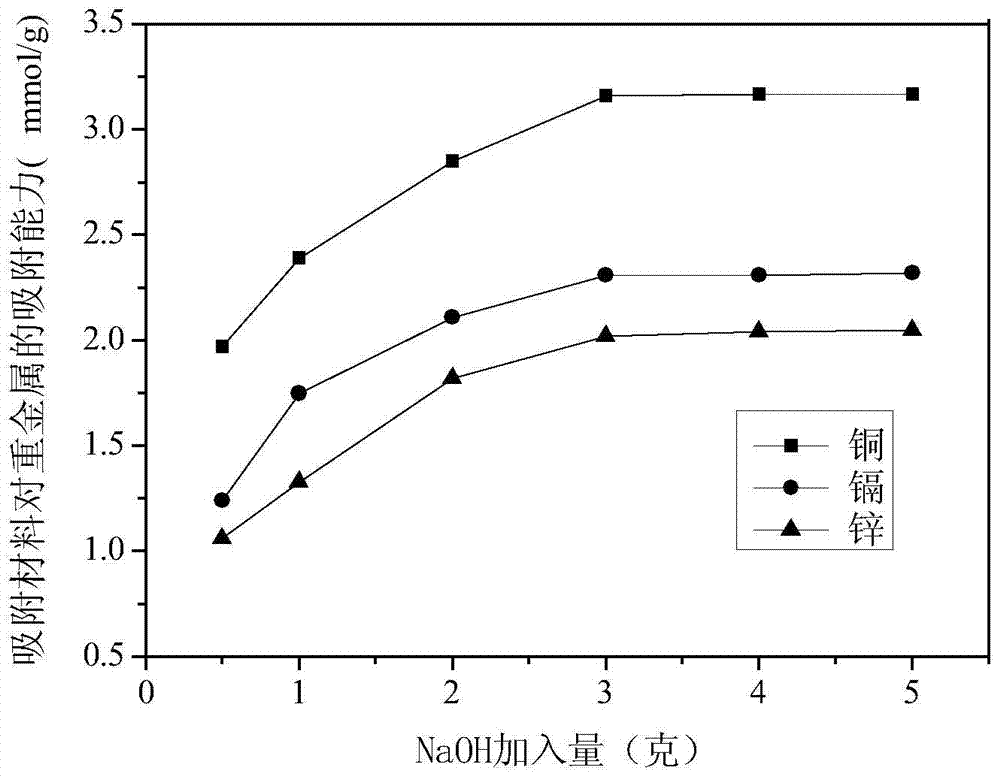

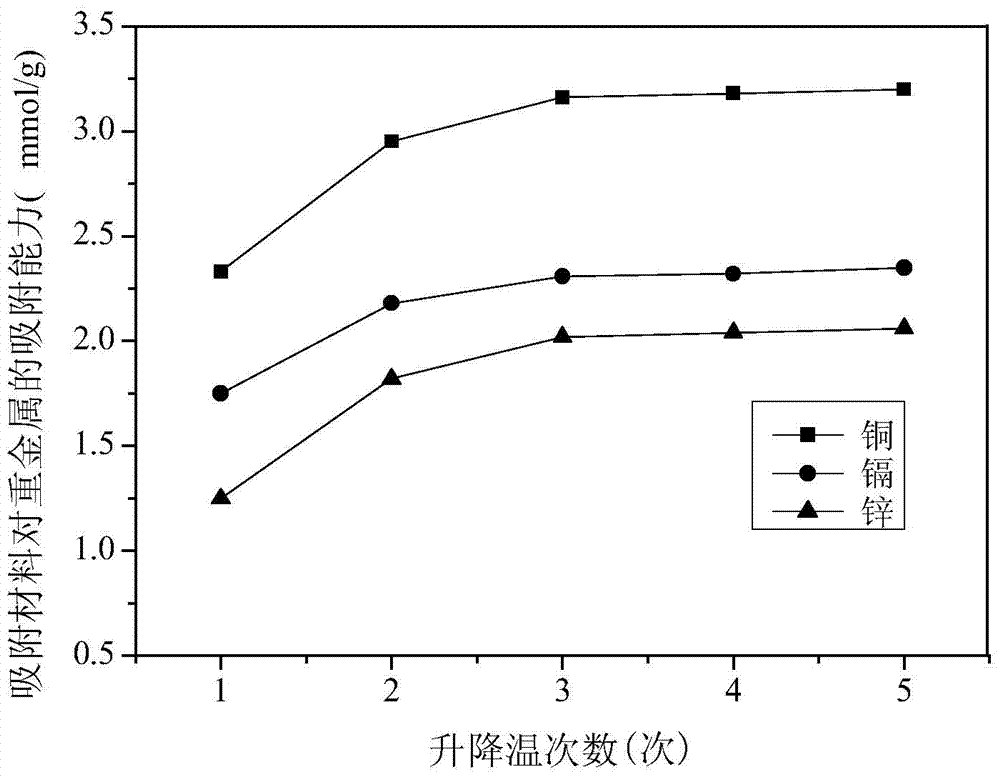

Method for preparing heavy metal adsorption material from waste circuit board non-metal powder

InactiveCN104707557AIncrease added valueOther chemical processesWater/sewage treatment by sorptionWastewaterAdditional values

The invention discloses a method for preparing a heavy metal adsorption material from a waste circuit board non-metal powder. The method includes the following steps: a, material placing; b, temperature rising-dropping reaction; and c, material obtaining. With combination of composition structural characteristics of the waste circuit board non-metal powder, a subcritical water alternative temperature rising and dropping-NaOH activation technique is adopted, and the waste circuit board non-metal powder is activated to prepare the high-efficiency adsorption material having high additional value and applied in heavy metal wastewater treatment, and the waste circuit board non-metal powder is allowed to obtain high additional value utilization.

Owner:FUJIAN UNIV OF TECH

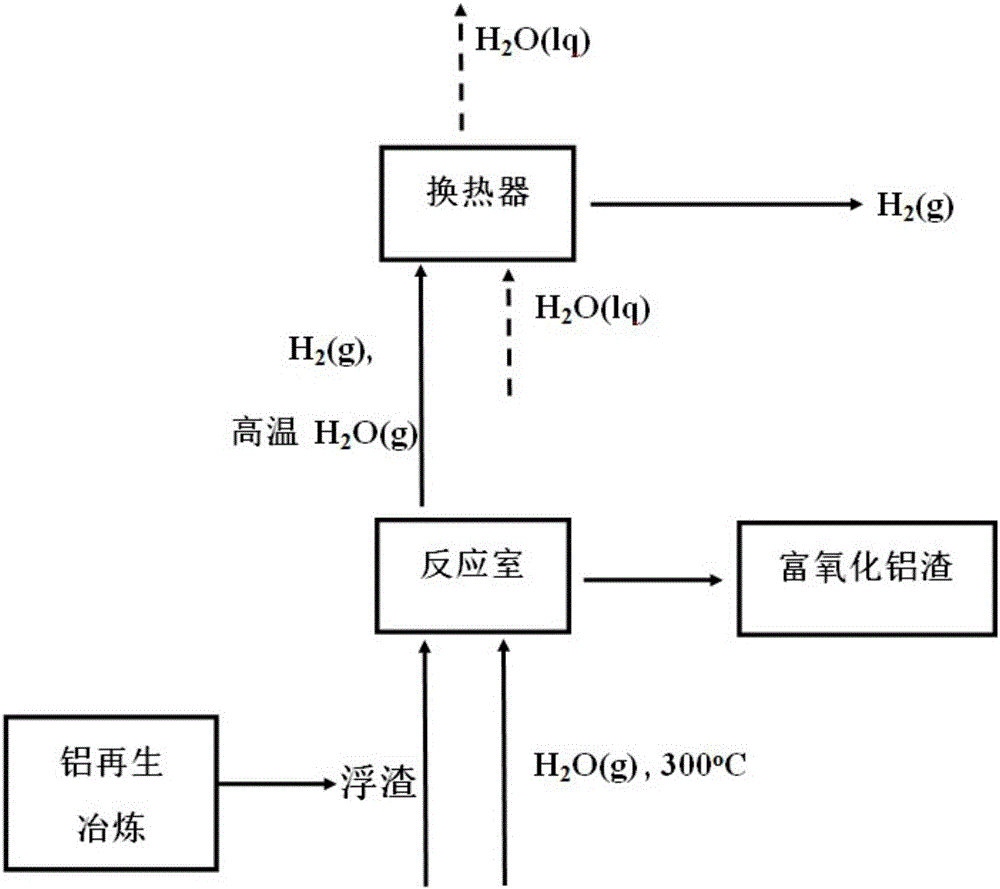

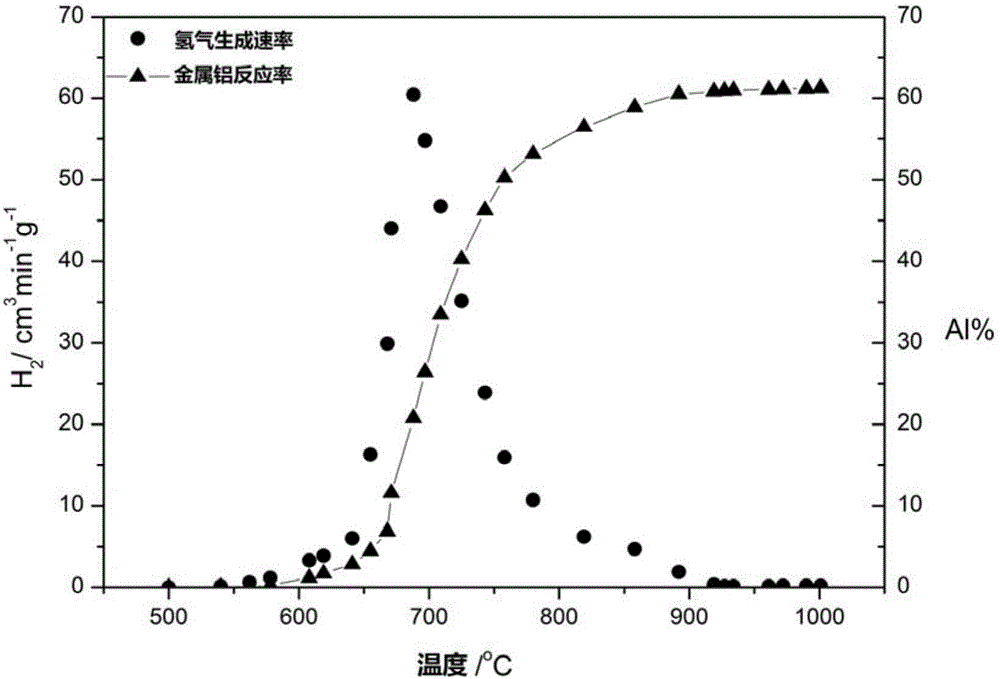

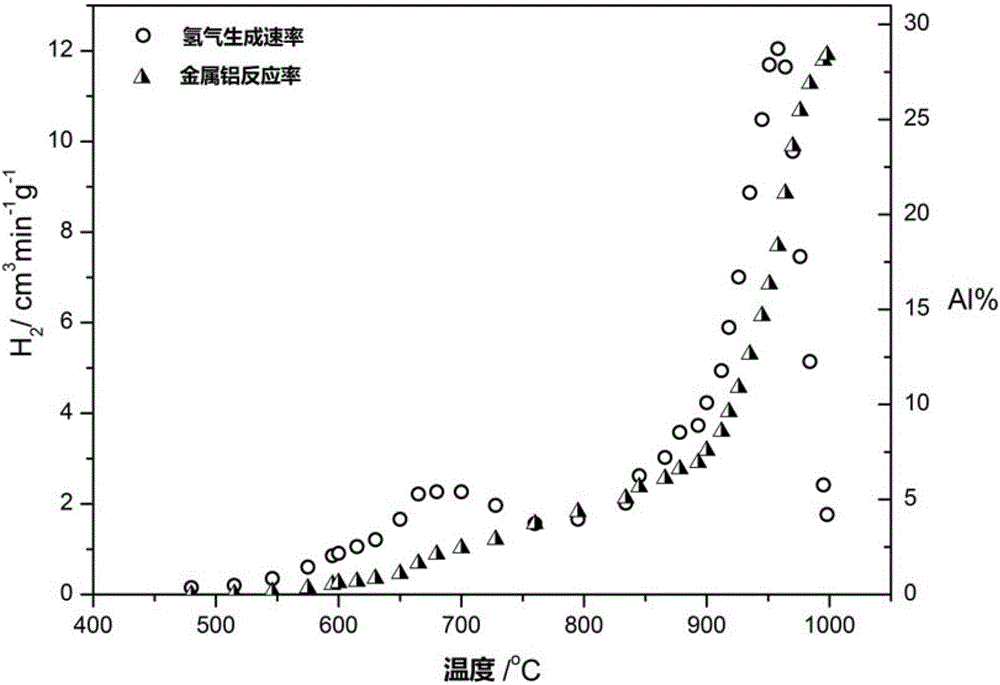

Method for preparing hydrogen gas by hot aluminum slag/vapor combined reaction

ActiveCN105836706AReduce consumptionReduce the burden onHydrogenChemical industryWater vaporLiquid water

The invention discloses a method for preparing hydrogen gas by hot aluminum slag / vapor combined reaction. The method comprises the following steps: in the metal aluminum regeneration smelting process, quickly putting removed aluminum slag into a reaction furnace, continuously introducing vapor to react with metal aluminum, recovering the aluminum-oxide-rich aluminum slag obtained after high-temperature reaction, and passing the generated high-temperature gas through a heat exchanger to obtain liquid water and pure hydrogen gas. The hot aluminum slag is used as an aluminum regeneration resource instead of the primary aluminum to prepare the hydrogen gas, thereby effectively lowering the energy consumption and environment load. The hydrogen production technique is lower in cost, does not need any additional activation technique link, and can further recover the aluminum oxide in the reaction solid product. The hydrogen production technique can obtain the hydrogen fuel, and can effectively utilize the reaction heat to obtain the high-temperature vapor, so that the energy utilization efficiency of the system is further enhanced.

Owner:SUZHOU UNIV

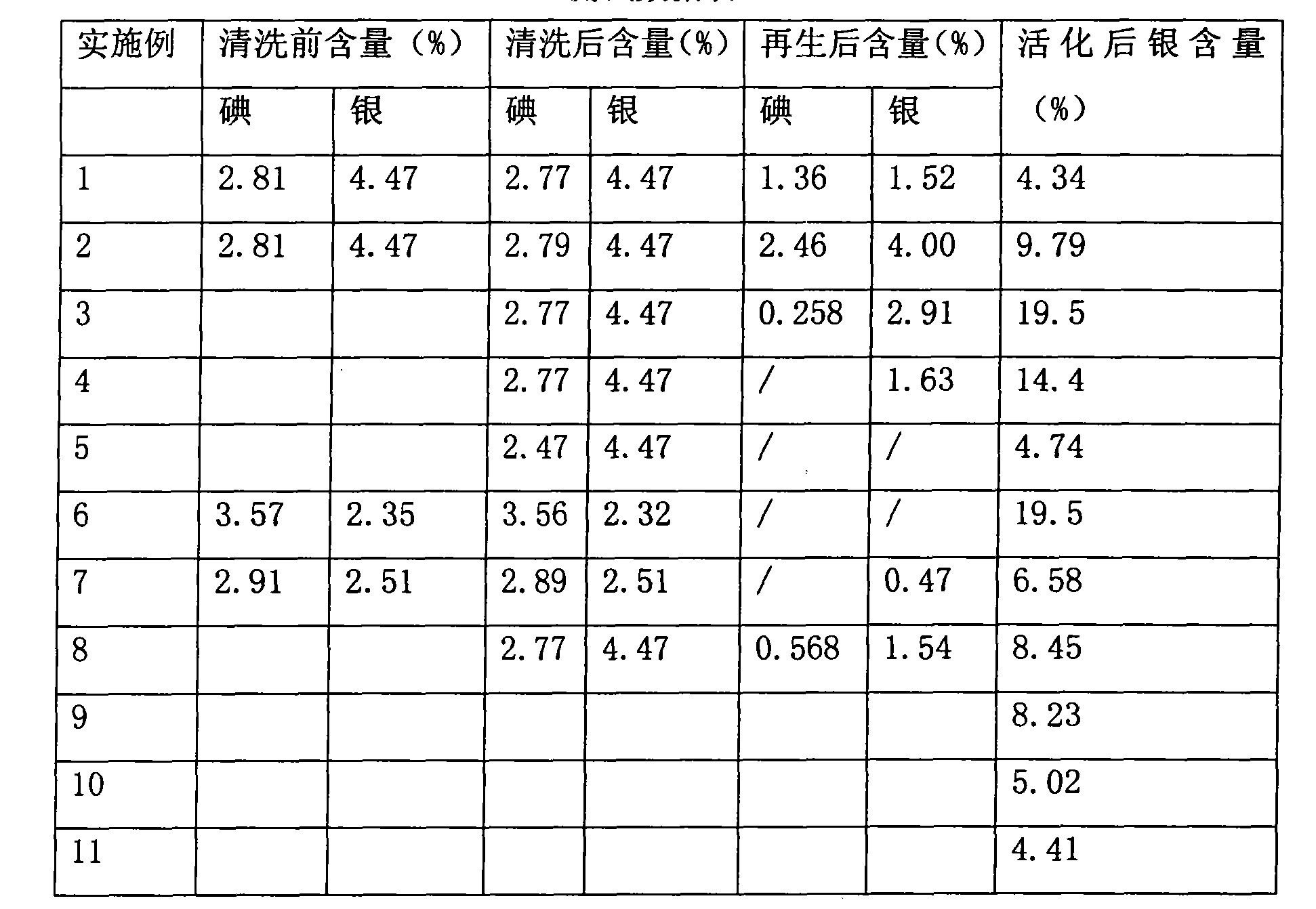

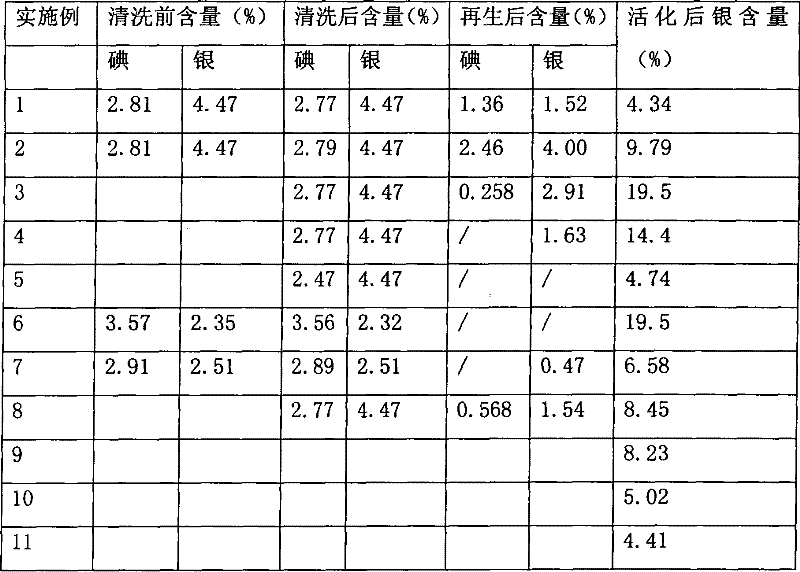

Regeneration and activation technique of iodine pollution solid adsorbent

ActiveCN101380567AEffective desorptionInhibitory activityDispersed particle separationCombustible gas purificationAcetic acidDesorption

The invention relates to a regeneration and activation technique of solid adsorbent polluted by iodine, which comprises the following steps in sequence: the solid adsorbent polluted by iodine is placed in 0.01 to 1 percent of acetic acid for cleaning; (2) the cleaned adsorbent is soaked in sodium thiosulfate solution with the concentration of 0.01 to 2 percent in static state or placed in a column and the sodium thiosulfate solution with the concentration of 0.01 to 2 percent is injected for regeneration so as to lead the pollutants in effective pore channels of the adsorbent polluted by iodine to be precipitated completely; (3) then the obtained adsorbent is placed in the column and ion exchange is carried out by injecting active metal Ag<+> solution till the concentration of the active metal Ag<+> on the solid adsorbent reaches the concentration before the solid adsorbent is polluted. The invention has low energy consumption and convenient operation, in particular to the regenerative technique condition that any heating facility is not used, the concentration of the used regenerative liquid is low and can effectively desorb iodine pollutants; the appearance of the activated adsorbent is same as new carriers, is off white, is characterized by high silver-loaded quantity and high adsorption and effectively prolongs the service life of the adsorbent, thus reducing the cost of iodine desorption.

Owner:SHANGHAI HUAYI ENERGY CHEM

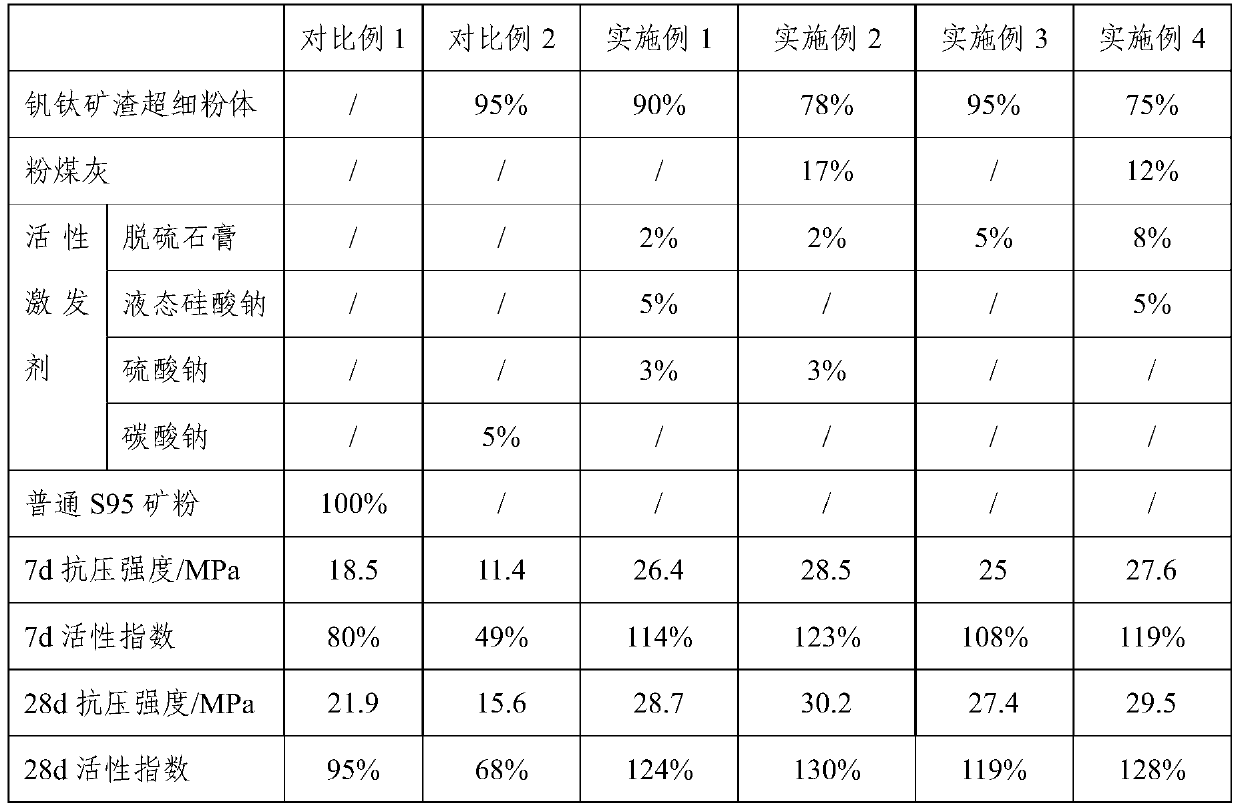

Vanadium-titanium mineral slag composite admixture for high-performance concrete and method

The invention relates to a vanadium-titanium mineral slag composite admixture for high-performance concrete and a method. The admixture comprises vanadium-titanium mineral slag superfine powder and anactivity stimulator, wherein the specific surface area of the vanadium-titanium mineral slag superfine powder is 650-800m<2> / kg; and the activity stimulator comprises one or more of liquid sodium silicate, sodium sulfate and desulphurization gypsum. By using a superfine powder grinding activation technique, vanadium-titanium mineral slag is grinded into superfine powder of a large specific surface area, a combined stimulation method of chemical activation is synergistically utilized to improve the hydration reaction activity of the vanadium-titanium mineral slag, and thus the mineral composite admixture for the high-performance concrete can be prepared.

Owner:中建材科创新技术研究院(山东)有限公司

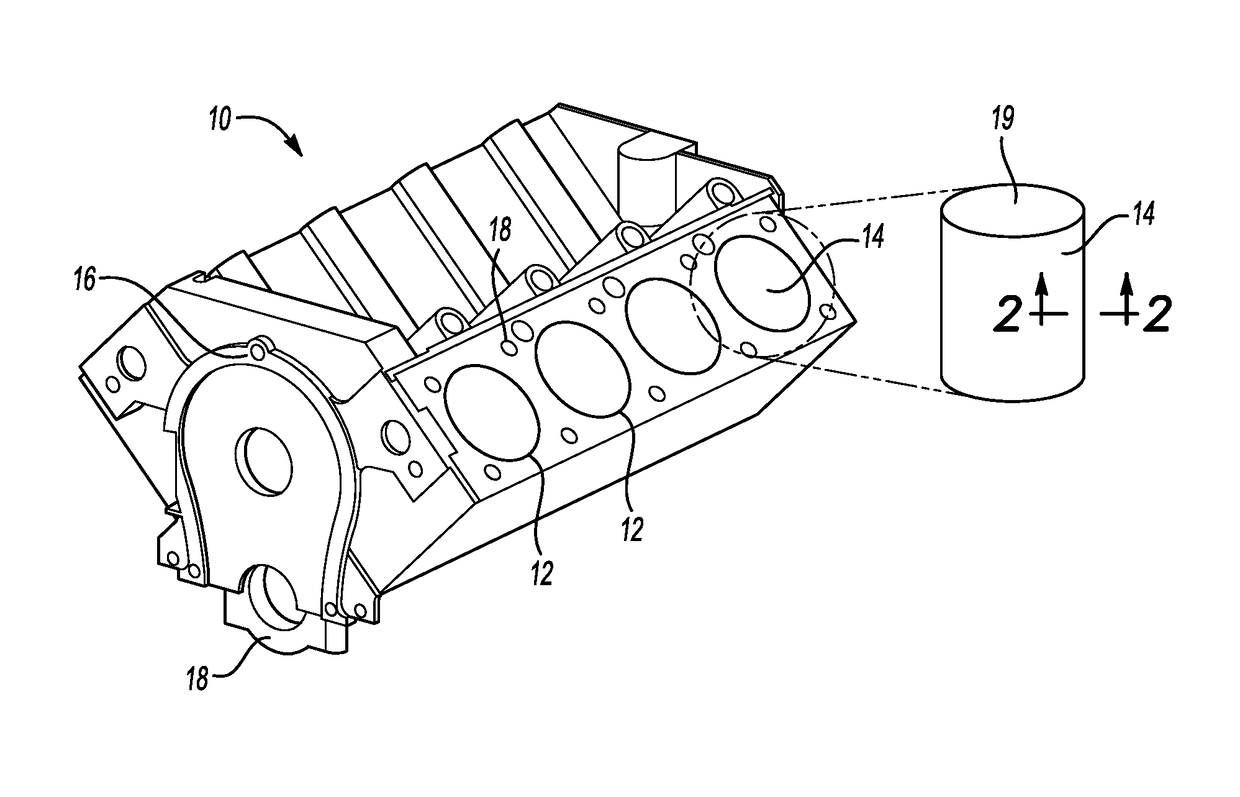

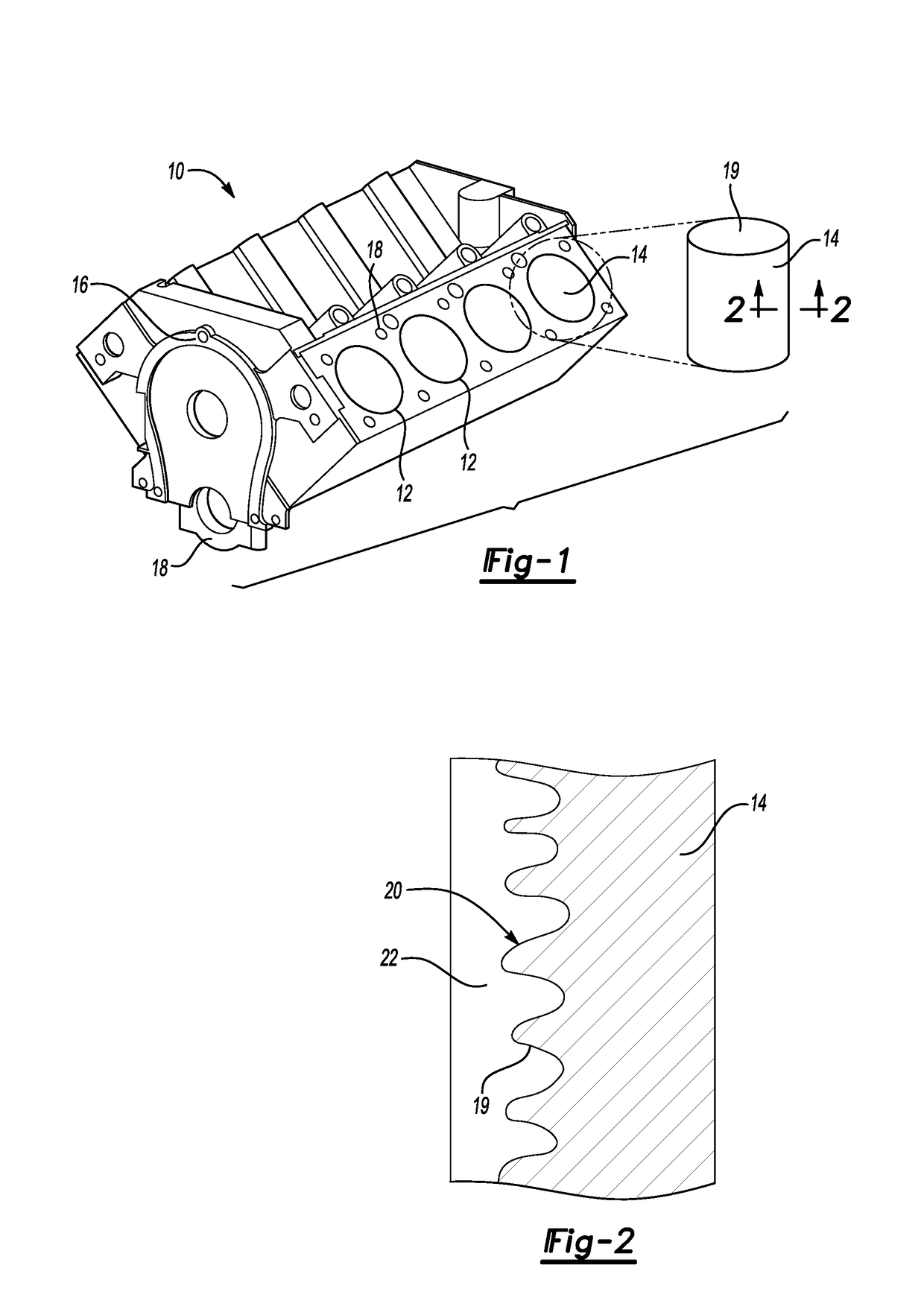

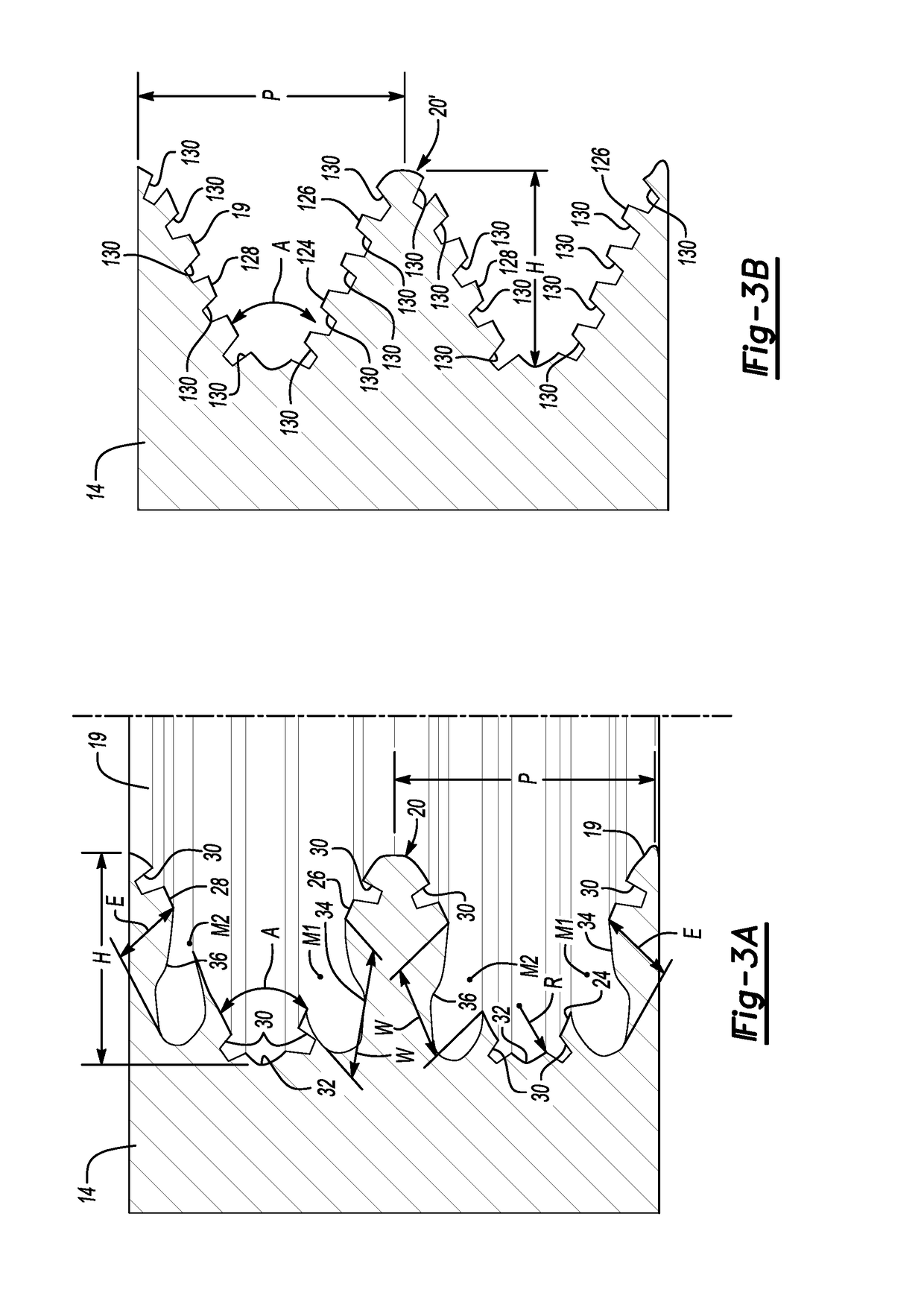

Adhesion of thermal spray using compression technique

ActiveUS20180045134A1Improve adhesionImprove textureCasingsMolten spray coatingThermal sprayingActivation technique

An improved surface activation technique improves the adhesion of thermal spray coatings, which is useful for engine cylinder bores. The new method includes compressing the cylinder bore surface to create a surface profile on the surface, such as through rolling a roller along the surface. An engine block is also provided, which includes a plurality of cylinder bores, each cylinder bore having an inner surface, and each inner surface having a surface profile that includes a helical groove and other surface profiles formed in the inner surface. A thermal spray coating is formed on the inner surface of each cylinder bore, the thermal spray coating being adhered to the surface profile of the inner surface. A roller assembly for activating the surface is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

A kind of preparation method of porous activated carbon/copper ion supercapacitor

InactiveCN105609327BRich sourcesLow costHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceInternal resistance

The invention discloses a preparation method of porous activated carbon / copper ion supercapacitor. In the invention, the residue after processing of edible plant fruit is used as a carbon source, and a porous activated carbon supercapacitor electrode material is prepared by hydrothermal treatment, carbonization and two-stage activation technology; a non-copper-containing substance is introduced into the copper ion aqueous solution to form a redox electrolyte of the supercapacitor. The supercapacitor of the present invention is provided by the porous activated carbon to provide the electric double layer capacitance and the reversible redox reaction of copper ions to provide the Faradaic capacitance, so as to realize the synergistic superposition of the two capacitances. The constructed porous activated carbon / copper ion supercapacitor has a specific capacitance of 492 F / g at a current density of 1 A / g and a specific capacitance of 285 F / g at a current density of 20 A / g, with low internal resistance and good cycle stability. , long life, high power and high energy density characteristics, and low cost, abundant resources, environmental friendliness, easy industrialization and so on.

Owner:XIANGTAN UNIV

Germination activation technique of ganoderma spores and extraction of active substances of ganoderma spores

InactiveCN102727535AGuaranteed stabilityGuaranteed automationAntinoxious agentsImmunological disordersSide effectActivation technique

The invention discloses a germination activation technique of ganoderma spores and extraction of active substances of ganoderma spores. The germination activation technique is characterized by firstly screening fresh, mature and plump ganoderma spores by using a seed sieving machine, automatically regulating temperature, moisture and oxygen required by the germination process of the ganoderma spores by using modern detection control technology, and determining the germination activation stage by determining the oxygen demand of the ganoderma spores. The technique guarantees the high effectiveness and stability of the germination activation of the ganoderma spores. The active substances of the ganoderma spores are extracted by carrying out ultralow temperature nanotechnology on the activated ganoderma spores, the defects of nonuniform particle size, difficulty for human to absorb, large loss of active substances of the ganoderma spores obtained by traditional technologies are overcome, thus new generation high quality ganoderma spore powder with high active ingredients, easiness for human to absorb, little side effect is obtained. The biologically-active substances of the ganoderma spore powder have wide application prospects in the fields of medical science and health care.

Owner:郑家德

Calcium base activation technique

The invention discloses a calcium-based activation process, which uses low-grade calcium-based bentonite, takes hydrochloric acid as an activator, thus preparing the active bentonite with the decoloration rate more than 99 percent and the activity of 220-225. The wet-method activation process takes the hydrochloric acid as the activator, has good activation effect, stable quality of the product and is easy to be operated.

Owner:葛坤忠

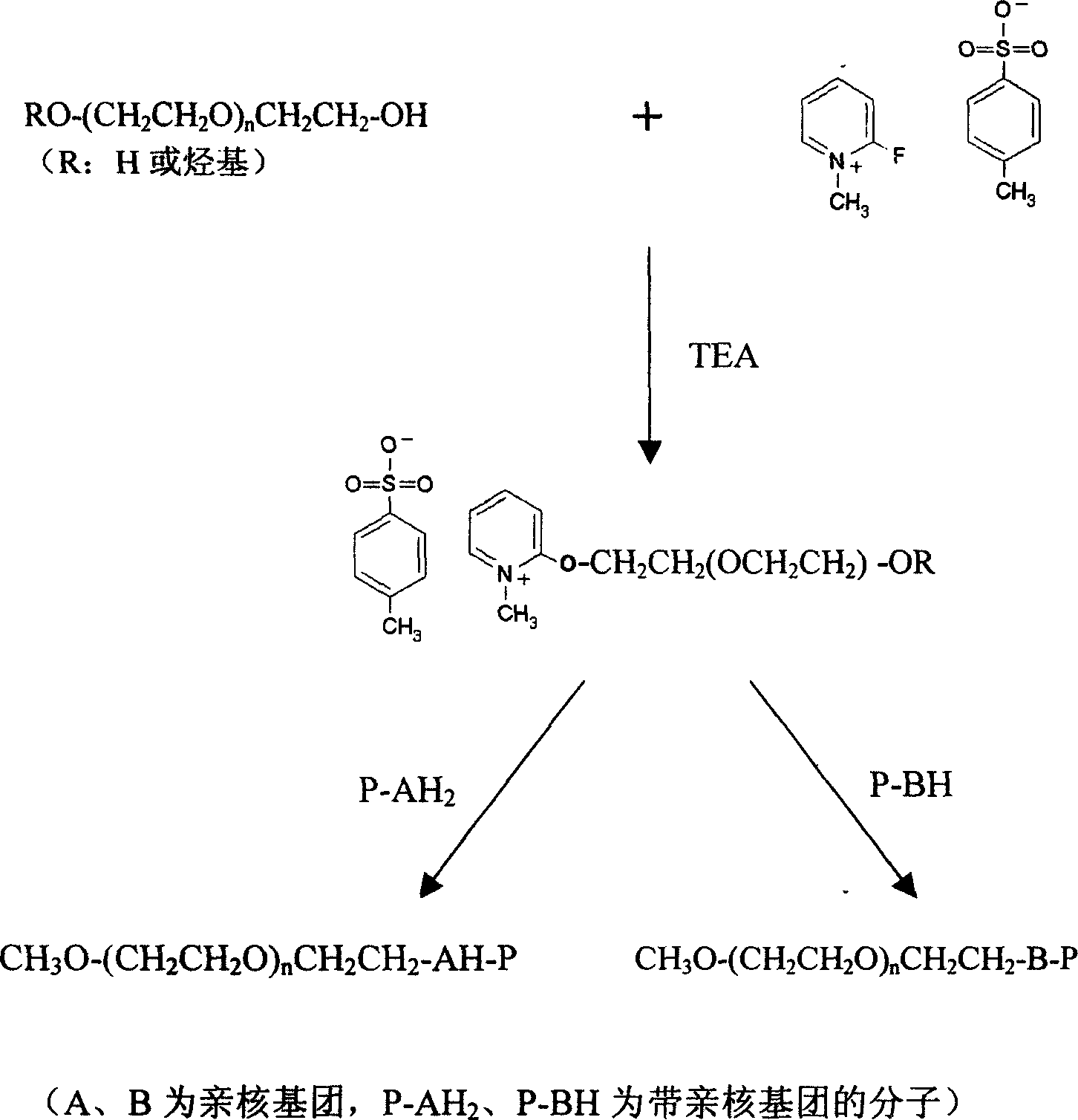

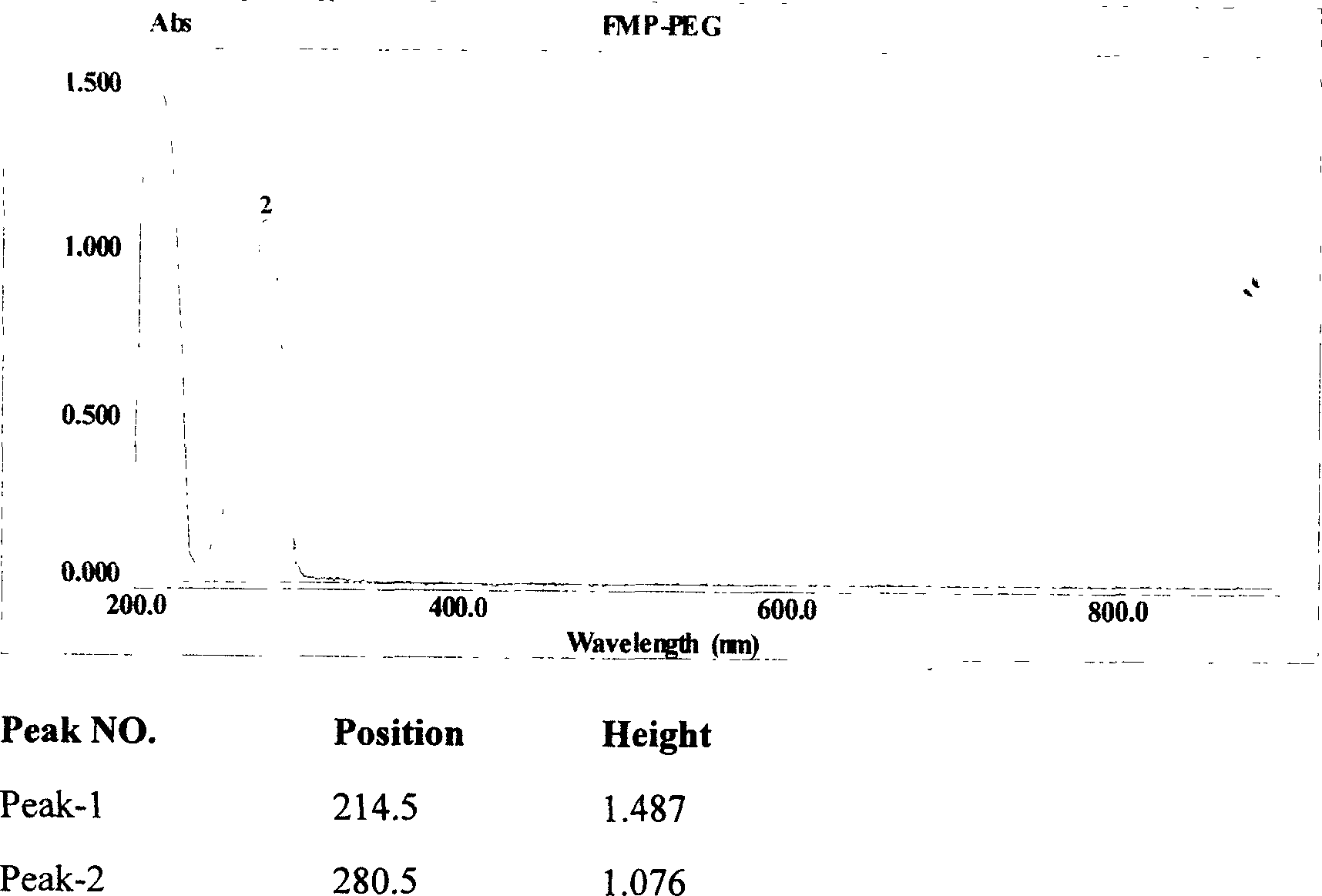

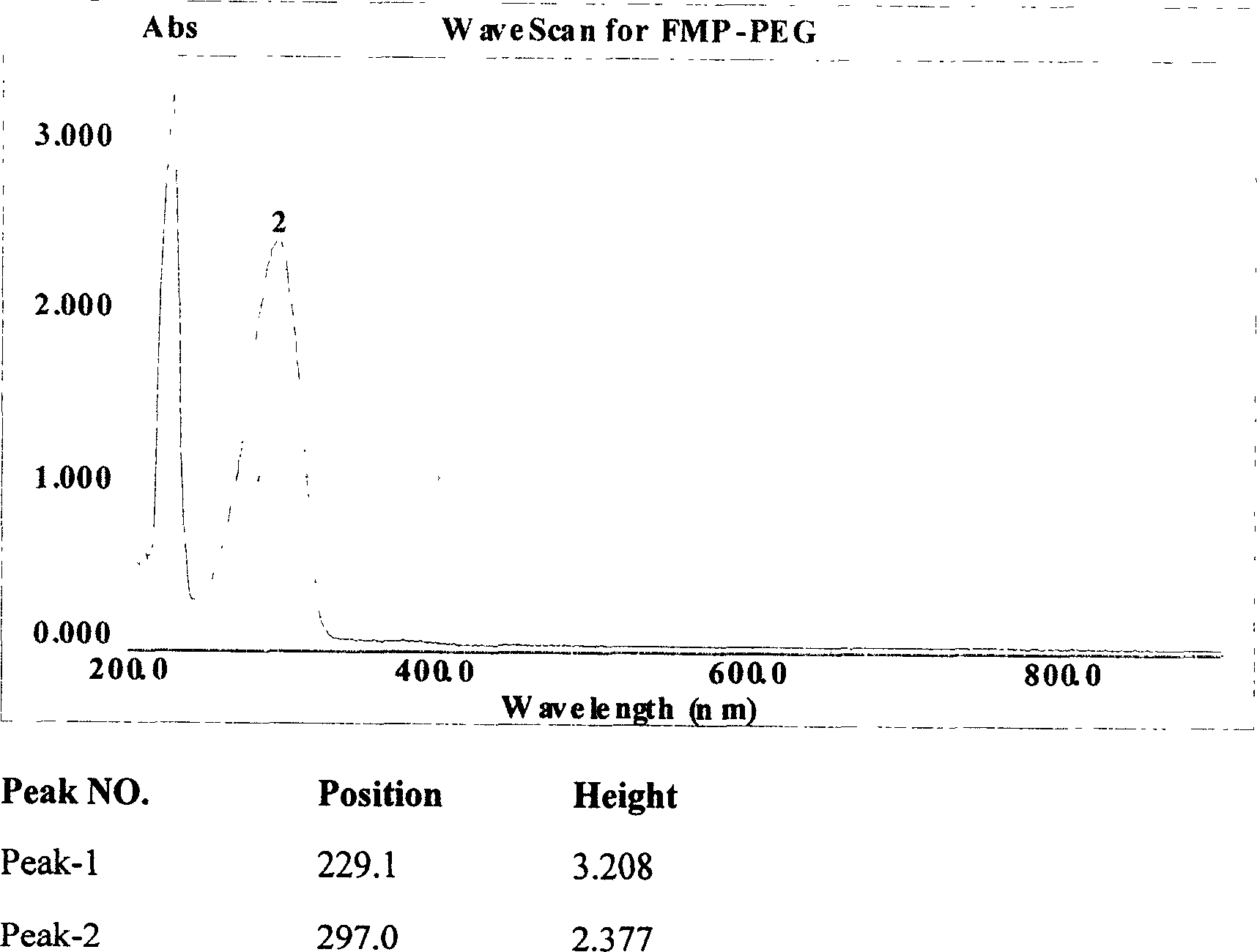

Efficent polyethylene glycol activating process and activate use for protein modification

InactiveCN1580082ALow immunogenicityAvoid being broken down by enzymesHaemoglobins/myoglobinsCarrier-bound/immobilised peptidesHigh activationPolyethylene glycol

The invention provides the effective method of the modification reaction of the biological active molecule of the activation technique of the hydroxyl at the end of the polyethylene glycol, its product, protein and other nucleophilic groups and the reaction products. Its characteristics are as follows: (1) heat the PEG and toluene to 140deg.C to get rid of the water in the PEG. (2) The anhydrous PEG and 2-fluorin-1-methyl pyridine onium toluene-4-sulfonate reacts in the anhydrous polar organic solvent. (3) Add organic base to keep the pH value between 8 and 9 during the reaction. (4) Deposit the PEG activates with aether and purify the activates through isopropyl alcohol recrystallization. (5) The PEG activates reacts with the protein and other biological active molecules with nucleophilic groups in the buffer solution to get the PEG and its coupling materials. The activation technique of the PEG in the invention has high activation rate (95%), high purity (99%), good controllability of the modification speed and good chemical stability of the modified products. The activated PEG of the invention is especially adaptable to the modifications of the polypeptides and proteins.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

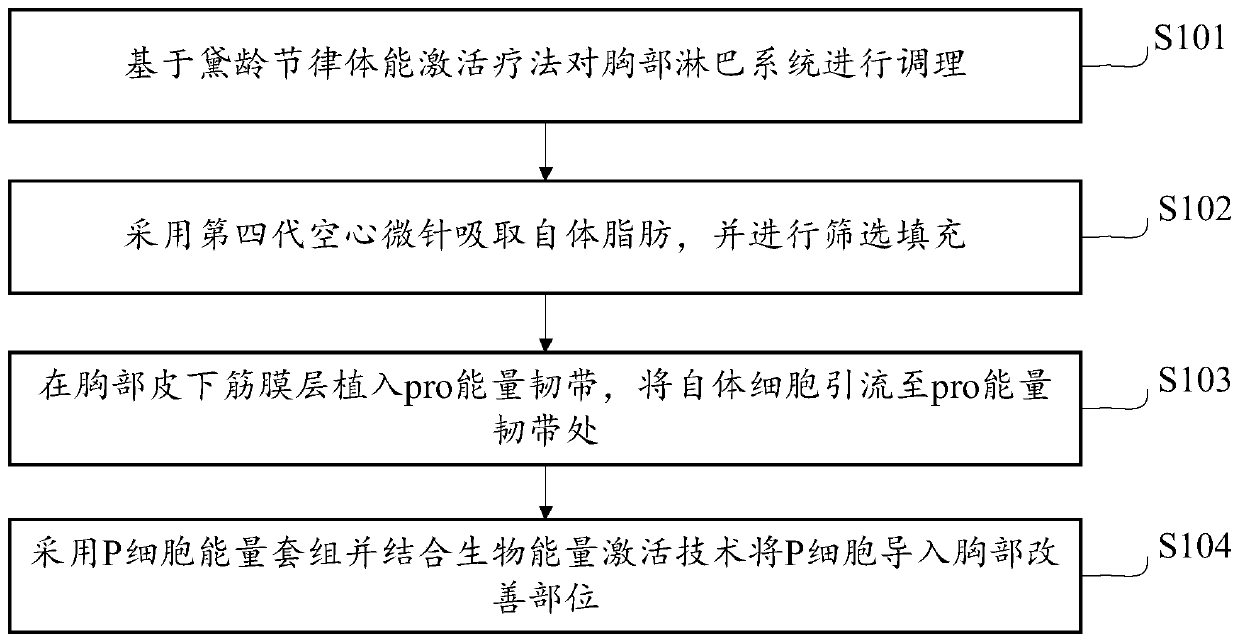

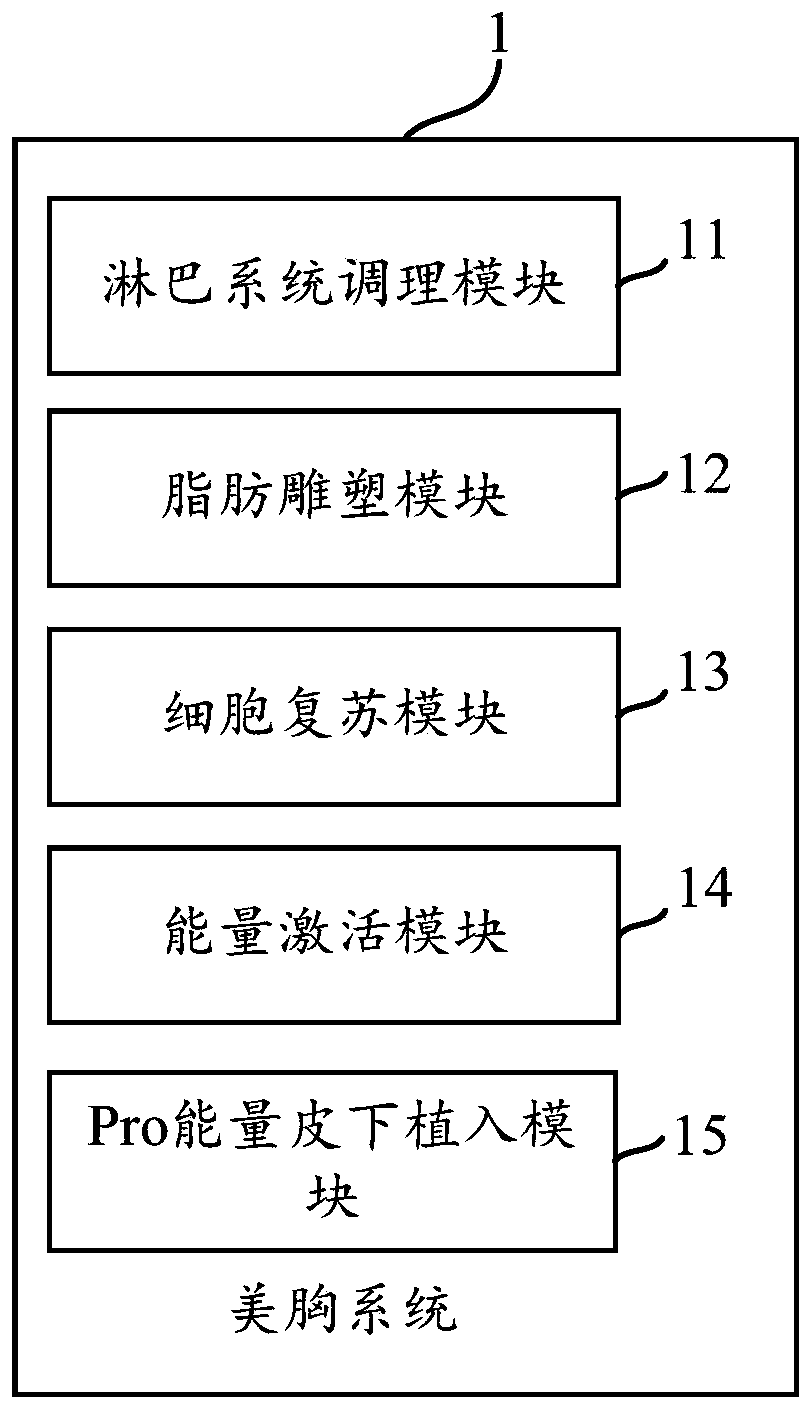

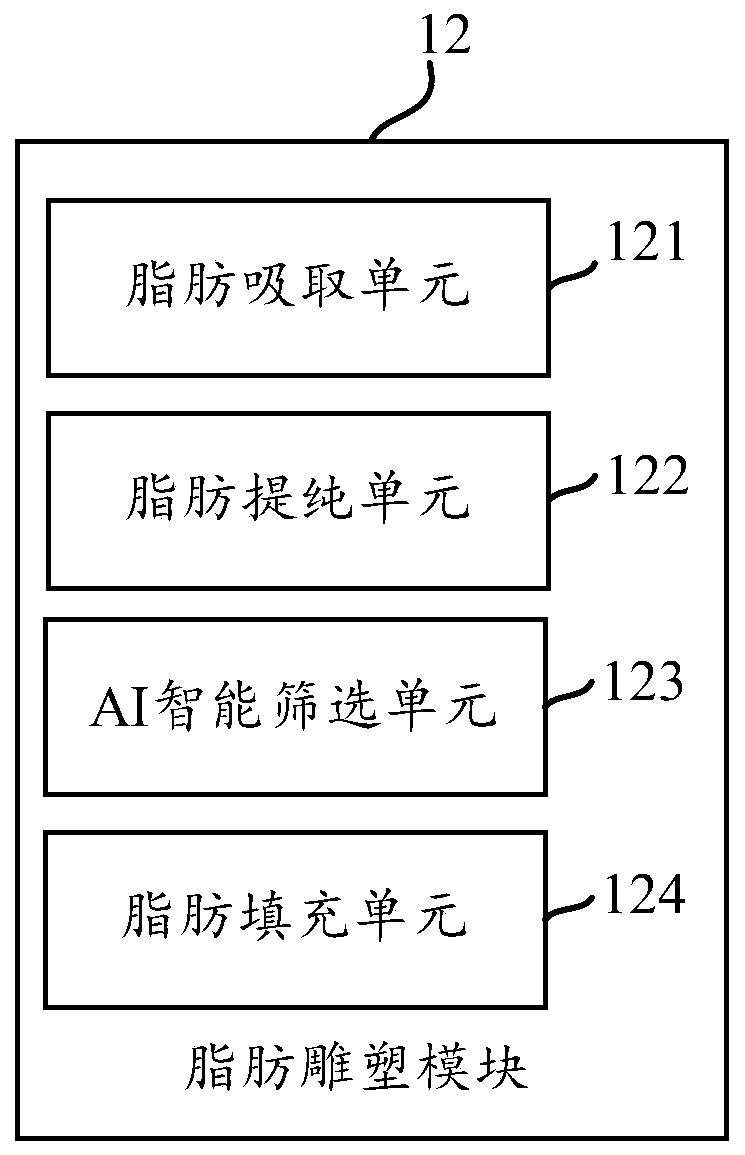

Breast beautifying method and system based on AI (artificial intelligence) autologous cell resuscitation

InactiveCN110368045ARelieve painImprove healthSurgeryMicrowave therapyFascial layerLigament structure

An embodiment of the invention discloses a breast beautifying method and system based on AI (artificial intelligence) autologous cell resuscitation, wherein the method comprises the steps of conditioning the breast lymphatic system based on a juvenilizing rhythmic physical activation therapy; sucking autologous fat with a fourth-generation hollow micro needle, and carrying screening and filling; implanting a pro energy ligament to a subcutaneous fascial layer of the breast, and introducing autologous cells to the pro energy ligament so that the autologous cells are activated by the pro energyligament; introducing P cells into the breast to improve the part through a P cell energy set combined with a bio-energy activation technique so that the survival rate and growth rate of micro fat cells are increased. The method and system of the invention have the advantages that naturalness and attractiveness are ensured through the fine design style in the breast beauty process, the breast beauty risk is lessened, and pain of a beauty pursuer is alleviated.

Owner:丁云凤

Production technique of cationic starch

ActiveCN102775508BIncrease the activation processAdvanced technologyNon-fibrous pulp additionPaper/cardboardActivation techniqueBiological activation

The invention relates to a production technique of cationic starch. A starch activation technique and a starch compounding and impregnation technique are added, and the rest of techniques are correspondingly innovated. The production technique of cationic starch comprises the following main steps: starch activation, etherifying agent activation, starch compounding and impregnation, etherification reaction, blast cooling, neutralization, blast cooling, pulverization and the like. The production technique provided by the invention has the advantages of safe material, no gelatinization of start particles, shorter reaction time, lower energy consumption, higher reaction efficiency and higher product yield, and is simple and practical to operate; and the prepared cationic starch product has the advantages of high quality and stable properties.

Owner:山东米能生物科技有限公司

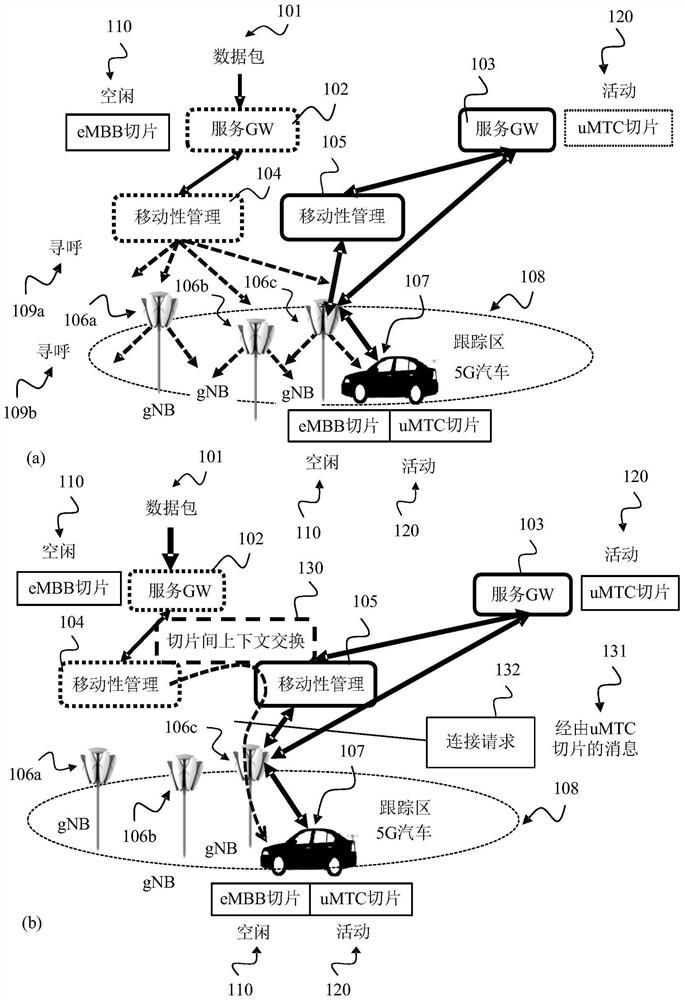

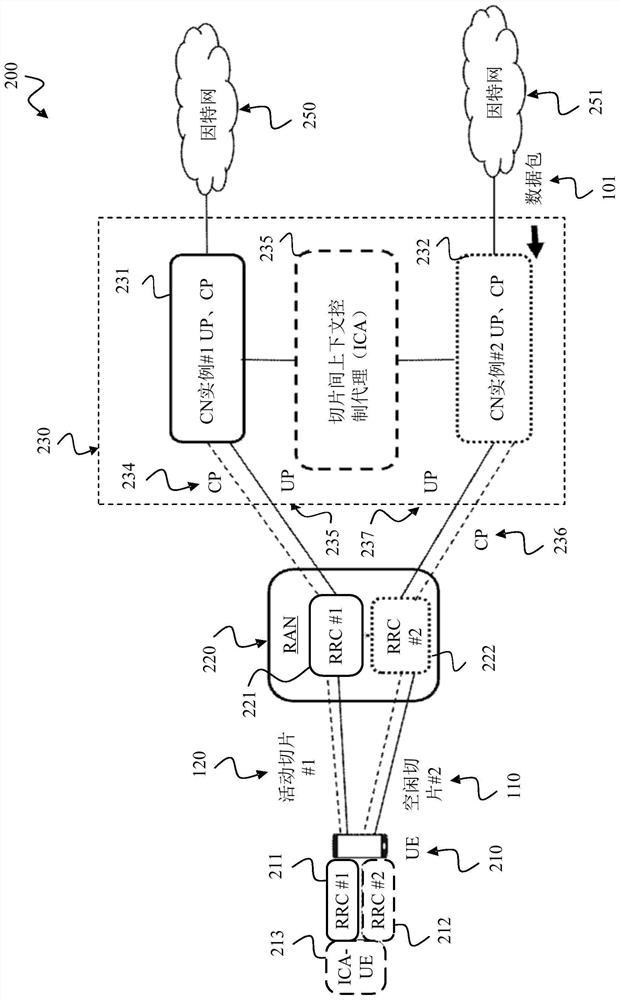

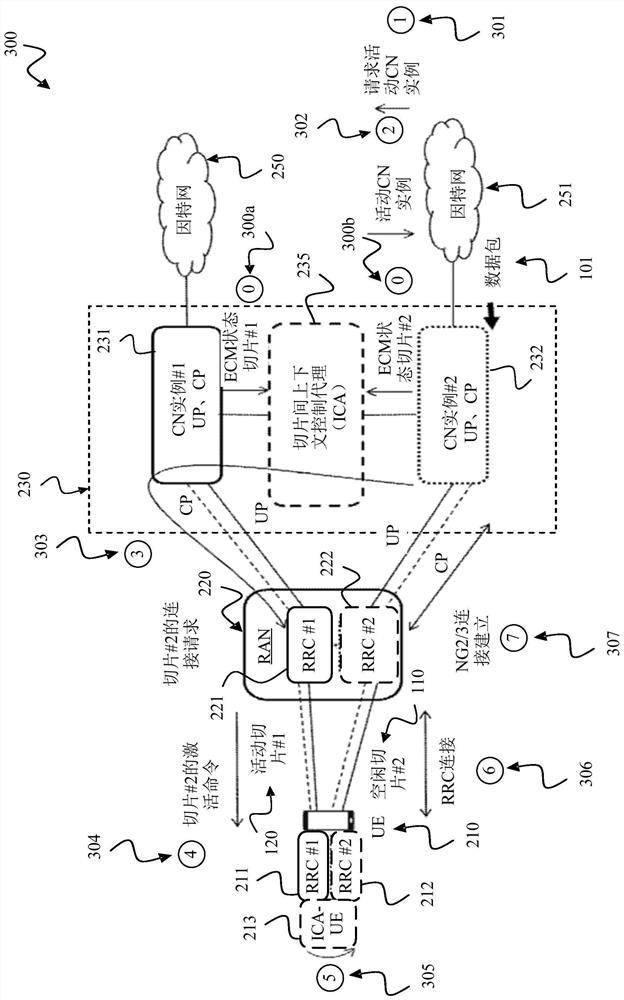

Slice Activation Techniques in Multi-Slice Networks

ActiveCN110326340BEfficient executionReduce latencyConnection managementAccess networkRadio access network

The present invention relates to a user equipment (UE for short), comprising a processor, configured to: receive an activation command for at least one idle slice among a plurality of slices, wherein the activation command commands execution of the at least one idle slice connection establishment; setting the UE to an active state to enable the connection establishment of the at least one idle slice. The present invention also relates to a core network (referred to as CN) system, comprising: an inter-slice control agent (ICA-CN), used to be associated with or can be associated with a user equipment (referred to as UE) from At least one slice among the plurality of slices collects context information; at least one CN instance is used to send a connection request to the UE, and the connection request requests the UE to establish a connection with at least one idle slice among the plurality of slices . The present invention also relates to a radio access network (radio access network, RAN for short) entity.

Owner:HUAWEI TECH DUESSELDORF

Regeneration and activation technique of iodine pollution solid adsorbent

ActiveCN101380567BImprove distributionIncrease distribution rateDispersed particle separationCombustible gas purificationAcetic acidSorbent

The invention relates to a regeneration and activation technique of solid adsorbent polluted by iodine, which comprises the following steps in sequence: the solid adsorbent polluted by iodine is placed in 0.01 to 1 percent of acetic acid for cleaning; (2) the cleaned adsorbent is soaked in sodium thiosulfate solution with the concentration of 0.01 to 2 percent in static state or placed in a column and the sodium thiosulfate solution with the concentration of 0.01 to 2 percent is injected for regeneration so as to lead the pollutants in effective pore channels of the adsorbent polluted by iodine to be precipitated completely; (3) then the obtained adsorbent is placed in the column and ion exchange is carried out by injecting active metal Ag+ solution till the concentration of the active metal Ag+ on the solid adsorbent reaches the concentration before the solid adsorbent is polluted. The invention has low energy consumption and convenient operation, in particular to the regenerative technique condition that any heating facility is not used, the concentration of the used regenerative liquid is low and can effectively desorb iodine pollutants; the appearance of the activated adsorbent is same as new carriers, is off white, is characterized by high silver-loaded quantity and high adsorption and effectively prolongs the service life of the adsorbent, thus reducing the cost of iodine desorption.

Owner:SHANGHAI HUAYI ENERGY CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com